Method for removing impurities in glycine synthetic process

A technology of glycine and glycine master, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc. It can solve problems such as increased viscosity, abnormal production, difficulty in crystallization and separation of glycine, etc., and achieves improved yield and suppressed The generation of impurities and the effect of reducing the cost of decolorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0037] Embodiment 2 glycine mother liquor direct alkaline hydrolysis treatment

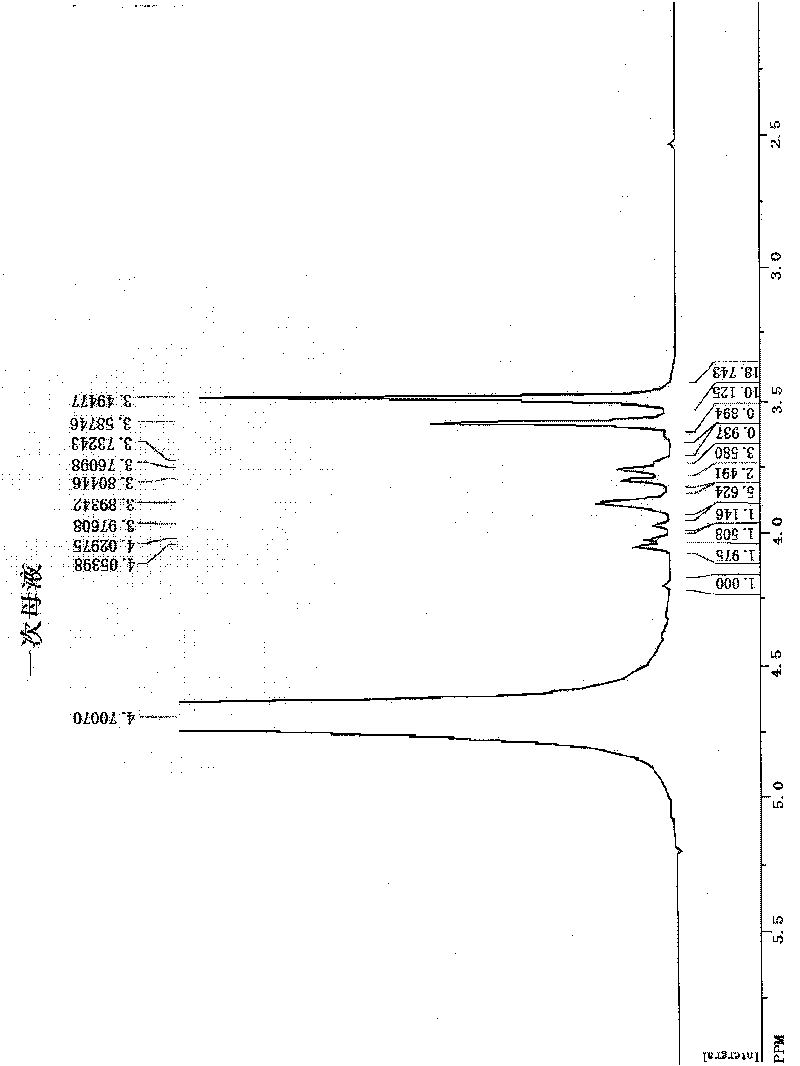

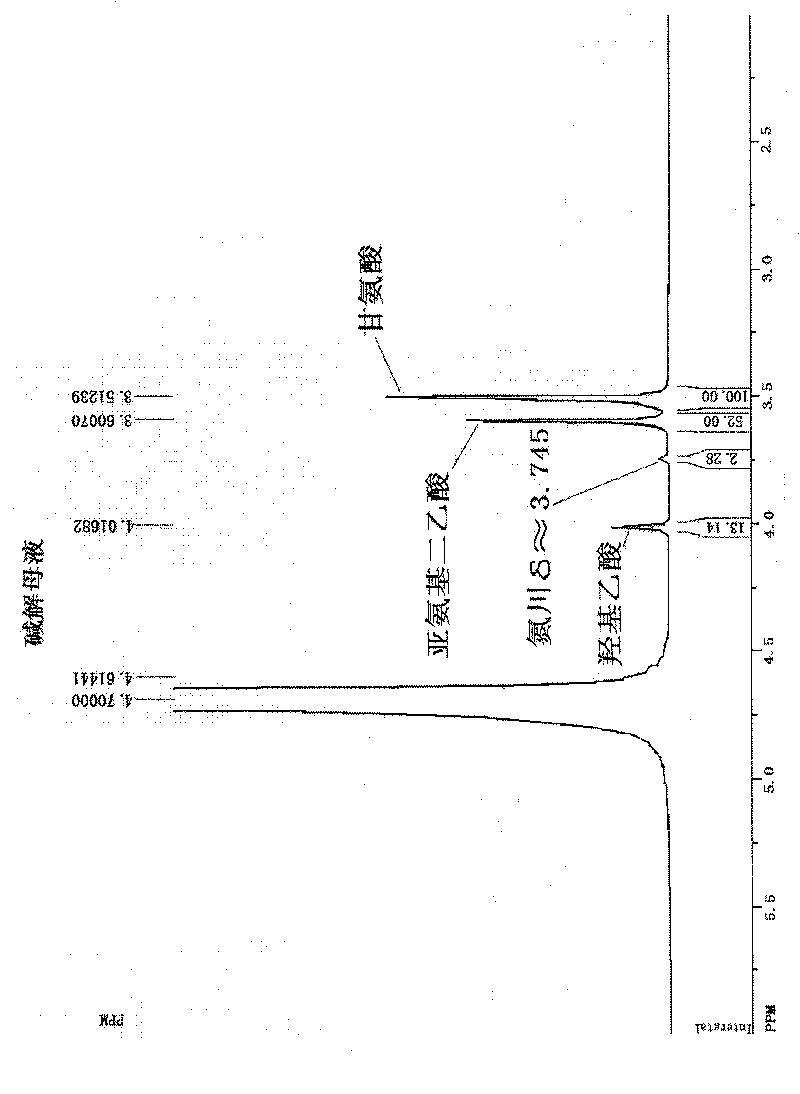

[0038] Get glycine mother liquor, analyze wherein α-acid content is 22.59%, and IDA content is 5.68%, detects that its visible light transmittance is 75.65% through ultraviolet-visible spectrophotometer, and its proton nuclear magnetic resonance spectrogram is shown in accompanying drawing 1.

[0039] This glycine mother liquor 100g is added in the 250ml four-neck flask, according to the alpha-acid in the glycine mother liquor and the OH in the liquid caustic soda - The mol ratio is 1: 2 and adds 75.3g of 32% liquid caustic soda altogether, and alkalinity is 13.1%, and α-acid content is 12.86%, and IDA content is 3.24%, then heating up reflux reaction. The reflux reaction temperature is controlled at about 115° C., and the reflux time is 8 hours.

[0040] After refluxing for 8 hours, the reaction was stopped, and a black precipitate was obtained by suction filtration. The precipitate weighed 1.82...

Embodiment 3

[0043] Embodiment 3 glycine mother liquor and alkaline hydrolysis solution mixed alkali hydrolysis treatment

[0044] Get glycine mother liquor, analyze wherein α-acid content is 22.59%, and IDA content is 5.68%, (NH 4 ) 2 SO 4 was 2.6%. The alkaline hydrolysis solution was taken, and the α-acid content was analyzed to be 15.87%, and the IDA content was 2.27%.

[0045] This glycine mother liquor 100g is joined in the 250ml four-necked flask, then adds 200g alkali hydrolysis solution in the flask, and the α-acid content is 18.14% in the analysis mixed solution, and IDA content is 3.41%, (NH 4 ) 2 SO 4 0.9%, the total alkalinity is 8.72%, and then the temperature rises to reflux reaction. The reflux reaction temperature is controlled at about 115° C., and the reflux time is 6 hours. Obtain filtrate 291.8g reaction liquid after reflux, analyze wherein α-acid (in terms of glycine) content is 19.43%, IDA (in terms of iminodiacetic acid) content is 3.73%, basically can't dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com