Plastic film mulching seeder for millet, corn and coarse cereals

A planter and corn technology, applied in the field of agricultural machinery (agricultural tools), can solve the problems of low seedling emergence rate, lost roots, and seedlings running under the plastic film, etc., and achieve economic benefits, long drought resistance time, and guaranteed seedling emergence rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

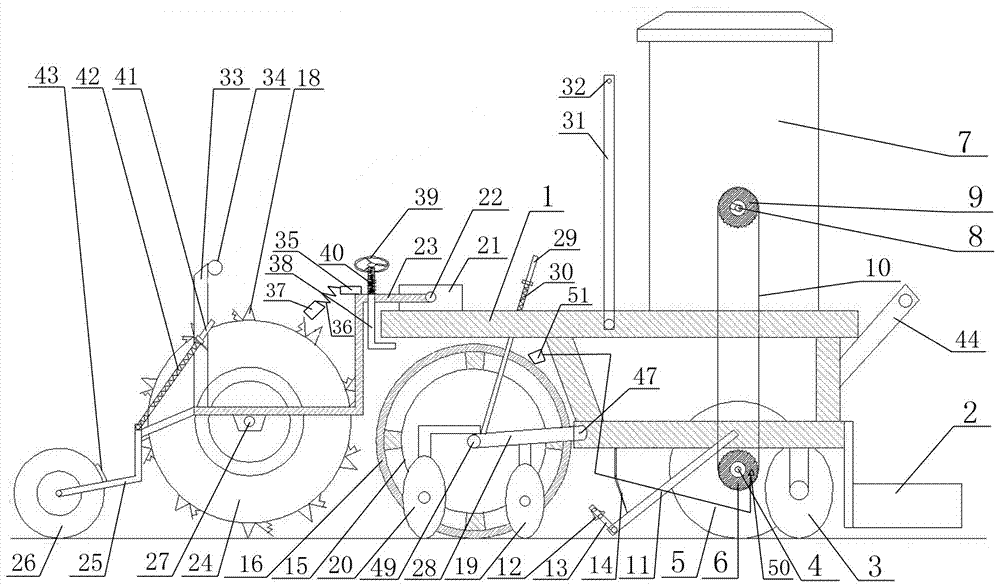

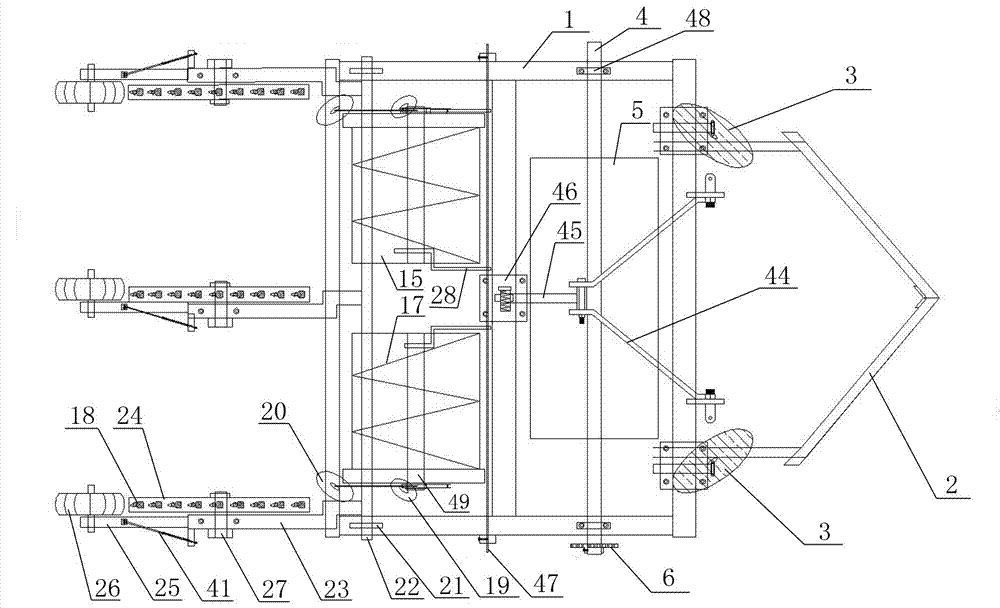

[0019] A kind of millet, corn miscellaneous grain film laying seeder, such as figure 1 , 2 As shown, the main frame 1 is included, and a traction frame 44 is installed on the main frame 1 to be connected with a tractor. The front portion of the main frame 1 is equipped with a leveler 2 for leveling the ground. Disc openers 3 are installed symmetrically on both sides of the main frame 1 to open two trenches for laying mulch. A ground wheel 5 is installed on the main frame 1 through a ground wheel shaft 4, which is used for compacting the ground and sowing and walking. The drive sprocket 6 is installed at the end of the ground wheel shaft 4, which is used to drive the feed shaft to rotate the lower fertilizer. The main frame 4 is positioned at the top of the ground wheel 5 and a fertilizer box 7 is installed, and a blanking shaft 8 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com