Patents

Literature

84 results about "Hydroxyacetonitrile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

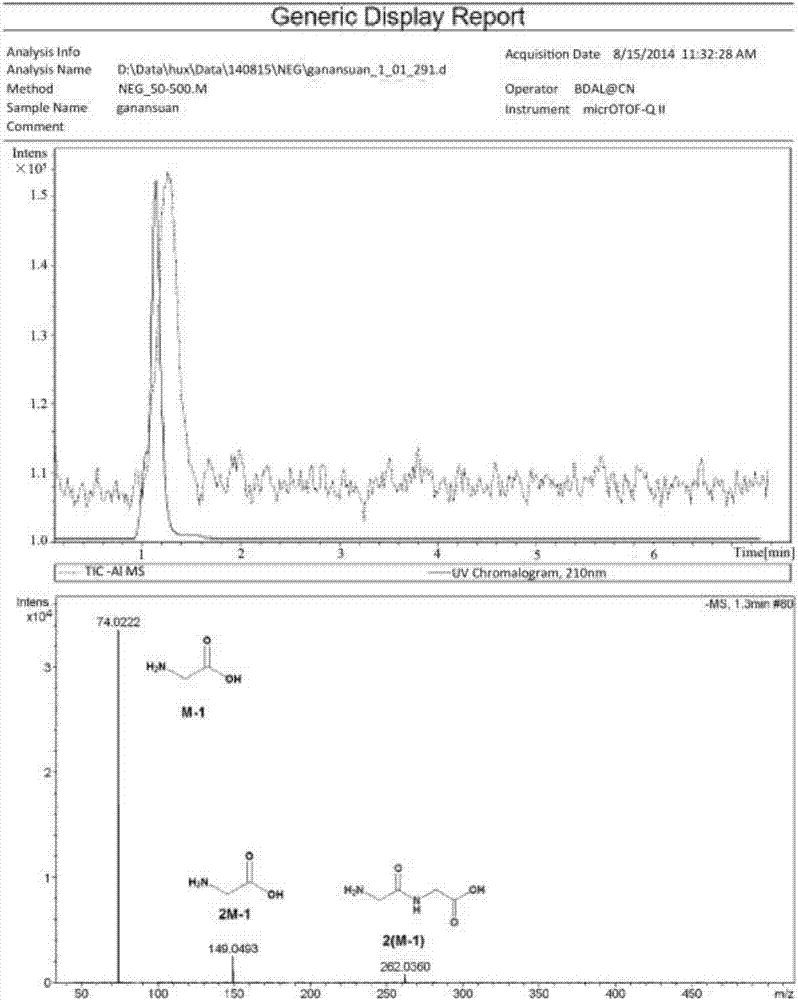

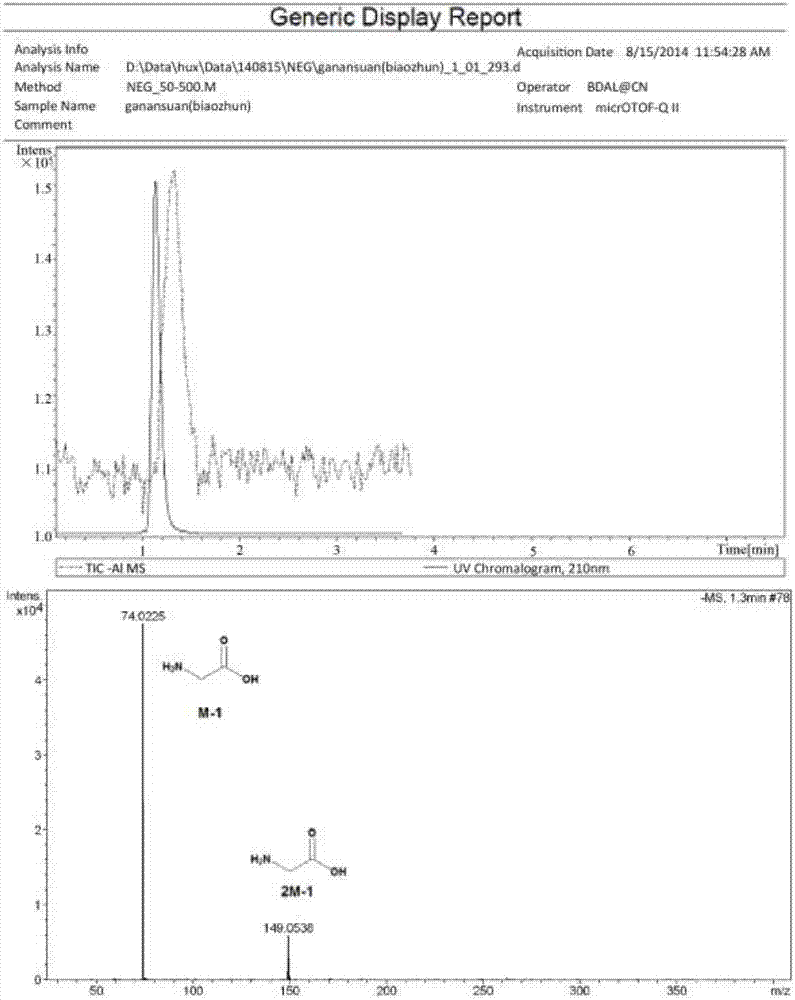

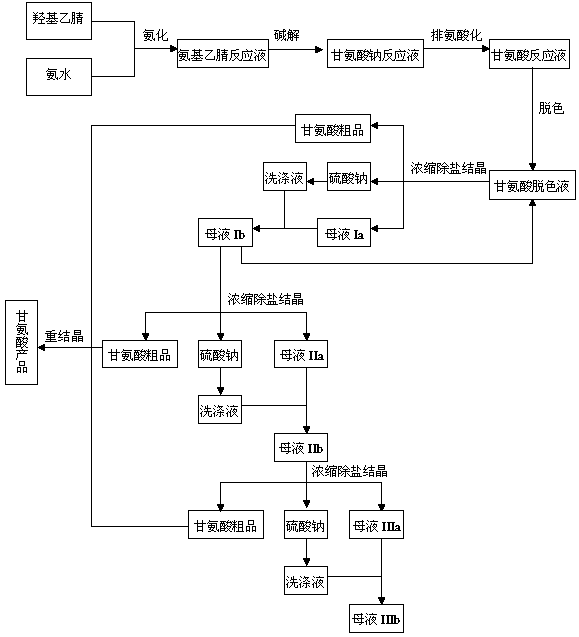

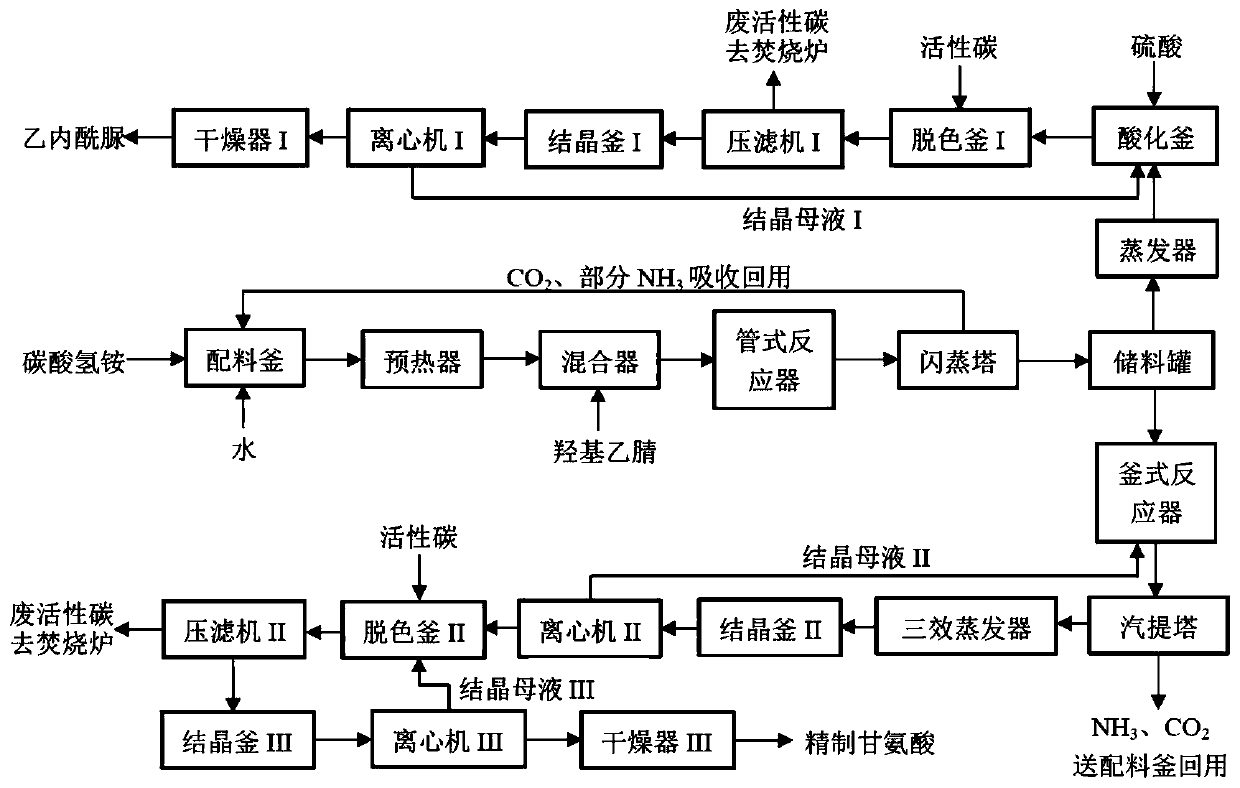

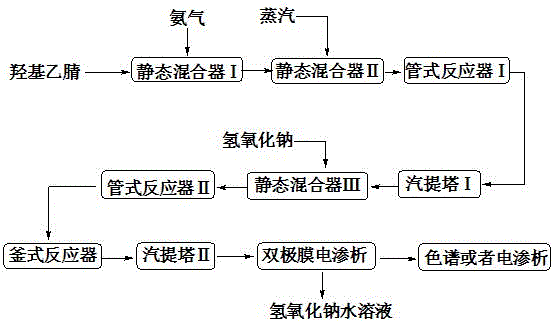

Preparation process of glycine

InactiveCN102432478AReduce pyrolysis polymerizationHigh yieldOrganic compound preparationAmino-carboxyl compound preparationReaction temperatureAlkaline hydrolysis

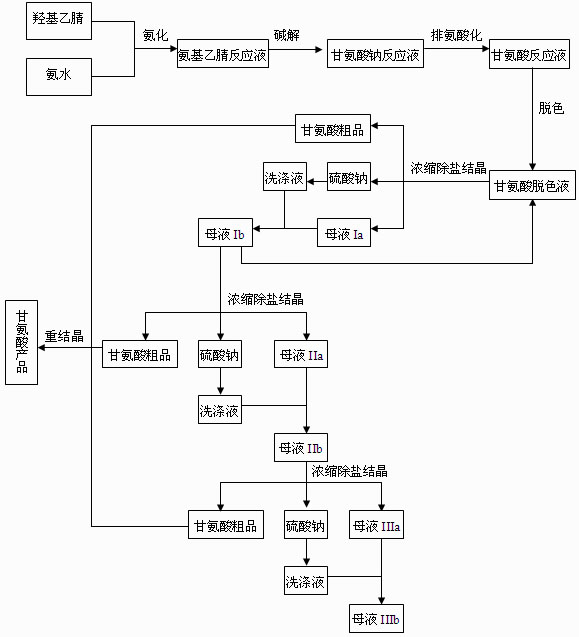

The invention discloses a preparation process of glycine, which comprises amination, alkaline hydrolysis, ammonia discharge acidification, decolorizing, concentration, desalting, crystallization and recrystallization steps, wherein in the amination step, hydroxyacetonitrile and ammonia water are mixed in a tubular reactor, and a reaction is undergone at the temperature of 50-100 DEG C under the pressure of 0.5-2.0 MPa for 4-10 minutes; and in the alkaline hydrolysis step, 30-50 percent of sodium hydroxide solution is added into an alkaline hydrolysis reactor in advance, an amination liquid is collected from an amination liquid outlet, a reaction is undergone at the temperature of 60-90 DEG C under the pressure of between -0.01 MPa and -0.09 MPa, and ammonia in a system is recovered simultaneously. In the process, the tubular reactor is taken as an amination reactor, so that the reaction temperature and pressure are raised, the reaction time is shortened, and raw material decomposition, pyrolytic polymerization of aminoacetonitrile and the generation of byproducts are reduced; alkaline hydrolysis is performed during the collection of the amination liquid, the concentration of an alkaline liquor and the alkaline hydrolysis temperature are raised simultaneously, and ammonia in the system is recovered under reduced pressure, so that the alkaline hydrolysis reaction is more complete, the speed is higher, and the generation of colored impurities is reduced; and a mother liquor circular utilizing mode is established, so that the treatment amount of waste mother liquor is reduced, the product yield is increased, and the production cost is reduced.

Owner:CHONGQING UNISPLENDOUR CHEM

Preparation method of methyl-glycine diacetate tri-sodium

ActiveCN102993034AEliminate the refining processAchieve preparationOrganic compound preparationAmino-carboxyl compound preparationAcetic acidGlycinonitrile

The invention relates to a preparation method of methyl-glycine diacetate tri-sodium, successively comprising the following steps of: preparation of hydroxy acetonitrile solution, preparation of iminodiacetonitrile solution, preparation of methyl-flycine nitrile diacetonitrile crystal, preparation of methyl-glycine diacetate tri-sodium (MGDA-3Na) and preparation of solid product MGDA-3Na. In the method, the yield of methyl-flycine nitrile diacetonitrile crystal is higher than 92%, the total yield of MGDA-3Na can reach more than 86%, the content of NTA (nitrilotriacetic acid) is less than 0.08%; and the equipment investment and energy consumption in the hydrocyanic acid refining process are saved on the premise that high yield and low toxic side product content are met, and the hydrocyanic acid refining process is not required, so that the production cost is reduced and the environment pollution is reduced.

Owner:CHONGQING UNISPLENDOUR CHEM

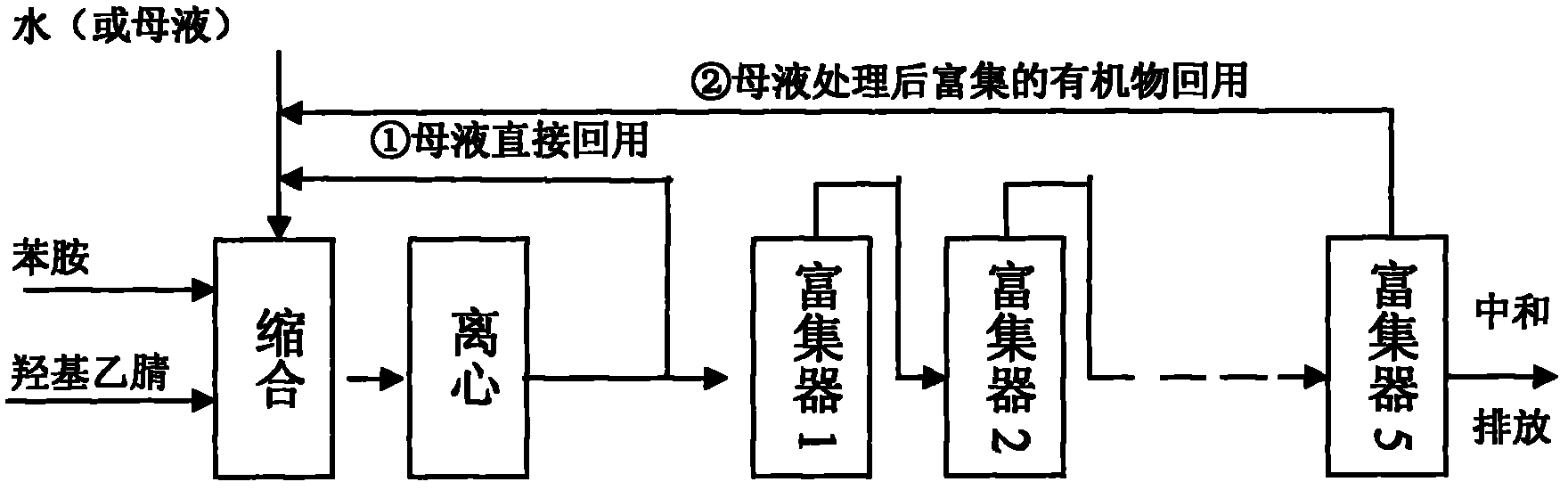

Preparation technology of N-phenylglycinonitrile

ActiveCN102627581AReduce ammonia nitrogen contentReduce dosageCarboxylic acid nitrile preparationOrganic compound preparationTotal nitrogenAniline

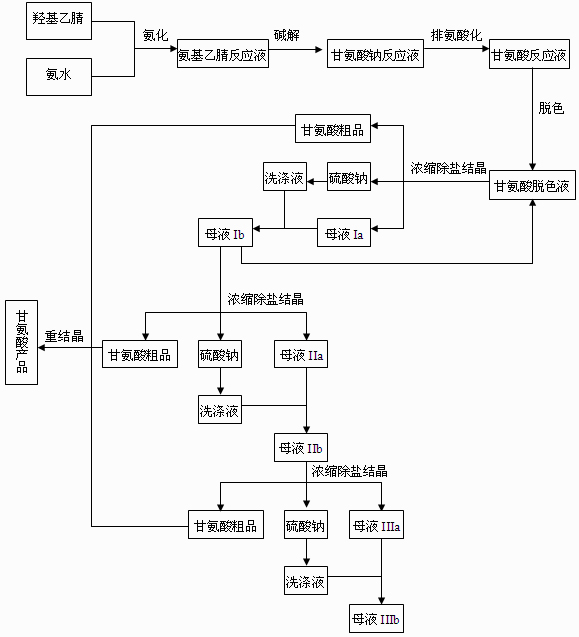

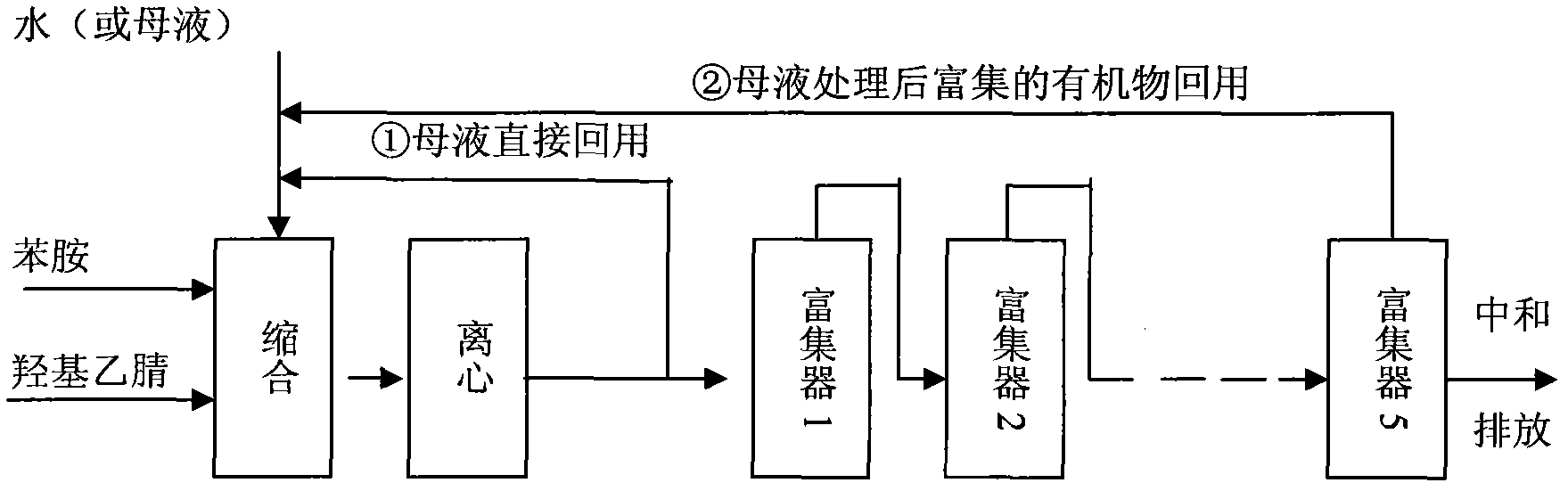

The invention relates to a preparation technology of N-phenylglycinonitrile with the characteristics of economy and environmental protection, and especially provides a technology for mother liquid utilization and wastewater processing in the production of N-phenylglycinonitrile. The preparation technology comprises operations of condensation reaction mother liquid recovery processing, N-phenylglycinonitrile is obtained by carrying out the condensation reaction on aniline, hydroxyacetonitrile and a catalyst in the presence of water (or the mother liquid), the content is greater than 97%, the liquid phase purity is greater than 97%, N-phenylglycinonitrile is a colorless or light yellow transparent crystal, and the yield is greater than 99.5%. The resulting reacted mother liquid can be directly reused in the condensation operation without processing, almost all organic matters can be recovered through physically processing exhaustless wastewater, COD of residual wastewater is less than 200ppm, and the total nitrogen content in the residual wastewater is less than 50ppm. By adopting above optimized technology, the ammonia nitrogen content is reduced, and the COD is reduced, so 75-90% of the mother liquid can be recycled to the condensation reaction and can be repeatedly reused, thereby the wastewater processing amount is reduced; and additionally, the recycle of the mother liquid makes the organic matters in the mother liquid be fully recovered, and yield improvement and cost saving be realized.

Owner:内蒙古诚信永安化工有限公司

Method for preparing diethylacetonitrile in imino group

InactiveCN101050191AHigh yieldQuality improvementCarboxylic acid nitrile preparationOrganic compound preparationAcetonitrilePhotochemistry

This invention provides a method for preparing iminodiacetonitrile. The method comprises: reacting hydroxyacetonitrile and 95-100 wt. % liquid ammonia to obtain iminodiacetonitrile. The method has such advantages as high yield, high product quality, and continuous and stable process.

Owner:四川省天然气化工研究院

Method of preparing hydroxyl acetonitrile in industrial scale from acrylonitrile apparatus by-product formonitrile

InactiveCN1907963AReduce manufacturing costSimple processPreparation by hydrogen cyanide additionAcrylonitrileGlycin

This invention involves an industrial scale preparation method for hydroxyacetonitrile by using acrylonitrile production byproduct hydrocyanic acid through a synthesis reaction with acetonitrile at the presence of catalyst. The method is characterized by (1) taking acrylonitrile production byproduct hydrocyanic acid as the raw material with content of 95% or above, (2) controlling a molar ratio of hydrocyanic acid : formaldehyde : catalyst at 1 : 1.0~1.5 : 0.001~ 0.015, (3) adding catalyst in formaldehyde while stirring, adding hydrocyanic acid at 0-20DEG C, and reacting at 0~40DEG C for 1~6 h, and (4) adjusting pH of 6 or below with inorganic acid to obtain hydroxyacetonitrile. The invention has the advantages of low cost, product content of 50% or above, simplified aftertreatment, no wastes discharge, and product with formaldehyde and hydrocyanic acid content less than 0.05%. Hydroxyacetonitrile can be used as the intermediates of glycin, malononitrile, and indigo dye to solve transport inconvenience of hydrocyanic acid and geographical limitation of production.

Owner:YINGKOU YINGXIN CHEM TECH CO LTD

Processing method of nitrile contained organic sewage difficult to degrade

InactiveCN1907881AWater/sewage treatment by flocculation/precipitationWater/sewage treatment by reductionElectrolysisDecomposition

This invention concerns a treatment method for the organic wastewater containing hydroxyacetonitrile, phenylaminoacetonitrile, aniline, diazo value, etc. nitrile-bearing refractory organism. Said method comprises carrying out microelectrolysis under acidic condition, and then adding ferrous sulfate for redox reaction and flocculation process. The mechanism is to make nitriles and CN-NH3-N into small molecules or produce insoluble precipitate through synergetic effect of a series reactions like electrolysis, redox and aeration oxidation, and further decomposition, oxidation and reduction, and remove them through flocculation. The nitriles and hydrogen cyanide like hydroxyacetonitrile and phenylaminoacetonitrile in the water can be removed completely. Aniline can be degraded and removed. CODcr removal percentage is 35-45%.

Owner:CHONGQING UNISPLENDOUR CHEM

Method for extracting and purifying hydroxy-acetic acid by ester solvents

InactiveCN1944380AStable in natureEasy to recycleCarboxylic compound separation/purificationAcetic acidSalting out

The present invention relates to process of extracting and purifying hydroxyacetic acid with ester solvent from hydroxyacetic acid aqua obtained through hydrolyzing hydroxyacetonitrile in acid medium. The process includes the steps of treating the hydrolysate, salting out, extracting hydroxyacetic acid, recovering salt and concentrating. The present invention has the technological advantages of simple technological process, low investment, no need of back extraction, facile extractant with stable property, low cost, etc; and may be used in industrial production.

Owner:SHIJIAZHUANG ZHONGTIAN BIOTECH

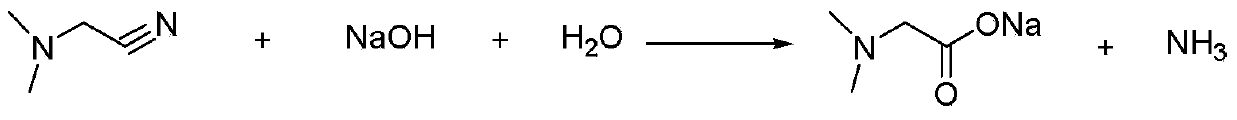

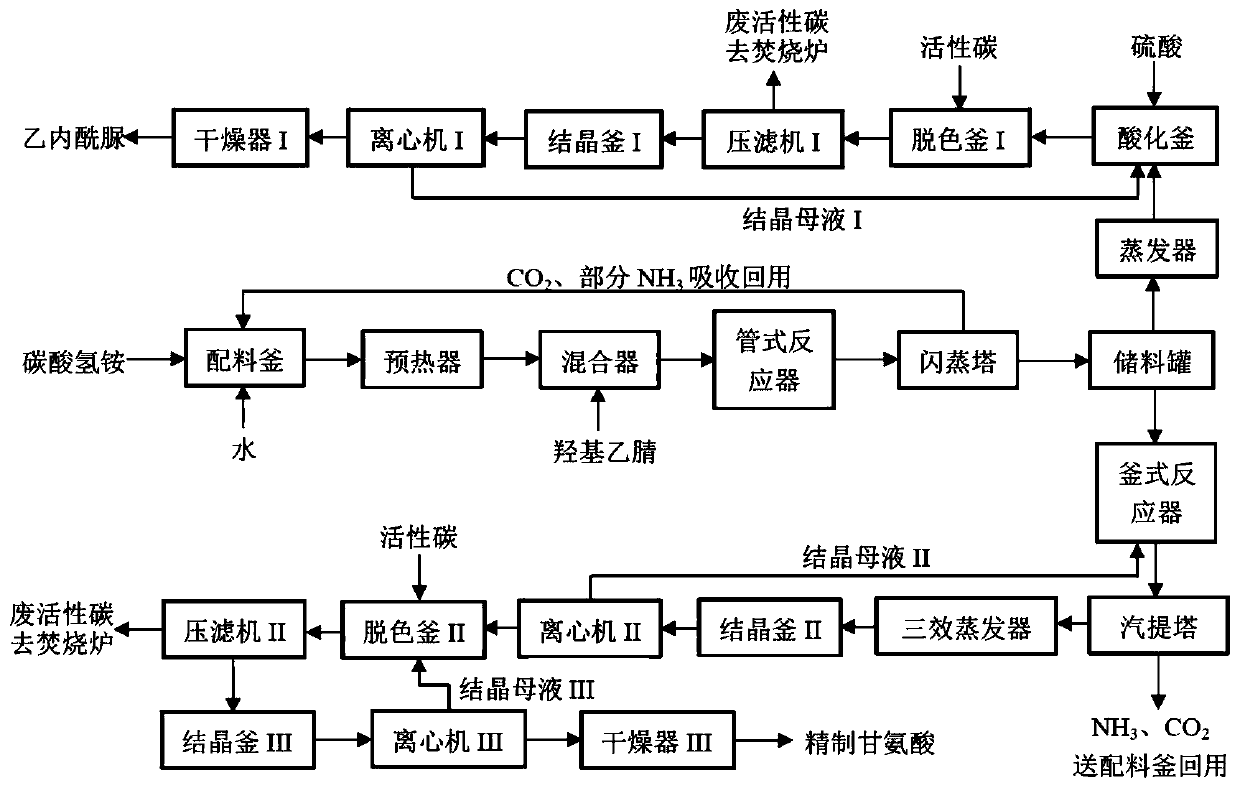

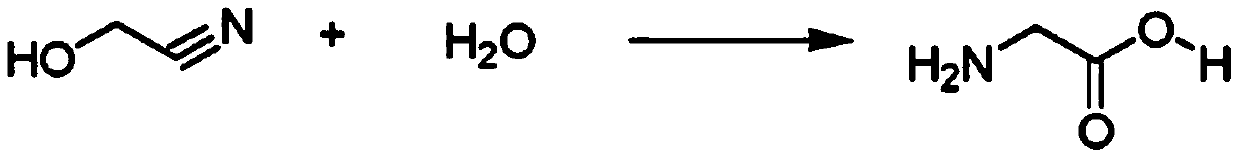

Method used for continuous preparation of glycine from hydroxyacetonitrile

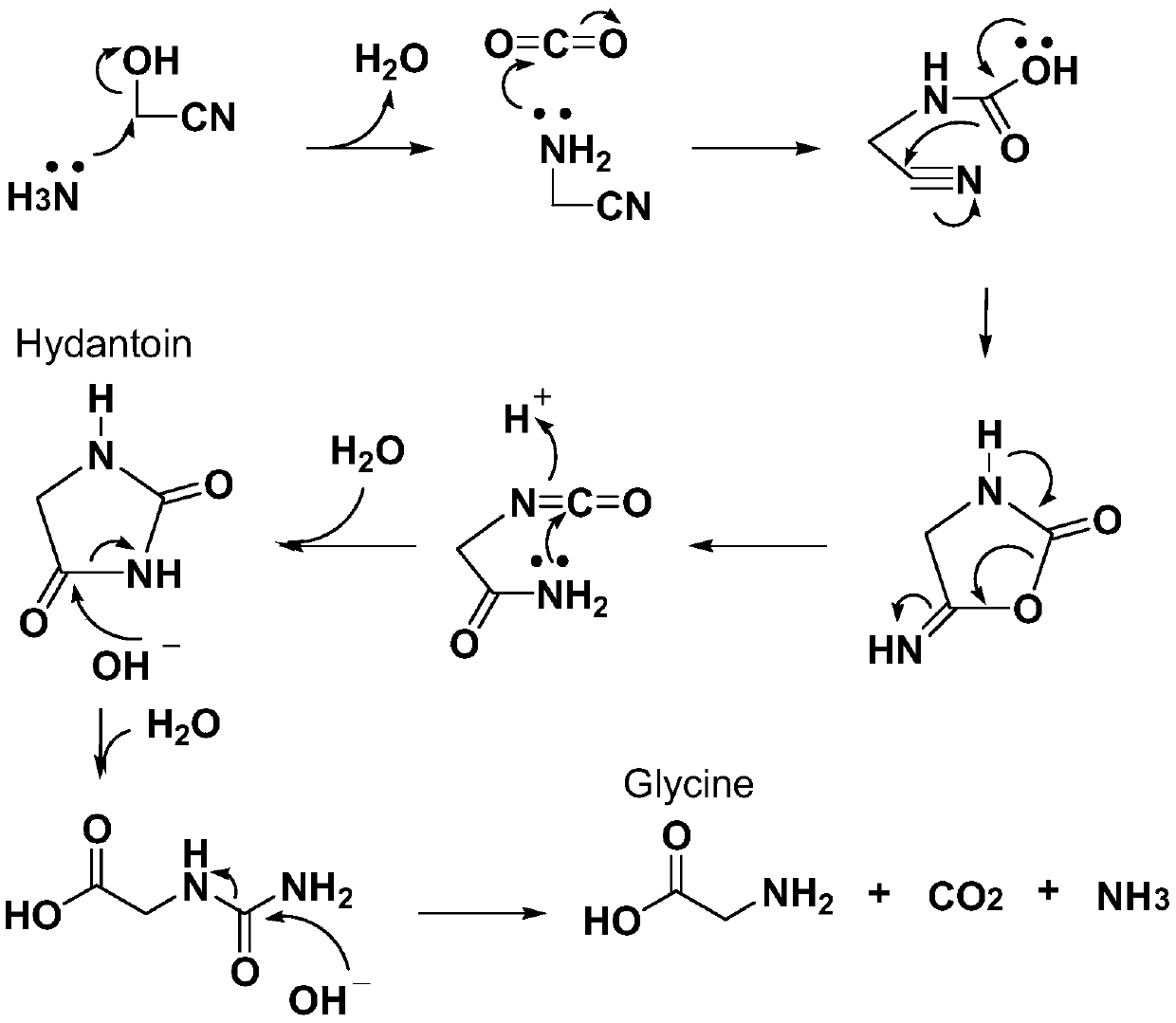

ActiveCN107325015AHigh yieldSolve the serialization problemOrganic compound preparationAmino-carboxyl compound preparationGlycineDistillation

The invention provides a method used for continuous preparation of glycine from hydroxyacetonitrile. According to the method, hydroxyacetonitrile, an ammonia source, and a carbon source are delivered into a device composed of a tubular packed reactor and a kettle-type tandem reactor for synthesis and hydrolysis reaction successively, and then high purity glycine is obtained via distillation, crystallization, separation, and drying. The kettle-type tandem reactor is composed of at least three hydrolysis reaction kettles connected in series via an overflow pipe. Compared with kettle-type batch process in the prior art, the method possesses following advantages: whole flow continuous production of glycine from hydroxyacetonitrile via hydantoin is realized, and no waste liquid is generated.

Owner:山西华阳集团新能股份有限公司

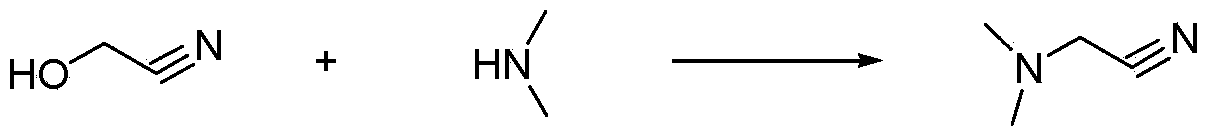

Preparation method of N,N-dimethylglycine

ActiveCN103387518AInhibit side effectsReduce manufacturing costCarboxylic acid nitrile preparationOrganic compound preparationOrganic acidBiochemical engineering

The invention relates to a preparation method of N,N-dimethylglycine and belongs to the field of chemical engineering. The preparation method comprises the following steps of: preparing N,N-dimethyl amino acetonitrile by taking hydroxyacetonitrile and dimethylamine as raw materials, obtaining an N,N-dimethylglycine crude product by alkalizing the reaction liquid with an inorganic base and neutralizing the reaction liquid with an organic acid on the basis of N,N-dimethyl amino acetonitrile reaction liquid, and finally separating and purifying the N,N-dimethylglycine crude product to obtain the high-quality N,N-dimethylglycine product. The preparation method has the advantages that the raw materials are environmentally-friendly and easily available, reaction conditions are mild, the environmental pollution is little, the after-treatment is simple and easy, the production efficiency is high, and the preparation method is suitable for industrial popularization and application.

Owner:CHONGQING UNISPLENDOUR CHEM

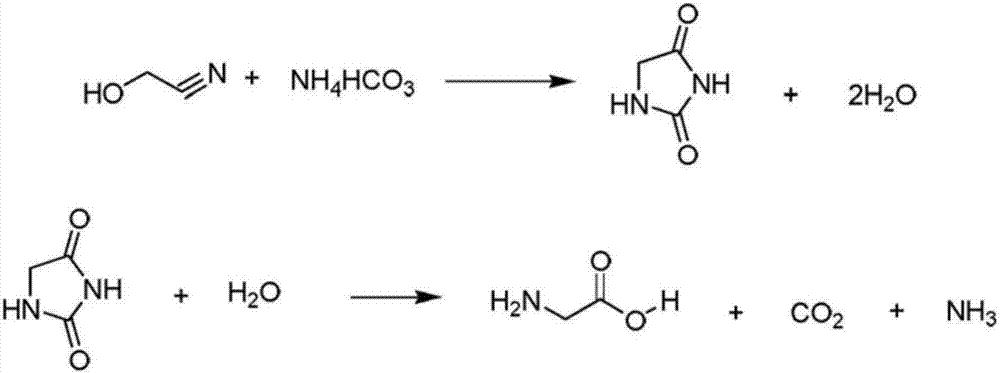

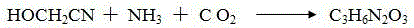

Process for preparing hydantoin by one-step method

InactiveCN1616435ARealize continuous preparationThe synthesis process is simpleOrganic chemistryCyanideSolid acid

The one-step process of preparing hydantoin is that in a trickle bed reactor hydroxy methyl cyanide, CO2 and ammonia as material and solid acid as stuffing and catalyst are prepared into hydantoin through one-step process. Hydroxy methyl cyanide is made to flow into the trickle bed from the top in the flow rate of 100-300 ml / hr, CO2 and ammonia are made to flow into the trickle bed from the bottom in the flow rate of 0.01-0.1 cu m / hr and 0.005-0.06 cu m / hr separately, and through reaction at 40-120 deg.c for 2-5 hr, the reaction liquid is collected and processed through concentration, crystallization, filtering to obtain initial crystal, recrystallization and drying to obtain hydantoin. The synthesis yield may reach 74.85 %.

Owner:NANJING UNIV OF TECH

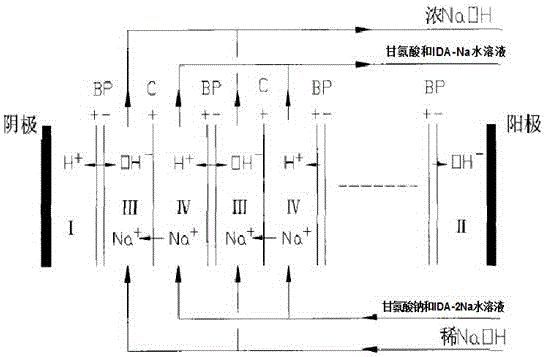

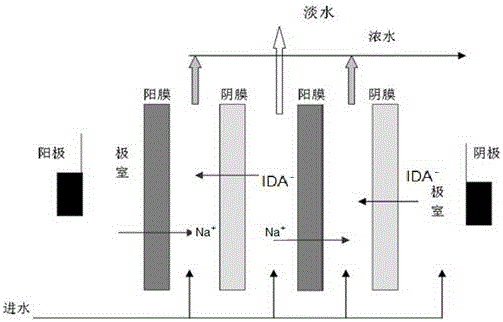

Solid sodium sarcosine preparation method

PendingCN103664665ALower requirementHigh purityOrganic compound preparationAmino-carboxyl compound preparationSodium methoxideSeparation technology

The invention discloses a high-purity solid sodium sarcosine preparation method. The specific technical scheme comprises the following steps: condensing hydroxyacetonitrile and methylamine to obtain methylaminoacetonitrile; adding sodium hydroxide, and hydrolyzing to obtain sodium methylaminoacetate, namely a sodium sarcosine liquid and free sodium hydroxide mixture; adding hydrochloric acid which is equal to the sodium sarcosine in mol, and neutralizing to obtain a sarcosine and sodium chloride mixture; separating sodium chloride and sarcosine through an electrodialysis membrane separation technology to obtain a high-purity sarcosine solution and an impurity solution; distilling the high-purity sarcosine solution with a multifunctional evaporator to obtain solid crystals, separating to obtain pure sarcosine, and dissolving the sarcosine with 0.5 time of purified water; and dropwisely adding 1:0.98 mol of sodium methoxide at 40 DEG C to precipitate solid sodium sarcosine, performing centrifugal separation to obtain white solids, and drying to obtain the finished product, wherein after the cycle is completed, the mother solution can be recovered through rectifying, and methanol can be for private use or can be sold as a byproduct. The process has peculiar characteristics; and high-purity sodium sarcosine solids can be prepared through the process.

Owner:TIANJIN TIANCHENG PHARMA

Preparation method of methyl-glycine diacetate tri-sodium

ActiveCN102993034BEliminate the refining processAchieve preparationOrganic compound preparationAmino-carboxyl compound preparationAcetic acidGlycinonitrile

The invention relates to a preparation method of methyl-glycine diacetate tri-sodium, successively comprising the following steps of: preparation of hydroxy acetonitrile solution, preparation of iminodiacetonitrile solution, preparation of methyl-flycine nitrile diacetonitrile crystal, preparation of methyl-glycine diacetate tri-sodium (MGDA-3Na) and preparation of solid product MGDA-3Na. In the method, the yield of methyl-flycine nitrile diacetonitrile crystal is higher than 92%, the total yield of MGDA-3Na can reach more than 86%, the content of NTA (nitrilotriacetic acid) is less than 0.08%; and the equipment investment and energy consumption in the hydrocyanic acid refining process are saved on the premise that high yield and low toxic side product content are met, and the hydrocyanic acid refining process is not required, so that the production cost is reduced and the environment pollution is reduced.

Owner:CHONGQING UNISPLENDOUR CHEM

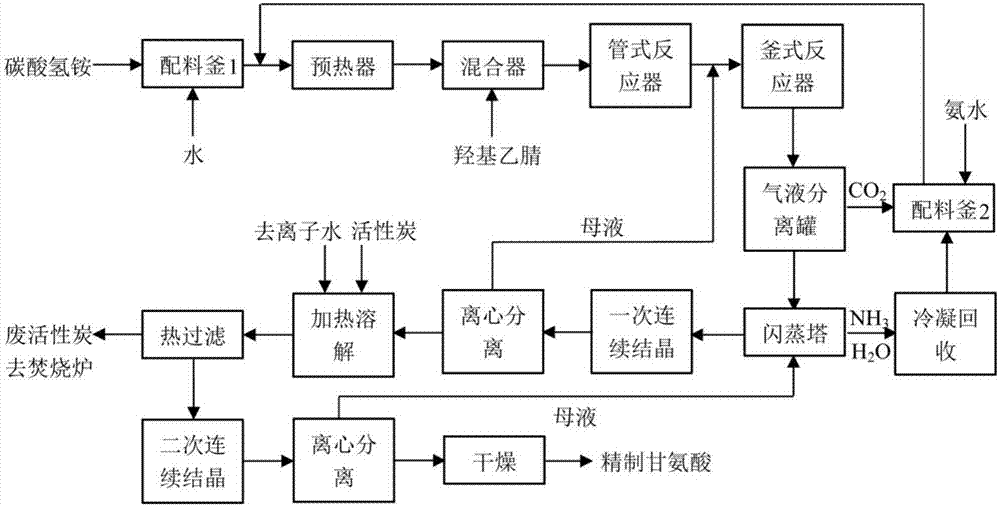

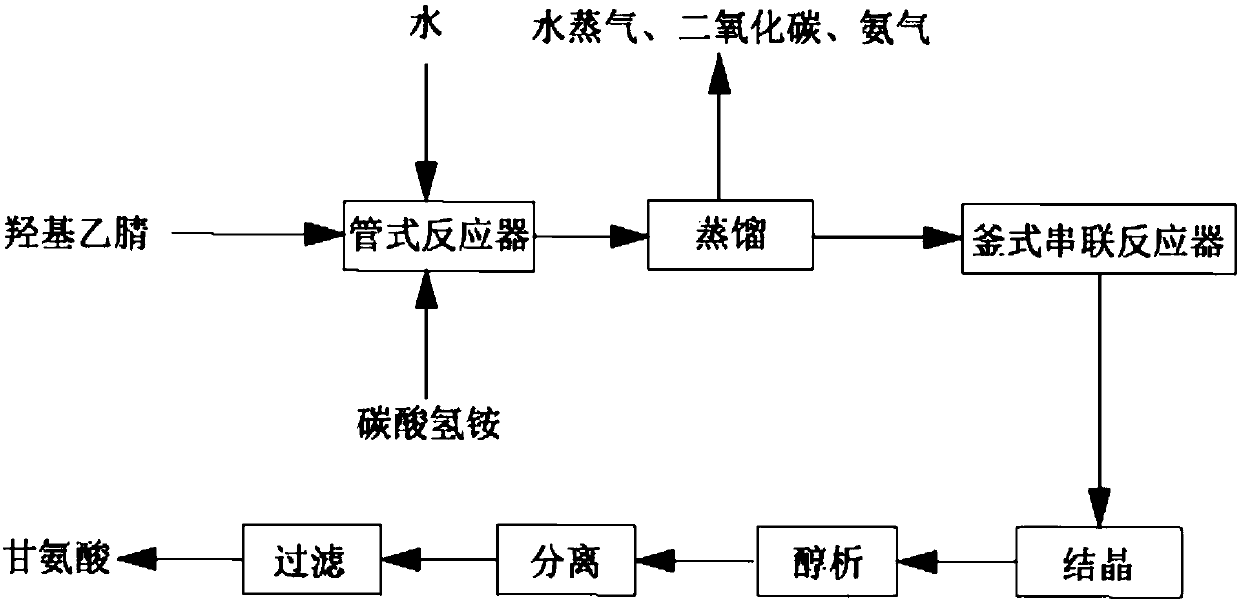

Method for continuously preparing glycine

ActiveCN109678744AIncrease mass concentrationRealize continuous productionOrganic compound preparationAmino-carboxyl compound preparationGlycineDistillation

The invention provides a method for continuously preparing glycine. The method comprises the steps that hydroxyacetonitrile is synthesized with an ammonia source and a carbon source in a tubular reactor, and an obtained solution is concentrated to obtain a concentrated solution; then the concentrated solution is fed into kettle type series reactors for a hydrolysis reaction to obtain a glycine-containing solution; and the glycine-containing solution is refined to obtain refined glycine. The method adopts a device composed of the tubular packing reactor and the kettle type series reactors to carry out hydantoin synthesis and the hydrolysis reaction, thereby achieving the purpose of continuous production; and meanwhile, a distillation device is added before the hydrolysis reaction, and the mass concentration of a hydantoin aqueous solution is increased, so that in the same glycine yield, the kettle type series reactors are reduced, the volume of the kettle type reactors is reduced, the reaction time is shortened, and the purpose of the continuous production is well achieved.

Owner:山西华阳集团新能股份有限公司

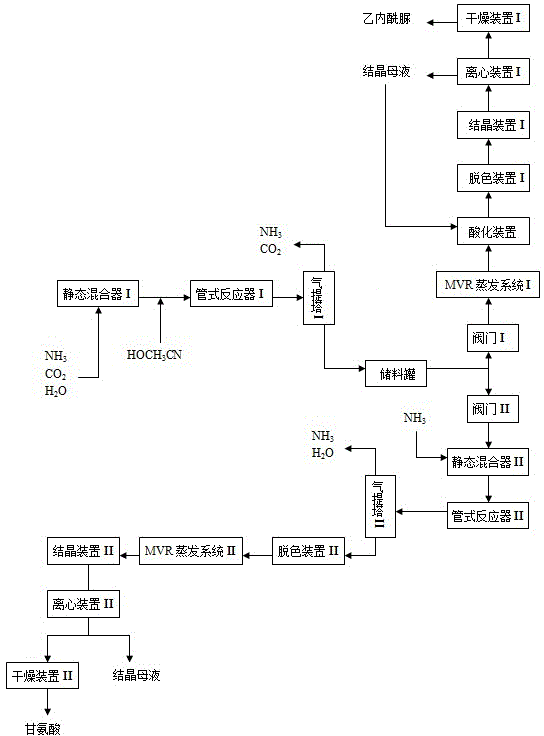

Method and device for clean production of glycine

InactiveCN107963975AImprove corrosion resistanceFlexible operationOrganic compound preparationAmino-carboxyl compound preparationChemical industryDipeptide

The invention belongs to the field of a chemical industry and particularly relates to a method and device for clean production of glycine. The method for clean production of glycine comprises that hydroxyacetonitrile, ammonia, carbon dioxide and water as raw materials undergo a reaction in a special material synthesis reactor, the pressure of the synthesis reactor is reduced to the normal pressureso that a material liquid I is obtained, the material liquid I is heated and hydrolyzed, the pressure of the hydrolysate is reduced to the normal pressure, ammonia is removed so that a material liquid II is obtained, and the material liquid II is treated through a conventional treatment method so that glycine is obtained. The method is environmentally friendly and clean, does not produce by-products, has a high effective conversion rate of hydroxyacetonitrile, greatly improves the glycine yield through a special material, reduces the hydroxyacetonitrile by-products and produces glycine dipeptide to increase corrosion resistance of the material. The device is simple. The method is easy to operate and realizes a low cost.

Owner:CHONGQING UNISPLENDOUR CHEM

Preparation process of glycine

InactiveCN102432478BReduce pyrolysis polymerizationHigh yieldOrganic compound preparationAmino-carboxyl compound preparationReaction temperatureAlkaline hydrolysis

The invention discloses a preparation process of glycine, which comprises amination, alkaline hydrolysis, ammonia discharge acidification, decolorizing, concentration, desalting, crystallization and recrystallization steps, wherein in the amination step, hydroxyacetonitrile and ammonia water are mixed in a tubular reactor, and a reaction is undergone at the temperature of 50-100 DEG C under the pressure of 0.5-2.0 MPa for 4-10 minutes; and in the alkaline hydrolysis step, 30-50 percent of sodium hydroxide solution is added into an alkaline hydrolysis reactor in advance, an amination liquid is collected from an amination liquid outlet, a reaction is undergone at the temperature of 60-90 DEG C under the pressure of between -0.01 MPa and -0.09 MPa, and ammonia in a system is recovered simultaneously. In the process, the tubular reactor is taken as an amination reactor, so that the reaction temperature and pressure are raised, the reaction time is shortened, and raw material decomposition, pyrolytic polymerization of aminoacetonitrile and the generation of byproducts are reduced; alkaline hydrolysis is performed during the collection of the amination liquid, the concentration of an alkaline liquor and the alkaline hydrolysis temperature are raised simultaneously, and ammonia in the system is recovered under reduced pressure, so that the alkaline hydrolysis reaction is more complete, the speed is higher, and the generation of colored impurities is reduced; and a mother liquor circular utilizing mode is established, so that the treatment amount of waste mother liquor is reduced, the product yield is increased, and the production cost is reduced.

Owner:CHONGQING UNISPLENDOUR CHEM

Method for continuous co-production of glycine and hydantoin

A method for continuous co-production of glycine and hydantoin is provided. The method includes subjecting an amino source, a carbon source, water and hydroxyacetonitrile to a hydantoin synthesizing reaction in a shell-and-tube reactor to obtain a first reaction product; feeding the first reaction product into a flash column for treatment to obtain a first treatment product; dividing the first treatment product into a first portion and a second portion; subjecting the first portion to first concentration treatment in an evaporator to obtain a first concentrate; reacting the first concentrate with concentrated sulfuric acid to obtain a second reaction product including hydantoin; subjecting the second portion to hydantoin decomposition in a tank series reactor to obtain a third reaction product including glycine. Compared with the prior art, the method realizes the continuous co-production of the glycine and the hydantoin.

Owner:HUAYANG NEW MATERIAL TECH GRP CO LTD +1

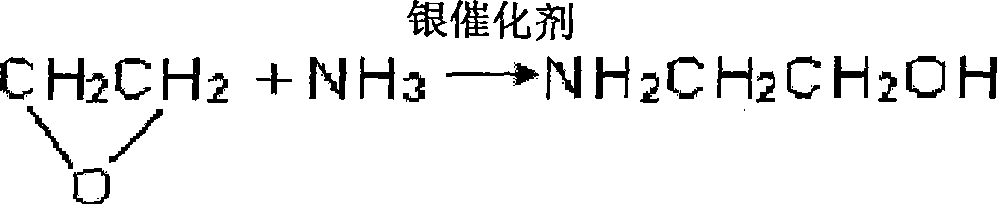

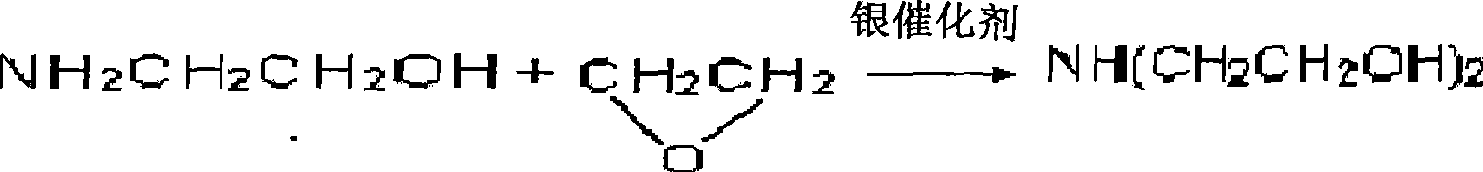

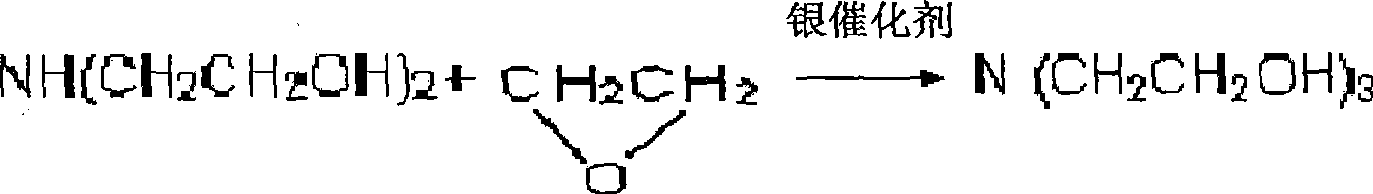

Method for synthesizing monoethanolamine

ActiveCN101434551AFully transformedHigh yieldOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsChemical synthesisHydrogen

The invention discloses a synthesis method of monoethanolamine, pertaining to the technical field of organic chemical synthesis. Hydroxyacetonitrile is adopted for carrying out reaction with hydrogen under the presence of a catalyst to obtain the monoethanolamine. Compared with the prior art, the technical proposal has the advantages of full transformation (more than 81 percent) and high yield (more than 70 percent).

Owner:JIANGSU YUANYANG PHARMA

Clean production method for co-producing glycine and iminodiacetic acid

InactiveCN106748839ARealize joint productionIncrease profitCarboxylic acid nitrile preparationOrganic compound preparationImpuritySodium hydroxide

Owner:CHONGQING UNISPLENDOUR CHEM

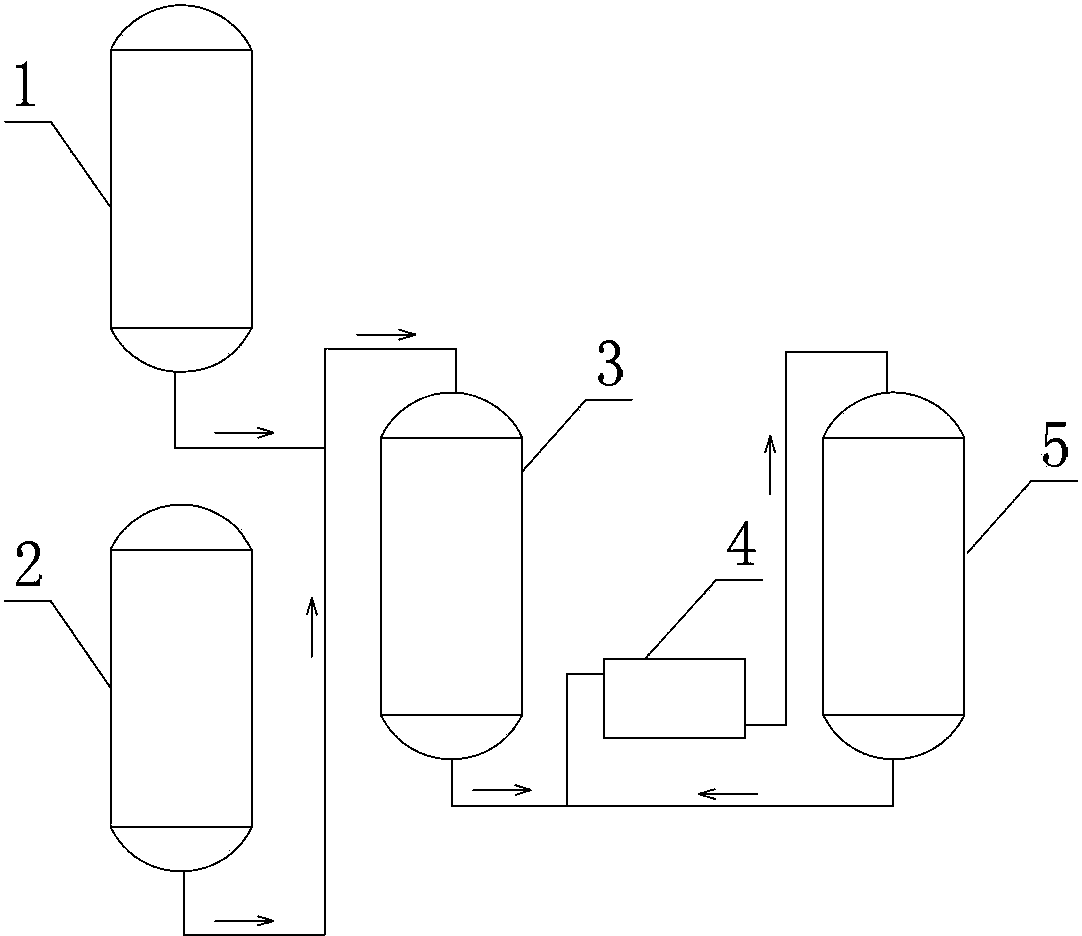

Method for co-producing glycine and hydantoin, and apparatus thereof

InactiveCN104910031AEasy to adjust outputLess investment in production equipmentOrganic compound preparationAmino-carboxyl compound preparationAmmonium carbonateHydrolysis

The invention discloses a method for co-producing glycine and hydantoin, and an apparatus thereof. The method adopting hydroxyacetonitrile, ammonia, carbon dioxide and water, or hydroxyacetonitrile, ammonia, ammonium bicarbonate and water, or hydroxyacetonitrile, ammonium carbonate, carbon dioxide and water as raw materials comprises the following steps: carrying out an amidocarbonylation reaction on the raw materials at a temperature of 60-120DEG C under a pressure of 1.5-3.0MPa according to a molar ratio of hydroxyacetonitrile: ammonia: carbon dioxide: water of 1:3-5:2-4:46-50 in a reaction system to prepare an amidocarbonylation reaction solution; acidifying the amidocarbonylation reaction solution to obtain a hydantoin product, or carrying out ammonification hydrolysis on the amidocarbonylation reaction solution to prepare a glycine product The method and the apparatus can save the investment of apparatuses for prodcuign glycine and hydantoin, reduce the production cost, are convenient for adjusting the outputs of glycine and hydantoin, and especially overcome the disadvantages of incomplete hydrolysis, generation of iminodiacetic acid, many byproducts, difficult purification of glycine, and low yield of present hydantoin methods for preparing glycine.

Owner:CHONGQING UNISPLENDOUR CHEM

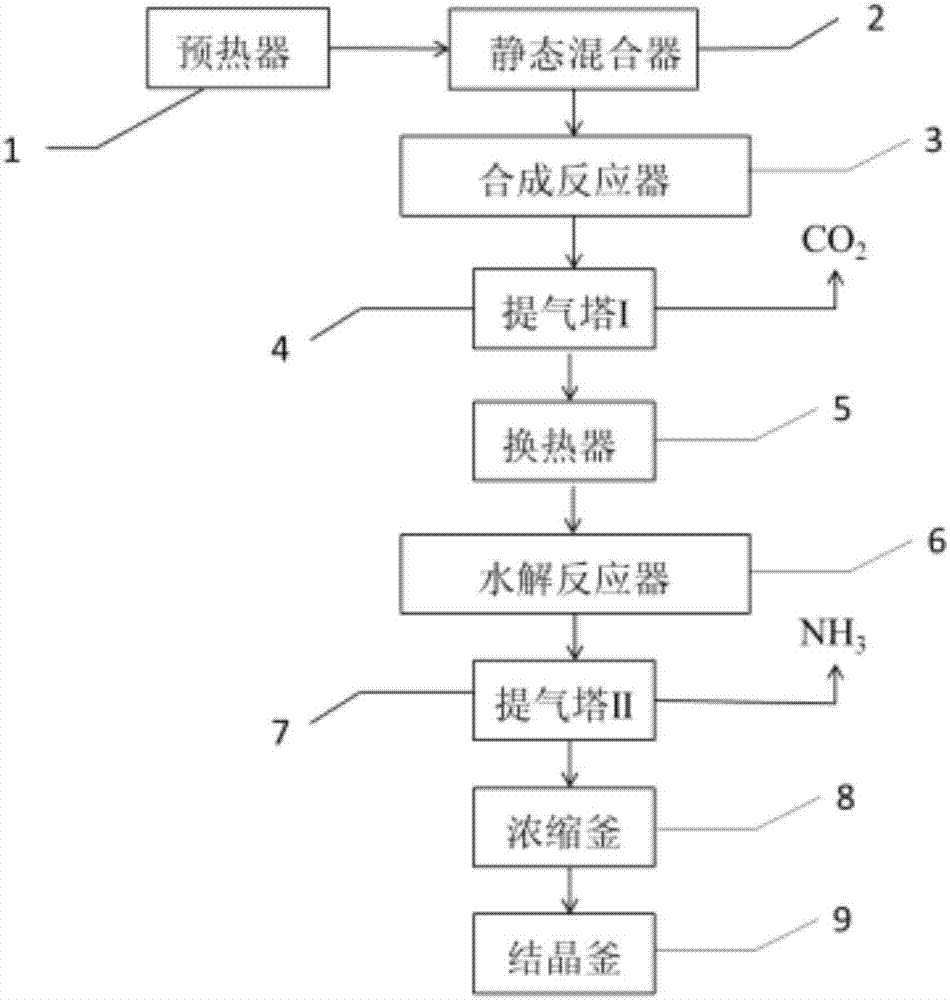

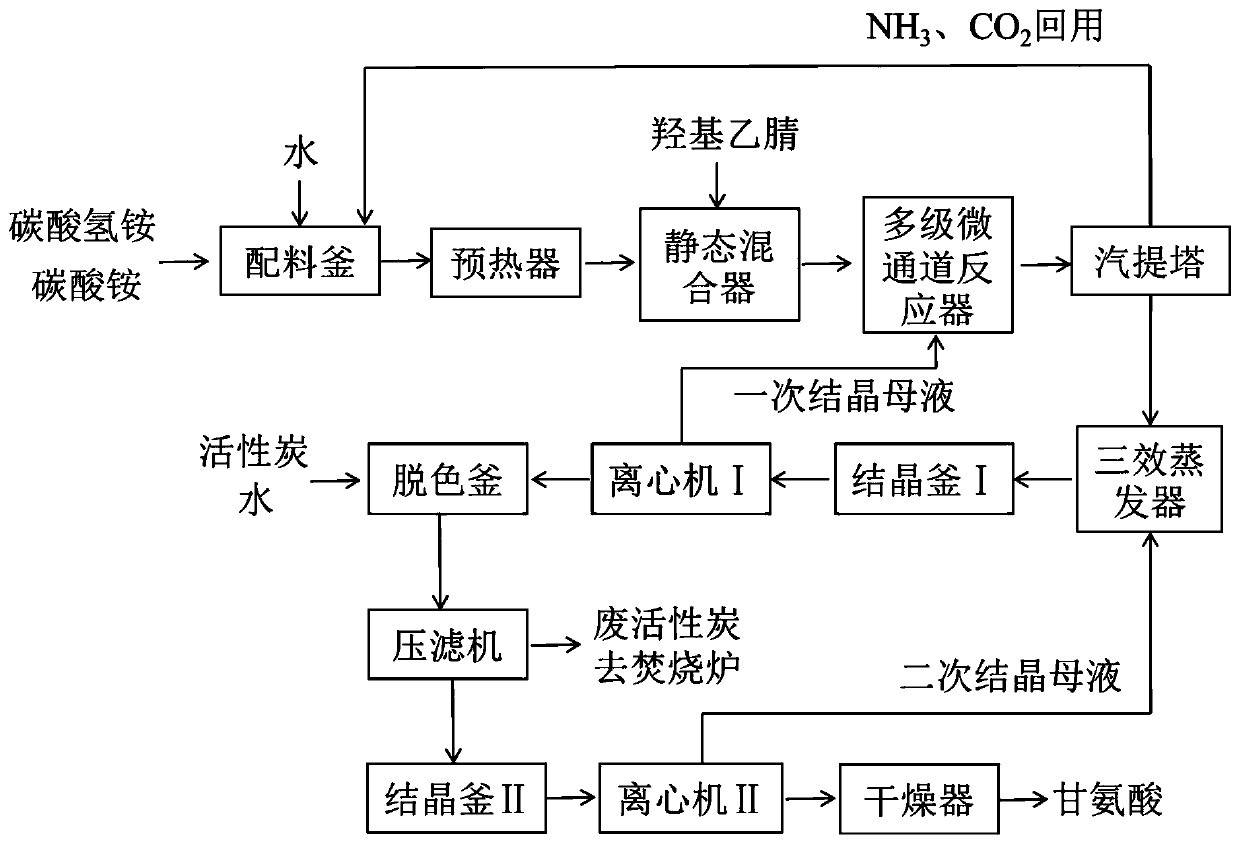

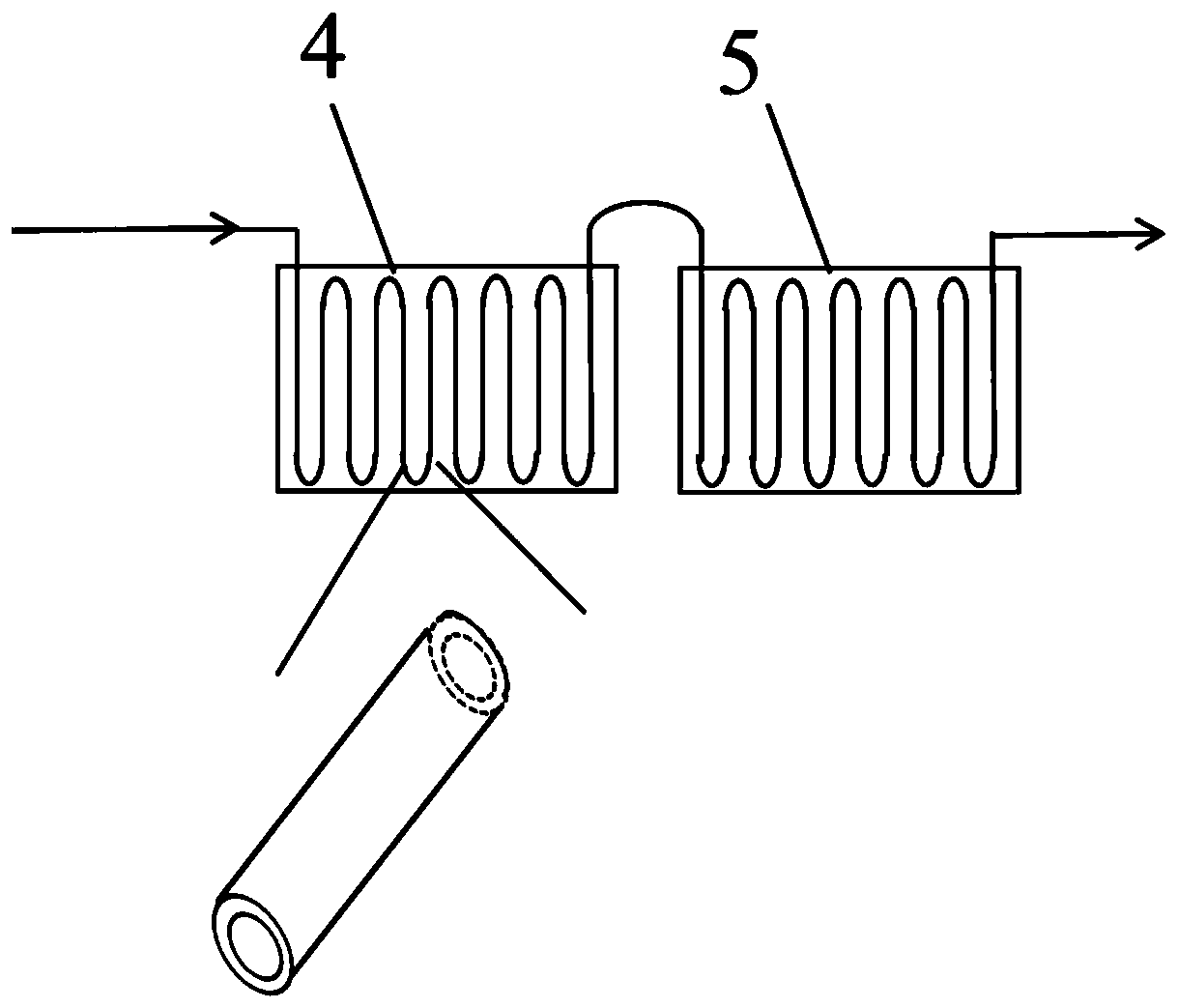

Method for continuously preparing glycine from hydroxyacetonitrile by microchannel reactor

PendingCN110698357AHigh yieldReduce manufacturing costOrganic compound preparationChemical/physical/physico-chemical microreactorsHydrolysisAqueous solution

The invention provides a method for continuously preparing glycine from hydroxyacetonitrile by a microchannel reactor. The method comprises the following steps: preheating and mixing hydroxyacetonitrile, a carbon source and an ammonia source which serve as raw materials, sequentially performing hydantoin synthesis and hydantoin hydrolysis reaction in the microchannel reactor to obtain a glycine aqueous solution, and performing steam stripping, evaporation and concentration, crystallization, separation, decoloration and drying to obtain the glycine product. Compared with an existing method, themethod realizes continuous preparation of the glycine by taking the hydroxyacetonitrile as the raw material, and has the advantages of short reaction time, few byproducts, high glycine yield and lowpreparation cost.

Owner:山西华阳集团新能股份有限公司

Technological method for jointly preparing liquid hydrogen cyanide and hydroxynitrile

ActiveCN104725269AIncrease profitReduce purification energy consumptionCarboxylic acid nitrile preparationOrganic compound preparationPtru catalystHCN poisoning

The invention provides a technological method for jointly preparing liquid hydrogen cyanide and hydroxynitrile. The technological method comprises the steps that a light oil cracking hydrogen cyanide gas mixture is used as a raw material and undergoes an ammonia removal process and a cryogenic process to obtain liquid hydrogen cyanide, wherein in the ammonia removal process, the hydrogen cyanide gas mixture is absorbed with a sulfuric acid aqueous solution; in the cryogenic process, the hydrogen cyanide gas mixture is cooled to minus 10-minus 20 DEG C, after the hydrogen cyanide gas mixture is cooled, a part of the hydrogen cyanide gas becomes liquid to obtain liquid hydrogen cyanide, and the other part of the hydrogen cyanide gas is the tail gas containing hydrogen cyanide; the tail gas containing hydrogen cyanide, which undergoes cryogenic treatment, is absorbed with a formaldehyde aqueous solution containing a catalyst to prepare a hydroxynitrile aqueous solution, and the tail gas absorbed with the formaldehyde aqueous solution directly enters an incinerator to be incinerated. By adopting the technological method, the purification efficiency and the utilization efficiency of hydrogen cyanide can be obviously improved, meanwhile, the energy consumption in the hydrogen cyanide purification process is greatly reduced and can be reduced by 90% at most, and the utilization rate of hydrogen cyanide is more than 99.9%.

Owner:枣阳市金鹿化工有限公司

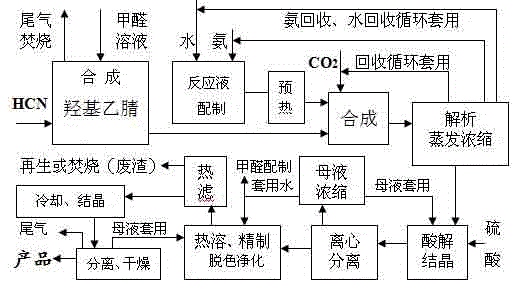

Clean production method for continuously synthesizing hydantoin

InactiveCN104876876AMinimize impact on product qualityReduce manufacturing costOrganic chemistryHydantoic acidEnvironmental resistance

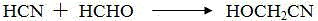

* An environmentally-friendly clean production method for continuously synthesizing hydantoin comprises the following steps: reacting an initial raw material hydrocyanic acid with formaldehyde to generate hydroxyacetonitrile, reacting hydroxyacetonitrile in a carbon dioxide and ammonia water system through a continuous reactor to obtain an aqueous solution of hydantoic acid, carrying out acid hydrolysis to obtain hydantoin crystals, and purifying to obtain a highly pure hydantoin product. The combined continuous reactor is adopted to synthesize hydantoin, so the device investment is highly effectively reduced, and the investment efficiency is improved by times; automatic control is very conveniently controlled, the continuity and the stability of production are well guaranteed, the labor cost is saved, and the safe production operationality of the whole process is guaranteed; generation of harmful impurities is well inhibited, decomposition and polymerization of hydroxyacetonitrile and other side reactions are effectively inhibited, and the purity and the yield of the above obtained product are improved; and the method has lower requirements of raw materials, fully and comprehensively utilizes resources, is an environmentally friendly clean production technology, and plays a very active synergistic role in natural environment protection.

Owner:李宽义

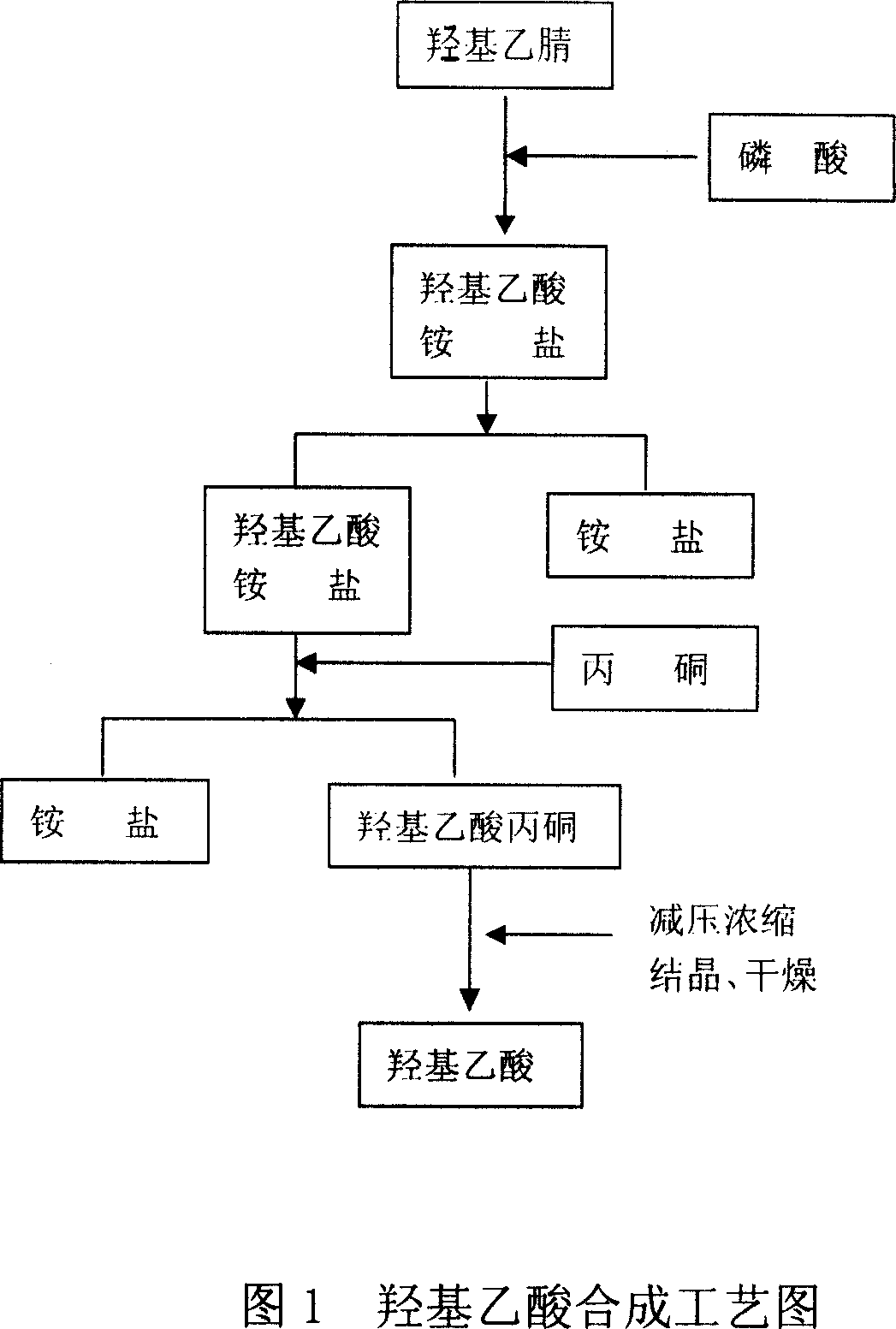

New process for preparing hydroxy-acetic acid using hydroxy-acetic nitrile as raw material

InactiveCN1944379AWill not cause aggregationEffective desalinationPreparation from nitrilesAcetic acidAqueous acetone

The present invention provides process of preparing hydroxyacetic acid with hydroxyacetonitrile. The process includes the following steps; 1. adding proper amount of phosphoric acid into water solution of hydroxyacetonitrile and heating to hydrolyze; 2. concentrating crystallization to eliminate great amount of salt and further desalting with acetone; and 3. vacuum concentrating the acetone water solution to obtain the product hydroxyacetic acid.

Owner:重庆三峡英力化工有限公司

Separation and purification method of hydroxyacetonitrile

ActiveCN106631889AHigh purityAvoid decompositionCarboxylic acid nitrile purification/separationPurification methodsAcetonitrile

The invention discloses a separation and purification method of hydroxyacetonitrile. The separation and purification method comprises the following steps: step a), using a first extraction agent to be in contact with a hydroxyacetonitrile water solution for extraction, and separating to obtain a first phase containing hydroxyacetonitrile and water and a second phase containing the first extraction agent and impurities; step b), using a second extraction agent to be in contact with the first phase for extraction, separating to obtain a third phase containing the second extraction agent and the hydroxyacetonitrile and a water phase; step c), using a drying agent to carry out drying treatment on the third phase; step d), separating the hydroxyacetonitrile from the third phase after drying treatment; and step e), carrying out purification treatment on the hydroxyacetonitrile obtained in the step d. Compared with the prior art, the first extraction agent is firstly used for separating the impurities from the hydroxyacetonitrile, then the second extraction agent is used for separating the hydroxyacetonitrile and water, and then drying and purification are carried out, so that the high-purity hydroxyacetonitrile can be obtained.

Owner:HUAYANG NEW MATERIAL TECH GRP CO LTD

Method for preparing and purifying hydroxyacetic acid by using hydroxyacetonitrile as raw material

InactiveCN101851157AWide variety of sourcesLow priceAmmonium sulfatesPreparation from nitrilesDistillationHydrolysis

The invention relates to a method for preparing and purifying hydroxyacetic acid by using hydroxyacetonitrile as a raw material, which comprises the following steps of: adding sulfuric acid into aqueous solution of the hydroxyacetonitrile, and performing hydrolysis under a heating condition; adding aqueous ammonia into the solution to neutralize excessive residual sulfuric acid; removing most of water in the system; removing salt by using a low-carbon alcohol precipitation method; and removing low-carbon alcohol through reduced pressure distillation to obtain a hydroxyacetic acid product. Themethod has the advantages of simple production device, saved investment cost, low operation cost, high purity of the obtained hydroxyacetic acid product, full recycle of side products, no waste discharge and practicability of large-scale industrialized production.

Owner:EAST CHINA UNIV OF SCI & TECH

Environmentally-friendly clean technologic production method of highly pure hydantoin

InactiveCN104876875AQuality improvementImprove refining efficiencyOrganic chemistryHydantoic acidEnvironmental resistance

The purpose of the invention is providing an environmentally-friendly clean technologic production method of highly pure hydantoin. The environmentally-friendly clean technologic production method of highly pure hydantoin comprises the following steps: reacting an initial raw mateiral hydrocyanic acid with formaldehyde to generate hydroxyacetonitrile, reacting hydroxyacetonitrile in a carbonated water system containing ammonia to obtain an aqueous solution of hydantoic acid, carrying out acid hydrolysis to obtain hydantoin crystals, and purifying to obtain a highly pure hydantoin product. The method effectively avoids decomposition and polymerization of hydroxyacetonitrile, well inhibits generation of harmful impurities, realizes a high yield, and allows the purity of the obtained product to be very high; the method reduces the device investment, and well guarantees the operation safety of the whole process; hot water dissolving, heat treatment and hot filtration are adopted in the purifying process, so consumed energy is saved; the above whole technology is a thoroughly environmentally-friendly and clean technology; and the method has lower requirements on raw materials, can fully and comprehensively utilize resources, and plays a very active role in natural environment protection.

Owner:李宽义

Preparation method of hydroxyacetic acid

ActiveCN104744239AMeet the use requirementsGuaranteed yieldOrganic compound preparationPreparation from carboxylic acid esters/lactonesReaction temperatureAmmonium sulfate

The invention relates to a preparation method of hydroxyacetic acid. The preparation method comprises the following steps: performing a hydrolysis reaction on an aqueous solution of hydroxynitrile and a sulfuric acid solution having the mass concentration of 70%-90% at a temperature within the range of 120-140 DEG C, thereby obtaining the mixed solution of hydroxyacetic acid and an acidic salt ammonia sulfate; at the same time of performing an esterification reaction by adding methanol to the mixed solution, distilling out the mixture of methanol, water and methyl hydroxylacetate, and controlling the temperature of the whole process within the range of 110-120 DEG C; adding water to adjust the mass percentage of methyl hydroxylacetate in the mixture to the range of 10%-25%, hydrolyzing methyl hydroxylacetate at a temperature less than or equal to 100 DEG C into hydroxyacetic acid, separating out methanol and water, and recycling separated methanol. According to the preparation method, due to the improvement of the reaction temperatures, the raw material concentration and the preparation method, the reaction time is shortened and the energy consumption and the methanol loss are reduced under the premise of guaranteeing the yield; as a result, the production cost is greatly reduced and the product competitiveness is improved.

Owner:太仓市新毛涤纶化工有限公司

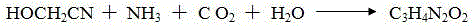

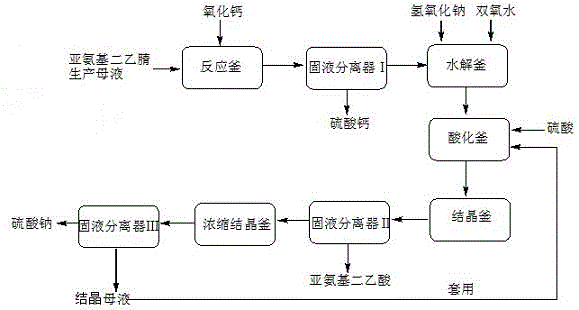

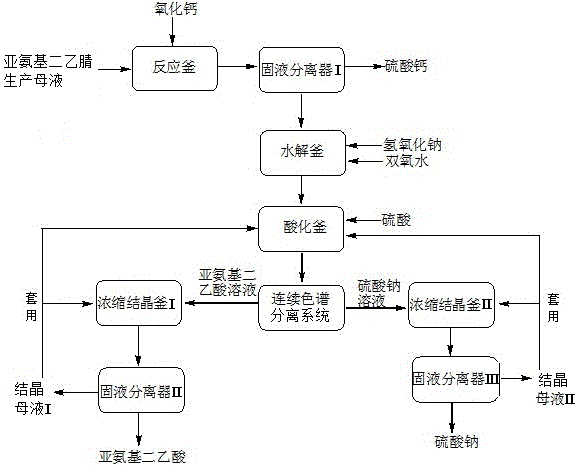

Method and apparatus for preparing iminodiacetic acid by using iminodiacetonitrile to produce mother liquor

InactiveCN104974054AEfficient recyclingAvoid secondary pollutionOrganic compound preparationAmino-carboxyl compound preparationSodium sulfateSodium salt

The invention discloses a method and apparatus for preparing an iminodiacetic acid by using iminodiacetonitrile to produce mother liquor. The method comprises: adding calcium oxide or calcium hydroxide to the mother liquor to react so that glycolonitrile and aminoacetonitrile contained in the mother liquor are transformed into minodiacetonitrile, transforming sulphuric acid, ammonium and ammonium sulfate into calcium sulfate, and thus obtaining solid calcium sulphate and iminodiacetonitrile solution through solid-liquid separation; and hydrolyzing the iminodiacetonitrile solution into iminodiacetic acid disodium salt by using sodium hydroxide, using peroxide to decolorize the iminodiacetic acid disodium salt, performing the separation of a destaining solution by using the sulfuric acid to acidify once and then perform multiple crystallization or firstly performing continuous chromatography and then performing crystallization separation separately, or using the sulfuric acid to perform graded acidification, and then performing crystallization separation separately so as to obtain solid iminodiacetic acid and solid sodium sulfate. The method of the invention is simple in process and low in investment; not only iminodiacetonitrile produced mother liquor is effectively treated, an expensive incinerator is not needed to be bought, and secondary pollution of waste gas from an incinerator can also be prevented; furthermore, the glycolonitrile, aminoacetonitrile and iminodiacetonitrile contained in the mother liquor can be effectively recovered so as to prepare iminodiacetic acid with economic value, thereby reducing the production cost.

Owner:CHONGQING UNISPLENDOUR CHEM

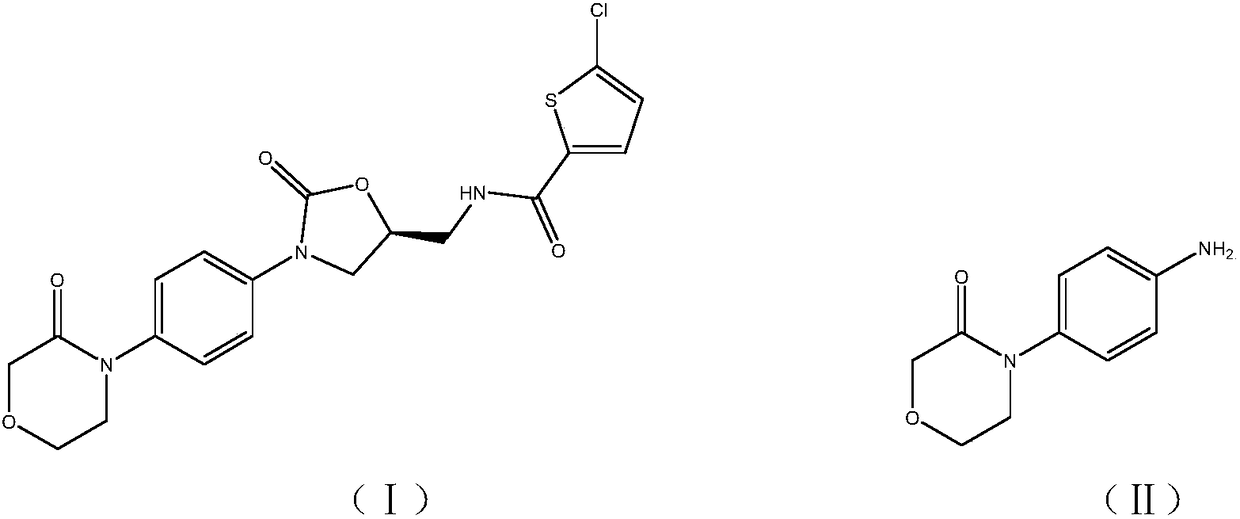

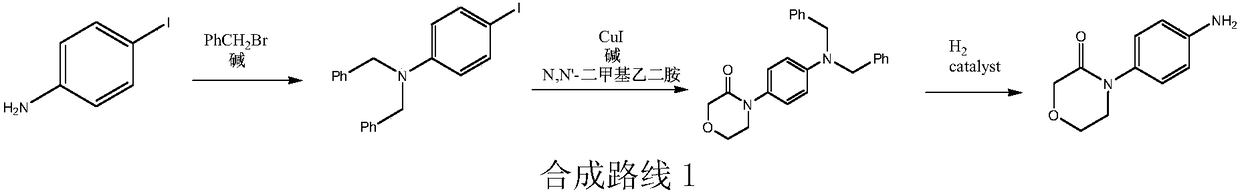

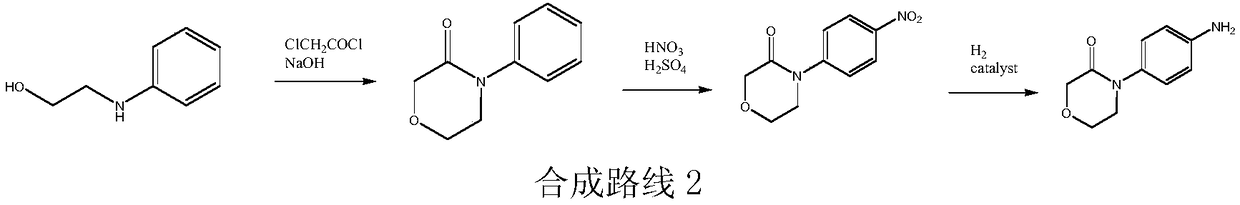

High-purity 4-(4-aminophenyl)morpholine-3-one preparation method

The invention relates to a low-cost high-purity 4-(4-aminophenyl)morpholine-3-one (II) preparation method, which comprises: carrying out a substitution reaction on hydroxyacetonitrile and 1,2-dihaloethane to prepare haloethyloxyacetonitrile (IV), carrying out a substitution reaction on the haloethyloxyacetonitrile (IV) and p-nitroaniline (III), carrying out cyclization under an acid condition to form 4-(4-nitrophenyl)morpholine-3-one (V), and carrying out hydrogenation reduction on the 4-(4-nitrophenyl)morpholine-3-one (V) to obtain the 4-(4-aminophenyl)morpholine-3-one (II). According to thepresent invention, the preparation method has characteristics of inexpensive and easily-available raw materials, low cost, simple process route, safety, environmental protection, high selectivity of each designed step and high yield, ensures the preparation of the high-purity 4-(4-aminophenyl)morpholine-3-one, and easily performs the industrial preparation of high-purity rivaroxaban.

Owner:XINFA PHARMA

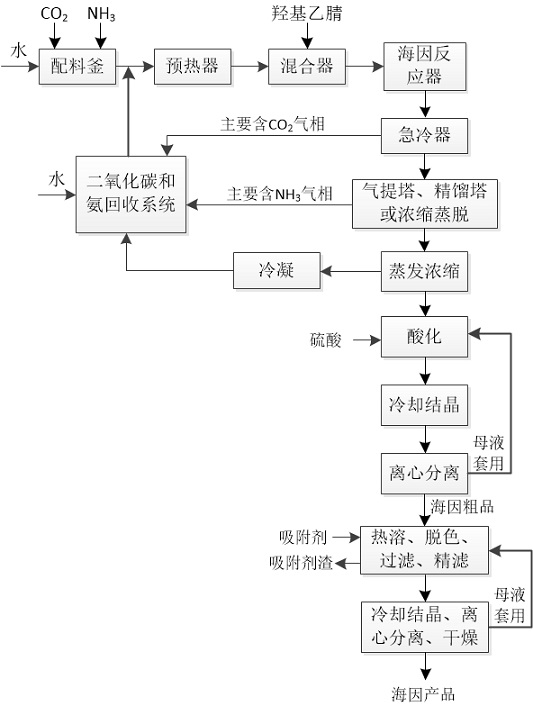

Clean production process for continuously synthesizing hydantoin

A clean production process for continuously synthesizing hydantoin comprises the following steps: preheating a carbon dioxide ammonia water solution prepared from an ammonia source, a carbon source and water, mixing with hydroxyacetonitrile, continuously synthesizing, carrying out reduced pressure flash evaporation, carrying out gas stripping, concentrating, acidifying, crystallizing, separating to obtain a crude hydantoin product, and refining to obtain the high-purity hydantoin product. A carbon dioxide and ammonia recovery system sequentially absorbs the gas phase separated by gas strippingand reduced pressure flash evaporation to obtain a carbon dioxide ammonia water solution, and the carbon dioxide ammonia water solution returns to a reaction system. By increasing the amount of carbon dioxide in the ratio, side reactions generating iminodiacetonitrile, nitrilotriacetonitrile and glycine are restrained, and the hydantoin yield is increased; and through timely release of each gas phase in the system and reasonable arrangement of a recovery sequence, the difficulty of recycling carbon dioxide and ammonia in the system is reduced, the loss of carbon dioxide and ammonia is reduced, zero discharge of wastewater and waste liquid can be realized, and the method is an environment-friendly and clean hydantoin production process method.

Owner:龙智

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com