Biological straw fertilizer, and production method and application thereof

A technology of biological straw and production method, applied in the direction of application, fertilization device, fertilizer mixture, etc., can solve the problems of restricting the development of agricultural production, limited potassium resources, etc., and achieve the effect of improving soil physical and chemical properties, complete nutrients, and stable fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Embodiment 1, the preparation of biosynergist

[0087] 1) Material selection: choose fresh, dry, mildew-free soybean stalks, mung bean stalks, pea stalks, millet stalks, barley stalks, rapeseed stalks, peanut stalks, chili stalks, tomato stalks and medicinal residues from industrial-scale pharmaceutical factories. 100kg (on a dry basis).

[0088] 2) Adjust humidity and PH: Weigh about 3-4kg of caustic soda and dissolve it in 45kg of clean water to fully dissolve it, stir it evenly and then spray it on the material, mix it well, and there should be no wet lumps. The PH is controlled at 6 (tested with a wide range of PH1-14 test paper), and the water content is controlled at about 50% (it needs to be controlled by hand to form a ball, and it will loosen when you let go). The specific amount of alkali and water should be determined according to the wetness and PH of raw materials.

[0089] 3) Bagging: Use cloth bags or woven bags, about 10kg per bag, not too much or too ...

Embodiment 2

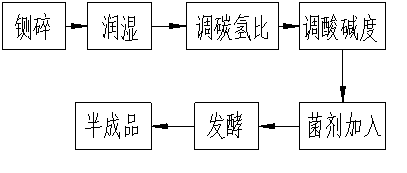

[0099] Embodiment 2, biological straw fertilizer semi-finished product preparation

[0100] (1) Crushing: Take soybean stalks, mung bean stalks, pea stalks, millet stalks, barley stalks, rape stalks, peanut stalks, chili stalks, tomato stalks and industrial (pharmaceutical factory) dregs, about 500Kg on a dry basis. Enter the hay cutter and cut into 3-5 cm fragments.

[0101] (2) Wetting: Wet the crushed straw with water, and the amount of water added is 70% of the wet weight of the raw material.

[0102] (3) Adjust the carbon-nitrogen ratio: add urea to the wet straw fragments to adjust the carbon-nitrogen ratio to 25:2 (weight ratio).

[0103] (4) pH adjustment: use lime to adjust pH to 6.5-8 in the above materials, and the amount of lime is about 3%.

[0104] (5) Add bacterial agents: mix biological agents (3 kg of microbial nitrogen-fixing bacteria, 3 kg of filamentous fungi, 5 kg of yeasts, and 1 kg of actinomycetes) with the materials after pH adjustment, and carry out...

Embodiment 3

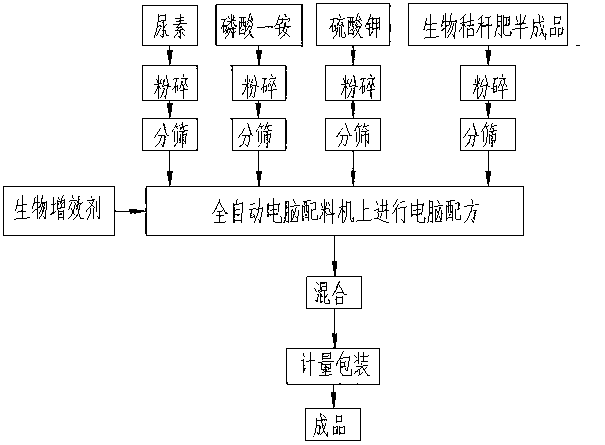

[0117] Embodiment 3, the preparation of finished product of biological straw fertilizer

[0118] (1) Carry out the computer formula on the automatic computer batching machine, set the batching amount of each raw material, that is, all the biological straw fertilizer semi-finished products 500kg, urea 217.5kg, monoammonium phosphate 100Kg, potassium sulfate 100Kg and embodiment 1 obtained in embodiment 2 The obtained biosynergist takes 82.5 Kg.

[0119] (2) Raw material pretreatment: all the semi-finished biological straw fertilizer obtained in Example 2, 217.5kg of urea, 100Kg of monoammonium phosphate, and 100Kg of potassium sulfate were respectively crushed and sieved.

[0120](3) Dry powder mixing: Add the pretreated raw materials into the high-efficiency mixer in batches according to the above weight ratio for mechanical mixing.

[0121] (4) Finished product: the appearance of powdery biological straw fertilizer is off-white, and the uniform powder does not agglomerate; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com