Method and apparatus for preparing iminodiacetic acid by using iminodiacetonitrile to produce mother liquor

A technology of iminodiacetonitrile and iminodiacetic acid is applied in the field of the reuse method of iminodiacetonitrile production mother liquor and its supporting device field, which can solve the problems of high phase separation temperature, lowering the recovery rate of iminodiacetonitrile and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

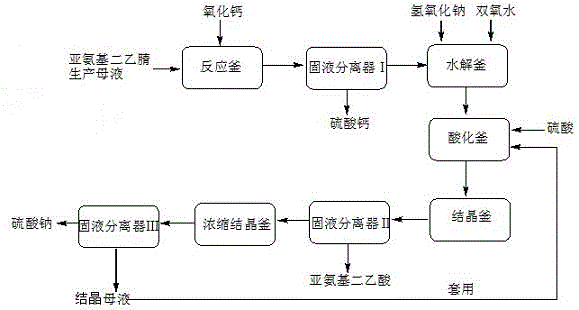

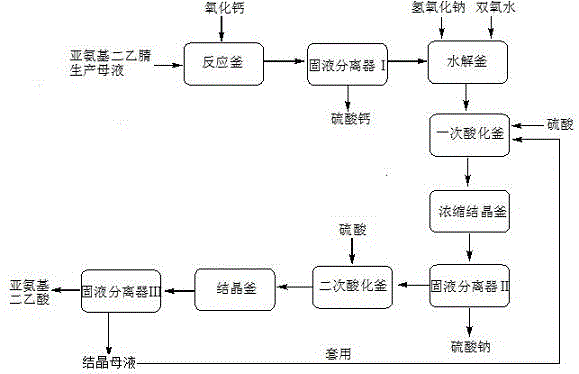

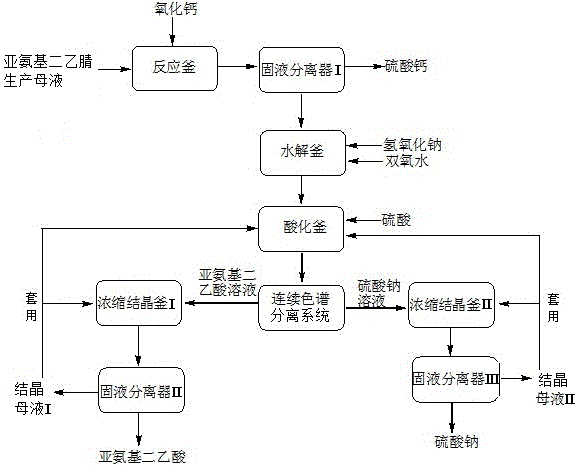

[0081]The schematic diagrams of the method and device of technical scheme one, two and three of the present invention are respectively as follows figure 1 , figure 2 , image 3 shown. The steps of the three technical schemes before obtaining the hydrogen peroxide decolorizing solution are exactly the same, and the difference lies in the subsequent processing steps of the hydrogen peroxide decolorizing solution. Therefore, their respective supporting devices are also the same in the first half and different in the second half.

[0082] The device of the technical scheme 1 includes a reaction kettle, a solid-liquid separator I, a hydrolysis kettle, an acidification kettle, a crystallization kettle, a solid-liquid separator II, a concentrated crystallization kettle and a solid-liquid separator III connected in sequence.

[0083] The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com