Catalytic membrane reactor with two component three dimensional catalysis

A catalytic membrane reactor, catalyst technology, applied in the reaction of gas and gas under the catalytic active body, chemical/physical/physicochemical fixed reactor, heterogeneous catalyst chemical elements, etc., can solve the problem of affecting reaction products, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

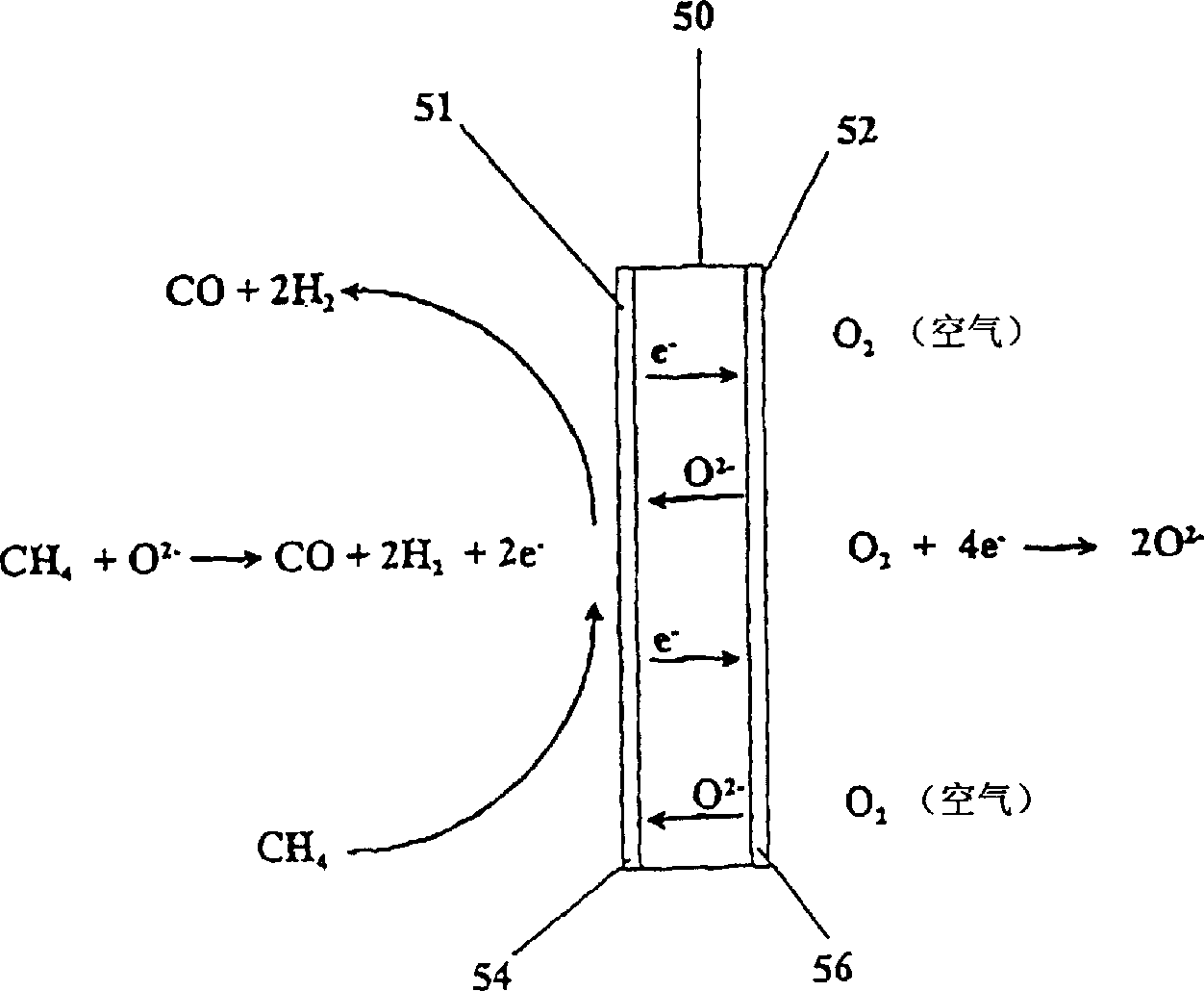

[0111] Example 1: Production of synthesis gas in a reactor with and without bonded catalyst layers.

[0112] By chemical formula Sr 1.7 La 0.3 Ga 0.6 Fe 1.4 o 5.15 A single-phase material for the fabrication of tubular membranes with one end closed. The powder of this composition is firstly prepared by conventional solid-state synthesis method, specifically as described in PCT / US96 / 14841 and Example 5. This single-phase powder was pressed into a tube shape by isostatic pressing method, followed by sintering to obtain a dense and strong tubular membrane. The grinding and sintering steps can be repeated, if desired, to ensure that the material is a single phase prior to isostatic pressing to form the tube.

[0113] Coating a layer of La on the inner surface (reducing surface) of the tubular membrane 0.8 Sr 0.2 CoO 3 (LSC) used as an oxidation / reduction catalyst; or coated with a metal on the oxidation / reduction catalyst, such as 5% by weight Pd on LSC.

[0114] The ou...

Embodiment 2

[0119] Example 2: Syngas Production in Reactors with and without Packed Bed Catalysts

[0120] Same as embodiment 1, by chemical formula Sr 1.7 La 0.3 Ga 0.6 Fe 1.4 o 5.15 A single-phase material for the fabrication of tubular membranes with one end closed.

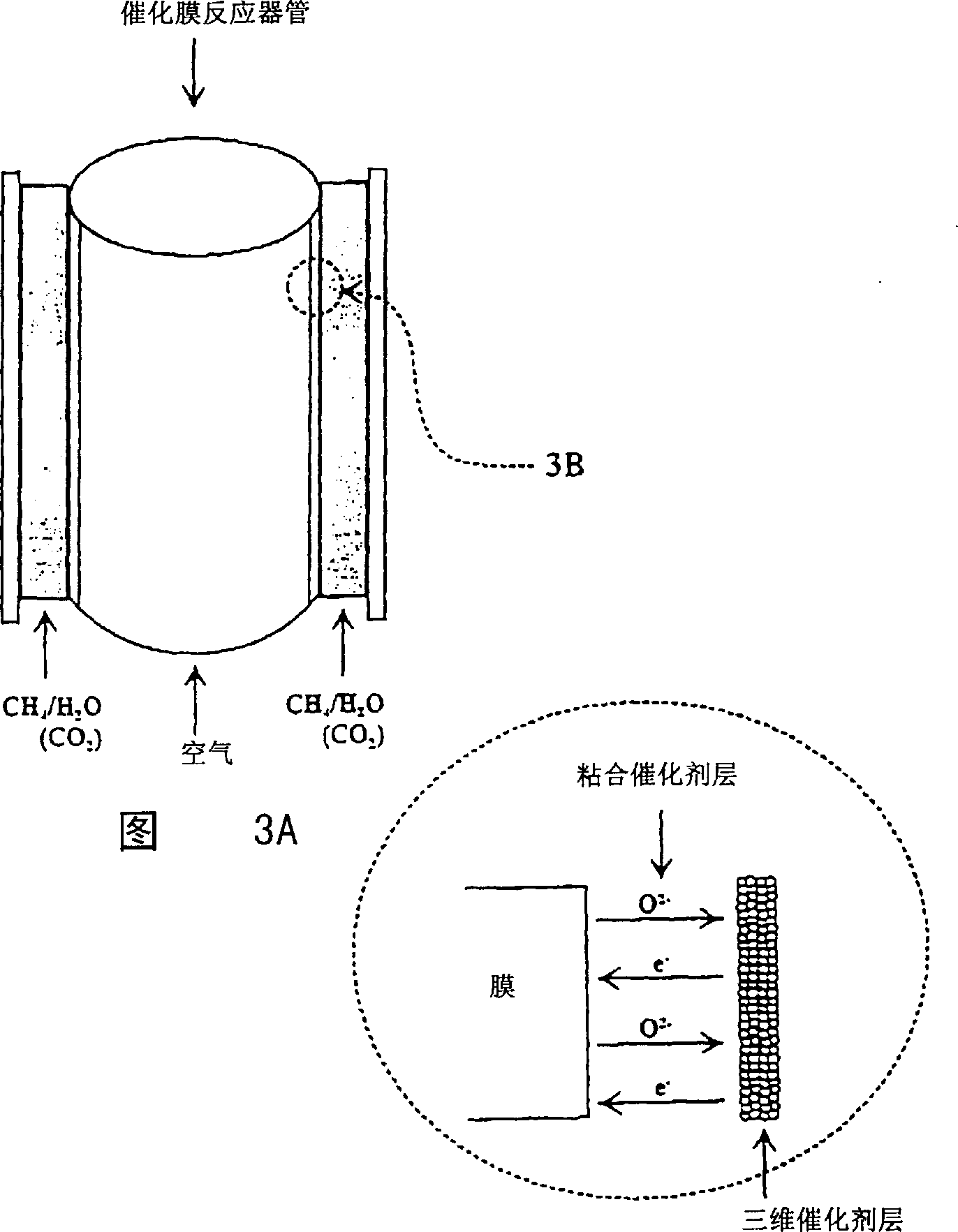

[0121] A layer of La was coated on the inner surface of the tubular membrane 0.8 Sr 0.2 COO 3 (LSC) was used as a redox catalyst. Adhesive catalyst coated on the outer surface of the tubular membrane: at La 0.8 Sr 0.2 MnO 3 Ni on (20% by weight).

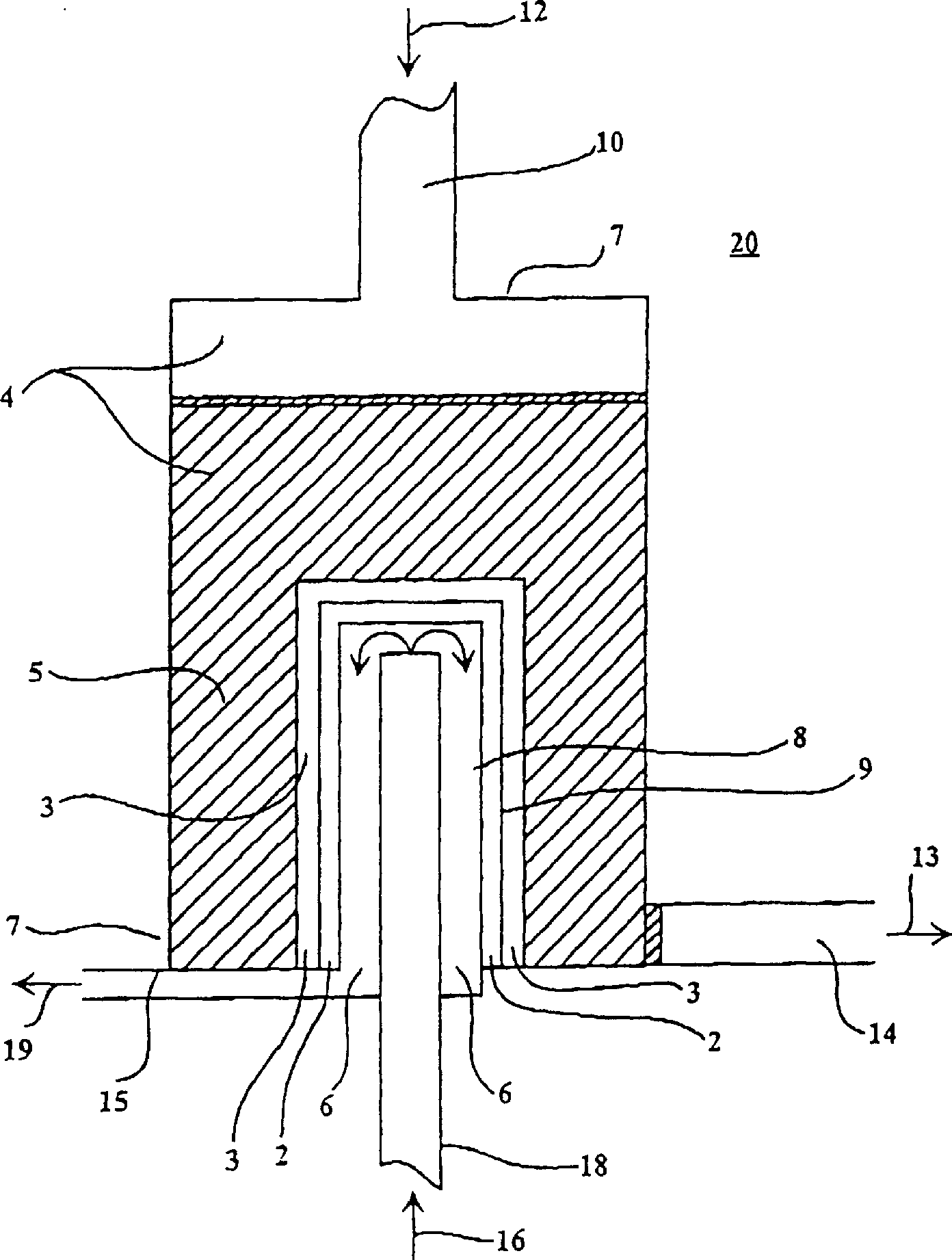

[0122] exist figure 1 The synthesis gas reactor shown compares tubular membranes. One reactor is supplied with Al in its oxidation zone 2 o 3 A packed bed of granules that were previously coated with La 0.8 Sr 0.2 MnO 3 Powder with Ni (10% by weight) on top: while one reactor had no packed bed. In both cases, air was used as the oxygen-containing gas passing through the interior of the tubular membranes and an 80% by volume methane mixture in helium was used ...

Embodiment 3

[0126] Example 3: Syngas production in reactors with different bonded catalyst layers

[0127] As described in Example 1, by chemical formula Sr 1.7 La 0.3 Ga 0.6 Fe 1.4 o 5.15 A single-phase material for the fabrication of tubular membranes with one end closed.

[0128] The inner surface of the tubular membrane is coated with a layer of La 0.8 Sr 0.2 COO 3 Used as a redox catalyst.

[0129] The outer surface of a tubular membrane is coated with La 0.8 Sr 0.2 MnO 3 . The outer surface of another tubular membrane was coated with La with Ni (20% by weight) on it. 0.8 Sr 0.2 MnO 3 . These two catalysts were used as the bonded catalyst layers on the oxidized surfaces of the two membranes, respectively.

[0130] in such as figure 1 The synthesis gas reactor shown compares tube membranes with different bonded catalyst layers. In both cases, the reactor was supplied with Al coated with Ni (5% by weight) in its oxidation zone. 2 o 3 Particle packed bed. Both used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com