Heat pump rectification steam stripping deamination method

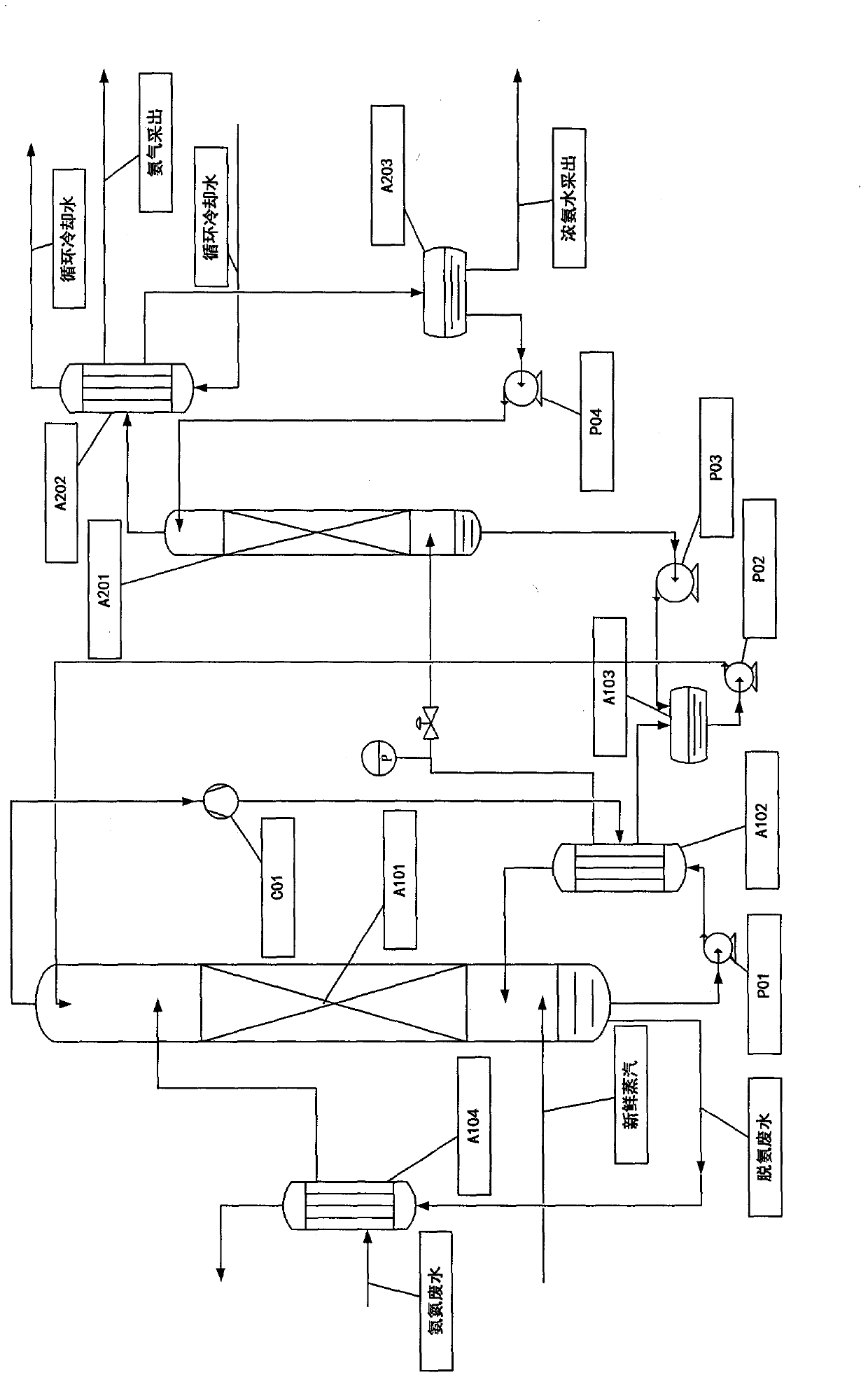

A technology of stripping ammonia removal and heat pump rectification, which is applied in ammonia preparation/separation, degassed water/sewage treatment, energy input, etc. It can solve the problems of high cost of ammonia nitrogen wastewater treatment and high steam unit consumption of ammonia nitrogen wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Adopt the present invention to process ammonia nitrogen waste water import ammonia nitrogen concentration 8000mg / L, processing capacity is 30m 3 / h. Nessler's reagent colorimetric method (GB7479-87) was used for analysis, and the concentration of ammonia nitrogen in the treated wastewater was 2.7mg / L. The steam consumption is 32kg / ton of waste water.

Embodiment 2

[0041] Use the present invention to process ammonia nitrogen waste water import ammonia nitrogen concentration 30000mg / L, processing capacity is 18m 3 / h. Nessler's reagent colorimetric method (GB7479-87) was used for analysis, and the concentration of ammonia nitrogen in the treated wastewater was 5.5 mg / L. The steam consumption is 40kg / ton of waste water.

Embodiment 3

[0043] Use the present invention to process ammonia nitrogen waste water import ammonia nitrogen concentration 60000mg / L, treatment capacity is 22m 3 / h. Nessler's reagent colorimetric method (GB7479-87) was used for analysis, and the concentration of ammonia nitrogen in the treated wastewater was 9.7mg / L. The steam consumption is 49kg / ton of waste water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com