Preparation technology of N-phenylglycinonitrile

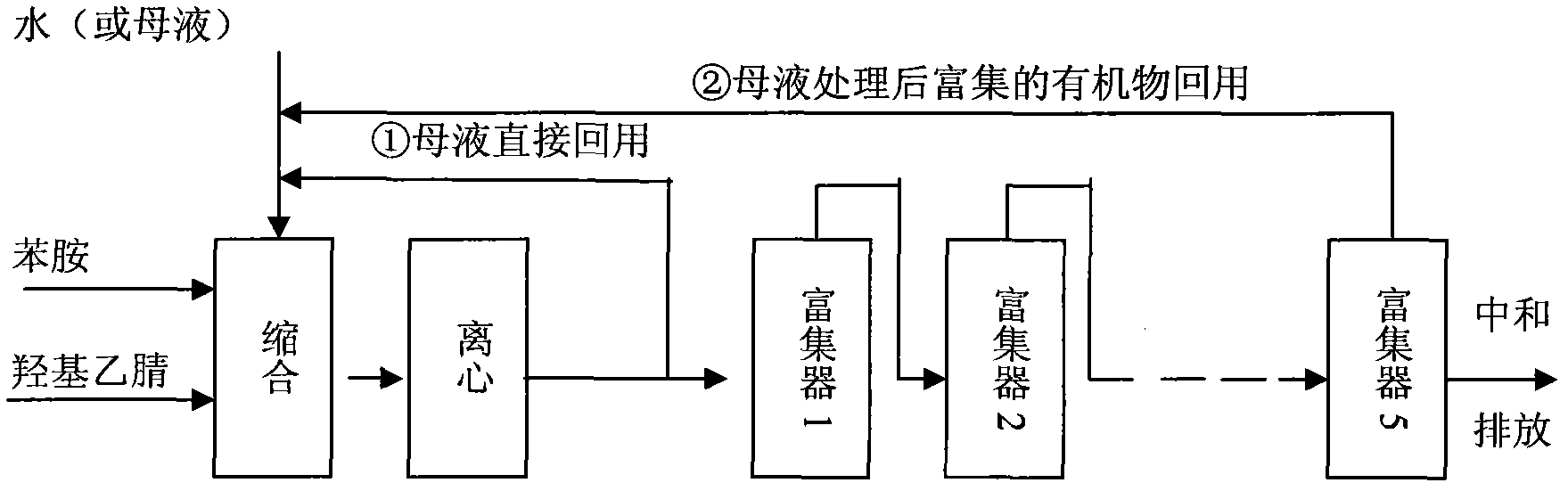

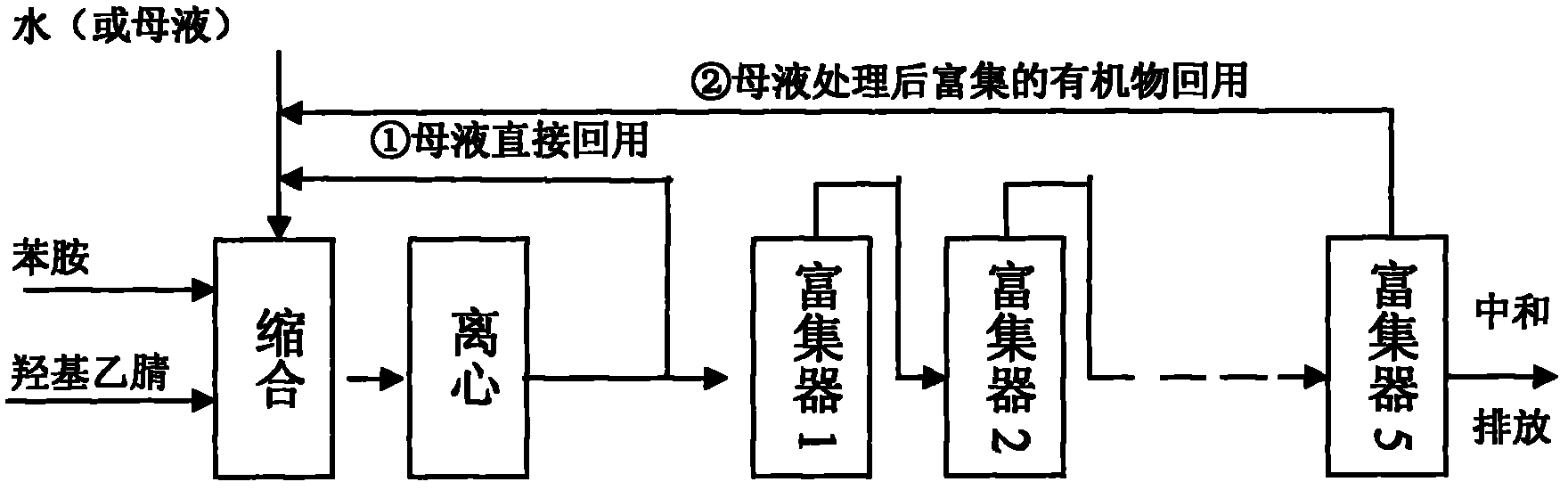

A technology of anilinoacetonitrile and preparation process, applied in the preparation of carboxylic acid nitrile, preparation of organic compounds, organic chemistry, etc., can solve the problems of complicated wastewater treatment process, low mother liquor reuse rate and high treatment cost, and reduce wastewater treatment. The effect of low production cost and good social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 200g of distilled water into a 500ml four-necked bottle, adjust the pH to 11 with 2g of 25% ammonia water, then add 50g of 99.5% aniline, stir evenly, then add 65g of 50% hydroxyacetonitrile within 5 minutes, and heat to 70-75°C React for 0.5h, then raise the temperature steadily to 90-95°C for 6h. Then gradually cooled to 40-45°C for crystallization, and centrifuged at 15-20°C to obtain N-anilinoacetonitrile with a content of 97.05%, a liquid phase purity of 97.12%, and a colorless transparent crystal with a yield of 99.50%.

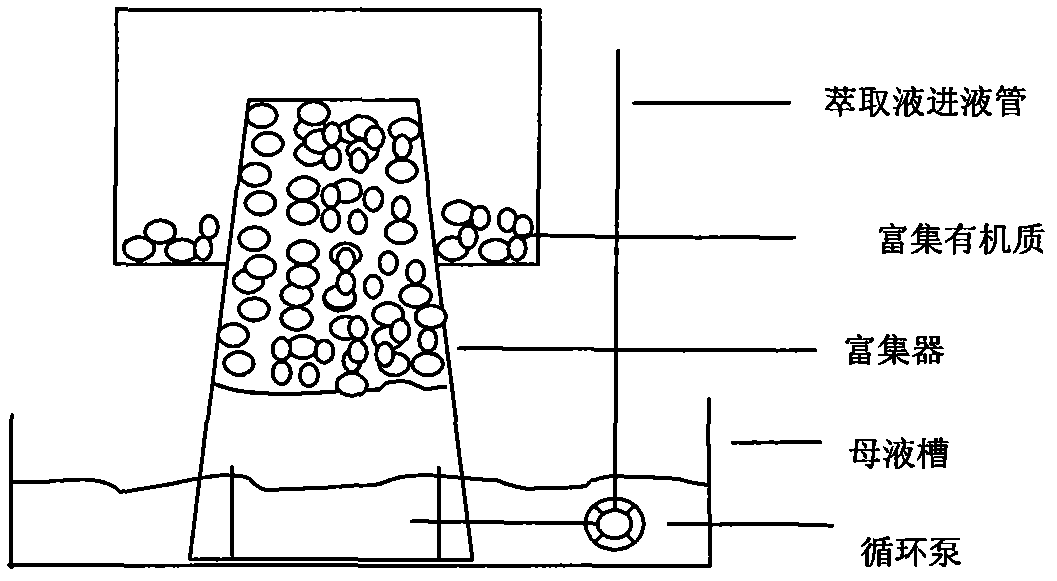

[0030] Obtain mother liquor waste water 240g, COD35000ppm, total nitrogen 2000ppm, pH value 11, after described mother liquor waste water can pass through 3 grades of organic matter enrichment devices (toluene is extraction agent), mother liquor waste water COD is reduced to 128ppm, total nitrogen is reduced to 46ppm, pH value 9, decolorized by activated carbon with 1% mother liquor for 0.5h, filtered to a colorless liquid, adjusted to pH 7 w...

Embodiment 2

[0032] Add 200g of mother liquor and 135g of distilled water into a 1000ml four-neck bottle, measure the pH to 10 without adjustment, then add 95g of 99.5% aniline, stir evenly, then add 119g of 50% hydroxyacetonitrile within 5 minutes, heat to 70-75°C for reaction After 1h, the temperature was raised steadily to 95-98°C for 4h. Then gradually cooled to 45-48°C to crystallize, and centrifuged at 20-25°C to obtain N-anilinoacetonitrile with a content of 97.35%, a liquid phase purity of 97.54%, and slightly yellow transparent crystals with a yield of 99.81%.

[0033] Obtain mother liquor waste water 380g, COD25000ppm, total nitrogen 1500ppm, pH value 9.5, after described mother liquor waste water can pass through 4 grades of organic matter enrichment devices (dichloromethane is extraction agent), mother liquor waste water COD is reduced to 155ppm, and total nitrogen is reduced to 40ppm, The pH value is 8, decolorized by activated carbon with 0.5% of the mother liquor for 0.5 h, ...

Embodiment 3

[0035] Add 535g of mother liquor into a 1000ml four-neck bottle, measure the pH to 9 without adjustment, then add 100g of 99.5% aniline, stir evenly, then add 127g of 50% hydroxyacetonitrile within 5 minutes, heat to 70-75°C for 1.5h, Then the temperature was raised steadily to 95-98°C for 2h. Then gradually cooled to 35-40°C for crystallization, and centrifuged at 25-30°C to obtain N-anilinoacetonitrile with a content of 97.65%, a liquid phase purity of 97.70%, and light yellow transparent crystals with a yield of 99.88%.

[0036] Obtain mother liquor waste water 560g, COD30000ppm, total nitrogen 1600ppm, pH value 8.5, after described mother liquor waste water can pass through 5 grades of organic matter enrichment devices (toluene is extraction agent), mother liquor waste water COD is reduced to 130ppm, total nitrogen is reduced to 42ppm, pH value 8, decolorized by activated carbon with 0.5% mother liquor for 0.5h, filtered to a colorless liquid, adjusted to pH 7 with hydroch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com