Patents

Literature

61 results about "Glycolonitrile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

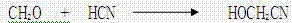

Glycolonitrile, also called hydroxyacetonitrile or formaldehyde cyanohydrin, is the organic compound with the formula HOCH₂CN. It is the simplest cyanohydrin and it is derived from formaldehyde. It is a colourless liquid that dissolves in water and ether. Because glycolonitrile decomposes readily into formaldehyde and hydrogen cyanide, it is listed as an extremely hazardous substance. In January 2019, astronomers reported the detection of glycolonitrile, another possible building block of life among other such molecules, in outer space.

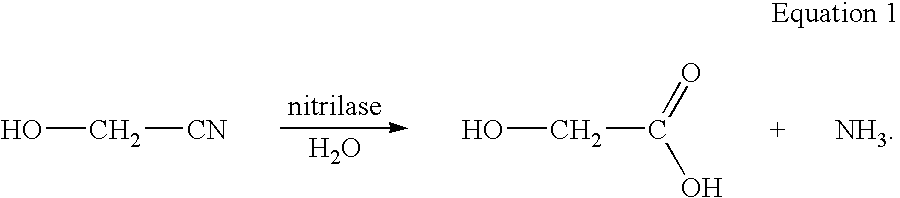

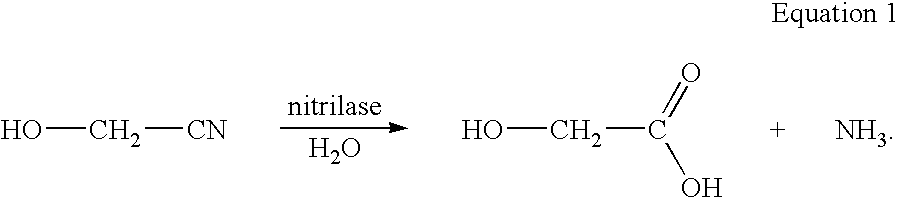

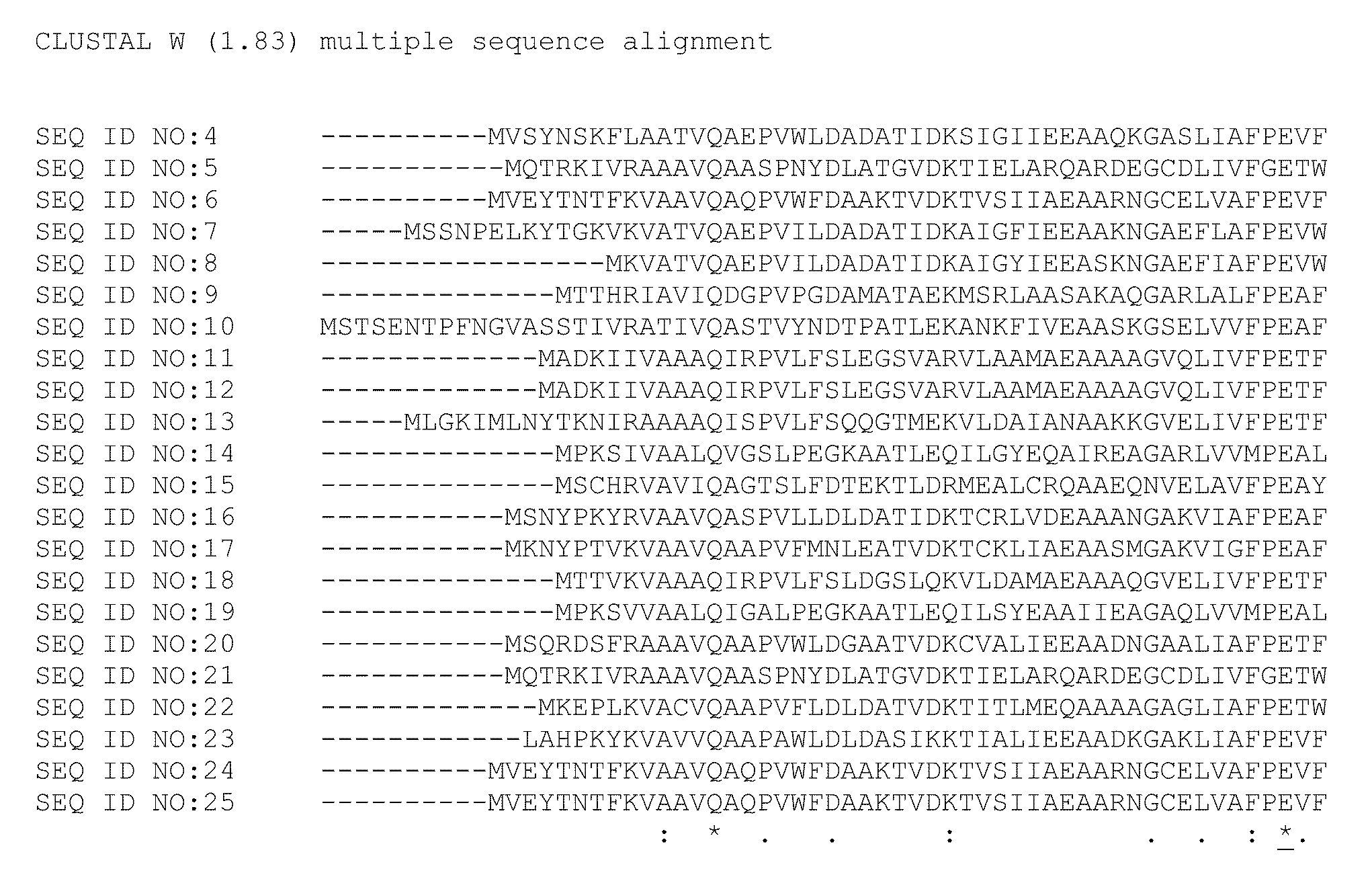

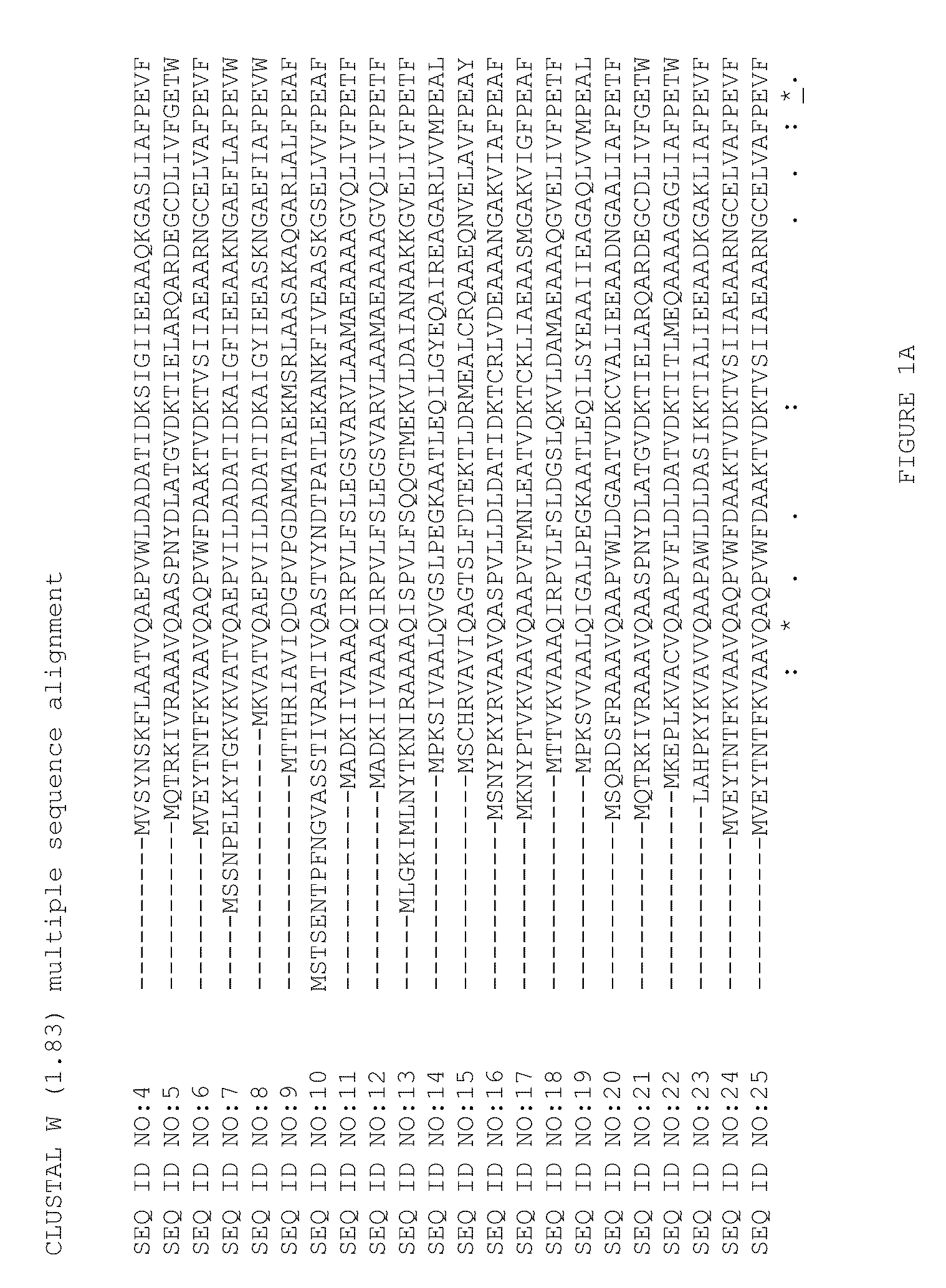

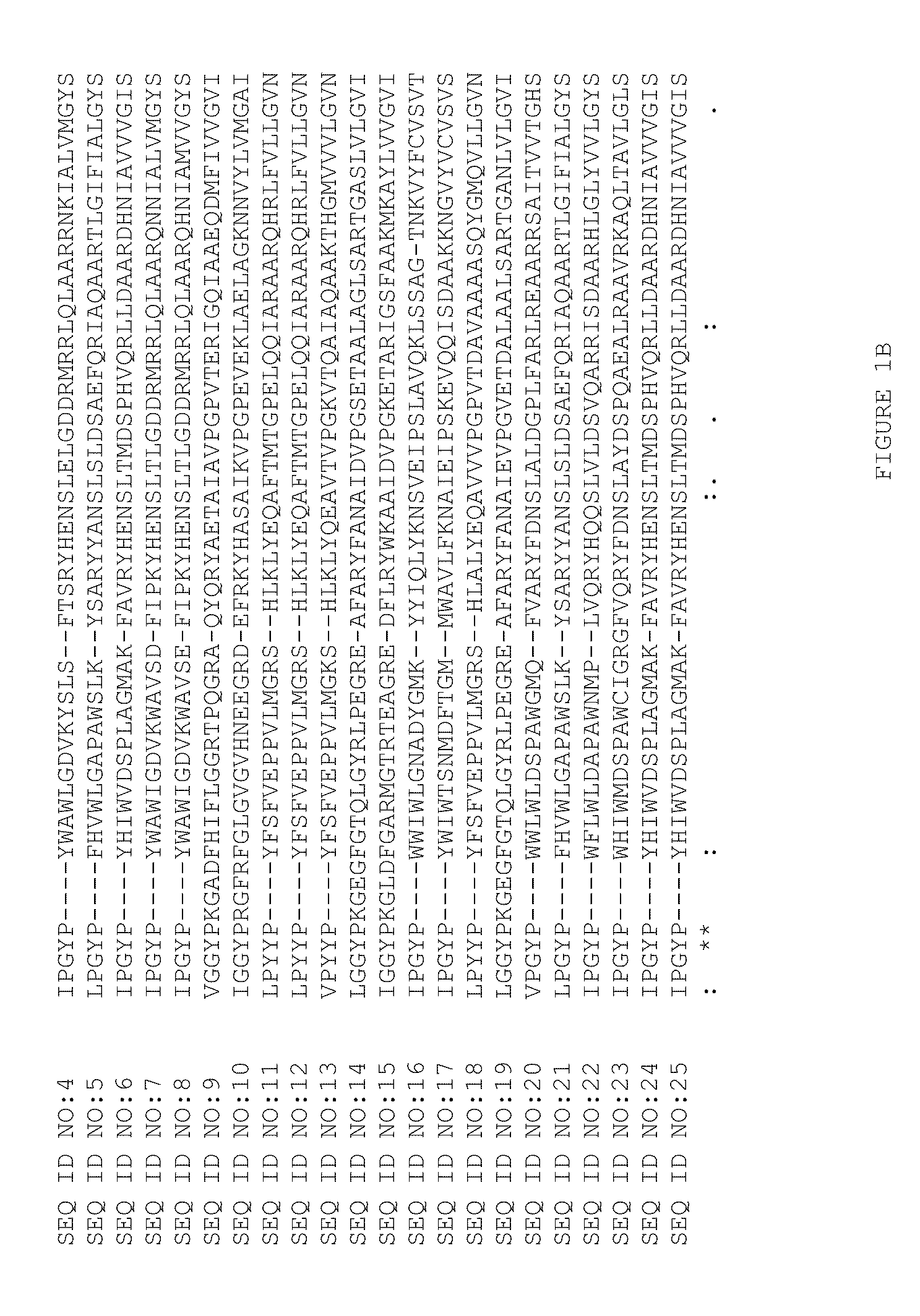

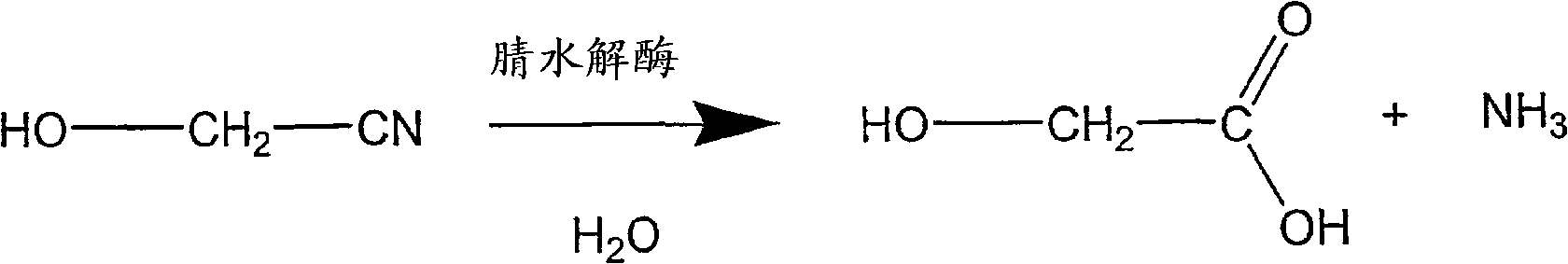

Enzymatic production of glycolic acid

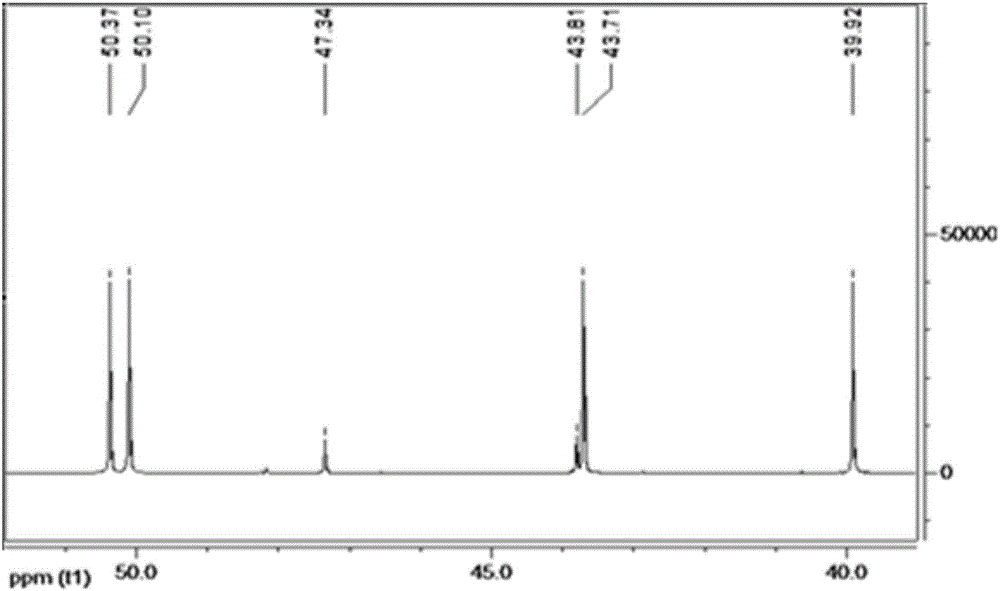

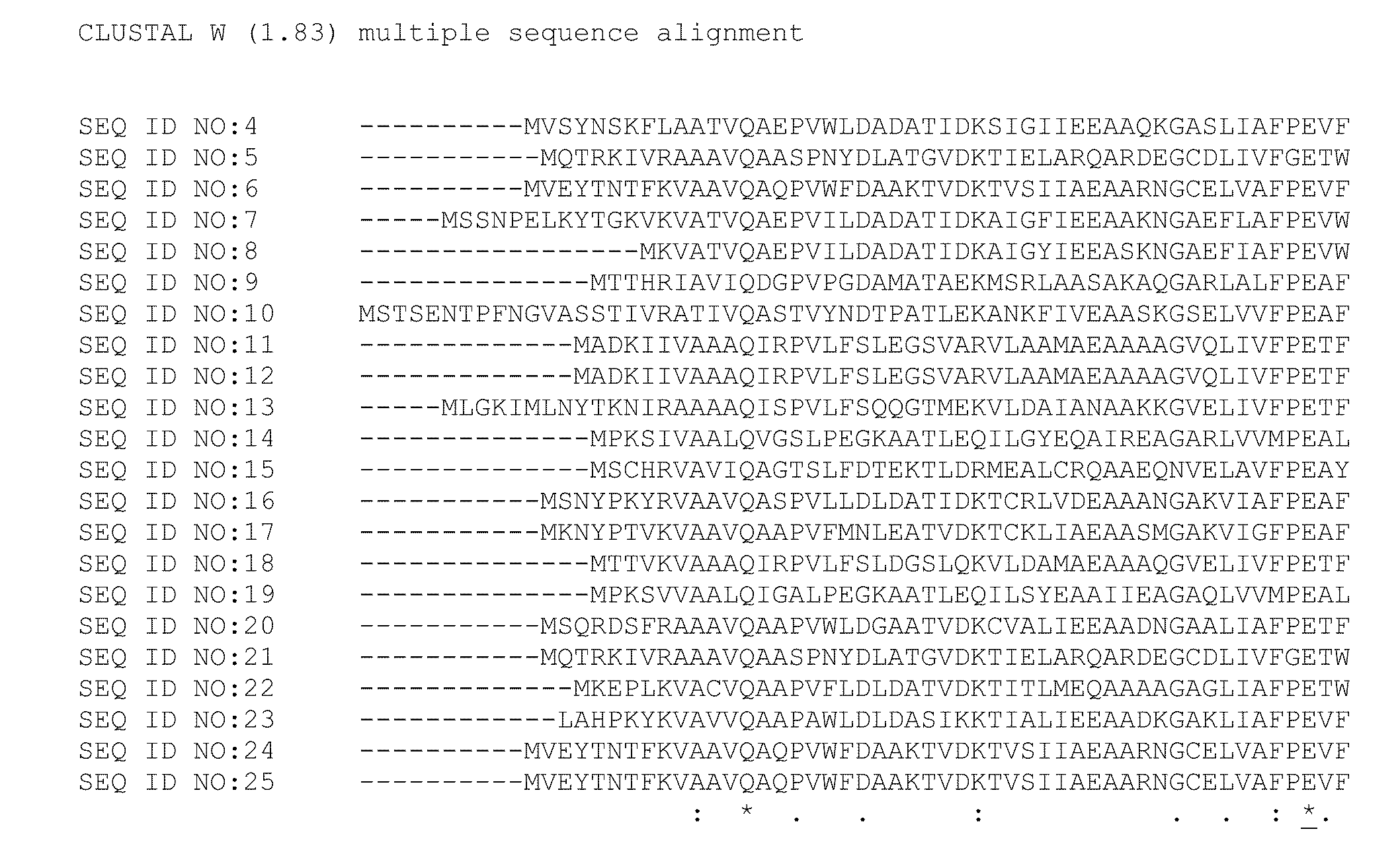

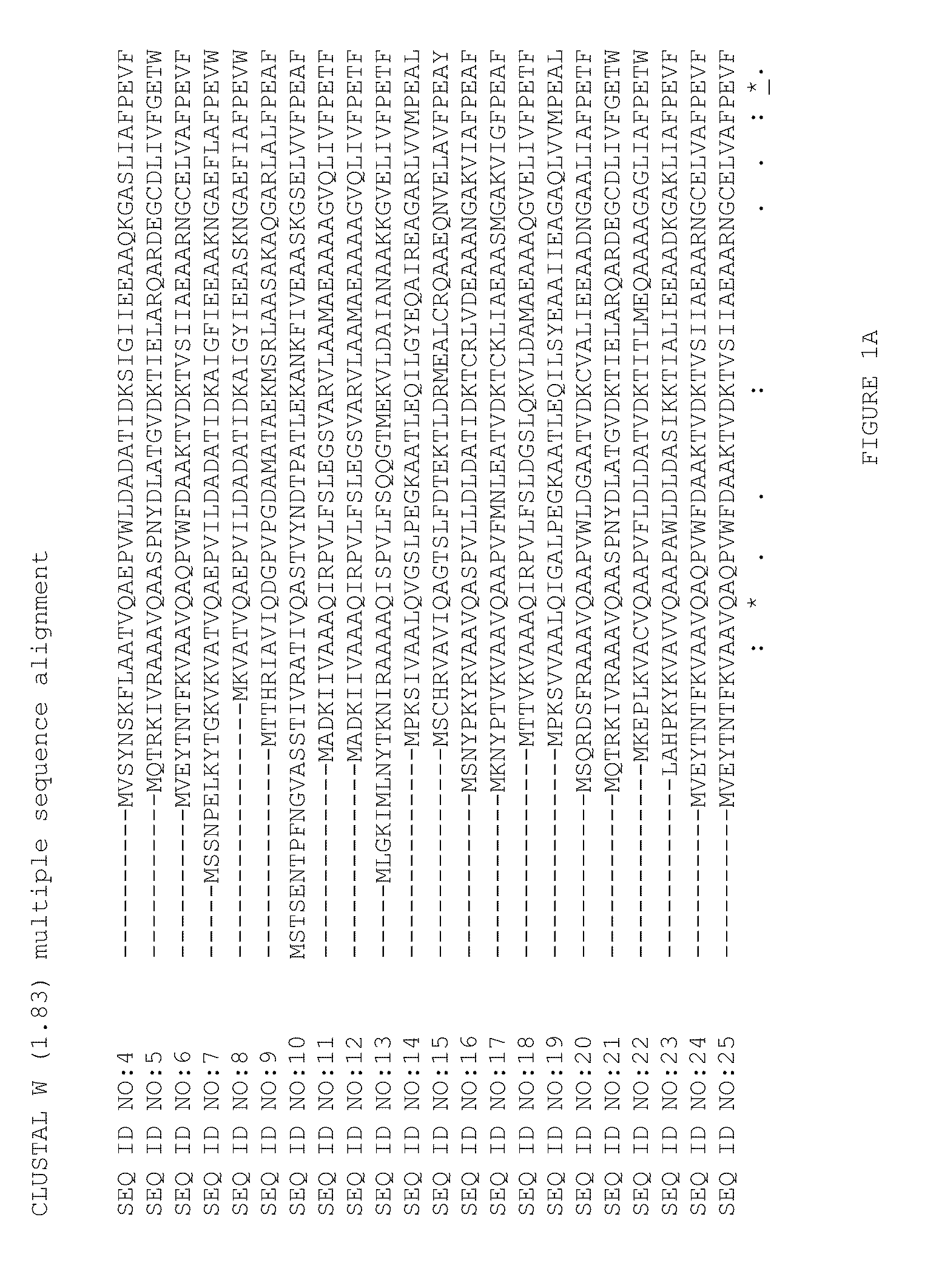

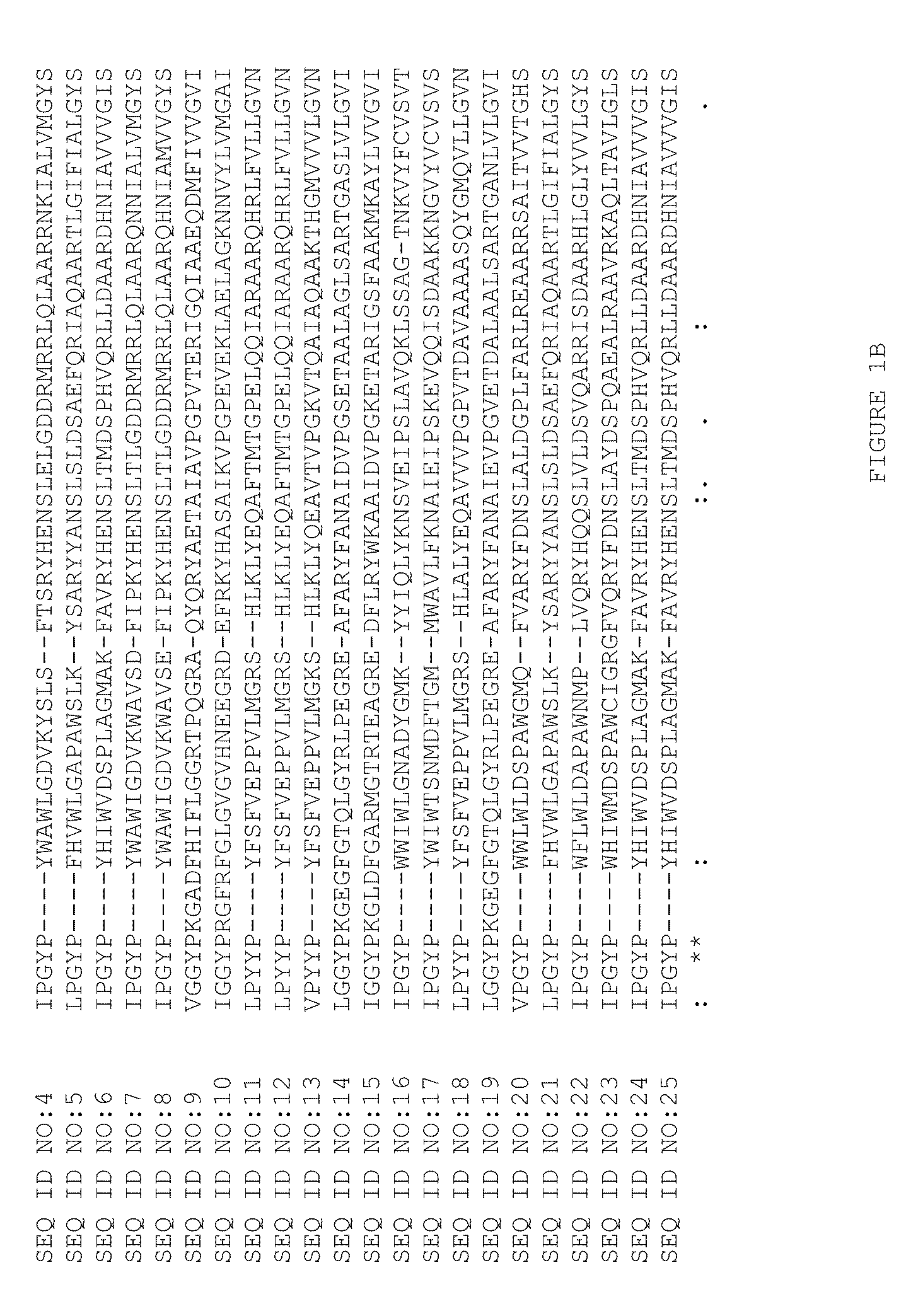

Various methods are provided for the enzymatic production of glycolic acid from glycolonitrile. These methods include: 1) use of Acidovorax facilis 72W nitrilase mutants having improved nitrilase activity for converting glycolonitrile to glycolic acid, and 2) methods to improve catalyst stability and / or productivity. The methods to improve catalyst stability / productivity include use of reaction stabilizers, running the reactions under substantially oxygen free conditions, and controlling the concentration of substrate in the reaction mixture.

Owner:PURETECH SCI LLC

Enzymatic production of glycolic acid

ActiveUS20060160199A1Facilitate recombinant expressionSugar derivativesBacteriaPtru catalystNitrilase activity

Various methods are provided for the enzymatic production of glycolic acid from glycolonitrile. These methods include: 1) use of Acidovorax facilis 72W nitrilase mutants having improved nitrilase activity for converting glycolonitrile to glycolic acid, and 2) methods to improve catalyst stability and / or productivity. The methods to improve catalyst stability / productivity include use of reaction stabilizers, running the reactions under substantially oxygen free conditions, and controlling the concentration of substrate in the reaction mixture.

Owner:PURETECH SCI LLC

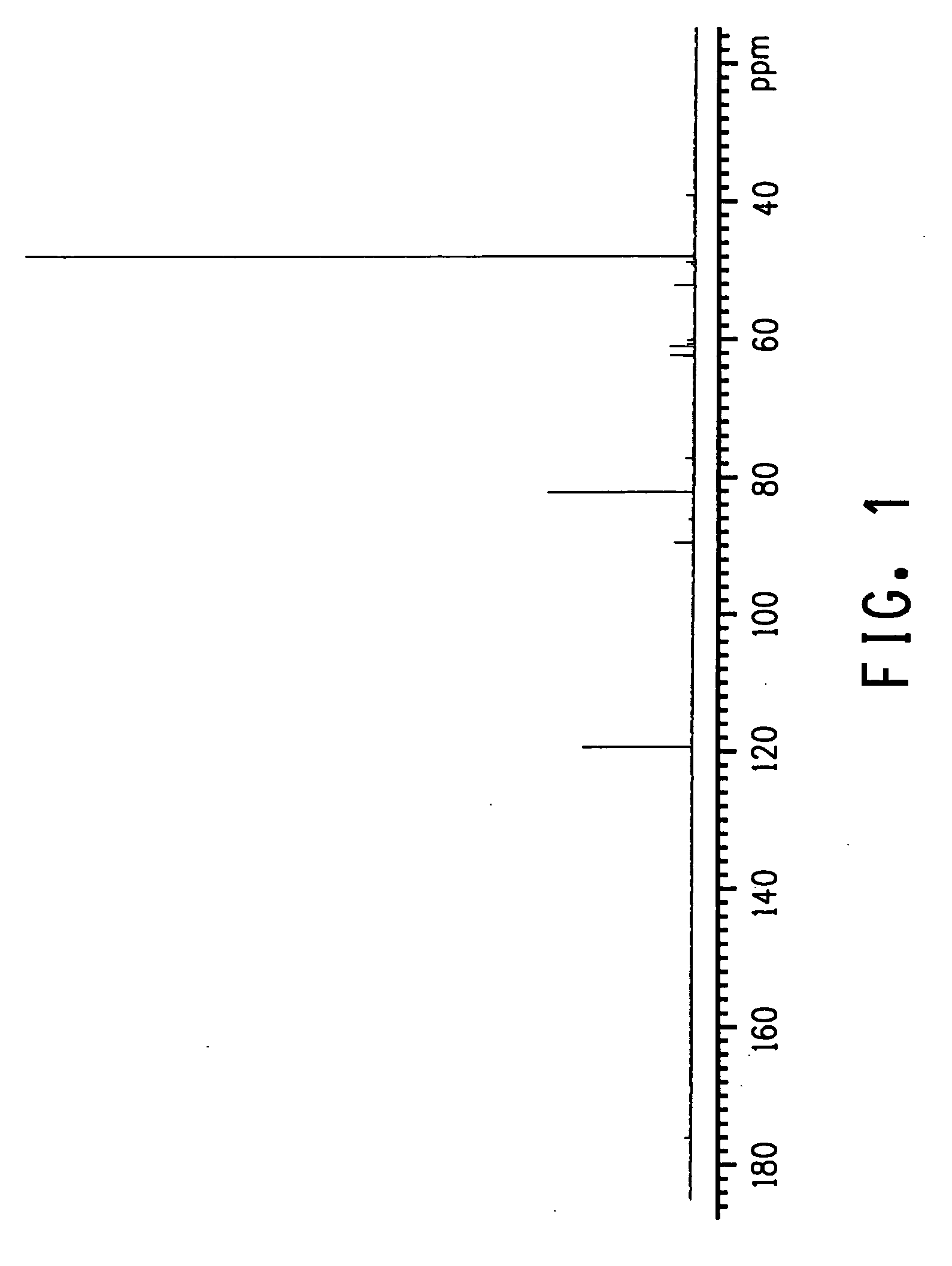

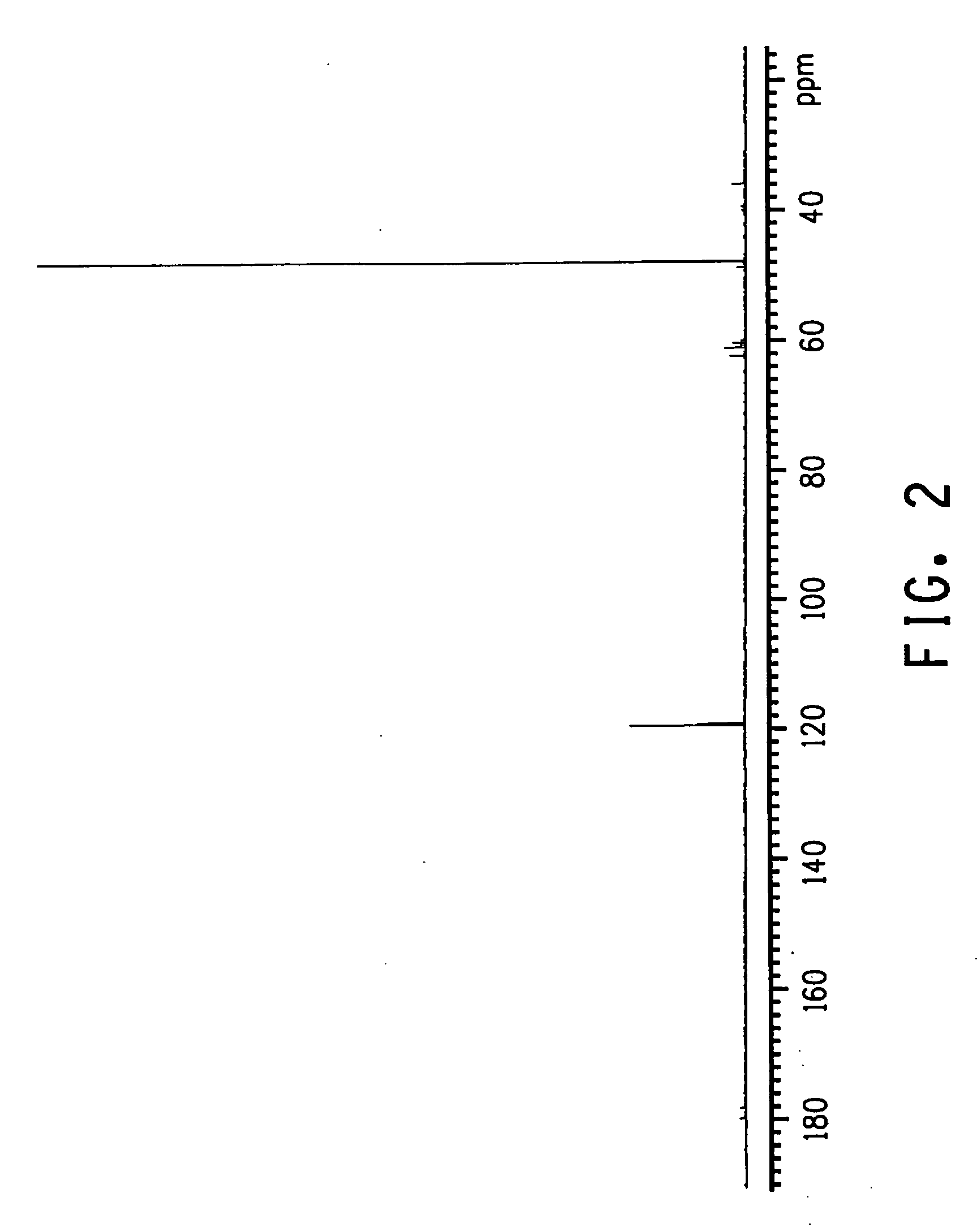

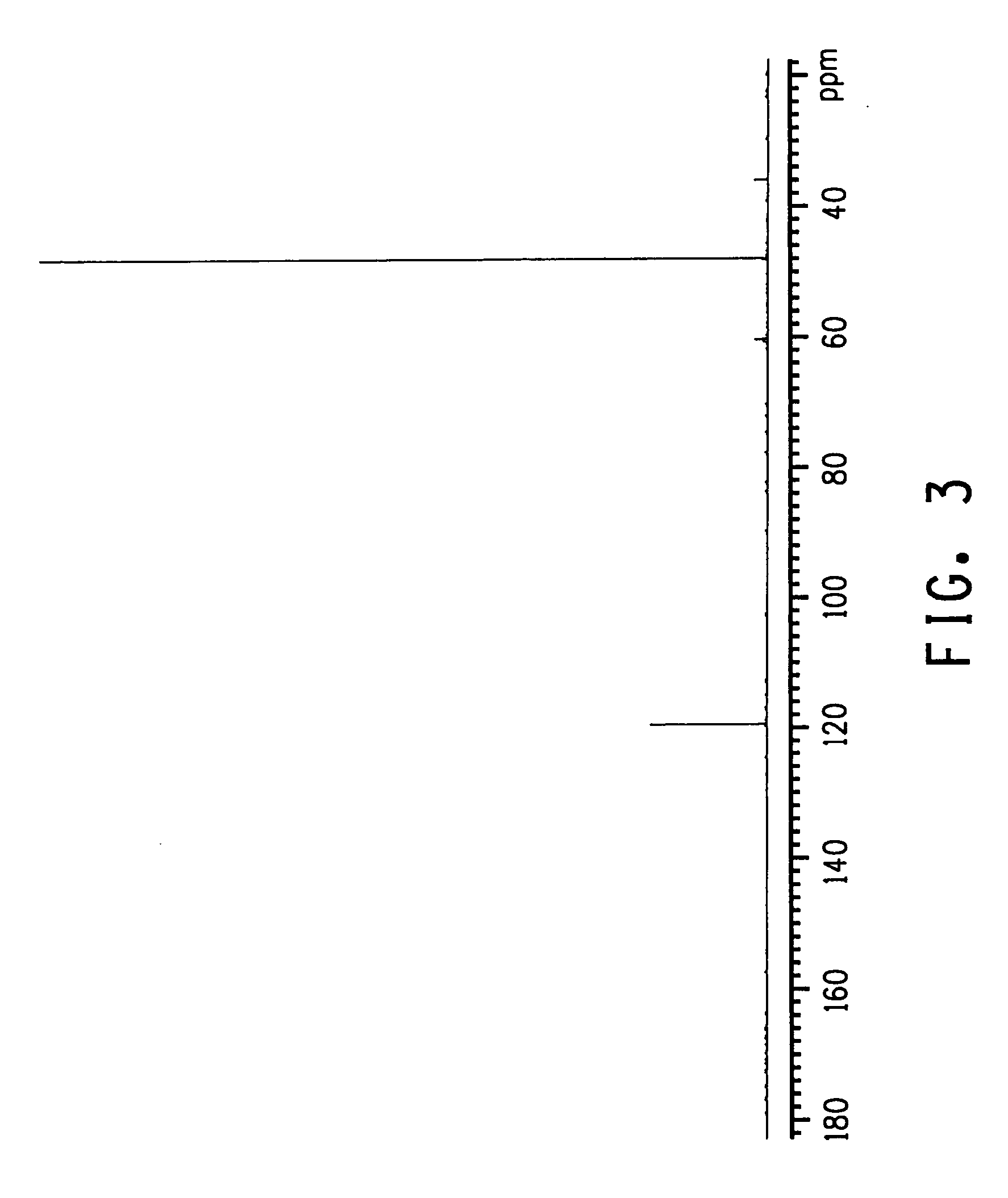

Process for the synthesis of glycolonitrile

ActiveUS20060160196A1Minimize glycolonitrile decompositionOrganic compound preparationPhosphorus organic compoundsGlycollic acidHCN poisoning

A process to prepare substantially pure glycolonitrile in an aqueous medium is provided by reacting hydrogen cyanide and formaldehyde. The formaldehyde feed stream is heated prior to reacting with hydrogen cyanide, resulting in an aqueous glycolonitrile solution with fewer impurities, especially less unreacted formaldehyde, than is obtained by other methods. The process enables production of an aqueous glycolonitrile solution that requires less post-reaction purification (if any at all) prior to enzymatically converting the glycolonitrile into glycolic acid.

Owner:THE CHEMOURS CO FC LLC

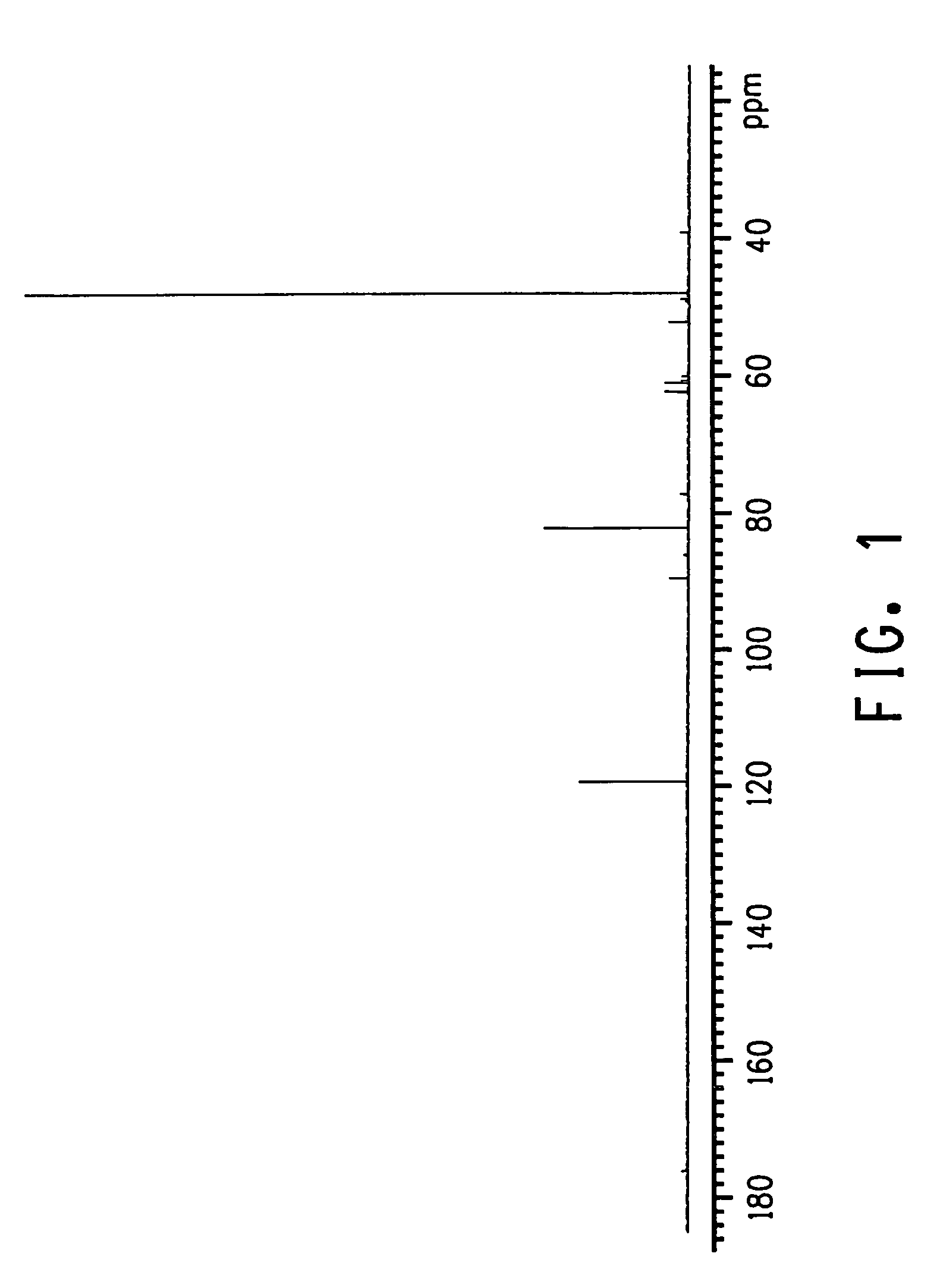

Process for producing glycolic acid from formaldehyde and hydrogen cyanide

A process is provided for producing glycolic acid from formaldehyde and hydrogen cyanide. More specifically, heat-treated formaldehyde and hydrogen cyanide are reacted to produce glycolonitrile having low concentrations of impurities. The glycolonitrile is subsequently converted to an aqueous solution of ammonium glycolate using an enzyme catalyst having nitrilase activity derived from Acidovorax facilis 72W (ATCC 57746). Glycolic acid is recovered in the form of the acid or salt from the aqueous ammonium glycolate solution using a variety of methods described herein.

Owner:THE CHEMOURS CO FC LLC

Method for preparing ethylenediamine esilate

ActiveCN106187829AImprove conversion rateReaction raw materials are cheap and easy to getHeterogenous catalyst chemical elementsSulfonic acids salts preparationEthylenediamineSilicon oxide

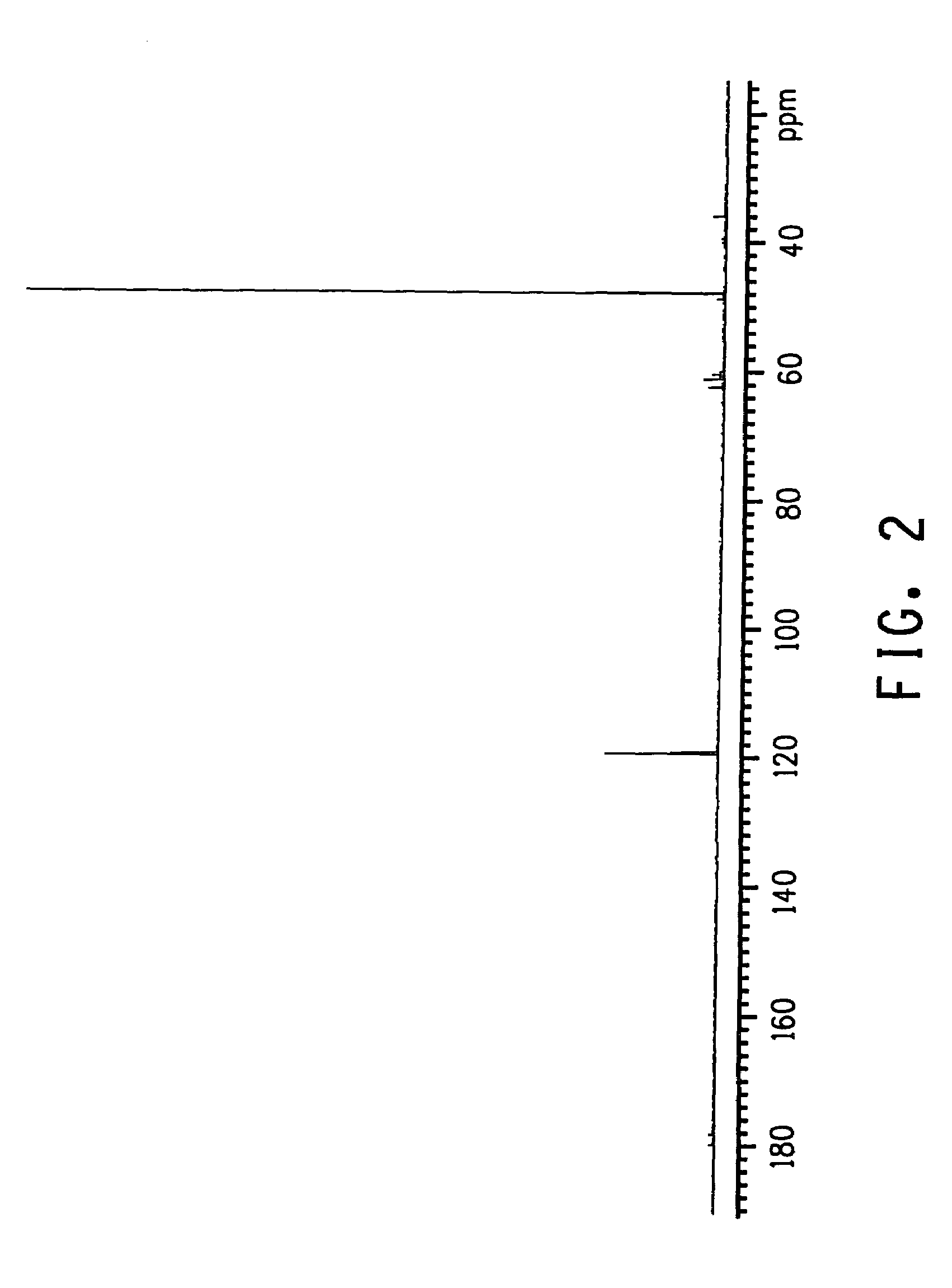

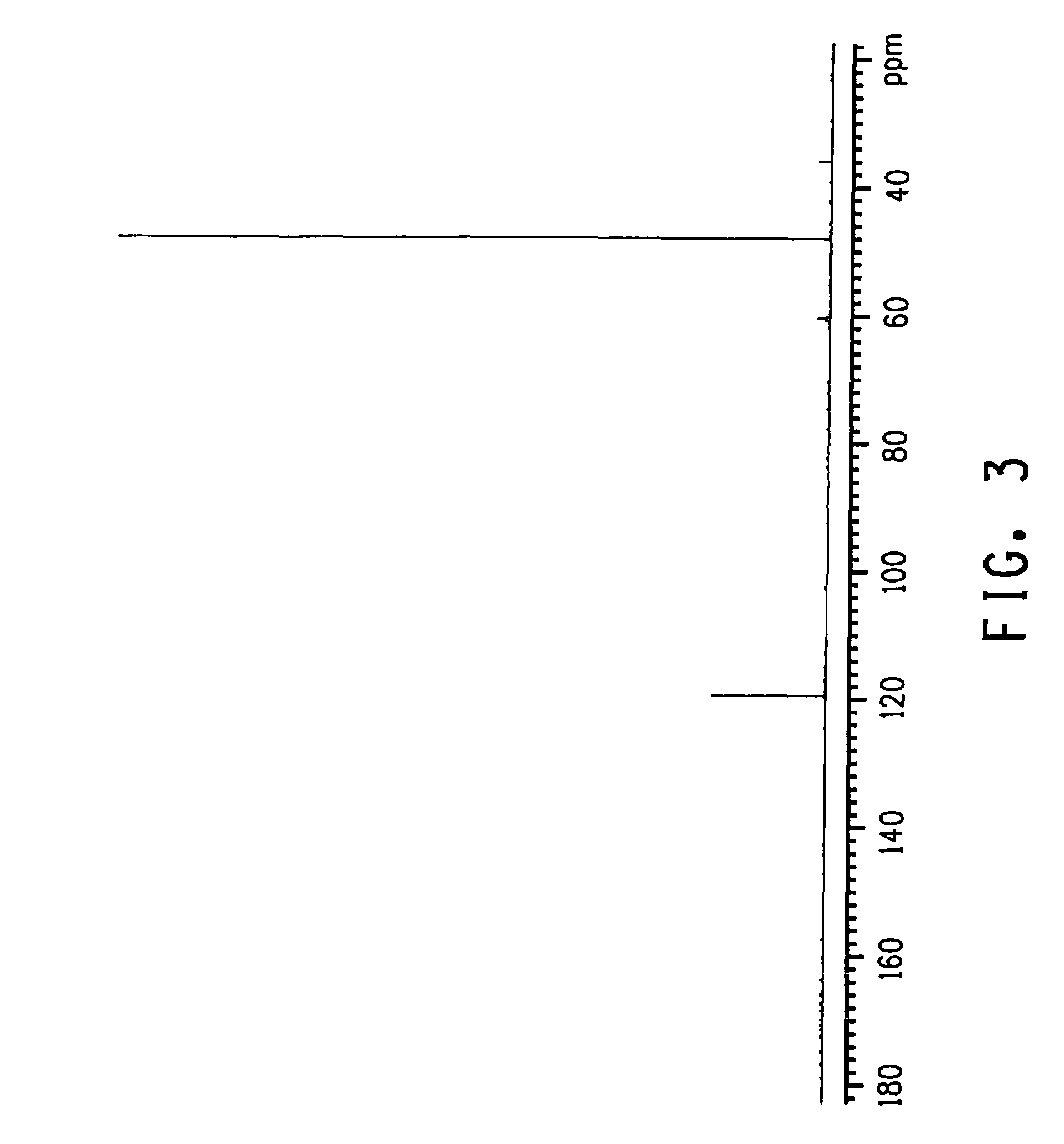

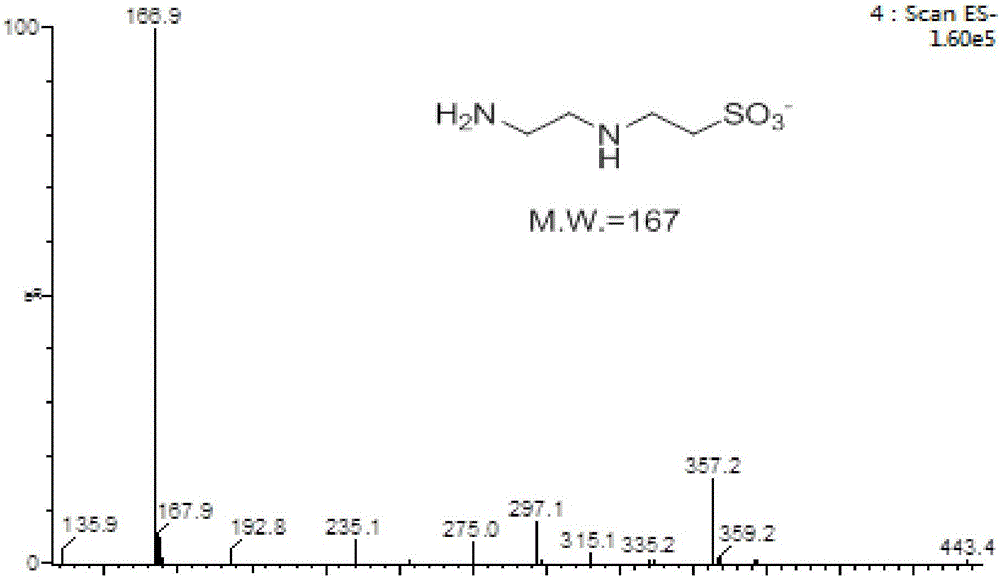

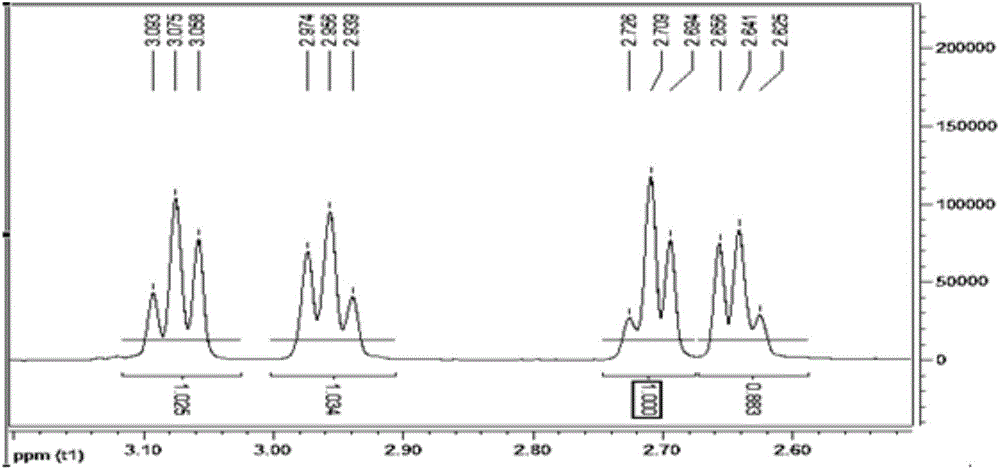

The invention relates to a method for preparing ethylenediamine esilate. The method comprises the steps that glycolonitrile and taurine salt serve as raw materials, or glycolonitrile, taurine and alkali metal hydroxide serve as raw materials, and cyanoethyl taurine salt is obtained through a dehydration condensation reaction; then, under the action of a hydrogenation catalyst, an ethylenediamine esilate hydrogenation solution is obtained through hydrogenation; a solvent is removed, and then the product ethylenediamine esilate is obtained. According to the catalyst, aluminum oxide and / or silicon oxide serve / serves as a carrier, and NiO, CoO, MoO3, MnO2 and Tc2O7 serve as active components. According to the method, ethylenediamine esilate can be obtained with a high conversion rate and high selectivity as long as light components such as the solvent in the hydrogenation solution are removed, the method is environmentally friendly in process, economical, safe and high in product yield, and has the industrialization amplification prospects, and purification is easy.

Owner:WANHUA CHEM GRP CO LTD

Immobilized microbial nitrilase for production of glycolic acid

ActiveUS20090111158A1High retention rateSpecific activitySugar derivativesHydrolasesGluconic acidNitrilase activity

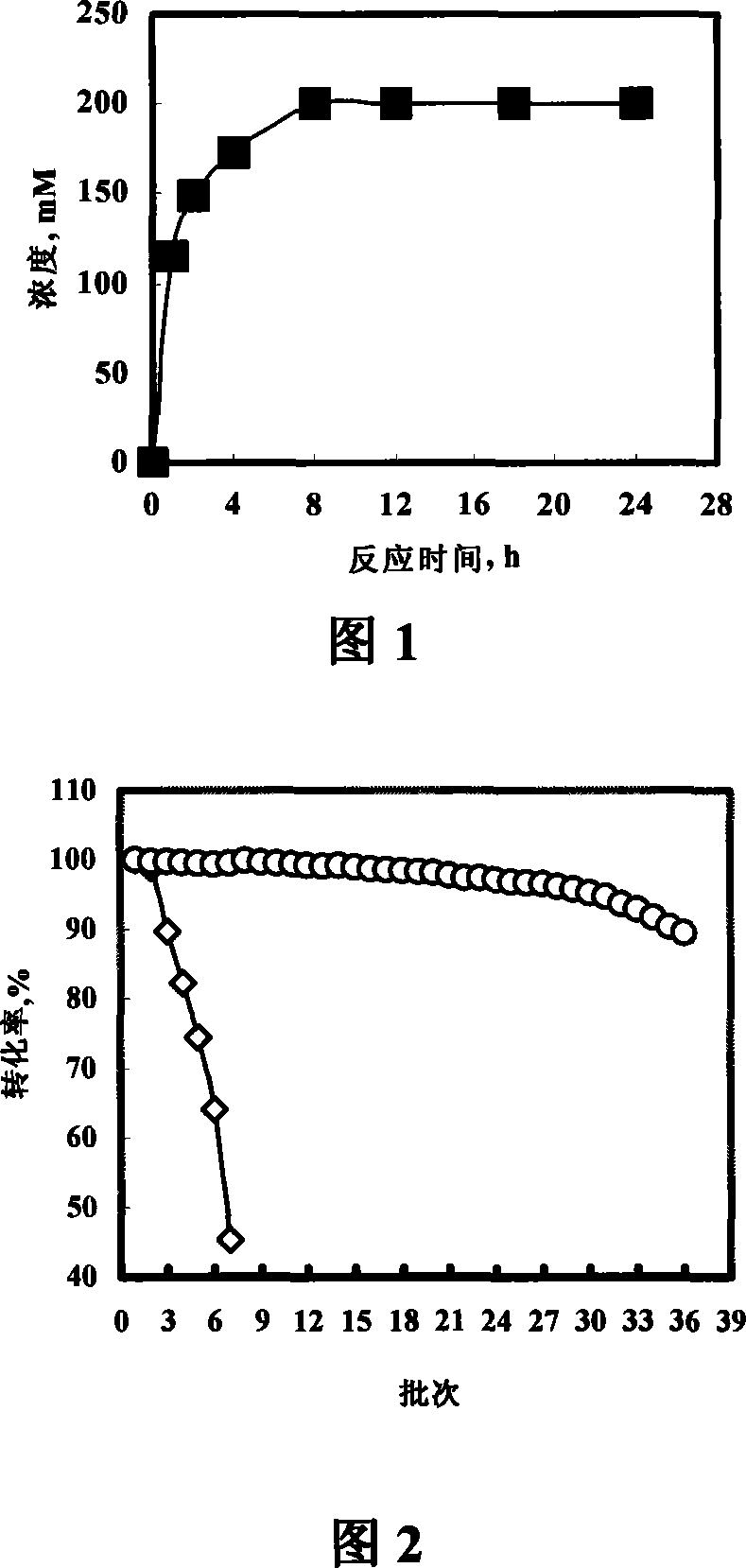

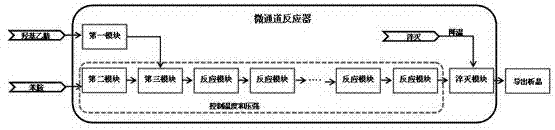

The present invention provides a process for preparing an enzyme catalyst having nitrilase activity for hydrolysis of glycolonitrile to glycolic acid with improved retention of recovered catalyst activity in consecutive batch reactions with catalyst recycle, said process comprising pretreating the enzyme catalyst with glutaraldehyde. The glutaraldehyde-pretreated enzyme catalyst has improved specific activity when compared to non-glutaraldehyde-pretreated enzyme catalysts, and thereby, has improved overall catalyst activity and productivity.

Owner:PURETECH SCI LLC

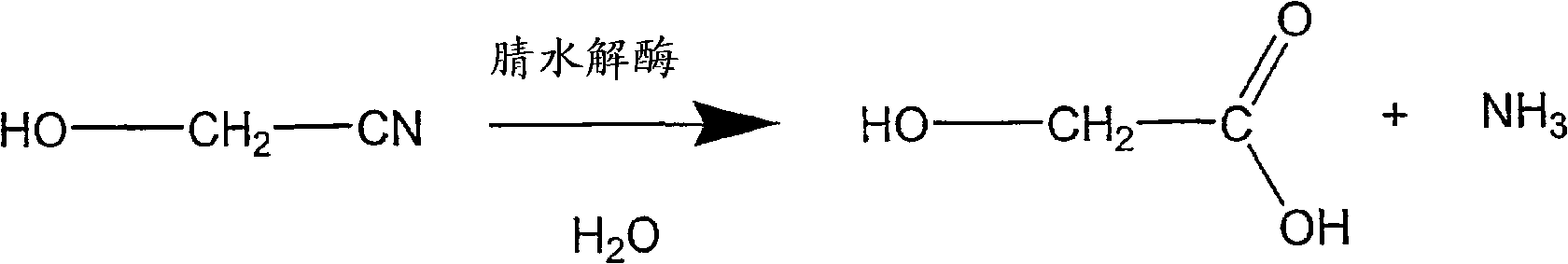

Culture of bacillus alcaligenes and method for preparing glycolic acid by using the same to hydrolyzing nitrile

The invention relates to cultivation of nitrilase producing bacterium Alcaligenes sp. ECU0401 which is recently separated from soil and a process for catalyzing glycolonitrile to be hydrolyzed and preparing glycollic acid. The invention employs nitrilase to be starting material, and Alcaligenes sp. ECU0401 cell which is achieved by proceeding enlarging culture in the fermentation culture medium is utilized as biocatalyst, and the product glycollic acid is achieved by the hydrolysis reaction of the glycolonitrile under certain condition. The invention has the advantages of mild reaction condition, non-pollution, simple technological route and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

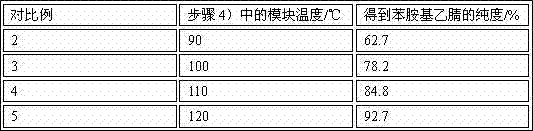

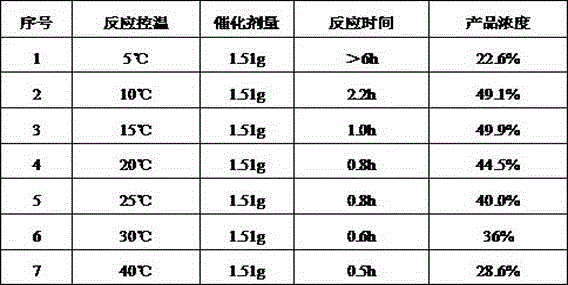

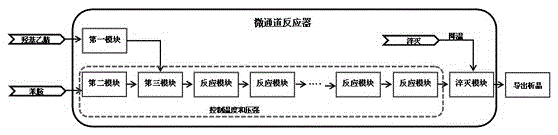

Method for preparing n-phenylglycinenitrile

ActiveCN104496848APost-processing saves time and effortReduce processCarboxylic acid nitrile preparationOrganic compound preparationAnilineOperation safety

The invention relates to a method for preparing n-phenylglycinenitrile. The method is characterized in that condensation reaction is continuously performed for aniline and glycolonitrile by a micro-channel reactor to obtain n-phenylglycinenitrile; the pH of glycolonitrile is pre-regulated to be 1.5 to 7 through a basic catalyst; the molar ratio of aniline to glycolonitrile is 1.00: 1.00-1.30. The method for preparing n-phenylglycinenitrile has the advantages that the process route is simple, and the reaction is fast, so that the working efficiency and production capacity can be ensured, and moreover, the production and operation safety of the process can also be ensured; with the adoption of the process method, the purity of a n-phenylglycinenitrile product exceeds 98.0% and the yield exceeds 99.9%.

Owner:内蒙古诚信永安化工有限公司

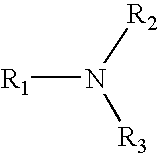

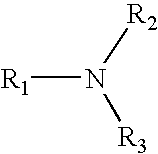

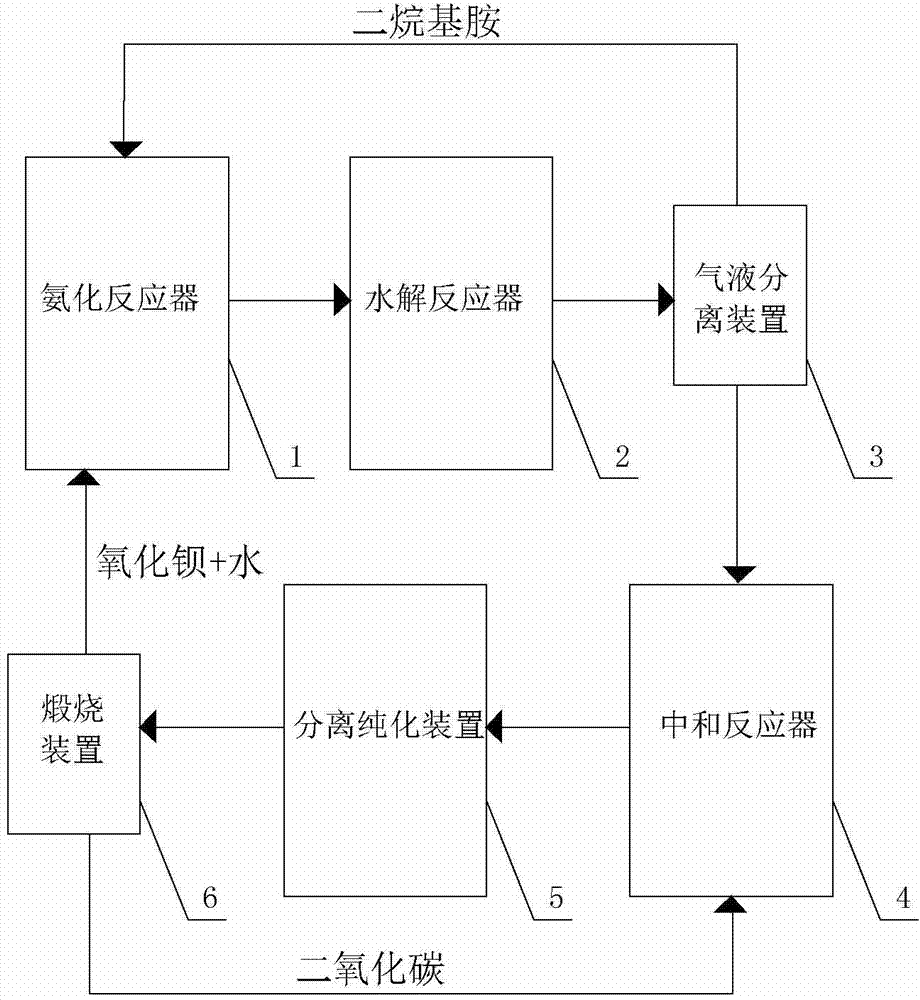

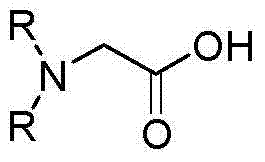

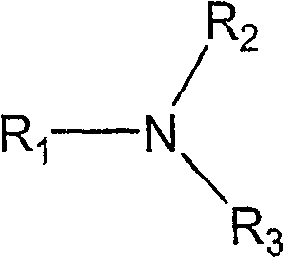

Clean and environment-friendly production method of N,N-dialkylglycine

InactiveCN103880691ATake advantage ofAvoid pollutionOrganic compound preparationAmino-carboxyl compound preparationGlycineBarium salt

The invention aims at the chemical engineering field and relates to a preparation method of N,N-dialkylglycine. The method comprises the following steps: mixing glycolonitrile with dialkyl amine, or mixing formaldehyde, hydrocyanic acid and the dialkyl amine, and carrying out ammonolysis reaction, so as to obtain an N,N-dialkylamino acetonitrile reaction liquid; mixing the N,N-dialkylamino acetonitrile reaction liquid with barium hydroxide, and carrying out hydrolysis reaction, so as to obtain an N,N-dialkyl glycine barium water liquid; carrying out neutral reaction on the N,N-dialkyl glycine barium by virtue of sulfuric acid or carbon dioxide to obtain the N,N-dialkylglycine, and simultaneously filtering a byproduct, namely a barium salt precipitate. The method has the beneficial effects that the N,N-dialkylglycine and the salt are easily separated and purified, the purity and yield of the N,N-dialkylglycine are high, the barium salt precipitate, namely barium carbonate can be re-prepared into barium hydroxide to be recycled, and the production process is environment-friendly and clean.

Owner:CHONGQING UNISPLENDOUR INT CHEM

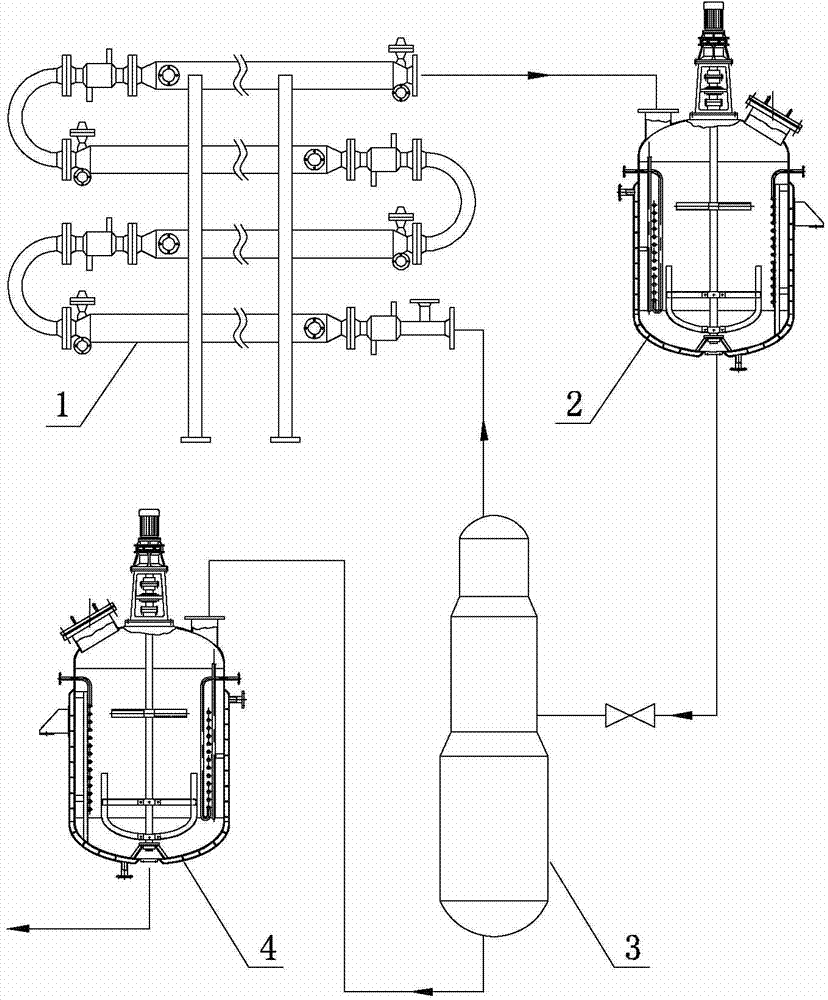

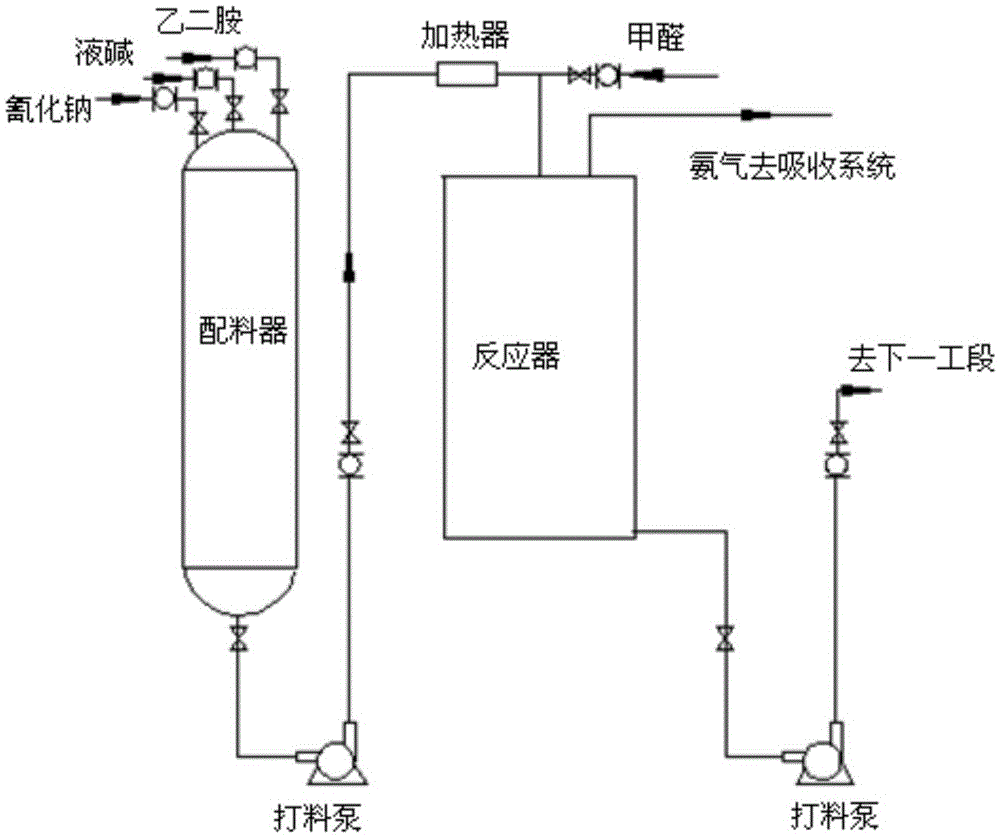

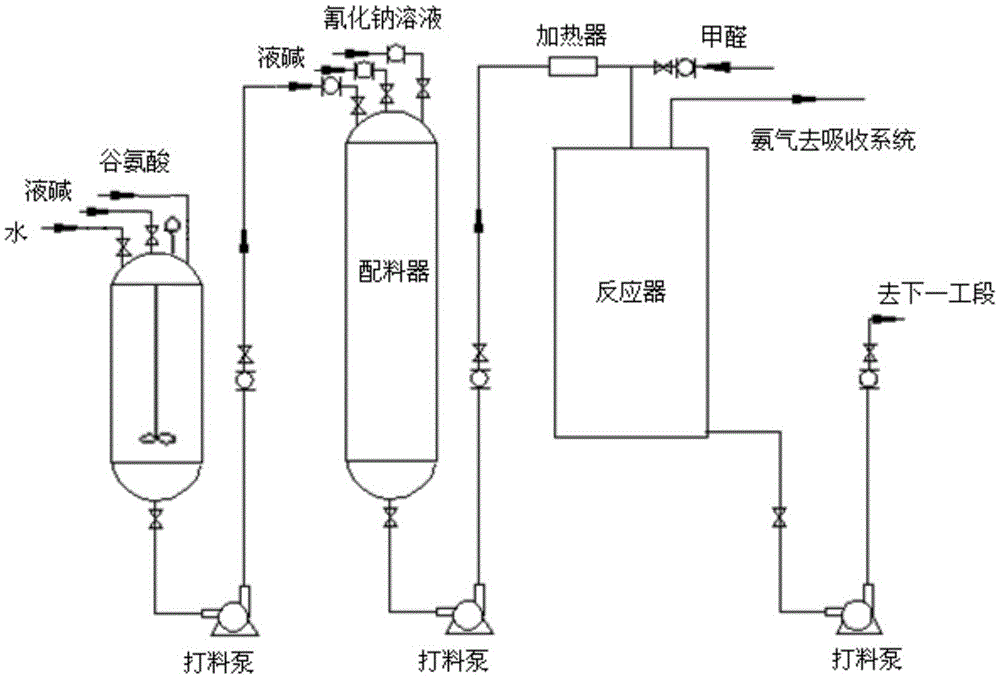

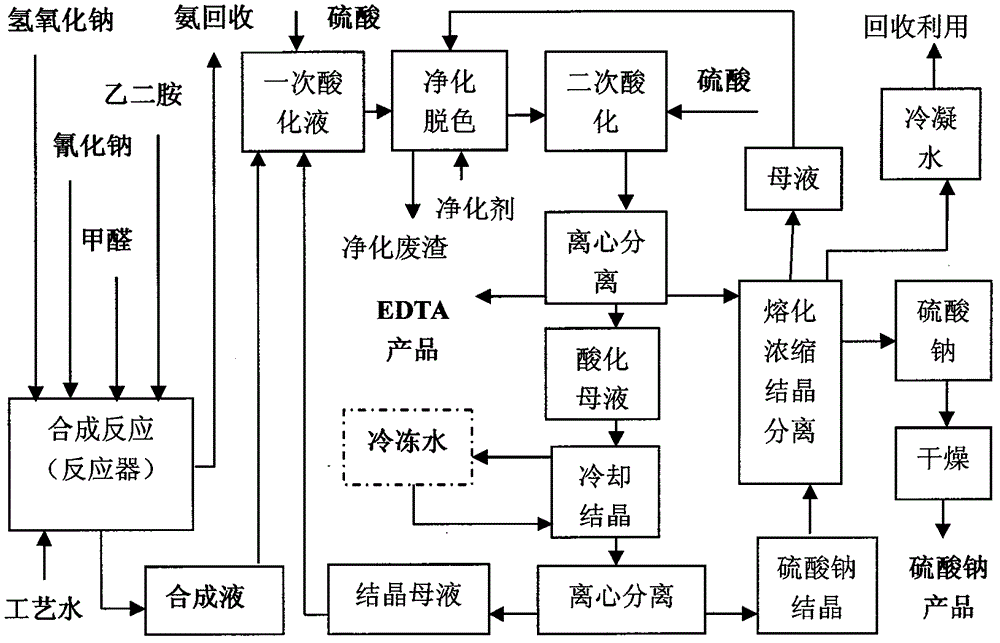

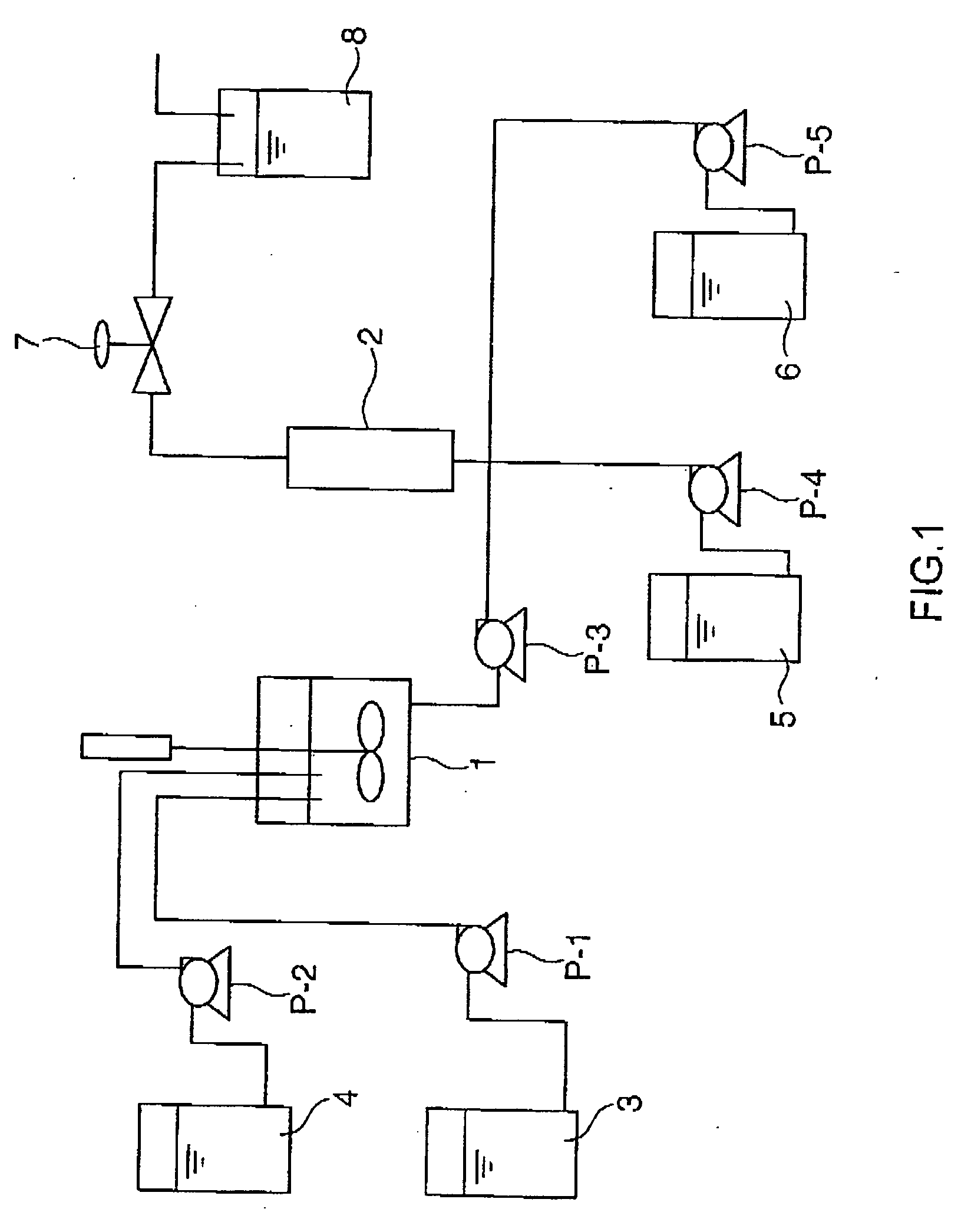

Novel continuous automated reaction process for preparing aminopolycarboxylic acids chelating agent

ActiveCN105646254AImprove qualityHigh yieldOrganic compound preparationAmino-carboxyl compound preparationContinuous reactorAfter treatment

The invention discloses a novel continuous automated reaction process for preparing an aminopolycarboxylic acids chelating agent and belongs to the technical field of aminopolycarboxylic acids chelating agents. Production is conducted through a flow reactor, a whole reaction system is under DCS automation control, and the process comprises the following steps: 1, material blending and mixing, wherein raw materials are continuously and stably pumped into a batcher for mixing, so that a liquid mixture is obtained; 2, preheating treatment, wherein the liquid mixture is pumped out of the batcher through a material delivering pump, and the liquid mixture which is pump out is subjected to heating treatment through a heater; 3, reaction and generation, wherein heated liquid materials and formaldehyde or heated liquid materials and a glycolonitrile solution are added into the reactor for a reaction, ammonia gas generated through the reaction is discharged through the top of the reactor and collected, and a reaction solution is drained through the bottom of the reactor and delivered to the acidification procedure for after-treatment through the material delivering pump, so that the aminopolycarboxylic acids chelating agent is obtained. By means of the process, the aminopolycarboxylic acids chelating agent can be produced in a continuous and automated mode, and stability of the reaction process is improved.

Owner:石家庄杰克化工有限公司

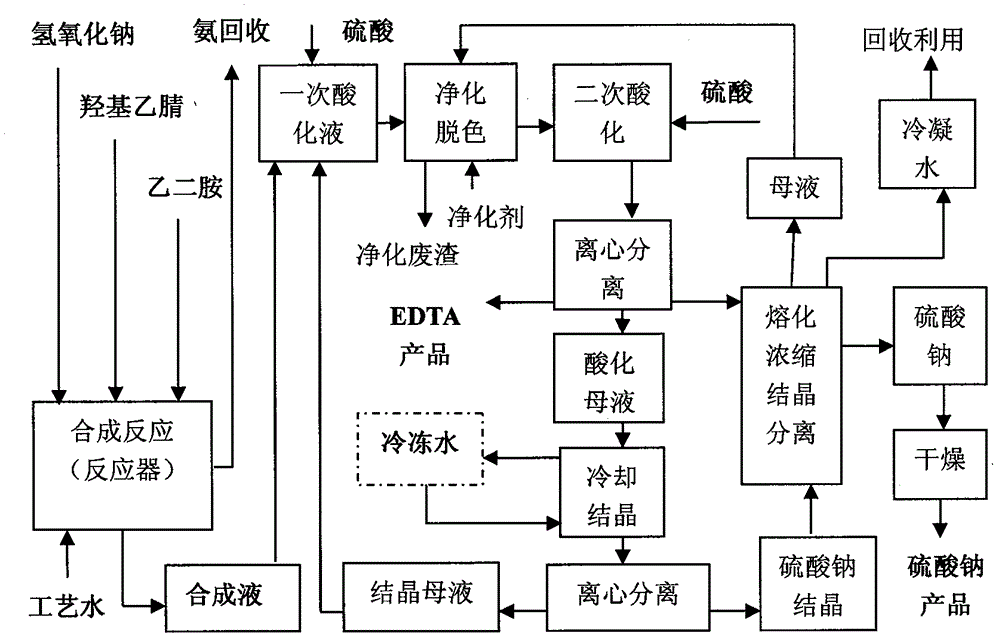

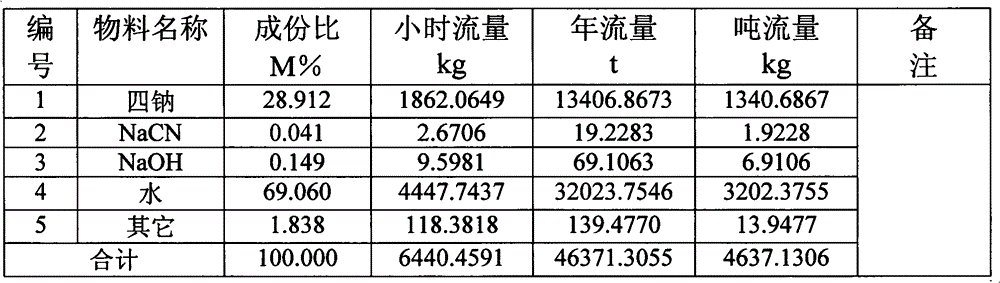

Method for environment-friendly clean production of high-purity ethylene diamine tetraacetic acid (EDTA)

InactiveCN102796019AGuaranteed to be pureRealize comprehensive utilizationOrganic compound preparationAmino-carboxyl compound preparationAcetonitrileSodium cyanide

A method for the environment-friendly clean production of high-purity ethylene diamine tetraacetic acid (EDTA) is an environment-friendly clean production method which takes sodium cyanide, formaldehyde and ethylenediamine or sodium hydroxide, glycolonitrile and ethylenediamine as main raw materials to synthesize the high-purity EDTA, and is characterized in that the acidization process of the synthetic EDTA solution is carried out by two steps, the purification decoloration treatment is carried out under the condition that a solution system is weak alkaline or approaches neutral, so the optimum effect of purification decoloration can be realized; the separation after the purification decoloration is carried out by two separation steps of centrifugal separation and fine filtration, so the relatively pure EDTA synthetic solution is obtained; the method is also characterized in that the mother solution which is produced by producing EDTA and is rich in sodium sulfate is subjected to comprehensive treatment for obtaining anhydrous sodium sulphate, the zero emission clean production method is realized, and is mainly realized through the technology that sodium sulfate hydrous crystalline solid is obtained through mother solution recovery treatment, and the byproduct of the anhydrous sodium sulphate is obtained through purification dehydration and other treatments of the sodium sulfate hydrous crystalline solid; and through recovering the sodium sulfate in the mother solution, not only can resources be saved, but also the environmental conservation of the EDTA production technology can be realized, and very good economic and social benefits are obtained.

Owner:李宽义

Enzymatic production of glycolic acid

Various methods are provided for the enzymatic production of glycolic acid from glycolonitrile. These methods include: 1) use of Acidovorax facilis 72W nitrilase mutants having improved nitrilase activity for converting glycolonitrile to glycolic acid, and 2) methods to improve catalyst stability and / or productivity. The methods to improve catalyst stability / productivity include use of reaction stabilizers, running the reactions under substantially oxygen free conditions, and controlling the concentration of substrate in the reaction mixture.

Owner:高纯技术科学有限责任公司

Immobilized microbial nitrilase for production of glycolic acid

ActiveUS20090111148A1Specific activityFully understandSugar derivativesHydrolasesCross-linkGluconic acid

The present invention is directed to a process for improving the specific activity of a dehydrated enzyme catalyst having nitrilase activity for hydrolysis of glycolonitrile to glycolic acid upon rehydration. In particular, a process is provided comprising pretreating an enzyme catalyst having nitrilase activity with glutaraldehyde, immobilizing the gutaraldehyde-preteated enzyme catalyst and chemically cross-linking the enzyme catalyst prior to dehydration. Upon rehydration, the enzyme catalyst exhibits improved specific nitrilase activity as compared to enzyme catalysts having nitrilase activity that are dehydrated and rehydrated without the processing described herein.

Owner:THE CHEMOURS CO FC LLC

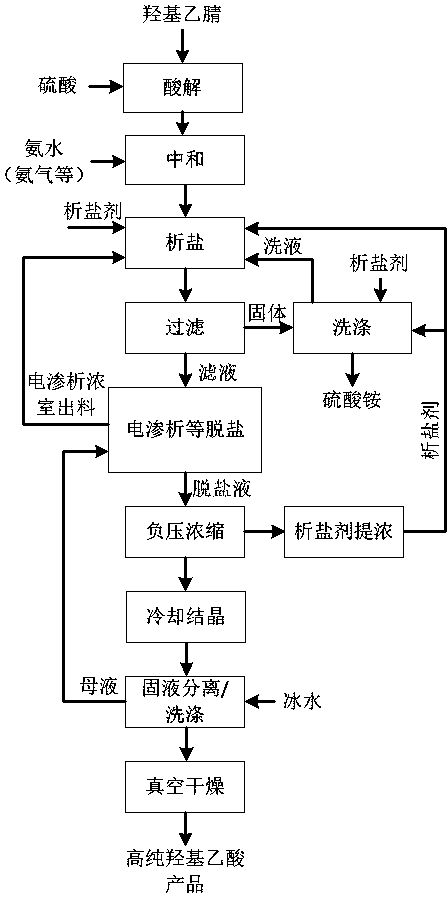

Environment-friendly clean production method of high-purity glycolic acid

InactiveCN111393281AAvoid the problem of spent acid and alkaliAchieve clean regenerationGeneral water supply conservationChemical industryDesalinationAmmonium carbonate

The invention relates to a production method of high-purity glycolic acid, which comprises the following steps: carrying out sulfuric acid acidolysis on glycolonitrile, adding ammonia or ammonium carbonate to neutralize to obtain an aqueous solution containing glycolic acid and ammonium sulfate, carrying out alcohol precipitation, electrodialysis and other desalination treatments, concentrating, carrying out solid-liquid separation, and drying to obtain the high-purity glycolic acid. According to the method disclosed by the invention, high desalination of the aqueous solution of glycolic acidis realized through a treatment mode of combining salting-out by a salting-out agent, electrodialysis and the like, and a high-purity solid glycolic acid product with the main content of 99.5% or above can be prepared. The whole process is energy-saving, environment-friendly and clean, and is a high-purity glycolic acid environment-friendly and clean production route with practical value.

Owner:高春燕

Enzymatic production of glycolic acid

Various methods are provided for the enzymatic production of glycolic acid from glycolonitrile. These methods include: 1) use of Acidovorax facilis 72W nitrilase mutants having improved nitrilase activity for converting glycolonitrile to glycolic acid, and 2) methods to improve catalyst stability and / or productivity. The methods to improve catalyst stability / productivity include use of reaction stabilizers, running the reactions under substantially oxygen free conditions, and controlling the concentration of substrate in the reaction mixture.

Owner:高纯技术科学有限责任公司

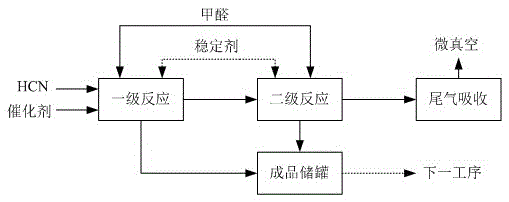

Industrial preparation method of hydroxy acetonitrile

InactiveCN108794346AImprove responseAvoid generatingCarboxylic acid nitrile preparationOrganic compound preparationHydrogenSulfite salt

The invention relates to an industrial preparation method of hydroxy acetonitrile. A formaldehyde solution is enabled to react with hydrocyanic acid at the temperature of 18-23 DEG C so as to obtain afinished hydroxy acetonitrile material, sulfuric acid is added in the finished hydroxy acetonitrile material to adjust a PH (potential of hydrogen) value to 1-2, the finished hydroxy acetonitrile material is cooled through a medium, and finally the finished hydroxy acetonitrile material is stored after being cooled to below 13 DEG C so as to avoid generation of by-products. In the reaction process of the formaldehyde solution and the hydrocyanic acid, anhydrous sodium sulfite as a catalyst is utilized to beneficially increase conversion rate of the reaction, qualified formaldehyde hydroxy acetonitrile is utilized as a solvent to beneficially increase the concentration of the final hydroxy acetonitrile product and to increase the conservation rate.

Owner:FUSHUN SHUNTE CHEM

Preparation and pre-use treatment method for glycolonitrile with cyanide-containing tail gas as raw material

InactiveCN105461592AAvoid pollutionCarboxylic acid nitrile preparationOrganic compound preparationReaction temperatureToxic industrial waste

The invention relates to a preparation and pre-use treatment method for glycolonitrile with cyanide-containing tail gas as the raw material. According to the method, the cyanide-containing tail gas is introduced into multiple stages of reaction stills containing formaldehyde and a catalyst to be directly subjected to an addition reaction, and a glycolonitrile product with a certain concentration is obtained; after material transferring, the glycolonitrile product is stored under the effect of a stabilizer for use, and before use, the pH is regulated with base or weak base till the glycolonitrile product is neutral. The catalyst is one of basic compounds including Na2SO3, Na2CO3, NaHCO3 and NaOH, the mass concentration of formaldehyde is 35%-37%, the mol ratio of formaldehyde to the catalyst is 1:(0.001-0.05), and the reaction temperature is 5-20 DEG C. According to the method, HCN in industrial waste gas of a steroid drug is chemically absorbed through formaldehyde, the catalyst and the stabilizer, glycolonitrile is generated through the reaction and serves as a raw material for biological preparation of glycollic acid, and therefore the cyanide-containing tail gas is fully absorbed and utilized and prevented from being directly exhausted to the atmosphere and polluting the environment.

Owner:ZHEJIANG QIANJIANG BIOCHEMICAL CO LTD

A kind of method for preparing anilinoacetonitrile

ActiveCN104496848BPost-processing saves time and effortReduce processCarboxylic acid nitrile preparationOrganic compound preparationAcetonitrileAniline

The invention relates to a method for preparing n-phenylglycinenitrile. The method is characterized in that condensation reaction is continuously performed for aniline and glycolonitrile by a micro-channel reactor to obtain n-phenylglycinenitrile; the pH of glycolonitrile is pre-regulated to be 1.5 to 7 through a basic catalyst; the molar ratio of aniline to glycolonitrile is 1.00: 1.00-1.30. The method for preparing n-phenylglycinenitrile has the advantages that the process route is simple, and the reaction is fast, so that the working efficiency and production capacity can be ensured, and moreover, the production and operation safety of the process can also be ensured; with the adoption of the process method, the purity of a n-phenylglycinenitrile product exceeds 98.0% and the yield exceeds 99.9%.

Owner:内蒙古诚信永安化工有限公司

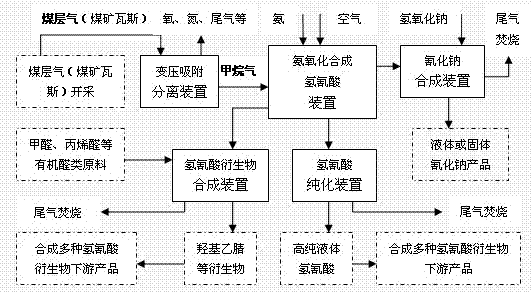

Environmentally-friendly clean technology for producing hydrocyanic acid derivatives from coal-bed methane

ActiveCN102897797AGood yieldAbundant raw materialsAlkali metal cyanidesPreparation by hydrogen cyanide additionSodium cyanideMethane gas

The invention provides an environmentally-friendly clean technology for producing hydrocyanic acid derivatives from coal-bed methane. The environmentally-friendly clean technology realizes production of hydrocyanic acid derivatives from low-concentration coal-bed methane. The environmentally-friendly clean technology is characterized in that hydrocyanic acid and its derivatives are prepared from concentrated methane having low content requirements; coal-bed methane is subjected to separation processes of pressure swing adsorption and the like to form relatively concentrated methane for production of hydrocyanic acid derivatives, wherein the relatively concentrated methane has relatively low concentration requirements and can retain residual nitrogen and oxygen having a large component ratio; and the relatively concentrated methane undergoes an ammoxidation synthesis reaction to produce hydrocyanic acid mixed gas, and the hydrocyanic acid mixed gas and a sodium hydroxide aqueous solution undergo a reaction to produce sodium cyanide for synthesis of downstream hydrocyanic acid derivatives, or the hydrocyanic acid mixed gas, formaldehyde and other aldehydes are synthesized into glycolonitrile and other derivatives for synthesis of downstream hydrocyanic acid derivatives, or the hydrocyanic acid mixed gas is absorbed by water or other solvents and then is purified to form high-purity liquid hydrocyanic acid for synthesis of downstream hydrocyanic acid derivatives.

Owner:李宽义

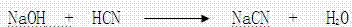

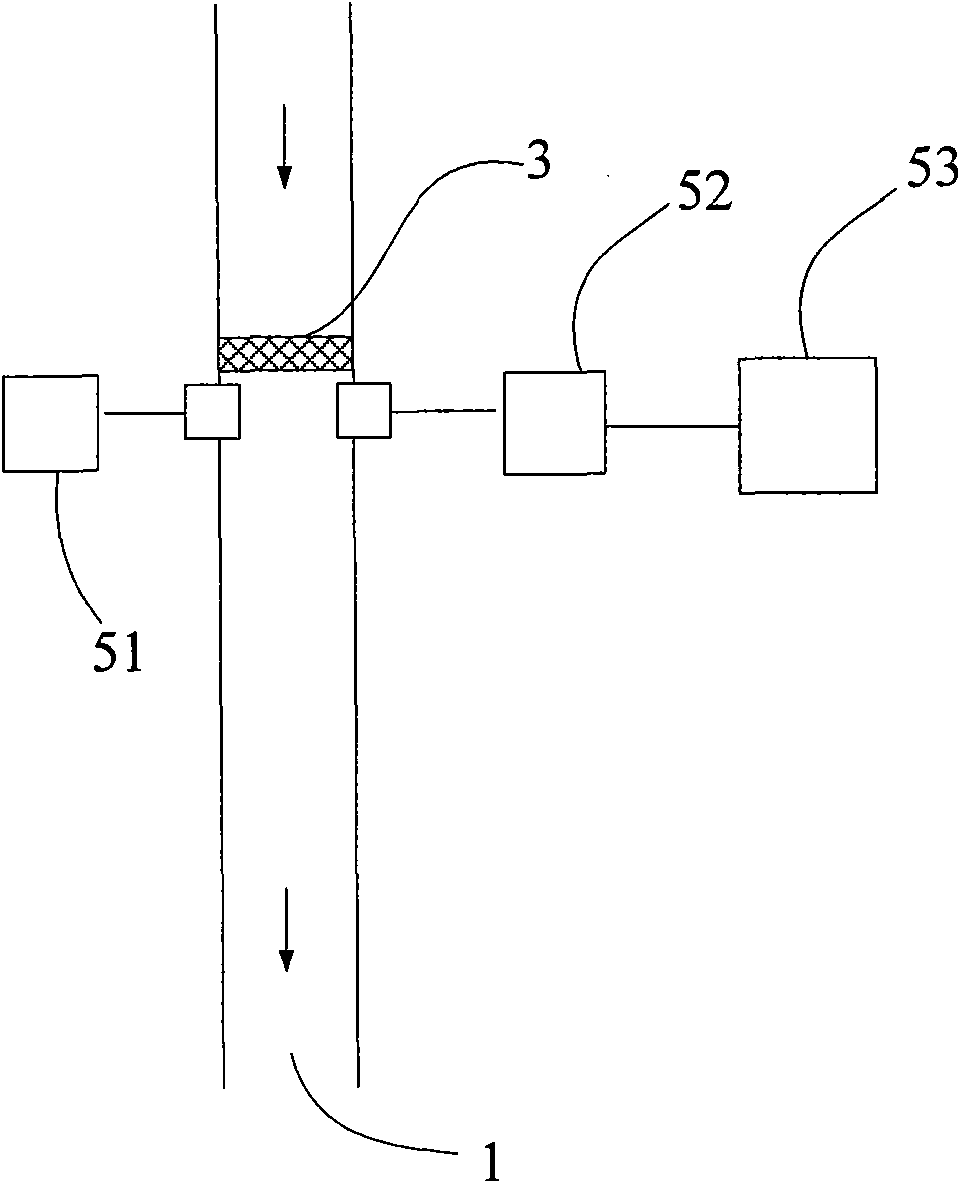

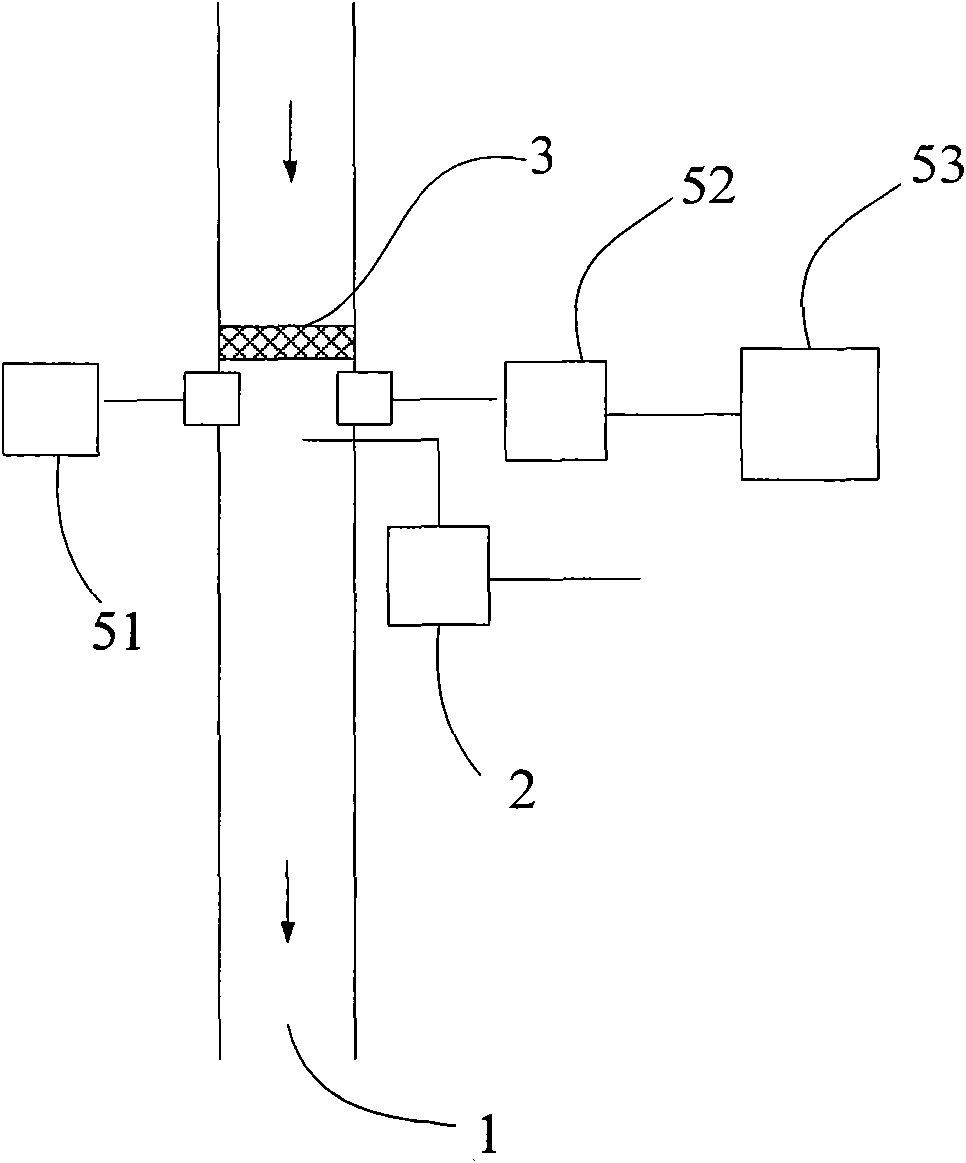

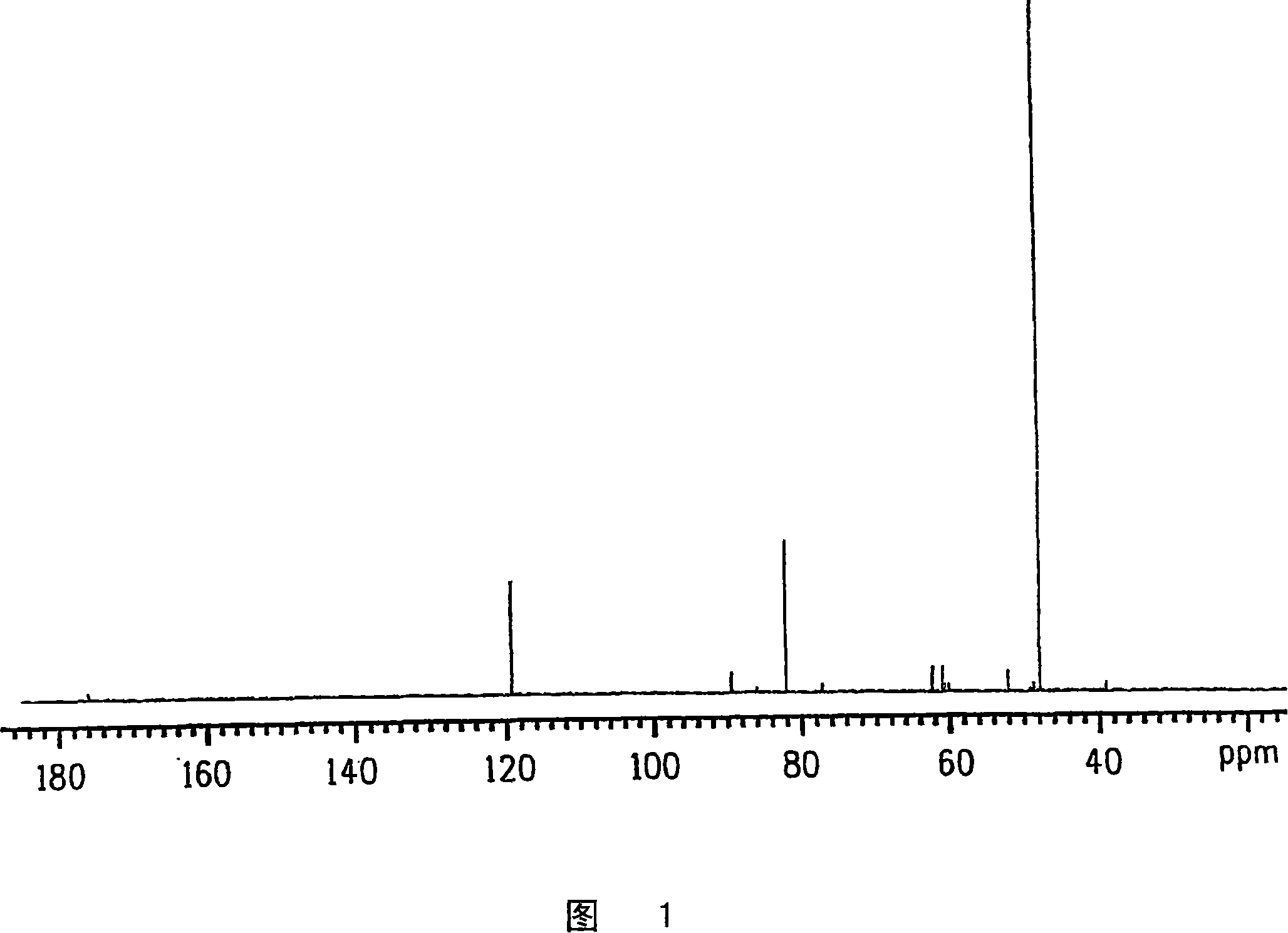

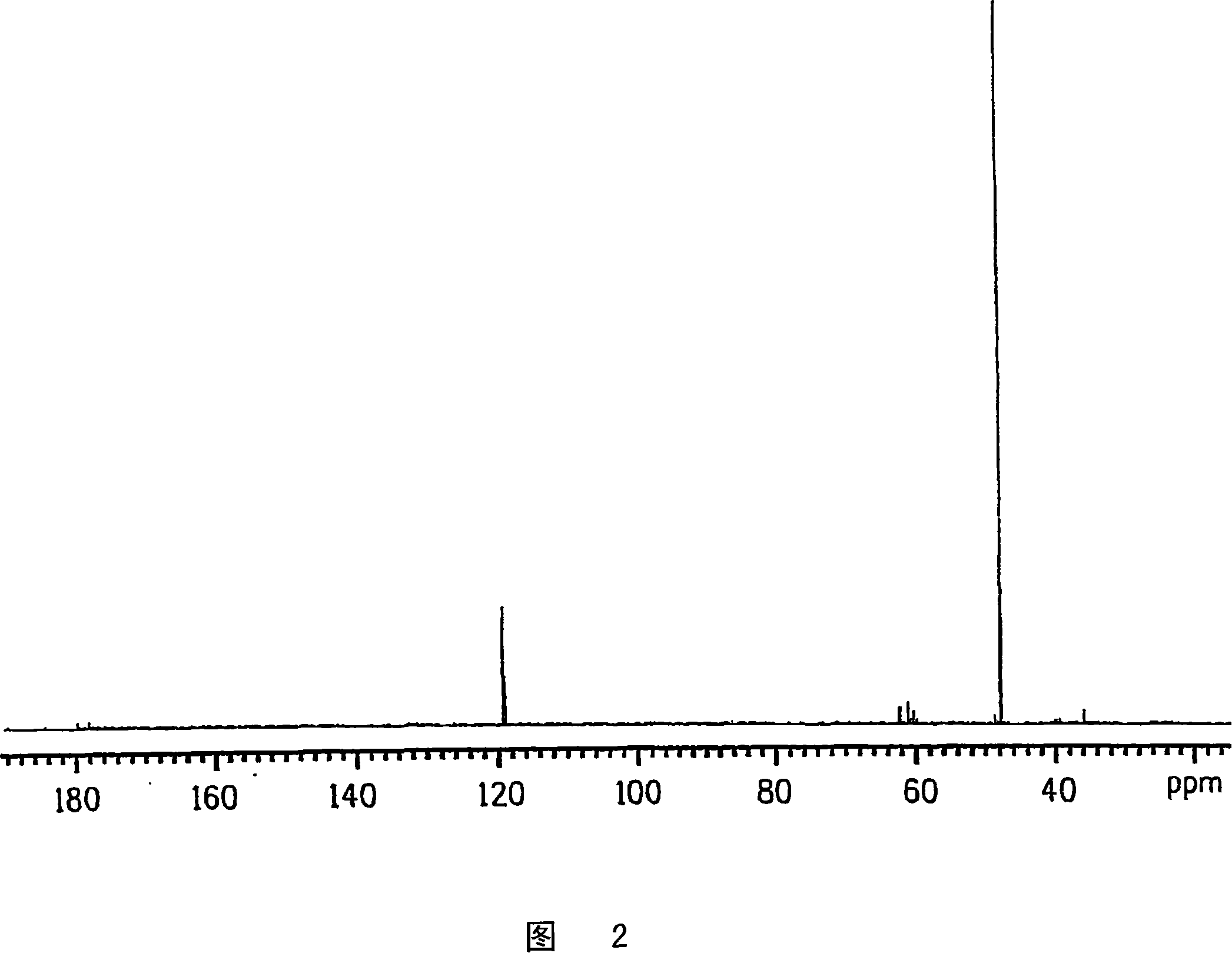

Method and device for monitoring glycolonitrile preparation technology in real time

InactiveCN101929950AShort timeFast analysisCarboxylic acid nitrile preparationOrganic compound preparationComputer sciencePollution

The invention relates to a method for monitoring a glycolonitrile preparation technology process in real time, comprising the following steps: a. selecting a group of samples and collecting a spectrum, wherein the spectrum scanning range is 400-2500 nm; building an analysis model by utilizing the content of sample component and the corresponding spectrum; b. collecting the spectrum of an unknown sample in the glycolonitrile preparation process, and inputting the spectrum into the analysis model; and determining the content of the unknown sample component. The invention also provides a device for monitoring the glycolonitrile preparation technology in real time. The invention has the advantages of quickness, instantaneity, simple operation, no pollution, high analysis accuracy and the like.

Owner:FOCUSED PHOTONICS

Process for producing glycolic acid from formaldehyde and hydrogen cyanide

ActiveCN101133161AOrganic compound preparationAmino-carboxyl compound preparationGluconic acidGlycollic acid

A process is provided for producing glycolic acid from formaldehyde and hydrogen cyanide. More specifically, heat-treated formaldehyde and hydrogen cyanide are reacted to produce glycolonitrile having low concentrations of impurities. The glycolonitrile is subsequently converted to an aqueous solution of ammonium glycolate using an enzyme catalyst having nitrilase activity derived from Acidovorax facilis 72W (ATCC 57746). Glycolic acid is recovered in the form of the acid or salt from the aqueous ammonium glycolate solution using a variety of methods described herein.

Owner:THE CHEMOURS CO FC LLC

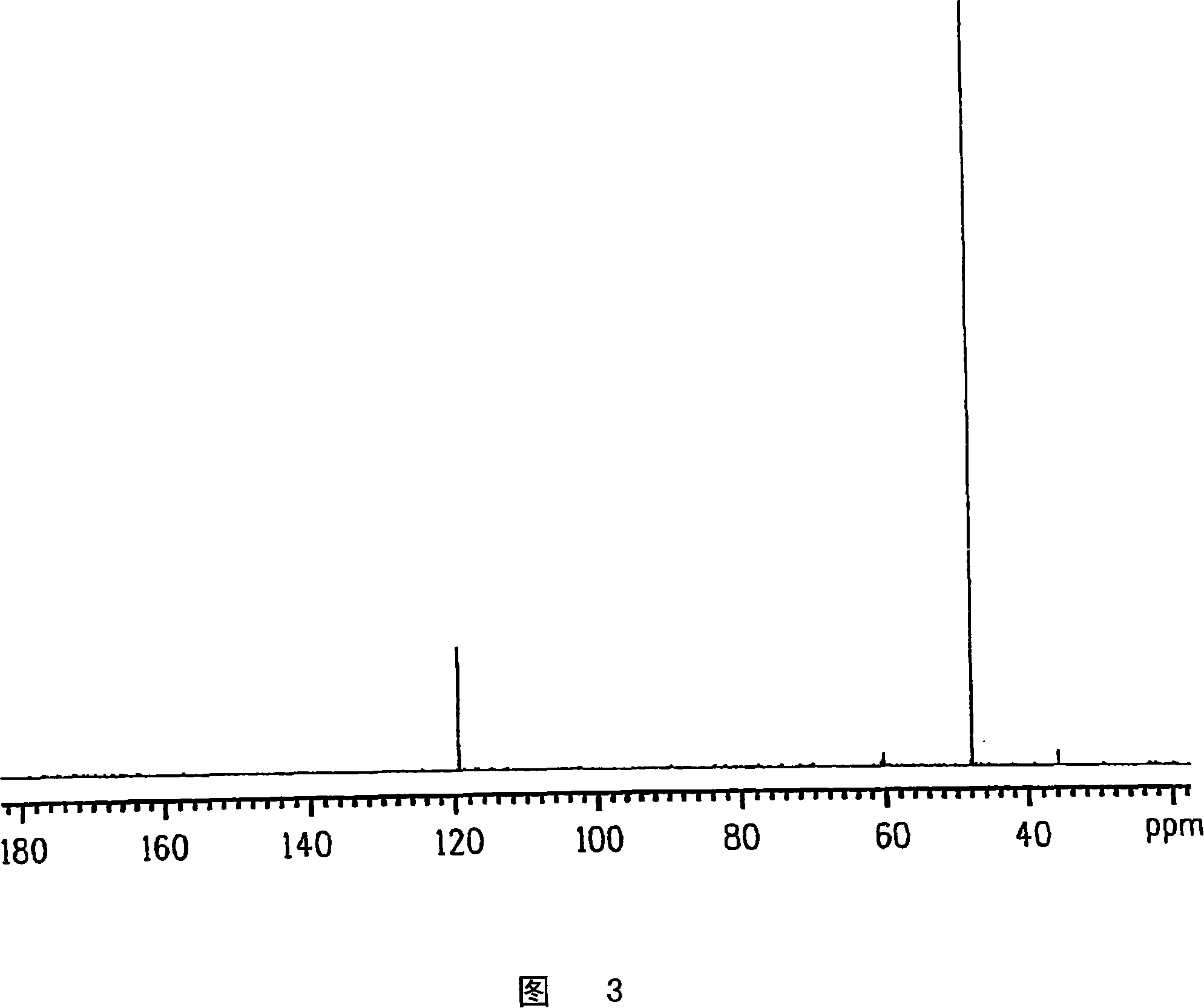

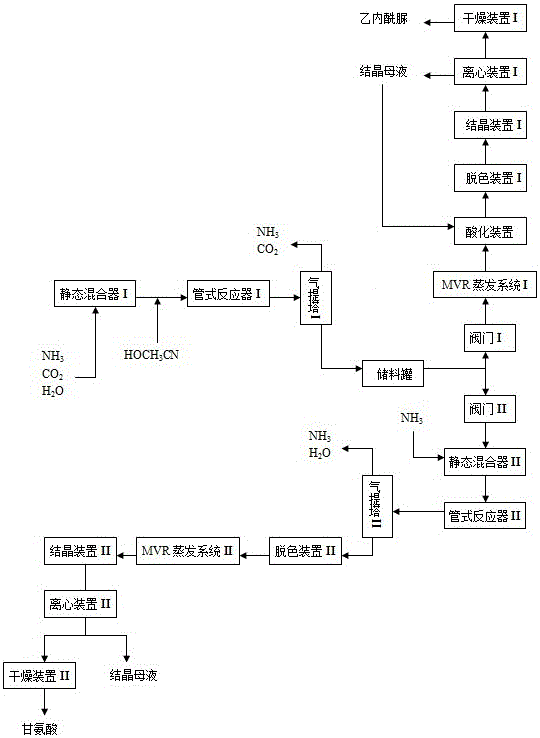

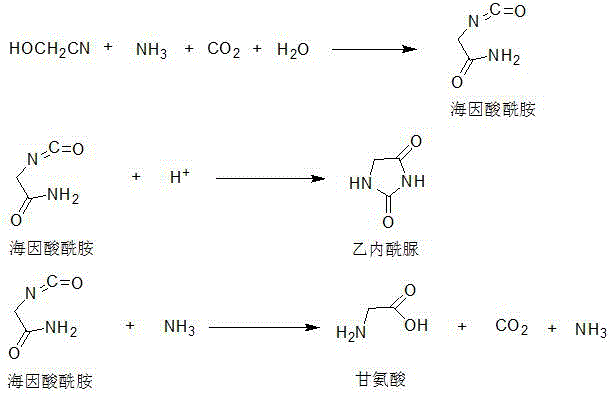

Combined production method and device of glycine and hydantoin

InactiveCN104910031BEasy to adjust outputLess investment in production equipmentOrganic compound preparationAmino-carboxyl compound preparationHydrolysisHydantoin

The invention discloses a method for co-producing glycine and hydantoin, and an apparatus thereof. The method adopting hydroxyacetonitrile, ammonia, carbon dioxide and water, or hydroxyacetonitrile, ammonia, ammonium bicarbonate and water, or hydroxyacetonitrile, ammonium carbonate, carbon dioxide and water as raw materials comprises the following steps: carrying out an amidocarbonylation reaction on the raw materials at a temperature of 60-120DEG C under a pressure of 1.5-3.0MPa according to a molar ratio of hydroxyacetonitrile: ammonia: carbon dioxide: water of 1:3-5:2-4:46-50 in a reaction system to prepare an amidocarbonylation reaction solution; acidifying the amidocarbonylation reaction solution to obtain a hydantoin product, or carrying out ammonification hydrolysis on the amidocarbonylation reaction solution to prepare a glycine product The method and the apparatus can save the investment of apparatuses for prodcuign glycine and hydantoin, reduce the production cost, are convenient for adjusting the outputs of glycine and hydantoin, and especially overcome the disadvantages of incomplete hydrolysis, generation of iminodiacetic acid, many byproducts, difficult purification of glycine, and low yield of present hydantoin methods for preparing glycine.

Owner:CHONGQING UNISPLENDOUR CHEM

Method for producing glycolic acid

ActiveUS20090118541A1Less energyEasy to produceOrganic compound preparationPreparation from nitrilesGluconic acidGlycollic acid

Provided is a production method of glycolic acid having a first step of preparing glycolonitrile from formaldehyde and hydrocyanic acid and a second step of hydrolyzing the glycolonitrile into glycolic acid directly or via a glycolate salt, which method can produce glycolic acid in easy production and purification steps while consuming less energy. In the production method, by carrying out the first and second steps continuously or by storing the glycolonitrile obtained in the first step at pH 4 or less and carrying out a hydrolysis reaction of the second step at from pH 5 to 9, a production yield of glycolic acid, activity for the production of glycolic acid and accumulated concentration of glycolic acid are improved, resulting in the production of glycolic acid having an improved purity and quality.

Owner:ASAHI KASEI CHEM CORP

Method for removing impurities in glycine synthetic process

ActiveCN101747218AGuaranteed qualityReduce difficultyOrganic compound preparationAmino-carboxyl compound preparationAcetonitrileAlkaline hydrolysis

The invention provides a method for removing impurities in glycine reaction liquid and mother liquid in a glycine preparing process by using a glycolonitrile method. The method comprises the following steps: carrying out independent backflow to alkaline hydrolysis synthetic liquid after alkaline hydrolysis is finished or mixing the glycine mother liquid and liquid alkaline synthetic liquid and then carrying out the alkaline hydrolysis; carrying out intermittent or continuous production under high-temperature backflow; and finally removing the impurities.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

Process for the synthesis of glycolonitrile

ActiveUS7368492B2Carboxylic acid nitrile preparationOrganic compound preparationAqueous mediumImpurity

A process to prepare substantially pure glycolonitrile in an aqueous medium is provided by reacting hydrogen cyanide and formaldehyde. The formaldehyde feed stream is heated prior to reacting with hydrogen cyanide, resulting in an aqueous glycolonitrile solution with fewer impurities, especially less unreacted formaldehyde, than is obtained by other methods. The process enables production of an aqueous glycolonitrile solution that requires less post-reaction purification (if any at all) prior to enzymatically converting the glycolonitrile into glycolic acid.

Owner:PURETECH SCI LLC

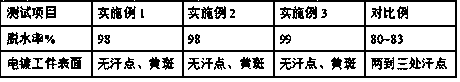

Preparation method for electroplating dehydrant

InactiveCN108277514AIncrease the effective volumeImprove rust resistanceN dimethylformamidePhosphorus trichloride

The invention discloses a preparation method for an electroplating dehydrant and belongs to the field of chemical engineering. Oxalyl chloride, N,N-dimethylformamide serve as raw materials, dehydration matter based on chloro imine salt is synthesized, dehydration reaction can be conducted under mild conditions, the dehydration matter can be recycled, the center carbon atom electron cloud density is low, dehydration reaction activity is also improved, and fast dehydration drying is achieved. Methylamine, glycolonitrile, oleic acid and phosphorus trichloride serve as raw materials to prepare matter which is capable of forming a film on the surface of metal and has a rust-proof function, the matter conducts adsorption on the surface of electroplated metal to achieve a corrosion inhibition effect, meanwhile water displacement performance of the matter is good, the matter can assist in dehydrating the surface of the metal at the normal temperature, and a later protection function on the electroplated metal is achieved. According to the preparation method, the problems that after an existing dehydrant is used, a certain proportion of sweat points, water drops, yellow spot defects and other phenomena appear on the surface of an electroplated workpiece are solved.

Owner:常州五荣化工有限公司

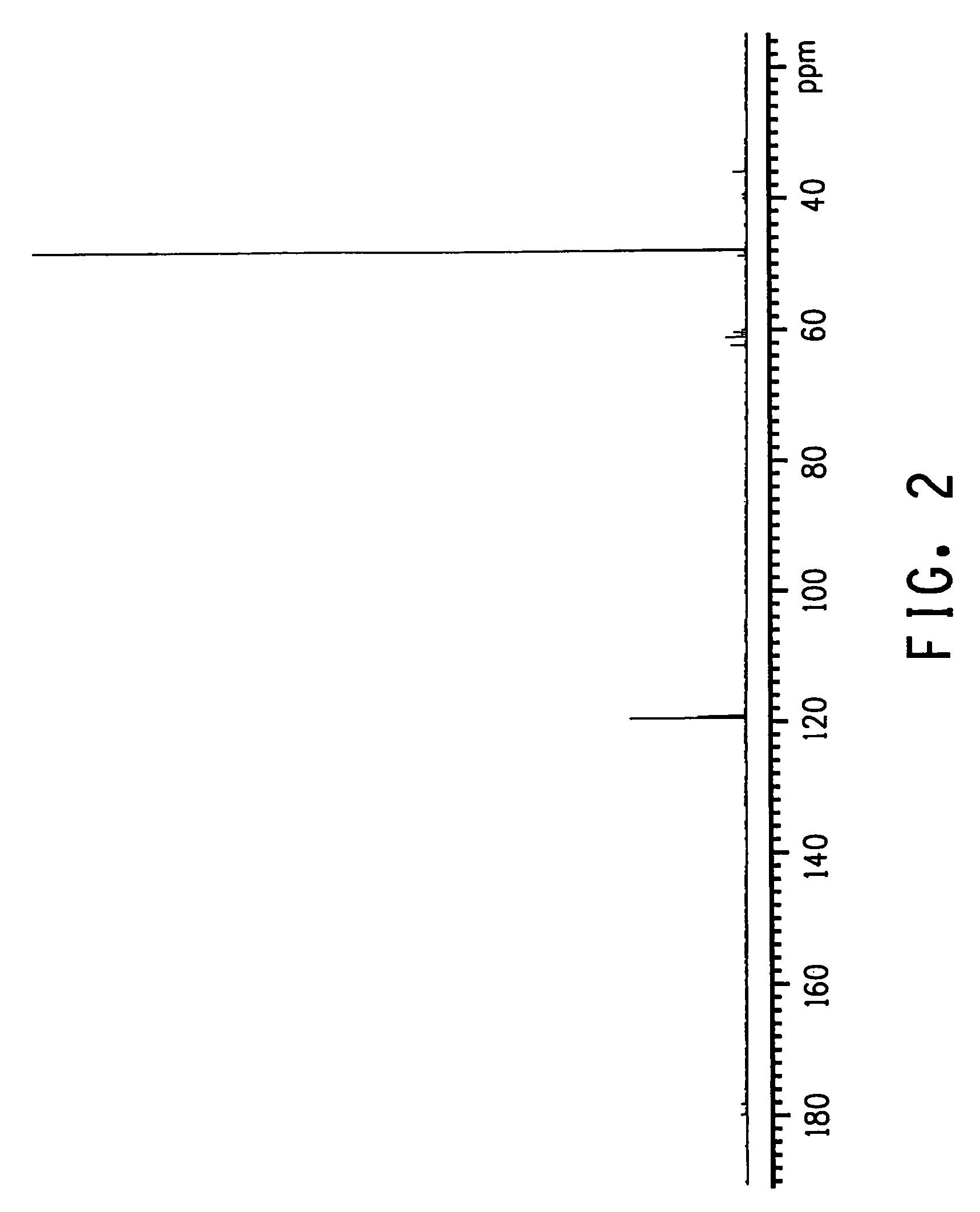

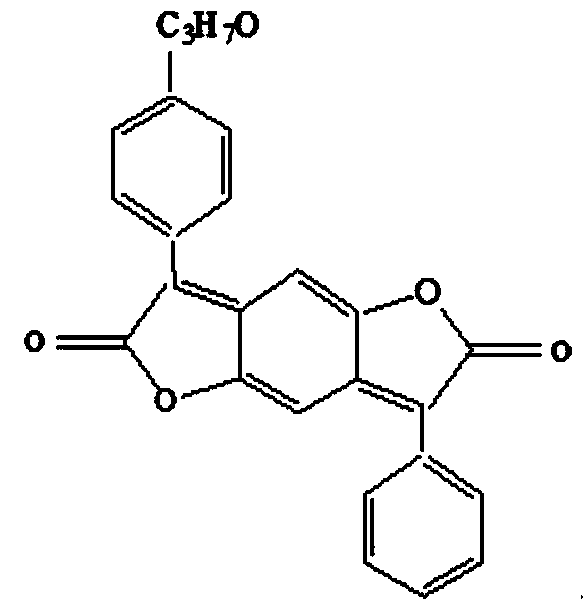

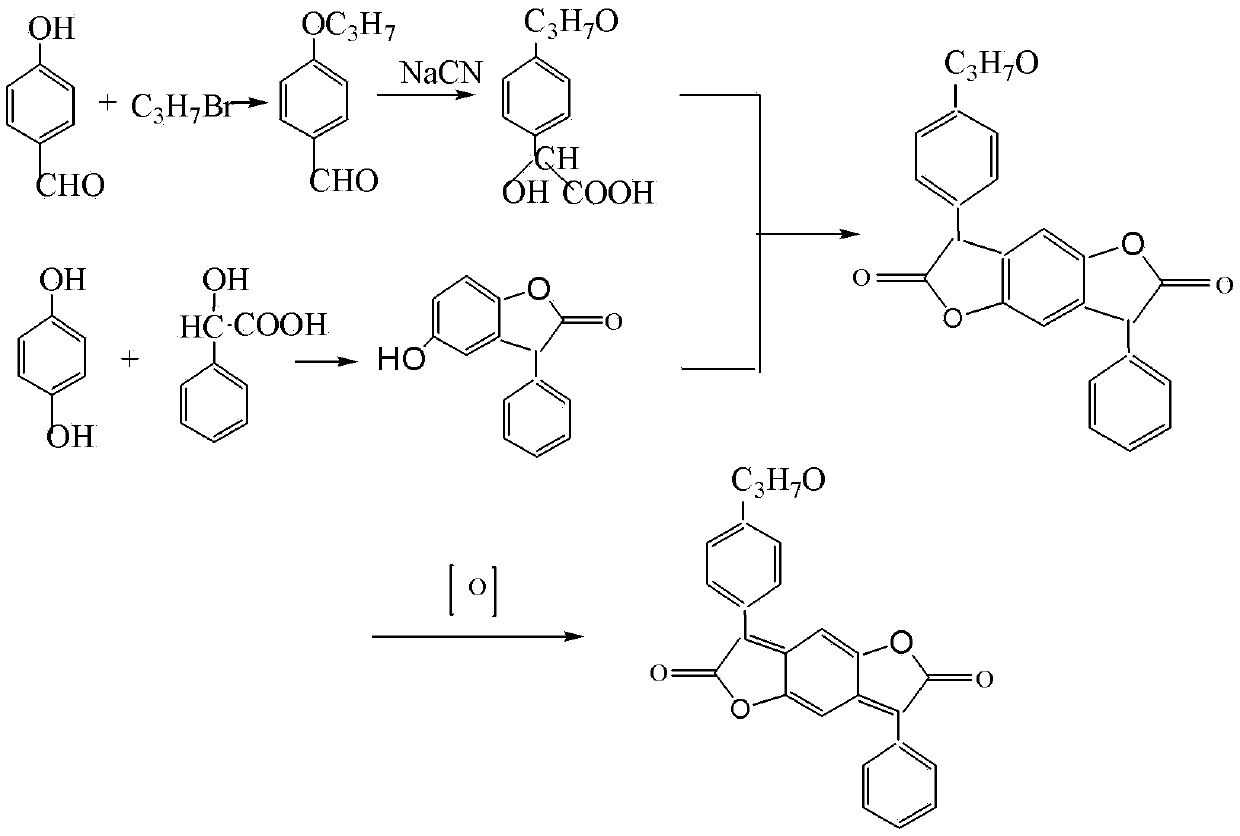

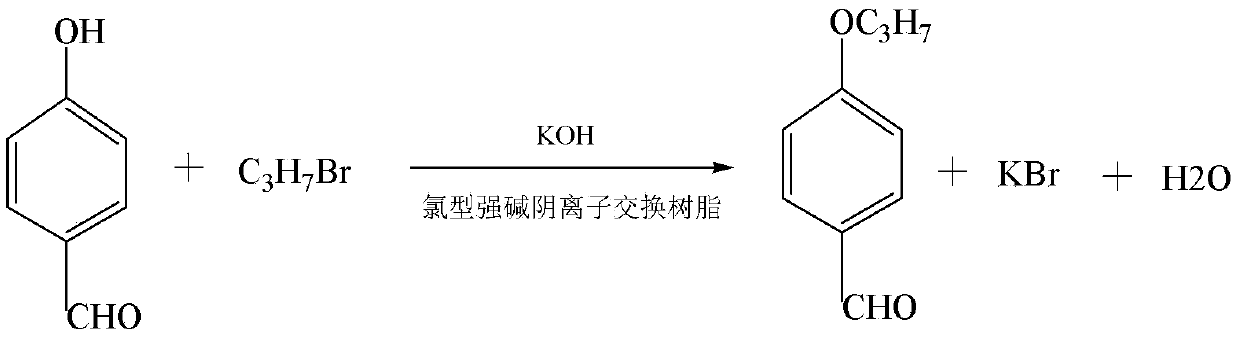

Disperse red 356 preparation method

InactiveCN103965650AAvoid it happening againReduce production processAzo dyesQuaternary ammonium cationReaction rate

The present invention discloses a disperse red 356 preparation method, which comprises five reaction units such as alkylation, cyanation, condensation, cyclization and oxidation. Comparison with the method in the prior art, the method of the present invention has the following significant advantages that: 1, alkylation adopts a DMF and toluene mixed solvent and a chlorine type strong base anion exchange resin to replace the original quaternary ammonium salt phase transfer catalyst so as to significantly increase the reaction rate, the purity and the yield; 2, in the cyanation process, the generation of toxic hydrogen cyanide during the reaction process is avoided, and the yield is improved; 3, in the cyclization process, a perphosphoric acid and concentrated sulfuric acid mixed acid is adopted as a catalyst, and a reaction of p-propoxy phenyl glycolonitrile and 3-phenyl-6-hydroxy-benzofuran-2-one is adopted to replace the original process so as to reduce the production of the byproduct; and 4, the oxidation experiment results of different oxidants are different, wherein sodium perborate is screened, and the total yield of cyclization and oxidation can achieve 80%.

Owner:JIANGSU DAOBO CHEM

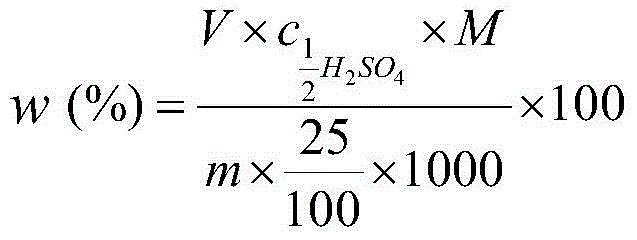

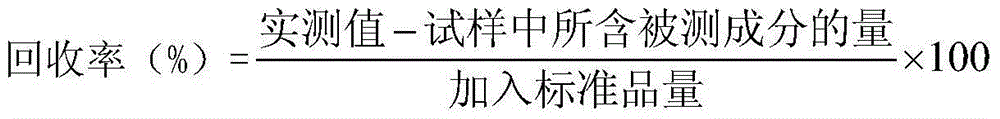

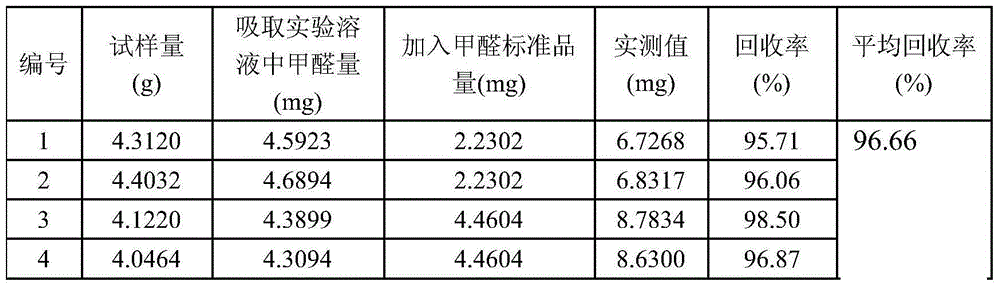

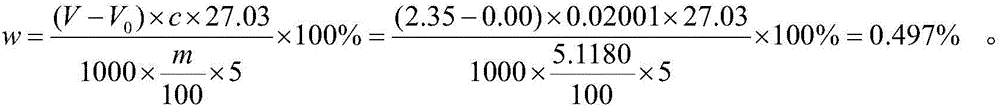

Method for determining content of formaldehyde in glycolonitrile product

InactiveCN104090017ASimple and fast operationEasy to operateMaterial electrochemical variablesSulfite saltSodium sulfite

The invention relates to a method for determining the content of formaldehyde in a glycolonitrile product. The method is characterized by comprising the following steps: accurately weighing a defined amount of glycolonitrile product sample to prepare an experiment solution, after regulating the experiment solution to be neutral, rapidly adding excessive sodium sulfite solution with the pH being 9.2, and immediately titrating a sulfuric acid standard titration solution until the pH is equal to 9.16-9.20 as an end point. The method has the advantages of simplicity and convenience in operation, rapidness, good reproducibility, high accuracy, and the like, and can be used for controlling the quality of the glycolonitrile product.

Owner:CHONGQING UNISPLENDOUR INT CHEM

Method for preparing solid glycolic acid

InactiveCN106588625AHigh purityEasy to operatePreparation from nitrilesCarboxylic compound separation/purificationHydrolysisVacuum drying

A method for preparing solid glycolic acid comprises the following steps: (1) hydrolysis reaction of glycolic acid: taking concentrated sulfuric acid, water and a glycolonitrile water solution as raw materials for hydrolysis reaction of glycolic acid; (2) neutral reaction: adding concentrated ammonia water while stirring for neutral reaction; (3) desalting: adding anhydrous isopropyl alcohol into a product of the step (2), stirring, performing suction filtration, drying filter cake obtained through suction filtration, retrieving filtrate, and adding injection carbon for decoloration to obtain a colorless transparent liquid; (4) alcohol recovery; and (5) crystallization: performing cooling crystallization, stopping cooling when the temperature of feed liquid reaches 5-20 DEG C, preserving the temperature for 1 h at the temperature, performing suction filtration, washing filter cake with 100 mL distilled water to obtain a glycolic acid wet product, and conducting vacuum drying at 30 DEG C for 6 h to obtain solid glycolic acid. The method for preparing the solid glycolic acid is simple to operate and high in product yield and purity.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

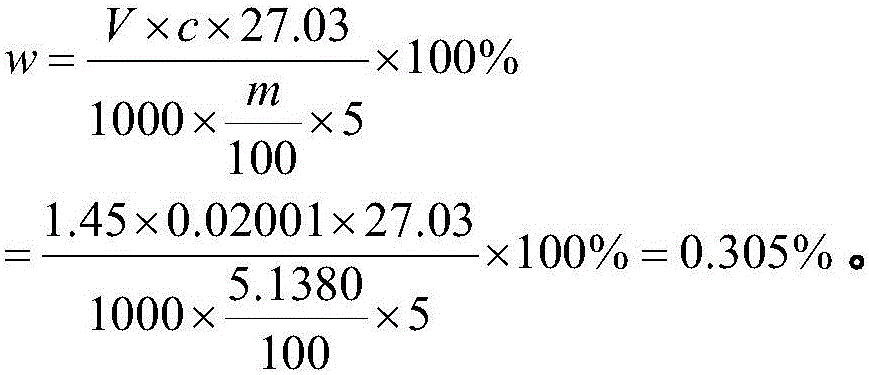

Assay method for hydrocyanic acid content in glycolonitrile product

InactiveCN106501252AQuick responseShort analysis timeMaterial analysis by observing effect on chemical indicatorChemical analysis using titrationCyanideThiobenzophenone

The invention provides an assay method for hydrocyanic acid content in a glycolonitrile product. While pH is equal to 6, cyanide (CN-) reacts with mercuric nitrate (Hg(NO3)2) to generate mercury cyanide (HG(CN)2), thiomichler ketone (4,4'-bi(dimethylamino)thiobenzophenone) is used as an indicator, mercuric nitrate standard titration solution is used for titration, and the hydrocyanic acid mass fraction in the glycolonitrile product is measured. The reaction speed is fast, the analysis time is short, and the process is not interfered by the glycolonitrile. The assay method has the characteristics of higher accuracy, simple and rapid operation, and better repeatability, and can be used as the quality control method of the hydrocyanic acid content index in the glycolonitrile product.

Owner:CHONGQING UNISPLENDOUR CHEM

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com