Patents

Literature

39 results about "Glycine synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

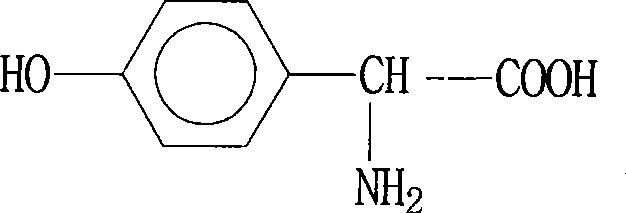

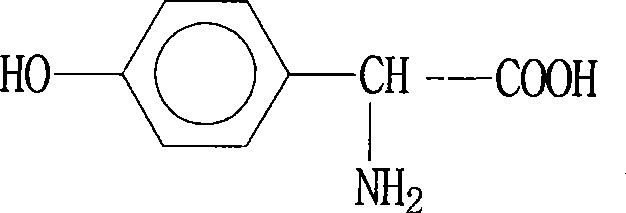

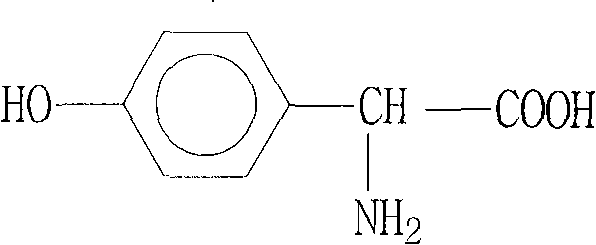

P-hydroxybenzene glycine synthesis technology

InactiveCN101362703AOrganic compound preparationAmino-carboxyl compound preparationSulfite saltHydroxylamine Hydrochloride

The invention belongs to the field of pharmaceutical chemical engineering intermediate production, which relates to a synthesis technology of p-hydroxyphenylglycine (HPG). The purpose of the invention is achieved by the following steps: phenol, glyoxylic acid, water and sulfamic acid carry out the one-pot braise reaction under the action of catalysts such as benzene sulfonic acid, p-toluenesulfonic acid, o-toluenesulfonic acid, and the like; after the reaction is finished, a small amount of reducing substances such as sodium sulfite, sodium bisulfite, hydroxylamine hydrochloride, and the like, are added; finally, the PH value is adjusted by alkali, the mother liquor separation is washed by large amount of water and then washed by organic solvents such as methanol, ethanol, acetone, glacial acetic acid, and the like; the obtained product HPG is white powder, wherein, the content of NPLC is equal to or more than 98.5, which can meet the requirement of splitting. The method has the advantages of low production cost, simple operation, stable quality, etc.

Owner:谢建中

Method for producing glycine by mixed solvent method

InactiveCN105859571AOrganic compound preparationAmino-carboxyl compound preparationHexamethylenetetramineOrganosolv

The invention provides a clean production process of glycine. An organic mixed solvent is used for producing glycine and a by-product ammonium chloride by combined production. The organic mixed solvent comprises methanol, ethanol, and dihydric alcohol solvents or dihydric alcohol derivative solvents. The mixed solvent is added into a glycine synthesis reactor, urotropine and chloroacetic acid are added, ammonia is added, and a mixed crystal solid of glycine and ammonium chloride is obtained. The mixed crystal solid is added into a mixed solvent for separation, the mixed solvent for separation is heated to 60-80 DEG C, after glycine crystal is filtered, the mixed solvent for separation is cooled to 0-20 DEG C, and an ammonium chloride solid is separated by centrifugation.

Owner:刘长飞

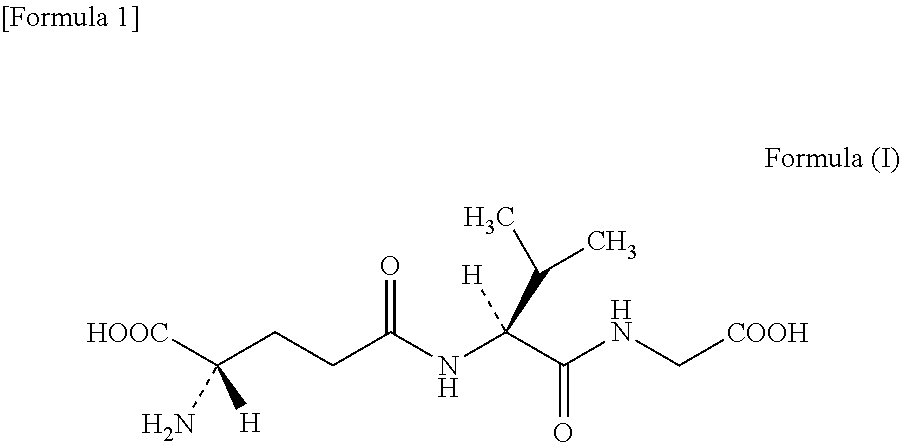

Method for biosynthesis of glutathione by using yeast

InactiveCN101255454AHigh yieldImprove permeabilityMicroorganism based processesFermentationGlycalAdenosine triphosphate

The invention relates to a method for synthesizing glutathione using yeast cells. Gamma-GCS and GS in yeast cells are used, glucose is used as the energy, an intracellular glucolysis system is used to produce triphosadenine, glutamic acid, cysteine and glycin in reaction liquid are synthesized to form glutathione; saccharomyces cerevisiae, baker's yeast, candida and other yeast cells are permeabilized and then react in a reaction liquid composed of phosphate buffer, MgCl2.6H2O, CaCl2.2H2O, glucose, L-glutamic acid and L-cysteine, gamma-L-glutamoyl L- cysteine is produced, then glycin is added to produce glutathione; in the two-stage reaction, the inhabitation effect of glutathione to gamma-GCS catalytic reaction is greatly reduced; glutathione produced by the method has obviously improved product concentration and reaction yield.

Owner:EAST CHINA UNIV OF SCI & TECH

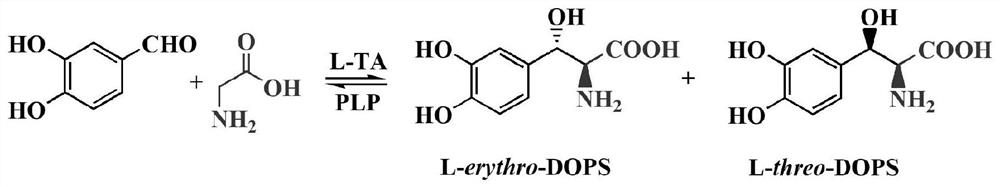

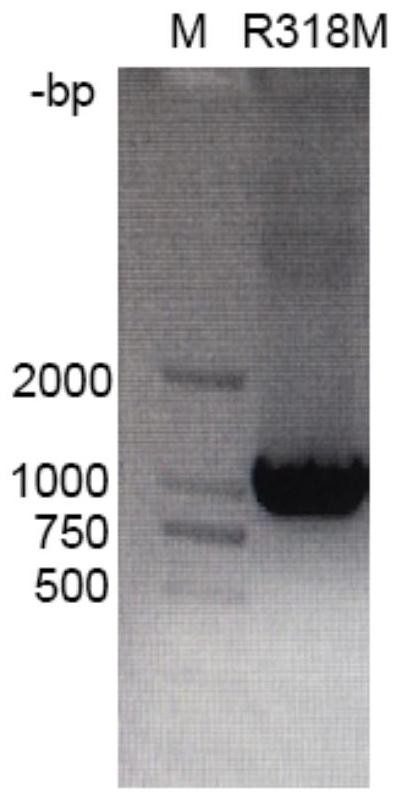

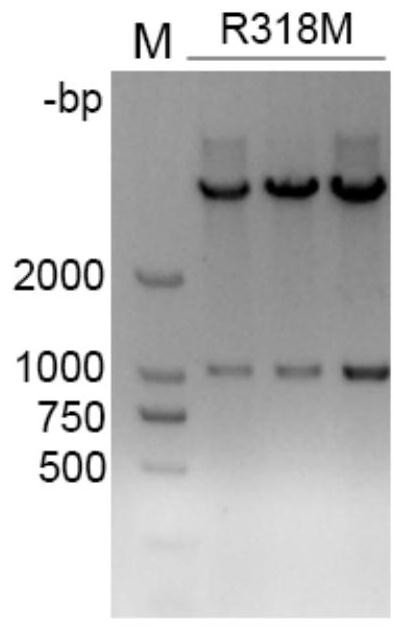

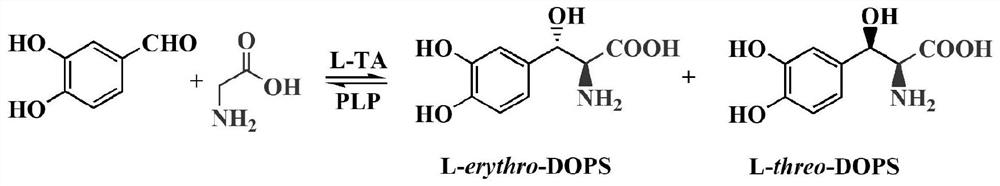

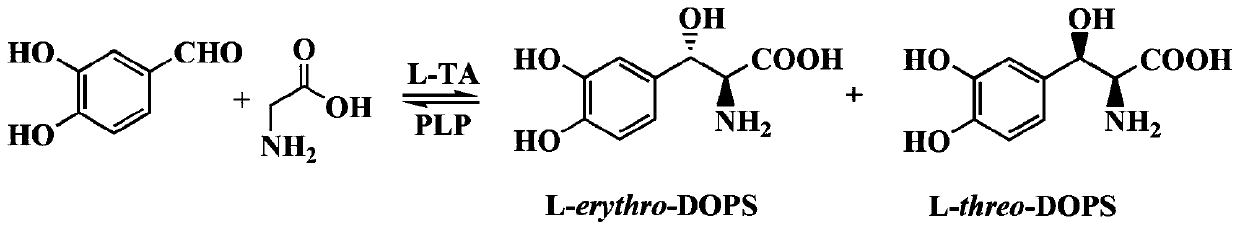

L-threonine aldolase mutant R318M and application thereof

The invention relates to threonine aldolase, in particular to an L-threonine aldolase mutant R318M and application thereof. The amino acid sequence of the L-threonine aldolase mutant is shown as SEQ ID NO: 3, and the L-threonine aldolase mutant is obtained by changing the 318th amino acid of L-threonine aldolase with the amino acid sequence of SEQ ID NO: 1 from Arg to Met. The mutant has diastereoselectivity (de) of 77.1% in a reaction of catalyzing 3, 4-dihydroxy benzaldehyde and glycine to synthesize droxydopa [L-threonine-(3, 4-dihydroxy) phenylserine], the diastereoselectivity (de) is morethan 2.5 times that of a wild type, and the mutant has huge application potential in industrial production of biosynthesis of droxydopa.

Owner:CHONGQING UNIV

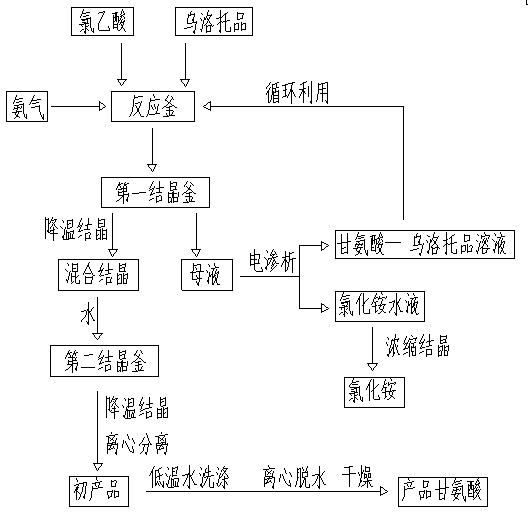

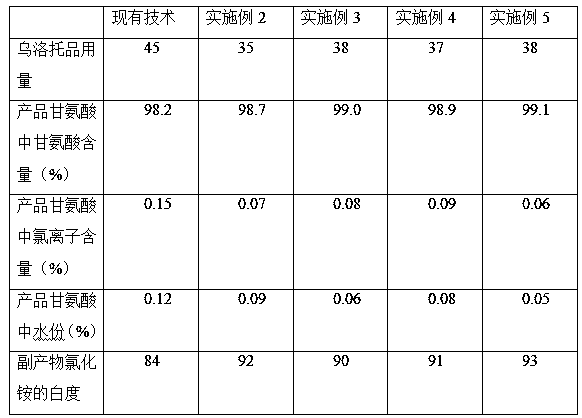

Novel glycine synthesis process

InactiveCN109574864ALow production costGuaranteed qualityOrganic compound preparationAmino-carboxyl compound preparationDistillationHexamethylenetetramine

The invention discloses a novel glycine synthesis process, and belongs to the technical field of glycine production. Chloroacetic acid and ammonia gas serve as raw materials, aminolysis reaction is performed in water solution of methenamine serving as a catalyst, first cooling crystallization is performed after reaction to obtain mixed crystals and mother solution, the mixed crystals are dissolvedby water and then subjected to second cooling crystallization, obtained initial products are washed by low-temperature water and then centrifugally separated and dried to obtain a glycine product, the mother solution is separated by electrodialysis to obtain glycine and methenamine mixed solution and ammonium chloride water solution; conveying the glycine and methenamine mixed solution to a preceding procedure for mechanical application; evaporating, concentrating and crystallizing the ammonium chloride water solution to obtain ammonium chloride. The novel glycine synthesis process solves theproblems that production cost is increased by alcohol-water mixture, mother solution distillation needs a large quantity of energy consumption, and by-product ammonium chloride product is low in theprior art.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

P-hydroxybenzene glycine synthesis technology

InactiveCN101362703BOrganic compound preparationAmino-carboxyl compound preparationSulfite saltHydroxylamine Hydrochloride

The invention belongs to the field of pharmaceutical chemical engineering intermediate production, which relates to a synthesis technology of p-hydroxyphenylglycine (HPG). The purpose of the invention is achieved by the following steps: phenol, glyoxylic acid, water and sulfamic acid carry out the one-pot braise reaction under the action of catalysts such as benzene sulfonic acid, p-toluenesulfonic acid, o-toluenesulfonic acid, and the like; after the reaction is finished, a small amount of reducing substances such as sodium sulfite, sodium bisulfite, hydroxylamine hydrochloride, and the like, are added; finally, the PH value is adjusted by alkali, the mother liquor separation is washed by large amount of water and then washed by organic solvents such as methanol, ethanol, acetone, glacial acetic acid, and the like; the obtained product HPG is white powder, wherein, the content of NPLC is equal to or more than 98.5, which can meet the requirement of splitting. The method has the advantages of low production cost, simple operation, stable quality, etc.

Owner:谢建中

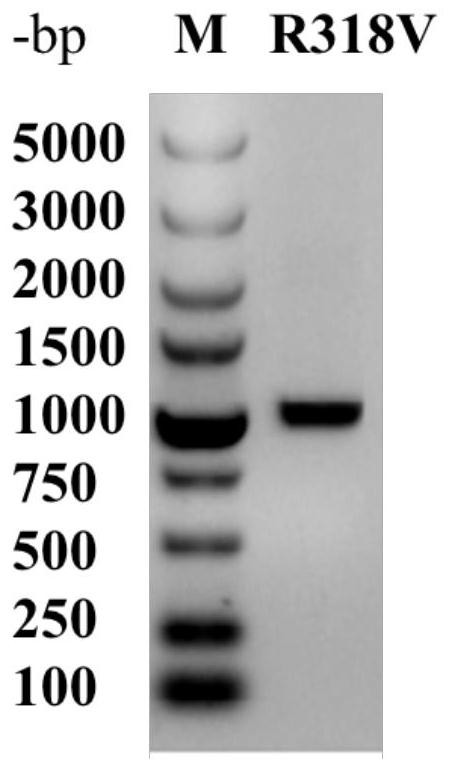

L-threonine aldolase mutant R318V and application thereof

The invention relates to threonine aldolase, in particular to an L-threonine aldolase mutant R318V and application thereof. The amino acid sequence of the L-threonine aldolase mutant is shown as SEQ ID NO: 3, and the L-threonine aldolase mutant is obtained by changing the 318th amino acid of L-threonine aldolase with the amino acid sequence of SEQ ID NO: 1 from Arg to Val. The mutant has 79.9% diastereoselectivity (de) in a reaction of catalyzing 3, 4-dihydroxy benzaldehyde and glycine to synthesize droxydopa [L-threonine-(3, 4-dihydroxy) phenylserine], the diastereoselectivity (de) is more than 2.6 times that of a wild type, and the mutant has huge application potential in industrial production of biosynthesis of droxydopa.

Owner:CHONGQING UNIV

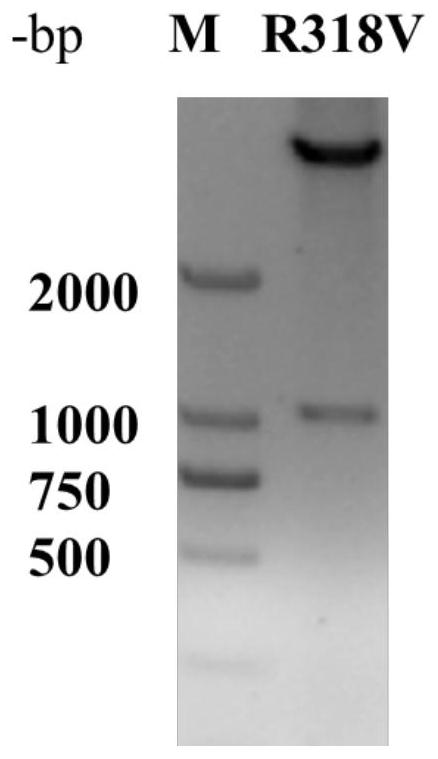

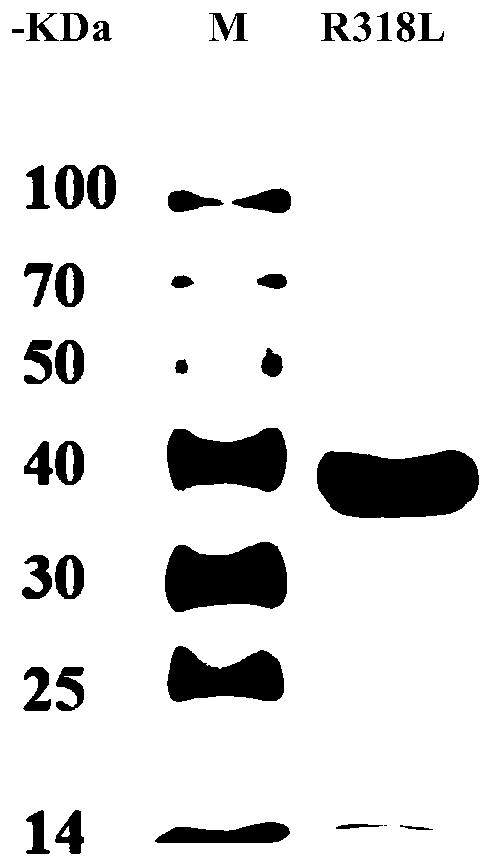

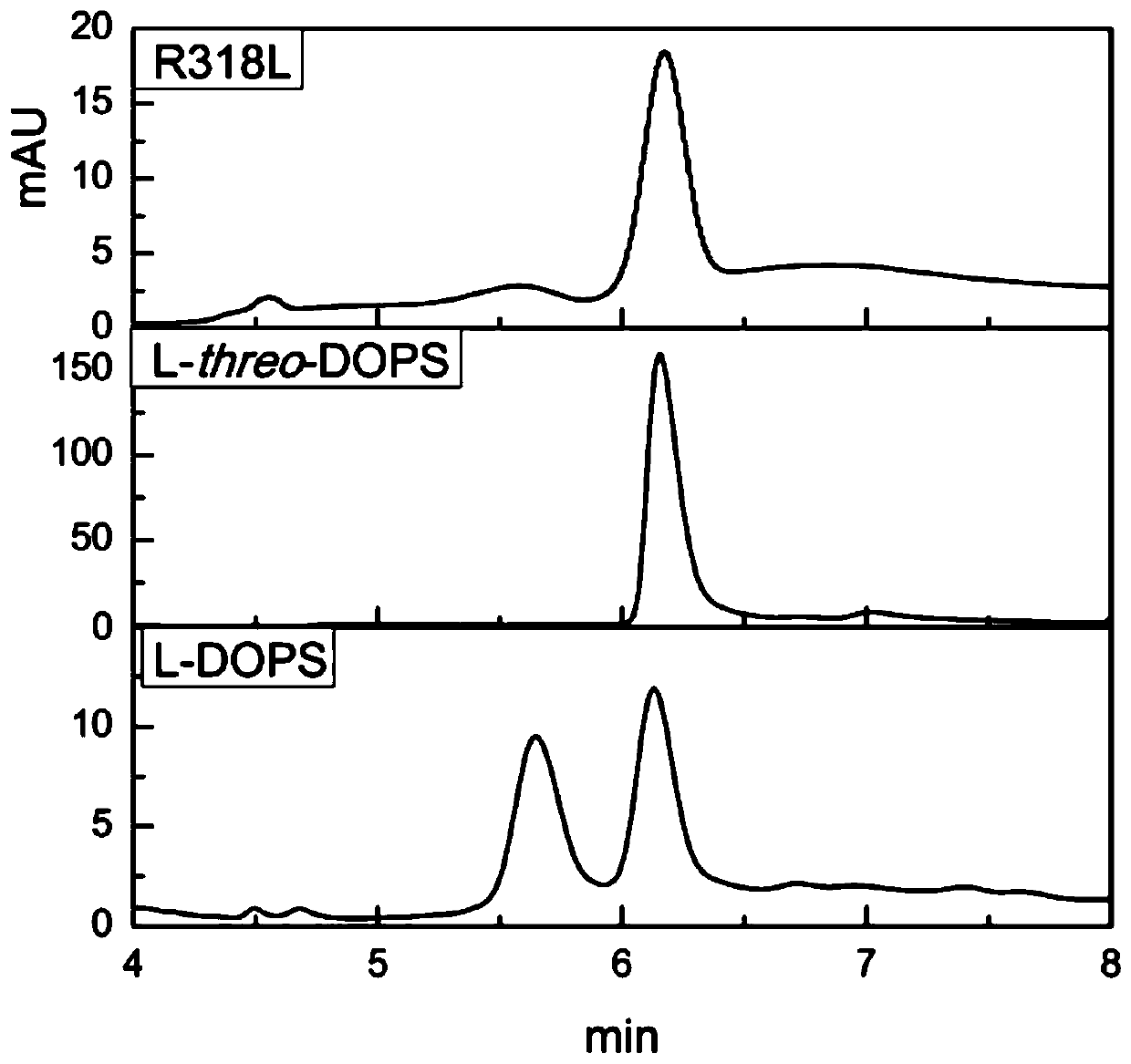

L-threonine aldolase mutant R318L and application thereof

The present invention relates to threonine aldolase and particularly to an L-threonine aldolase mutant R318L and an application thereof. An amino acid sequence of the L-threonine aldolase mutant is shown in SEQ ID NO:3 and the L-threonine aldolase mutant is obtained by changing the 318th site amino acid of L-threonine aldolase with an amino acid sequence of SEQ ID NO:1 from Arg to Leu. The mutanthas a diastereoselectivity of 84.9% in catalyzing synthesis of droxidopa [L-threo-(3,4-dihydroxy)phenylserine] from 3,4-dihydroxybenzaldehyde and glycine, the diastereoselectivity of the mutant is 2.8 times that of the wild type, and the mutant has huge application potential in the biosynthesis of the droxidoca.

Owner:CHONGQING UNIV

Technology for treating phenol-contained wastewater in synthetic process of L-(+)-D-p-hydroxyphenylglycine

InactiveCN101759268AWater contaminantsMultistage water/sewage treatmentDistillationTherapeutic effect

The invention relates to a technology for treating phenol-contained wastewater in the synthetic process of L-(+)-D-p-hydroxyphenylglycine, which belongs to the technical field of the treatment of organic chemical wastewater. In the method, after the distillation pretreatment is carried out on synthesized wastewater, the macroporous resin adsorption treatment is carried out on the collected phenol-contained wastewater, wherein the pretreatment comprises the step of carrying out acidized pretreatment on the synthesized wastewater. In the method, because a phenol-contained substance in the wastewater is removed in advance, the recycling and processing difficulty of the subsequent inorganic salt can be greatly improved. The recycled sodium phenolate can be charged back to the synthesizing section of p-hydroxyphenylglycine. The method has stable and reliable treatment effect, low treatment cost and simple, convenient and easily-applied operation and is easy to realize industrialized application.

Owner:HENAN NEWLAND PHARMA

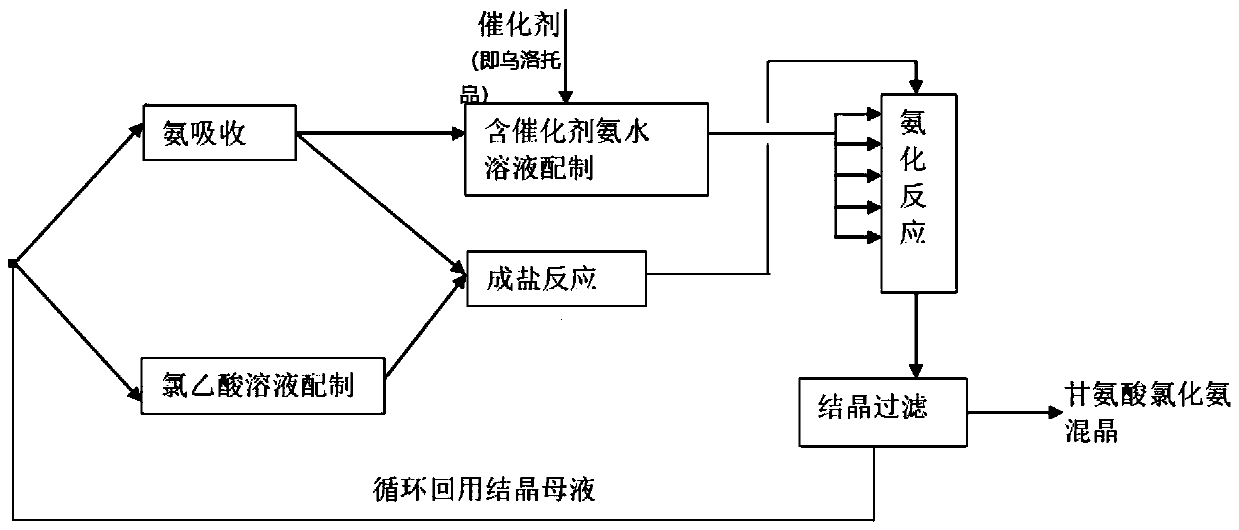

Method for preparing glycine by utilizing common ion effect

ActiveCN111196768AHigh yieldQuality improvementOrganic compound preparationAmino-carboxyl compound preparationCommon-ion effectPtru catalyst

The invention relates to a clean production process for preparing glycine in an alcohol-water mixed solvent by utilizing the common ion effect. A novel catalyst pyridine base compound or a traditionalcatalyst urotropine and paraformaldehyde is adopted as the catalyst. The method comprises the following steps: ammoniating ammonium chloroacetate in an alcohol-water mixed solvent under the conditionof a catalyst by introducing ammonia to synthesize glycine, carrying out centrifugal separation to obtain glycine, adding a solid chlorethamin into the mixed solvent obtained by centrifugation, cooling to 0-20 DEG C, and carrying out centrifugal separation to obtain ammonium chloride, and centrifugally separating ammonium chloride to obtain a circular reaction mixed solvent, and circularly carrying out a glycine synthesis reaction.

Owner:北京长邦科技有限公司

Method of catalytically synthesizing para hydroxybenzene hydantoin by solid acid

InactiveCN107987023ASolve pollutionSolve corrosivePhysical/chemical process catalystsOrganic chemistryHigh concentrationPara-hydroxymandelic acid

The invention relates to a method of catalytically synthesizing para hydroxybenzene hydantoin by solid acid. The method is characterized by synthesizing para hydroxybenzene hydantoin in the presence of a solid superacid catalyst SO4<2-> / ZrO2 / TiO2 or SO4<2-> / ZrO2 / SiO2. The technical scheme comprises synthesis of hydroxymandelic acid, synthesis of N-carbamyl-4-hydroxyl phenylglycine and synthesis ofpara hydroxybenzene hydantoin. The method not only solves the pollution problem of high concentration phenol waste acid and corrosion problem of production equipment, but also can control generationof o-hydroxybenzene hydantoin effectively, so that the synthetic yield of para hydroxybenzene hydantoin is improved.

Owner:TIANJIN VOCATIONAL INST

Process for treating glyphosate mother liquid

ActiveCN1277835CReduce solubilityReduce manufacturing costGroup 5/15 element organic compoundsEnergy consumptionGlycine synthesis

The present invention relates to the process of treating glyphosate mother liquor from glycine synthesis process. The treating process includes the following successive steps: 1) introducing ammonia into glyphosate mother liquor to regulate pH to 7-10, letting stand and recovering triethylamine from the upper layer; and 2) decompression distilling lower layer of the mother liquor, cooling, filtering to eliminate ammonium chloride crystal and to obtain concentrated ammonium glyphosate liquid. The said treating process has low production cost, low power consumption and environment friendship, and can obtain concentrated liquid with raised effect. Furthermore, glyphosate may be separated from the mother liquor to raise total glyphosate yield.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Technology for treating DL-p-hydroxyphenylglycine synthetic mother liquor phenol-containing sewage

InactiveCN101759267AWater contaminantsMultistage water/sewage treatmentDistillationTherapeutic effect

The invention relates to a technology for treating DL-p-hydroxyphenylglycine synthetic mother liquor phenol-containing sewage, which belongs to the technical field of the treatment of organic chemical sewage. In the method, the distillation pretreatment is carried out firstly on the synthetic sewage, and then the macroporous resin adsorption treatment is carried out on the collected phenol-containing sewage, wherein the pretreatment comprises the step of carrying out acidized pretreatment on the synthetic sewage firstly. Because phenol-containing substances in the sewage are removed in advance in the method, the difficulty of subsequent inorganic salt recycling treatment can be greatly improved. The recycled sodium phenolate can be charged back to the synthetic working section of p-hydroxyphenylglycine. The method has stable and reliable treatment effect, low treatment cost and simple and easily-applied operation, is easy to realize industrialized application, reduces the production cost and solves the problem of environmental protection.

Owner:HENAN NEWLAND PHARMA

Raw materials for synthesizing glycine and method for improving glycine synthesis process

InactiveCN101735084ARapid responseOrganic compound preparationAmino-carboxyl compound preparationHexamethylenetetramineReaction temperature

The invention provides raw materials for synthesizing glycine and a method for improving glycine synthesis process. In the method, the glycine is synthesized by using industrial products of solid ammonium chloroacetate and ammonium bicarbonate as raw materials, water as a solvent and urotropine as a catalyst. The method has the advantages of lower reaction temperature, a few side reaction, a few impurities in the products of glycine, high quality and over 90 percent synthesis rate; and the method also has the advantages of cyclic utilization of mother liquor, less consumption of the catalyst, easy operation, high safety, low corrosiveness and little pollution.

Owner:郭颖

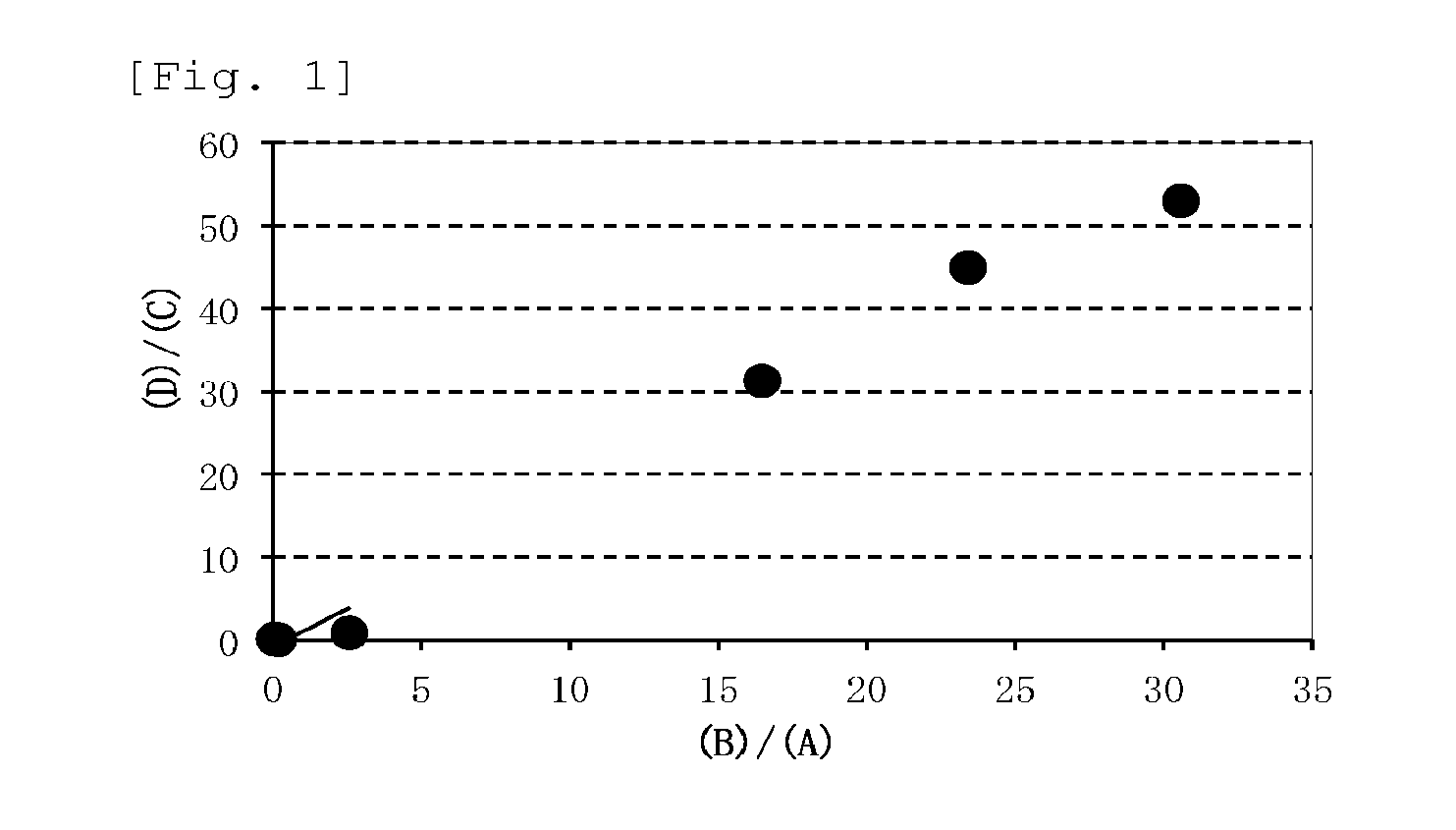

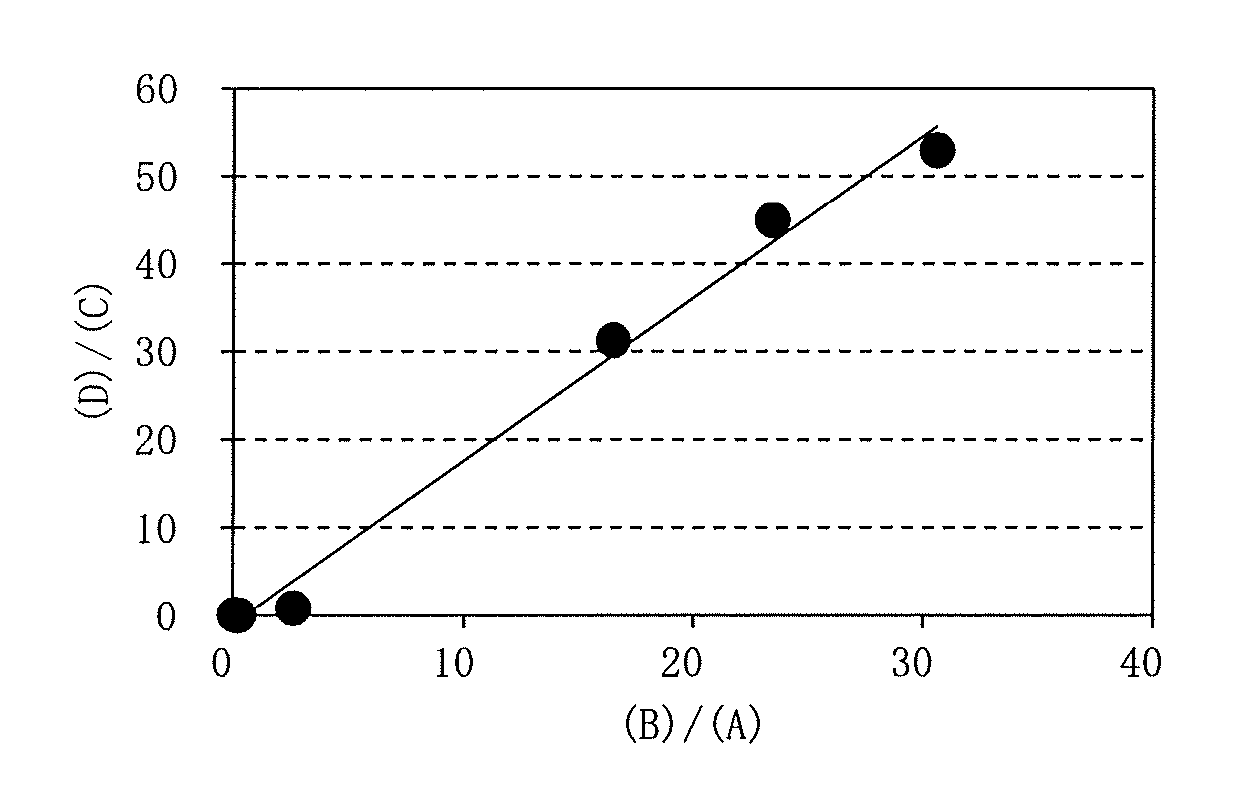

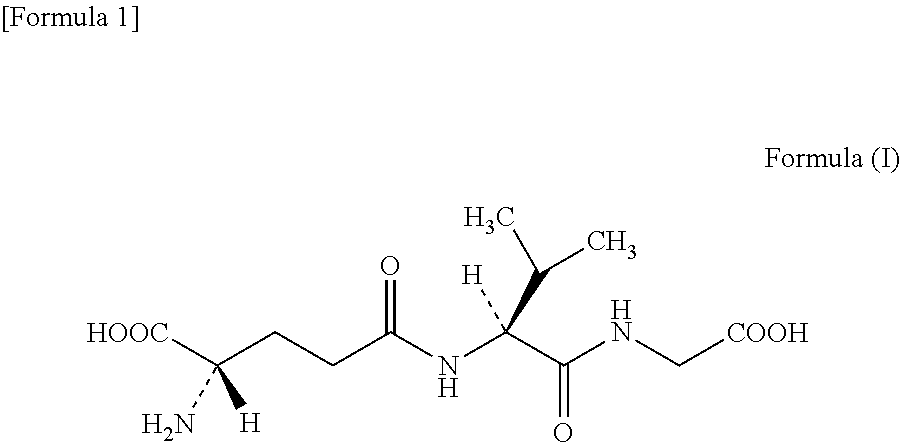

Gamma-glutamyl-valine synthase, and method for producing gamma-glutamyl-valyl-glycine

γ-Glu-Val synthetase suitable for generating γ-Glu-Val, and a method for producing γ-Glu-Val-Gly using the same are provided. By using γ-Glu-Val synthetase showing a ratio of γ-glutamylvaline synthetase activity to γ-glutamylglycine synthetase activity of 2.0 or higher, such as γ-Glu-Val synthetase of Kocuria rosea (AJ3132), γ-Glu-Val-Gly is produced from Glu, Val, and Gly as raw materials.

Owner:AJINOMOTO CO INC

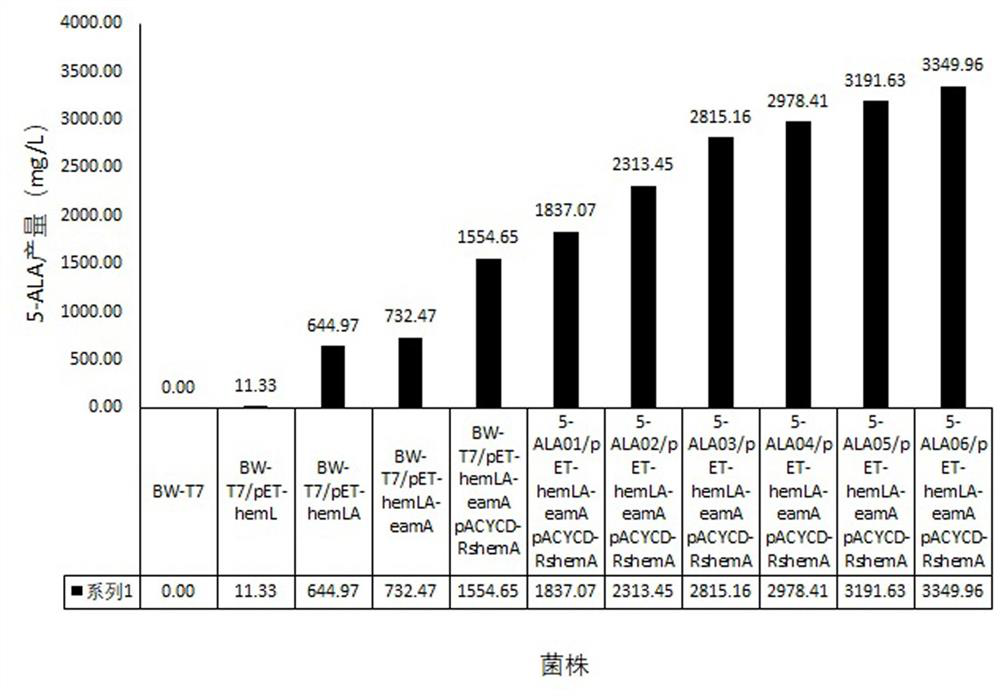

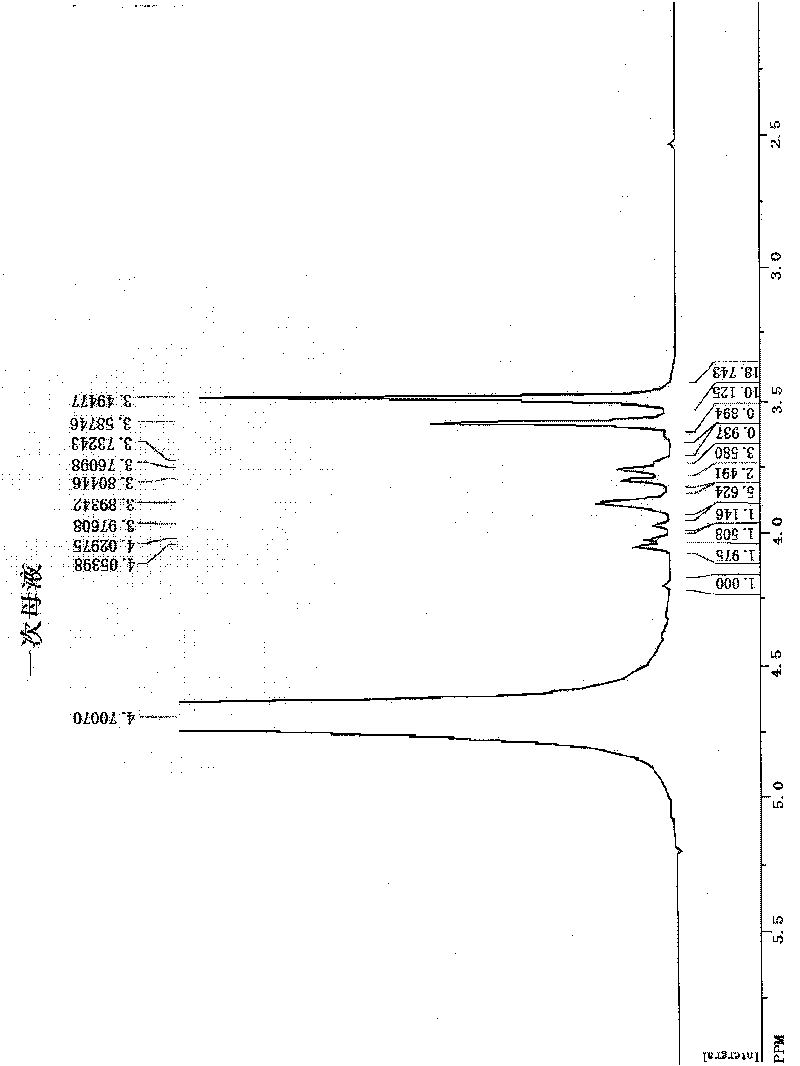

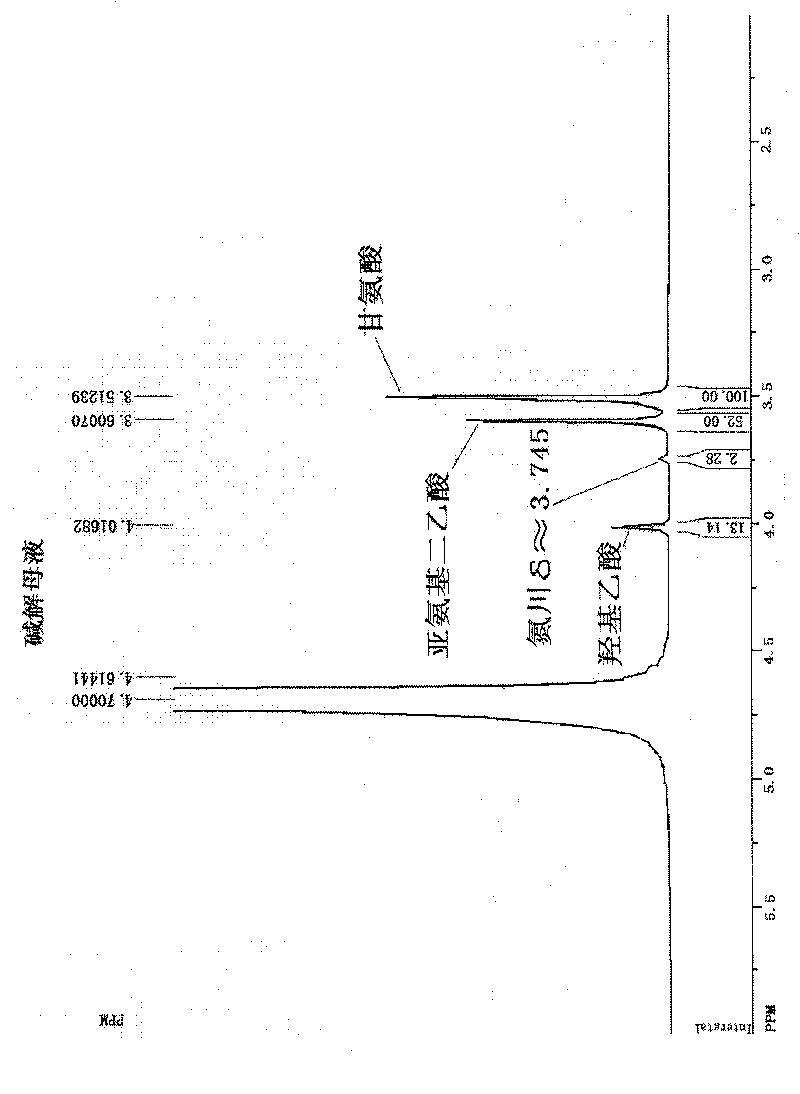

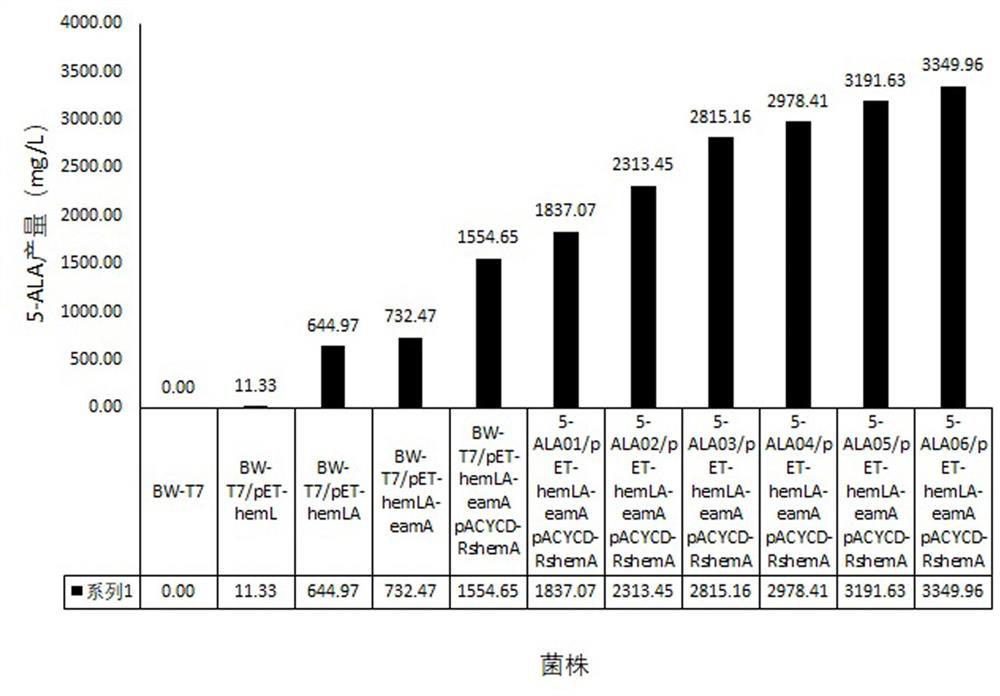

Recombinant escherichia coli strain with high yield of 5-aminolevulinic acid and application of recombinant escherichia coli strain

ActiveCN114381416AImprove efflux capacityImprove utilization efficiencyBacteriaMicroorganism based processesEscherichia coliGlucose utilization

The invention discloses a recombinant escherichia coli strain for producing 5-aminolevulinic acid (5-ALA). The invention also discloses a way for efficiently synthesizing the 5-aminolevulinic acid, wherein the 5-aminolevulinic acid synthetase (HemL and HemA) of the escherichia coli is enhanced, and the strain has the capability of synthesizing the 5-aminolevulinic acid preliminarily; the expression of the 5-aminolevulinic acid efflux protein eamA gene is enhanced, and the 5-aminolevulinic acid efflux capability of the strain is improved; an exogenous 5-aminolevulinic acid synthetase hemA gene is introduced, so that the 5-aminolevulinic acid synthesis capability of the strain is enhanced; galR, glk and ppc genes of a glucose utilization way are modified, and the utilization efficiency of glucose is improved; and genes (hemF, poxB and aceB) of metabolic bypasses are knocked out. The recombinant Escherichia coli strain constructed by the invention has the capability of efficiently synthesizing 5-aminolevulinic acid by using glucose and glycine, so that the recombinant Escherichia coli strain has the application of industrially producing 5-aminolevulinic acid.

Owner:北京道合成企业管理有限公司

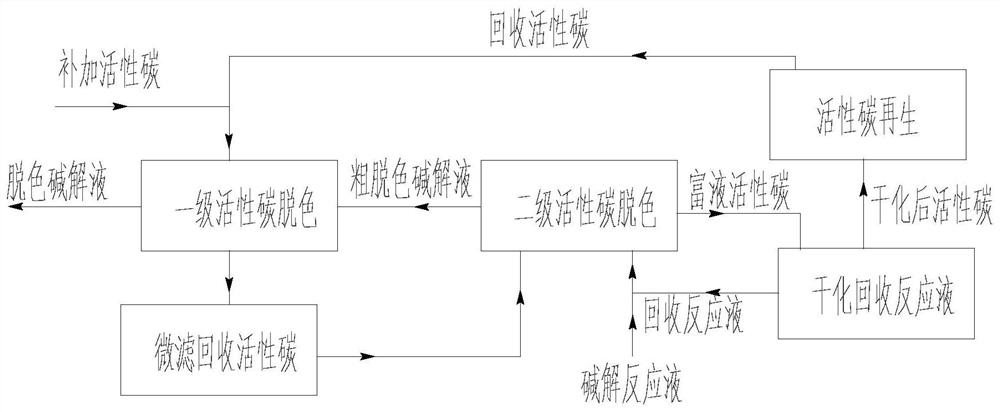

Method for removing impurities in glycine synthetic process

ActiveCN101747218AGuaranteed qualityReduce difficultyOrganic compound preparationAmino-carboxyl compound preparationAcetonitrileAlkaline hydrolysis

The invention provides a method for removing impurities in glycine reaction liquid and mother liquid in a glycine preparing process by using a glycolonitrile method. The method comprises the following steps: carrying out independent backflow to alkaline hydrolysis synthetic liquid after alkaline hydrolysis is finished or mixing the glycine mother liquid and liquid alkaline synthetic liquid and then carrying out the alkaline hydrolysis; carrying out intermittent or continuous production under high-temperature backflow; and finally removing the impurities.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

Device and process for washing glycine crude product through alcohol phase method

ActiveCN110305028AWill not affect the overall yieldGuaranteed industrial productionOrganic compound preparationAmino-carboxyl compound preparationChloroacetic acidsSolvent

The invention relates to a device and a process for washing a glycine crude product through an alcohol phase method. A glycine centrifuge is connected with a diluted methanol washing tank which is connected with a glycine extraction kettle through a diluted methanol pump, the glycine extraction kettle is connected with an extracted glycine centrifuge which is connected with a methanol rectifying tower through an extract transfer pump, and the methanol rectifying system is connected to a red ammonium concentration system. Alcohol and chloroacetic acid are taken as a solvent and an initial raw material respectively in the process, a glycine product meeting glyphosate synthesis requirements and reaching national standards (main content being greater than or equal to 98.5% and chlorine root being less than or equal to 0.4%) is obtained by treating the glycine crude product (glycine main content being 93-96%, chlorine root being 2-4% and other impurities being lower than 1%) produced by newprocesses like a mixed solvent or organic amine or novel halogen formula reagent method through a systematic industrial washing process, and glycine synthesis yield is unaffected; wastewater is completely recycled into a system, so that clean production is realized.

Owner:HUBEI TAISHENG CHEM

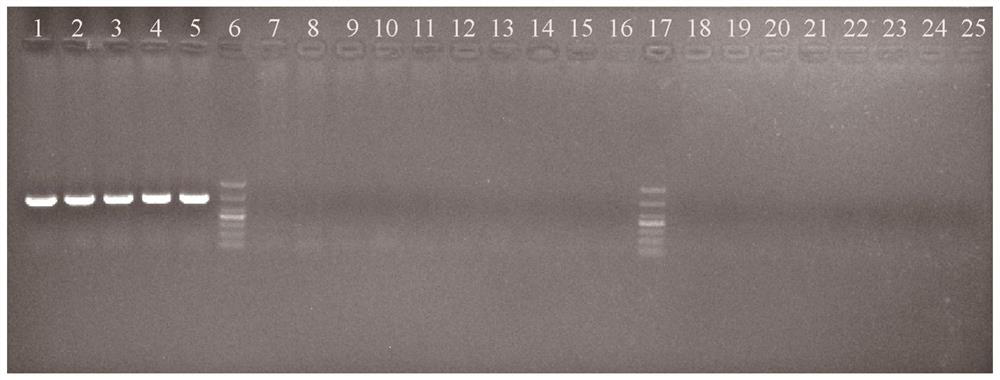

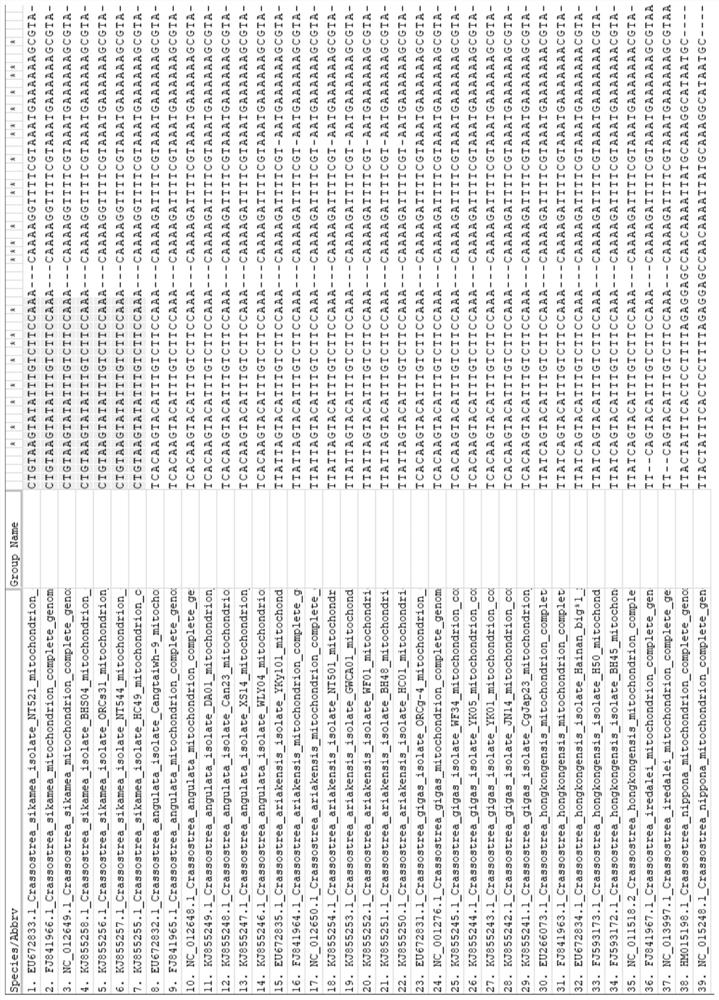

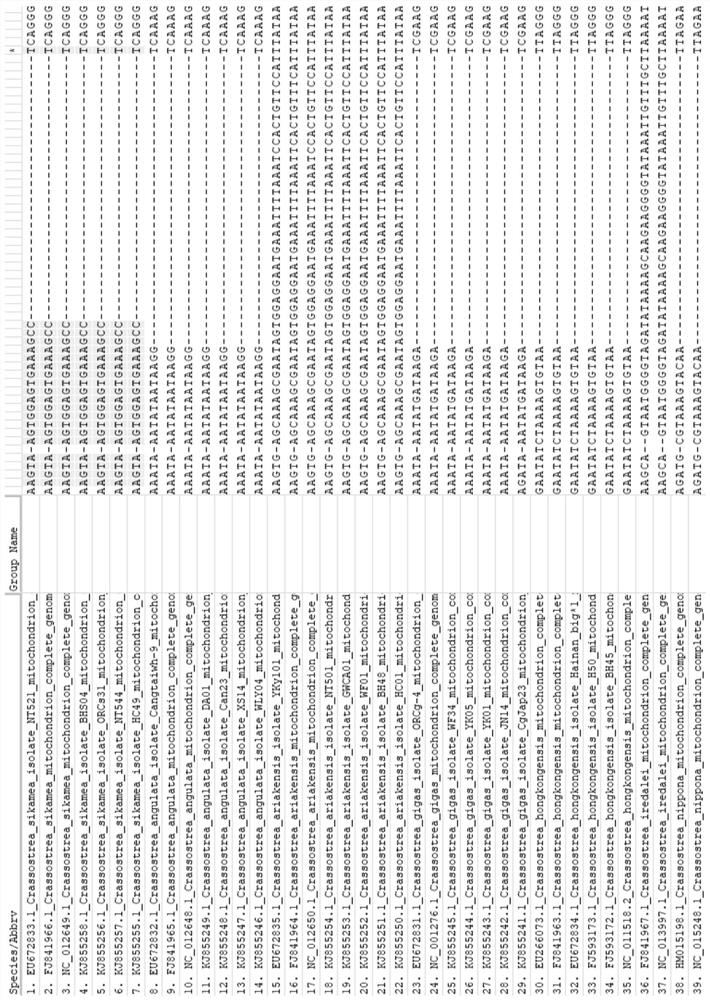

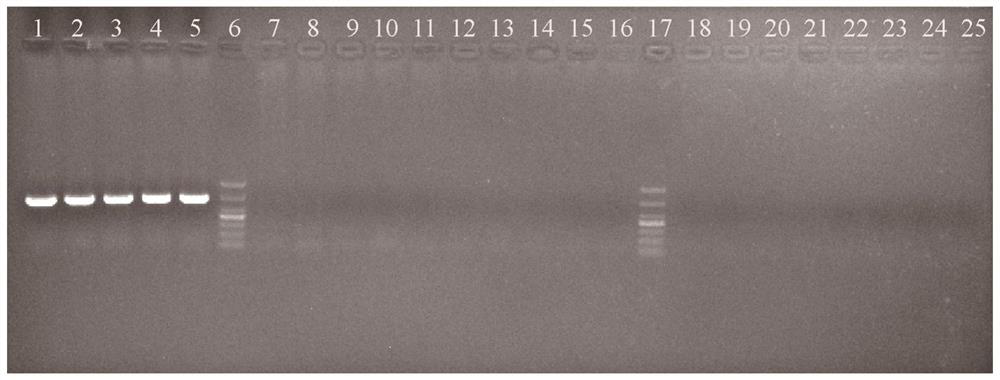

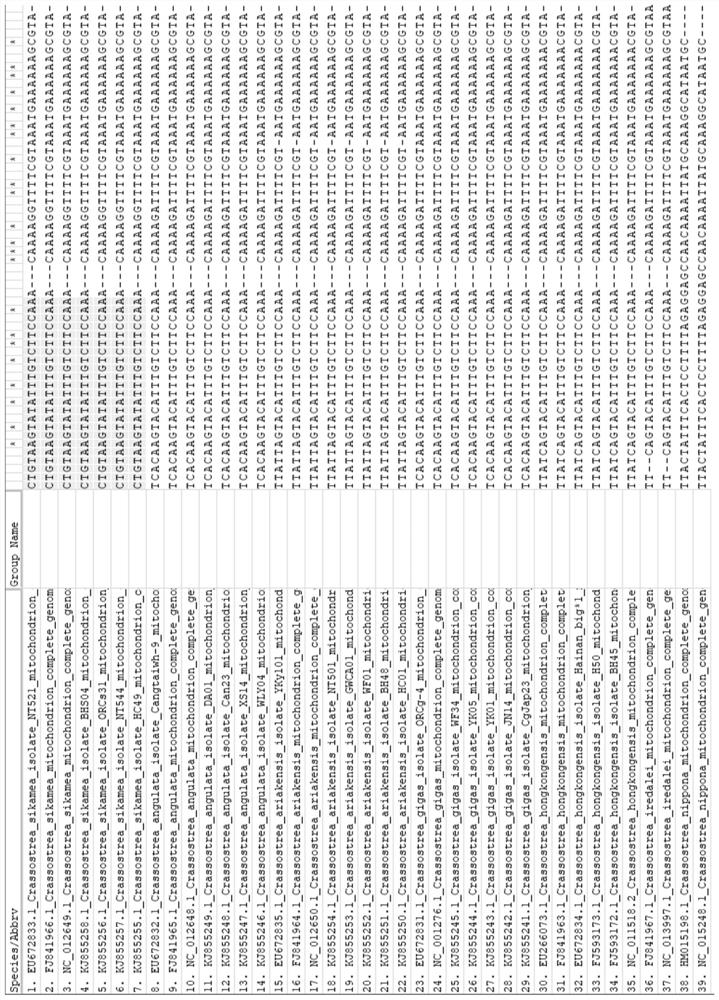

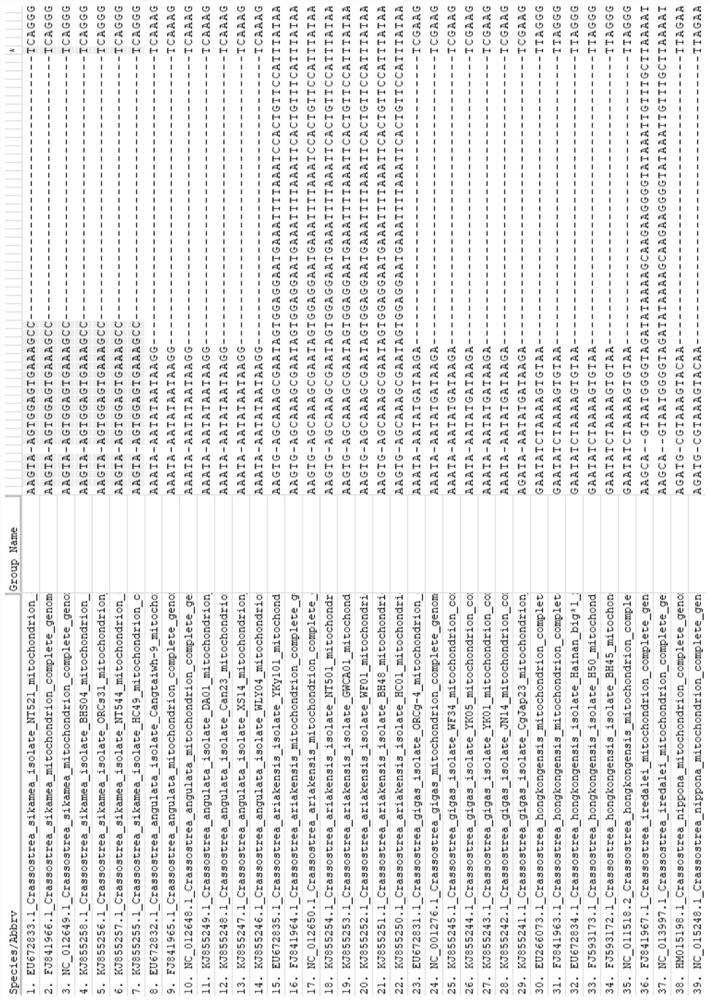

Characteristic sequence, specific identification primer and identification method for identifying crassostrea sikamea

ActiveCN112626238ARapid identificationHigh polymorphismMicrobiological testing/measurementDNA/RNA fragmentationBiotechnologyNucleotide

The invention discloses a characteristic sequence, specific identification primer and identification method for identifying crassostrea sikamea. The characteristic sequence is located in a mitochondrial non-coding region between glycine tRNA synthetase and proline tRNA synthetase of the crassostrea sikamea, and the characteristic sequence is a nucleotide sequence as shown in SEQ ID NO.1; a sequence of the specific identification primer comprises an upstream primer MNR-F: 5' -CTGTAAGTATATTTGTCTTCCA-3' ; and a downstream specific primer MNR-S-R: 5' -AGGCTTTCACTCCACTTACT-3' . According to the invention, the crassostrea sikamea can be effectively distinguished from other four drassostrea species, the length of the determined characteristic sequence of the crassostrea sikamea is 660+ / -5 bp, and whether the crassostrea sikamea exists or not can be judged according to the existence and the size of a specific band. In the field of crassostrea sikamea germplasm resource protection and crassostrea sikamea breeding, species identification can be conducted on parent crassostrea sikamea before seed breeding, and it is guaranteed that bred seeds are purebreds and are not affected by other species possibly hybridized with the bred seeds.

Owner:浙江万里学院宁海海洋生物种业研究院 +1

Method for processing triethylamine method glycine circulating mother liquid according to membrane separation technology

InactiveCN103420789ACalcareous fertilisersAmino compound purification/separationSeparation technologyNanofiltration

The invention provides a method for processing triethylamine method glycine circulating mother liquid according to the membrane separation technology. Through the trapping performance and the charge performance of a nanofiltration membrane, separation of colored by-products generated in the reaction process of triethylamine hydrochloride, glycine and the mother liquid is achieved. Through the separation of the nanofiltration membrane, most of the triethylamine hydrochloride, most of the glycine and part of urotropine in the glycine reaction circulating mother liquid permeate the nanofiltration membrane to enter nanofiltration percolate, and most of the colored by-products and part of the urotropine are trapped into trapped liquid. The nanofiltration percolate returns to a glycine synthesis system to be recycled.

Owner:刘长飞

Gamma glutamyl-valine synthase, and method for producing gamma glutamyl-valyl-glycine

γ-Glu-Val synthetase suitable for generating γ-Glu-Val, and a method for producing γ-Glu-Val-Gly using the same are provided. By using γ-Glu-Val synthetase showing a ratio of γ-glutamylvaline synthetase activity to γ-glutamylglycine synthetase activity of 2.0 or higher, such as γ-Glu-Val synthetase of Kocuria rosea (AJ3132), γ-Glu-Val-Gly is produced from Glu, Val, and Gly as raw materials.

Owner:AJINOMOTO CO INC

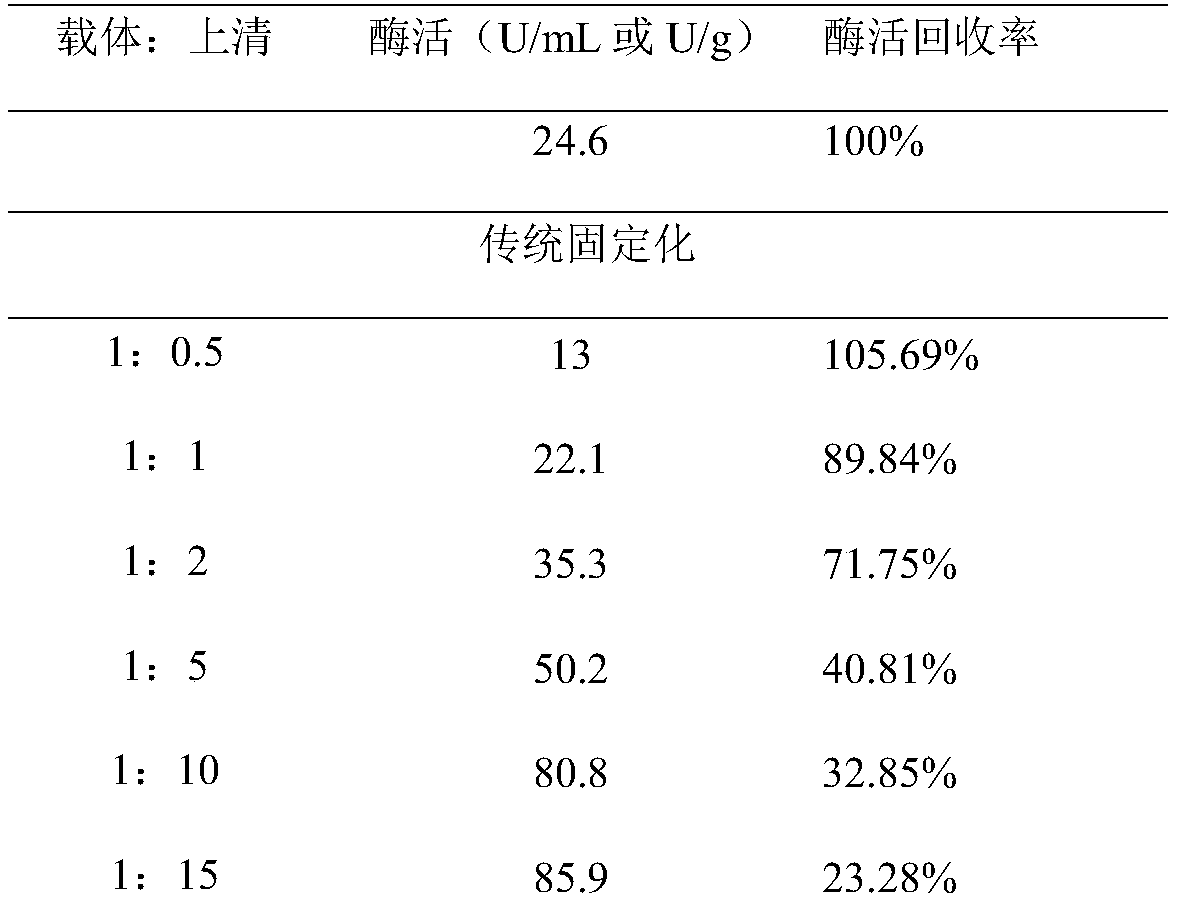

Method for performing one-step purification and immobilization on alpha-amino acid fatty acyl transferase

ActiveCN108728424AAchieve one-step purificationReduced purification stepsTransferasesVector-based foreign material introductionProtein targetAcyl group

The invention relates to the technical field of enzyme immobilization and particularly discloses a method for performing one-step purification and immobilization on alpha-amino acid fatty acyl transferase. The method comprises the following steps: performing aldehyde labeling on the alpha-amino acid fatty acyl transferase, performing synchronous induction on the alpha-amino acid fatty acyl transferas and formylglycine synthetase in host cells to obtain a bacterial strain with high expression quantity, crushing the thallus, taking supernatant, and mixing the supernatant and an amino carrier torealize one-step immobilization of the alpha-amino acid fatty acyl transferase, wherein an additional purification step is not needed. By the method, the operation steps are saved, expression of the target protein is guaranteed, immobilization can be realized by the common amino carrier, and the method is suitable for industrialized production.

Owner:HEBEI FITNESS BIOTECH CO LTD

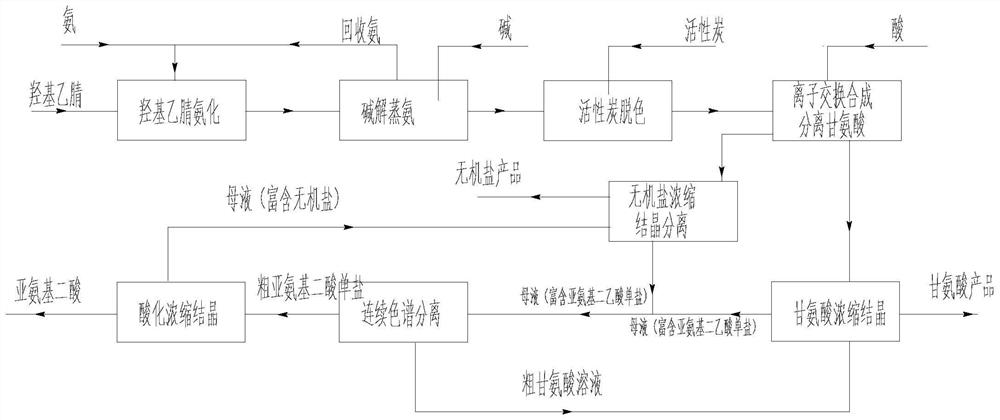

Production process of glycine

PendingCN113563215ASuitable for industrial productionReduced unevenness coefficientOrganic compound preparationAmino-carboxyl compound preparationIminodiacetic acidInorganic salts

The invention discloses a production process of glycine. The production process comprises the following steps of: S1, performing ammonification; S2, performing alkaline hydrolysis ammonia distillation; S3, performing decolorizing with activated carbon; S4, performing ion exchange acidification separation, specifically, performing ion exchange reaction on metal ions of discolored glycinate and H < + > on ion exchange resin to generate glycine, discharging the glycine out of a system along with an aqueous solution, performing ion exchange reaction on iminodiacetic acid disalt and the H < + > to generate iminodiacetic acid monosalt, adsorbing the iminodiacetic acid monosalt on the resin, discharging the iminodiacetic acid monosalt and an inorganic salt solution generated in a resin regeneration process out of the system; S5, concentrating and crystallizing glycine, and when the iminodiacetic acid monosalt in circulating mother liquor is accumulated to 10% or above of the total solute, pumping out the mother liquor, concentrating and crystallizing the inorganic salt, and when iminodiacetic acid monosalt in the solute of the circulating mother liquor is accumulated to 15% or above of the total solute, extracting the mother liquor; S6, mixing the extracted mother liquor, and carrying out continuous chromatographic separation; and S7, recycling the iminodiacetic acid. The production process of the glycine provided by the invention has good glycine synthesis and separation effects.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

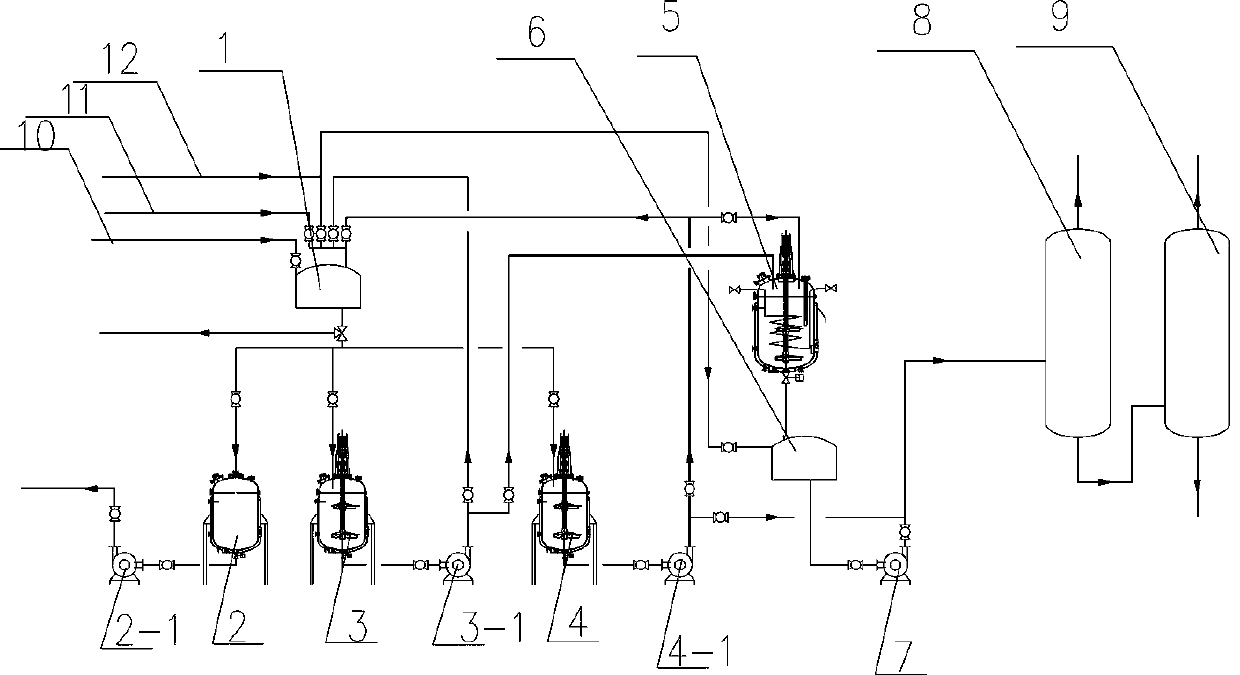

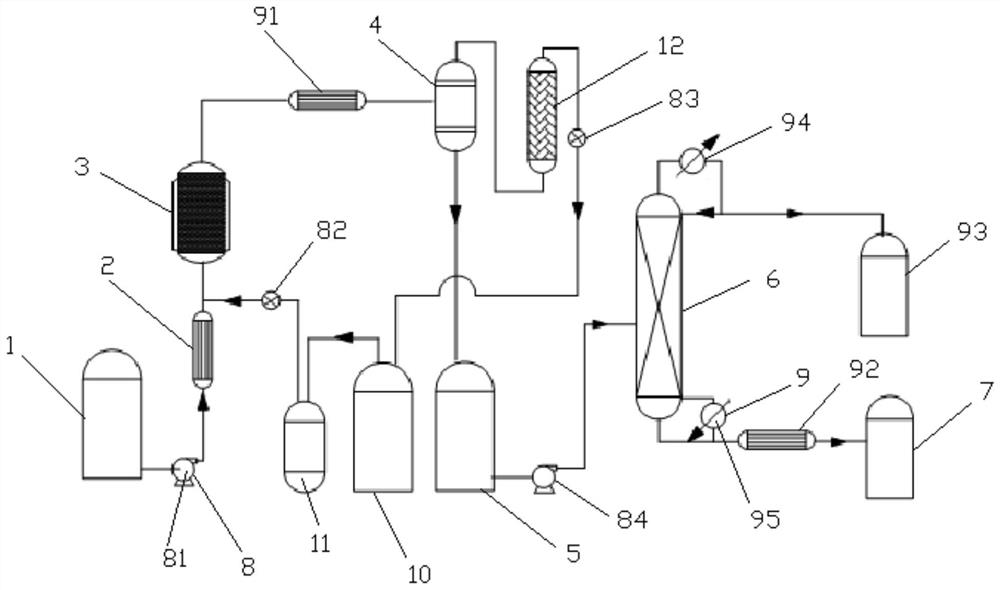

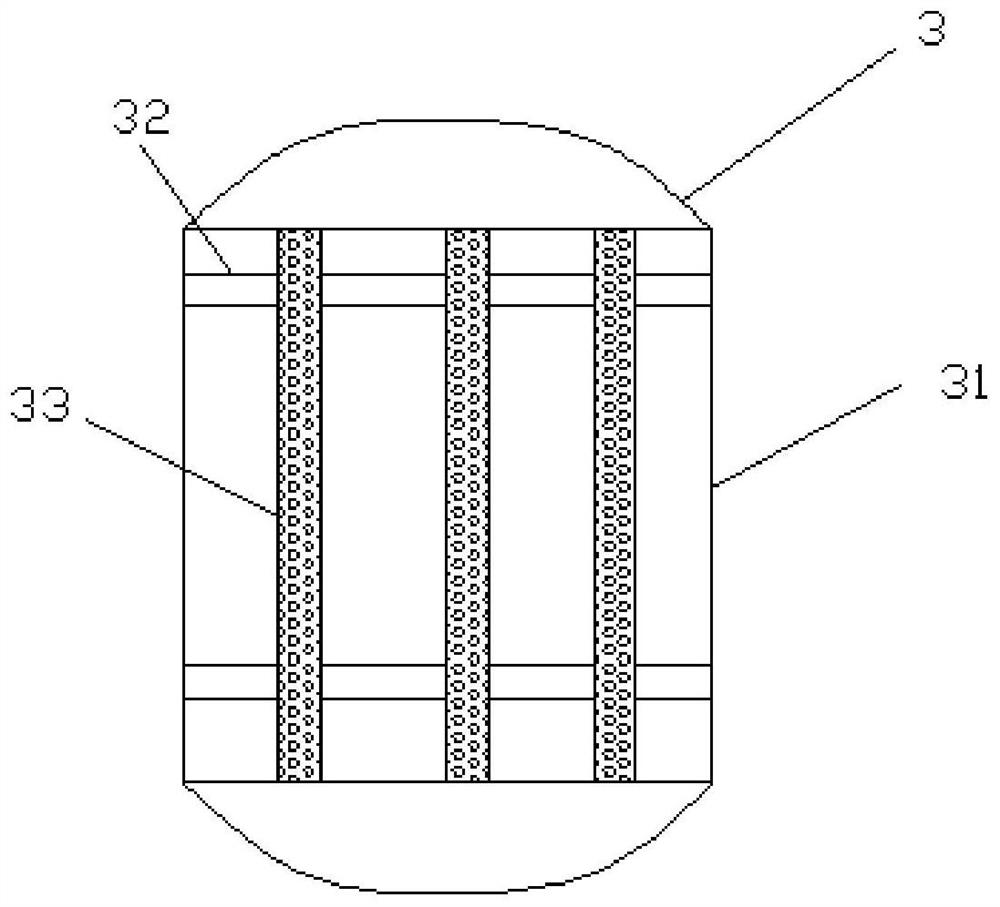

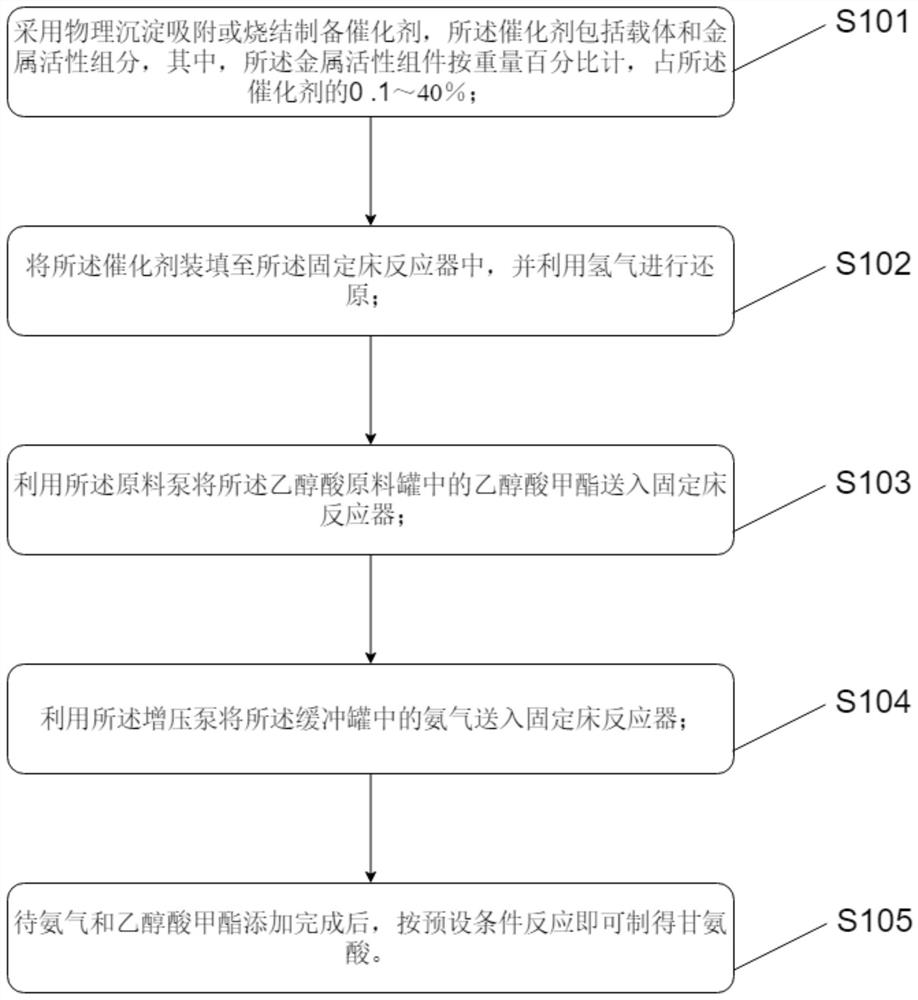

Glycine production process and device

PendingCN112358408AMild reaction conditionsHigh reaction conversion rateOrganic compound preparationAmino-carboxyl compound preparationPtru catalystVapor–liquid separator

The invention discloses a glycine production device, which comprises a methyl glycolate raw material tank, a preheater, a reactor, a gas-liquid separator, a first temporary storage tank, a product refining tower, a product tank, a pump set and an accessory set. An outlet of the methyl glycolate raw material tank is communicated with an inlet of the preheater through the pump set, an outlet of thepreheater is communicated with an inlet of the reactor, and the outlet of the reactor is communicated with the inlet of the gas-liquid separator through the accessory set. The invention also disclosesa glycine production process adopting the glycine production device. The process comprises the following steps: preparing a catalyst; adding methyl glycolate and ammonia gas; preparing glycine through reaction according to preset conditions. A new synthesis route is provided on the basis of an existing glycine synthesis route, methyl glycolate which is easy to obtain serves as a raw material, glycine is synthesized through catalytic ammonolysis, and compared with other routes, the route is mild in reaction condition, high in reaction conversion rate, free of participation of other solvents and small in emission.

Owner:江苏凯美普瑞工程技术有限公司

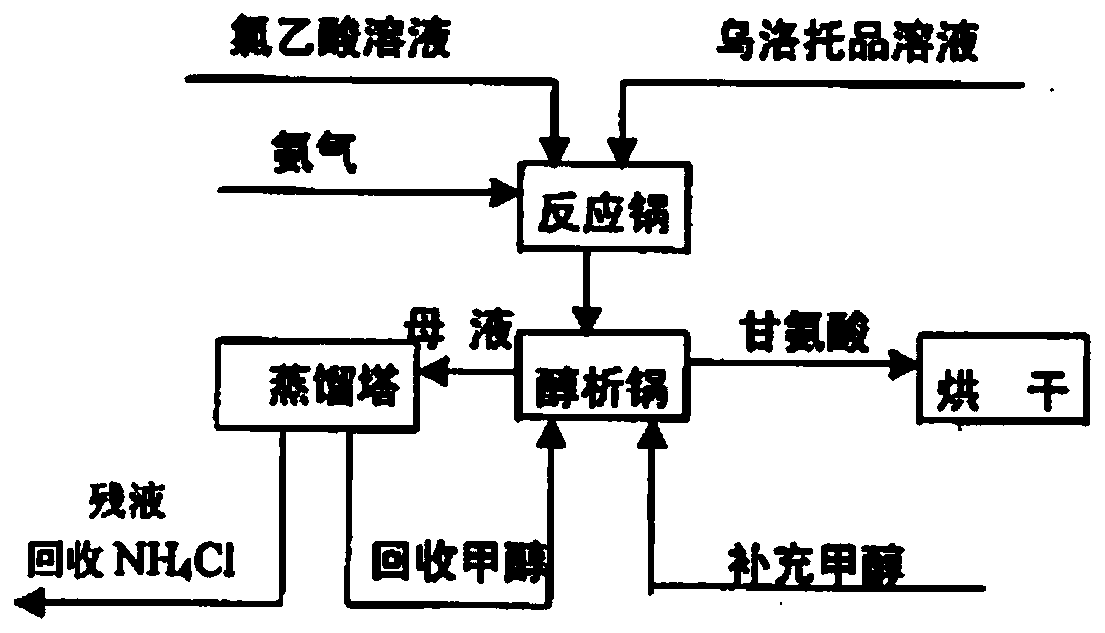

Continuous glycine synthesis method

ActiveCN111187173ASolve production environmental problemsAvoid the problem of low reaction yieldOrganic compound preparationAmino-carboxyl compound preparationHexamethylenetetramineChloroacetic acids

The invention relates to a continuous glycine synthesis method. The method comprises the following steps: preparing ammonia water; then mixing a chloroacetic acid solution with the ammonia water for asalifying reaction to obtain a solution A; dividing a mixed solution containing urotropin and ammonia water into a plurality of parts, separately adding the plurality of parts of the mixed solution into the solution A, carrying out an ammoniation reaction, and then performing cooling, crystallizing, and separating to obtain a mixed crystal of glycine and ammonium chloride and a mixed crystal mother liquor; taking the mixed crystal mother liquor as a solvent for preparing the ammonia water used in the step (1) or the chloroacetic acid solution used in the step (2); and continuing the reactionto realize continuous synthesis of glycine. According to the invention, a conventional one-step method is divided into three parts, i.e., ammonia dissolution, a salifying reaction and the ammoniationreaction, so a required amount of the ammonia water can be uniformly mixed with feed liquid, the problem of generation of many byproducts caused by local overheating due to ammonia absorption or a toohigh pH value of local feed liquid is avoided, the defects of conventional processes are effectively avoided, glycine yield is increased, and urotropine consumption is reduced.

Owner:TIANJIN TIANDI CHUANGZHI TECH DEV +1

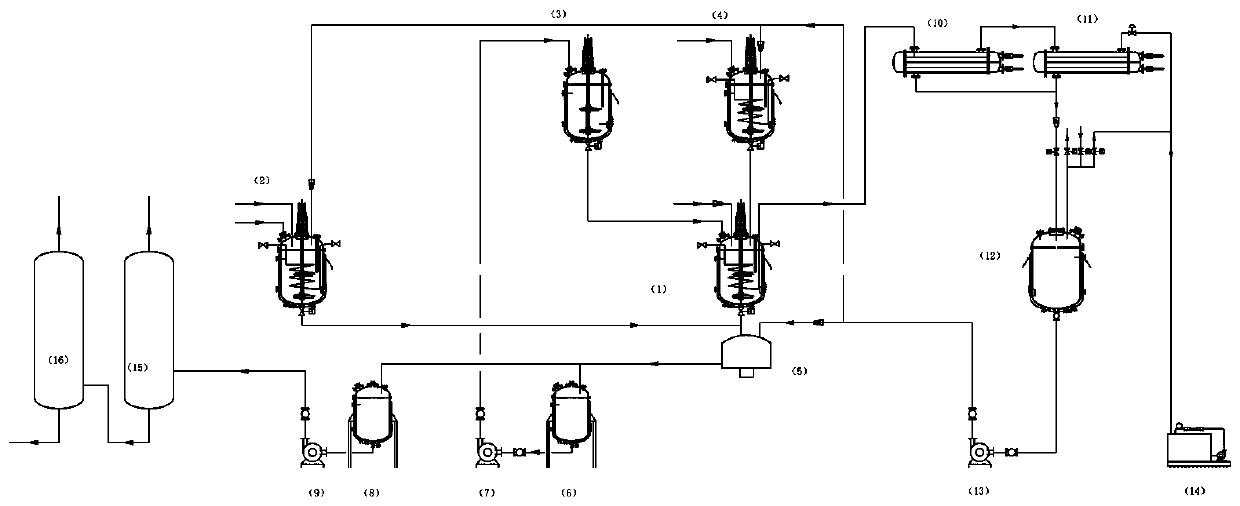

Process and device for producing glycine by alcohol phase method

PendingCN111362819ASignificant environmental benefitsLow cost of industrializationOrganic compound preparationAmino-carboxyl compound preparationPtru catalystAlcohol

The invention relates to a process and a device for producing glycine by an alcohol phase method. The main process comprises the following steps: taking methanol as a solvent, urotropin as a catalystand liquid or solid chloroacetic acid as an initial raw material, firstly introducing ammonia to produce a mixed crystal of glycine and ammonium chloride, centrifuging to obtain a mixed crystal, repeatedly applying the filtrate to synthesis of the mixed crystal, dissolving the mixed crystal by using pure water, extracting a glycine product by using methanol; enabling filtrate after glycine is centrifuged out to enter a rectifying tower to recover methanol, enabling rectified residual liquid to enter a film evaporator, concentrating the rectified residual liquid until water is completely evaporated to directly obtain an ammonium chloride byproduct, and repeatedly using water evaporated from the film evaporator to dissolve mixed crystals. The process mainly uses a glycine synthesis kettle, aglycine extraction kettle, a mixed crystal filtrate elevated tank, a centrifugal machine, a mixed crystal filtrate receiving tank, a chloroacetic acid dissolving kettle, a methanol rectifying tower,a film evaporator, and the like. According to the method, the unit consumption levels of urotropin, liquid ammonia, and steam can be greatly reduced, the production cost is further reduced, and no wastewater is generated.

Owner:HUBEI TAISHENG CHEM

Efficient synthesis process of glycine

InactiveCN105646250AOvercome the problems of many processes and heavy workloadIncrease conversion rate per passOrganic compound preparationAmino-carboxyl compound preparationWater bathsReaction temperature

The present invention discloses an efficient synthesis process of glycine, and provides a glycine synthesis process with characteristics of short time consuming, simple operation and high synthesis yield. The synthesis steps comprise that 700 ml of a circulating mother liquor is added to a beaker, 6-11 g of methenamine is added to the mother liquor in a supplemented manner, 16-30 g of a co-catalyst Cat is added, 270-280 g of ammonium bicarbonate is completely added to the beaker, 334-340 g of ammonium-monochloracetat is poured into the beaker in one time, the temperature of the reaction system is increased to 30-40 DEG C by using water bath, CO2 escapes from the solution in the reaction, the reaction temperature is increased to 40-50 DEG C within 1 h, the reaction is significantly accelerated, the reaction releases heat to make the temperature of the system automatically rise, the temperature is controlled through water bath, the temperature of the system is maintained at 50-55 DEG C for 2 h, the temperature is increased to 60-62 DEG C and is maintained for 1 h so as to complete the reaction, and natural cooling is performed to achieve a room temperature, wherein the total reaction time is about 4 h.

Owner:吕艳

Method for biosynthesis of glutathione by using yeast

InactiveCN101255454BLow costIncrease concentrationMicroorganism based processesFermentationBiologyAdenosine triphosphate

The present invention relates to a method for synthesizing glutathione using yeast cells. Gamma-GCS and GS in yeast cells are used, glucose is used as the energy, an intracellular glucolysis system is used to produce triphosadenine, glutamic acid, cysteine and glycin in reaction liquid are synthesized to form glutathione; saccharomyces cerevisiae, baker's yeast, candida and other yeast cells are permeabilized and then react in a reaction liquid composed of phosphate buffer, MgCl2.6H2O, CaCl2.2H2O, glucose, L-glutamic acid and L-cysteine, gamma-L-glutamoyl L- cysteine is produced, then glycin is added to produce glutathione; in the two-stage reaction, the inhabitation effect of glutathione to gamma-GCS catalytic reaction is greatly reduced; glutathione produced by the method has obviously improved product concentration and reaction yield.

Owner:EAST CHINA UNIV OF SCI & TECH

The Characteristic Sequence, Specific Identification Primer and Identification Method of Oyster Kumamoto

ActiveCN112626238BRapid identificationHigh polymorphismMicrobiological testing/measurementDNA/RNA fragmentationNucleotideGermplasm

The invention discloses a characteristic sequence for identifying Kumamoto oyster, specific identification primers and an identification method, wherein the characteristic sequence is located in the mitochondrial non-coding region between glycine tRNA synthetase and proline tRNA synthetase of oyster, and the characteristic sequence is The nucleotide sequence shown in SEQ ID NO.1; the sequence of the specific identification primer is: upstream primer MNR-F: 5'-CTGTAAGTATATTTGTCTTCCA-3'; downstream specific primer MNR-S-R: 5'-AGGCTTTCACTCCACTTACT ‑3'. The present invention can effectively distinguish Kumamoto oyster from other four species of Pyramid oyster, the determined characteristic sequence length of Kumamoto oyster is 660±5bp, and whether it is Kumamoto oyster can be judged by the existence and size of the specific band. In the field of Kumamoto oyster germplasm resource protection and Kumamoto oyster breeding, species identification can be carried out on broodstock before seed breeding to ensure that the breeding seed is pure and not affected by other species that may hybridize with it.

Owner:浙江万里学院宁海海洋生物种业研究院 +1

A kind of high-yield 5-aminolevulinic acid recombinant Escherichia coli strain and its application

ActiveCN114381416BImprove efflux capacityImprove utilization efficiencyBacteriaMicroorganism based processesEscherichia coliGlucose utilization

The invention discloses a recombinant Escherichia coli strain for producing 5-aminolevulinic acid (5-ALA); the invention also discloses a high-efficiency approach for synthesizing 5-aminolevulinic acid: strengthening the 5-aminolevulinic acid of Escherichia coli itself Aminolevulinic acid synthase (HemL and HemA), the strain initially has the ability to synthesize 5-aminolevulinic acid; strengthen the expression of the 5-aminolevulinic acid efflux protein eamA gene, and increase the 5-aminolevulinic acid efflux of the strain Removal ability; introduce exogenous 5-aminolevulinic acid synthase hemA gene to enhance the 5-aminolevulinic acid synthesis ability of the strain; transform galR, glk, ppc genes in the glucose utilization pathway to improve glucose utilization efficiency; knock out metabolism Bypassed genes (hemF, poxB, and aceB). The recombinant Escherichia coli strain constructed by the invention has the ability to efficiently utilize glucose and glycine to synthesize 5-aminolevulinic acid, making it useful for industrial production of 5-aminolevulinic acid.

Owner:北京道合成企业管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com