Process and system for preparing high-purity liquid hydrogen cyanide

A hydrogen cyanide, liquid state technology, applied in the field of high-purity liquid hydrogen cyanide production process and system, can solve the problems of inability to meet the use requirements of downstream users and high water content, and achieve the benefits of safe production, smooth production, and alleviation of environmental protection. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

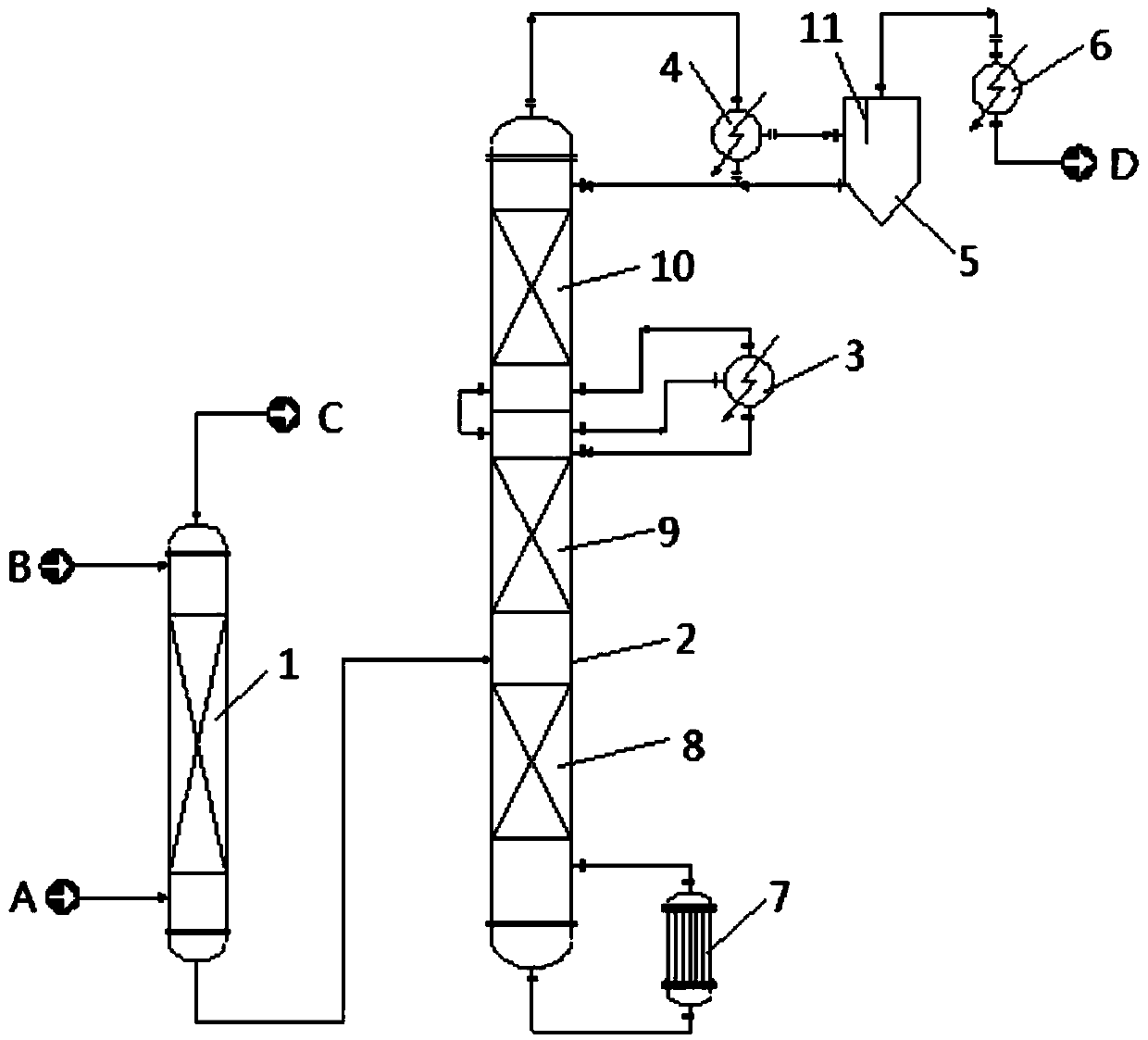

[0030] The gas A containing hydrogen cyanide at 30°C enters the absorption tower 1, and the low-temperature water B at 10°C is sprayed into the top of the absorption tower 1. After absorption, a 3% HCN aqueous solution is obtained in the tower reactor, and the tail gas C after absorption is sent to the top of the tower. into the tail gas absorption device for treatment. The HCN aqueous solution is sent into the three-section rectifying tower 2 for separation and purification, and the HCN aqueous solution is fed between the lower tower 10 and the middle tower 9, and enters the upper tower 8 through the middle tower 9 and the middle condenser 3, and the middle tower 9 part reflux ratio is 10. Finally, the HCN gas is evaporated from the top of the tower, and then enters the reflux condenser 4 and the gas-liquid separator 5, wherein the gas-liquid separator 5 has a baffle 11 that is conducive to the separation of water vapor, and the partially condensed liquid phase is returned to ...

Embodiment 2

[0032] The gas A containing hydrogen cyanide at 40°C enters the absorption tower 1, and the low-temperature water B at 8°C is sprayed into the top of the absorption tower 1. After absorption, a 2.8% HCN aqueous solution is obtained in the tower kettle, and the tail gas C after absorption is sent from the top of the tower. into the tail gas absorption device for treatment. The HCN aqueous solution is sent into the three-section rectifying tower 2 for separation and purification, and the HCN aqueous solution is fed between the lower tower 10 and the middle tower 9, and enters the upper tower 8 through the middle tower 9 and the middle condenser 3, and the middle tower 9 part reflux ratio is 10. Finally, the HCN gas is evaporated from the top of the tower, and then enters the reflux condenser 4 and the gas-liquid separator 5, wherein the gas-liquid separator 5 has a baffle 11 that is conducive to the separation of water vapor, and the partially condensed liquid phase is returned t...

Embodiment 3

[0034] The gas A containing hydrogen cyanide at 20°C enters the absorption tower 1, and the low-temperature water B at 15°C is sprayed into the top of the absorption tower 1, and 2.5% HCN aqueous solution is obtained in the tower kettle after absorption, and the tail gas C after absorption is sent from the top of the tower into the tail gas absorption device for treatment. The HCN aqueous solution is sent into the three-section rectifying tower 2 for separation and purification, and the HCN aqueous solution is fed between the lower tower 10 and the middle tower 9, and enters the upper tower 8 through the middle tower 9 and the middle condenser 3, and the middle tower 9 part reflux ratio is 10. Finally, the HCN gas is evaporated from the top of the tower, and then enters the reflux condenser 4 and the gas-liquid separator 5, and the partially condensed liquid phase returns to the tower as reflux, with a reflux ratio of 15, and the uncondensed HCN gas enters the finished product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com