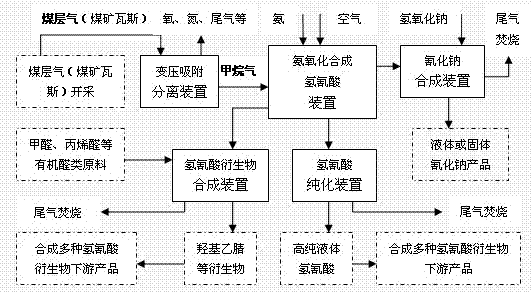

Environmentally-friendly clean technology for producing hydrocyanic acid derivatives from coal-bed methane

A process method and technology for coalbed methane, applied in the direction of cyanide, metal cyanide, chemical instruments and methods, etc., can solve the problems of affecting the utilization of coalbed methane and high purification cost, and achieve rich raw material guarantee, improve purification efficiency, and reduce purification requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

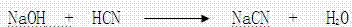

[0038] Embodiment 1: coal bed gas: methane 48.3%, oxygen 10.1%, nitrogen 39.1%, water 1.5%, other 1.0%, separate by pressure swing adsorption and other auxiliary separation devices, obtain O respectively 2 and N 2 Mixed gas, CH 4 Gas and tail gas; CH 4 The gas is used for the synthesis of hydrocyanic acid by Angler's ammoxidation.

[0039] Separation of coalbed methane to get CH 4 (methane gas) composition:

[0040] serial number component name Component ratio% serial number component name Component ratio% 1 CH 4 73.520 6 CO 2 0.213 2 H 2 0.978 7 CO 0.133 3 h 2 o 0.112 8 Ar 0.016 4 N 2 20.013 9 other 0.004 5 O 2 5.011 10

[0041] Using the above coalbed methane separation to obtain CH 4 (Methane gas) According to the requirements of Angle's ammoxidation synthesis reaction, the calculated amount of ammonia and air is obtained by secondary mixing. The composition is as follows:

[0042] ...

Embodiment 2

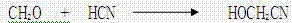

[0059] Embodiment 2: same as embodiment 1, utilize above-mentioned coal bed gas separation to obtain CH 4 (Methane gas) Synthesis gas is obtained through Angle's ammoxidation synthesis reaction; reaction synthesis gas is combined to remove ammonia to obtain reaction synthesis gas without ammonia or trace ammonia; synthesis gas after ammonia removal is absorbed by formaldehyde solution to obtain high-purity Aqueous solution of hydroxyacetonitrile for the synthesis of high-purity hydrocyanic acid derivatives.

[0060] The composition of the synthesis gas is as follows:

[0061] serial number component name Component ratio% serial number component name Component ratio% 1 HCN 8.092 6 N 2 54.328 2 NH 3 1.508 7 CO 2 0.503 3 h 2 o 25.513 8 CO 4.705 4 CH 4 0.462 9 H 2 4.765 5 O 2 0.020 10 other 0.104

[0062] Syngas uses phosphoric acid or ammonium dihydrogen phosphate as a carrier to perform primary a...

Embodiment 3

[0071] Embodiment 3: same as embodiment 2, utilize above-mentioned coal bed gas separation to obtain CH 4 (Methane gas) Synthesis gas is obtained through Angle's ammoxidation synthesis reaction; reaction synthesis gas is obtained through joint removal of ammonia to obtain reaction synthesis gas without ammonia or trace ammonia; the synthesis gas after ammonia removal is absorbed by deionized water to obtain hydrogen The cyanic acid aqueous solution is refined to obtain high-purity liquid hydrocyanic acid, which is used for the synthesis of hydrocyanic acid derivatives; the tail gas is absorbed and sent to the tail gas incineration device for incineration. The quality that obtains high-purity liquid hydrocyanic acid is as follows:

[0072] Hydrocyanic acid (%) CO 3 2- (%) NH 3 + (%) other 99.78 - - water, trace impurities

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com