Patents

Literature

242 results about "Bulrush millet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

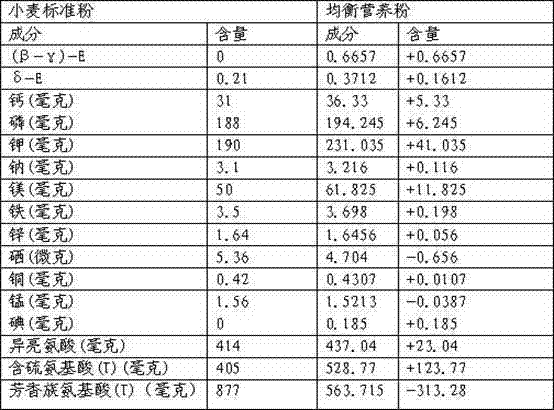

Staple food flour with balanced nutrition and preparation method of staple food flour

InactiveCN105433201AGood therapeutic effectGood effectFood ingredient functionsBiotechnologyBulrush millet

The invention relates to staple food flour with balanced nutrition. The staple food flour is prepared from wheat flour, oat flour, potato flour, coix seed flour, millet flour, corn flour, sorghum flour, rice flour, glutinous rice flour, soy flour, mung bean flour, small red bean flour and navy bean flour. The production method comprises the following steps of a, respectively drying wheat, oat, unhusked rice, corn, sorghum, rice and glutinous rice, and grinding the dried wheat, the dried oat, the dried unhusked rice, the dried corn, the dried sorghum, the dried rice and the dried glutinous rice; b, respectively drying coix seeds, dried potatoes, soybeans, mung beans, small red beans and kidney beans, and performing superfine grinding; and c, pouring the powdery materials into a mixer, uniformly stirring the powdery materials so as to obtain mixtures, and loading the mixtures into bags so as to obtain finished products. The staple food flour with balanced nutrition, disclosed by the invention, is made by scientifically compounding 13 kinds of food materials in food grains, beans and potatoes, and is good in mouth feel; people can eat cereals every day in a balanced manner, nutrient components of the staple food flour can be sufficiently neutralized, a traditional habit that single wheat flour or single rice is eaten is changed, the constitutions and the immunity of people are enhanced, the purpose of increasing the physical health level of people is achieved, and the staple food flour disclosed by the invention can be used as staple food flour in daily life of people.

Owner:李青簃

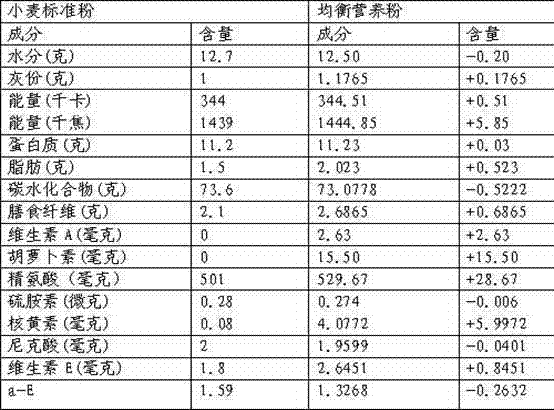

Compounded herbicidal composition of single sulphur ester compounds

ActiveCN101161072APlay a synergistic roleDelay drug resistanceBiocideAnimal repellantsMonosulfuronSuspending Agents

The present invention relates to herbicide composition of monosulfuron ester compound as well as its application, which is compounded with two-element or three-element from herbicide monosulfuron ester or its natrium salt (0.1 to 90 percent) as main active component, and other herbicide (0.1 to 85 percent) of ethyl carboxylic fluorine grass ether, Starane, thifensulfuron-methyl, tribenuron-methyl, 2,4D as well as its ramification, Prometrex prometryn, acetochlor, atrazine, triallate, metolachlor, bensulfuron-methyl or 2 armour 4 chlorin natrium etc., and the herbicide composition can be made into breast oil, wettable powder, soluble powder, water emulsion, microemulsion agent, aqua, suspending agent, microcapsule agent or water disperse particle agent by adding proper amount auxiliary agent and carrier accepted in agriculture. The composition can be used to prevent single and double cotyledon weed in wheat, corn and millet field.

Owner:NANKAI UNIV

Formula and production method of five-cereal beer

ActiveCN102746962AWith health functionRich varietyBeer fermentationMicroorganism based processesBulrush milletSteeping

The invention discloses a formula and a production method of five-cereal beer. The five-cereal beer is prepared from barley, broom corn millet, foxtail millet, buckwheat and highland barley which are mixed in proportion. The production method of the five-cereal beer comprises the following process steps: careful selecting, steeping, sprouting, drying, root removing and storing, crushing, saccharifying, boiling, inoculating, pre-fermenting and main fermenting, after-fermenting and beer storing and the like. According to the invention, the nutrient characteristics of the five cereals including barley, broom corn millet, foxtail millet, buckwheat and highland barley are well used; and the novel beer prepared by the step of fermenting the five cereals has a certain health-care function, is quite suitable to women and the aged, and diversifies the variety of the traditional beer.

Owner:甘肃省轻工研究院有限责任公司

Plant leaf green powder feed

InactiveCN101606578ANo pollution in the processHigh nutritional valueFood processingAnimal feeding stuffGenus LoliumLivestock

The invention relates to plant leaf green powder feed prepared by evenly mixing the straw powder of crops, such as corn, sorghum, millet, paddy, wheat and the like, the leaf green powder of plants, such as clover, pachyrhizus leaves, ryegrass, pine needles, tung tree leaves, locust tree leaves, shrubby falseindigo leaves, bean seedlings, ginseng leaves, reed and the like, the corn, bean cakes, wheat bran and lees by a certain mechanical processing. The invention makes full use of the straws of the crops and the stem and leaf resources of green plants, furthest retains chlorophyll and various nutrition in the stems and leaves of plants, saves large numbers of grains, avoids a condition that livestock and fowl feed uses large numbers of grains and vies for the grains with people, overcomes meat food contamination caused by using a chemical additive in the existing feed and effectively prevents animals from suffering from various diseases in the growing process, and the bred animals quickly grow, lay eggs and have much milk.

Owner:田新亮 +1

Setaria bipolaris strain and use for preventing and killing off weed

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

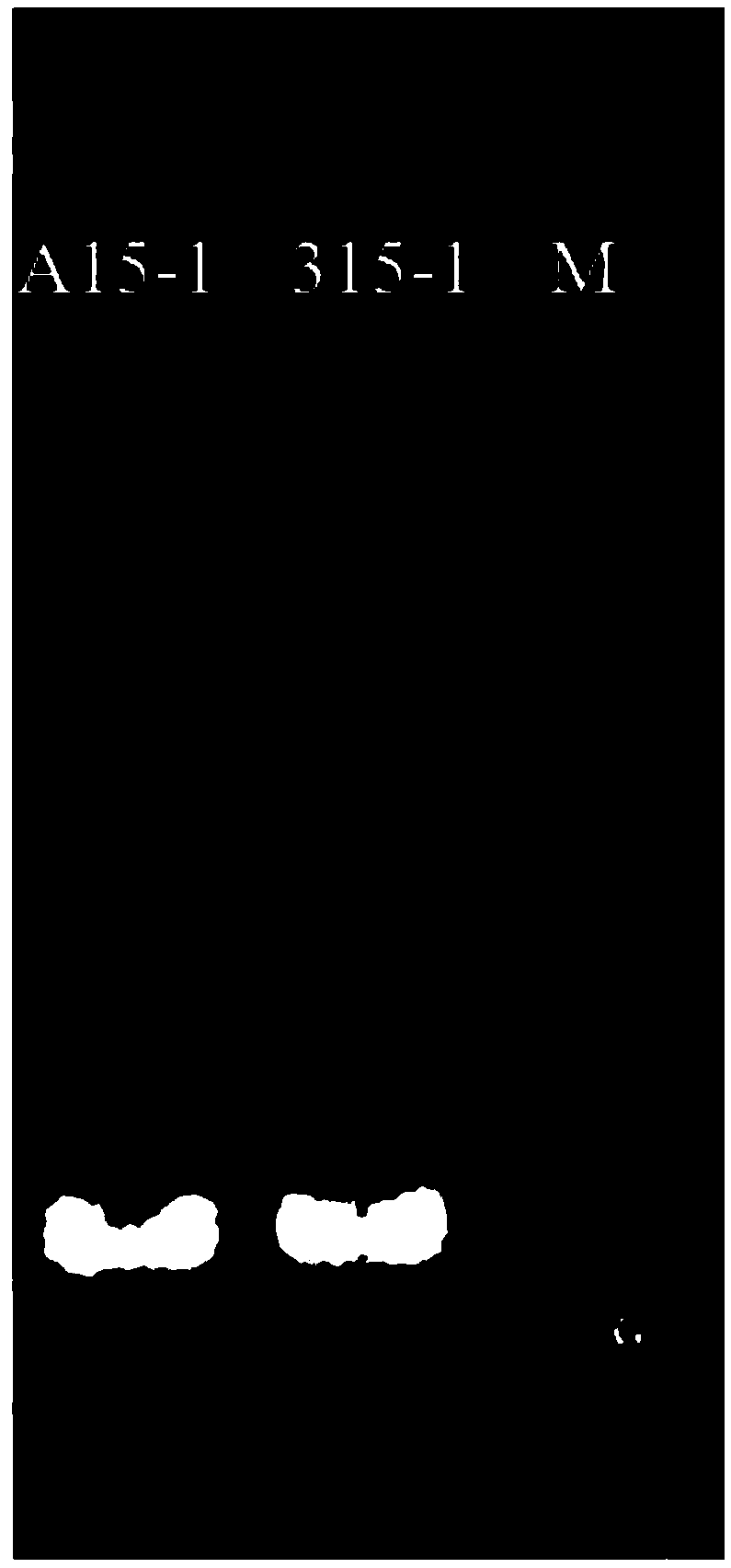

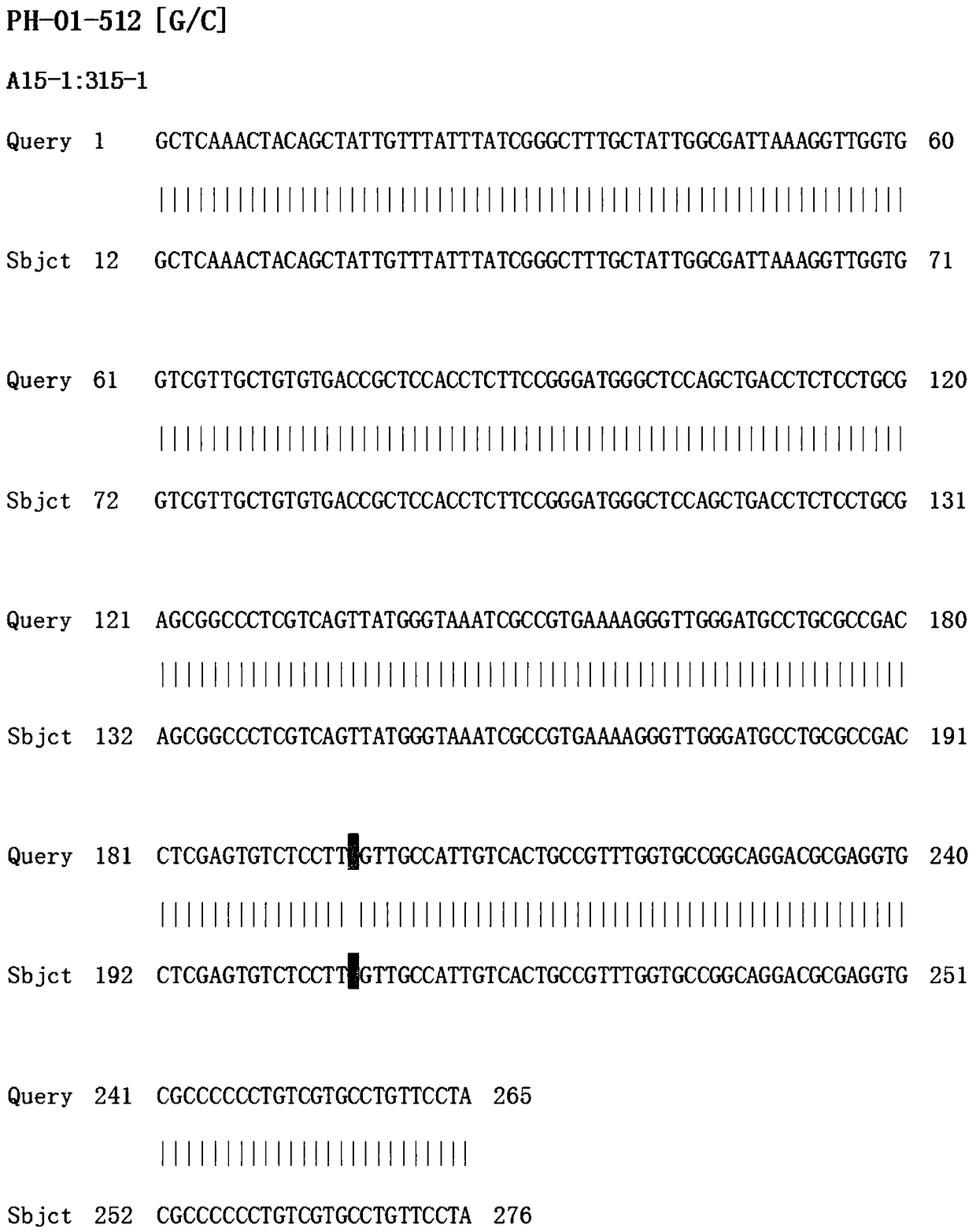

SNP markers linked with color of husked millet, and primers and application thereof

InactiveCN106939342AGood typingSpeed up breedingMicrobiological testing/measurementDNA/RNA fragmentationTypingAssistive technology

The invention discloses SNP markers linked with the color of husked millet. The SNP markers comprise a marker HC-06-436 and a marker HC-06-250, wherein the marker HC-06-436 is located at the site 34024436 bp of the sixth chromosome of millet and the marker HC-06-250 is located at the site 34035250 bp of the sixth chromosome of millet. The invention also discloses amplimers for acquiring the SNP markers and application of the SNP markers. The SNP markers linked with the color of husked millet and the amplimers thereof can realize good typing of the color of husked millet and detection of SNP differences, are applicable to molecular marker-aided breeding of the character of the color of husked millet, provide molecular assistive technology support for early identification of the character of the color of husked millet and for screening and breeding, and are of important theoretical and practical guidance significance to acceleration of genetic breeding and improvement of millet varieties.

Owner:山西省农业科学院谷子研究所 +1

Artificial breeding method of locust

The invention provides an artificial breeding method of a locust. The method is characterized in that geographical place is selected, wherein the place has sufficient sunlight, good drainage, and is in peace, in east-west direction, and far away from a cotton field, an orchard and other places to which pesticides are generally applied, so as to prevent locust from poisoning and death as well as facilitate water drainage in the rainy season. The breeding method is easy to master, simple to manage, free of limitation from area, suitable for all people to breed, and low in requirements on operators; the feed in the method includes maize, wheat, corn seedling and some monocotyledons, so that the feed is low in price, and the breeding cost is low; the locust reproduction rate is high, the reproduction cycle is short, and the economic benefit is high; the building adopted in the method is a greenhouse which is simple to construct and low in cost; proper place benefits the breeding; in addition, a rainproof layer covers the outer side of the greenhouse, so that the locust can be effectively prevented from being influenced by natural rainwater, and the production and survival rate can be ensured.

Owner:DIQISHUN TIANJIN FARMING TECH DEVCO

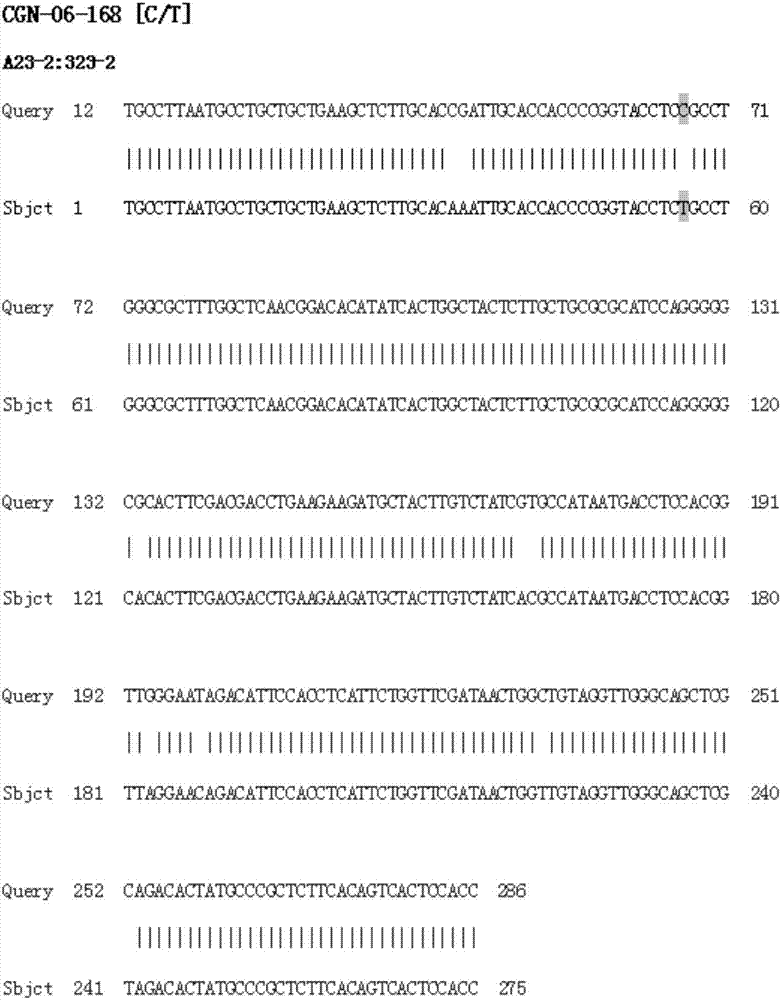

Molecular marker related to grain yard seed number character and detection primer and application thereof

ActiveCN107090494ASpeed up genetic selectionSpeed up the optimization processMicrobiological testing/measurementDNA/RNA fragmentationAgricultural scienceYard

The invention discloses a molecular marker related to the grain yard seed number character and a detection primer and application thereof. The molecular marker is CGN-06-168 and is located at the position 5236168bp of the sixth chromosome, and the basic group is C / T. By means of the molecular marker and the detection primer thereof, the grain yard seed number can be predicted, and molecular auxiliary technical support is provided for early-stage authenticating, screening and breeding of the grain yard seed number character.

Owner:ZHANGJIAKOU ACAD OF AGRI SCI

Breeding of New Varieties of High Yield and Drought Resistant Millet and Its Supporting Cultivation Techniques

Breeding and matching cultivation techniques of a new high-yield and drought-resistant millet variety (Laojinhuang No. 1) with both grain and grass abundance. Its characteristics are: under the natural conditions of nine droughts and windy conditions in ten years, select the mutant grain varieties with short plants, thick necks, wind resistance, drought resistance, and double abundance of grain and grass; the lineage is stable, and the declining lines and mixed lines are eliminated. Seeding, cultivation, high-yield comparative experiments, disease resistance surveys, stable varieties, and selection of the best among the best; after six years and six generations, a new high-yield and drought-resistant millet variety with strong adaptability to the natural climate and soil of the region has been cultivated and tested. (Old Golden No. 1) and supporting cultivation techniques. Using the present invention can reduce millet production cost, increase yield, and increase economic benefits; the yield of millet per hectare can be as high as 6000-6500kg, which is about 3 times that of common millet; The dream of producing more than 1,000 jin of millet per mu is of great significance to the adjustment of the planting industrial structure, the development of grain production, and the improvement of farmers' income in this region.

Owner:侯国权

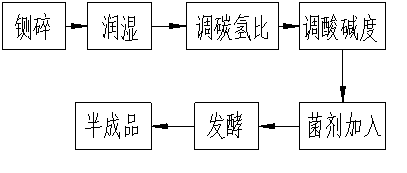

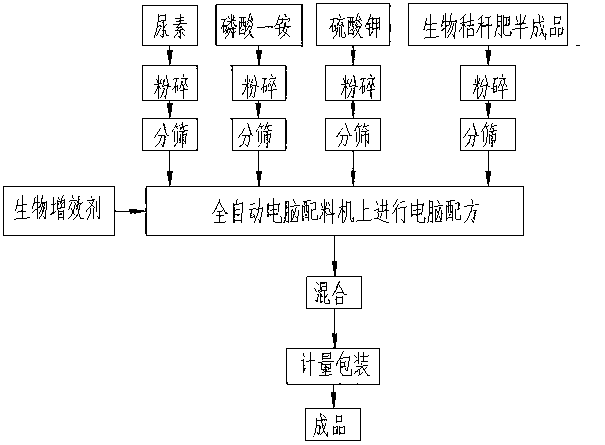

Biological straw fertilizer, and production method and application thereof

InactiveCN102718596AComprehensive nutritionFertilizer effect is stable and longFertilizer mixturesEcological environmentPotassium

The invention discloses a biological straw fertilizer, and a production method and application thereof, and belongs to the field of fertilizer. The biological straw fertilizer contains the following components: nitrogen, phosphorus and potassium (N + P2O5 + K2O); straw organic matters; and biological synergist. A single nutrient content of the nitrogen, phosphorus, potassium and straw organic is not less than 1.6-2.5%; and the biological synergist is prepared by biological fermentation on soybean straw, mung bean straw, pea straw, millet straw, barley straw, rape straw, peanut straw, capsicum rod, tomato rod and drug residue from industrial scale pharmaceutical factory. The biological straw fertilizer protected by the present invention combines effects of microbial fertilizer, and organic and inorganic fertilizer, and can protect the ecological environment. From farm to table, standard safe production of grain can be executed. Therefore, the biological straw fertilizer is a non-toxic, harmless, green and environment-friendly fertilizer.

Owner:四川宏塔生物有机肥有限公司

Herbicide resistance mutant and application thereof

Owner:深圳洁田模式生物科技有限公司

Method for processing fragile millet by using millet and the application

InactiveCN101040679APromote absorptionIt has the effect of strengthening intestines and astringentFood preparationNutrientHorticulture

The invention relates to a method for using millet to prepare crisp rice, and relative application, to be used on rice, edible rice powder, rice tea or the like. The invention via biological enzyme transfers amidon of rice, to avoid regenerating amidon, improve taste and improve crisp. The preparation comprises that selecting rice, enzyme solution immergy, boiling, steaming, drying via hot air, frying via pot, packing and outputting final product. The invention can improve the nutrient value and economic benefits of rice.

Owner:战丁恺

Nutrition balanced miscellaneous cereals food and preparation method thereof

InactiveCN1994096ASolve processabilityAddress nutritional deficienciesDough treatmentMetabolism disorderRipeningMillet flour

The invention discloses a process for preparing food product containing various powders of coarse cereals including wheat flour, dried potato powder, millet flour, naked oat flour, black soybean flour, black sesame seed powder, carrot powder, sea-tangle powder, chicken egg powder, peanut oil and frosted sugar. The preparing process consists of steps of mixing, boiling, ripening, fermenting, fermenting, steaming and baking.

Owner:甘肃省商业科技研究所有限公司

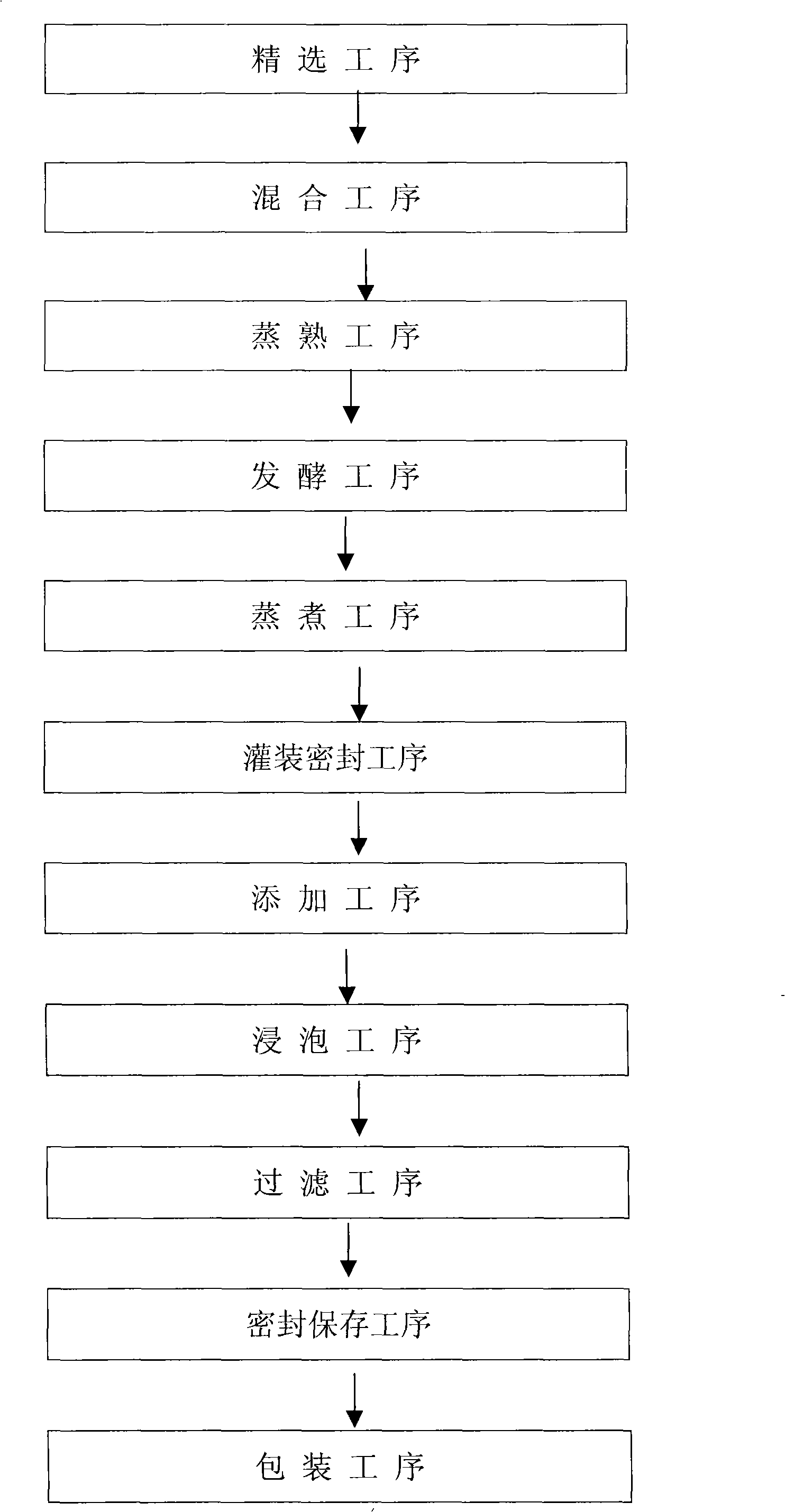

Hawthorn wine and brewing method thereof

The invention discloses a haw wine and the preparation method. Haw, sorghum, corn, wheat and foxtail millet are taken as the raw materials, after all the raw material being mixed, steamed, fermented and digested, the haw white wine is made, which is filled and sealed to be stand-by; the haw, Chinese wolfberry and red date are slagged, cleaned, disinfected and air dried, then the Chinese wolfberry and red date are immerged in the haw white wine, the sealing immersion lasts for 7 to 30 days, finally the haw wine of the invention can be made through the separation of the solid and the liquor, filling and sealing. The haw wine of the invention can eliminate the retention of food, dissipate the passive congestion, activate blood circulation, and can be used in the treatment of flatulence, which is benefit for the stomach, the liver, the spleen, the intestine and the kidney. The haw wine is provided with the functions of good clearing the bloody sputum, reinforcing the vital energy, and resolving the food stagnancy, promoting the blood circulation and removing the blood stasis, decreasing the blood pressure and lowering the lipid and strengthening the stomach and benefiting the spleen etc. which has obvious efficiency to restore the physical fatigue, promote the appetite and prolong the life span. The haw wine is an ideal green health protection food of people.

Owner:陈森淼

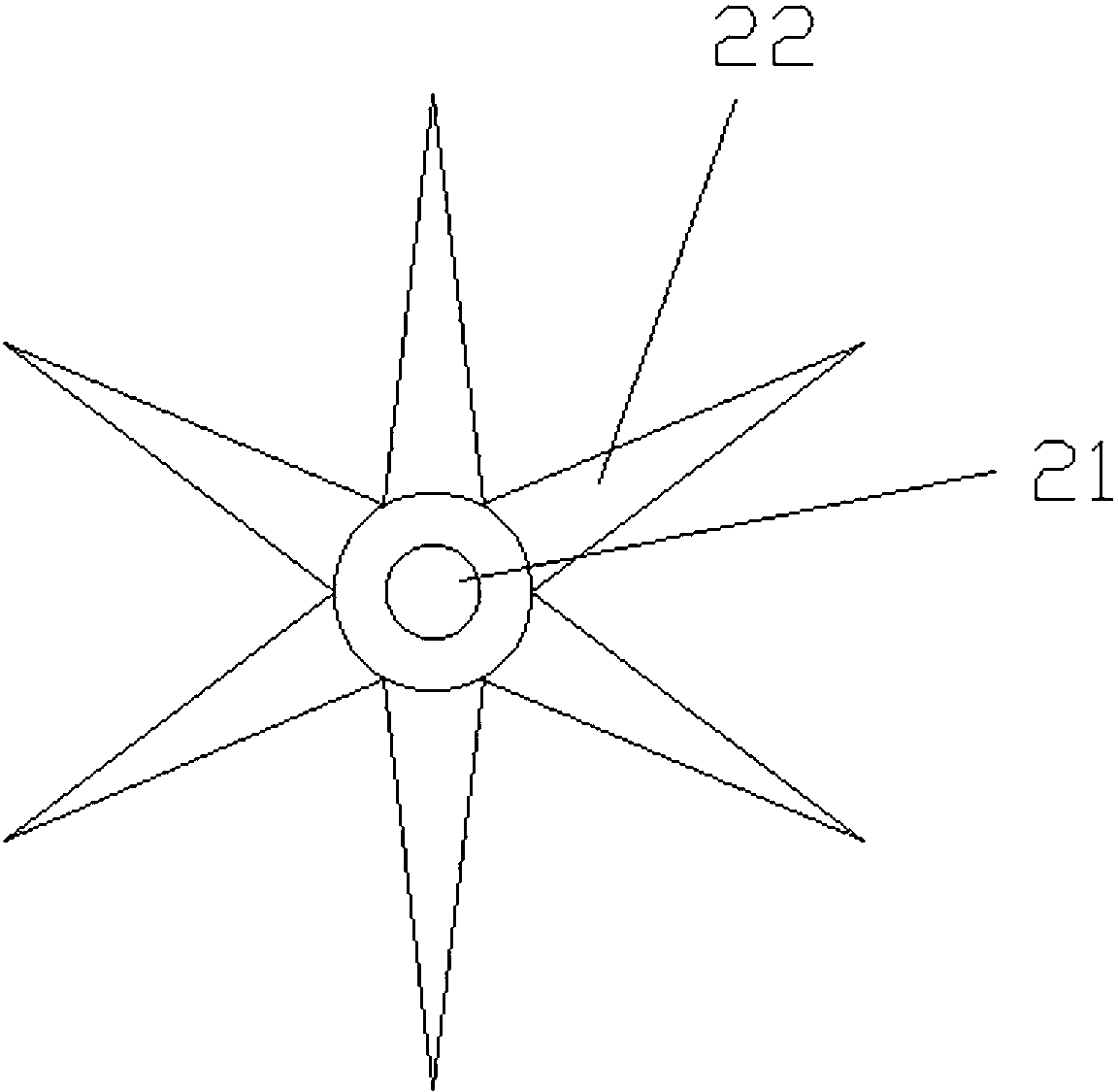

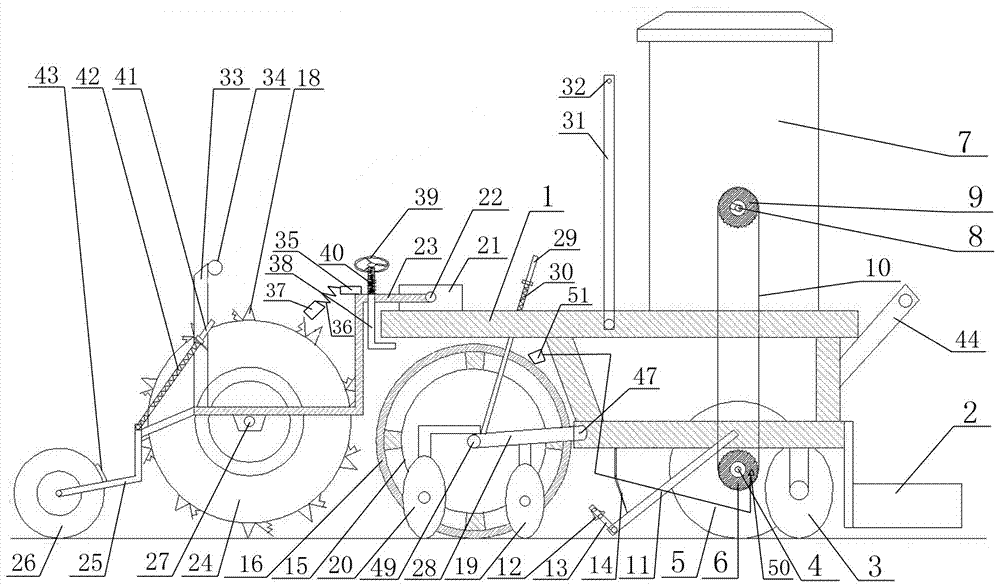

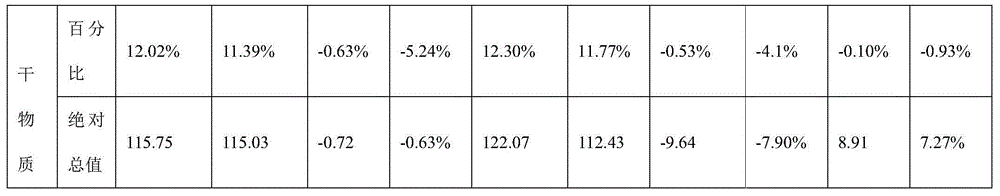

Novel fully feeding combine harvester

The invention relates to a novel fully feeding combine harvester. The novel fully feeding combine harvester comprises a harvester frame, wherein a header is arranged at the front end of the harvester frame; a threshing device is directly connected and installed behind the header; a threshing cylinder in a threshing device is connected to two drive shafts in a manner of a motive power; a grain receiving hopper is arranged below the threshing cylinder; an exhaust inlet is arranged at the lower end of the grain receiving hopper; the exhaust inlet is communicated with a multi-cylinder grain and sundry separation device through an air suction pipe, so that grain and sundry in the grain receiving hopper enter into the multi-cylinder grain and sundry separation through the air suction pipe for separation; grains are discharged from a grain outlet for bagging; and sundries are blown away by a draught fan. The novel fully feeding combine harvester has the advantages of a simple and rational structure, strong practicability, convenience in production, installation as well as maintenance, and good use effects.

Owner:SHAOGUAN FENGYI IND & TRADE

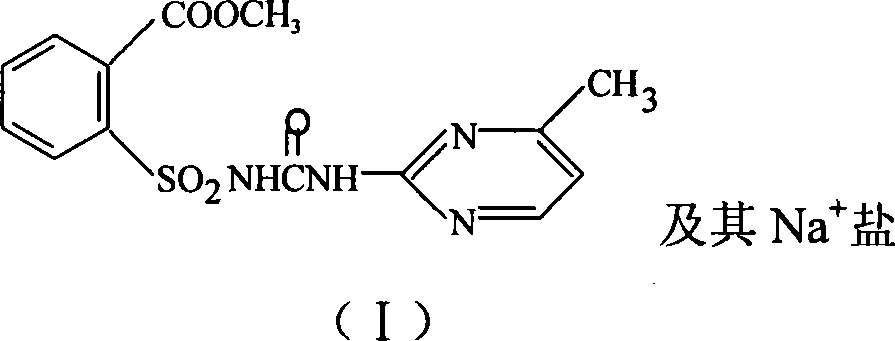

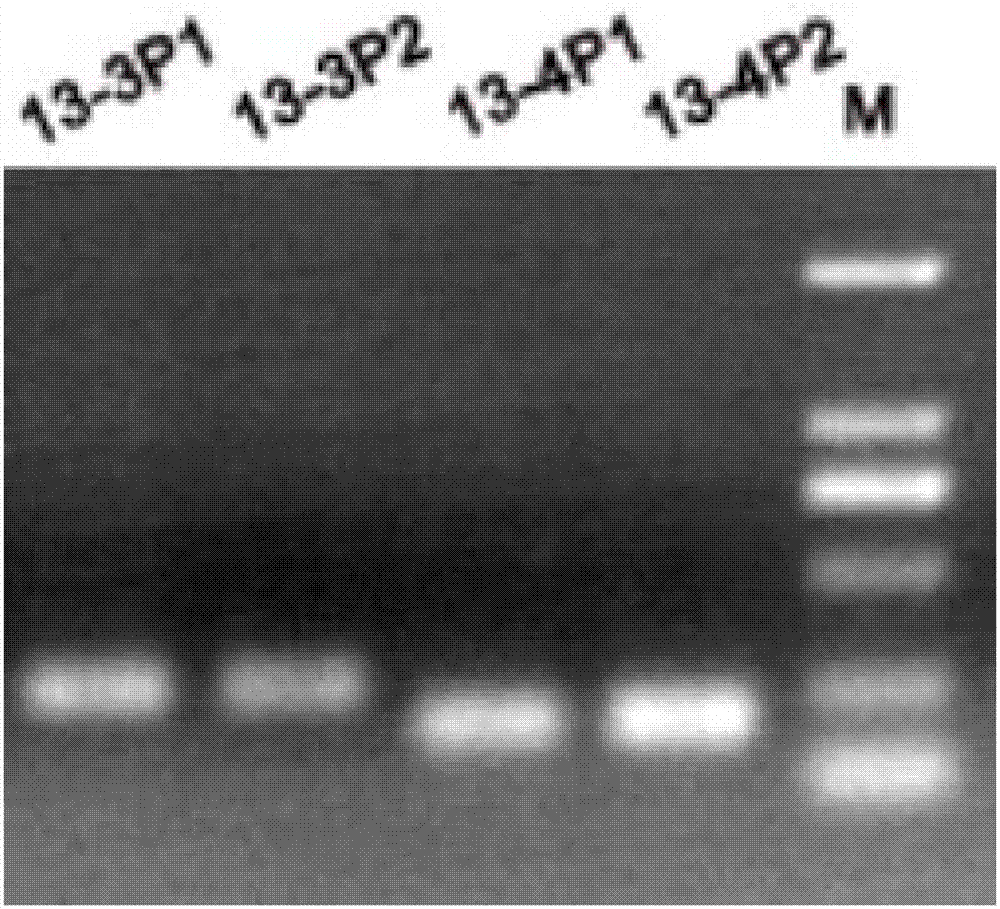

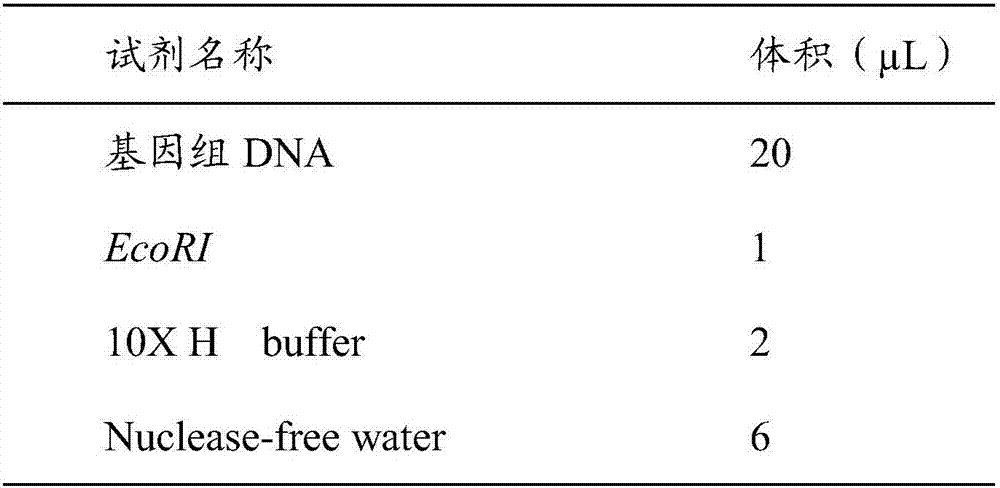

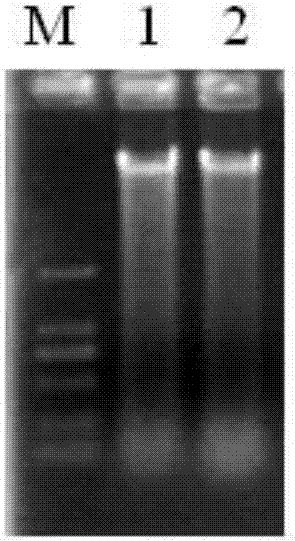

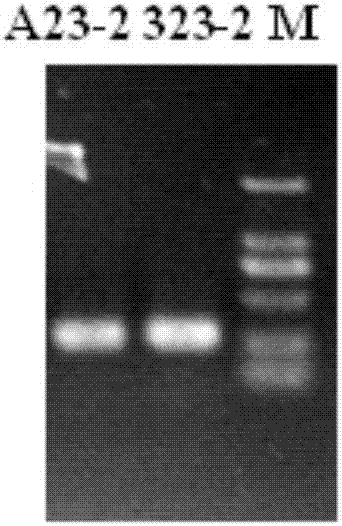

Method for rapid genetic transformation by utilizing mature millet seeds

InactiveCN104004784AShort conversion timeAccelerate the breeding progressFermentationGenetic engineeringBiotechnologyBulrush millet

The invention relates to an agrobacterium-mediated transformation system for rapid genetic transformation by utilizing mature millet seeds, and the agrobacterium-mediated transformation system is a rapid genetic millet transformation system without relying on tissue culturing. The transformation efficiency of the agrobacterium-mediated transformation system is 1.77%; the plant regeneration time is 3 months. According to the agrobacterium-mediated transformation system, only 45 days are required from the infection of the mature seeds to the final obtainment of a plant; only 3 months are required up until the seeds are harvested, so that the plant transformation time is greatly shortened. As the agrobacterium-mediated transformation system is used, the clonal variation of cytoplasts during the tissue culturing is reduced; meanwhile, a plurality of important agronomic trait genes can be introduced into millets, thereby promoting the breeding progress rate of millet molecules.

Owner:刘颖慧 +1

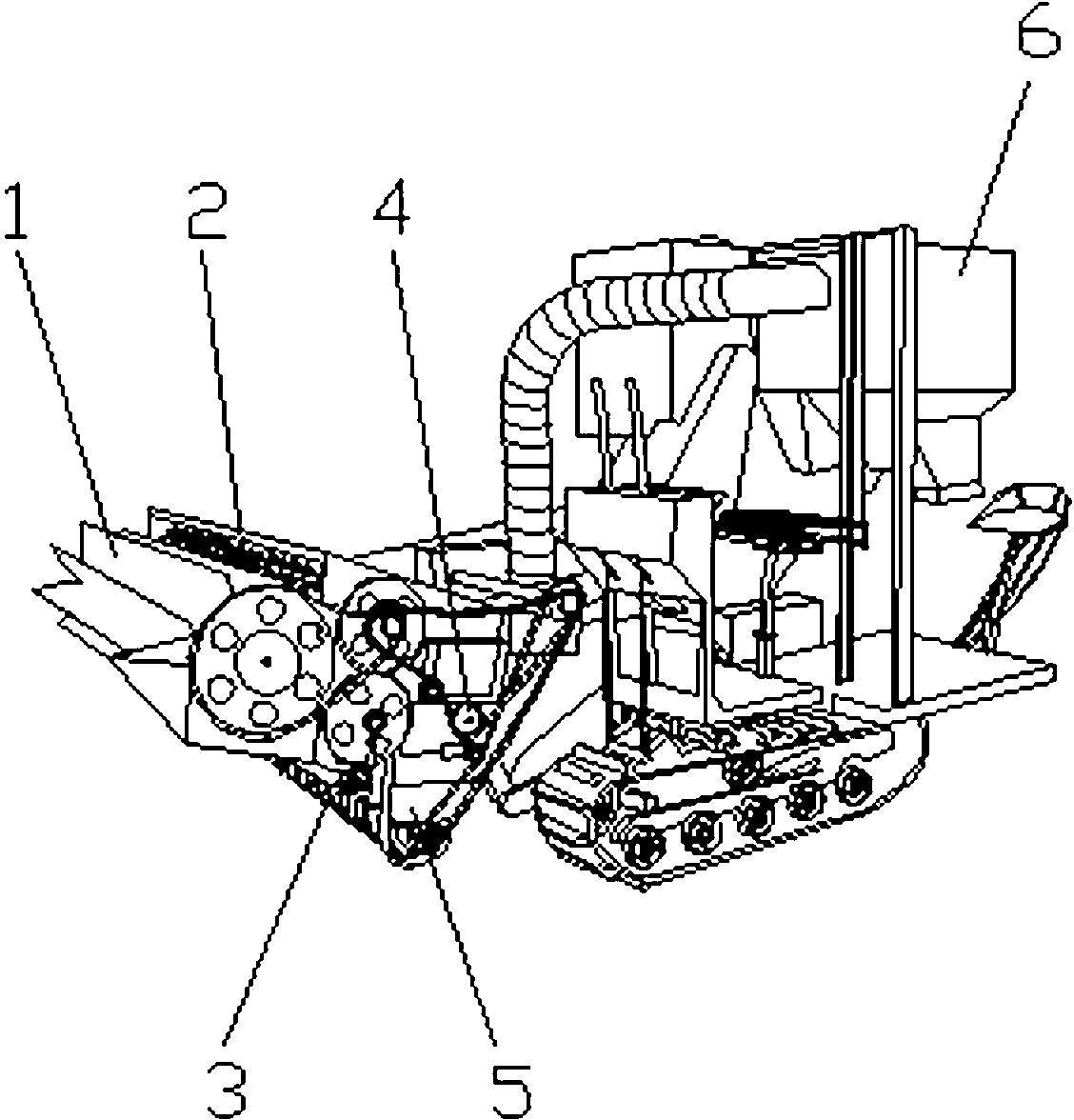

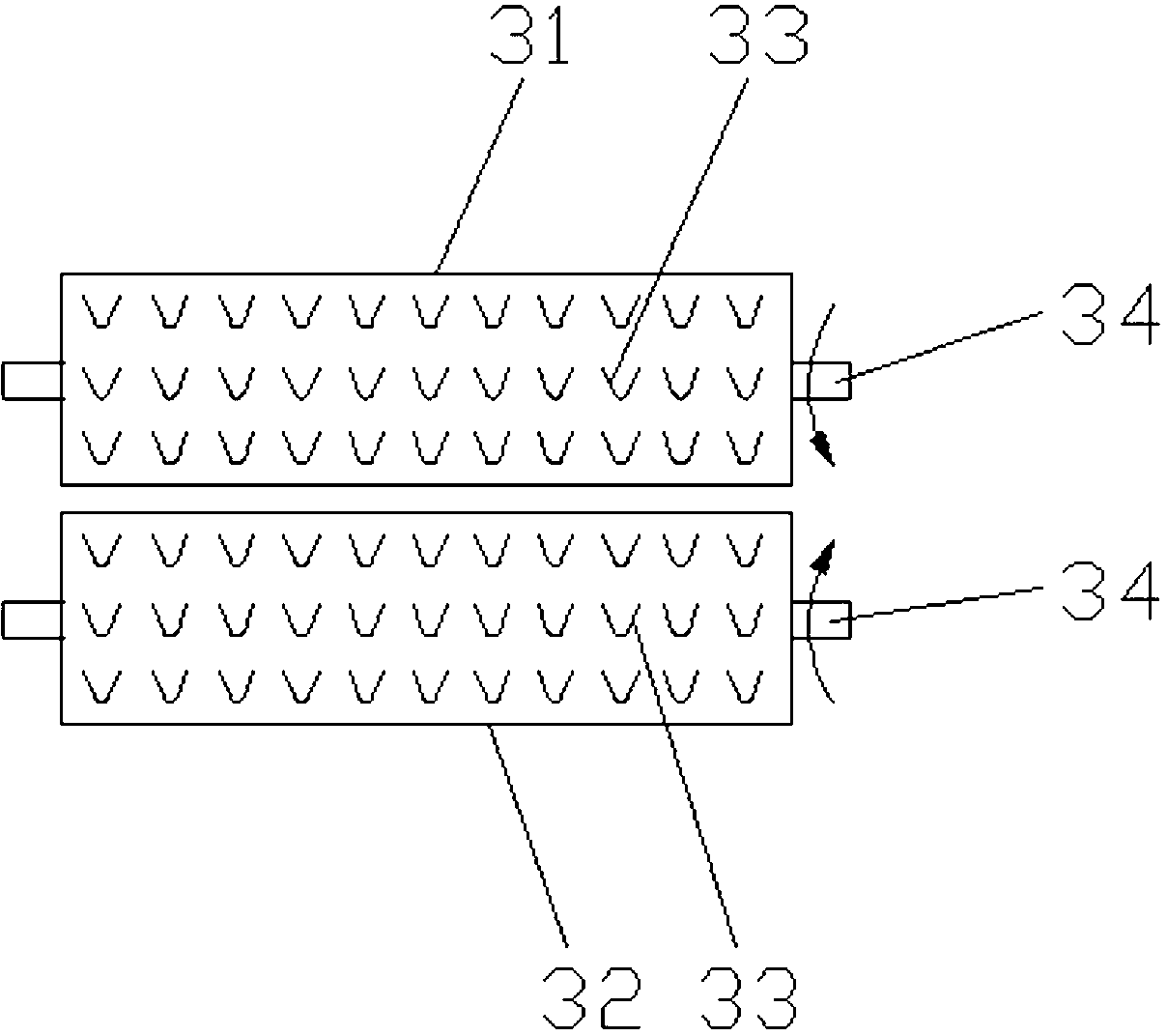

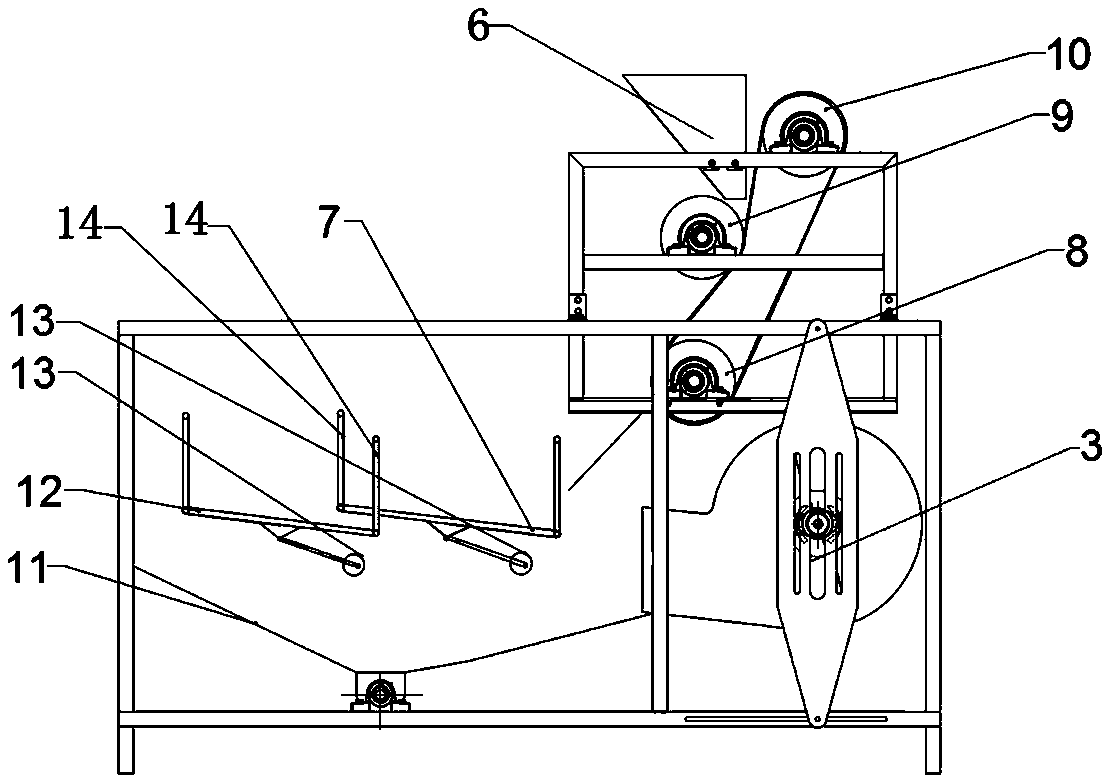

Stripping type combine harvester

The invention relates to a stripping type combine harvester. A blade type crop-poking device is arranged at the front end of a harvester frame; the harvester frame is provided with upper and lower double-roller type threshing devices behind the blade type crop-poking device; a vibrating sieve and a grain receiving hopper are arranged below the upper and lower double-roller type threshing devices; a lower threshing roller is connected to the vibrating sieve and the grain receiving hopper through an eccentric wheel in a manner of a motive power; an upper threshing roller is connected to the blade type crop-poking device in a manner of the motive power; a rotary spiral roller stem-crushing device is arranged on the harvester frame and below the vibrating sieve and the grain receiving hopper; a back threshing roller is arranged on the harvester frame and behind the upper and lower double-roller type threshing devices; the vibrating sieve and the grain receiving hopper are arranged below the back threshing roller; an air suction hole is arranged at the bottoms of both the vibrating sieve and the grain receiving hopper; the air suction hole is communicated with a multi-cylinder grain and sundry separation device through an air suction pipe, so that the grains and the sundries enter into the multi-cylinder grain and sundry separation device for separation through the air suction pipe; the grains are discharged from a grain outlet for bagging; and the sundries are blown away from a draught fan opening.

Owner:SHAOGUAN FENGYI IND & TRADE

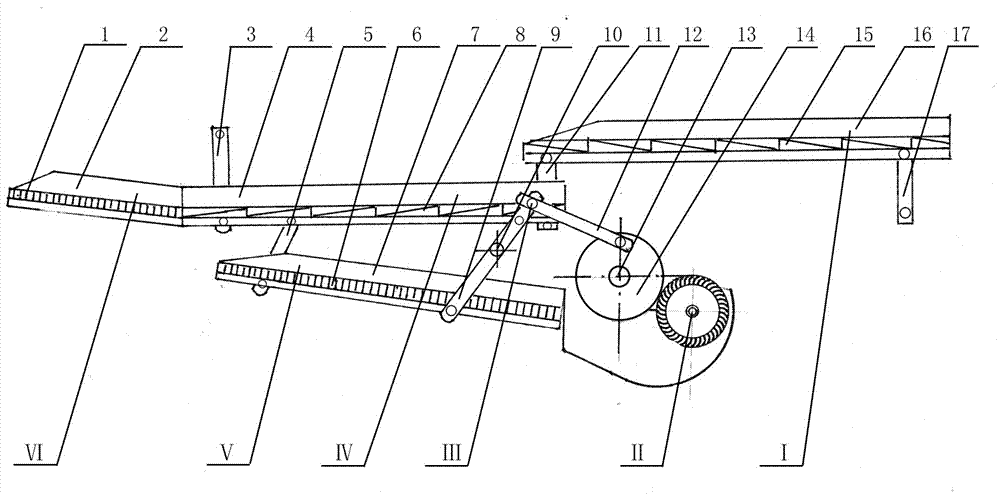

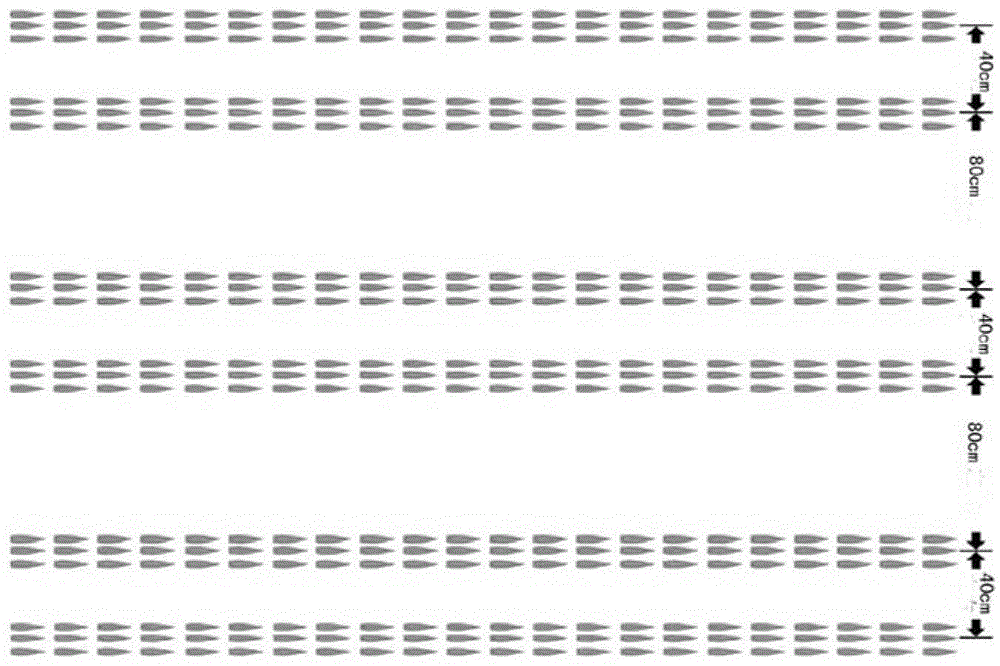

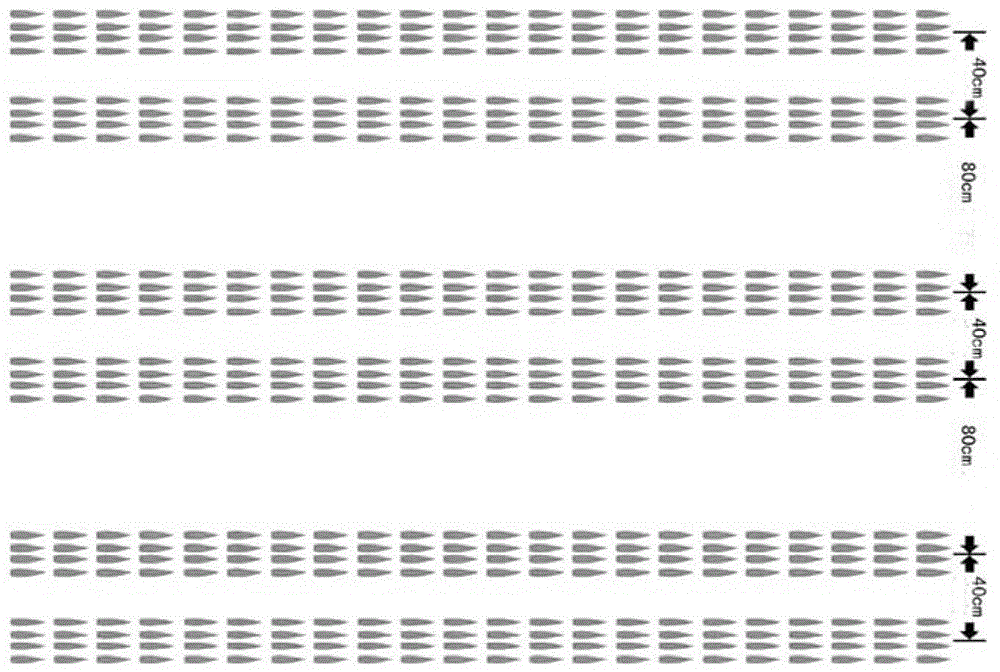

High-yield and cost-saving simple cultivation method for large-group small-entity summer sowing foxtail millet

InactiveCN104365327AImprove lodging resistanceConforms to the "mass hair" growth and development lawCultivating equipmentsPlant cultivationSeederBulrush millet

The invention provides a high-yield and cost-saving simple cultivation method for large-group small-entity summer sowing foxtail millet. The high-yield and cost-saving simple cultivation method aims at achieving the mechanical wide-ridge plantation, simplifying procedures and reducing cost. The method includes the steps of selecting a ten-line wheat seeding machine with the sowing width of 200 cm; sequentially blocking seed discharge holes of the ten-line wheat seeding machine in an alternate mode from left to right, wherein the average line spacing is 40 cm; grasping the effective rainfall opportunity after the wheat harvest to complete the rotary tillage procedure, the sowing procedure and the pressing procedure at a time through the wheat sowing machine before the last ten days of June for the regions which have the accumulated temperature larger than or equal to 10 DEG C and have the temperature of about 1800 DEG C to 2000 DEG C during the period between the time when the wheat harvest is completed and the first ten days of October; spraying weed killers after sowing and before emergence or after emergency; adopting the thinning-free and final singling method when 3 to 5 main leaves appear on each millet seedling; conducting topdressing with 10 kilograms of urea in each mu at the elongation state through an intertillage soil moisture preservation and topdressing machine; conducting harvesting through a wheat harvester; reducing the speed of a draught fan system of the wheat harvester till grains can not be blown away.

Owner:WHEAT RES INST OF AGRI SCI

SNP marker relevant to plant height character of millet, detection primers for SNP marker, and applications

ActiveCN108642201ASpeed up genetic selectionSpeed up the optimization processMicrobiological testing/measurementDNA/RNA fragmentationChromatophoreSnp markers

The invention discloses an SNP marker relevant to the plant height character of millet, detection primers for the SNP marker, and applications. For the SNP marker relevant to the plant height character of millet, the SNP marker is located in the bin markers of the 30703512bp to the 30784296bp of the first chromosome, and the SNP marker is in close linkage with the plant height of millet. The SNP marker relevant to the plant height character of millet can be used for the molecular marker-assisted breeding for the plant height character of millet, through the detection of the SNP marker, the plant height of millet can be predicated, a scientific basis is provided for realizing the early identification or screening breeding for the plant height character of millet, and great theory and practice guiding significance is achieved for accelerating the genetic breeding or improvement process of the varieties of millet. The primer pair for detecting the SNP marker provided by the invention canrealize typing on the plant height of millet and detect the differences of SNP expression.

Owner:ZHANGJIAKOU ACAD OF AGRI SCI

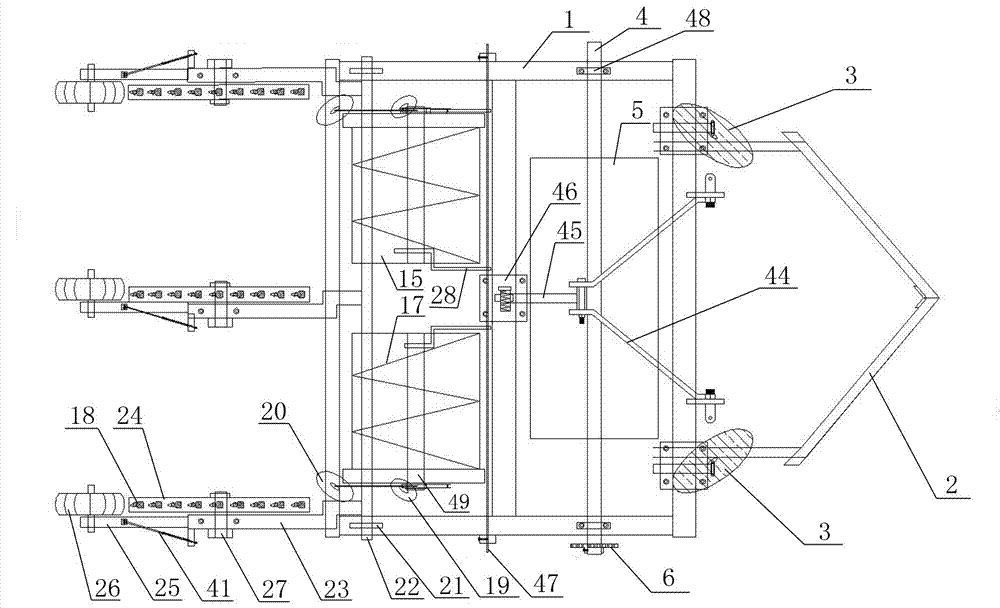

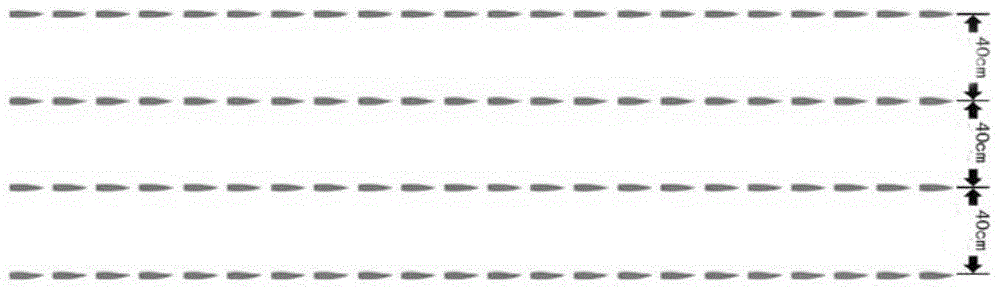

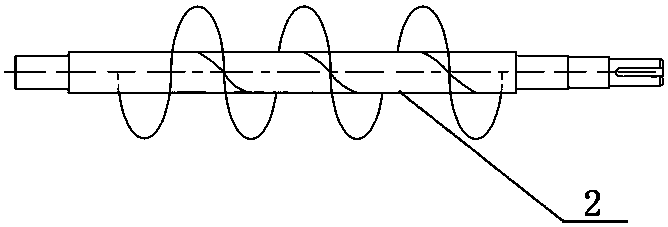

Plastic film mulching seeder for millet, corn and coarse cereals

ActiveCN106954411ASolve problems such as failure to unearth normally, soil compaction on the mulch film, etc.Guaranteed germination rateDibble seedersClimate change adaptationSeederBulrush millet

The invention discloses a plastic film mulching seeder for millet, corn and coarse cereals, which comprises a main chassis (1), an earth leveler (2) is mounted on the front part of the main chassis (1), disk coulter (3) are symmetrically mounted on both sides of the main chassis (1), a land roller (5) is mounted on the main chassis (1) through a land roller axle (4), and a driving sprocket wheel (and an eccentric shaft) (6) is mounted at the end of the land roller axle (4). Through the rotation of the driving sprocket wheel (and the eccentric shaft), a pull rod (pull chain) lever structure is utilized to drive a knocking hammer to knock a soil intake roller, so that soil in the soil intake roller can be smoothly discharged out, and the soil is suitable for seeding in the middle row. The difference of the seeder from similar seeders is that soil is first put on a mulching film and the mulching film is shaped and laid before seeding, consequently, phenomena, such as the dislocation of sprouts from holes and soil hardening on the mulching film, cannot occur, and labor is saved. Pressed by press wheels behind dibbling rollers, concave arcs are formed, so that even a small amount of dew in the morning can flow into holes, consequently, the germination rate and emergence rate of seeds are ensured, the sowed seeds can effectively germinate through soil, and yield is increased.

Owner:大同市悦祥农业机械制造有限责任公司

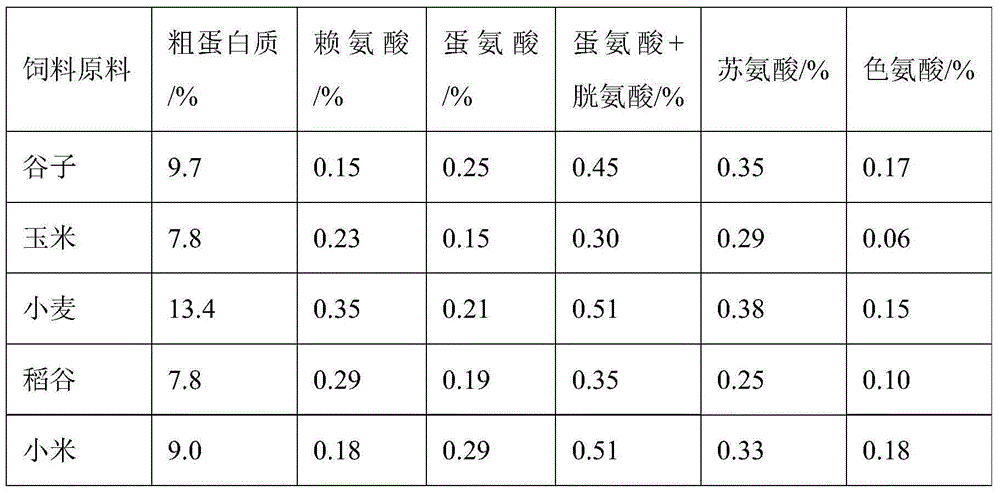

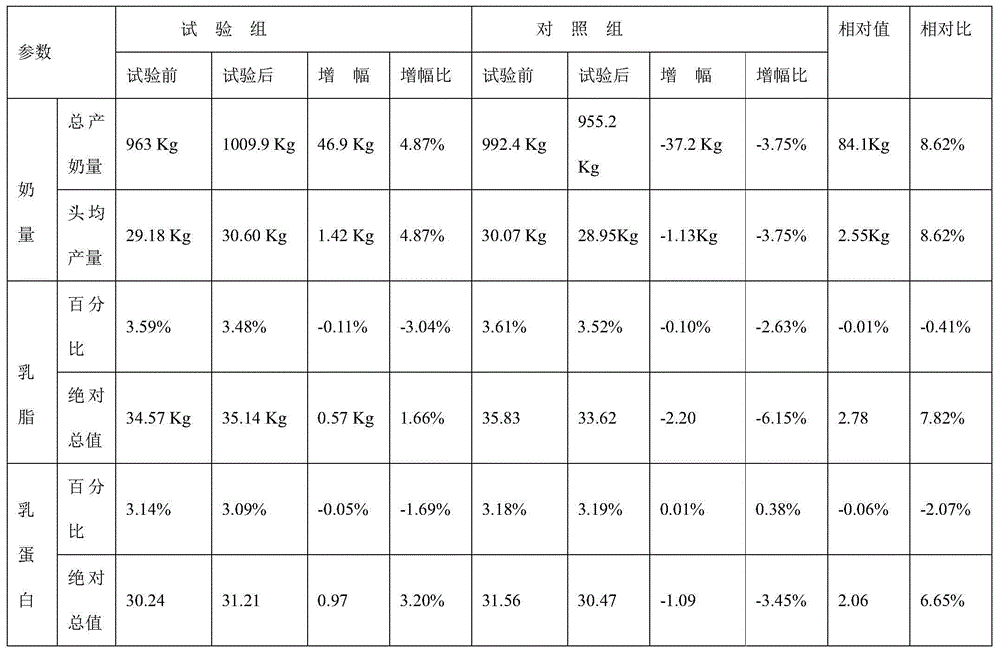

Millet straw leavening technology for mixed granulated feed for ruminants, and mixed granulated feed for ruminants

InactiveCN104855725AImprove nutrient absorption and conversion functionImprove anti-infection functionAnimal feeding stuffSodium bicarbonateAnimal science

The invention discloses a millet straw leavening technology for a mixed granulated feed for ruminants. The millet straw leavening technology comprises the following steps: (a) preprocessing raw materials: smashing whole millet straw into small segments; (b) activating bacteria: placing a millet straw leavening agent in a growth factor nutrient solution of which the temperature is 25-35 DEG C, and activating bacteria for 0.5-1.5 hours; (b) performing anaerobic leavening: uniformly mixing the millet straw leavening agent activated in step (b) with the raw materials smashed in step (a) according to 10-20% of inoculation amount, and leavening the mixture under the temperature of 20-35 DEG C and 40-60% of humidity for 4-7 days so as to obtained the leavened millet straw. The invention further discloses the mixed granulated feed for ruminants. The mixed granulated feed is obtained by processing refined materials and the leavened millet straw, wherein the refined materials comprise the following materials in percentage by weight: 26-30 wt% of corn, 30-35 wt% of millet, 12-13 wt% of bean meal, 14-16 wt% of cottonseed meal, 5-8 wt% of dried vinasse and soluble substances thereof, 1-2 wt% of fat powder, 0.8-1.2 wt% of sodium bicarbonate, 0.4-0.8 wt% of slow releasing urea, 0-2 wt% of molasses, 0.2-0.4 wt% of microbe feed additives, and 1-5 wt% of premix.

Owner:北京好友巡天生物技术有限责任公司

Piglet compound feed

InactiveCN104472951APromote rapid growthImprove disease resistanceAnimal feeding stuffBiotechnologyCalcium biphosphate

The invention relates to a piglet compound feed. The piglet compound feed is prepared from the following raw materials in parts by weight: 30-40 parts of unhusked rice, 20-30 parts of puffed soybeans, 20-30 parts of rice bran, 3-5 parts of rhizoma nardostachyos, 3-5 parts of Chinese dates, 3-5 parts of common goldenrod herb, 3-5 parts of kadsura coccinea, 0.5-2 parts of calcium hydrophosphate and 0.5-2 parts of methionine. The piglet compound feed is added with Chinese herbal medicines and is scientifically prepared, so that the piglet compound feed has the functions of activating the middle and spleen of piglets and whet the appetite of the piglets; cultivation practice proves that the diarrhea of the piglets is obviously reduced, the disease resistance of the piglets is improved, and the growth speed of the piglets is increased.

Owner:HARBIN JINYU SCI & TECH

Artificial hybridization method for millet

InactiveCN102742500AAvoid mechanical damageAvoid crackingPlant genotype modificationRelative air humidityBiology

The invention discloses an artificial hybridization method for millet. The method comprises the following steps: 1) for ears of maternal plants of millet with the total number of flowers accounting for 10 to 15% of the total number of spikelets, removing a part of seed strings of the ears until each of the ears has 15 to 25 seed strings and removing all the blossomed flowerets and unfully-grown flowers in the retained seed strings; 2) wetting the ears of the maternal plants processed in step 1), wrapping the ears of the maternal plants to allow the ears to be in an environment with a temperature of 23 to 30 DEG C and relative air humidity of more than 95% and carrying out emasculation and pollination after 18 to 21 h; and 3) culturing pollinated plants under the condition that the ears ofthe maternal plants are isolated from external pollen and collecting seeds. According to the invention, a method of moisture retention and emasculation through wrapping is employed; therefore, cracking of anther of the maternal plants is effectively prevented, working time for emasculation can be prolonged, and mechanical damage to stigma during manual emasculation is avoided.

Owner:ZHANGJIAKOU ACAD OF AGRI SCI

Breeding and cultivating method for millet varieties resisting sethoxydim and imidazolone herbicides

ActiveCN106613900AFlexible seedling retentionModerate maturityBiocidePlant growth regulatorsWeedCrop

The invention discloses a breeding method for millet varieties resisting sethoxydim and imidazolone herbicides, and belongs to the technical field of crop breeding and cultivating. The breeding method includes the steps: (1) taking millet resisting sethoxydim as female parents, performing hybridization for the millet resisting sethoxydim and millet resisting imidazolone herbicides to obtain F1-generation seeds, and spraying imidazolone herbicides; (2) performing self-cross for the F1-generation seeds sprayed the imidazolone herbicides to obtain 4-5-generation seeds, spraying the imidazolone herbicides and sethoxydim, and selecting from high-generation seeds to obtain the millet varieties. The invention further provides an application and a cultivating method of the millet varieties. According to the breeding method, novel millet varieties resisting sethoxydim and imidazolone herbicides are cultivated, cultivation technologies matched with the millet varieties are researched, the method has high flexibility in thinning weed killing aspect of herbicides, and the cost of the herbicides is low.

Owner:GRAIN RES INST HEBEI ACAD OF AGRI & FORESTRY SCI

Method for sowing alfalfa in spring and summer

The invention discloses a method for sowing alfalfa in spring and summer. The method includes that seeds of the alfalfa and millets are evenly mixed to form seed mixtures to be sown from April to July. The method has the advantages that growth of weeds can be effectively restricted by growth vigor of millet seedlings subjected to mixture sowing; the alfalfa can be favorably fixed in root due to long time span from summer sowing to winter time and water temperature condition is moderate, and the problem of getting through the winter is solved; the innovated method for sowing the alfalfa in spring and summer provides convenience for plant farmers to select sowing periods.

Owner:SHANDONG GREEN WIND COUNTY AGRI DEV

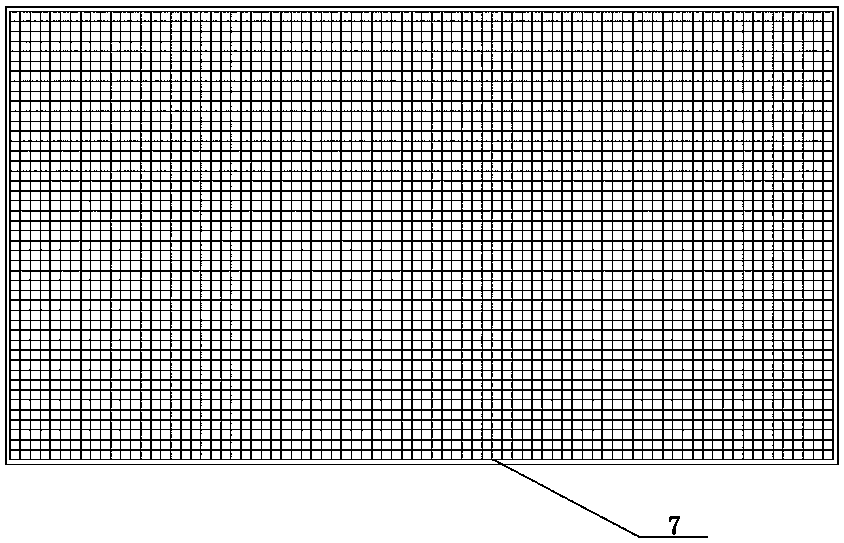

Air-screen cleaning device for self-propelled longitudinal dual-axial millet combine harvester

The invention discloses an air-screen cleaning device for a self-propelled longitudinal dual-axial millet combine harvester. The air-screen cleaning device consists of main operation functional parts including a step type shaking plate, a step punching type upper cleaning screen, a woven lower cleaning screen, a woven tail screen, a cross-flow fan, and a crank rocking arm drive mechanism. The air-screen cleaning device has grain cleaning operation functions such as a constant shaking, loosening, dispersing and uniform material conveying function, a rough fine two stage large area relative reciprocating shaking cleaning function, a fine crushed leaf and stem airflow blowing discharging function, a bilateral supporting balanced synchronous drive operation function, and a spikelet grain-contained residue collection and threshing function, can solve the technical problems that in a grain cleaning operation technical link, the conventional millet harvesters are low in cleaning trafficability, and are small in effect cleaning operation area; crushed straw and leaves are kinked and gathered to block a screen surface, cleaning material feeding is uneven, the trash content of grains is high, and carrying loss is huge. The air-screen cleaning device can meet the grain cleaning technical condition demand of mechanical harvesting of millet crops in different conditions.

Owner:四平市顺邦农机制造有限公司

2-oculture multi-plant close planting method for foxtail millet

InactiveCN106613185AEasy to manageTo achieve the effect of ventilation and light transmissionPlant cultivationCultivating equipmentsDiseaseHectare

Provided is a 2-oculture multi-plant close planting method for foxtail millet. The method comprises the steps of choosing fine breeds, choosing land for crop rotation, preparing soil before sowing, sowing the foxtail millet, managing the density of reserved seedlings, applying fertilizer, conducting field management on the foxtail millet, controlling pests and diseases, and harvesting timely. According to the wide-narrow row planting method, the original linewidth about 40 cm is maintained, two lines are sowed in and one line is skipped, marginal superiority can be fully utilized, the ventilation and photopermeability effects to the greatest extent are achieved, 3-4 plants are planted in each hole to achieve reasonable close planting, meanwhile systematic cultivation and management measures are coordinated, the effect of increasing both production and income is achieved, more about 15,000 plants are planted each mu (a Chinese unit of area, about 0.0667 hectares) by adopting the planting mode compared with the common planting technique, so that the yield of the foxtail millet per unit area is increased greatly. According to the 2-oculture multi-plant close planting method for the foxtail millet, the operation method is simple, it is only required that a sowing case is picked off and replaced with a three or four grain seed tray in the middle of a four-case seeder to sow, the planting method not only facilitates ventilation and photopermeability, but also is convenient to egress and ingress and conducive to field management, and both film mulching and drip irrigation planting can be achieved.

Owner:宫力臣

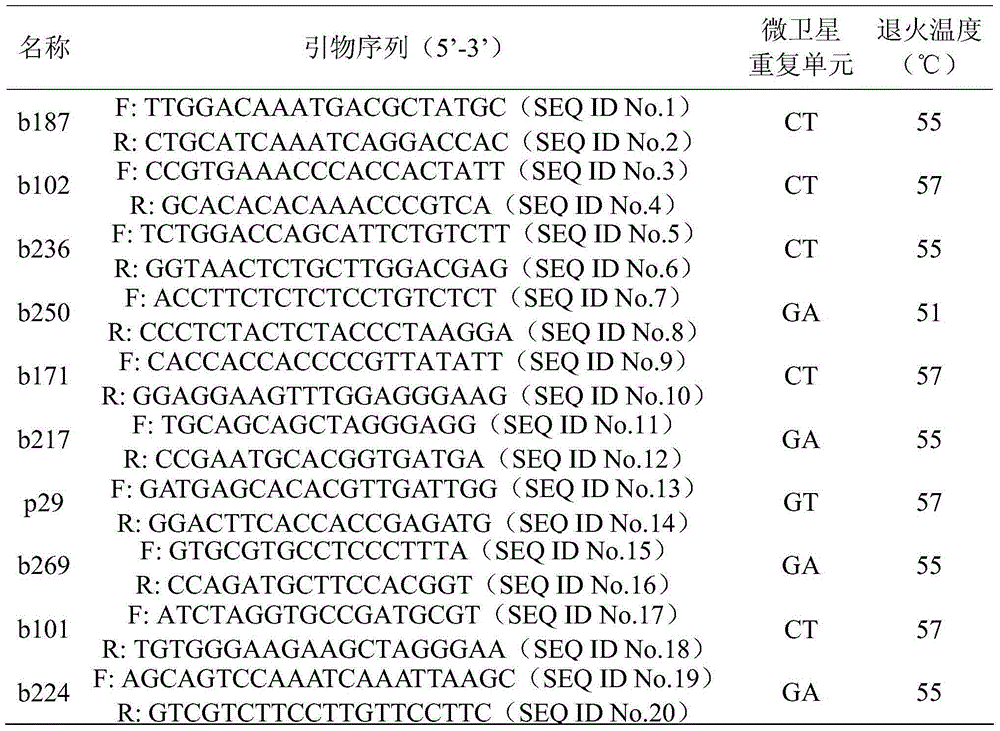

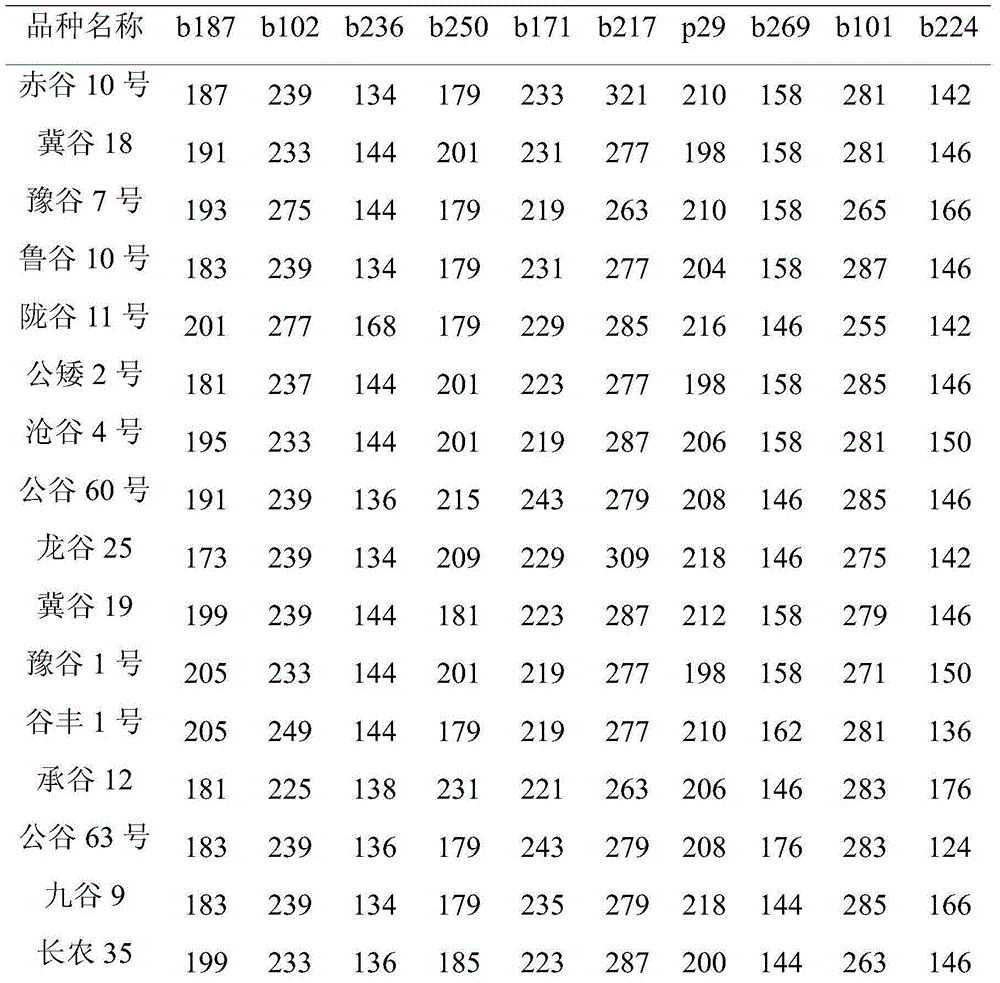

Group of SSR markers for differentiating millet varieties as well as application of markers

Owner:INST OF CROP SCI CHINESE ACAD OF AGRI SCI

Unhusked rice cleaning device

PendingCN107771535AImprove qualitySimple structureThreshersSaving energy measuresPower controlEngineering

The invention provides an unhusked rice cleaning device. The cleaning device comprises a rack, and a feeding assembly, a threshing assembly, a screening assembly, a winnowing assembly, a grain conveying assembly, a power assembly and a control mechanism which are arranged on the rack, wherein the control mechanism is electrically connected with the power assembly, the threshing assembly, the screening assembly, the winnowing assembly and the grain conveying assembly and is used for regulating and controlling the power assembly to drive the threshing assembly, the screening assembly, the winnowing assembly and the grain conveying assembly to finish threshing, screening, winnowing and grain conveying work of unhusked rice raw materials respectively. According to the unhusked rice cleaning device provided by the invention, the cleaning quality of unhusked rice is remarkably improved through effectively matched manners of unhusked rice stacking, rubbing and rolling, centrifugal winnowing,multi-grade vibration screening and the like.

Owner:HENAN UNIV OF SCI & TECH

A high-calcium selenium-rich chromium-rich multifunctional fertilizer for rice and a preparing method thereof

InactiveCN106866257AFertilizer slow releaseImprove fertilizer efficiencyCalcareous fertilisersExcrement fertilisersBiologyProper weights

The invention relates to a high-calcium selenium-rich chromium-rich multifunctional fertilizer for rice and a preparing method thereof. The fertilizer prepared by adopting maifan stone, zeolite, bone meal and the like as raw materials and by a proper weight ratio can restore and improve soil after the fertilizer is applied to the soil. The fertilizer can also be used for producing disease-preventing functional grain products. The fertilizer controls disease and pest harm, is slow-release, has durable fertilizer efficiency and promotes nutrient absorption of crops. The fertilizer is suitable for plantation of rice, wheat, millet, and other types of grains. By virtue of a compulsive cultivation technique, organic mineral elements are accumulated in fruits after the elements are absorbed by the crops, quality of obtained grain products is good, contents of calcium, selenium and chromium in the products are obviously increased, and the grain yield can be effectively increased. In grains planted by utilizing the fertilizer, the calcium content is as high as 58.6 mg, the selenium content is as high as 0.18 mg, the chromium content is as high as 0.028 mg, and the grains are substantially free of harmful elements and residual toxicity and meets requirements of green food.

Owner:陈海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com