Metal supported catalyst and HCN synthesis method

A supported catalyst and metal technology, which is applied in the field of plasma chemical synthesis, can solve unrelated problems and achieve the effects of simple process, green method and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

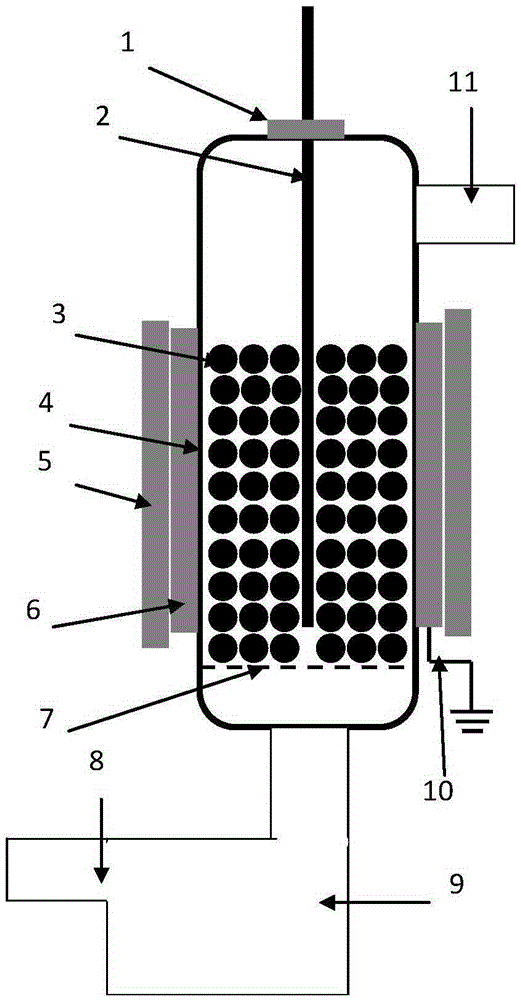

Embodiment 1

[0033] Repeat comparative example 1, the iron catalyst (expressed as Fe / SiO 2) is filled in the discharge area of the wire barrel type dielectric barrier discharge plasma reactor. The catalyst particles were of irregular shape (20-40 mesh) with an active ingredient loading of 10% by weight based on elemental iron (Fe). The discharge parameters are set as follows: discharge voltage 13kV (peak-peak value), discharge frequency 12kHz, high-voltage power supply 35W. After the reaction was stabilized, the wall temperature of the reactor was stabilized at 300°C. At this time, CH 4 Conversion rate 10%, HCN selectivity 45%.

Embodiment 2

[0035] Repeat Example 1, the platinum catalyst (expressed as Pt / SiO 2 ) is filled in the discharge area of the wire barrel type dielectric barrier discharge plasma reactor. The catalyst particles were of irregular shape (20-40 mesh) with an active ingredient loading of 2% by weight based on elemental platinum (Pt). The discharge parameters are set as follows: discharge voltage 13kV (peak-peak value), discharge frequency 12kHz, high-voltage power supply 34W. After the reaction was stabilized, the wall temperature of the reactor was stabilized at 300°C. At this time, CH 4 Conversion rate 9%, HCN selectivity 70%.

Embodiment 3

[0037] Example 1 was repeated, with 6 g of silica-supported sodium catalyst (expressed as Na / SiO 2 ) is filled in the discharge area of the wire barrel type dielectric barrier discharge plasma reactor. The catalyst particles were of irregular shape (20-40 mesh) with an active ingredient loading of 10% by weight expressed as elemental sodium (Na). The discharge parameters are set as follows: discharge voltage 13kV (peak-peak value), discharge frequency 12kHz, high-voltage power supply 36W. After the reaction was stabilized, the wall temperature of the reactor was stabilized at 300°C. At this time, CH 4 Conversion rate 6%, HCN selectivity 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com