Patents

Literature

202results about "Hydrogen cyanide preparation/purification/separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

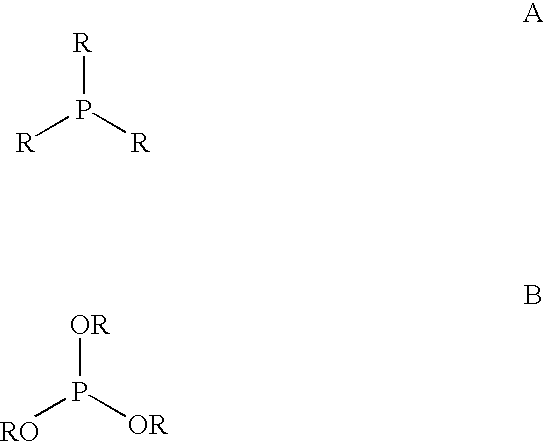

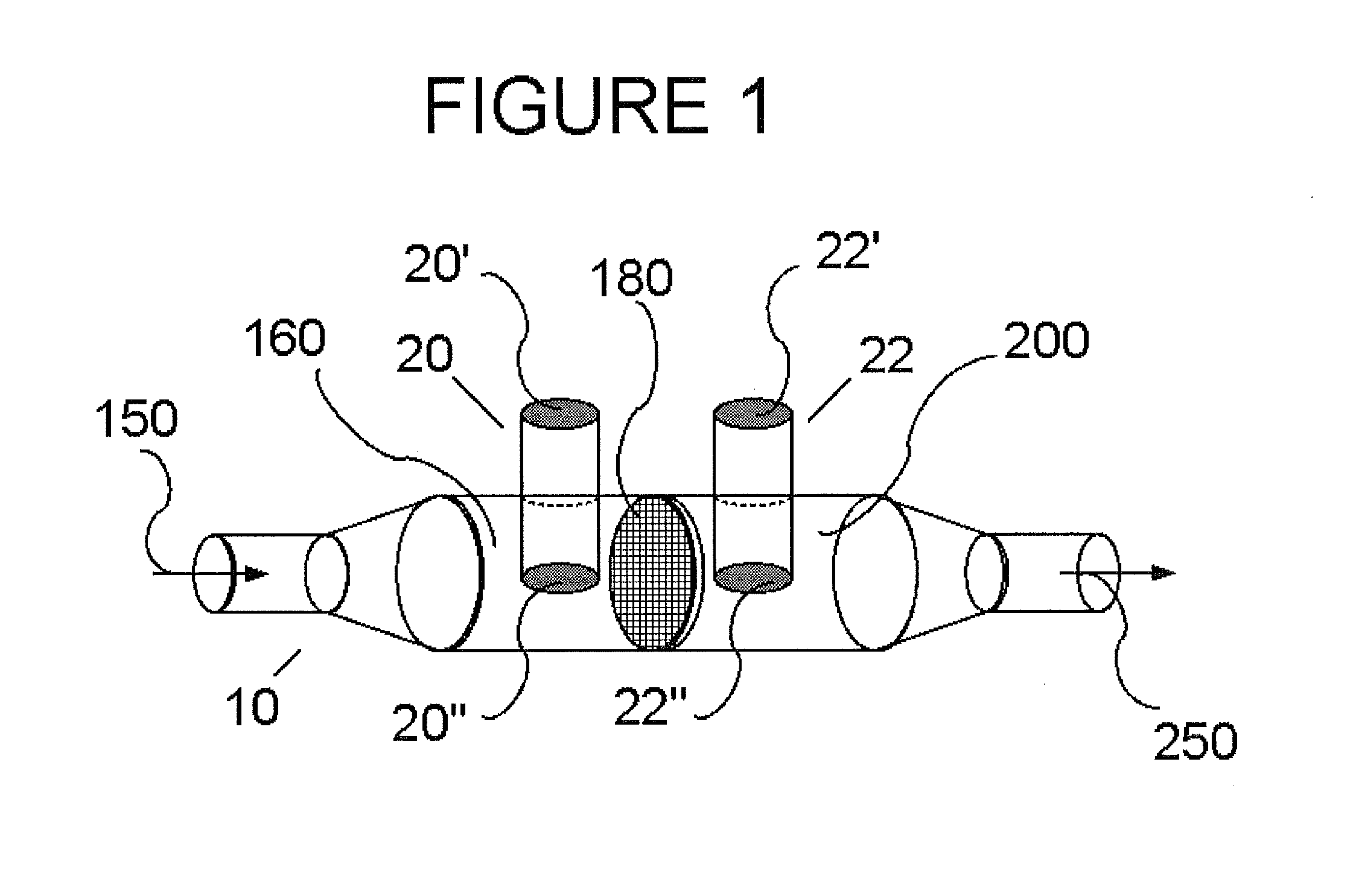

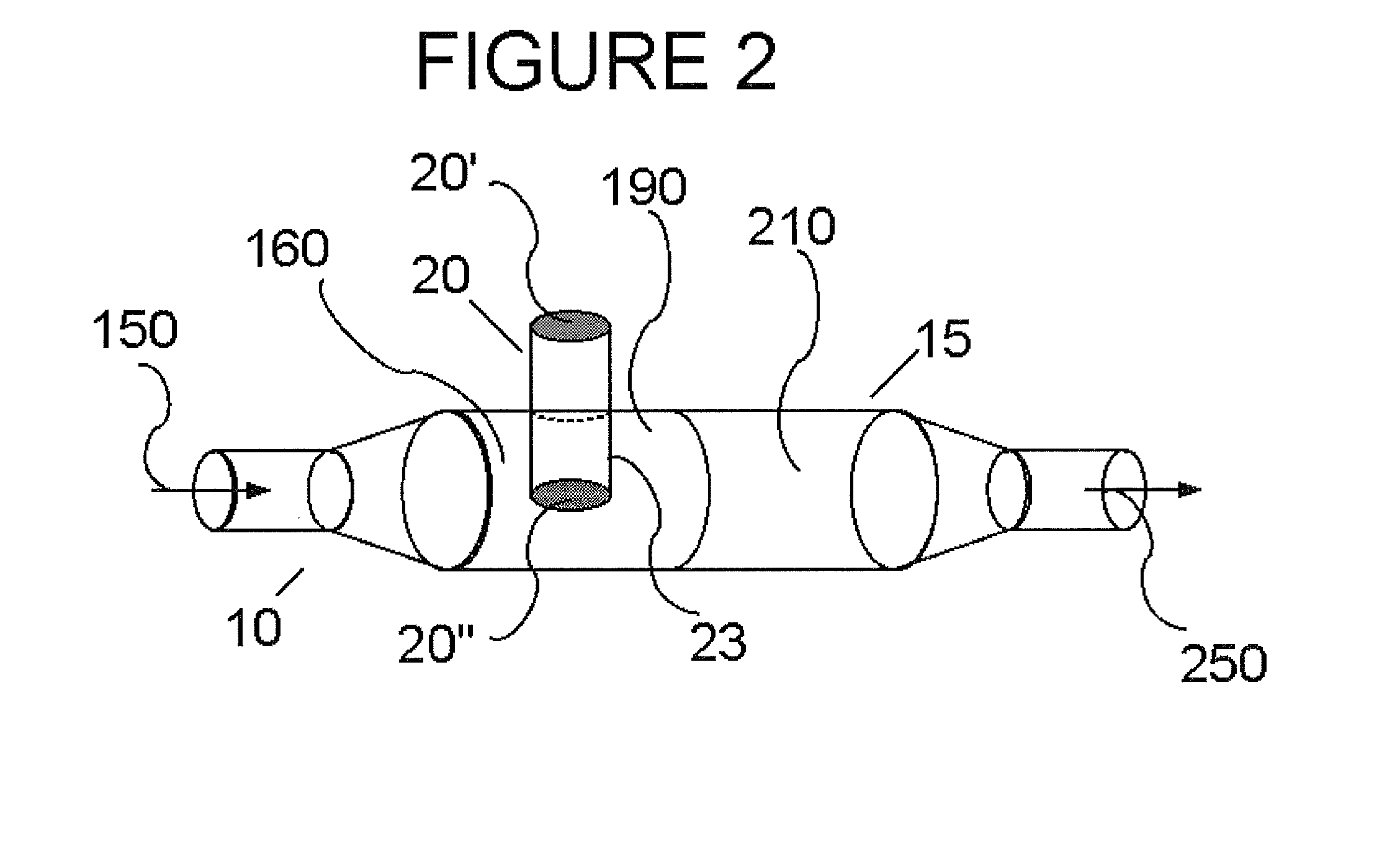

Supported bis(phosphorus) ligands and their use in the catalysis

InactiveUS6984604B2High selectivityHigh yieldOther chemical processesOrganic compound preparationIsomerizationOrganic compound

Supported bis(phosphorus) ligands are disclosed for use in a variety of catalytic processes, including the isomerization, hydrogenation, hydroformylation, and hydrocyanation of unsaturated organic compounds. Catalysts are formed when the ligands are combined with a catalytically active metal, such as nickel.

Owner:INVISTA NORTH AMERICA R L

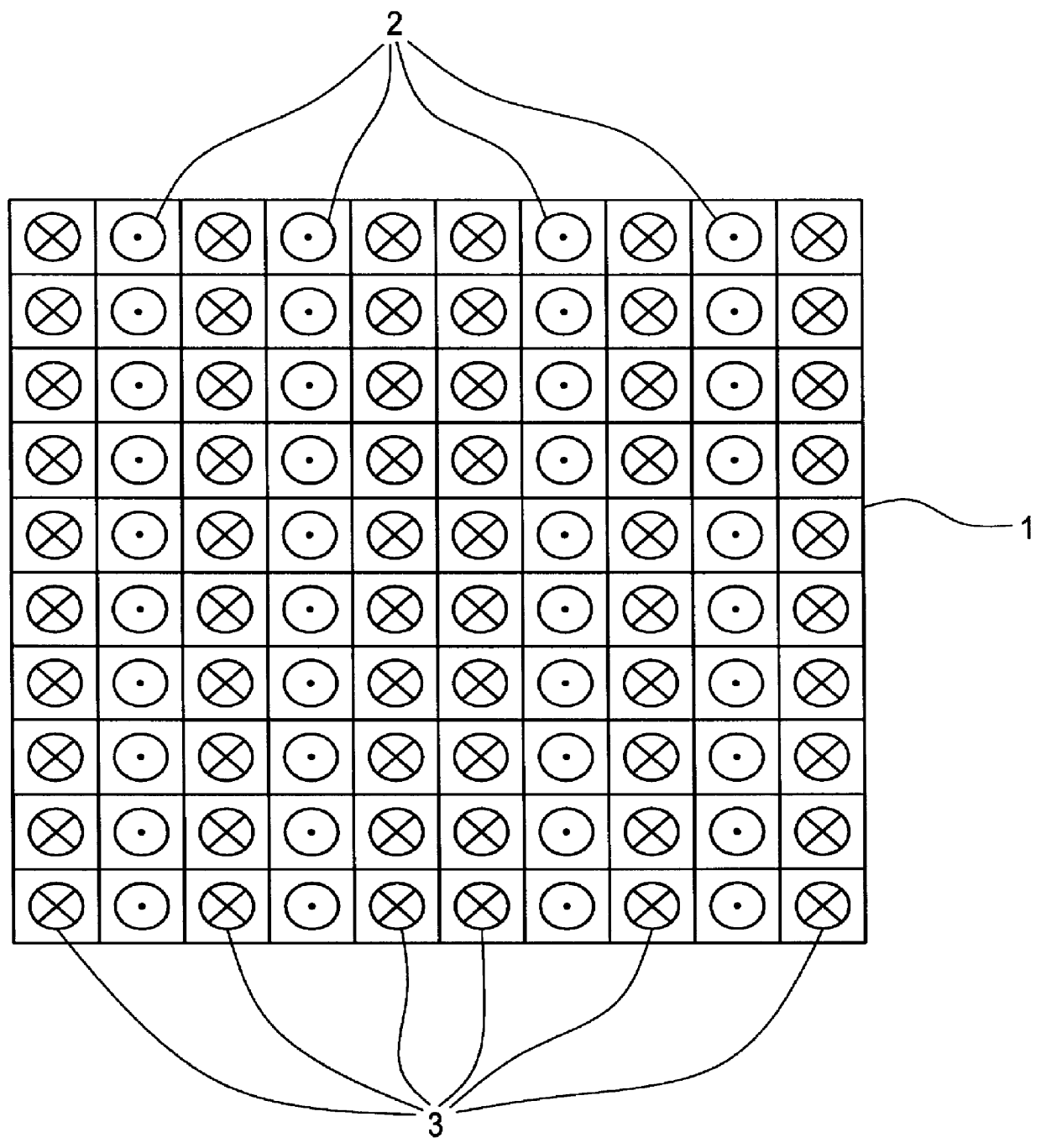

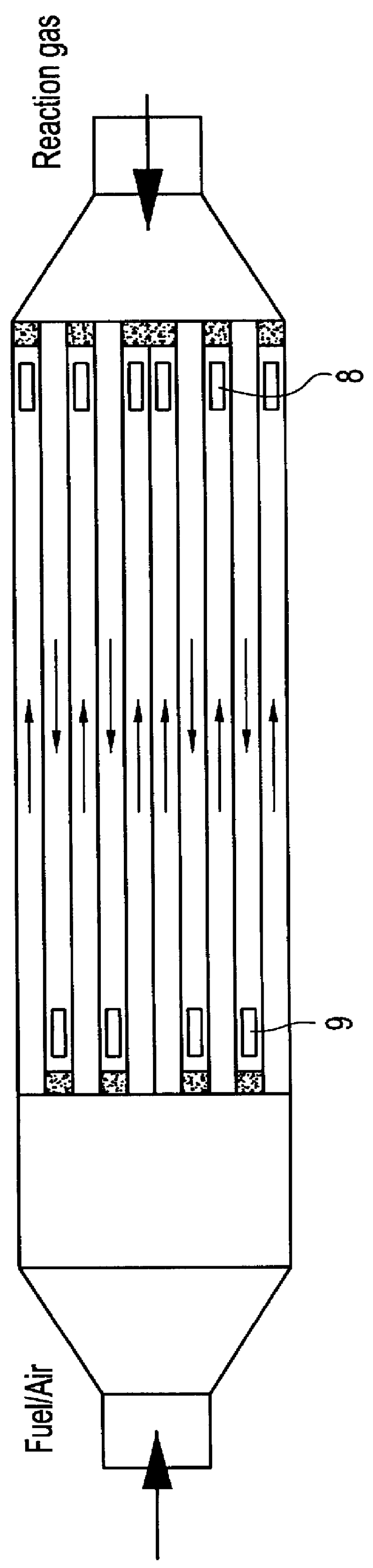

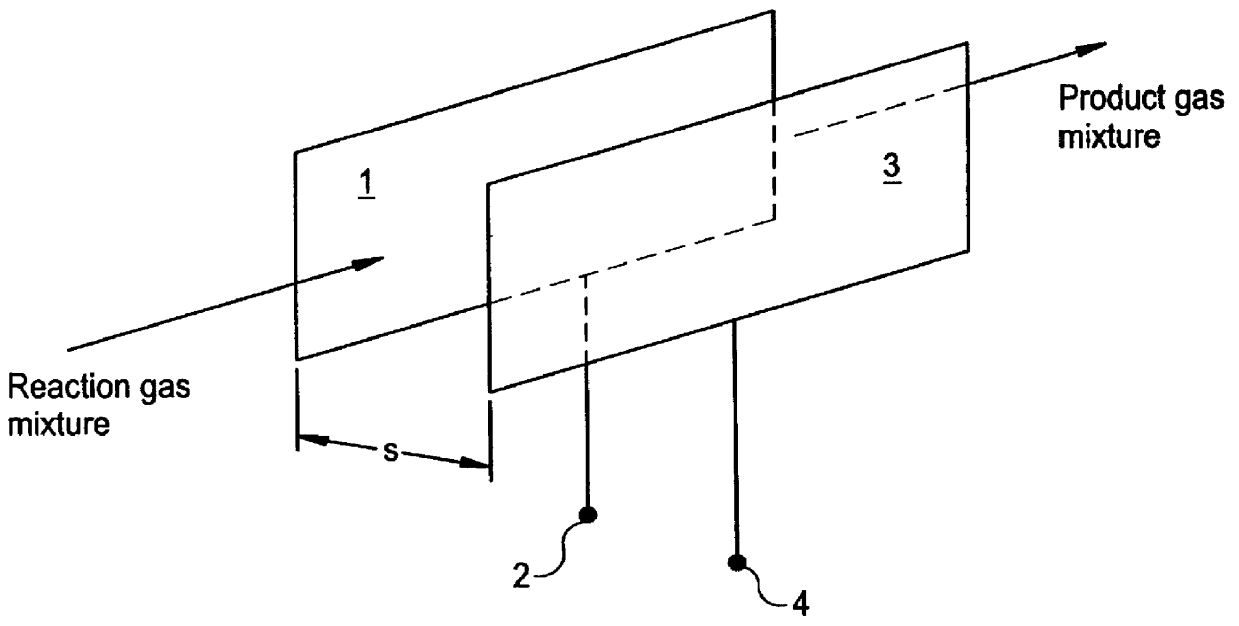

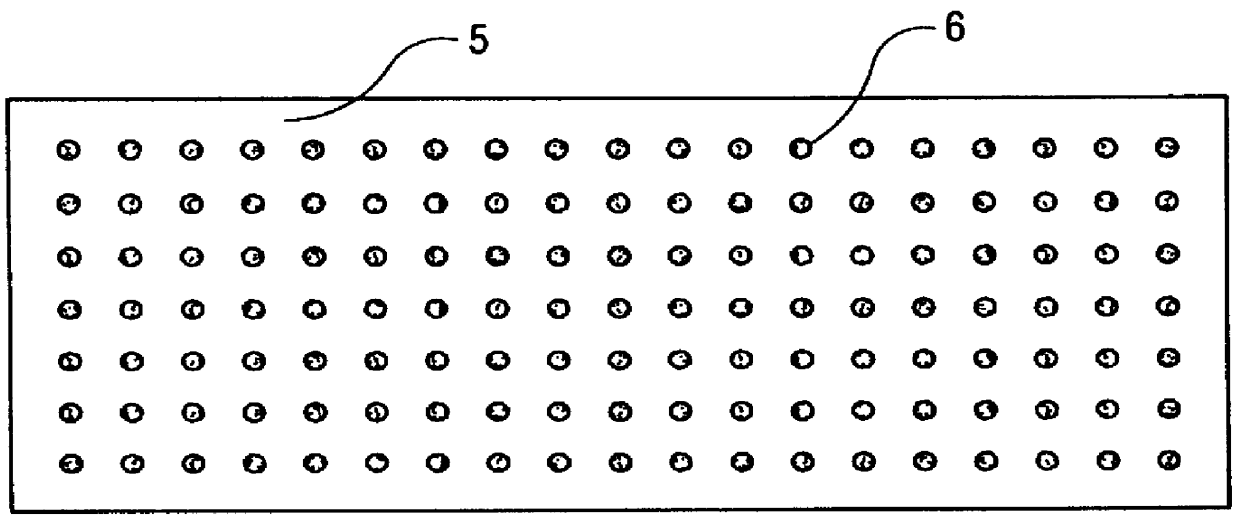

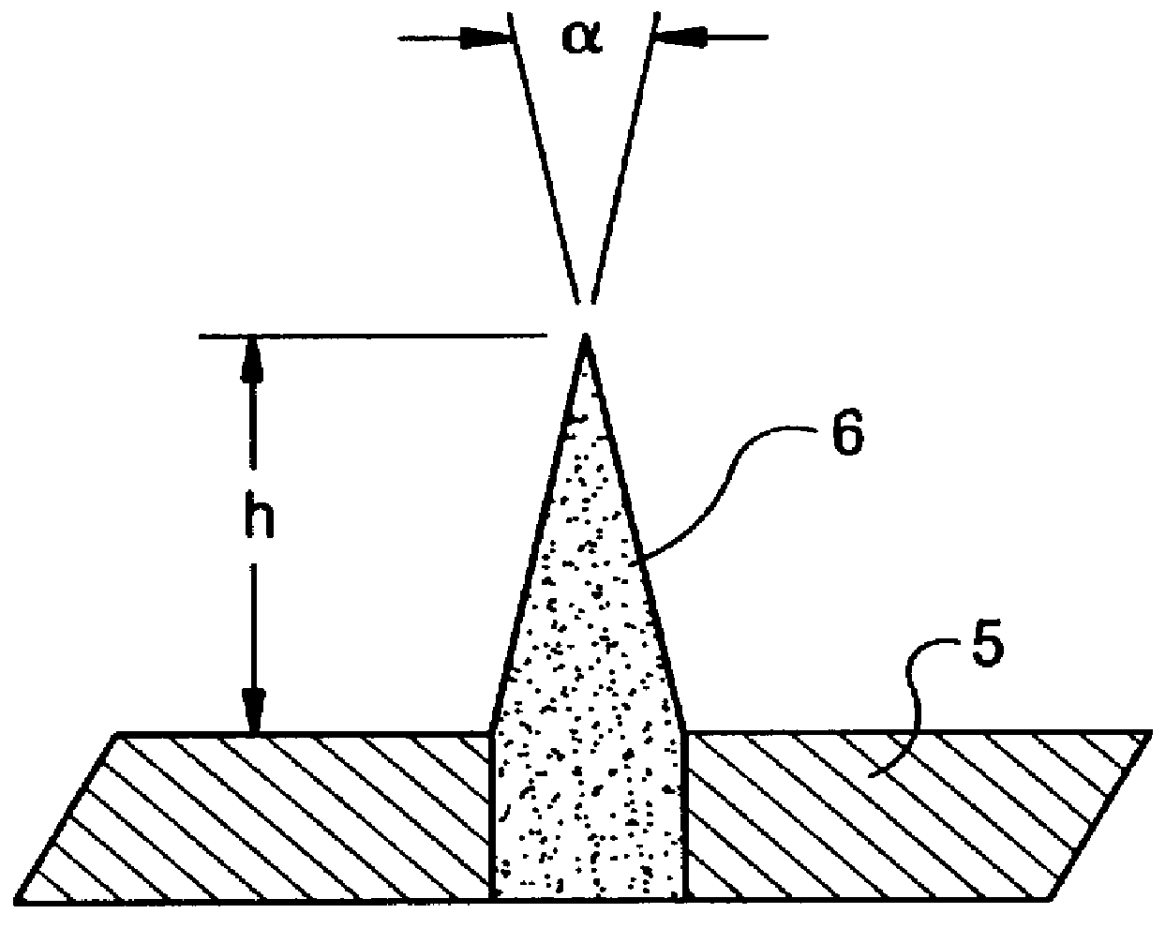

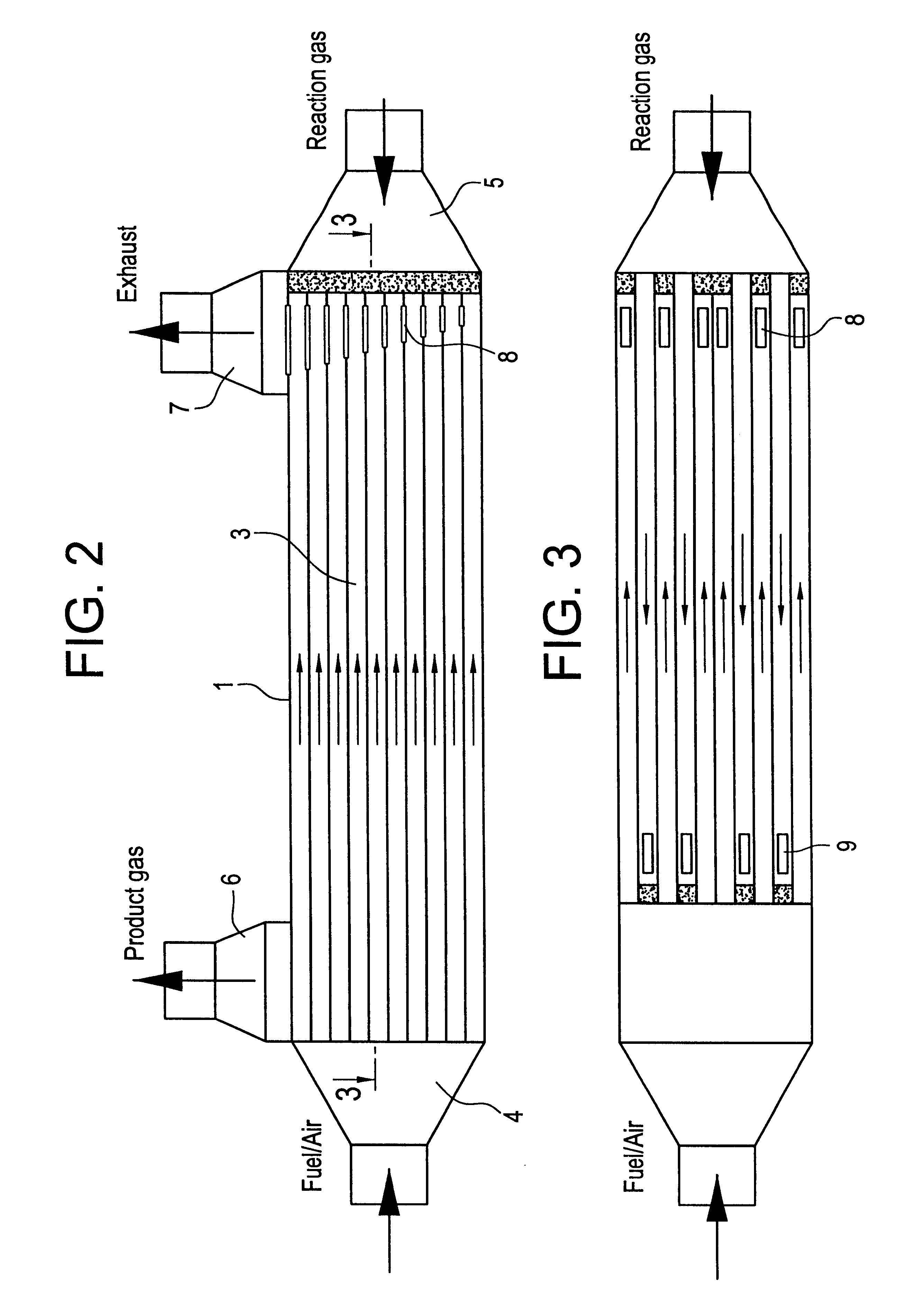

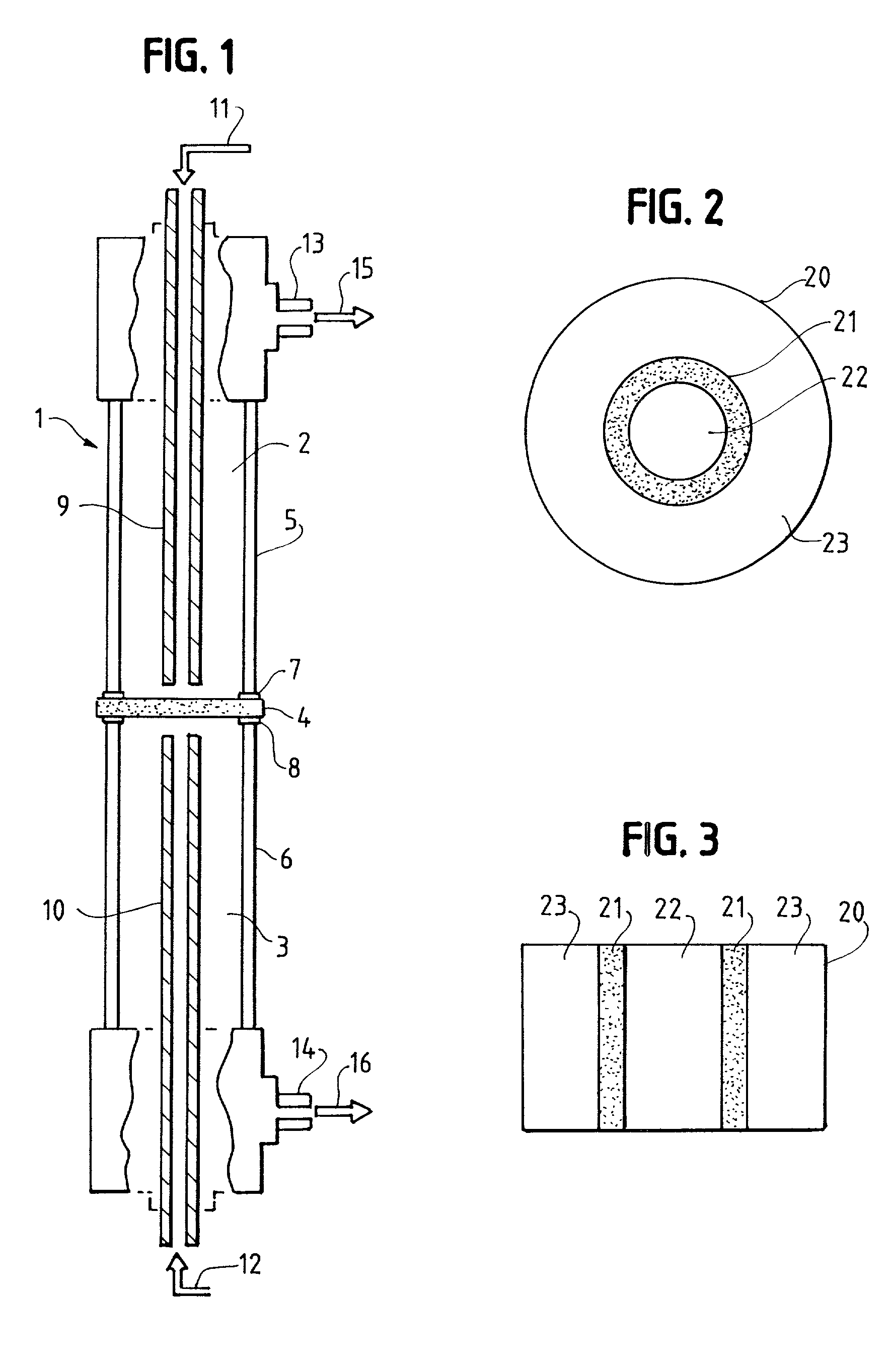

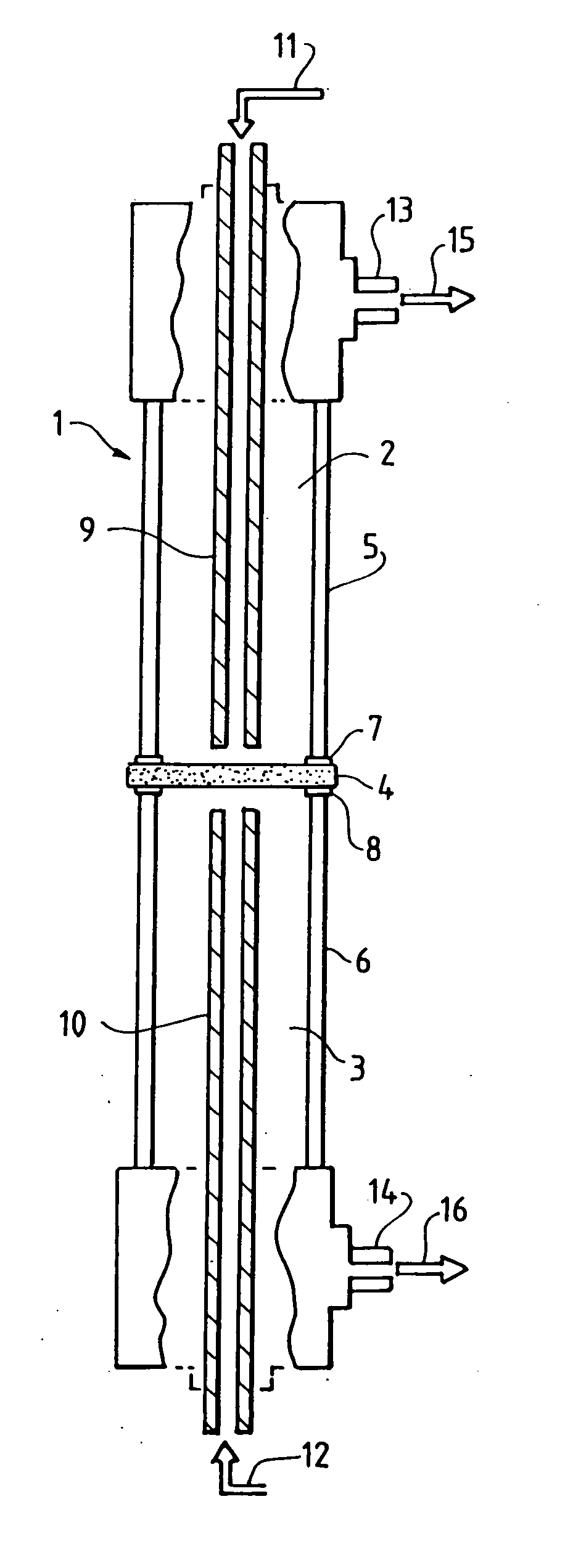

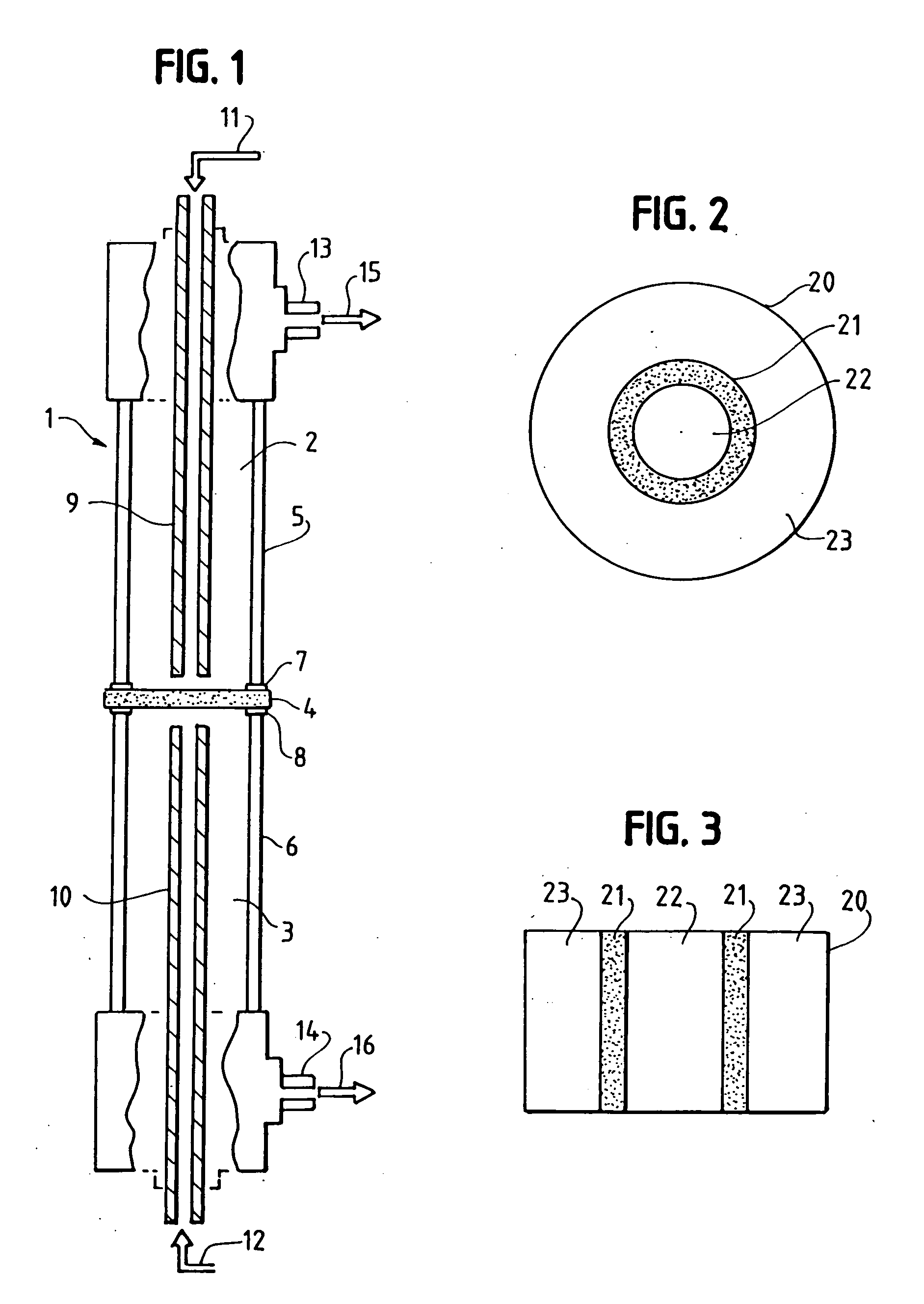

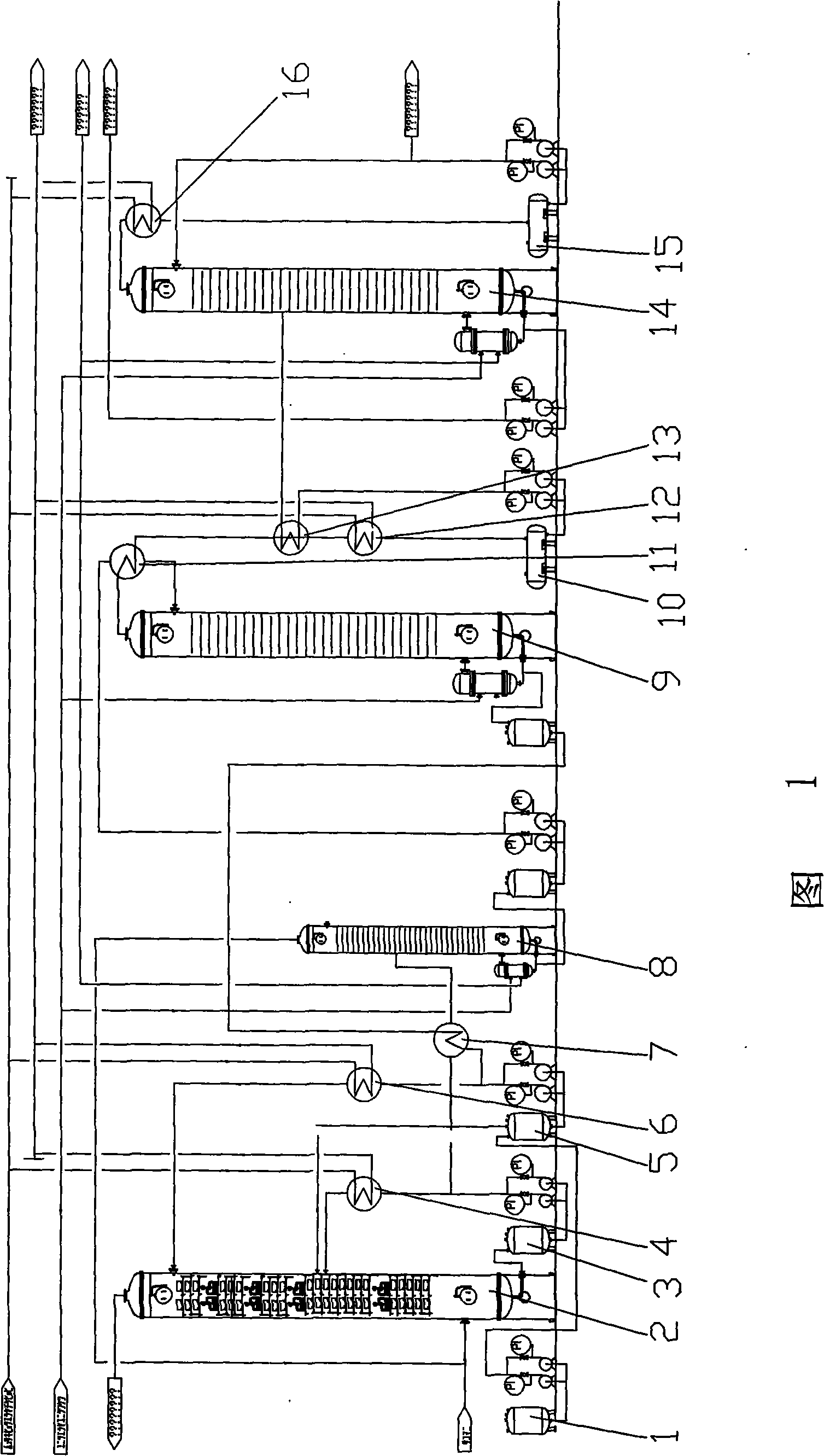

Reactor for performing endothermic catalytic reactions

InactiveUS6056932ACatalytic gas-gas reactionPhysical/chemical process catalystsOrganic chemistryCatalytic combustion

A reactor for performing endothermic catalytic reactions is disclosed formed of a monolithic counterflow reactor with parallel heating and reaction channels. The internal walls of the reaction channels are coated with a catalyst for the catalytic reaction to be performed, while the internal walls of the heating channels have a catalyst for the catalytic combustion of a fuel gas / air mixture.

Owner:DEGUSSA AG

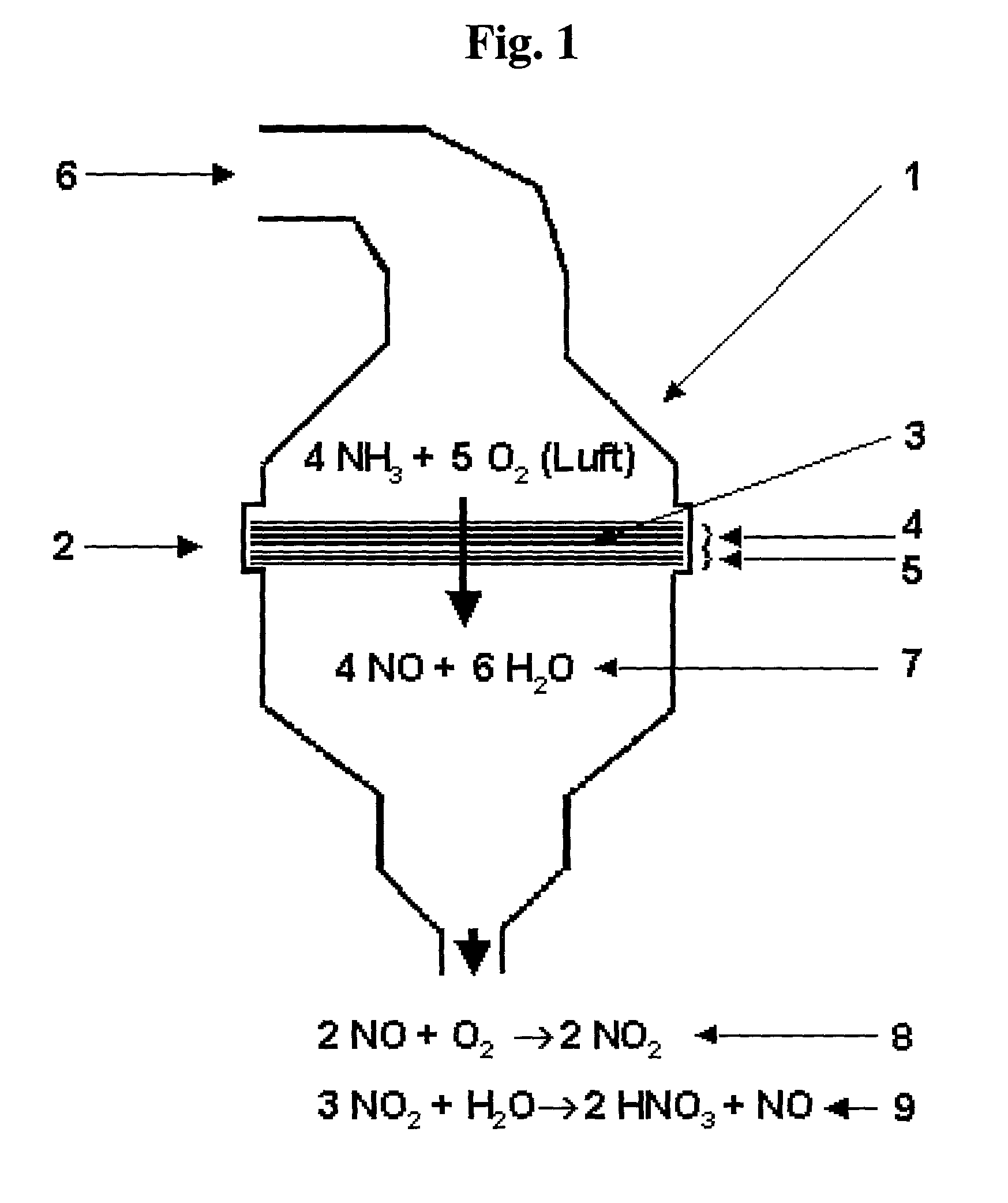

Method of producing hydrogen cyanide

InactiveUS6096173AReduce the temperatureCurrent densityEnergy based chemical/physical/physico-chemical processesHydrogen cyanide preparation/purification/separationGas phaseCorona discharge

A method of producing hydrogen cyanide by the gas-phase reaction of methane with ammonia at elevated temperature and an ammonia / methane ratio of 1.001 to 1.1. The conducting of the gaseous reaction mixture through a corona discharge causes the reaction to start at temperatures below 1000 DEG C. without the action of a catalyst. This results in considerable savings of the necessary investment expenses as well as of the running costs for energy.

Owner:DEGUSSA HULS AG

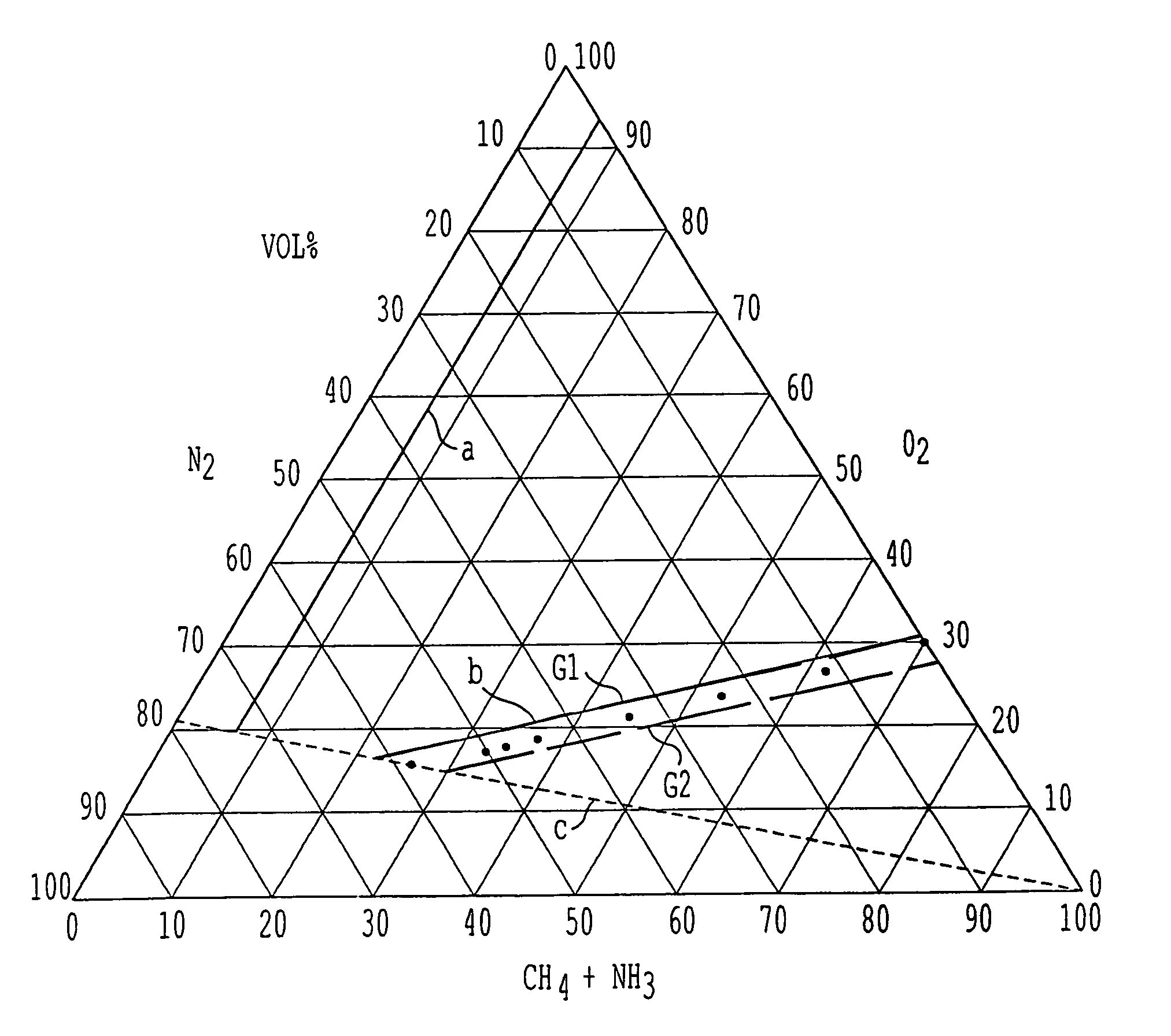

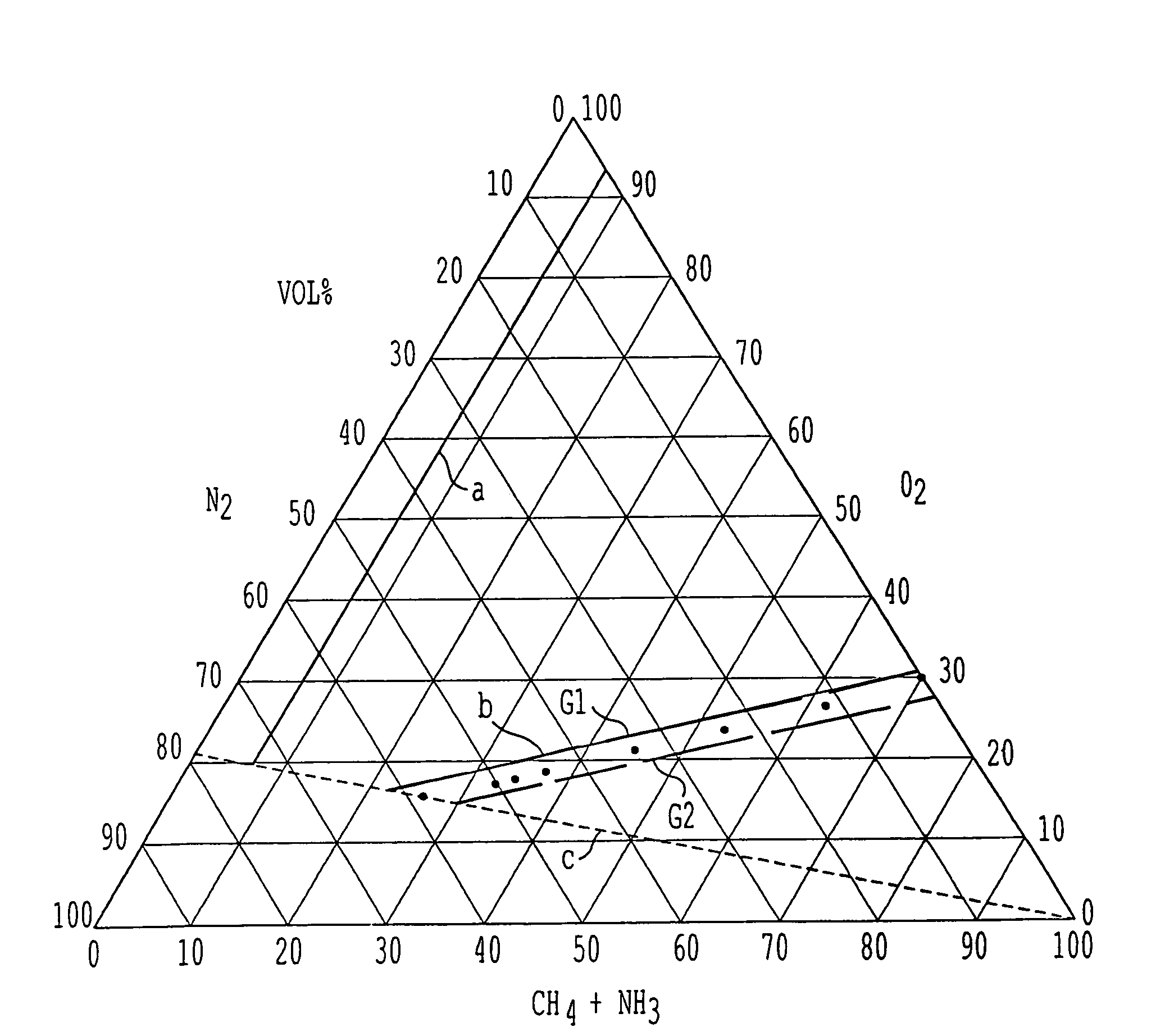

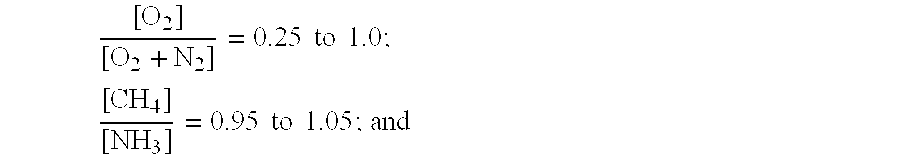

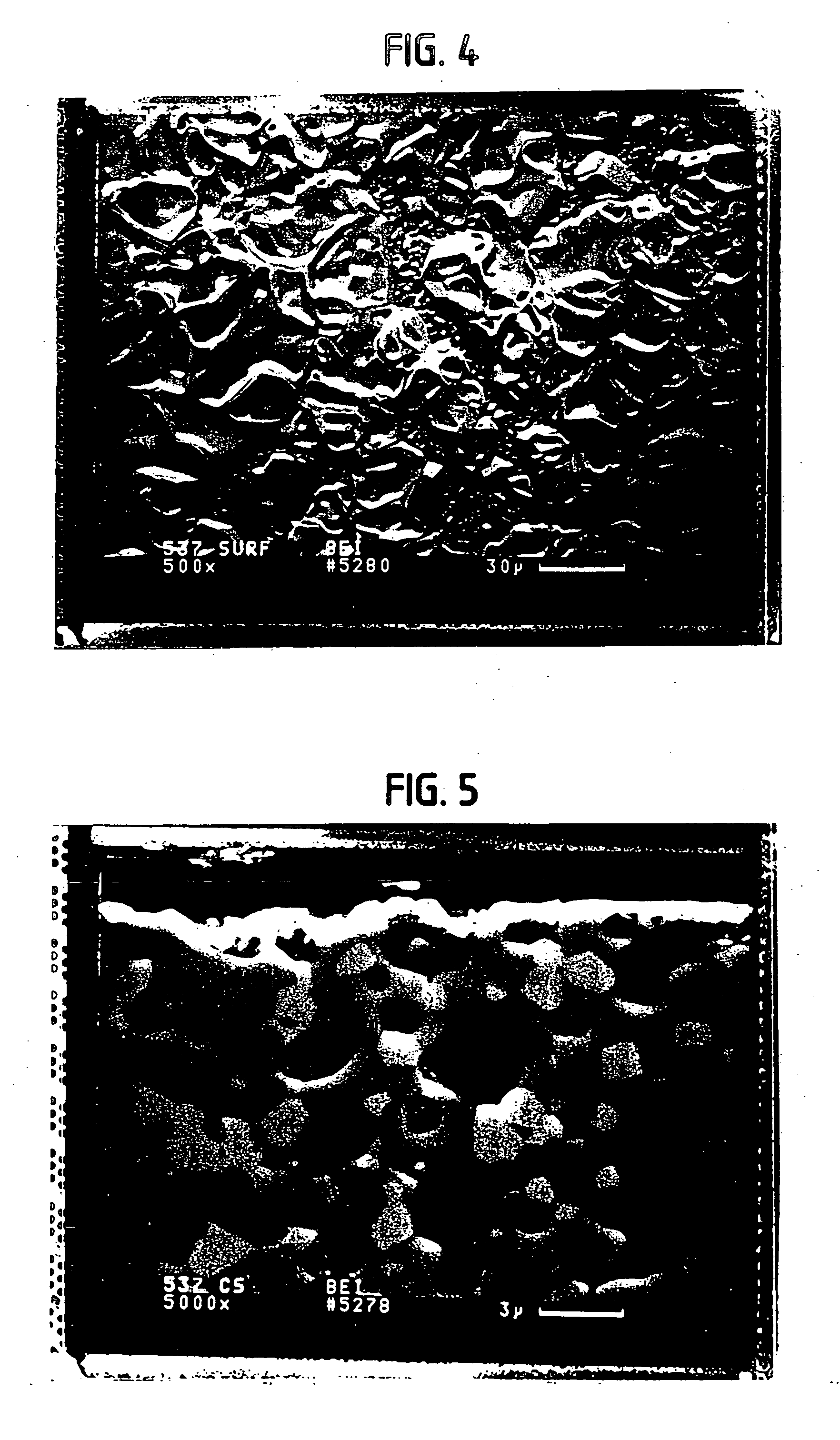

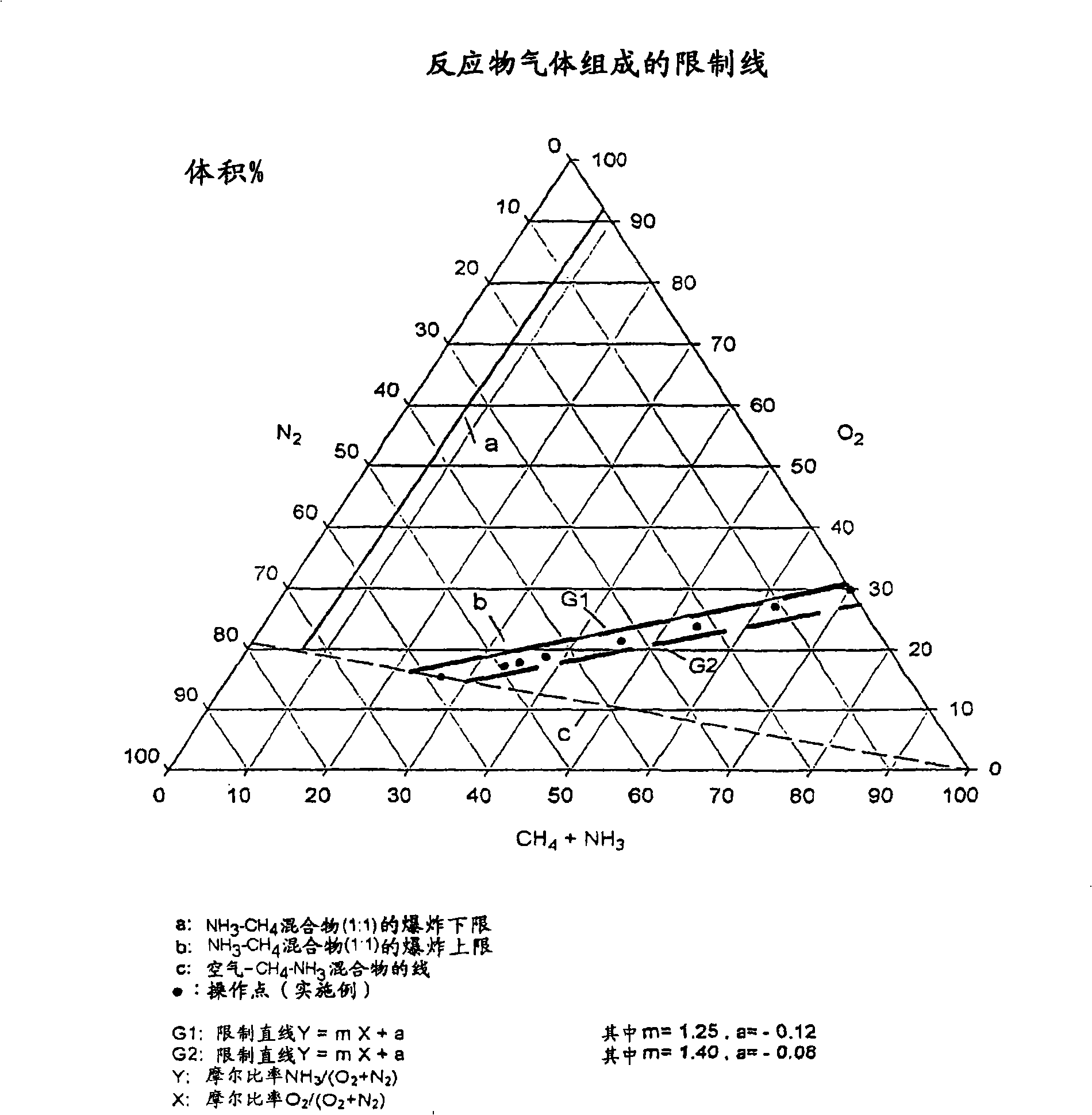

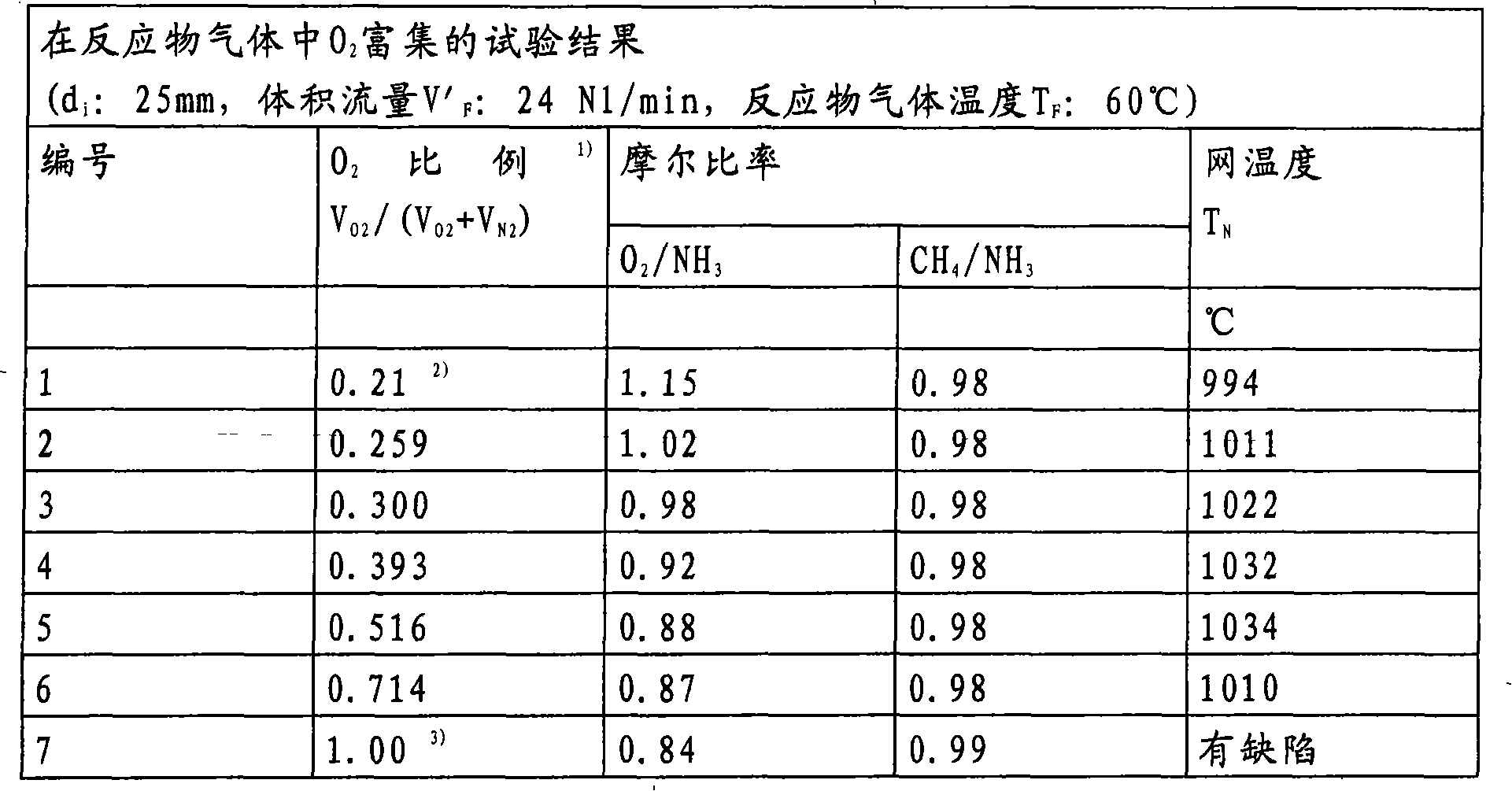

Hydrogen cyanide synthesis process

InactiveUS6979432B2Improve productivityOperational securityHydrogen cyanide preparation/purification/separationPlatinumNitrogen

A process for the production of hydrogen cyanide is provided, wherein hydrogen cyanide is synthesized by reacting methane or methane-containing natural gas, ammonia and oxygen-enriched air or oxygen in the presence of a catalyst comprising platinum or a platinum alloy; wherein the reactants are present in the following molar ratios [O2][O2+N2]=0.25to1.0;[CH4][NH3]=0.95to1.05;andwhere a molar ratio of ammonia to the sum of oxygen and nitrogen obeys the following relationship:Y=m·X−a,wherein Y=[NH3][O2+N2]X=[O2][O2+N2]m=1.25 to 1.40; and a=0.05 to 0.14.

Owner:EVONIK OPERATIONS GMBH

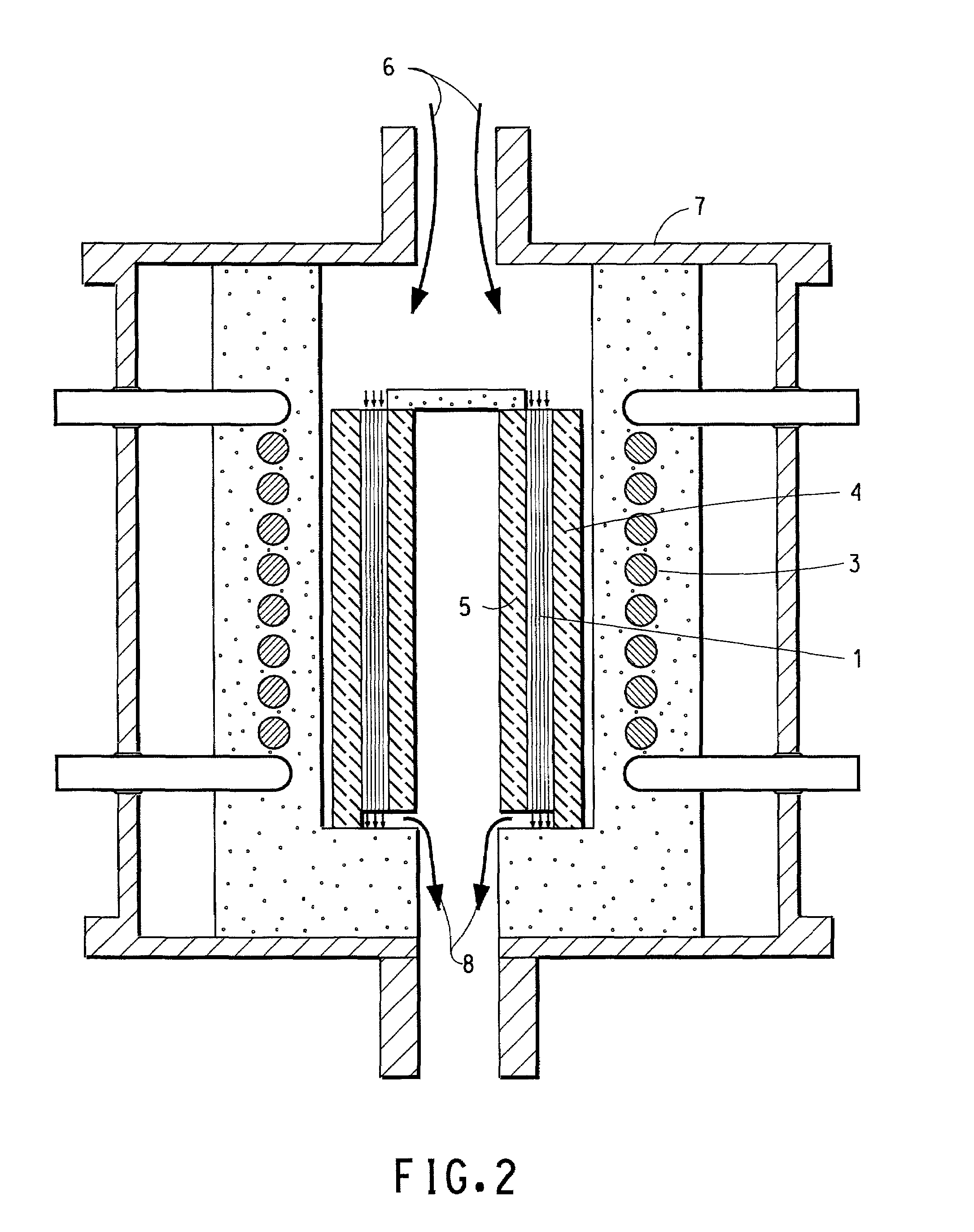

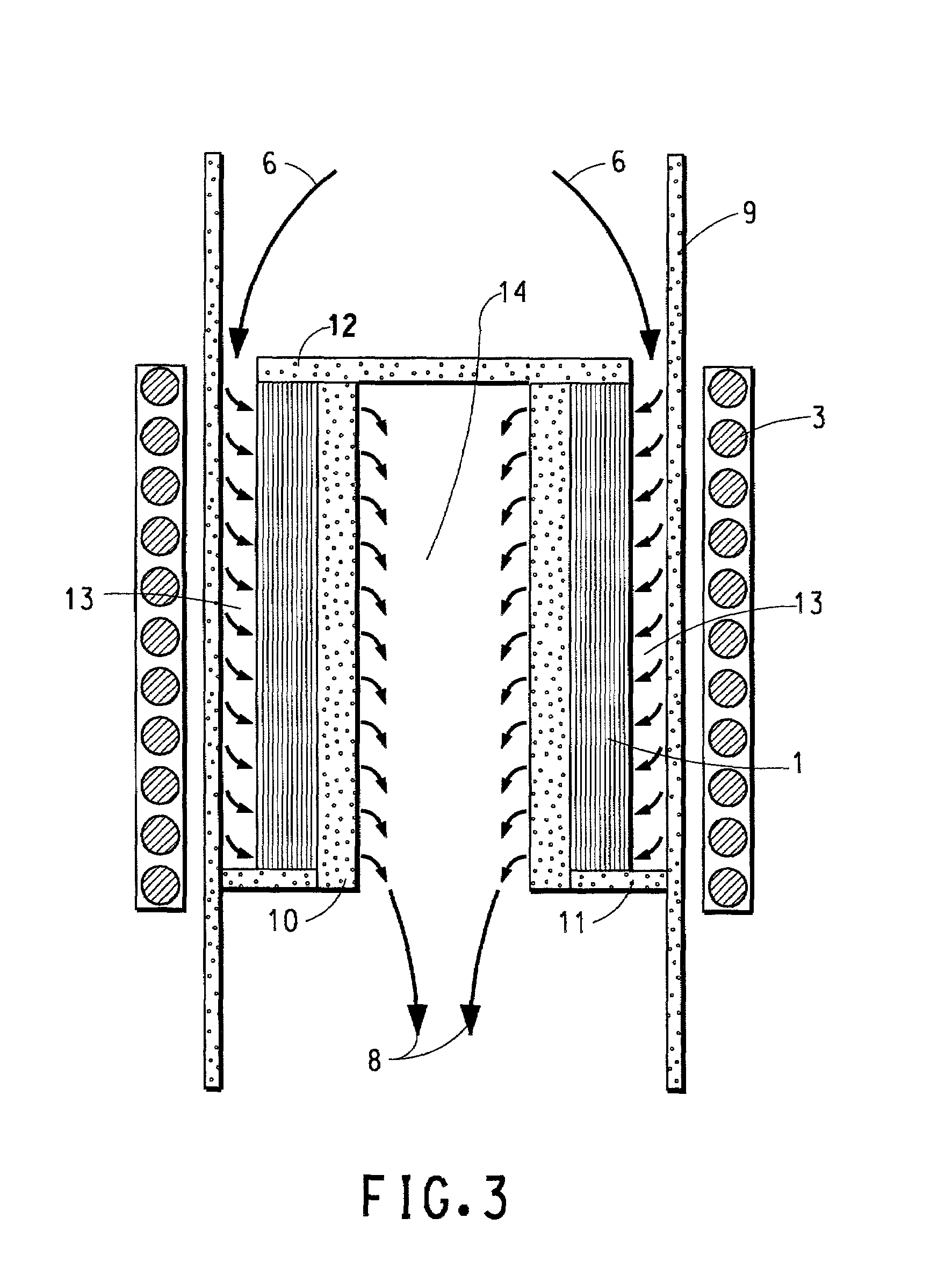

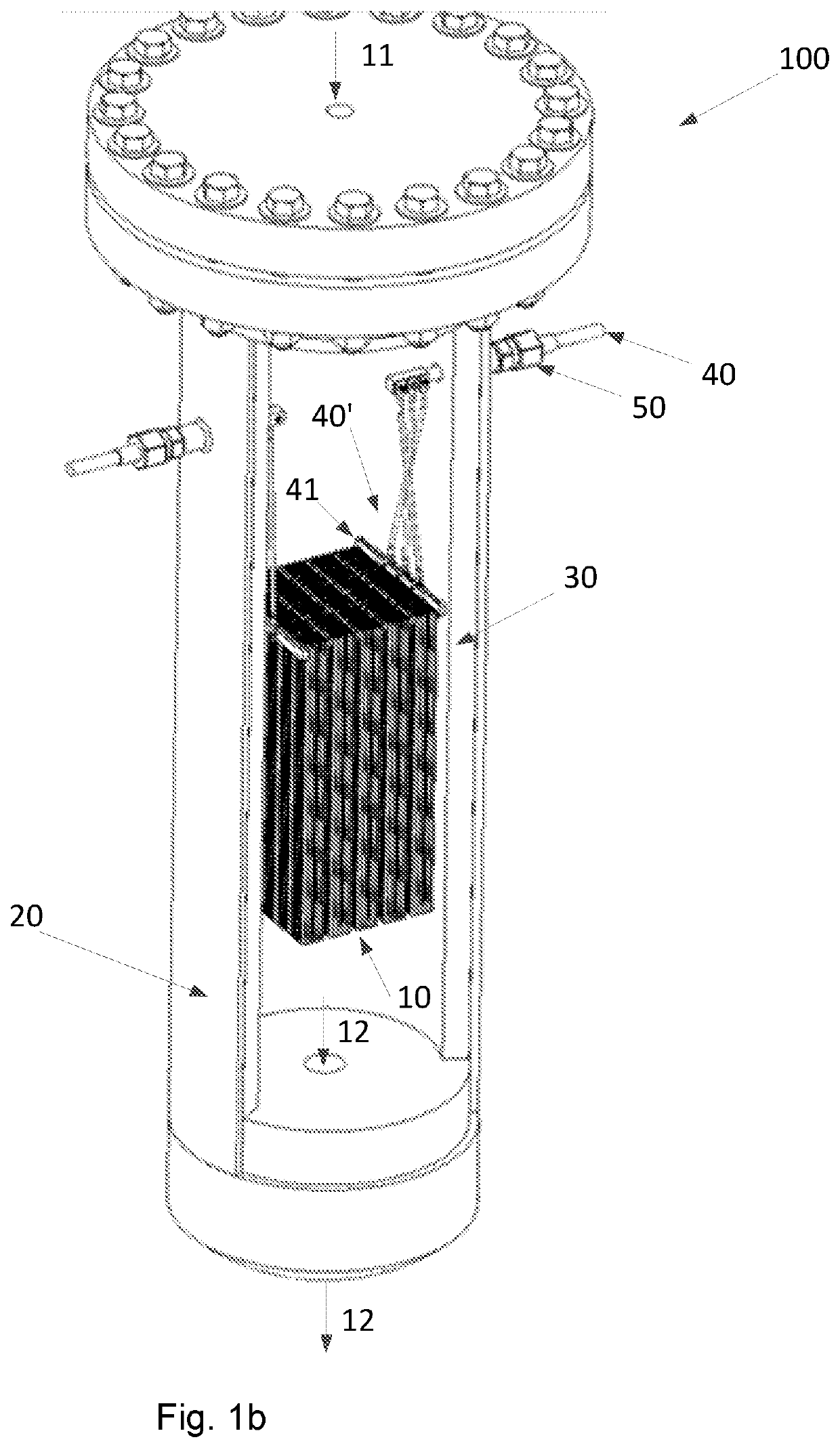

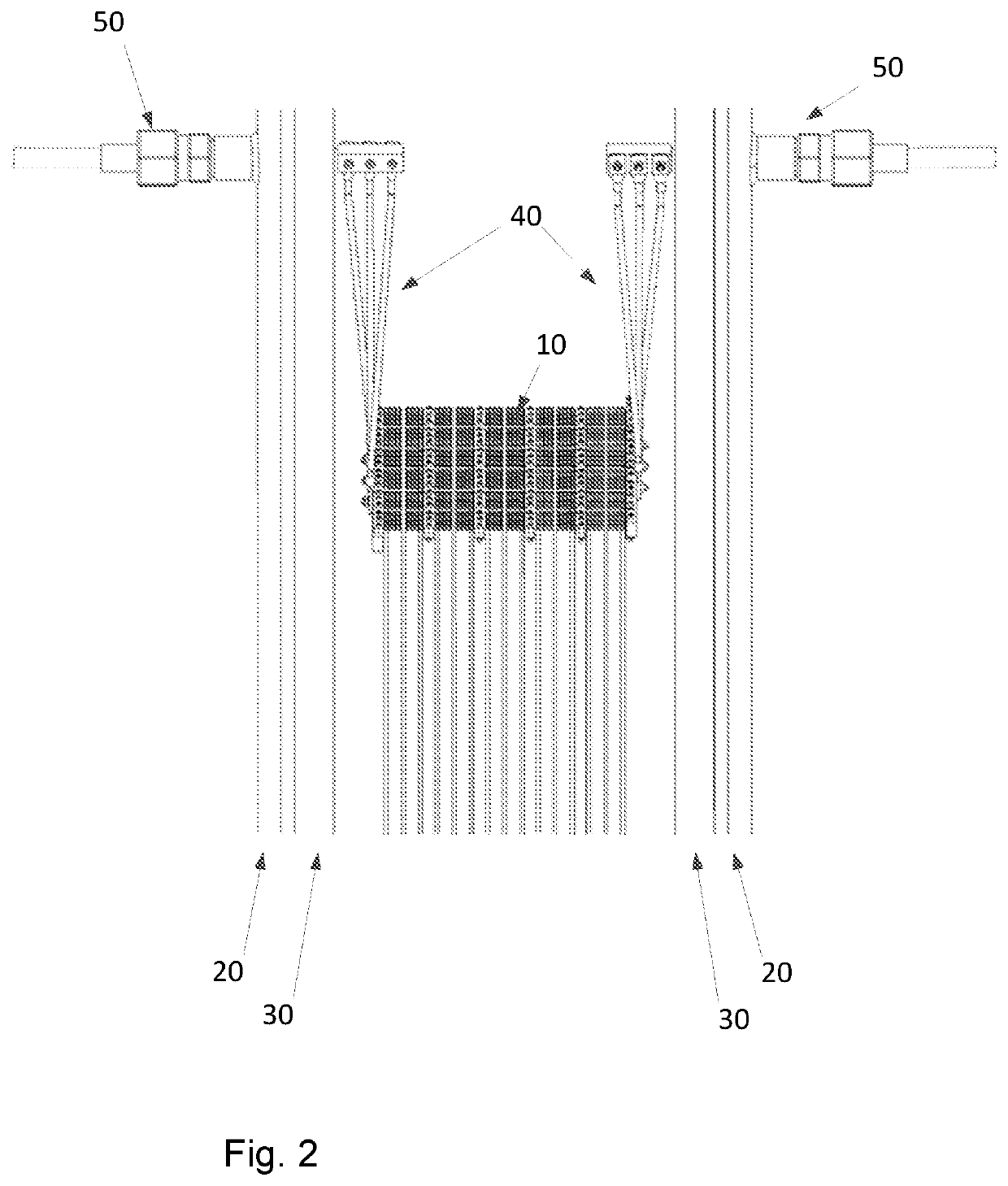

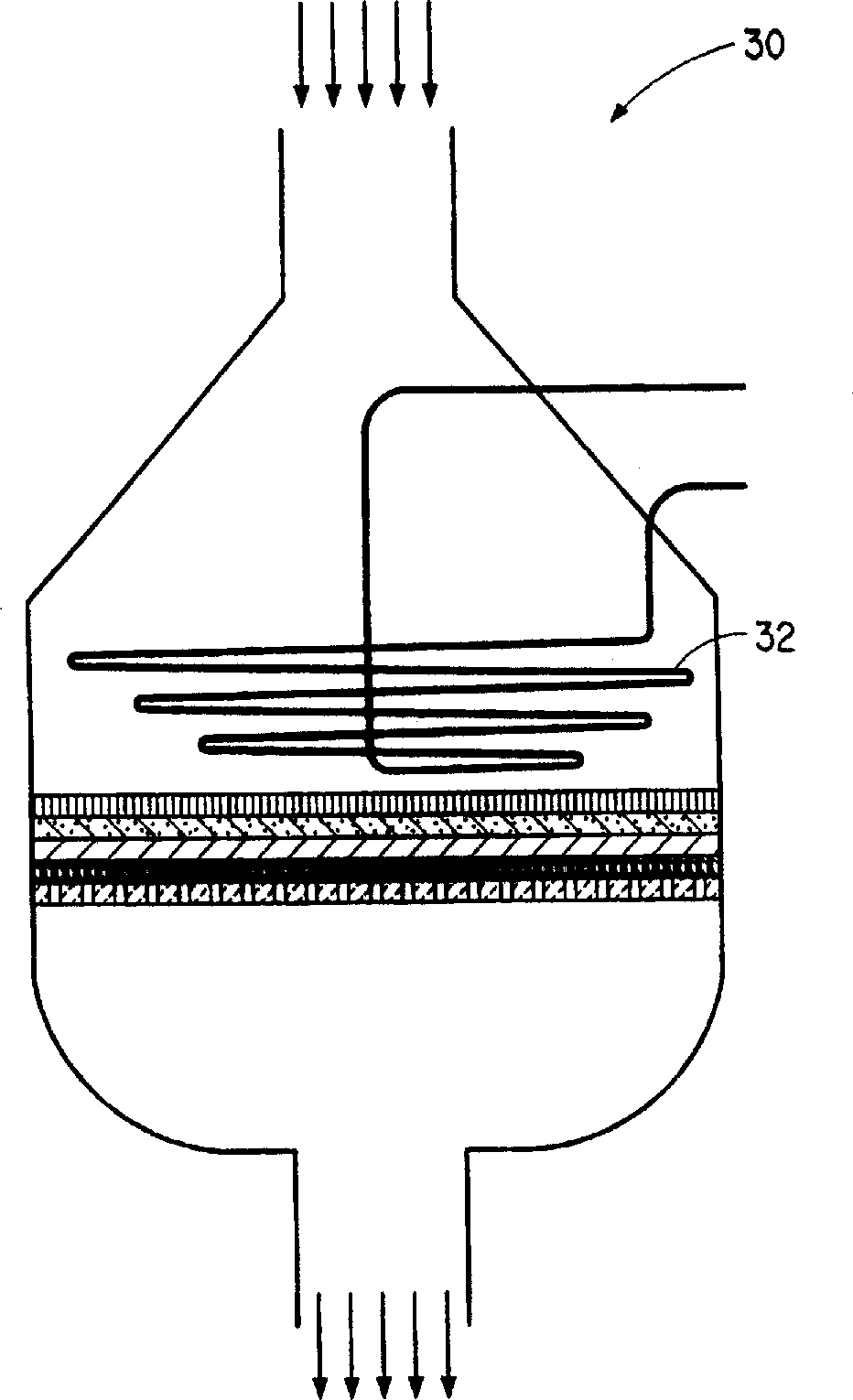

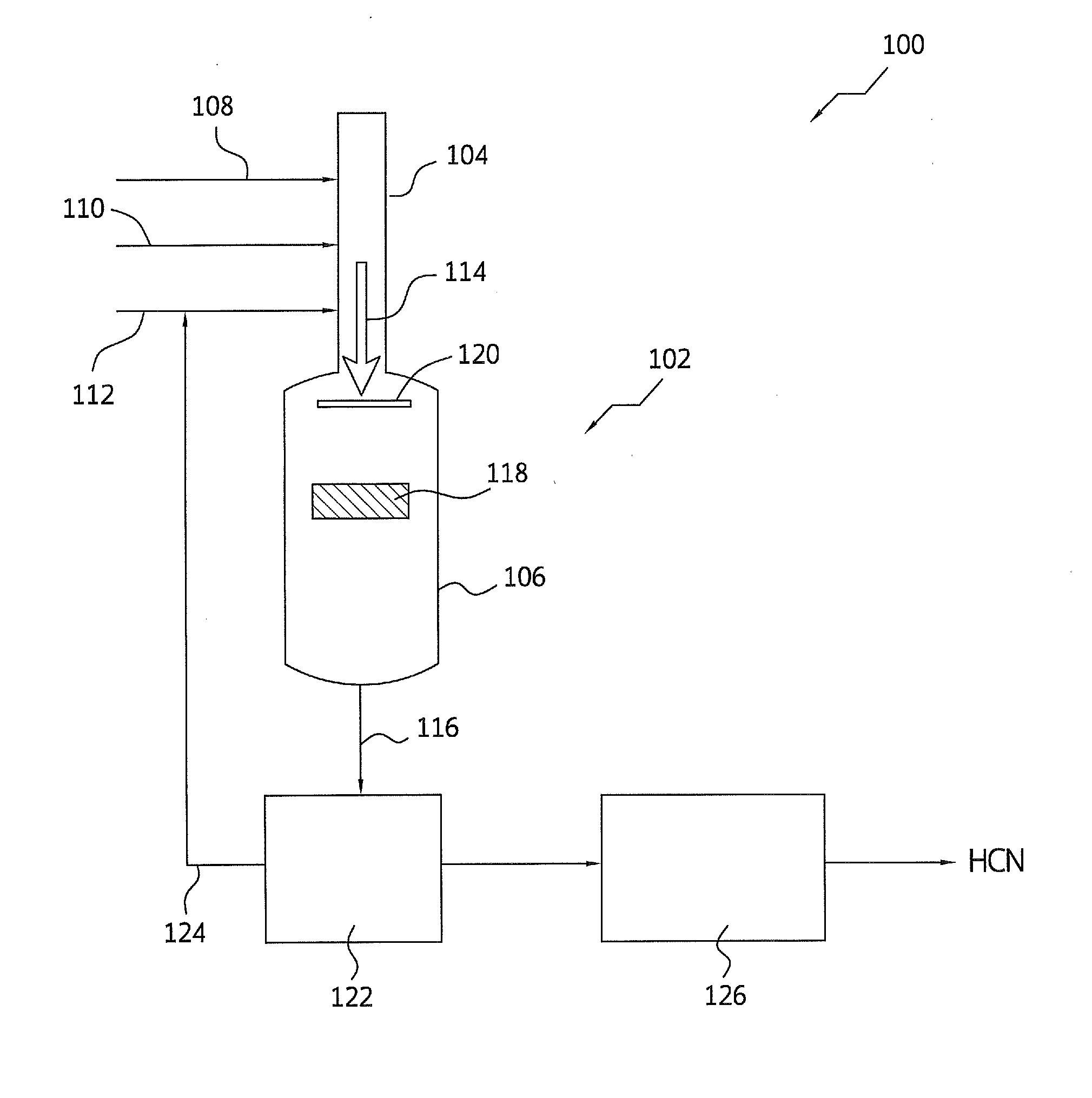

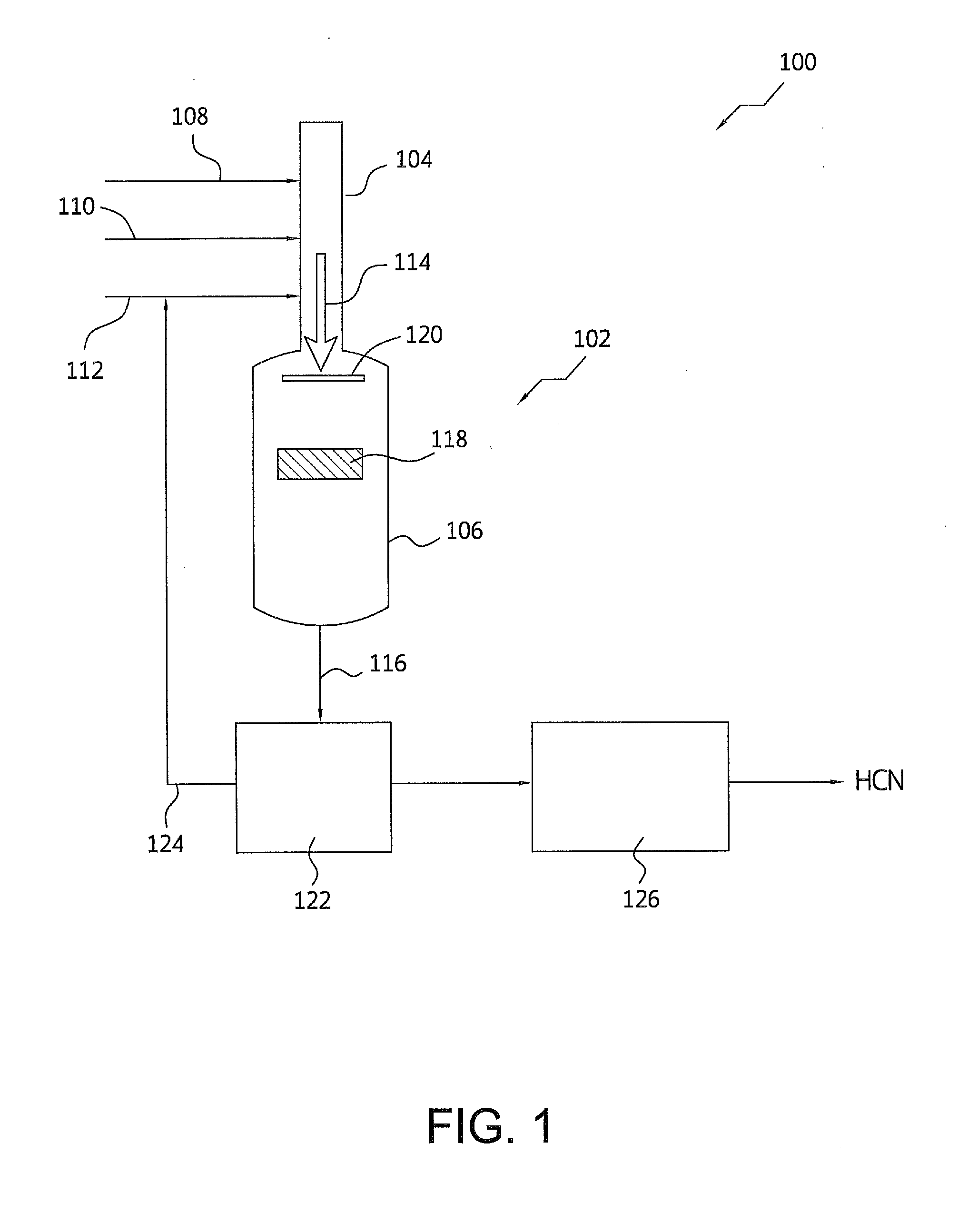

Induction-heated reactors for gas phase catalyzed reactions

Elevated temperature, gas-phase, catalyzed processes for preparing HCN in which induction heating is used as a source of energy, and novel apparatus for carrying out said processes.

Owner:INVISTA NORTH AMERICA R L

Reactor for performing endothermic catalytic reactions

Owner:DEGUSSA AG

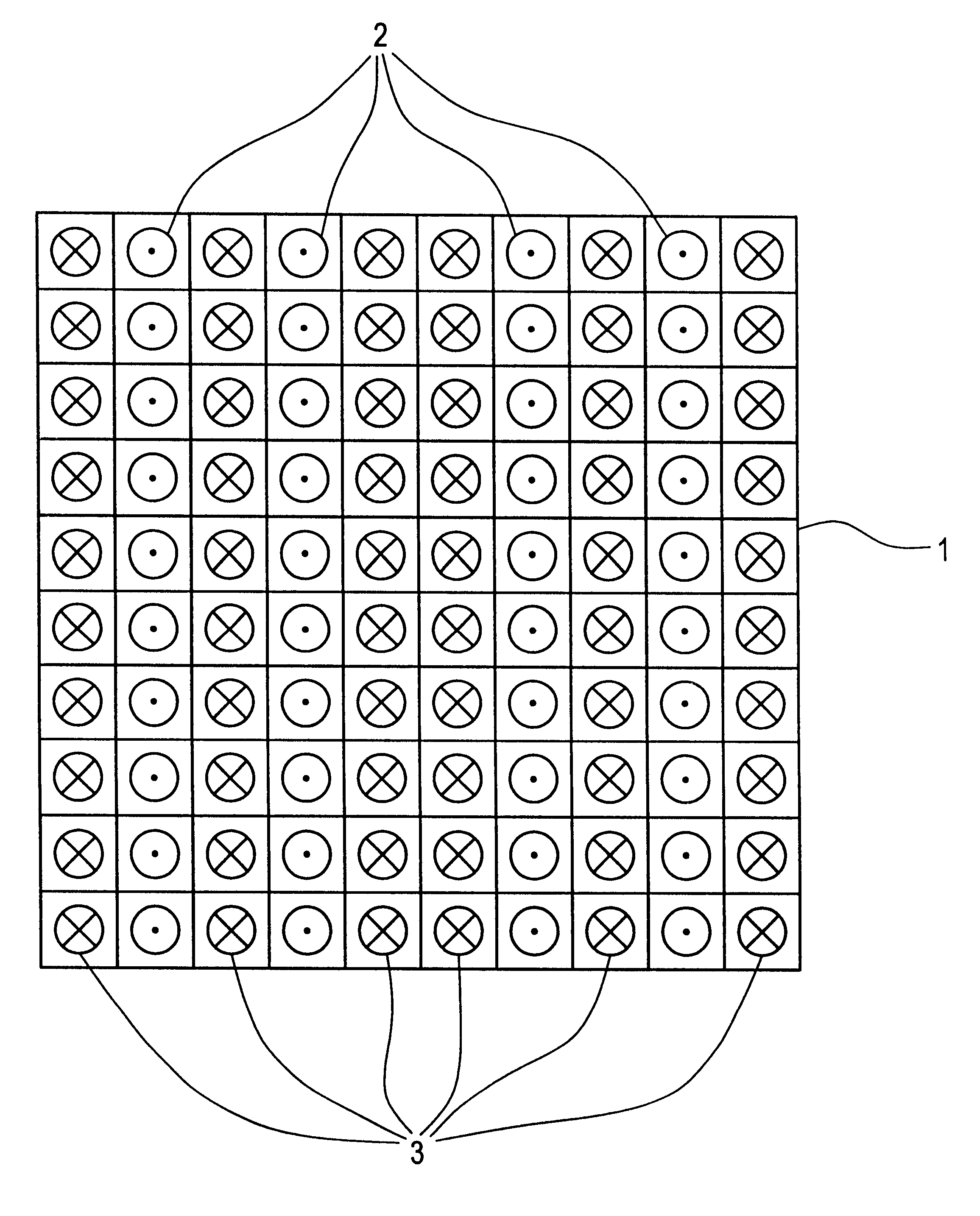

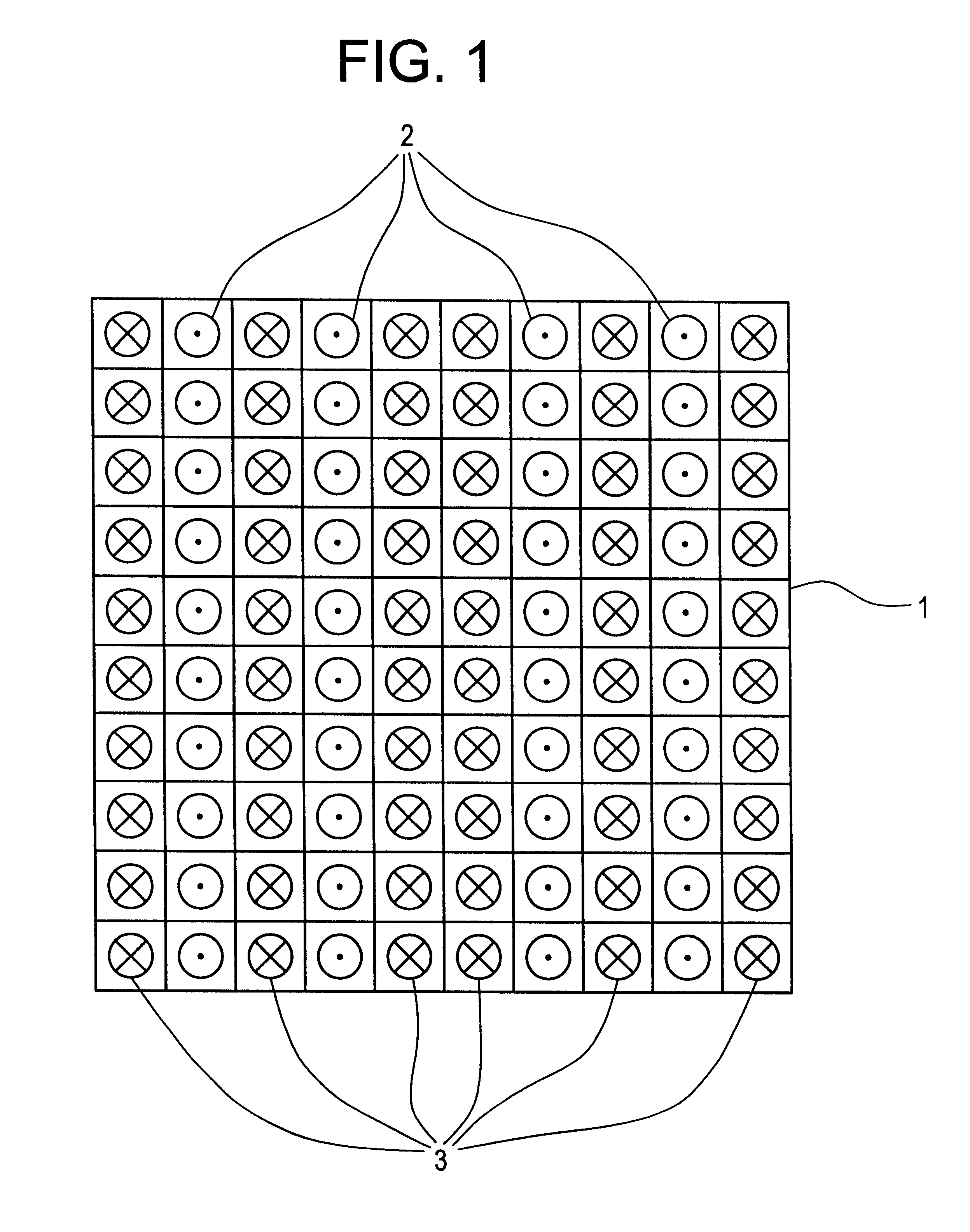

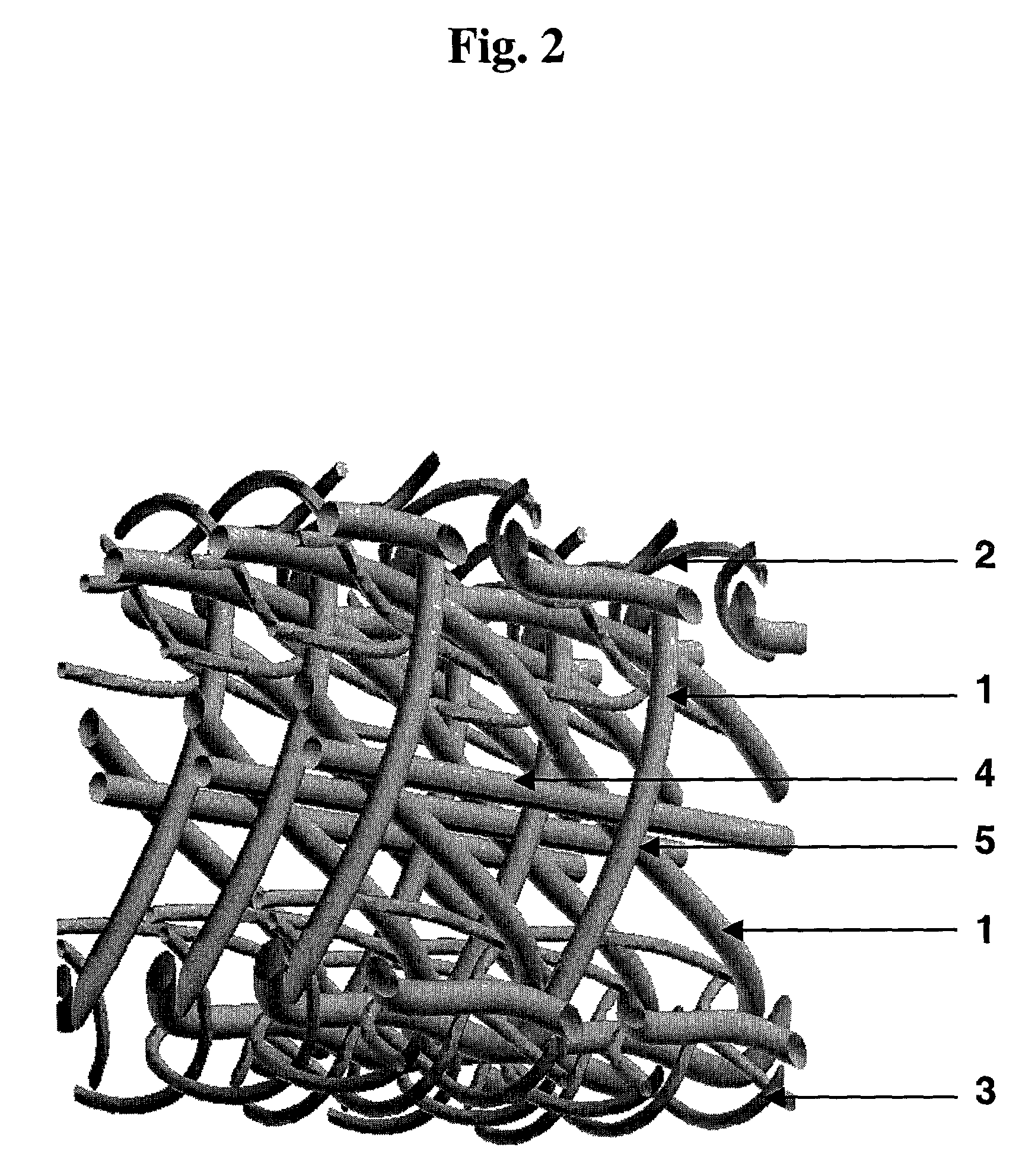

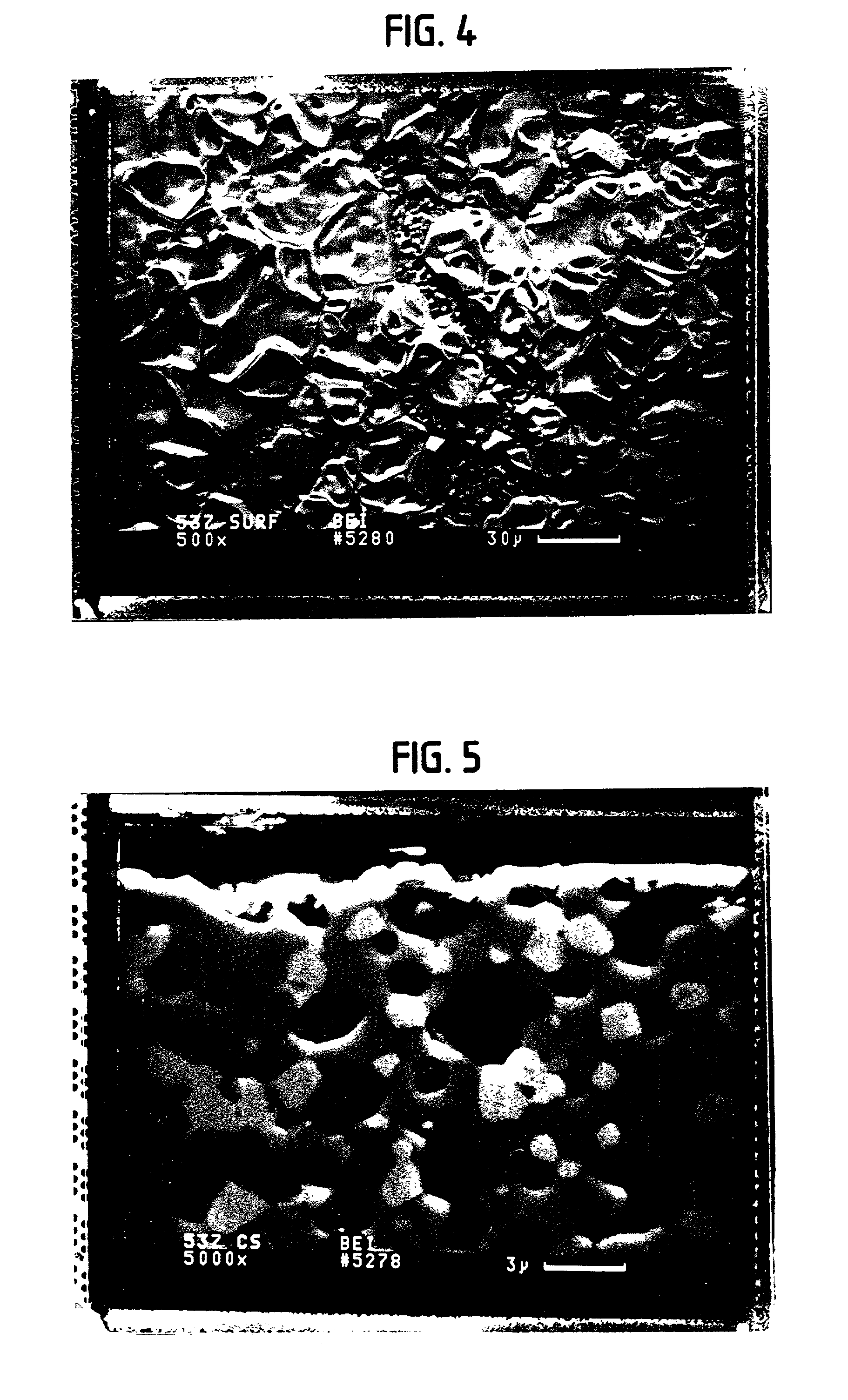

Three-dimensional catalyst gauzes knitted in two or more layers

The present invention relates to three-dimensional catalyst gauzes for gas reactions knitted in two or more layers from noble metal wires in which the meshes of the individual layers are joined to one another by pile threads. In these catalyst gauzes weft threads are inserted between the mesh layers. These catalyst gauzes have an increased catalytic activity and efficiency in gas reaction. These improvements enable operation with a lower total amount of noble metal employed, for example by reducing the number of gauzes and / or the length of the wire processed in the catalyst gauze and / or the wire thickness, without thereby having to accept disadvantages with respect to the yield and selectivity of the gas reaction, mechanical strength and service life of the gauzes or unavoidable loss of noble metal.

Owner:UMICORE AG & CO KG

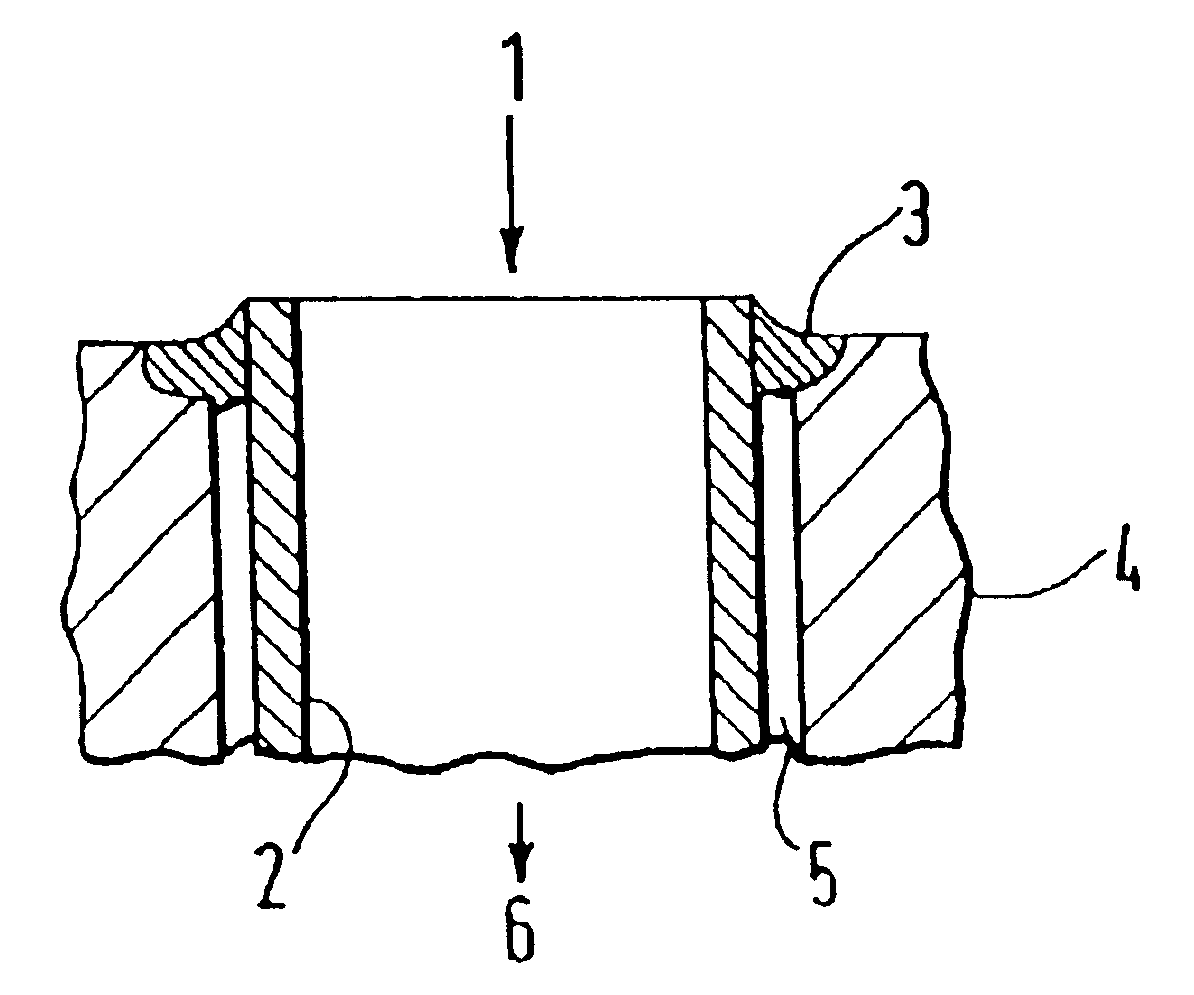

High performance heat exchangers

InactiveUS6960333B2Extended service lifeCorrosion preventionStationary conduit assembliesChemical reactorEngineering

Disclosed are means for improving the service-life of indirect tubesheet type heat exchangers used in chemical reactors, particularly those exposed to reducing, nitridizing and / or carburizing environments. Such means include the use of certain ferrules within the heat exchange tubes and / or weld types used in construction of these heat exchangers.

Owner:ROHM & HAAS CO

Method for purifying hydrocyanic acid from mixed gas containing hydrocyanic acid

InactiveCN102502707AImprove purification efficiencyReduce cooling energy consumptionHydrogen cyanide preparation/purification/separationAcid waterAqueous solution

The invention discloses a method for purifying hydrocyanic acid from mixed gas containing the hydrocyanic acid, which comprises an absorption step and a rectification step, wherein in the absorption step, pressurizing the mixed gas containing the hydrocyanic acid to 0.11-1.5 MPa, then cooling to 10-80 DEG C, introducing into a pressure absorption tower, and pressurizing and absorbing the hydrocyanic acid in the mixed gas with absorption liquid, i.e. acidic aqueous solution with a pH value of 1-6 under the conditions that the pressure in the tower is 0.11-1.0 MPa, and the temperature is 0-60 DEG C to obtain hydrocyanic acid absorption liquid. The method has the beneficial effects that the existing atmospheric absorption method is replaced by a pressure absorption method to absorb the hydrocyanic acid in the mixed gas containing the hydrocyanic acid; the absorption temperature can be improved to 60 DEG C; the concentration of the hydrocyanic acid in the hydrocyanic acid absorption liquid can be improved by 3-10 times, so that the purifying efficiency of the hydrocyanic acid can be remarkably improved; and meanwhile, the energy consumption is greatly reduced and can be reduced by 80 percent to a maximum extent.

Owner:CHONGQING UNISPLENDOUR CHEM

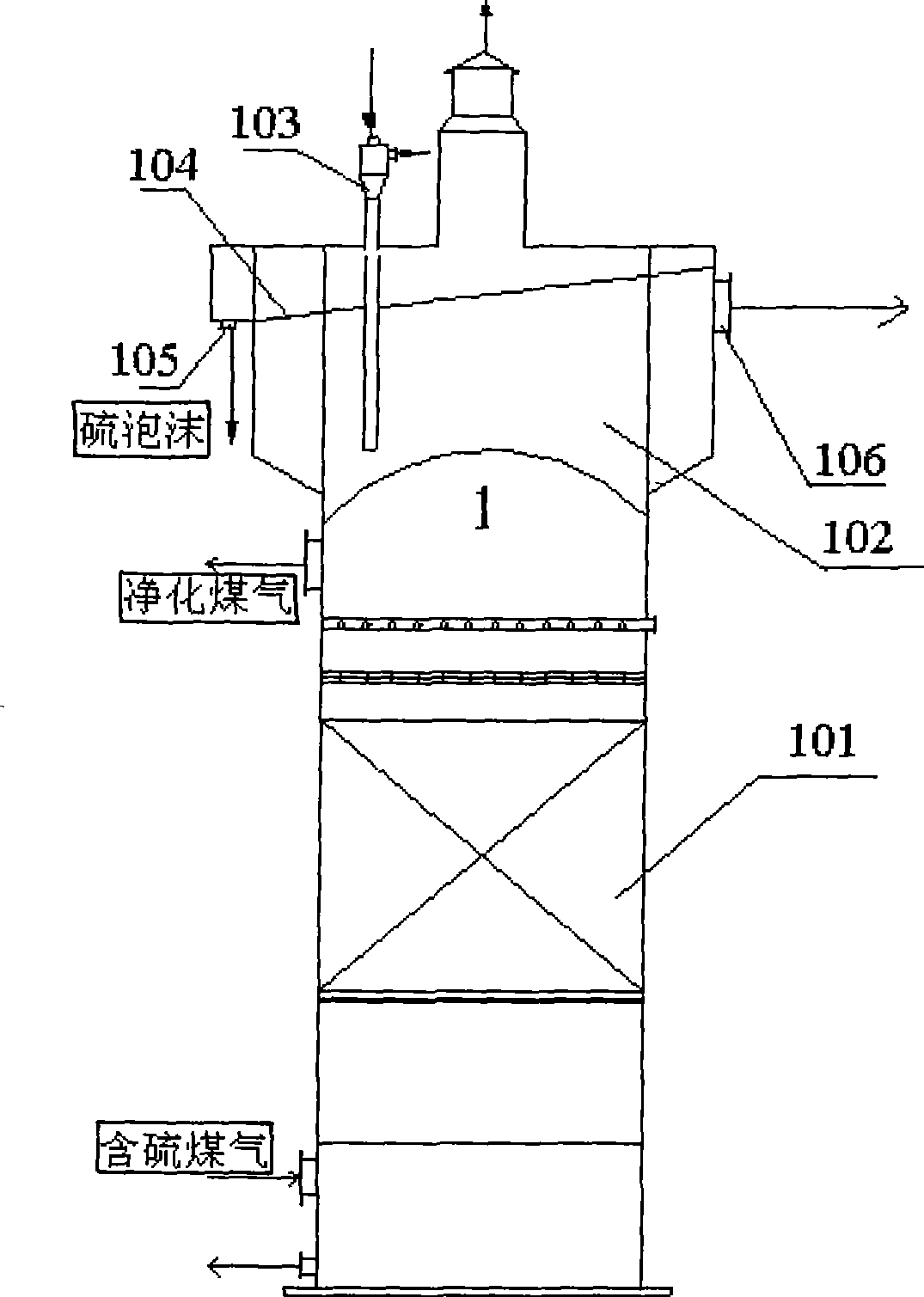

Novel process for reclaiming waste water containing CN- and NH3 or NH4-

ActiveCN101274806ASolve the problem of energy consumptionSolve the costMultistage water/sewage treatmentHydrogen cyanide preparation/purification/separationCyanideWastewater

The invention relates to a method for separating HCN and NH3 for reclamation or realizing standardized discharge from wastewater solution that contains CN<-> and NH3 or NH4<+>, particularly relates to a new technique of resource cyclic utilization of high-salt cyanide and ammonium bearing wastewater, which is represented by cyanuric chloride industry, thus opening a new way of resource cyclic utilization of the high-salt cyanide and ammonium bearing wastewater, which is represented by cyanuric chloride, and providing a totally new clean production technology with simple technique, investment-saving and low operation fee and resource cyclic used feature of the integrated utilization of wastewater that contains the CN<-> and NH3 or NH4<+>.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD +1

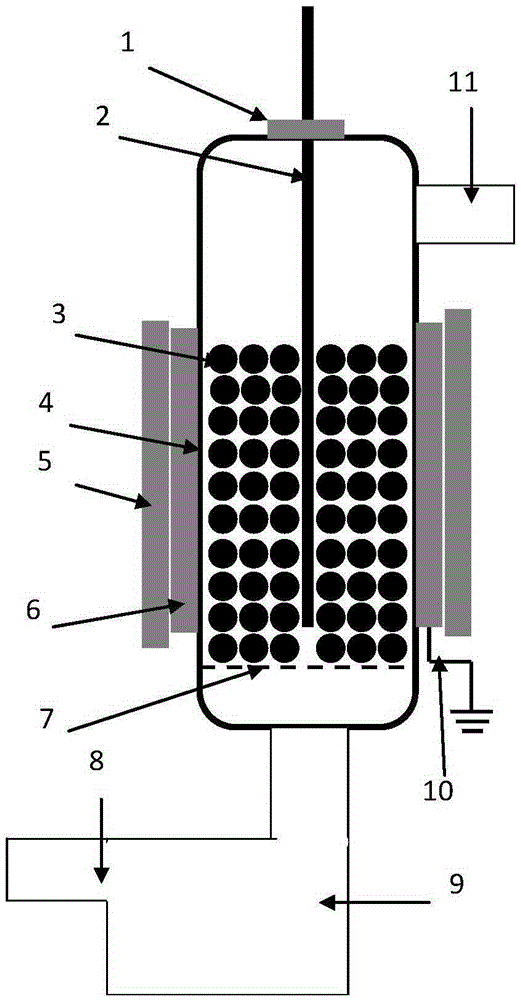

Metal supported catalyst and HCN synthesis method

ActiveCN105396589AMild reaction conditionsSimple processMolecular sieve catalystsHeterogenous catalyst chemical elementsChemical synthesisPtru catalyst

The invention belongs to the technical field of plasma chemical synthesis, and provides a metal supported catalyst and an HCN synthesis method. The metal supported catalyst comprises an active component and a carrier, the active component is one or two or above of non-noble metals, alkali metals, noble metals and rare earth metals, and the weight percentage of the active component in the catalyst is 0.4-50%; and a ratio of the equivalent diameter of carrier particles to the internal diameter of a reactor is 0.01-0.4. The retention time of methane and ammonia gas in a discharge zone is 0.01-100s, the reaction temperature is 200-650DEG C, the reaction pressure is -0.06 - 0.2 Mpa, and a molar ratio of methane to the ammonia gas in the reaction system is 0-10. The method has the advantages of mild reaction conditions, implementation at a low temperature under normal pressure, cheap and easily available raw materials comprising methane and ammonia gas, and realization of simple flow and environmental protection because the plasma catalytic synthesis method is a one-step direct synthesis method.

Owner:DALIAN UNIV OF TECH

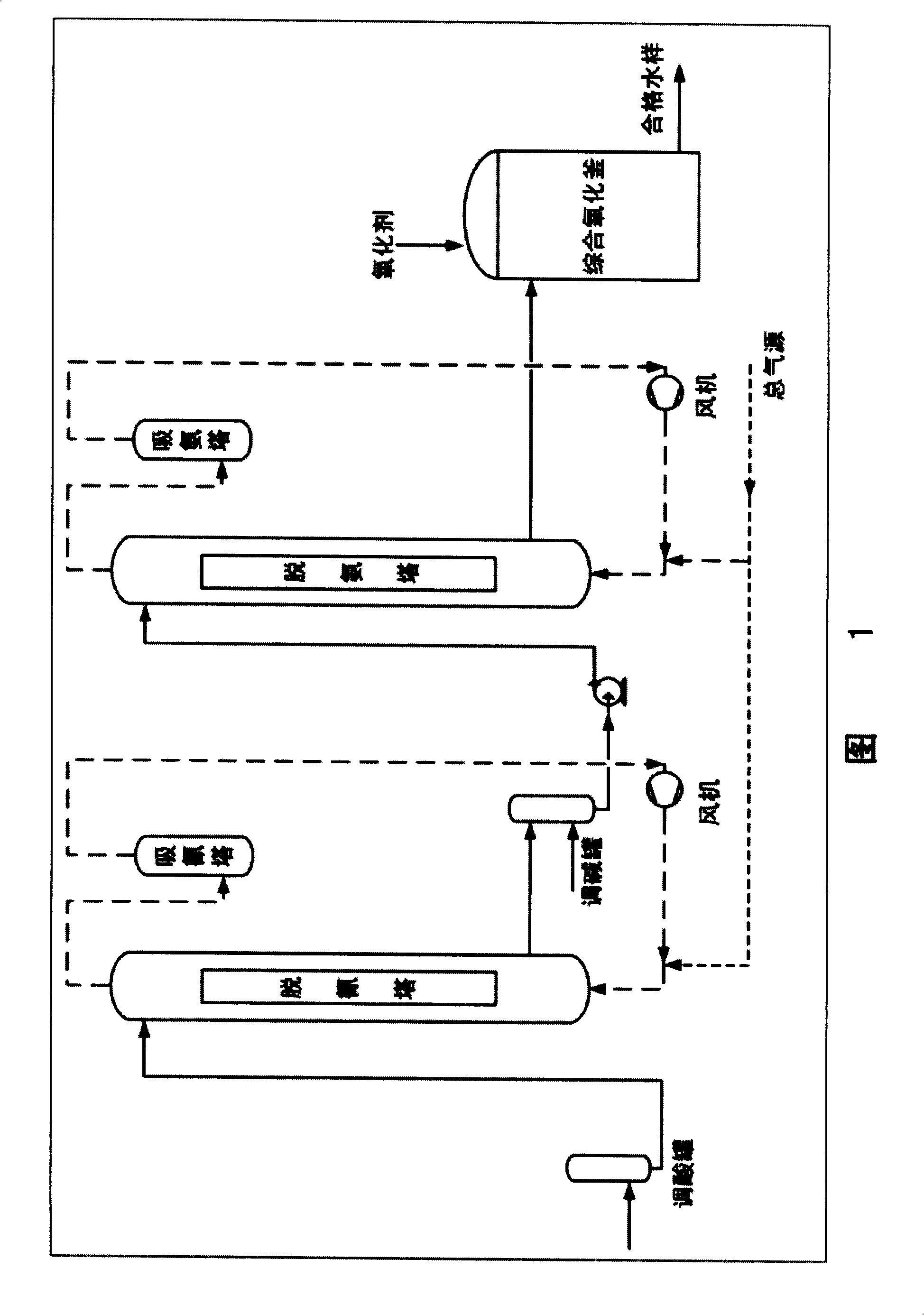

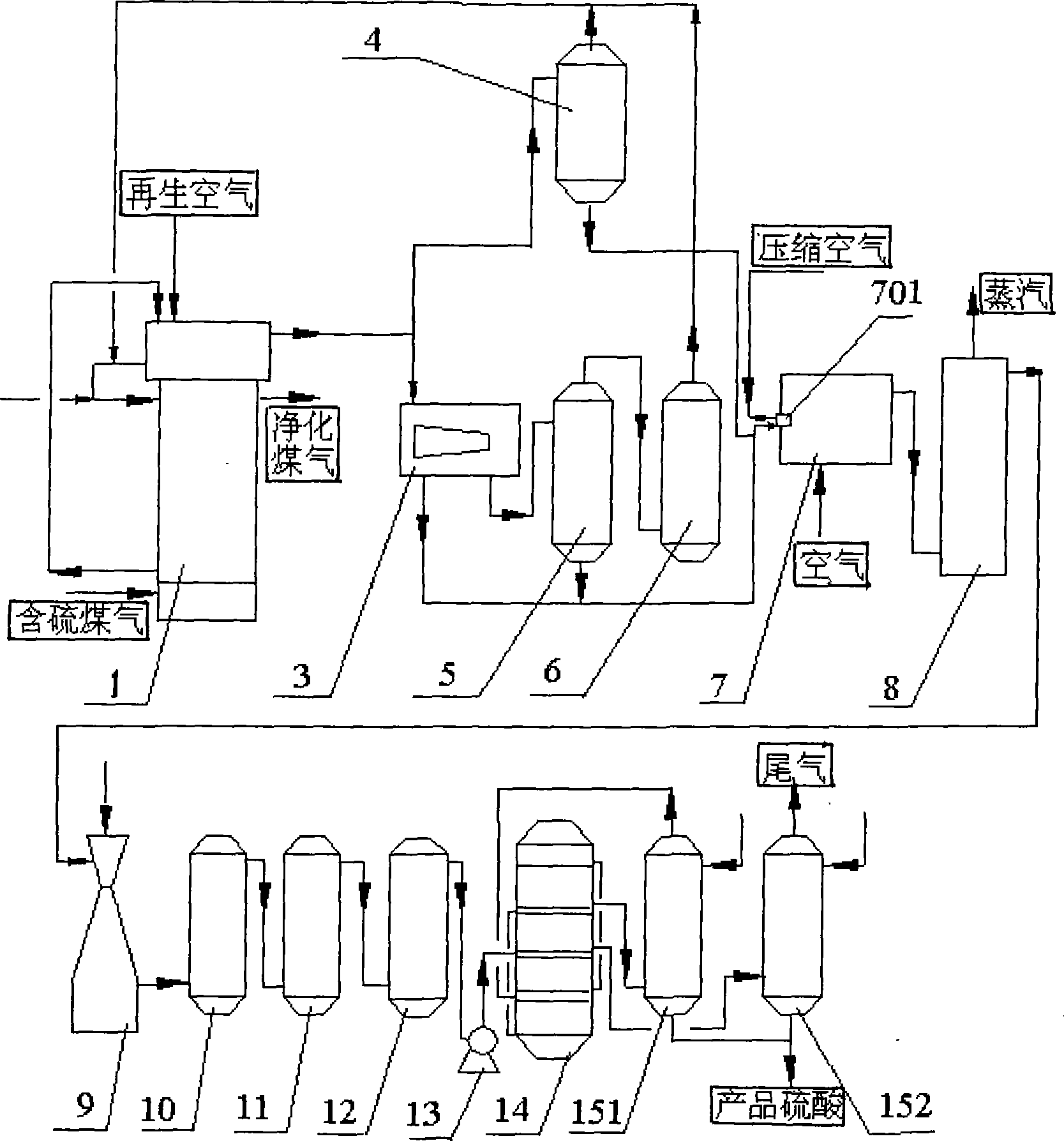

Acid preparing method by coal gas wet oxidation and desulfurization

ActiveCN101519193AImprove desulfurization efficiencyAvoid influenceSulfur-trioxide/sulfuric-acidHydrogen cyanide preparation/purification/separationLiquid wasteSulfur containing

The invention provides an acid preparing method by coal gas wet oxidation and desulfurization, which comprises the following steps of: introducing sulfur-containing coal gas into an absorption section of a desulfurization regeneration tower from the bottom, and then introducing desulfurization barren solution into the absorption section from the upper part to contact the coal gas countercurrent; delivering desulfurization rich liquid from the bottom of the absorption section at the lower part of the desulfurization regeneration tower into a regeneration section at the top of the desulfurization regeneration tower; introducing regeneration air into the regeneration section to obtain the mixture of the desulfurization barren solution and sulfur foam; concentrating the sulfur foam into sulfur pulp to be delivered in a combustion furnace after being atomized by adopting compressed air through a nozzle and then delivered into a converter provided with vanadium catalyst to be converted to sulfur trioxide after the furnace gas is cooled, washed and dried; and delivering the sulfur trioxide into an absorption tower to be converted into product sulfuric acid with weight concentration of 94 percent to 98 percent. The method reduces exhaust emissions, does not emit liquid waste outwards, and has conversion rate of sulfur dioxide over 99.6 percent and good economic and social benefits.

Owner:NINGBO KEXIN CHEM ENG TECH

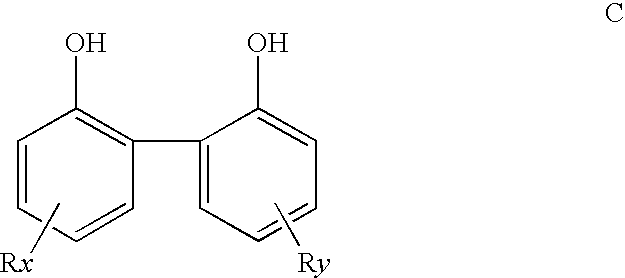

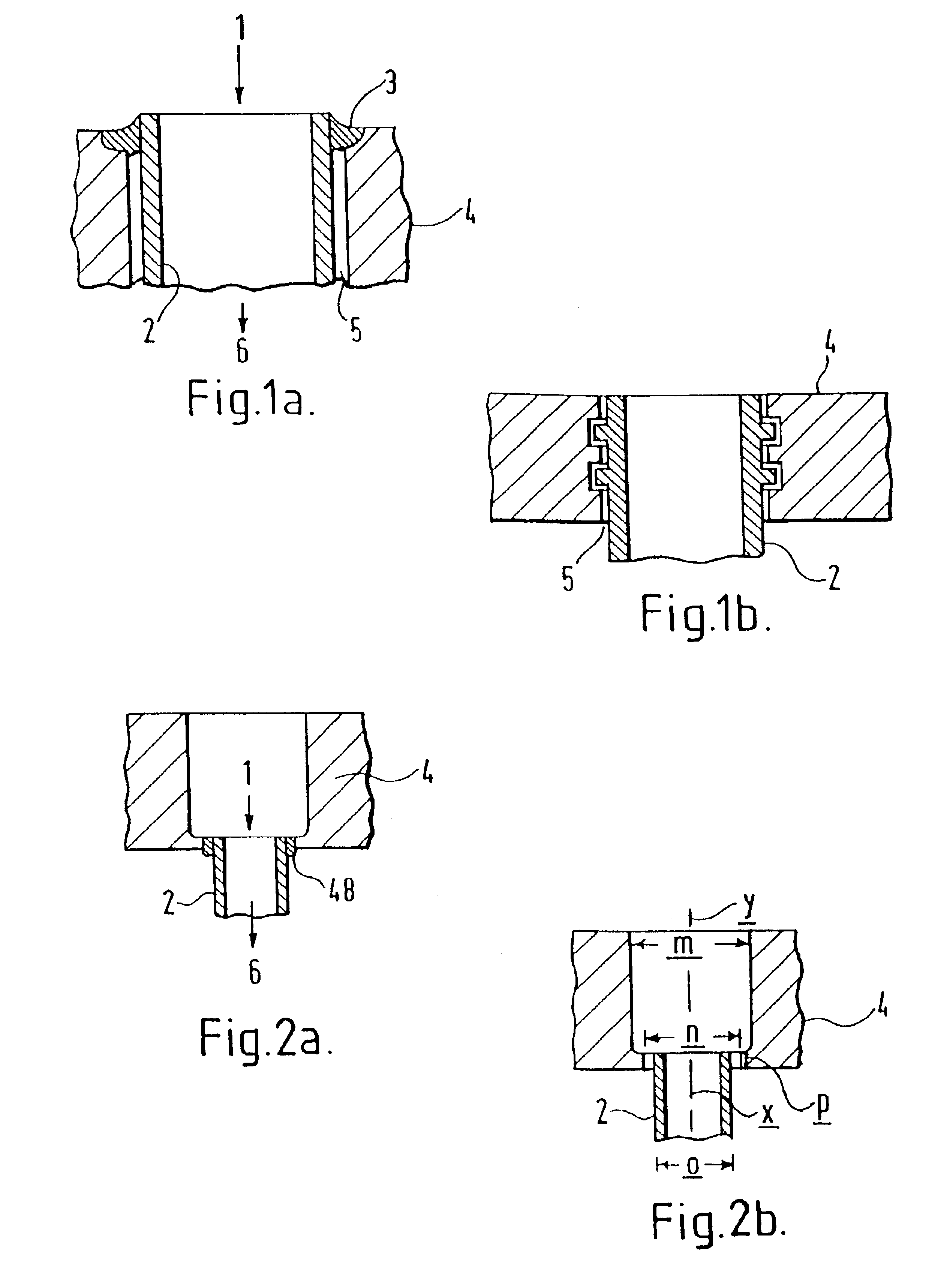

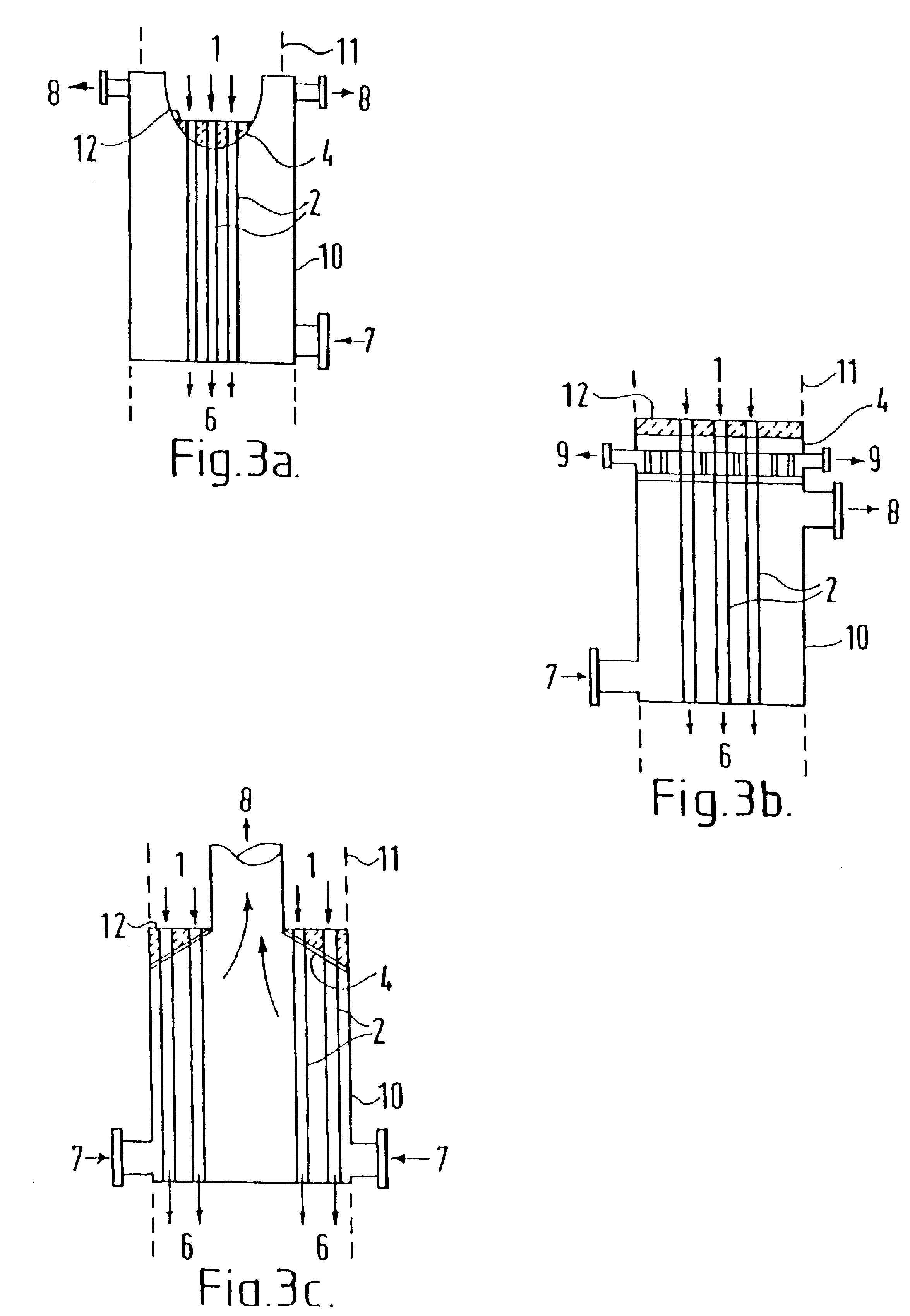

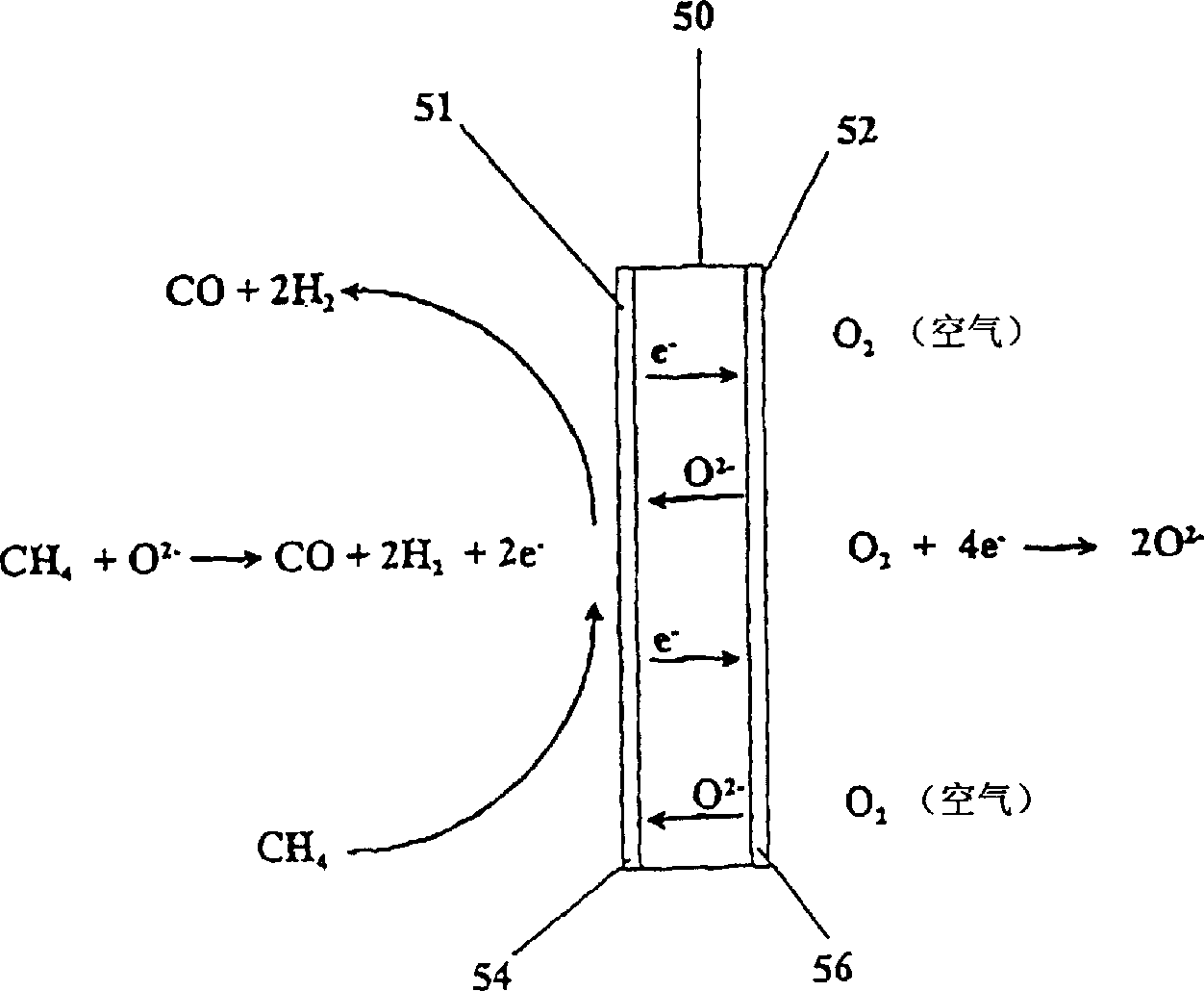

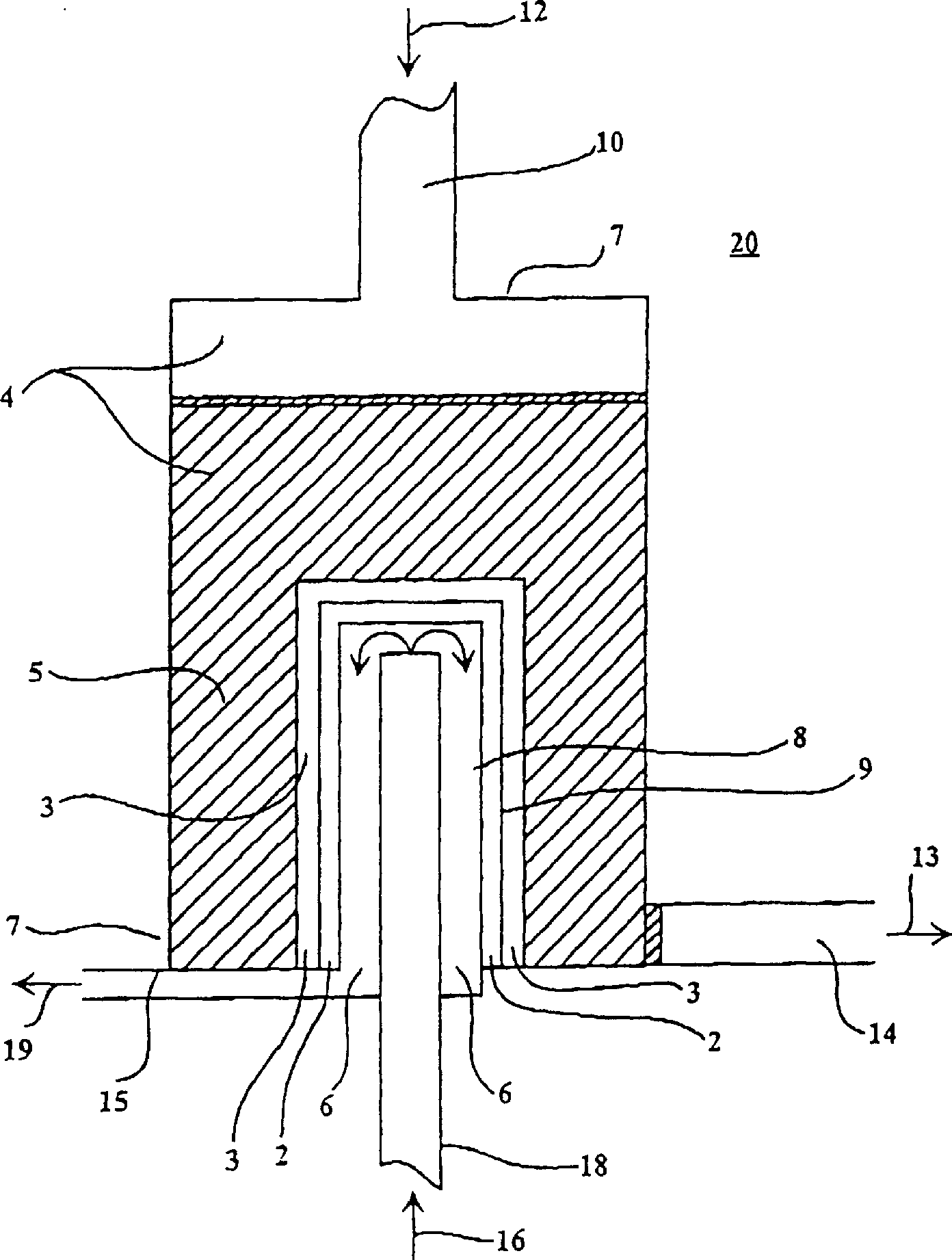

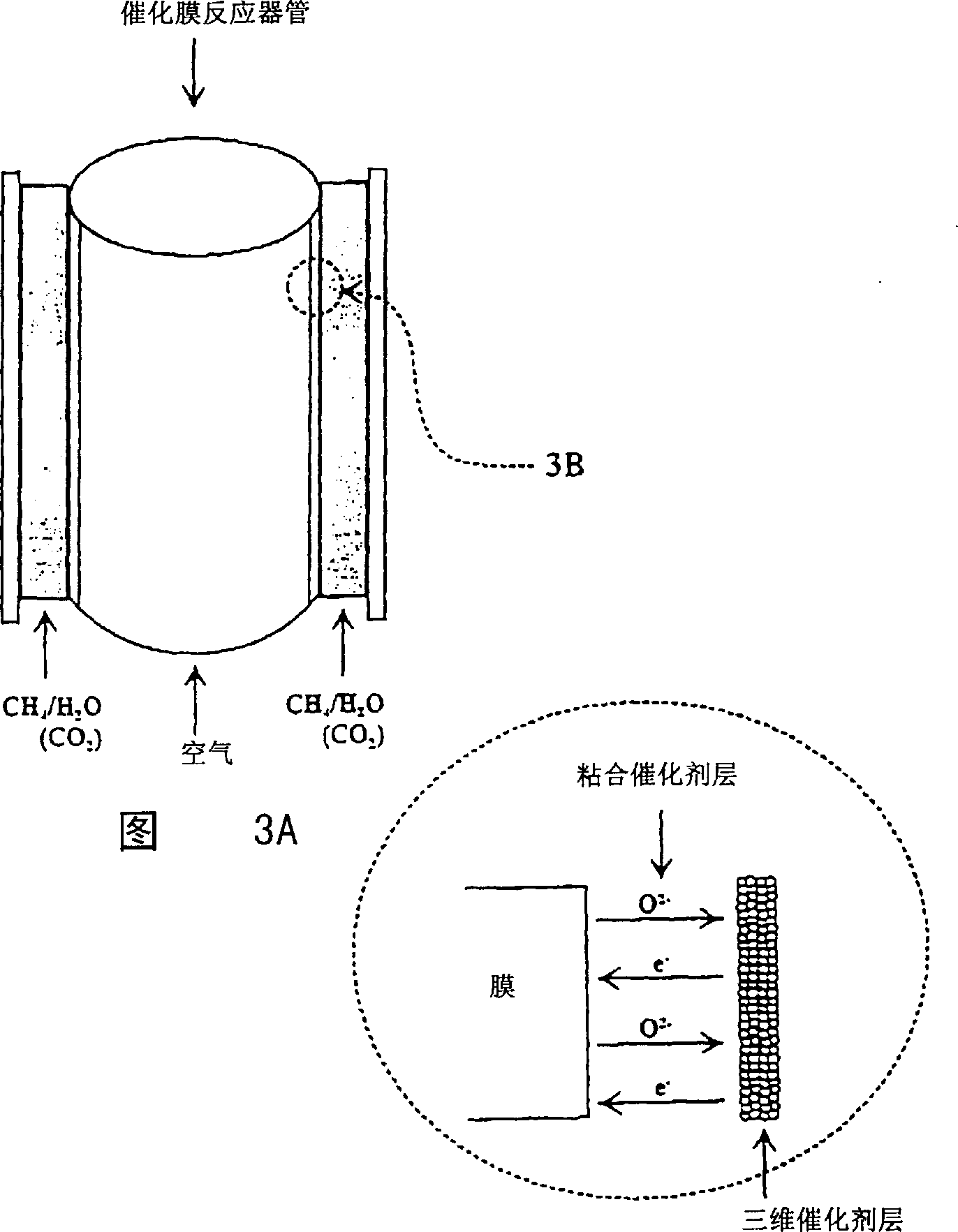

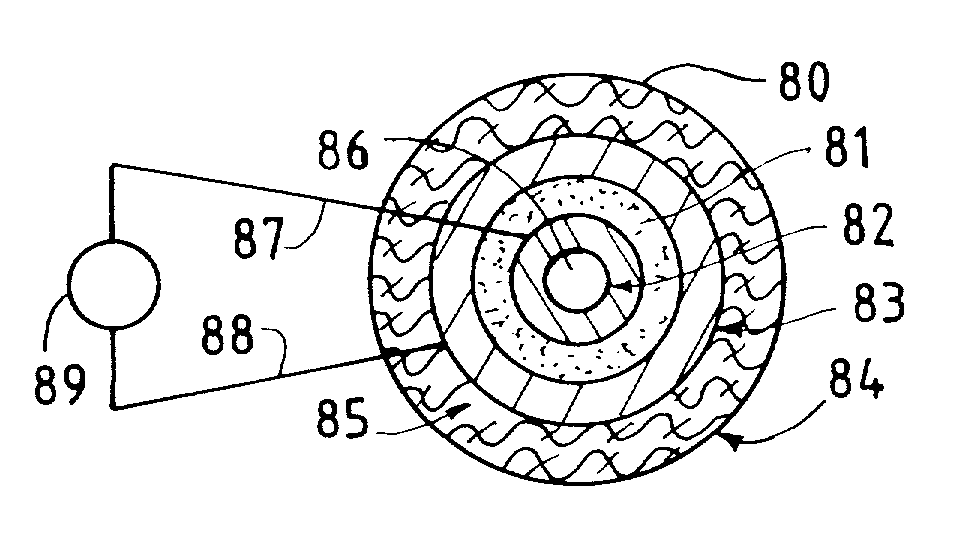

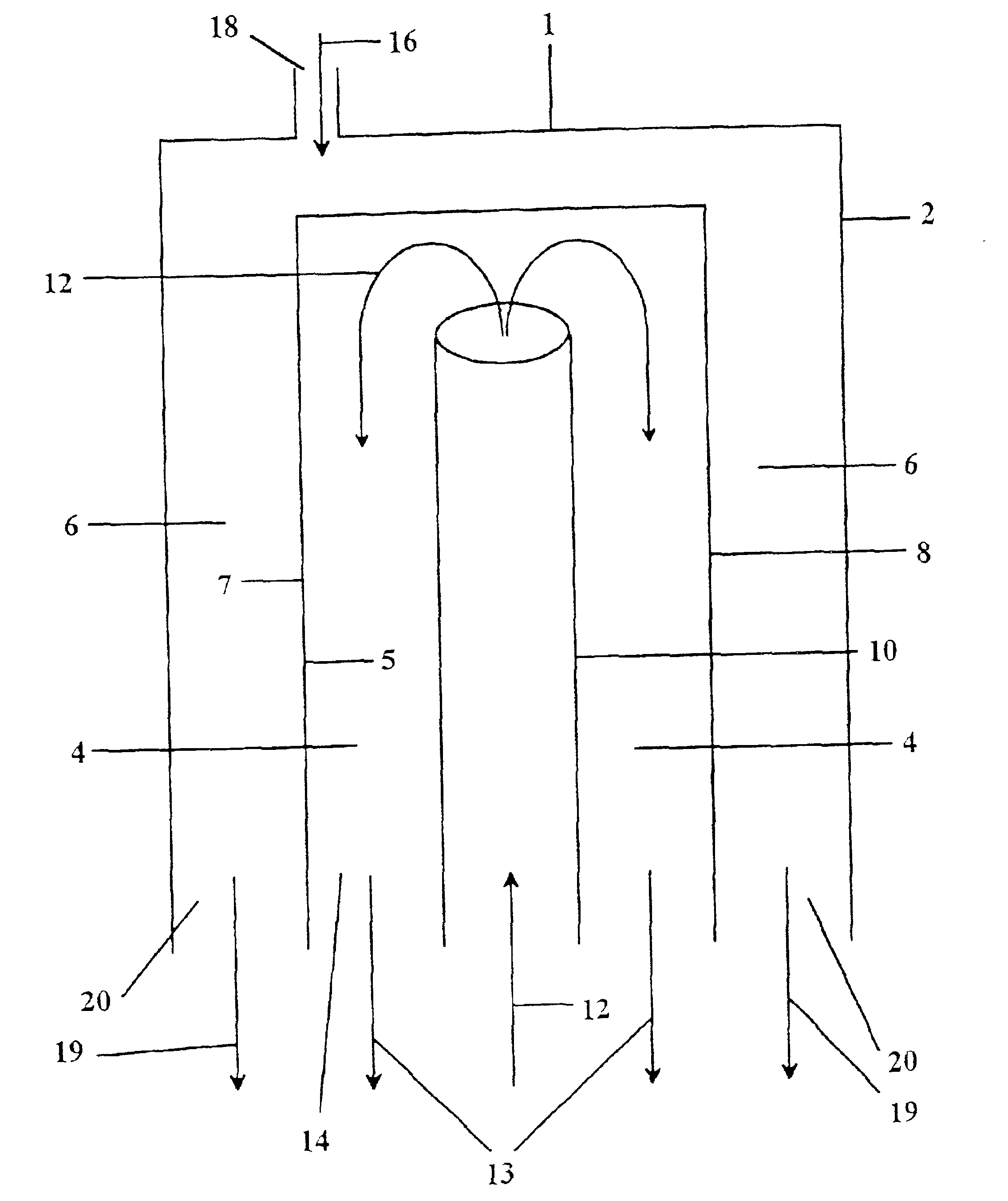

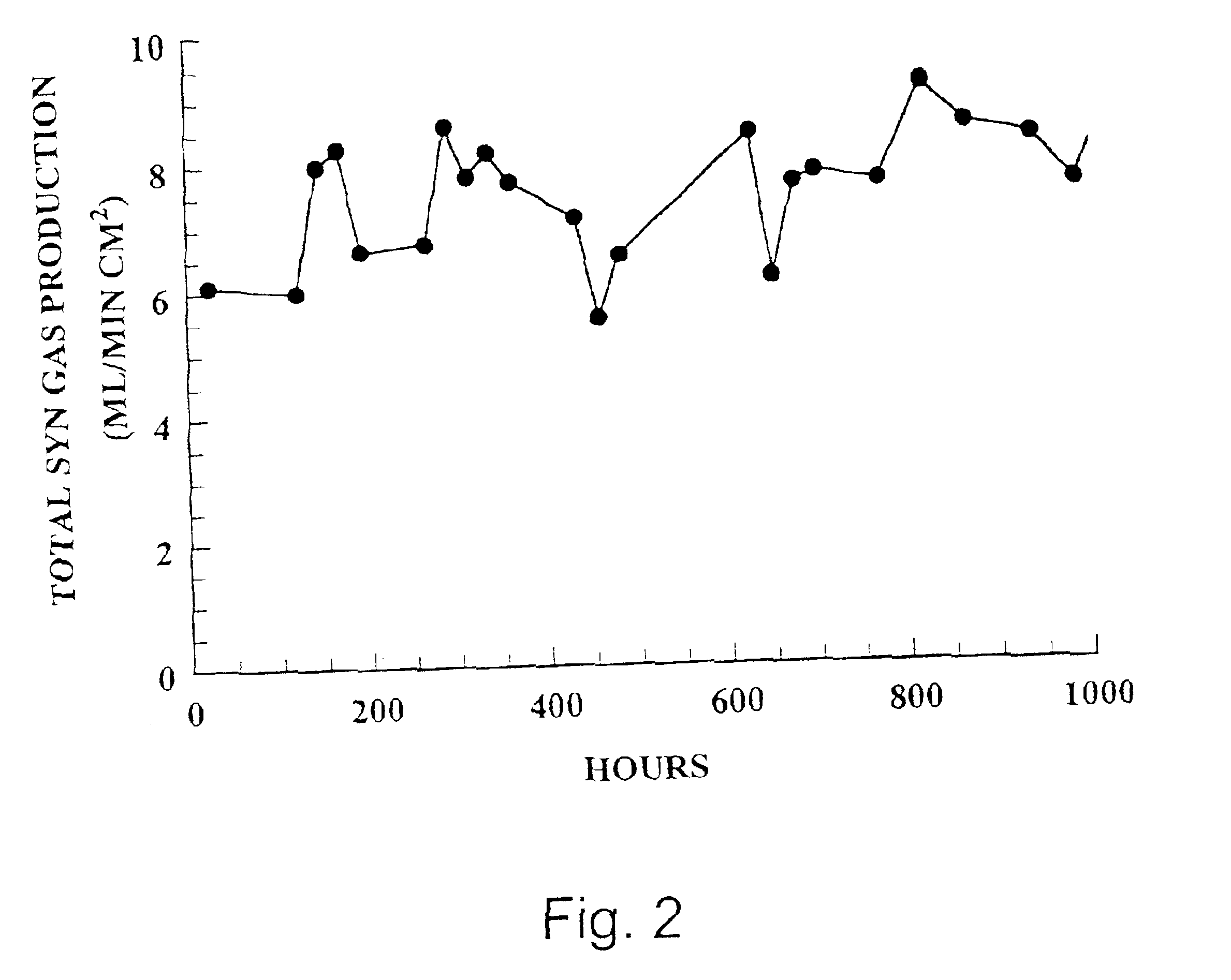

Catalytic membrane reactor with two component three dimensional catalysis

This invention relates to catalytic reactor membranes having a gas-impermeable membrane (2) for transport of oxygen anions. The membrane (2) has an oxidation surface and a reduction surface. The membrane (2) is coated on its oxidation surface with an adherent catalyst layer and is optionally coated on its reduction surface with a catalyst that promotes reduction of an oxygen-containing species (e.g., O2, NO2, SO2, etc.) to generate oxygen anions on the membrane. The reactor (20) has an oxidation zone (4) and a reduction zone (6) separated by the membrane (2). A component of an oxygen-containing gas in the reduction zone (6) is reduced at the membrane (2) and a reduced species in a reactant gas in the oxidation zone (4) of the reactor is oxidized. The reactor (20) optionally contains a three-dimensional catalyst (5) in the oxidation zone (4). The adherent catalyst layer and the three-dimensional catalyst (5) are selected to promote a desired oxidation reaction, particularly a partial oxidation of a hydrocarbon. Preferred membrane materials of this invention are mixed metal oxides which are derived from brownmillerite and can, themselves, have brownmillerite structure. In a preferred embodiment, the oxygen reduction catalyst is Pd (5% by weight) on La0.8Sr0.2CoO3-x. The adherent catalyst layer is Ni (20% by weight) on La0.8Sr0.2MnO3 and the three-dimensional catalyst is Ni (5% by weight) on alumina.

Owner:ELTRON RES

Solid multi-component membranes, electrochemical reactor components, electrochemical reactors and use of membranes, reactor components, and reactor for oxidation reactions

InactiveUS7033470B2Final product manufactureHydrogen/synthetic gas productionPorous substrateElectrochemical response

Solid membranes comprising an intimate, gas-impervious, multi-phase mixture of an electronically-conductive material and an oxygen ion-conductive material and / or a mixed metal oxide of a perovskite structure are described. Electrochemical reactor components, such as reactor cells, and electrochemical reactors are also described for transporting oxygen from any oxygen-containing gas to any gas or mixture of gases that consume oxygen. The reactor cells generally comprise first and second zones separated by an element having a first surface capable of reducing oxygen to oxygen ions, a second surface capable of reacting oxygen ions with an oxygen-consuming gas, an electron-conductive path between the first and second surfaces and an oxygen ion-conductive path between the first and second surfaces. The element may further comprise (1) a porous substrate, (2) an electron-conductive metal, metal oxide or mixture thereof and / or (3) a catalyst. The reactor cell may further comprise a catalyst in the zone which comprises a passageway from an entrance end to an exit end of the element. Processes described which may be conducted with the disclosed reactor cells and reactors include, for example, the partial oxidation of methane to produce unsaturated compounds or synthesis gas, the partial oxidation of ethanes substitution of aromatic compounds, extraction of oxygen from oxygen-containing gases, including oxidized gases, ammoxidation of methane, etc. The extraction of oxygen from oxidized gases may be used for flue or exhaust gas cleanup.

Owner:STANDARD OIL CO

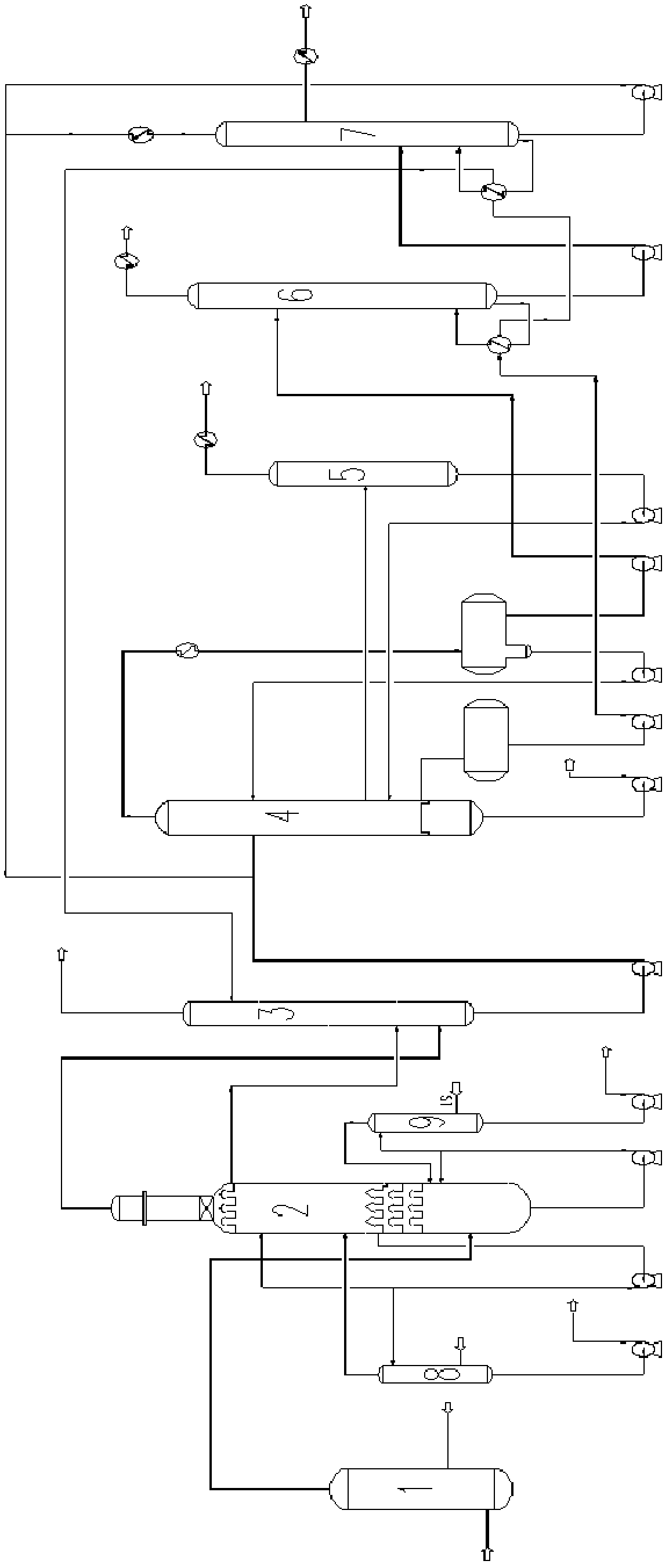

Industrial production method of acrylonitrile

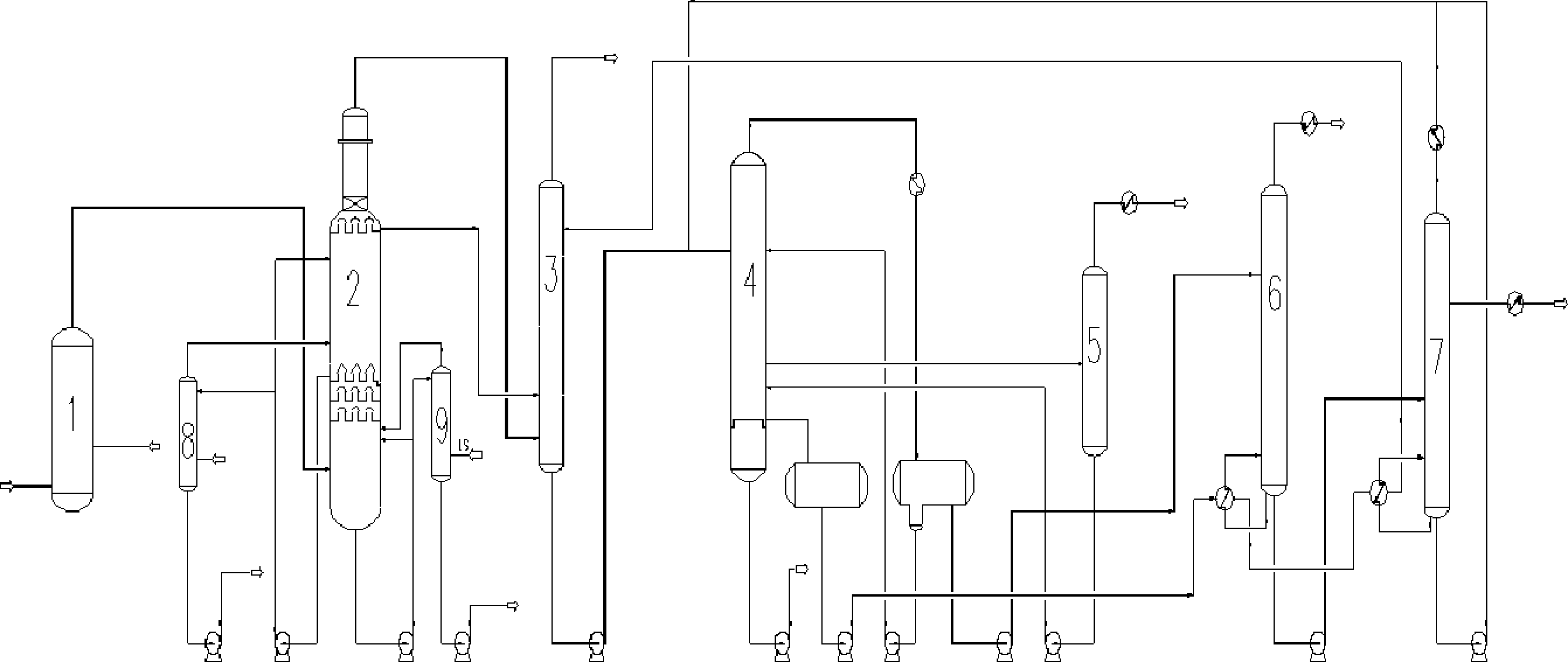

ActiveCN102659625AIncrease device functionFunction increaseCarboxylic acid nitrile preparationOrganic compound preparationWater vaporGas phase

The invention provides an industrial production method of acrylonitrile, which comprises that the air, propylene and ammonia are subjected to ammoxidation inside a reactor and generate a reaction gas containing the acrylonitrile; the reaction gas enters a first tower and shock cooling, neutralization and cooling are achieved; the reaction gas which is subjected to shock cooling, neutralization and cooling enters a second tower and the water absorbs organic materials contained in the reaction gas; the water absorbing liquid enters a third tower, the acrylonitrile, hydrocyanic acid and water vapor steamed out by the third tower are subjected to condensation, and then separation of an aqueous phase and an organic phase is achieved in a quantizer of the third tower; the water phase inside the quantizer of the third tower are delivered to the third tower; the water phase introduced from a last piece of tower plates of a tower kettle of the third tower is subjected to heat exchange and then serves as absorbing water of the second tower; a gas phase containing acetonitrile is extracted from the side lines of the third tower and sent into a fourth tower and a rough acetonitrile product is obtained; and the organic phase in the quantizer of the third tower enters a fifth tower and a sixth tower sequentially and hydrocyanic acid and a acrylonitrile product are respectively obtained. According to the method, the reliability of a device is improved and the energy utilization is high.

Owner:CHINA TIANCHEN ENG +3

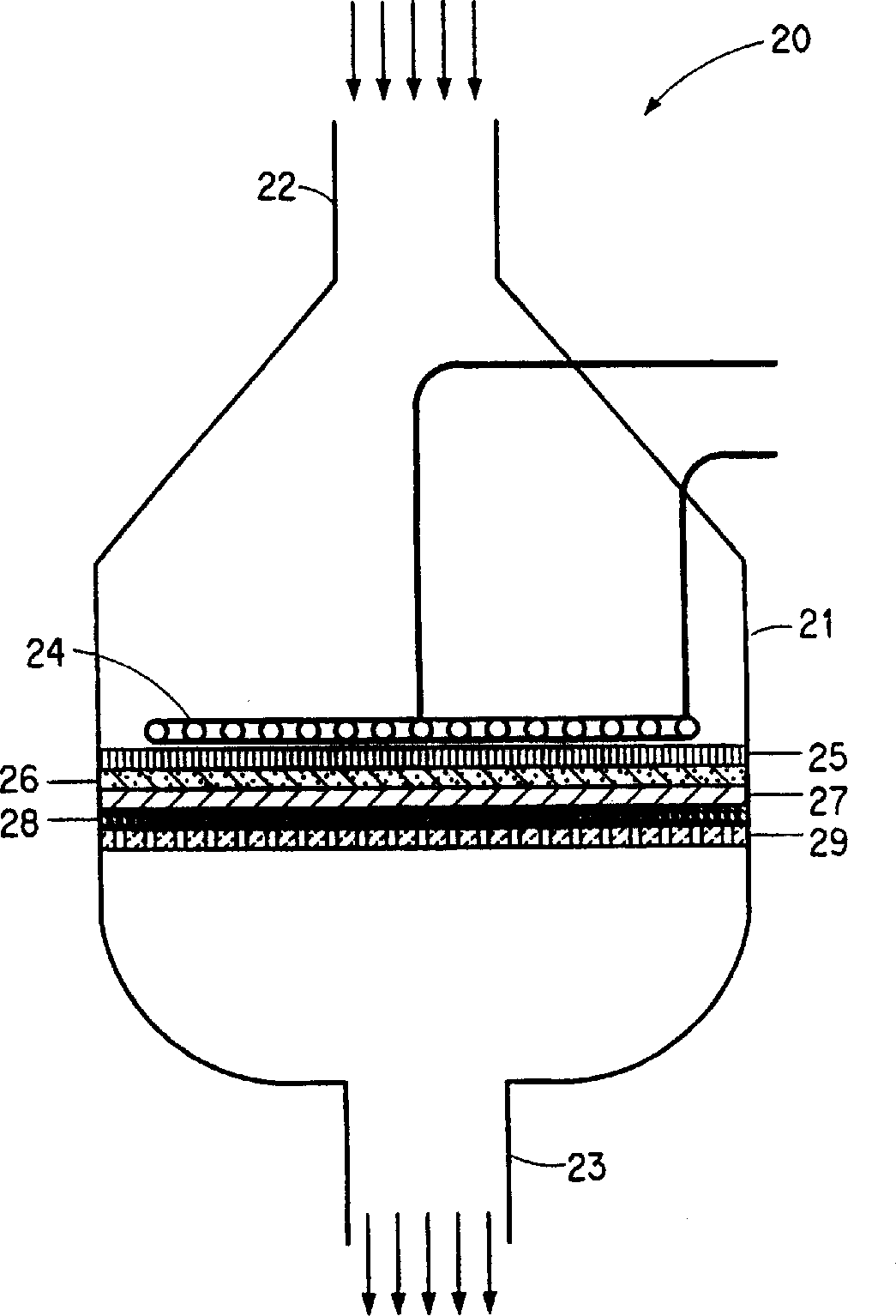

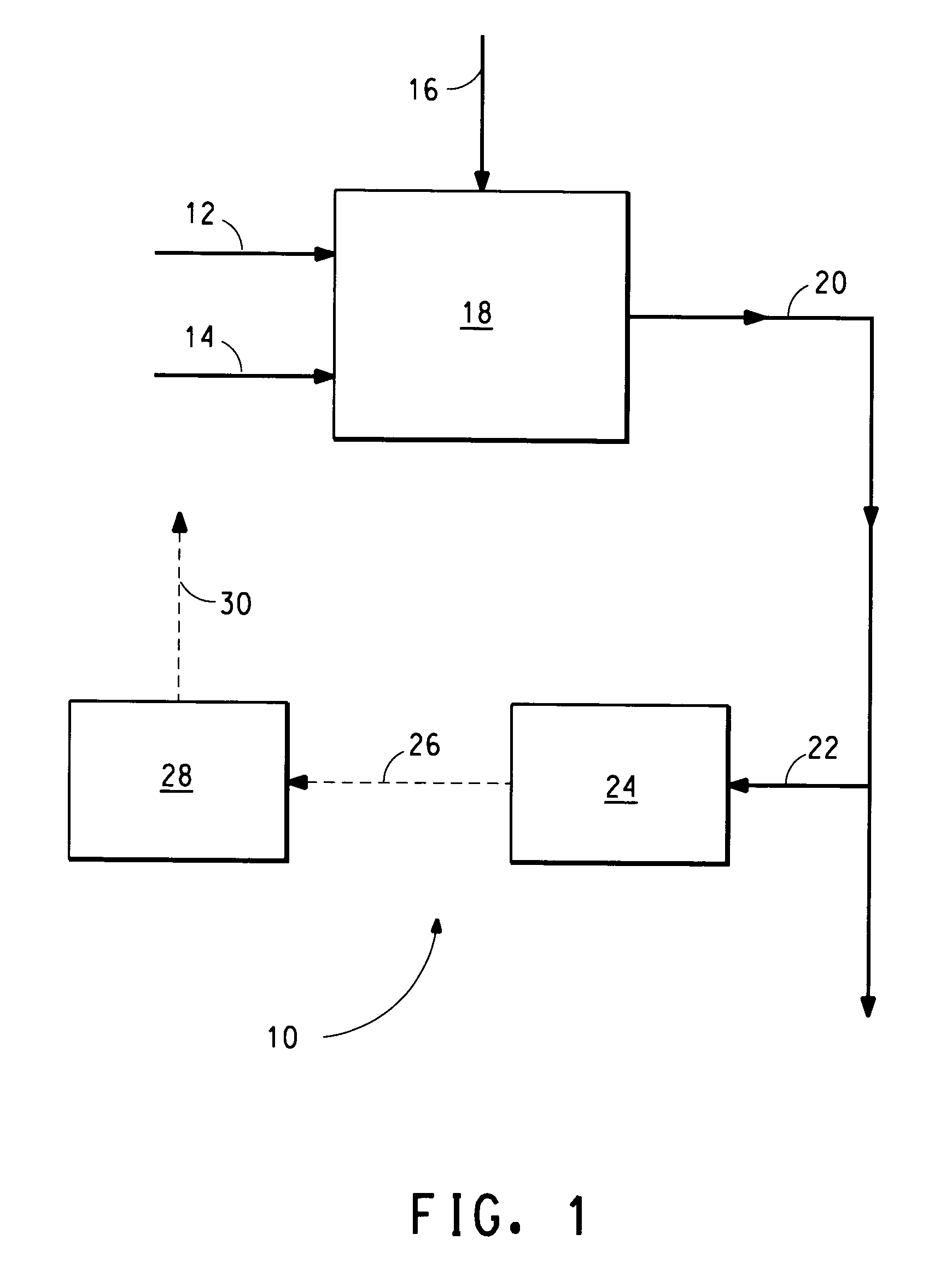

High Efficiency reactor and process

InactiveUS20120141345A1High yieldHigh selectivityCatalytic gas-gas reactionMethane captureProduct gasAmmonia

The invention includes an apparatus and process for the catalytic production of HCN from a feed gas of ammonia and a hydrocarbon gas by means of heat tubes supplying heat to the feed gas stream and heat tubes for removal of heat from the products. The invention further includes a process for N2O abatement comprising transferring heat from an exothermic N2O degradation reaction through a heat pipe.

Owner:INVISTA NORTH AMERICA R L

Solid multi-component membranes, electrochemical reactor components, electrochemical reactors and use of membranes, reactor components, and reactor for oxidation reactions

InactiveUS20060131182A1Final product manufactureIron compoundsPorous substrateElectrochemical response

Solid membranes comprising an intimate, gas-impervious, multi-phase mixture of an electronically-conductive material and an oxygen ion-conductive material and / or a mixed metal oxide of a perovskite structure are described. Electrochemical reactor components, such as reactor cells, and electrochemical reactors are also described for transporting oxygen from any oxygen-containing gas to any gas or mixture of gases that consume oxygen. The reactor cells generally comprise first and second zones separated by an element having a first surface capable of reducing oxygen to oxygen ions, a second surface capable of reacting oxygen ions with an oxygen-consuming gas, an electron-conductive path between the first and second surfaces and an oxygen ion-conductive path between the first and second surfaces. The element may further comprise (1) a porous substrate, (2) an electron-conductive metal, metal oxide or mixture thereof and / or (3) a catalyst. The reactor cell may further comprise a catalyst in the zone which comprises a passageway from an entrance end to an exit end of the element. Processes described which may be conducted with the disclosed reactor cells and reactors include, for example, the partial oxidation of methane to produce unsaturated compounds or synthesis gas, the partial oxidation of ethane, substitution of aromatic compounds, extraction of oxygen from oxygen-containing gases including oxidized gases, ammoxidation of methane, etc. The extraction of oxygen from oxidized gases may be used for flue or exhaust gas cleanup.

Owner:MAZANEC TERRY J +3

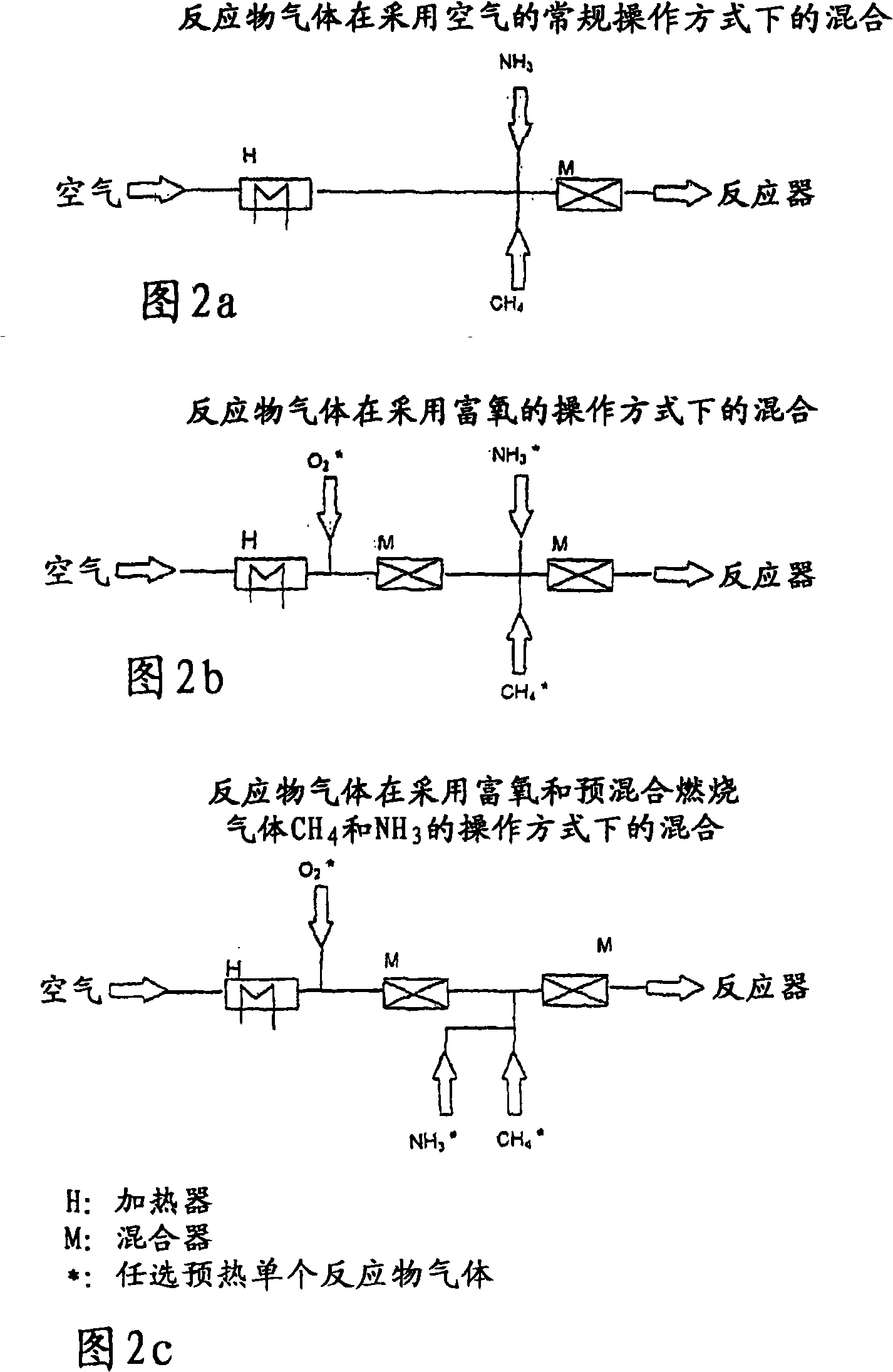

Method for producing hydrocyanic acid (HCN)

InactiveCN101269824AHigh yieldIncrease production capacityHydrogen cyanide preparation/purification/separationNitrogenMethane gas

The invention relates to a method for preparing hydrogen cyanide according to andrussow process, which is carried out by reacting methane gas, ammonia gas and oxygen-containing gas at rising temperature on catalyst. Oxygen has a volume proportion (O<2> / (O<2>+N<2>) of 0.2 to 1.0 corresponding to total volume of nitrogen and oxygen, and the reaction is carried out by adopting mixture of incombustible reactant gas.

Owner:EVONIK ROEHM GMBH

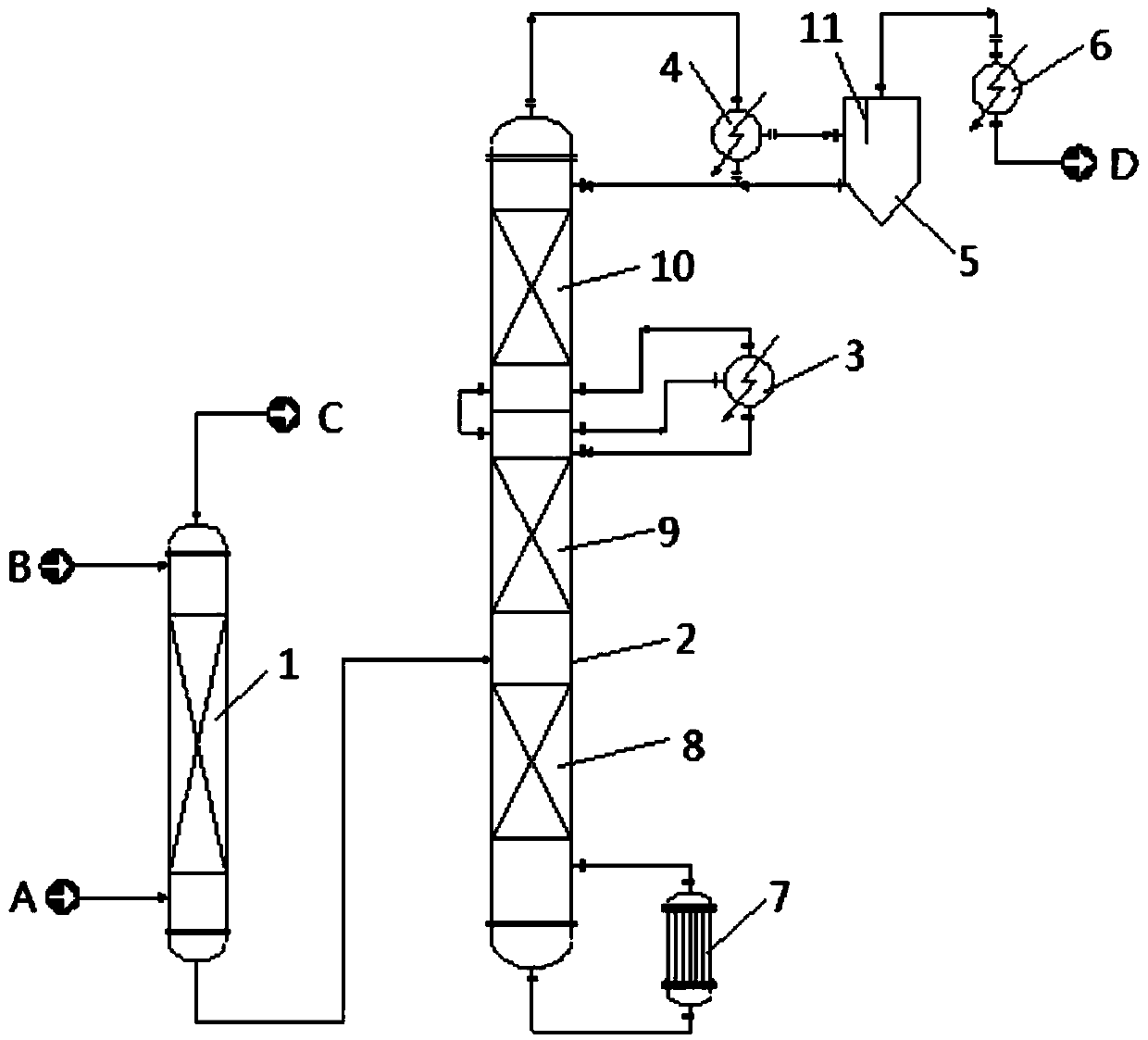

Ammonia recovery method for gas mixture in hydrogen cyanide production

ActiveCN101264901AAvoid lossReduce manufacturing costHydrogen cyanide preparation/purification/separationAmmonia preparation/separationRecovery methodDesorption

The invention discloses an ammonia recovery method from the mixing gas produced in the process of hydrogen cyanide production, comprising ammonia absorption process, decyanation process, desorption process and rectifying process for solving the technical problem. The invention is characterized in that decyanation process is set separately to recovery hydrogen cyanide gas, avoiding the loss of hydrogen cyanide caused by a large amount of acid gas like hydrocyanic acid contained in the ammonium phosphate solution directly steamed in Versum method, reducing production cost of hydrogen cyanide, reducing the emission of the harmful acid gas like hydrogen cyanide, and avoiding the serious pollution of peripheral enviroment. Besides, the ammonium phosphate solution contains a much smaller amout of hydrocyanic acid after hydrogen cyanide is recovered, which can not influence production process and make the production process more safety.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

Method and apparatus for reducing nitrous oxide

InactiveUS6649134B2Promote resultsImprove mechanical stabilityNitrous oxide captureCombination devicesPlatinumNitrogen oxide

Owner:WC HERAEUS HOLDING GMBH & CO KG

Endothermic reactions heated by resistance heating

PendingUS20210113983A1Facilitate steam reforming reactionEfficient heatingCatalytic gas-gas reactionGaseous chemical processesReactor systemPtru catalyst

A reactor system for carrying out an endothermic reaction of a feed gas, including: a structured catalyst arranged for catalyzing the endothermic reaction of a feed gas, the structured catalyst including a macroscopic structure of electrically conductive material, the macroscopic structure supporting a ceramic coating, wherein the ceramic coating supports a catalytically active material; a pressure shell housing the structured catalyst; heat insulation layer between the structured catalyst and the pressure shell; at least two conductors electrically connected to the electrically conductive material and to an electrical power supply placed outside the pressure shell, wherein the electrical power supply is dimensioned to heat at least part of said structured catalyst to a temperature of at least 200° C. by passing an electrical current through the electrically conductive material. Also, a process for performing an endothermic reaction of a feed gas.

Owner:HALDOR TOPSOE AS

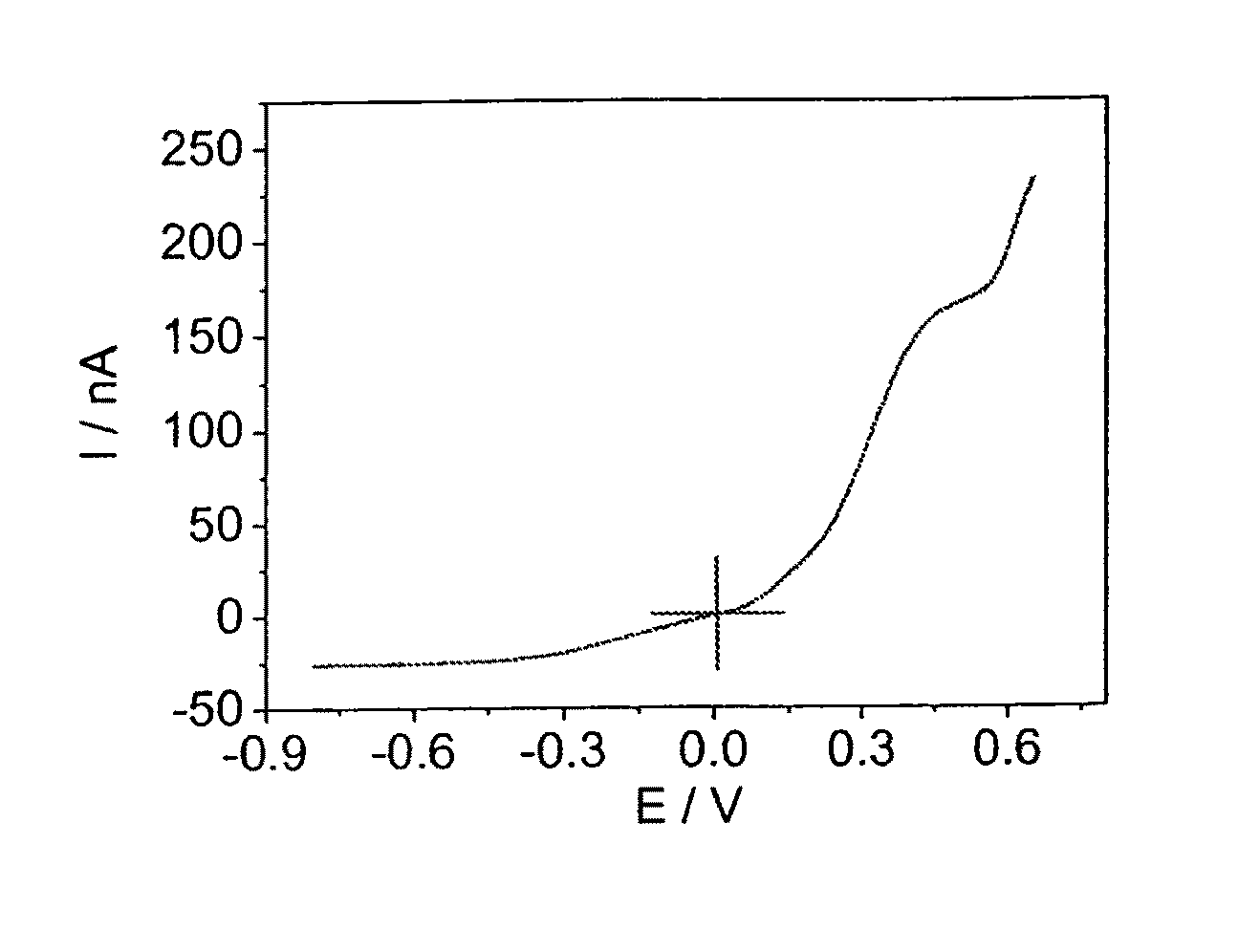

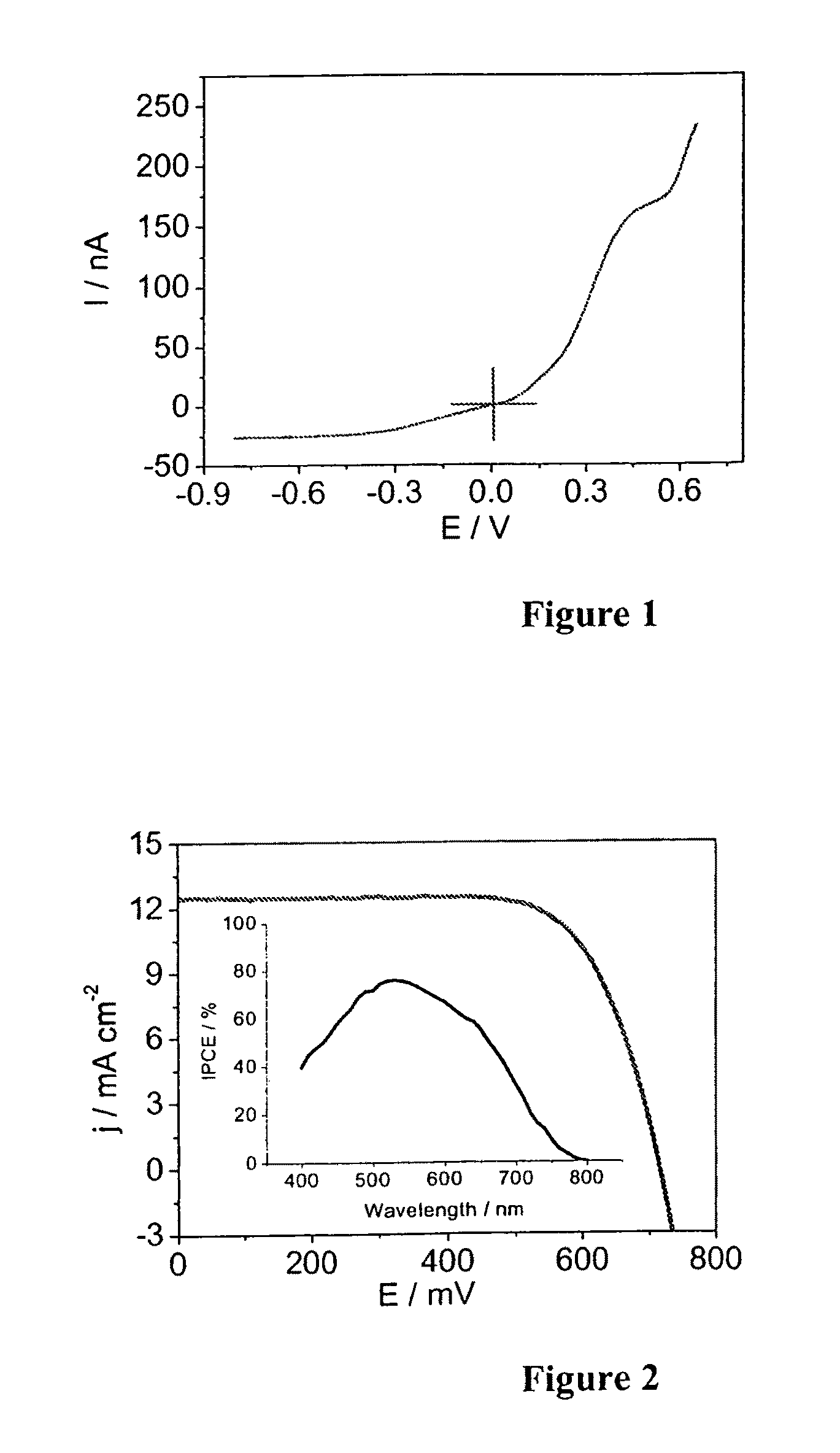

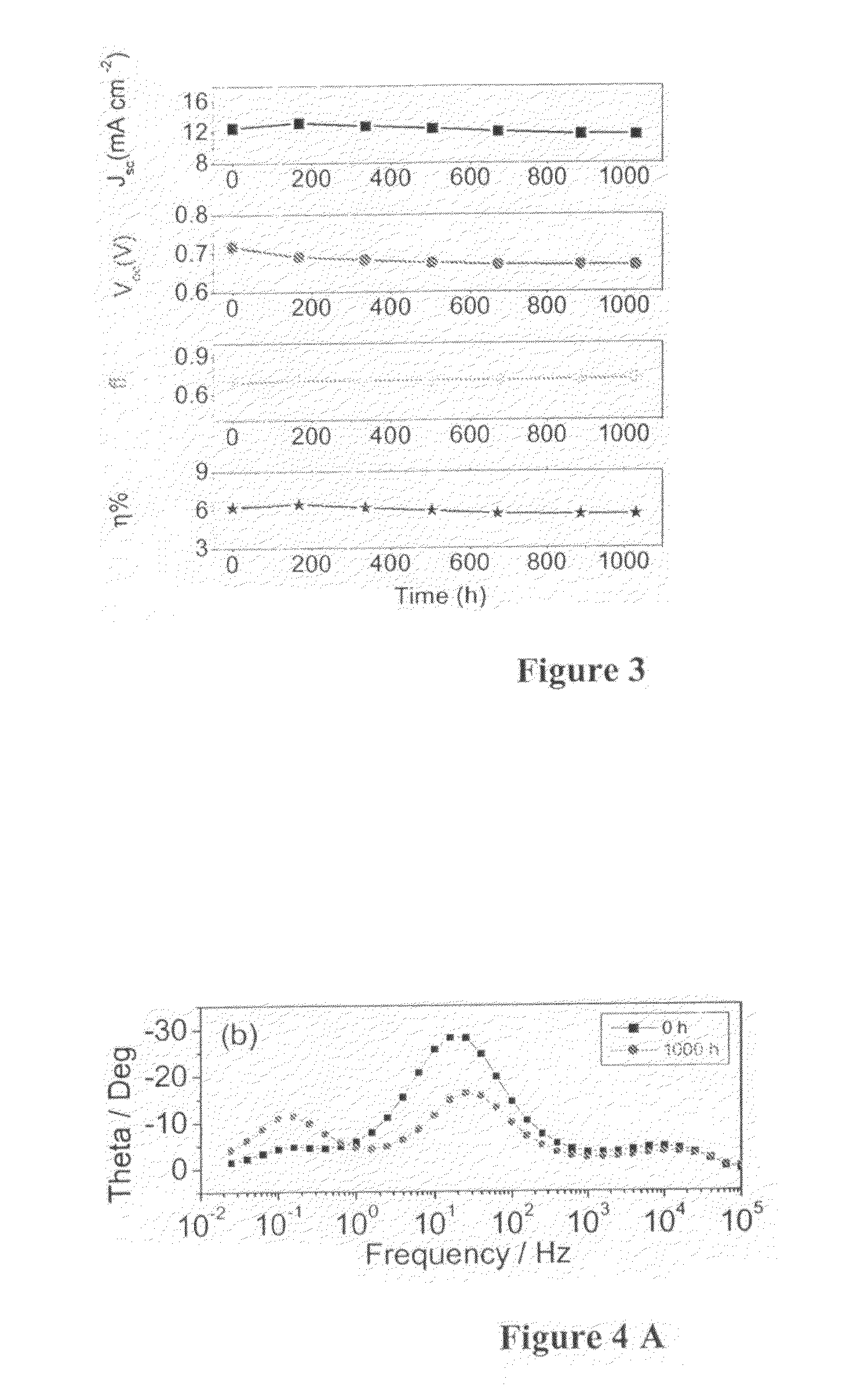

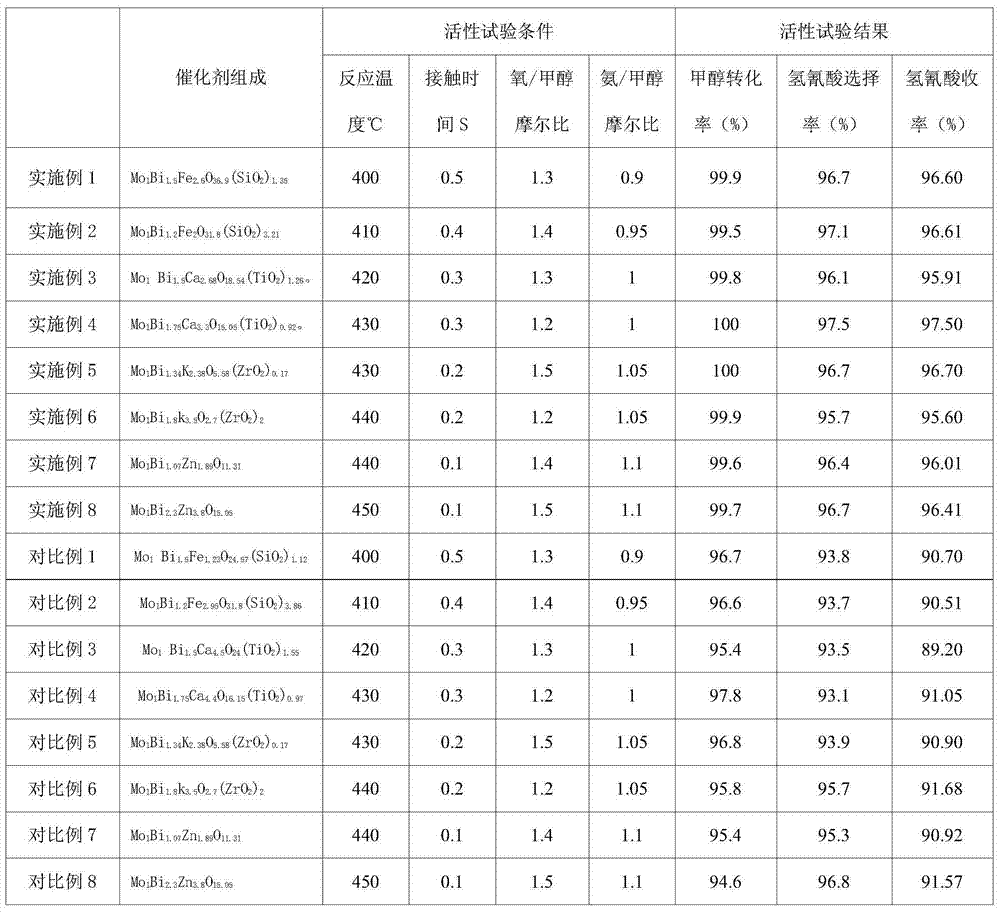

Ionic liquid electrolyte

InactiveUS8114318B2Improve performanceImprove stabilityLiquid organic insulatorsElectrolytic capacitorsSolventElectrochemistry

The present invention relates to electrolytes comprising tetracyanoborate and an organic cation as components of electrolytes in electrochemical and / or optoelectronic devices, in particular solar cells. This ionic liquid has low viscosity and can be used as electrolyte in the absence of a solvent. Importantly, the ionic liquid remains stable in solar cells even after prolonged thermal stress at 80° C. for 1000 hours. Photovoltaic conversion efficiency remained stable and keeping more than 90% of the initial value.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

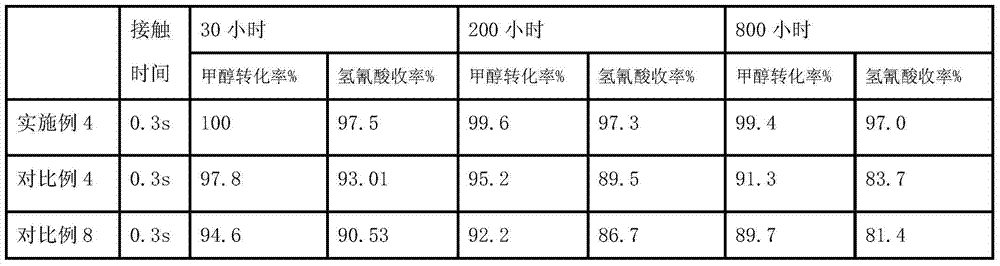

Catalyst for preparing hydrocyanic acid by adopting methanol ammonia oxidization as well as preparation method and application of catalyst for preparing hydrocyanic acid by adopting methanol ammonia oxidization

ActiveCN104275190ASimple compositionHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsHydrogen cyanide preparation/purification/separationChemical combinationOxygen

The invention discloses a catalyst for preparing hydrocyanic acid by adopting methanol ammonia oxidization as well as a preparation method and application of the catalyst for preparing the hydrocyanic acid by adopting the methanol ammonia oxidization. Most existing catalysts for preparing the hydrocyanic acid by adopting the methanol ammonia oxidization are complicated in structure, inconvenient to prepare and non-ideal in yield. The catalyst disclosed by the invention consists of elements such as molybdenum, bismuth and an oxide of X; the experimental form of the catalyst is MoaBibXcOd, wherein X is one of Fe, K, Ca and Zn; a, b and c are atomic ratios; when a is equal to 1, b is equal to a number from 1 to 2.5, c is equal to a number from 1 to 5, and d is a total number of oxygen atoms in a corresponding oxide generated by chemical combination of catalyst components. The catalyst disclosed by the invention is simple in constituent, high in catalysis activity and stability and convenient to prepare; when the catalyst is applied to preparation of the hydrocyanic acid by adopting the ammonia oxidization, the ammonia oxygen amount is greatly reduced.

Owner:SHANDONG XINHECHENG AMINO ACID +1

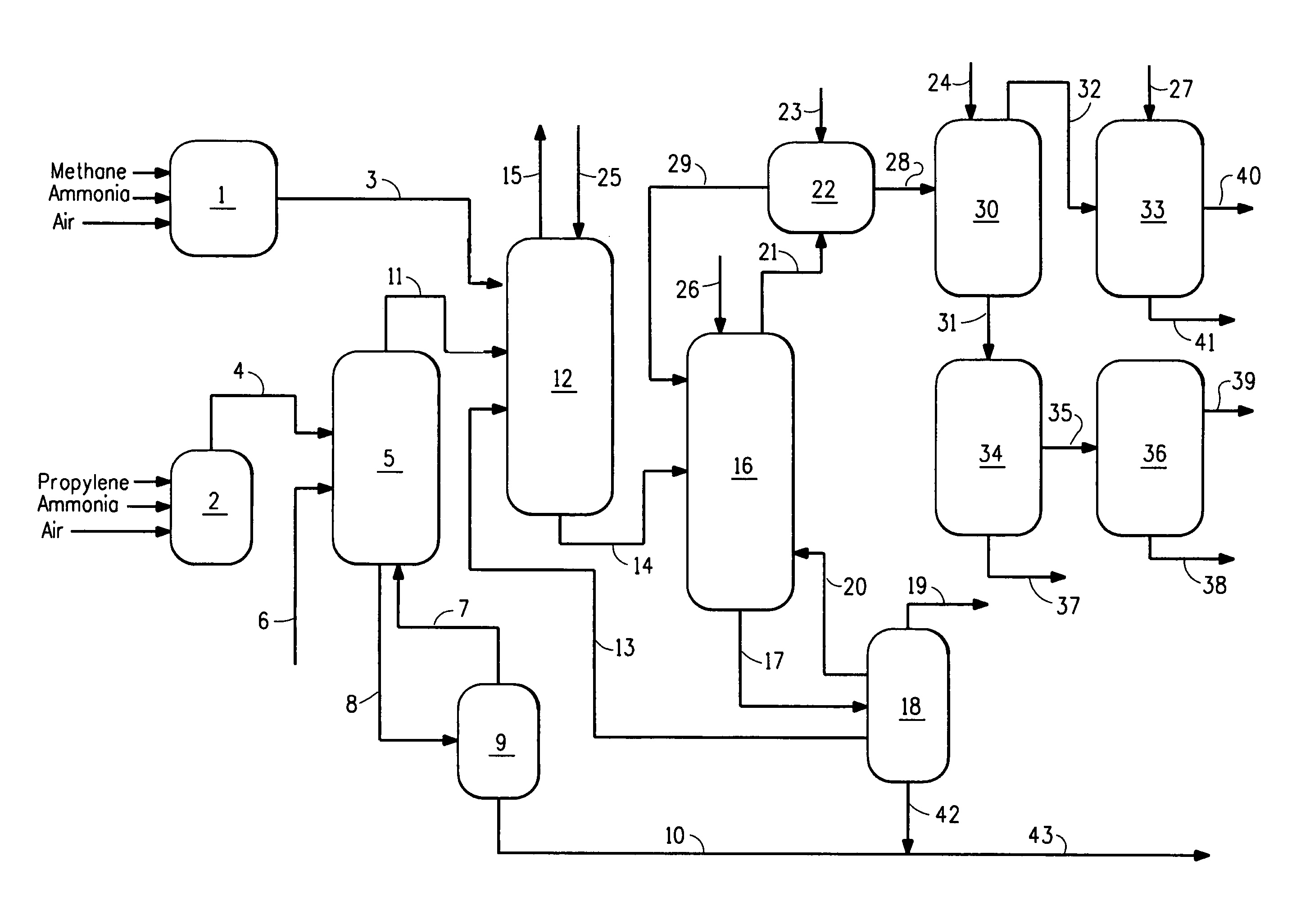

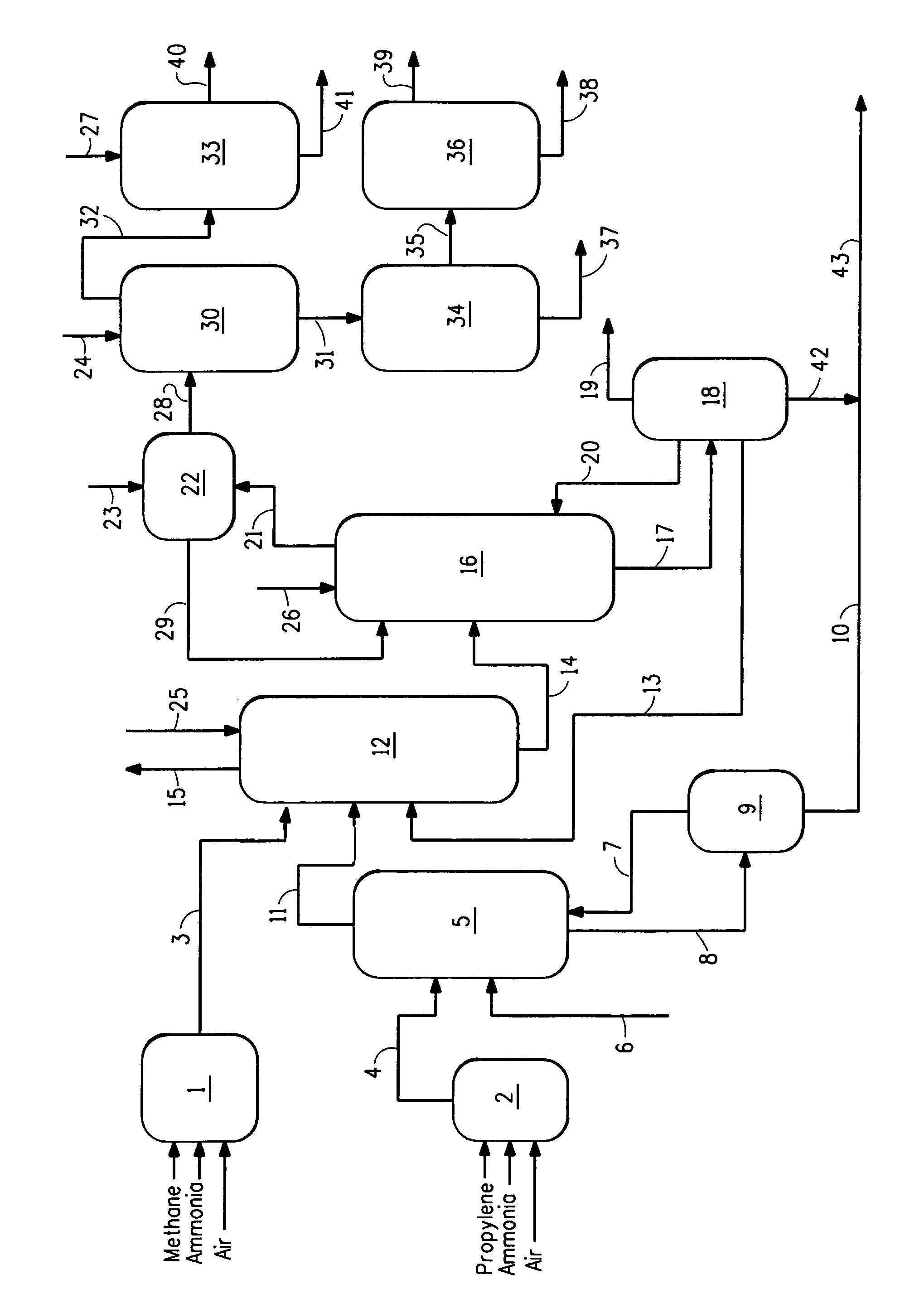

Process to C-manufacture acrylonitrile and hydrogen cyanide

ActiveUS8585870B2Conveniently providedWeight controlOrganic compound preparationUsing liquid separation agentAcrylonitrilePhotochemistry

A process for co-manufacture of acrylonitrile and hydrogen cyanide comprises combining a stream comprising hydrogen cyanide and an acrylonitrile reactor product stream, to produce a combined product stream, having a ratio of acrylonitrile to hydrogen cyanide of about 9 to 1 or less, which can be varied; and treating the combined product stream in a recovery / purification system of acrylonitrile process wherein pH is controlled by addition of an acid to prevent HCN polymerization. The ratio of acrylonitrile to hydrogen cyanide is generally between 2 to 1 and 9 to 1. The stream comprising hydrogen cyanide is advantageously a hydrogen cyanide product stream from a hydrogen cyanide synthesis reactor.

Owner:THE CHEMOURS CO FC LLC

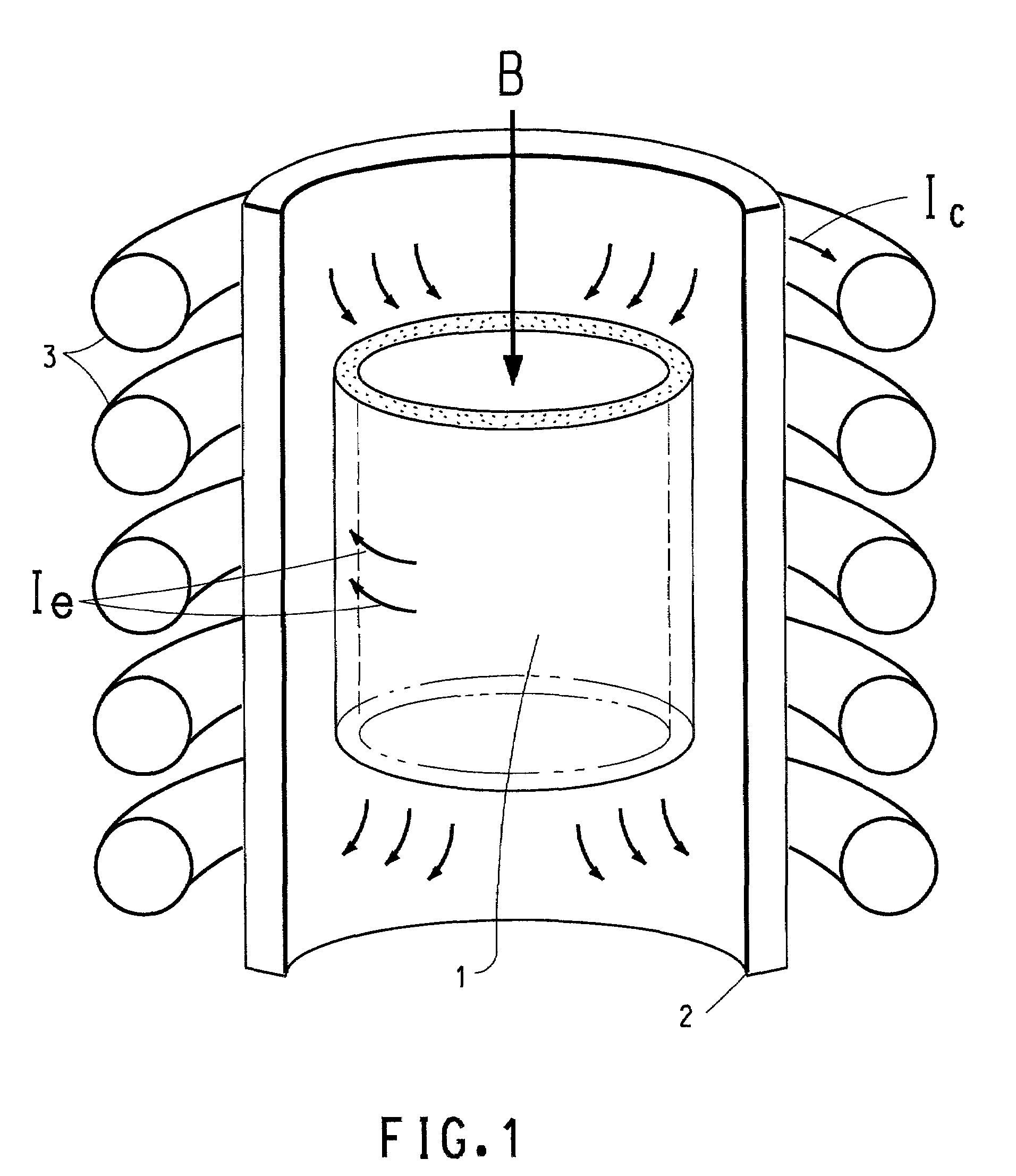

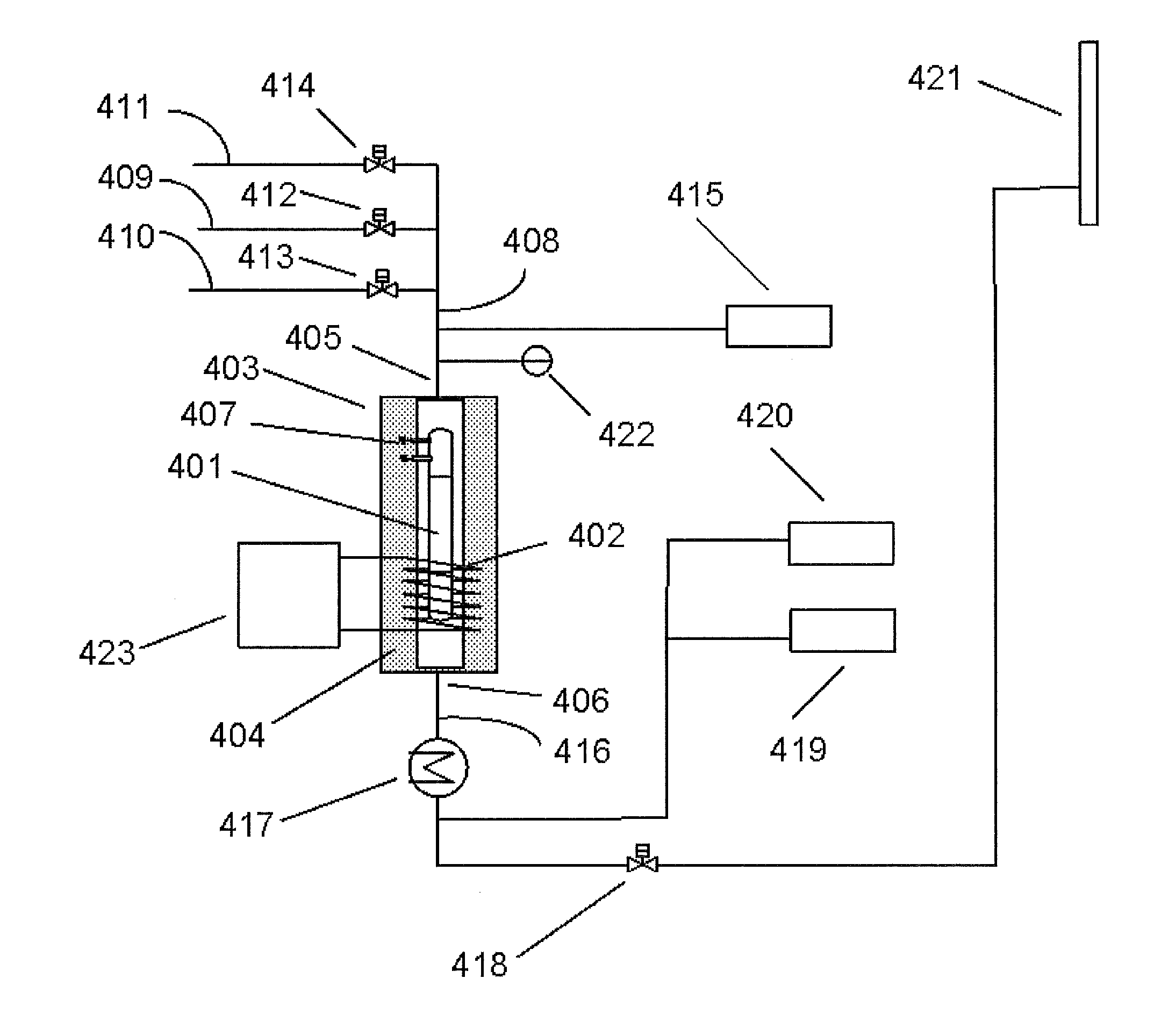

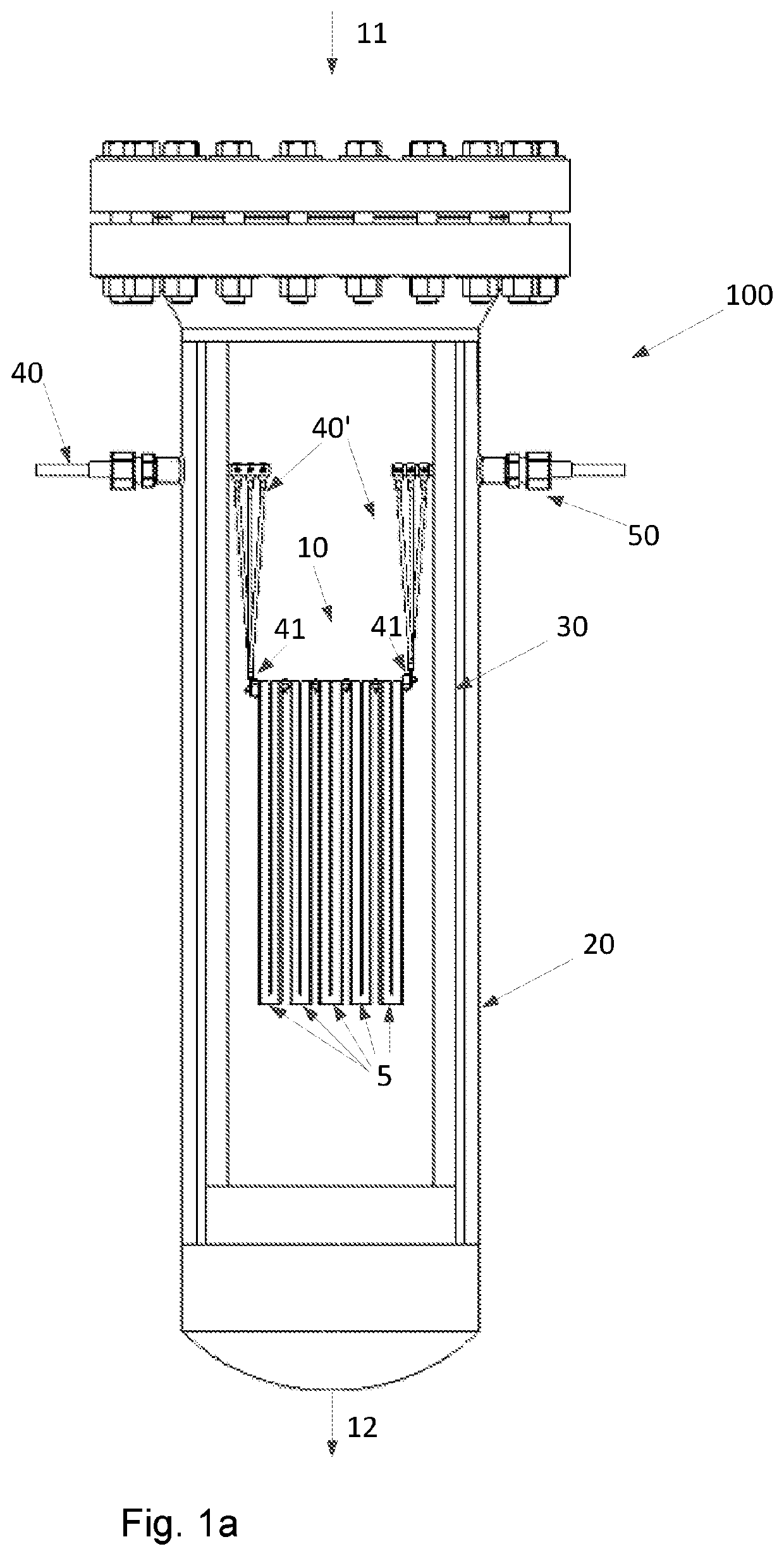

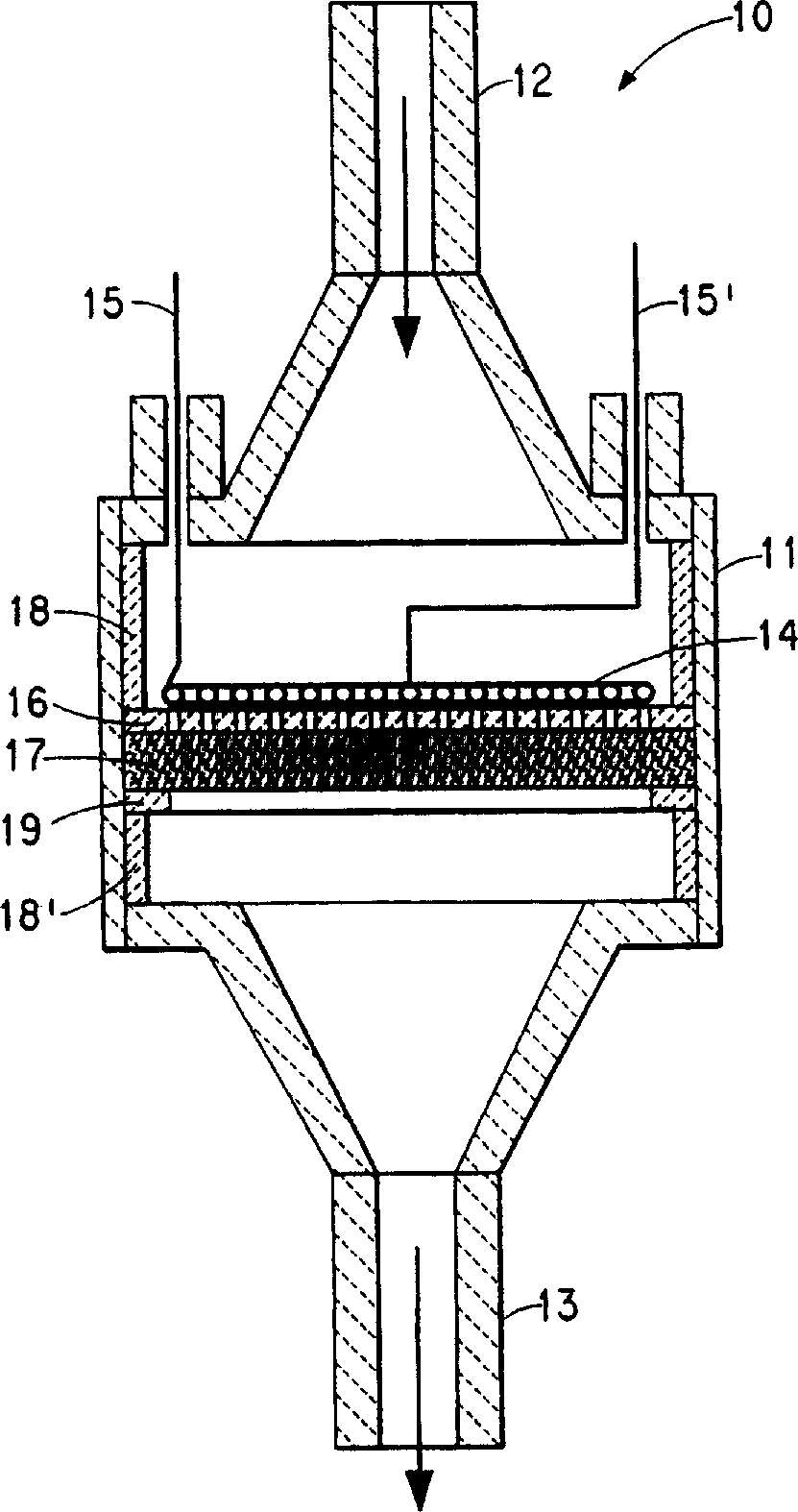

Inductively heated catalytic reactor

InactiveCN1261821ACatalytic gas-gas reactionEnergy based chemical/physical/physico-chemical processesTemperature controlChemical reaction

An improved gas phase reactor (10) for continuously conducting a catalyzed chemical reaction at elevated temperature involving a reactor vessel (11) wherein the gaseous reactant passing through the reactor makes contact with an inductively heated solid phase catalyst media (17). By placing the induction coil (14) used to inductively heat the catalyst (17) directly within the reactor in close proximity to the solid catalyst improved temperature control and uniform heating of the catalyst is achieved. Such a reactor is particularly useful for continuous production of hydrogen cyanide.

Owner:INVISTA TECHNOLOG IES S A R L

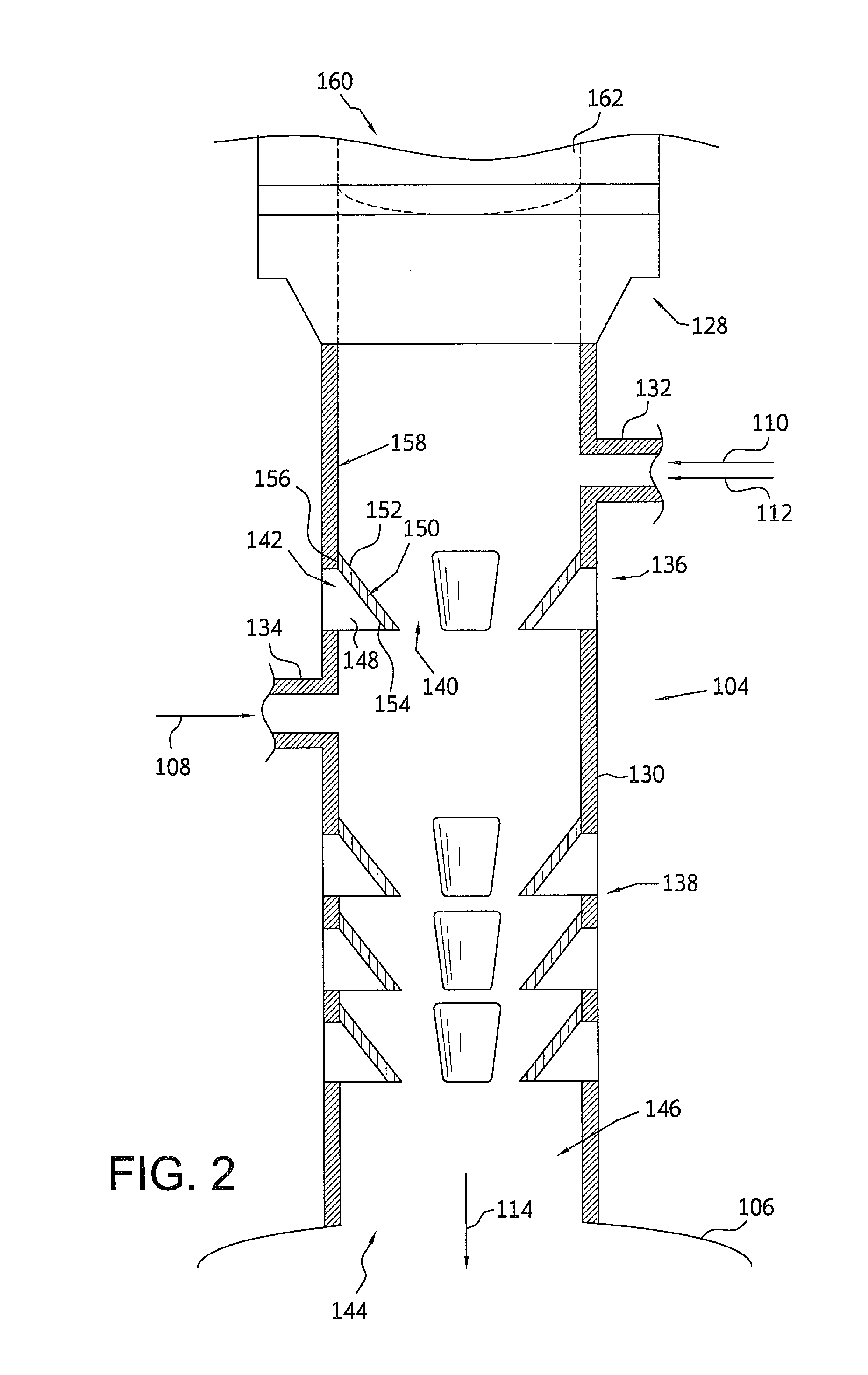

Processes for producing hydrogen cyanide using static mixer

InactiveUS20150353371A1Easy to adaptCooking-vessel materialsFlow mixersStatic mixerCoefficient of variation

A static mixer is disclosed for a hydrogen cyanide reaction process that thoroughly mixes the reactant gases to form a ternary gas mixture that has a coefficient of variation of less than 0.1 across the diameter of the catalyst bed. The static mixer comprises tabs that are inserted through non-continuous slots in the conduit and the tabs are secured to the external wall of the conduit.

Owner:INVISTA NORTH AMERICA R L

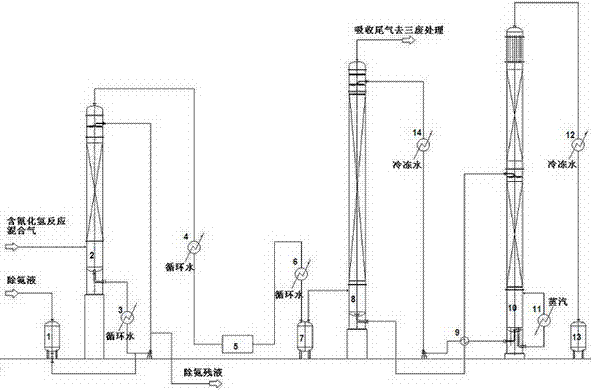

Process and system for preparing high-purity liquid hydrogen cyanide

ActiveCN105366692AImprove absorption efficiencyReduce loadHydrogen cyanide preparation/purification/separationEnvironmental resistanceVapor–liquid separator

The present invention provides a method for producing a high-purity liquid hydrogen cyanide for hydrogen cyanide gas obtained by ammoxidation. The liquid hydrogen cyanide of a low water content is obtained by absorption of low-temperature water in an absorbing tower and operation of a three-stage distillation tower and a gas-liquid separator. The process and method have the beneficial effects that by virtue of adoption by low-temperature water, the absorption efficiency of HCN gas is improved, the load on subsequent exhaust gas processing facilitates is alleviated, and the environmental protection pressure is relieved. Refined by the process disclosed by the invention, the content of a finished product hydrogen cyanide water can reach below 50 ppm, thereby sufficiently satisfying the using requirements on downstream users; the leakage risk of the hydrogen cyanide is effectively avoided, thereby more facilitating the safe production; and self-polymerization of hydrogen cyanide can be further slowed, so that production is more smooth and the production efficiency is improved.

Owner:CHINA TIANCHEN ENG +1

Method of making hydrocyanic acid using a mass spectrometer control system

Owner:INVISTA NORTH AMERICA R L

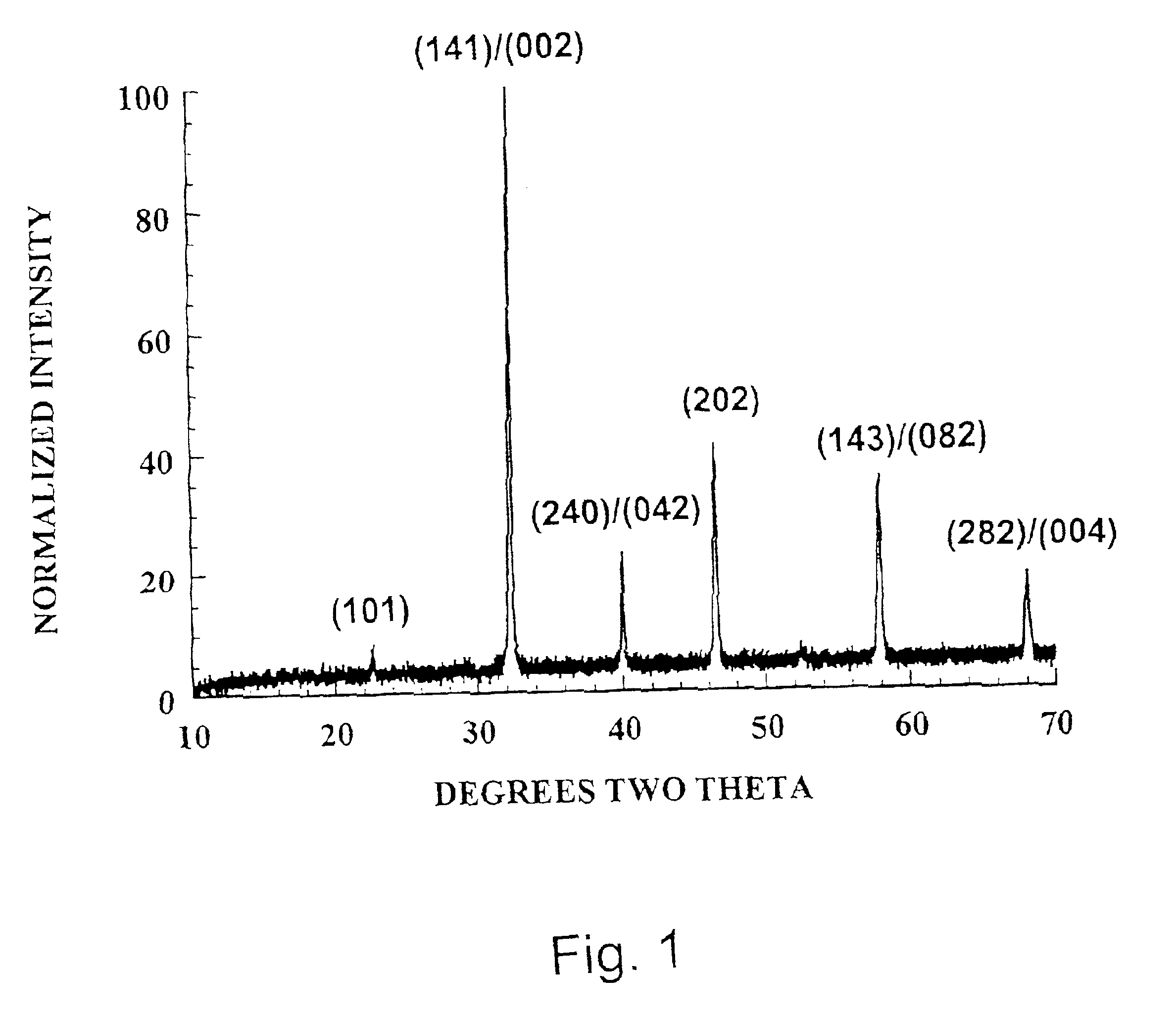

Solid state oxygen anion and electron mediating membrane and catalytic membrane reactors containing them

InactiveUS6949230B2Improve membrane efficiencyImprove efficiencyFinal product manufactureCell electrodesChemical speciesDecomposition

This invention relates to gas-impermeable, solid state materials fabricated into membranes for use in catalytic membrane reactors. This invention particularly relates to solid state oxygen anion- and electron-mediating membranes for use in catalytic membrane reactors for promoting partial or full oxidation of different chemical species, for decomposition of oxygen-containing species, and for separation of oxygen from other gases. Solid state materials for use in the membranes of this invention include mixed metal oxide compounds having the brownmillerite crystal structure.

Owner:ELTRON RES

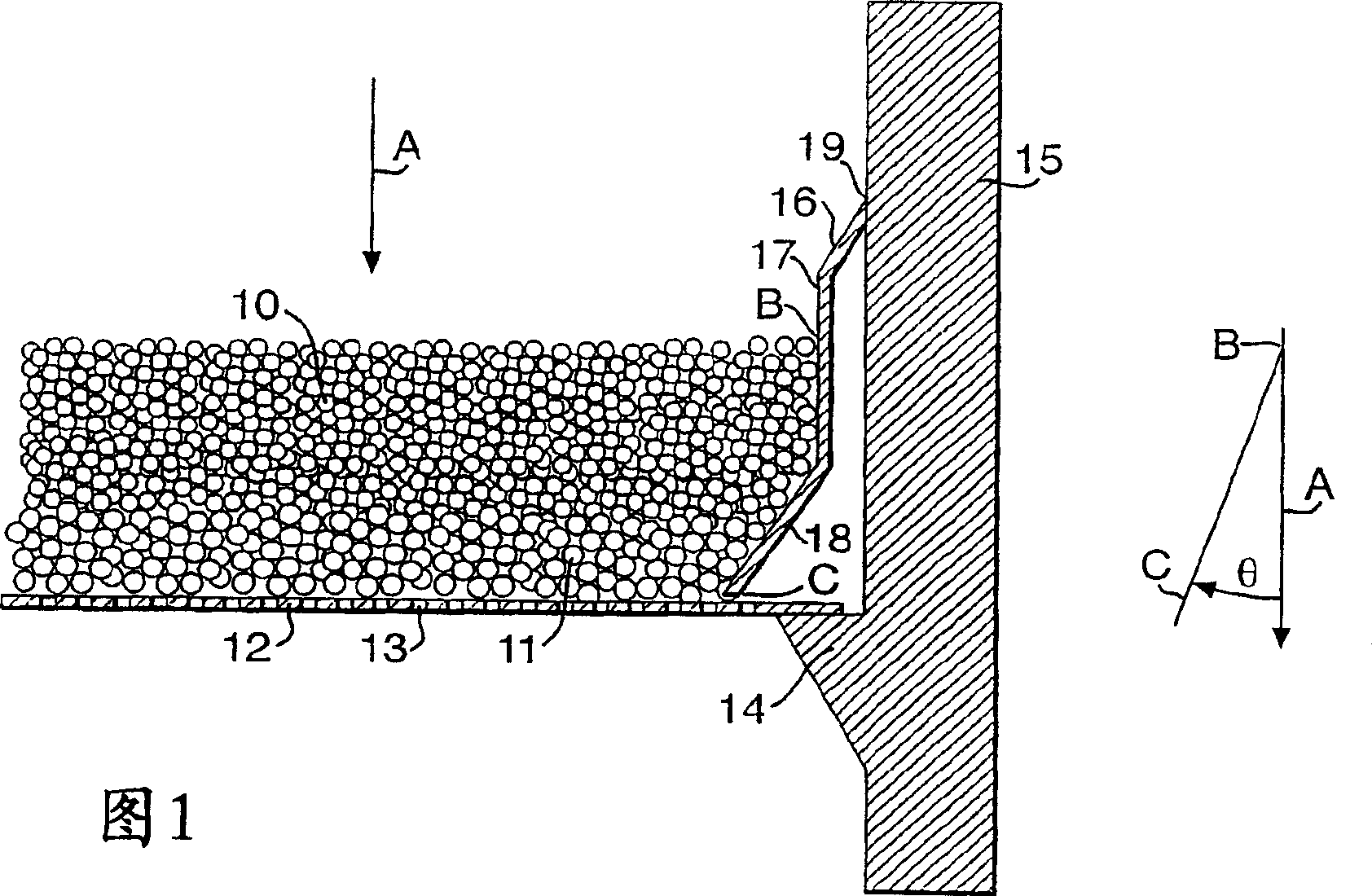

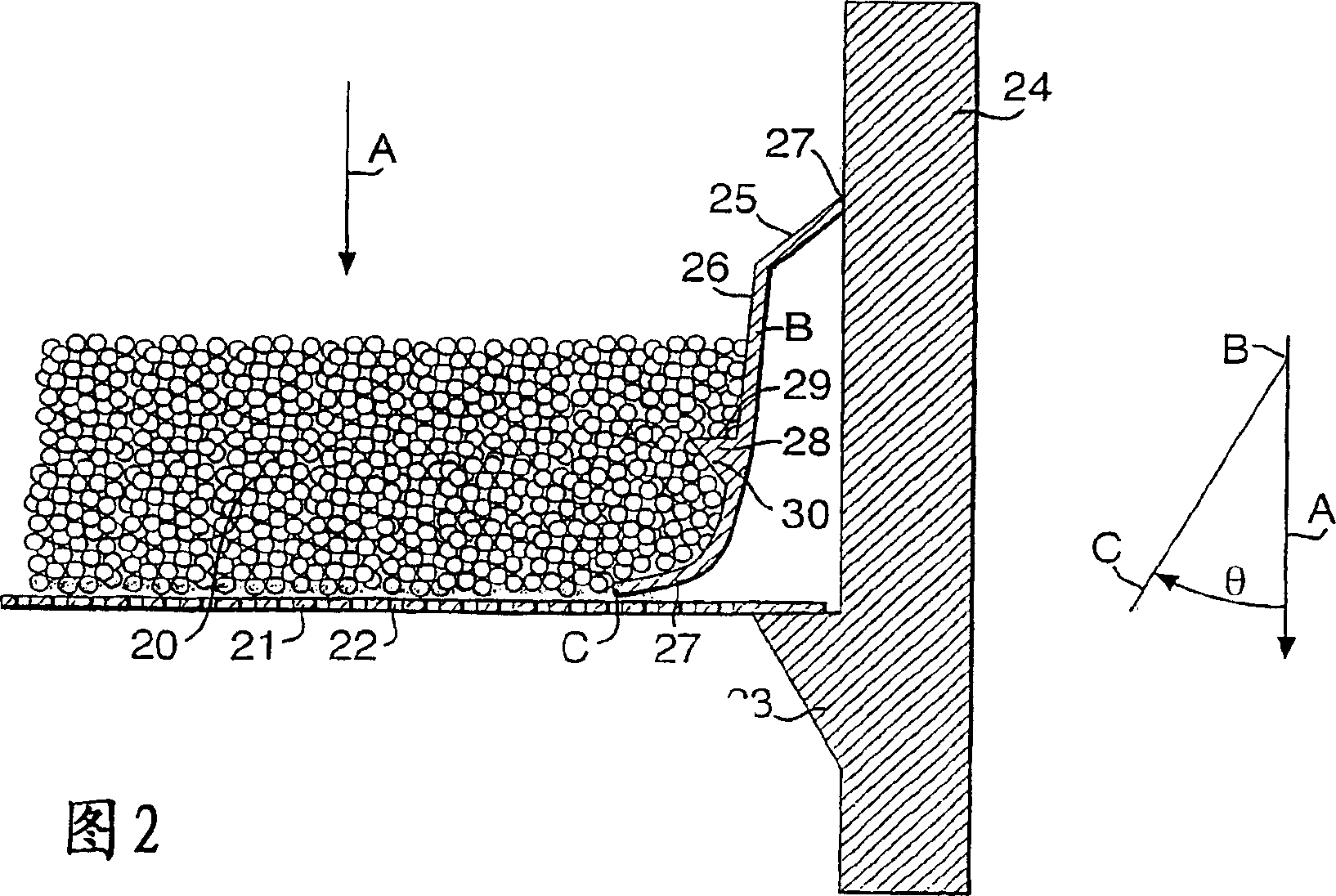

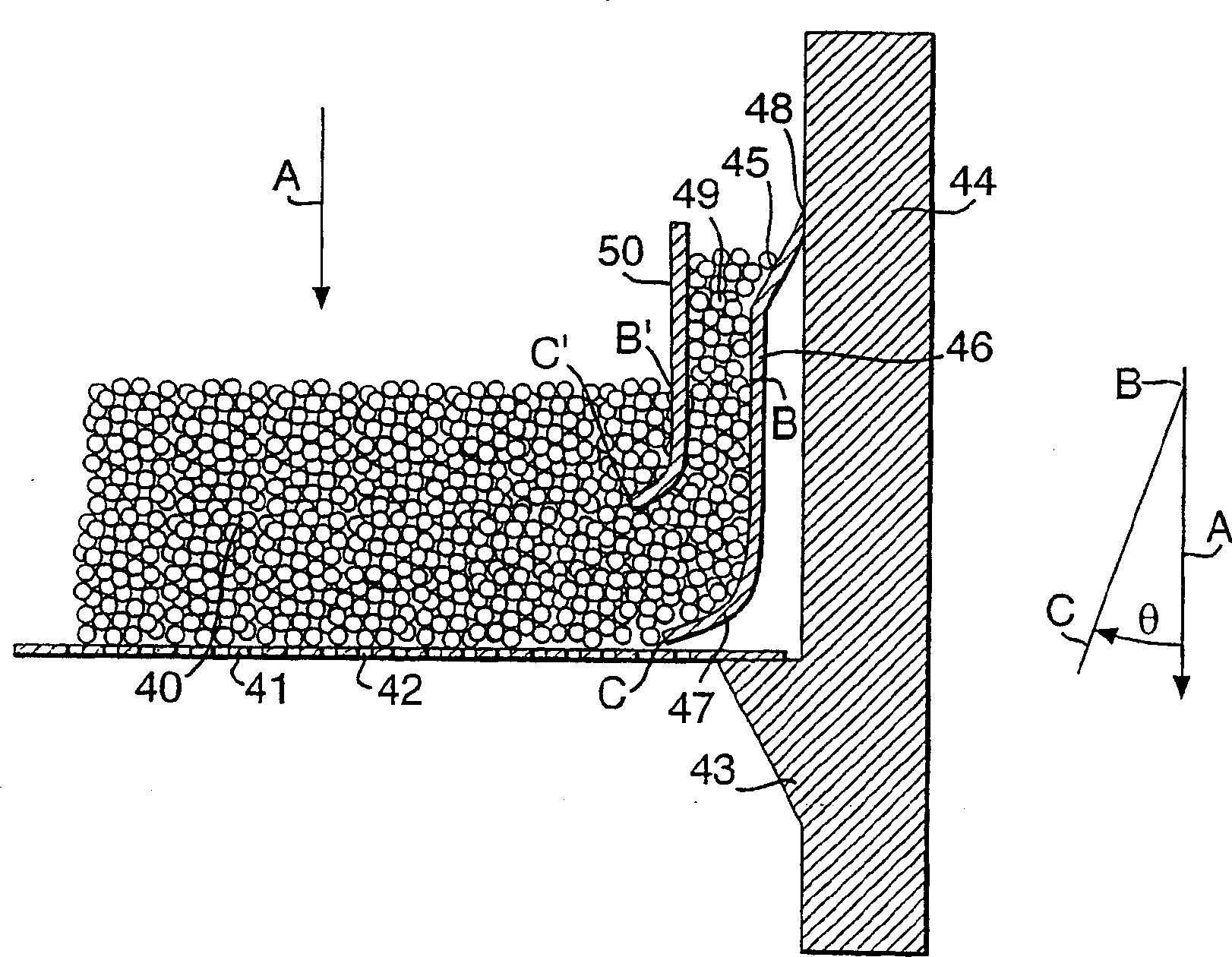

Catalyst or sorbent beds

InactiveCN1545434AReduce the possibility of bypassingSolid sorbent liquid separationHydrogen/synthetic gas productionParticulatesSorbent

A fixed bed containing a particulate catalyst or sorbent material (10) subject to operation at high temperature having a shaped boundary member (16) inclined to the direction of fluid flow through the bed that maintains the depth of said catalyst or sorbent at the boundary of the bed through a series of thermal expansion-thermal contraction cycles is described. By maintaining bed depth, the shaped boundary member (16) can prevent bypass of, e.g. ammonia through a bed of particulate ammonia oxidation catalyst.

Owner:JOHNSON MATTHEY PLC

Popular searches

Group 5/15 element organic compounds Organic-compounds/hydrides/coordination-complexes catalysts Organic chemistry methods Catalytic reactions Preparation by carbon monoxide reaction Preparation by hydrogen cyanide addition Chemical industry Solid fuel combustion Chemical/physical/physico-chemical stationary reactors Stationary tubular conduit assemblies

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com