Preparation method of N,N-dimethylglycine

A technology of dimethylglycine and dimethylglycine salt, which is applied in the chemical industry, can solve problems such as application limitations, and achieve the effects of high production efficiency, reduced production costs, and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

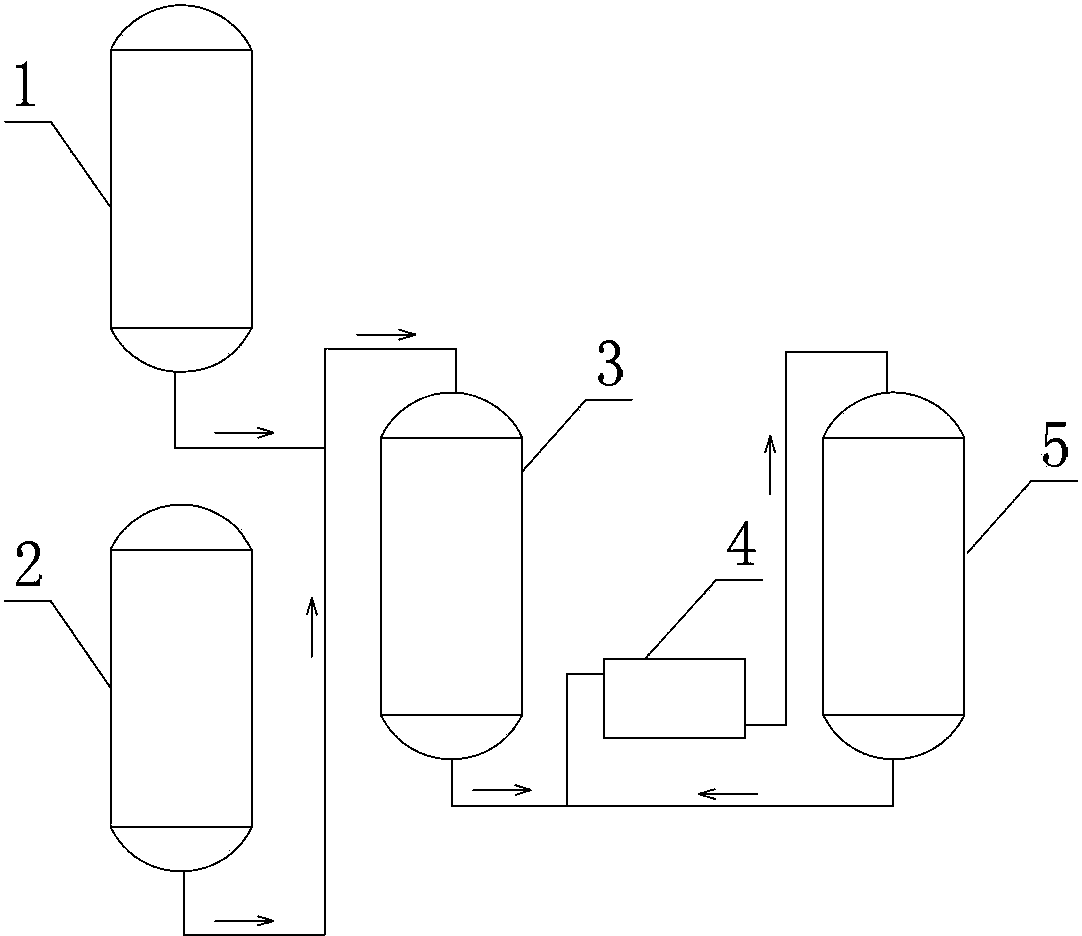

Image

Examples

Embodiment 1

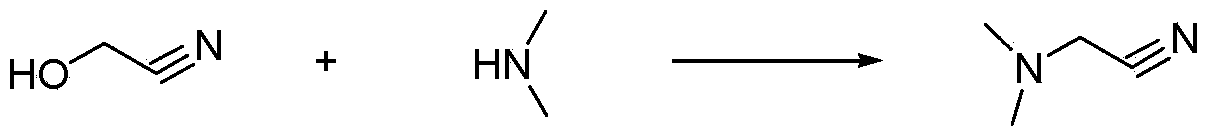

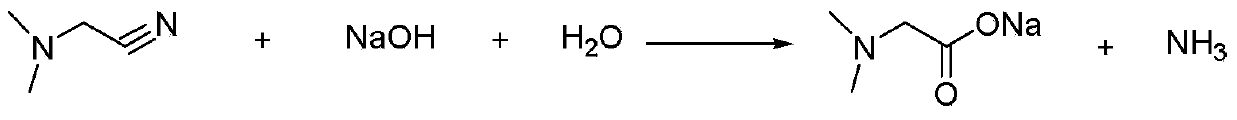

[0041] Embodiment 1 hydroxyacetonitrile method prepares N, N-dimethylglycine

[0042] At room temperature, add 1000g of 40% hydroxyacetonitrile aqueous solution to the high-pressure reactor, then pass through 1435g of 33% dimethylamine aqueous solution, heat up to 60°C, pressure 0.7MPa, after 0.5 hours of reaction, stop the reaction, and transfer the reaction solution to 3000ml In the flask, add 561g of 50% sodium hydroxide aqueous solution to the reaction solution, and keep it warm at 80°C for 5 hours to obtain an ammonia solution of N,N-dimethylglycine sodium salt, and deamination to obtain N,N-dimethylglycine Sodium salt solution, followed by adding 98% sulfuric acid to adjust the pH to 5.0 to obtain a mixture of N,N-dimethylglycine and sodium sulfate. Add 8g of activated carbon for decolorization, remove the activated carbon by suction filtration, cool the filtrate to 10°C, crystallize, centrifuge to remove sodium sulfate crystals, and crystallize and purify the filtrate a...

Embodiment 2

[0043] Embodiment 2 hydroxyacetonitrile method prepares N, N-dimethylglycine

[0044] At room temperature, add 1000g of 40% hydroxyacetonitrile aqueous solution to the high-pressure reactor, then pass through 1435g of 33% dimethylamine aqueous solution, heat up to 60°C, pressure 0.7MPa, after 0.5 hours of reaction, stop the reaction, and transfer the reaction solution to 3000ml In the flask, add 786g of 50% potassium hydroxide aqueous solution to the reaction solution, and keep it warm at 80°C for 5 hours to obtain an ammonia solution of N,N-dimethylglycine potassium salt, and deamination to obtain N,N-dimethylglycine Potassium salt solution, followed by adding 37% hydrochloric acid to adjust the pH to 5.0 to obtain a mixture of N,N-dimethylglycine and potassium chloride. Add 7g of activated carbon for decolorization, remove the activated carbon by suction filtration, cool the filtrate to 10°C, crystallize, centrifuge to remove potassium chloride crystals, and crystallize and ...

Embodiment 3

[0045] Embodiment 3 hydroxyacetonitrile method prepares N, N-dimethylglycine

[0046] At room temperature, add 1000g of 40% aqueous solution of hydroxyacetonitrile to the high-pressure reactor, then pass through 1435g of 33% aqueous solution of dimethylamine, raise the temperature to 60°C, and pressurize at 0.6MPa. After reacting for 0.5 hours, stop the reaction, and transfer the reaction solution into a In the flask, add an aqueous solution composed of 497g of sodium sulfate and 259g of calcium hydroxide to the reaction solution, and incubate at 85°C for 7 hours to obtain an ammonia solution of N,N-dimethylglycine sodium salt, and deamination to obtain N,N- Dimethylglycine sodium salt solution, followed by adding 37% hydrochloric acid to adjust the pH to 4.5, to obtain a mixed solution of N,N-dimethylglycine, sodium chloride and calcium sulfate. Add 8g of activated carbon for decolorization, remove the activated carbon by suction filtration, cool the filtrate to 10°C, crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com