Unhusked rice cleaning device

A cleaning device and millet technology, applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of entrainment loss and single cleaning function, and achieve the effect of low entrainment loss rate, simple overall structure and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the drawings:

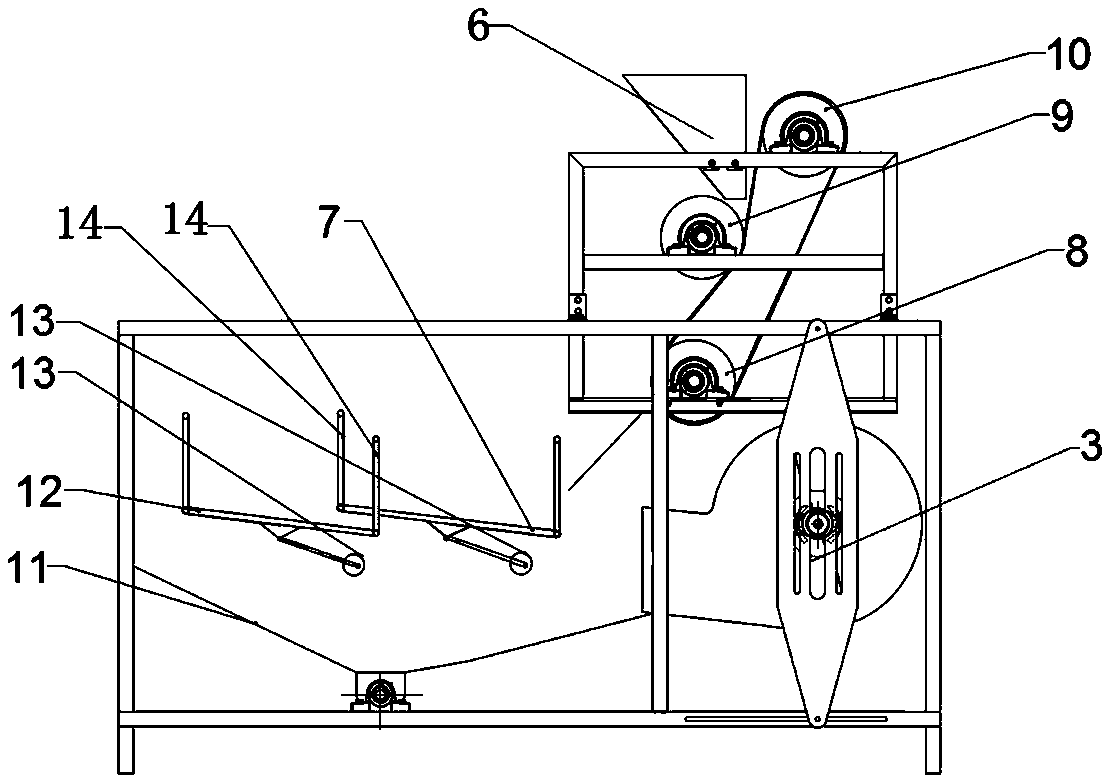

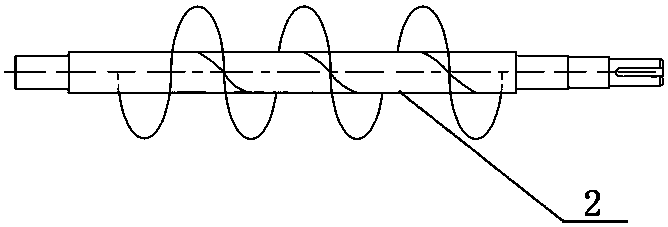

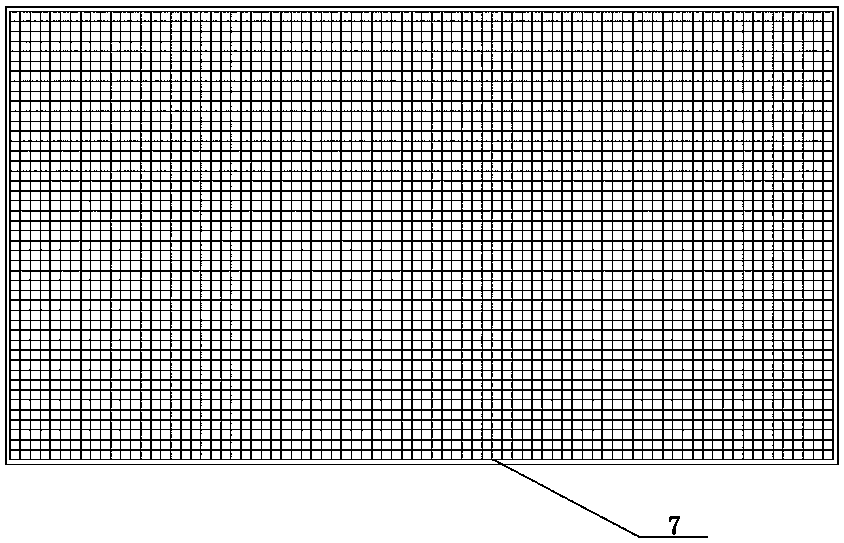

[0031] As shown in the figure, a millet cleaning device includes a frame 4 and a feeding assembly, a threshing assembly, a screening assembly, a winnowing assembly, a grain conveying assembly, a power assembly, and a control set on the frame 4. Mechanism, the control mechanism is electrically connected with the power assembly, threshing assembly, screening assembly, winnowing assembly and seed conveying assembly to regulate and control the power assembly to drive the threshing assembly, screening assembly, winnowing assembly and seed conveying assembly to complete the threshing of millet raw materials. Screening, winnowing and grain conveying operations;

[0032] The feeding assembly includes a feeding hopper 6 arranged at the top of the frame 4, and the feeding hopper 6 is placed above the active roller 8 of the threshing assembly, and is shaped like a triangular funnel with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com