Novel process for reclaiming waste water containing CN- and NH3 or NH4-

A waste water and acid waste water technology, which is applied in the new process field of resource recycling containing CN- and NH3 or NH4+ waste water, can solve the problems of no export value, cannot be reused, and high processing cost, and achieves low equipment investment and operating costs, absorption and absorption. The effect of improved recycling efficiency and process economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

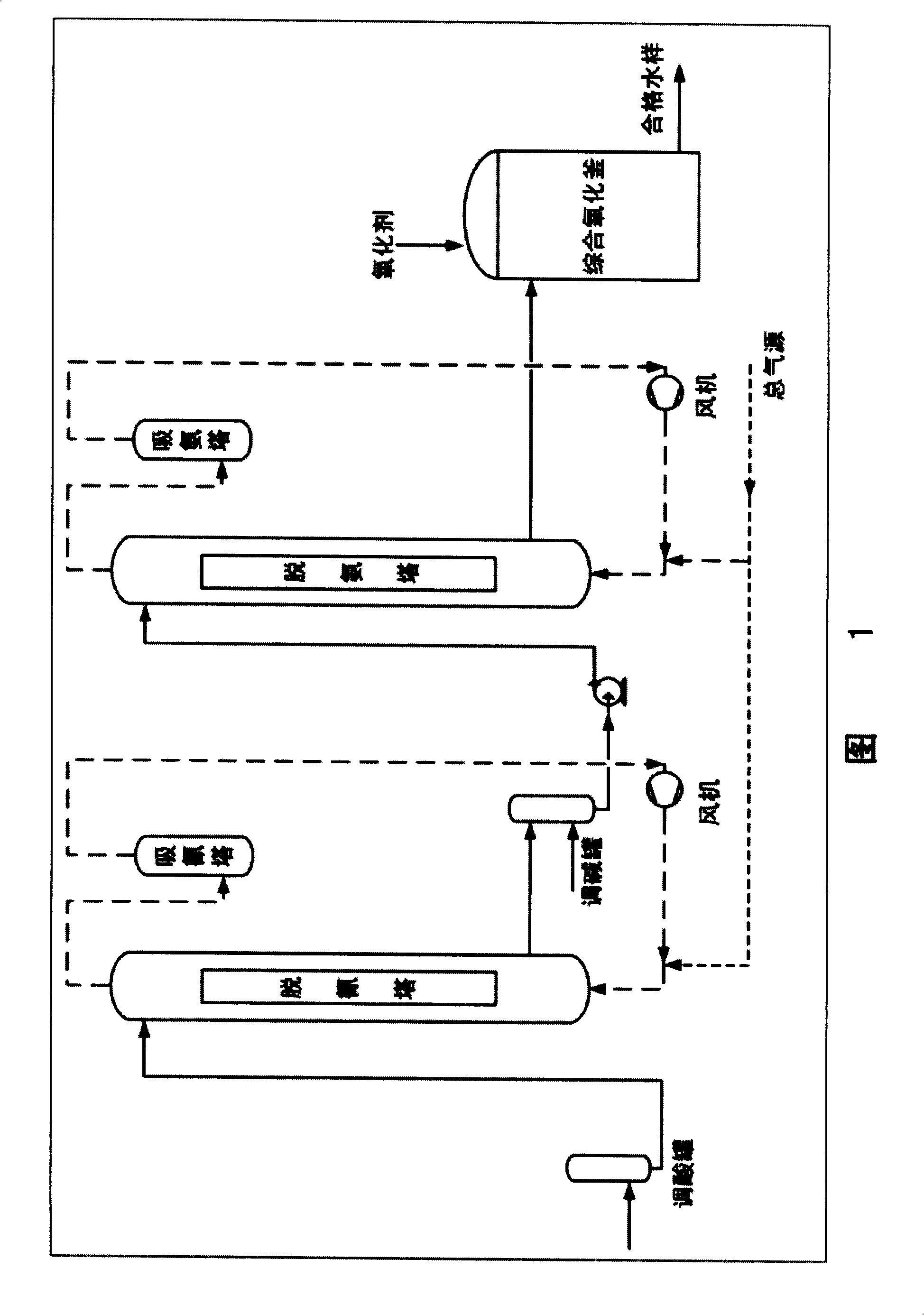

[0023] According to the flow process shown in Figure 1, the high-salt cyanuric chloride-containing ammonium-containing sodium formate wastewater (containing CN - : 800mg / L, NH 4 + -N: 1200mg / L, NaCl: 200000mg / L, HCOONa: 1200mg / L, pH: 8.0) sent to the decyanation tower, added hydrochloric acid to adjust the pH value to 2.0, and the gas-liquid ratio was 250:1 (m 3 / m 3 ) air is blown off, and the air entrained with HCN after the blow off returns to the decyanation tower after the sodium hydroxide solution absorbs HCN. After stripping, the concentration of cyanide in the wastewater dropped from 800mg / L at the beginning to 20mg / L, and the stripping rate was 97.5%. The total amount of cyanide in the absorption tower was 7640mg, and the absorption rate was 97.4%.

[0024] The waste water that comes out from the decyanation tower adds sodium hydroxide to adjust the pH value to 11.5, and sends it into the deamination tower with a gas-liquid ratio of 900:1 (m 3 / m 3 ) air to blow ...

Embodiment 2

[0027] According to the flow process shown in Figure 1, the high-salt cyanuric chloride-containing ammonium-containing sodium formate wastewater (containing CN - : 800mg / L, NH 4 - -N: 1200mg / L, NaCl: 200000mg / L, HCOONa: 1200mg / L, pH: 8.0) sent to the decyanation tower, added hydrochloric acid to adjust the pH value to 6.0, and the gas-liquid ratio was 250:1 (m 3 / m 3 ) air is blown off, and the air entrained with HCN after the blow off returns to the decyanation tower after the sodium hydroxide solution absorbs HCN. After stripping, the concentration of cyanide in the wastewater dropped from 800mg / L at the beginning to 40mg / L, and the stripping rate was 95%. The total amount of cyanide in the absorption tower was 7334mg, and the absorption rate was 96.5%.

[0028] Add sodium hydroxide to the wastewater from the decyanation tower to adjust the pH value to 10.5, and send it to the deamination tower with a gas-liquid ratio of 900:1 (m 3 / m 3 ) air to blow off, the entrained ...

Embodiment 3

[0031] According to the process shown in Figure 1, CN will be included - : 800mg / L, CaCl 2 : 20000mg / L, NH 4 Cl: 8000mg / L, pH: 3.0 waste water is sent to the decyanation tower, and the gas-liquid ratio is 200:1 (m 3 / m 3 ) air is blown off, and the air entrained with HCN after the blow off returns to the decyanation tower after the potassium hydroxide solution absorbs HCN. After stripping, the concentration of cyanide in the wastewater dropped from 800mg / L at the beginning to 10mg / L, and the stripping rate was 98.8%. The total amount of cyanide in the absorption tower was 7750mg, and the absorption rate was 98.1%.

[0032] The waste water that comes out from the decyanation tower adds calcium hydroxide to adjust the pH value to 11.5, and sends it into the deamination tower with a gas-liquid ratio of 1000:1 (m 3 / m 3 ) air to blow off, the entrained NH after blow off 3 The air absorbs NH by acetic acid 3 Then return to the deamination tower. After stripping, the concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com