Catalyst or sorbent beds

A fixed bed and element technology, applied in solid adsorbent liquid separation, cyanide, inorganic chemistry, etc., can solve the problem of reducing the contact time between fluid and catalyst or adsorbent, and achieve the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

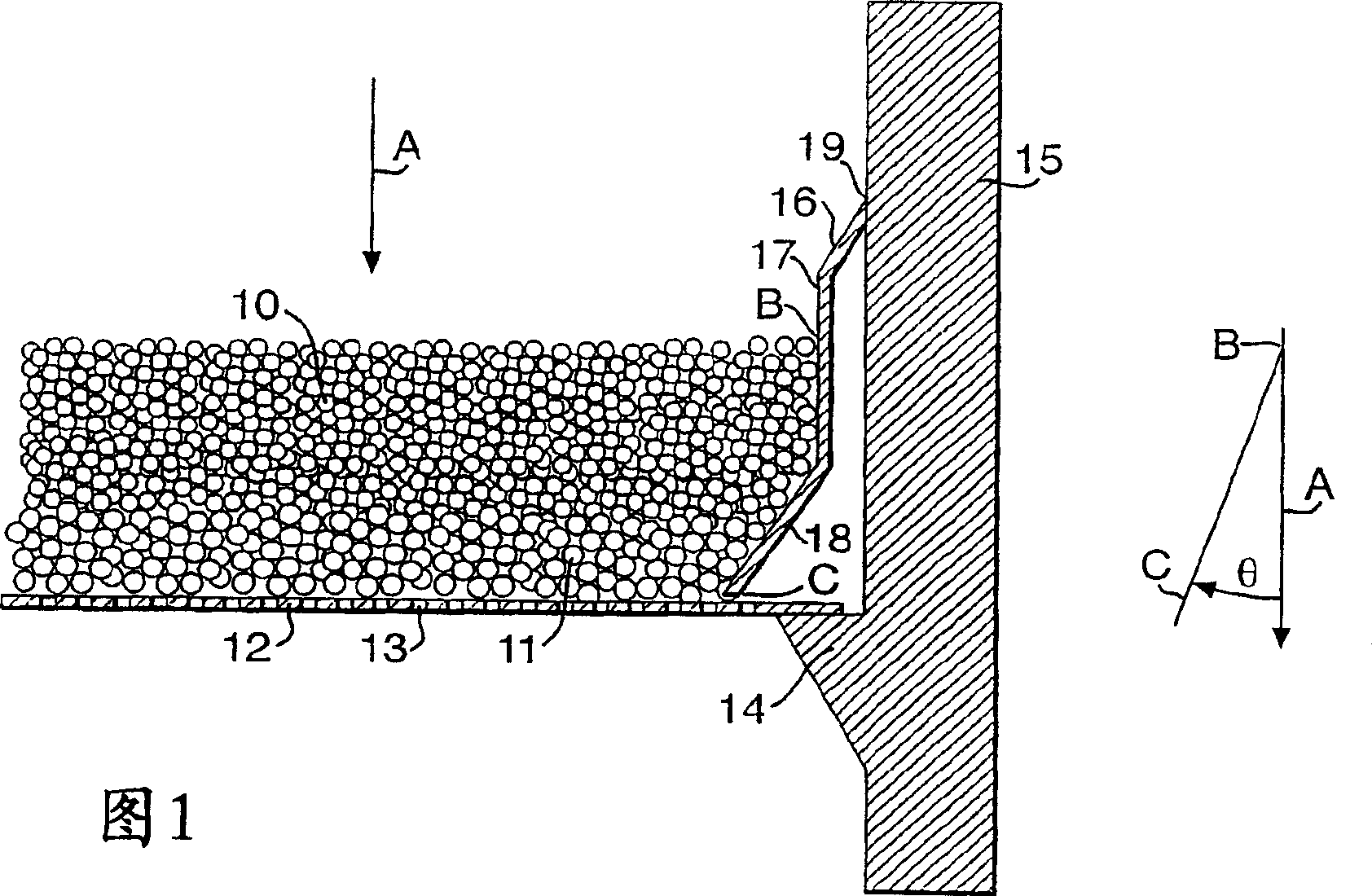

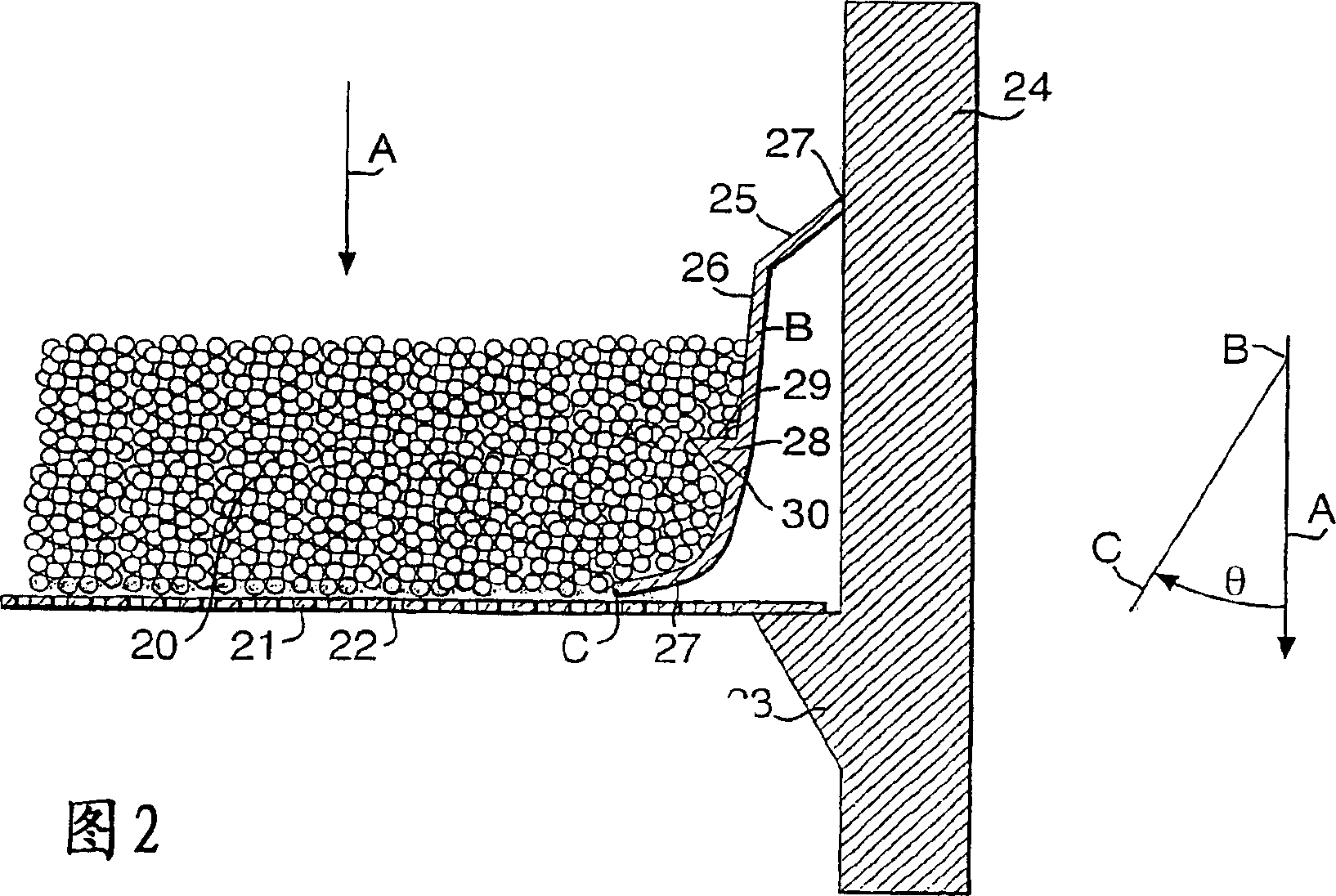

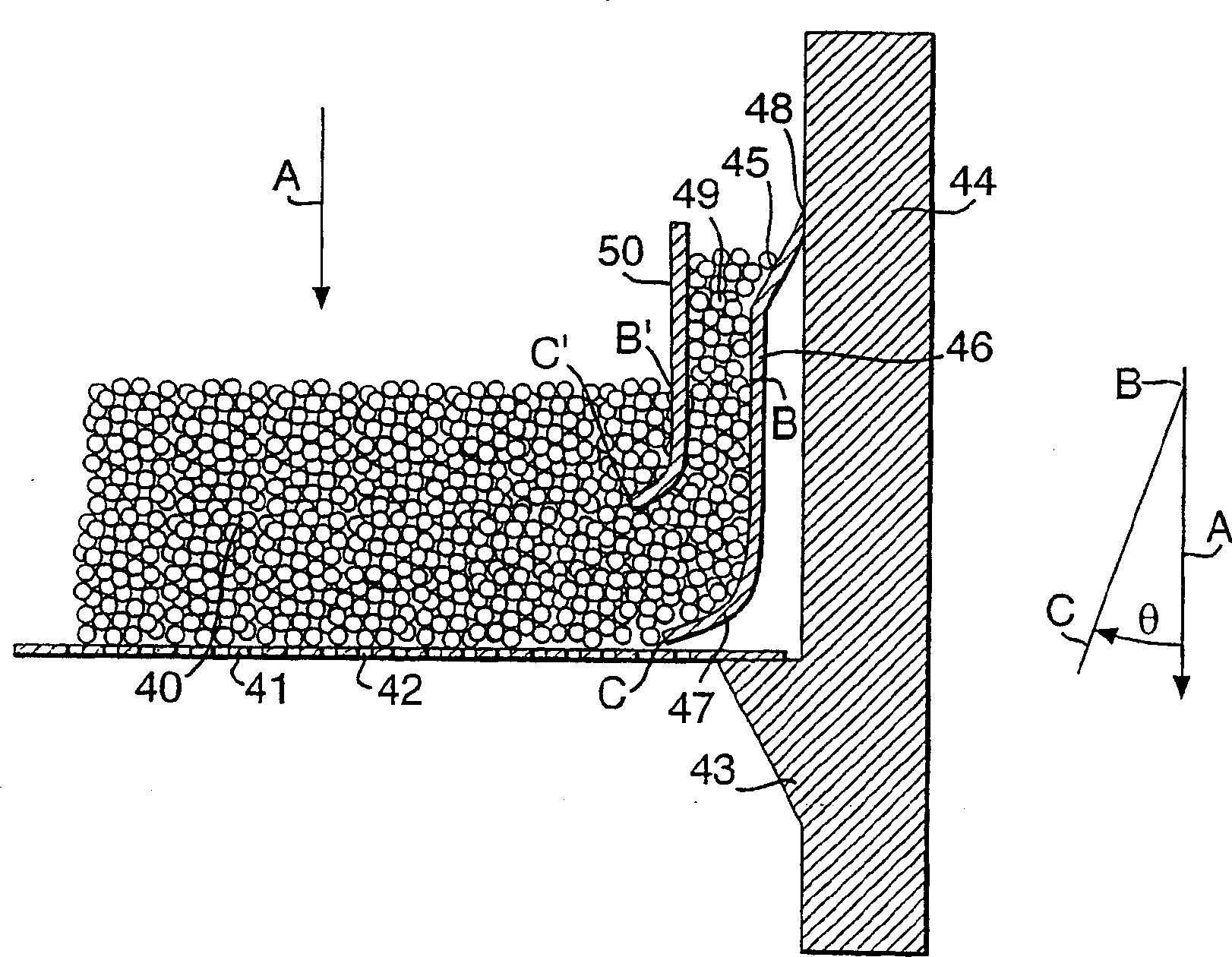

[0030] In Figures 1, 2 and 3, the direction of treatment fluid flow through the majority of the bed is indicated by arrow "A", which direction is substantially vertical. For clarity, Figures 1, 2, and 3 show the direction of treatment fluid flow through the majority of the bed (A) and the line drawn between the lower end of the boundary element (C) and the surface of the bed (B). The total angle (θ) of .

[0031] Referring to the drawings, Figure 1 shows a catalyst bed for example for ammoxidation. The bed is provided by a layer of cobalt-containing catalyst particles 10 on a layer of relatively large size inert alumina particles 11 disposed on a perforated element 12 having holes 13 enabling gas to flow through the bed. The bed is supported by perforated elements 12 which rest against lugs 14 connected to the container wall 15 .

[0032] The boundary elements include straight facets 16 , 17 and 18 that prevent the bed 10 from contacting the vessel wall 15 . The facet 16 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com