Acid preparing method by coal gas wet oxidation and desulfurization

A wet oxidative desulfurization and sulfur trioxide technology, which is applied to the preparation/purification/separation of sulfur trioxide/sulfuric acid and hydrogen cyanide, etc., can solve the problems of high corrosion of desulfurization waste liquid, unfavorable industrial production, and large environmental impact , to achieve strong applicability and promotion value, increase utilization value, and improve the effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

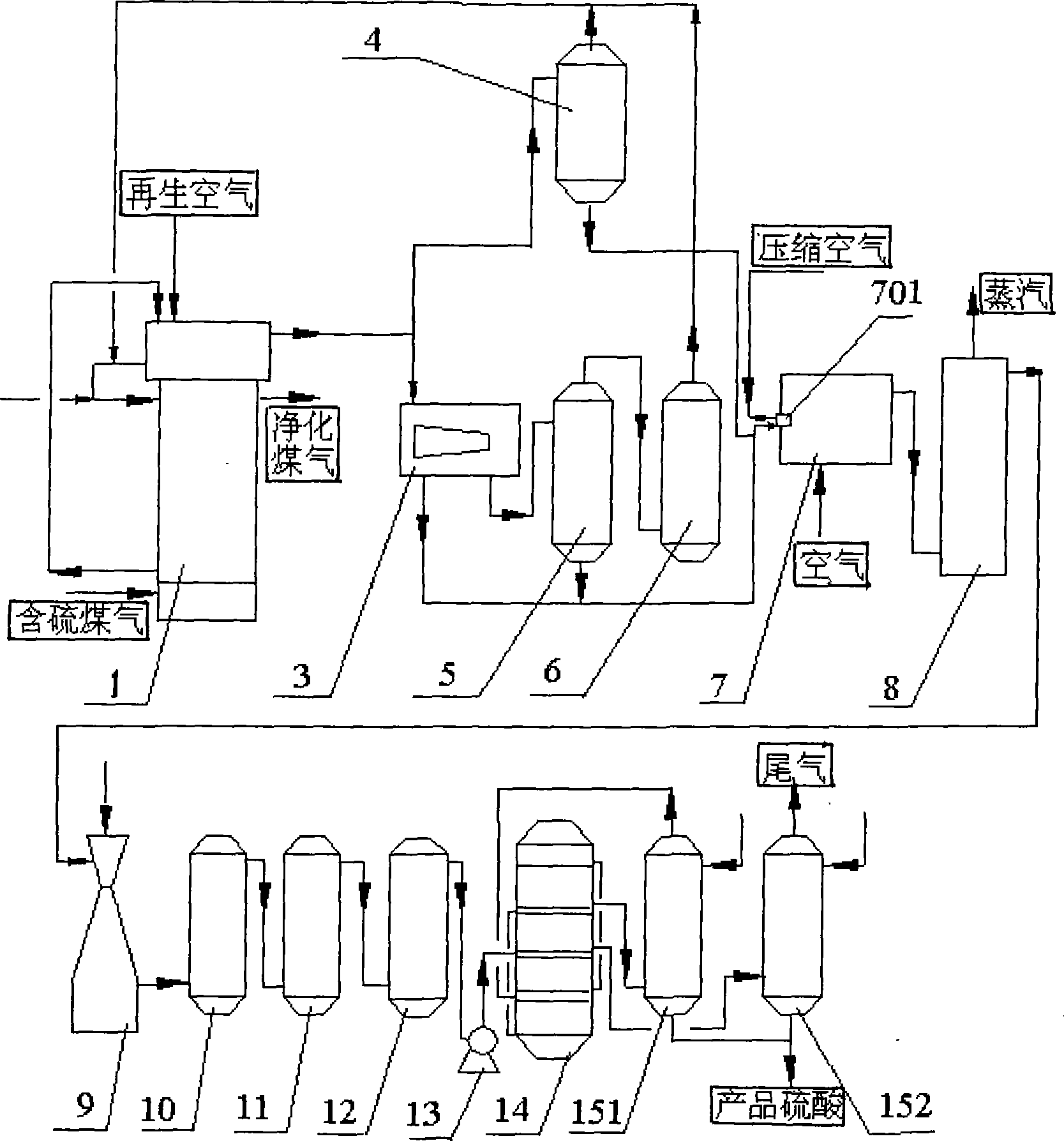

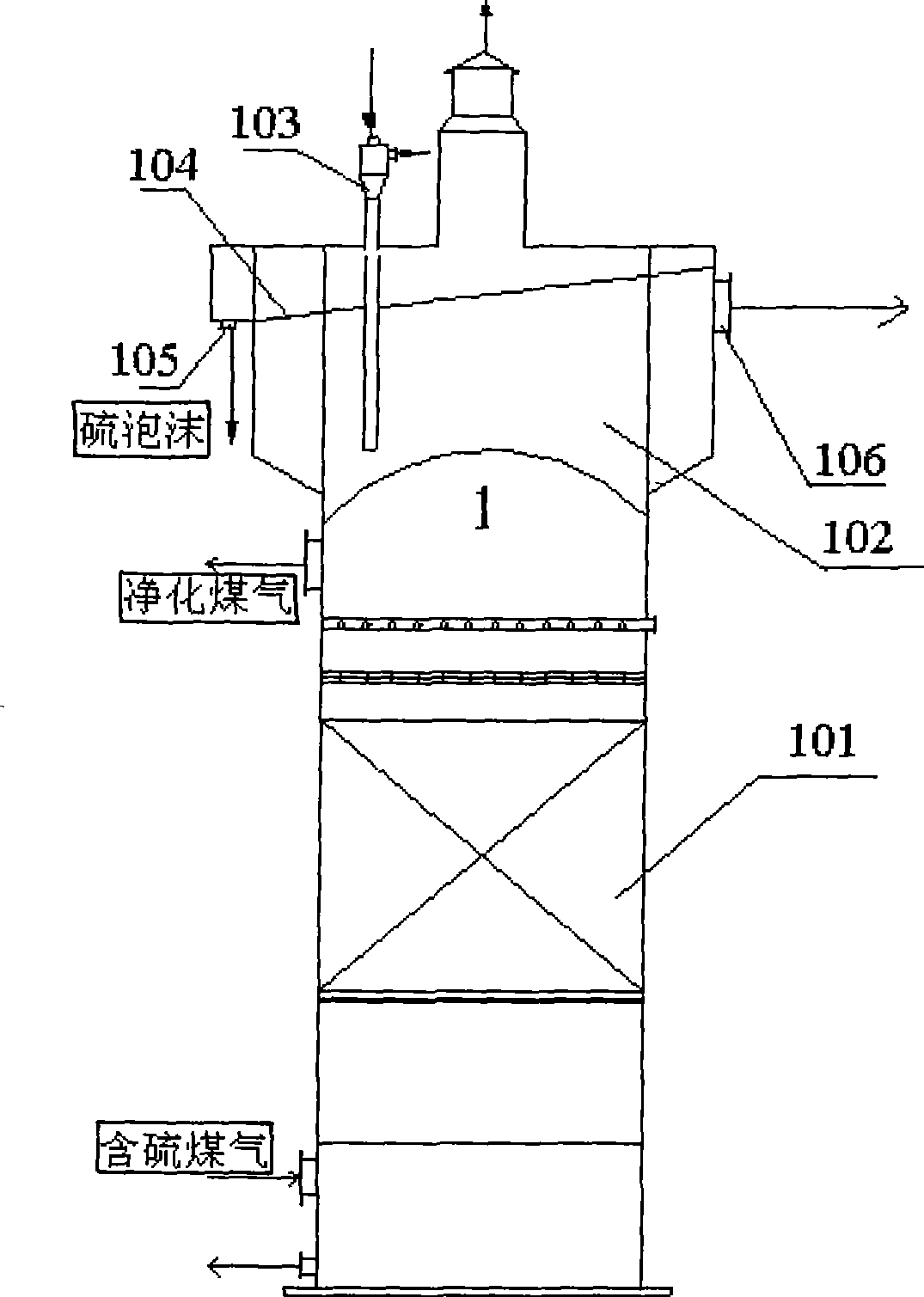

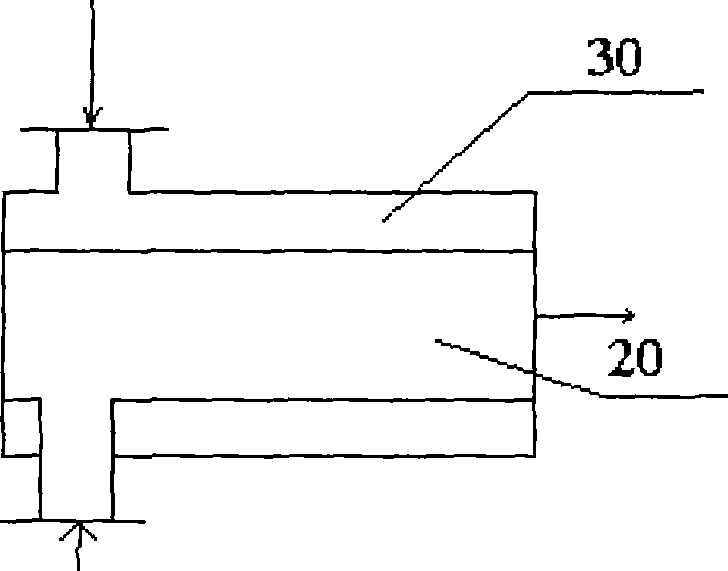

[0063] use figure 1 process, figure 2 desulfurization regeneration tower, image 3 the nozzle and Figure 4 the converter. The basic process conditions are as follows:

[0064] Composition and content of sulfur-containing gas:

[0065] Hydrogen sulfide 8g / m 3 , hydrogen cyanide 2g / m 3 , hydrogen 35g / m 3 , carbon monoxide 5g / m 3 , methane 30g / m 3 , carbon dioxide 1g / m 3 .

[0066] The composition and concentration of desulfurization lean solution are as follows:

[0067] The ammoniacal liquor contains ammonia 18 grams per liter, the pH value is 9.5, the catalyst is hydroquinone and phthalocyanine cobalt sulfonate metal organic compound, and the weight content of the catalyst is 5 grams per liter;

[0068] The absorption temperature is 40°C and the absorption pressure is 15Kpa;

[0069] The ratio of sulfur-containing gas to desulfurized lean liquid is: 50 standard meters 3 Sulfur-containing gas / liter desulfurized lean liquid;

[0070] Such as figure 1 , the sulf...

Embodiment 2

[0089] use figure 1 process, figure 2 desulfurization regeneration tower, image 3 the nozzle and Figure 4 the converter. The basic process conditions are as follows:

[0090] Composition and content of sulfur-containing gas:

[0091] Hydrogen sulfide 1g / m 3 , hydrogen cyanide 1g / m 3 , hydrogen 60g / m 3 , carbon monoxide 60g / m 3 , methane 1g / m 3 , carbon dioxide 20g / m 3 .

[0092] The composition and concentration of desulfurization lean solution are as follows:

[0093] Sodium carbonate 0.5N, (normal concentration), pH value is 8.5, catalyst is 1,4-naphthoquinone-2-sodium sulfonate, and the weight content of catalyst is 3%;

[0094] The absorption temperature is 25°C and the absorption pressure is 10Kpa;

[0095] The ratio of sulfur-containing gas to desulfurized lean liquid is: 40 standard meters 3 Sulfur-containing gas / liter desulfurized lean liquid;

[0096] Such as figure 1 , the sulfur-containing gas is passed into the desulfurization regeneration tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com