Method for continuous co-production of glycine and hydantoin

A technology of glycine and hydantoin, applied in organic chemistry and other directions, can solve the problems of low-value inorganic salts, high production costs and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

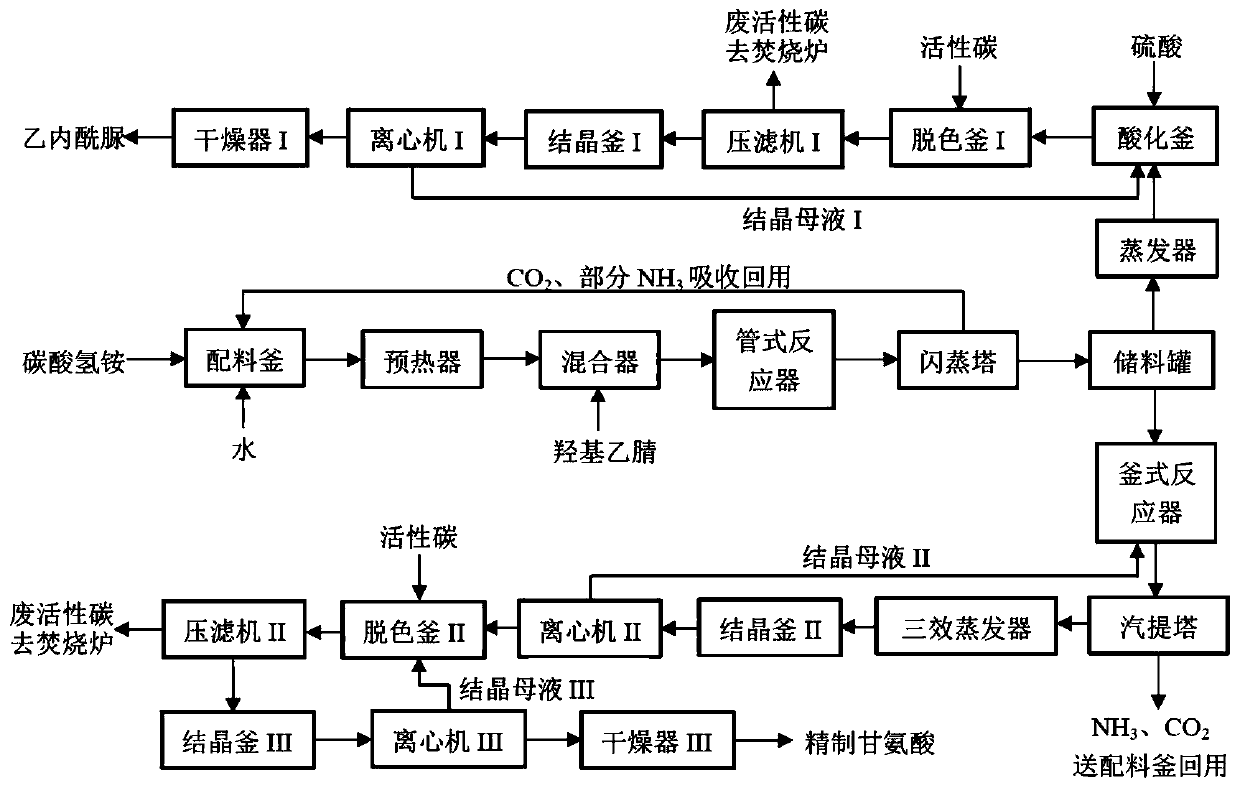

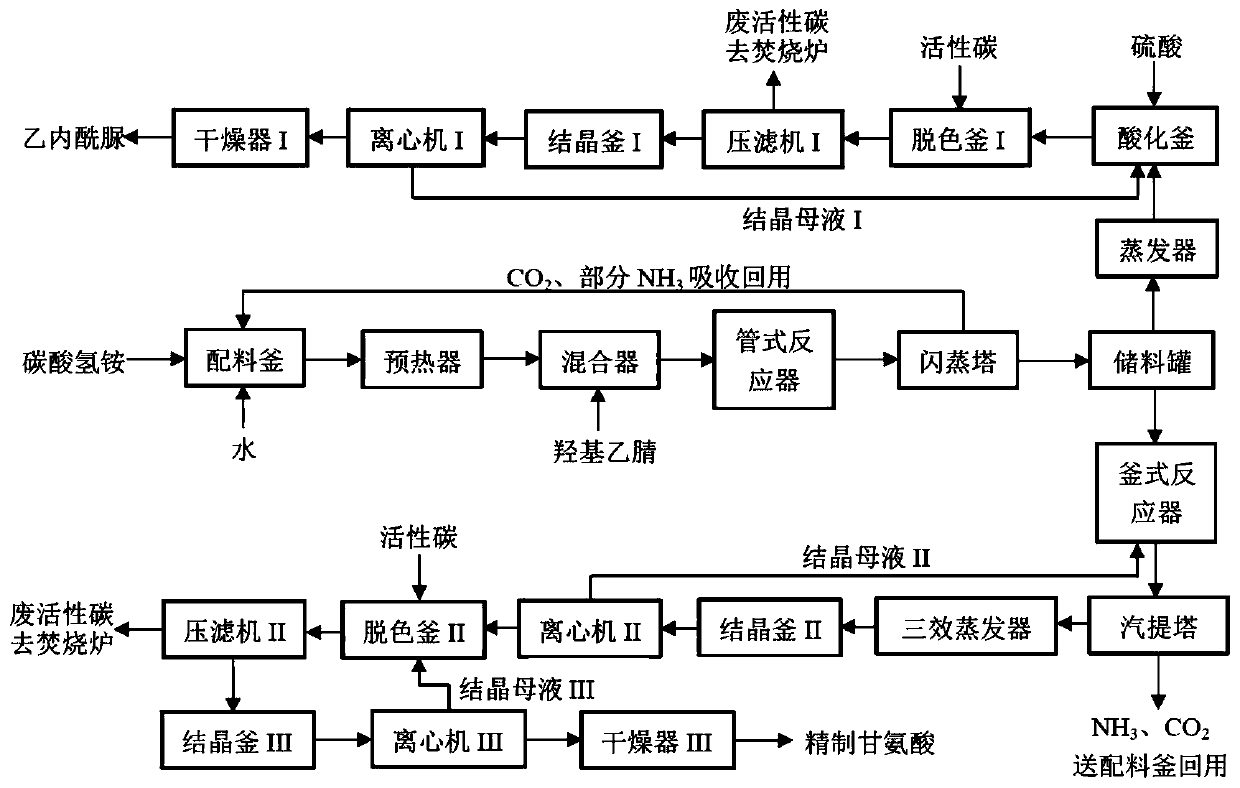

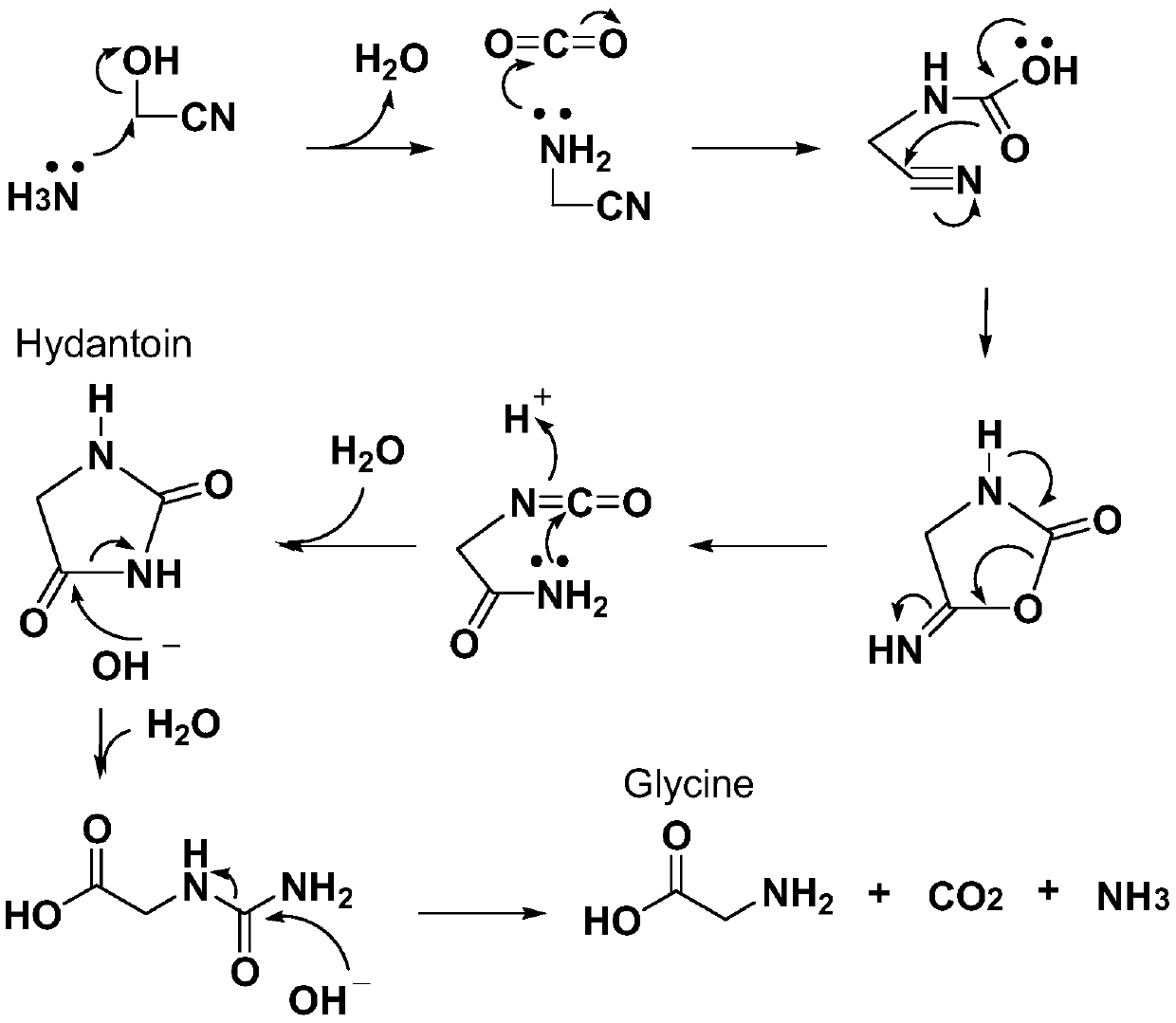

Method used

Image

Examples

Embodiment 1

[0048] Hydroxyacetonitrile, ammonium bicarbonate, and water are mixed according to the ratio of 1:2:50, and transported by the metering pump to the tubular reactor at 143L / min for synthetic hydantoin reaction. The reaction temperature is 100°C, the pressure is 2.0MPa, The residence time is 20min, and then the feed liquid enters the flash tower to remove all CO 2 , some NH 3 and a small amount of water, 1 / 4 of the obtained synthetic hydantoin reaction liquid enters the evaporator, and the remaining 3 / 4 enters the tank reactor. The reaction liquid that enters the evaporator is evaporated and concentrated to 1 / 3 of the original volume, then enters the acidification reactor, adds 98wt% concentrated sulfuric acid equivalent to 15wt% of the concentrated solution, and reacts for 2 hours at 90°C for acidification (cyclization), and then enters the decolorization reactor 1, add 2wt% activated carbon, decolorize at 90°C for 0.5 hour, then filter, crystallize, centrifuge, and dry to obt...

Embodiment 2

[0050] Hydroxyacetonitrile, ammonium bicarbonate, and water are mixed according to the ratio of 1:3:55, and transported by the metering pump to the tubular reactor at 151L / min for synthetic hydantoin reaction. The reaction temperature is 110°C, the pressure is 2.5MPa, The residence time is 18min, and then the feed liquid enters the flash tower to remove all CO 2 , some NH 3 and a small amount of water, 1 / 4 of the obtained synthetic hydantoin reaction liquid enters the evaporator, and the remaining 3 / 4 enters the tank reactor. The reaction liquid that enters the evaporator is evaporated and concentrated to 1 / 3 of the original volume, then enters the acidification reaction tank, adds 98 wt% concentrated sulfuric acid equivalent to 15 wt% of the concentrated solution, and reacts for 2.5 hours at 90°C for acidification (cyclization), and then enters the decolorization tank 1, add 3wt% activated carbon, decolorize at 90 DEG C for 0.6 hours, then filter, crystallize, centrifuge, an...

Embodiment 3

[0052] Hydroxyacetonitrile, ammonium bicarbonate, and water are mixed according to the ratio of 1:3.5:60, and transported by the metering pump to the tubular reactor at 135L / min for synthetic hydantoin reaction. The reaction temperature is 90°C, the pressure is 2.0MPa, The residence time is 23min, and then the feed liquid enters the flash tower to remove all CO 2 , some NH 3 and a small amount of water, 1 / 2 of the resulting synthetic hydantoin reaction liquid enters the evaporator, and the remaining 1 / 2 enters the tank reactor. The reaction liquid that enters the evaporator is evaporated and concentrated to 1 / 4 of the original volume, then enters the acidification reactor, adds 98wt% concentrated sulfuric acid equivalent to 17wt% of the concentrated solution, and reacts for 3 hours at 90°C for acidification (cyclization), and then enters the decolorization reactor 1, add 2.5wt% activated carbon, decolorize at 90°C for 0.6 hours, then filter, crystallize, centrifuge, and dry t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com