Landform simulation sugarcane harvesting machine

A harvester and terrain imitation technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as affecting harvesting efficiency, inaccurate cutting of sugarcane, damage and cracking of sugarcane pockets, etc., so as to improve harvest quality and reduce missed harvesting. Phenomenon, the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

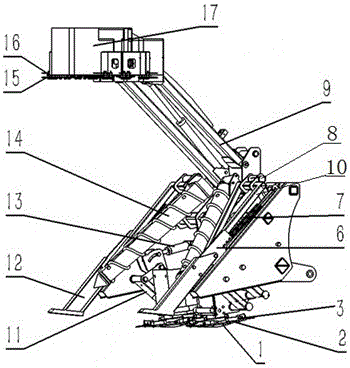

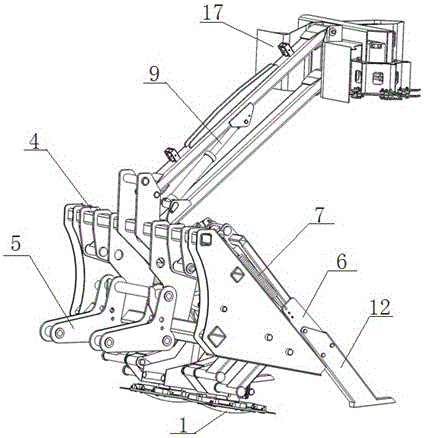

[0025] like figure 1 and figure 2 Shown, a kind of terrain-like sugarcane harvester comprises a harvester main body and a tractor, and the harvester main body includes a cane-supporting device assembly, a header assembly, a tip cutter assembly, a hydraulic power system and a harvester suspension 4, each The main body of the table harvester is equipped with two sets of cane lifter assemblies and two sets of header assemblies; The rear end of the suspension 4 is provided with a suspension main arm 5 that is suspended and connected with the tractor.

[0026] The cane-supporting device assembly comprises a triangular support 10, a conical screw 14 and a spring 7, the screw 14 is fixedly connected to one side of the triangular support 10, the bottom of the triangular support 10 is provided with a boat-shaped base 12, and the upper end of the triangular support 10 is provided with a support The sugarcane device swing arm 8 is connected with the harvester suspension 4, and the out...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the screw 14 is inclined forward at an angle of 55° with the horizontal plane, the angle between the boat-shaped base 12 and the horizontal plane is 45°, and the angle between the header cutter head 2 and the horizontal plane is 25°. °, all the other working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com