Patents

Literature

50results about How to "Good processing cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polypropylene composition for water-heater inner containers and preparation method thereof

ActiveCN101812201AGood room temperatureImprove low temperature impact strengthFluid heatersSolar heat devicesHeat deflection temperatureProcedure Agents

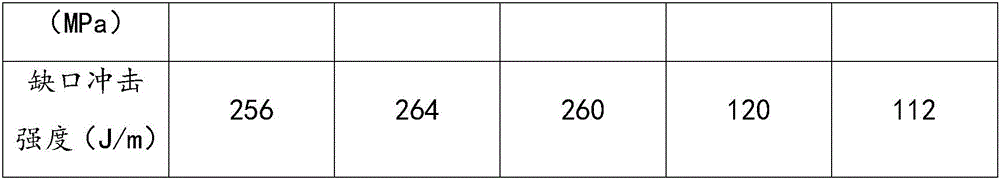

The invention provides a polypropylene composition for water-heater inner containers, which comprises the following components in portions by weight: (a) 100 portions of homopolymerized polypropylene; (b) 0.01-10 portions of thermal stabilizer; (c) 0.01-10 portions of processing aid; and (d) 0.01-10 portions of alpha-crystal form nucleating agent and / or beta-crystal form nucleating agent. The processing aid is selected from one or a plurality of low-molecular-weight ester compounds, metallic soap compounds, stearic acid-compounded ester compounds and amide compounds. The polypropylene material of the invention overcomes the defect of insufficient rigidity of the common polypropylene, and has the advantage of high heat distortion temperature; and the tensile strength is greater than or equal to 20 MPa, the elongation at break is greater than or equal to 300%, the bending modulus is greater than or equal to 1200 MPa, and the notch impact strength is greater than or equal to 30 Kj / m<2>.

Owner:SHANGHAI KINGFA SCI & TECH

Air conditioner ventilation pipeline

InactiveCN104455759ASmooth inner wallReduce resistanceDucting arrangementsLighting and heating apparatusVentilation ductSteel plates

The invention provides an air conditioner ventilation pipeline. The air conditioner ventilation pipeline comprises a body piece and a covering piece which are both in a strip shape. Embedding and buckling portions in a bent hook shape are arranged on the two sides of the body piece. The covering piece is connected with the body piece through the embedding and buckling portions. A ventilation pipe cavity is formed between the body piece and the covering piece. The body piece and the covering piece are formed by galvanized steel sheets. The air conditioner ventilation pipeline has the advantages that the ventilation pipeline is formed by the galvanized steel sheets, and compared with stainless steel plates, the inner wall is smooth, resistance is small, the air tightness is high, the bearing strength is high, and the production cost is low; the covering piece is connected with the body piece through the embedding and buckling portions, and when the air conditioner ventilation pipeline needs to be washed, a user only needs to draw the covering piece out of the body piece; the air conditioner ventilation pipeline has the advantages of being simple in structure, reasonable in design, convenient to maintain, low in machining cost, good in use performance and the like.

Owner:天津吉泰空调通风设备有限公司

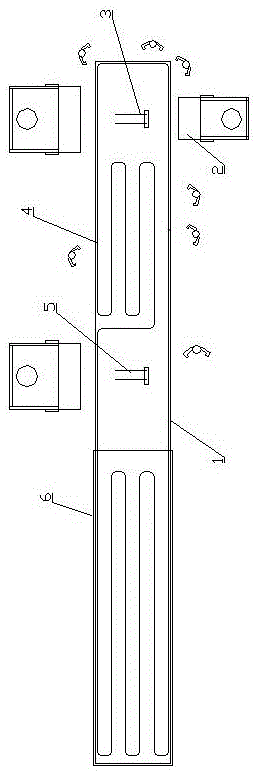

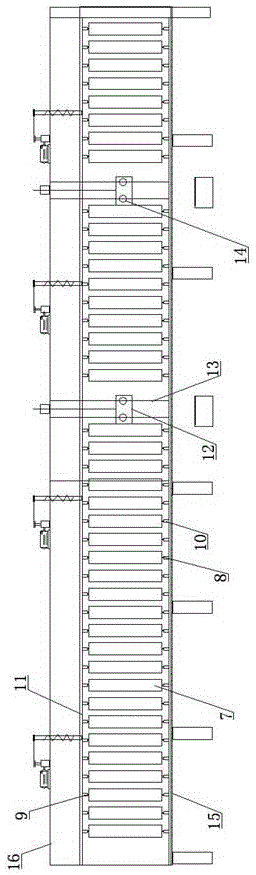

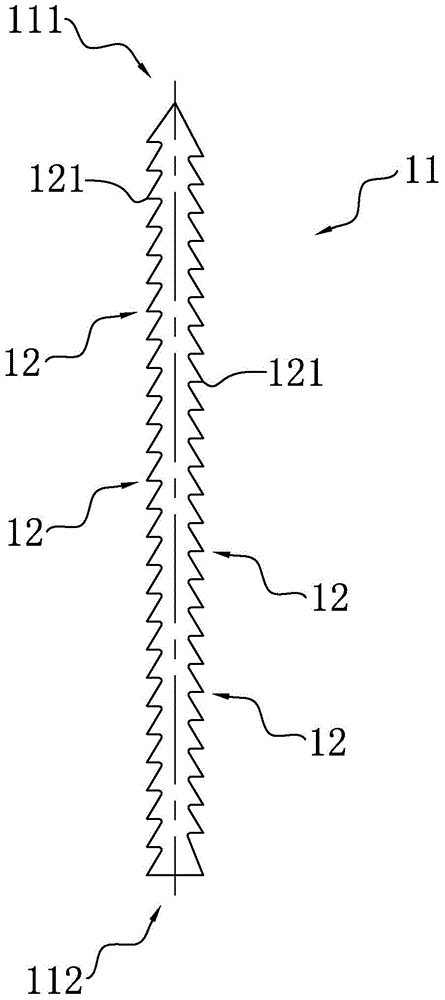

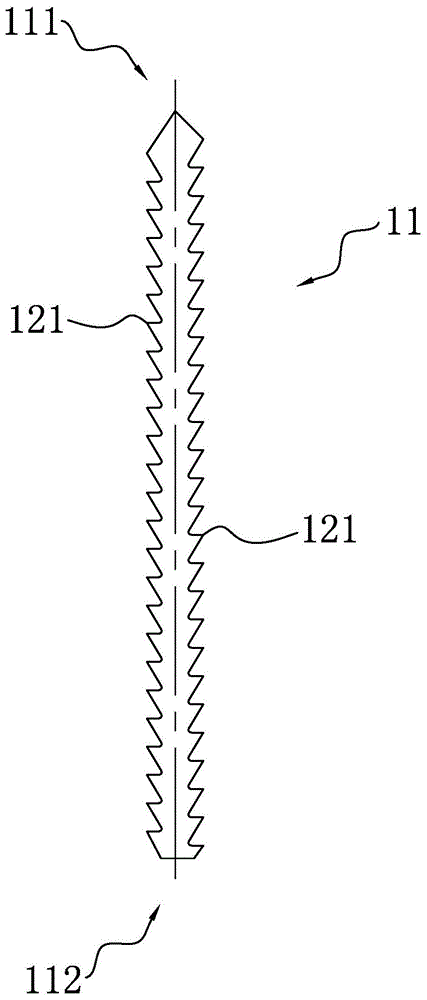

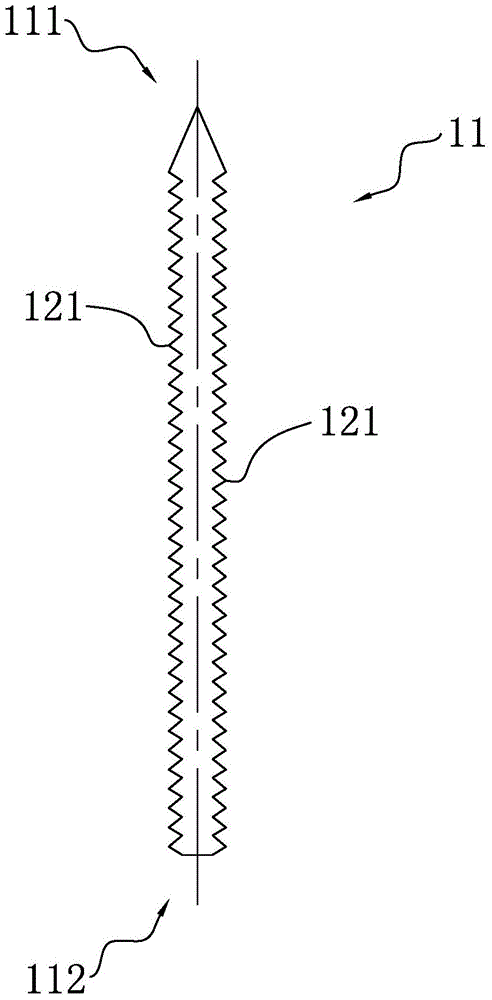

Integrated device and method for producing handrails

ActiveCN105057151AEasy to fixPrevent dumpingFencingPretreated surfacesIntegrated productionMachining

The invention provides an integrated device and method for producing handrails. The device comprises a machine frame. A handrail conveying guide rail is arranged on the machine frame. One end of the handrail conveying guide rail is a feeding end, the other end of the handrail conveying guide rail is a discharging end, and an automatic dust blowing device, an automatic embellishing device, a drying device, a finish paint spraying device and an airing bin are sequentially arranged on the handrail conveying guide rail from the feeding end to the discharging end. The handrail conveying guide rail comprises upper and lower conveying chains arranged in parallel. Handrail locating mechanisms for vertically arranging the handrails between the upper and lower conveying chains are arranged between the upper and lower conveying chains at intervals. Rotary drive mechanisms for driving the handrails to rotate are arranged at the portions, opposite to the automatic dust blowing device, the automatic embellishing device and the finish paint spraying device, on the handrail conveying guide rail. Due to the fact that the handrails are vertically arranged between the upper and lower conveying chains at intervals, the batch treatment of the handrails is guaranteed, and integrated production and machining equipment is formed; and the handrails are conveyed forwards and rotated at the same time so as to be conveniently machined and treated circumferentially, and machining quality is improved.

Owner:LIANYUNGANG MOBO HOUSEHOLD

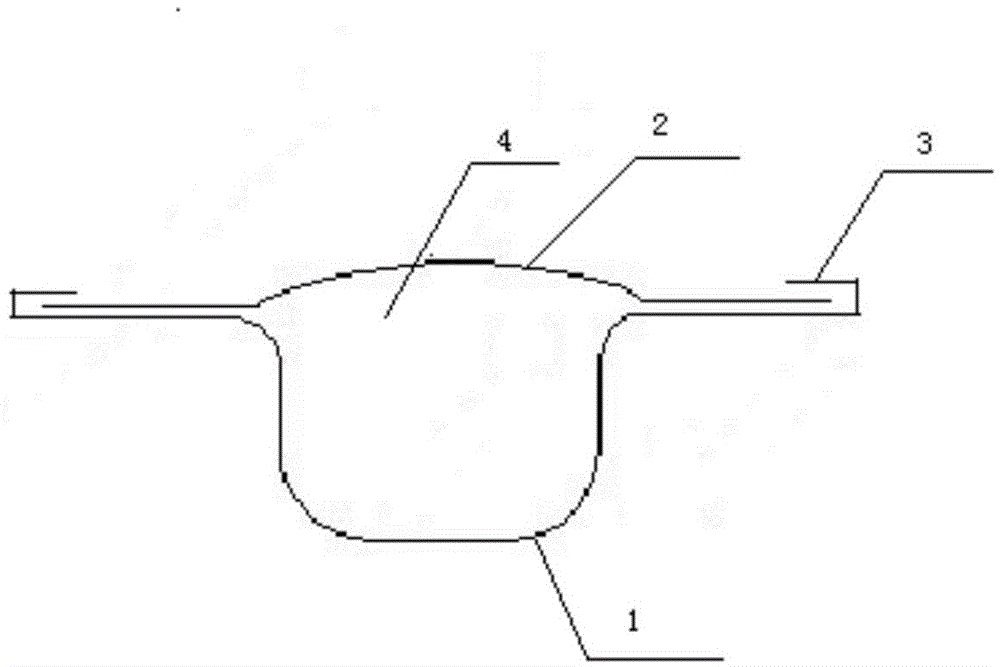

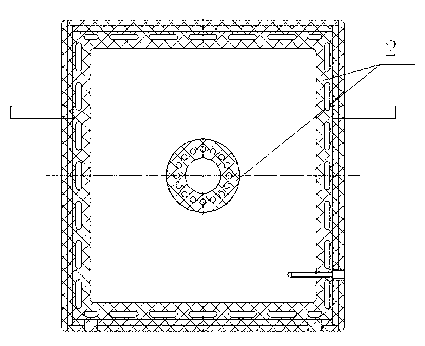

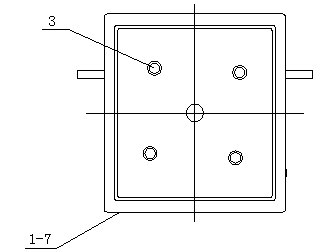

Integral composite rubber diaphragm filter plate and one-step molding method thereof

The invention relates to an integral composite rubber diaphragm filter plate and a one-step molding method thereof. The integral composite rubber diaphragm filter plate comprises an inner liner core plate and two rubber diaphragms which covers and are fixed at the two sides of the inner liner core plate, wherein the inner liner core plate is provided with a liquid passing through hole, an external connecting through hole, an internal connecting through hole and a vent pipe; bonding fixation areas are arranged at the two sides of the inner liner core plate and at the periphery of the liquid passing through hole respectively; the two sides of the inner liner core plate are respectively covered by the two rubber diaphragms; the rubber diaphragms are fixed at the two sides of the inner liner core plate by being stuck with the bonding fixation areas; the rubber diaphragms at the two sides of the inner liner core plate are stuck with each other on the side wall around the inner liner core plate, on the wall of the liquid passing through hole and in the internal and the external connecting through hole. The molding method of the filter plate comprises the steps of firstly, making the inner liner core plate, coating an adhesive onto the inner liner core plate, and molding the rubber diaphragms and the inner liner core plate for once by vulcanizing, pressing and bonding. The filter plate is good in sealing effect, reduces the springback gas energy consumption of the rubber diaphragms, is corrosion-resistant, high in strength and long in service life, has few working procedures, and reduces the cost and the manipulation strength.

Owner:JIANGSU XINGXIN SEPARATION EQUIP MFR

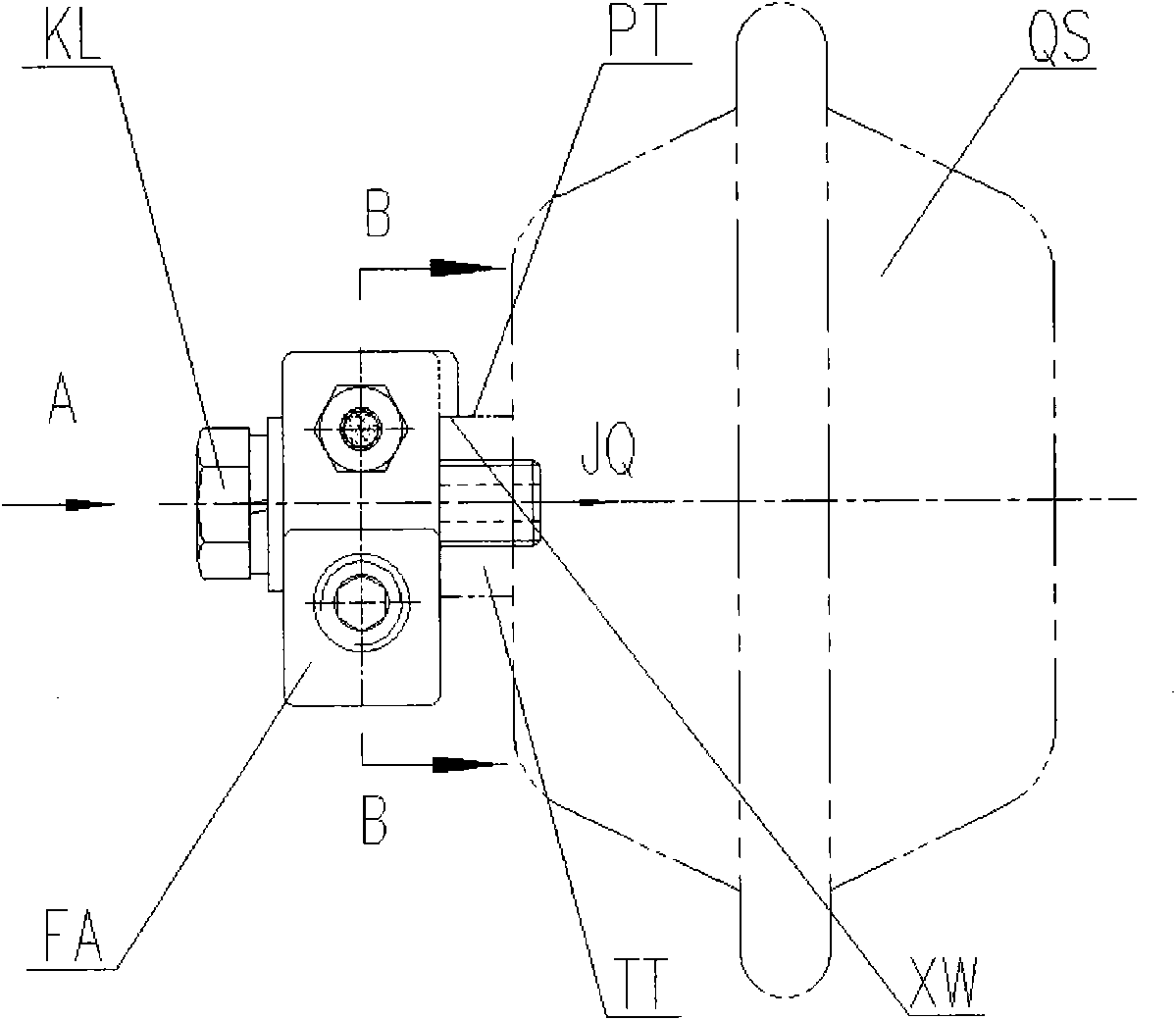

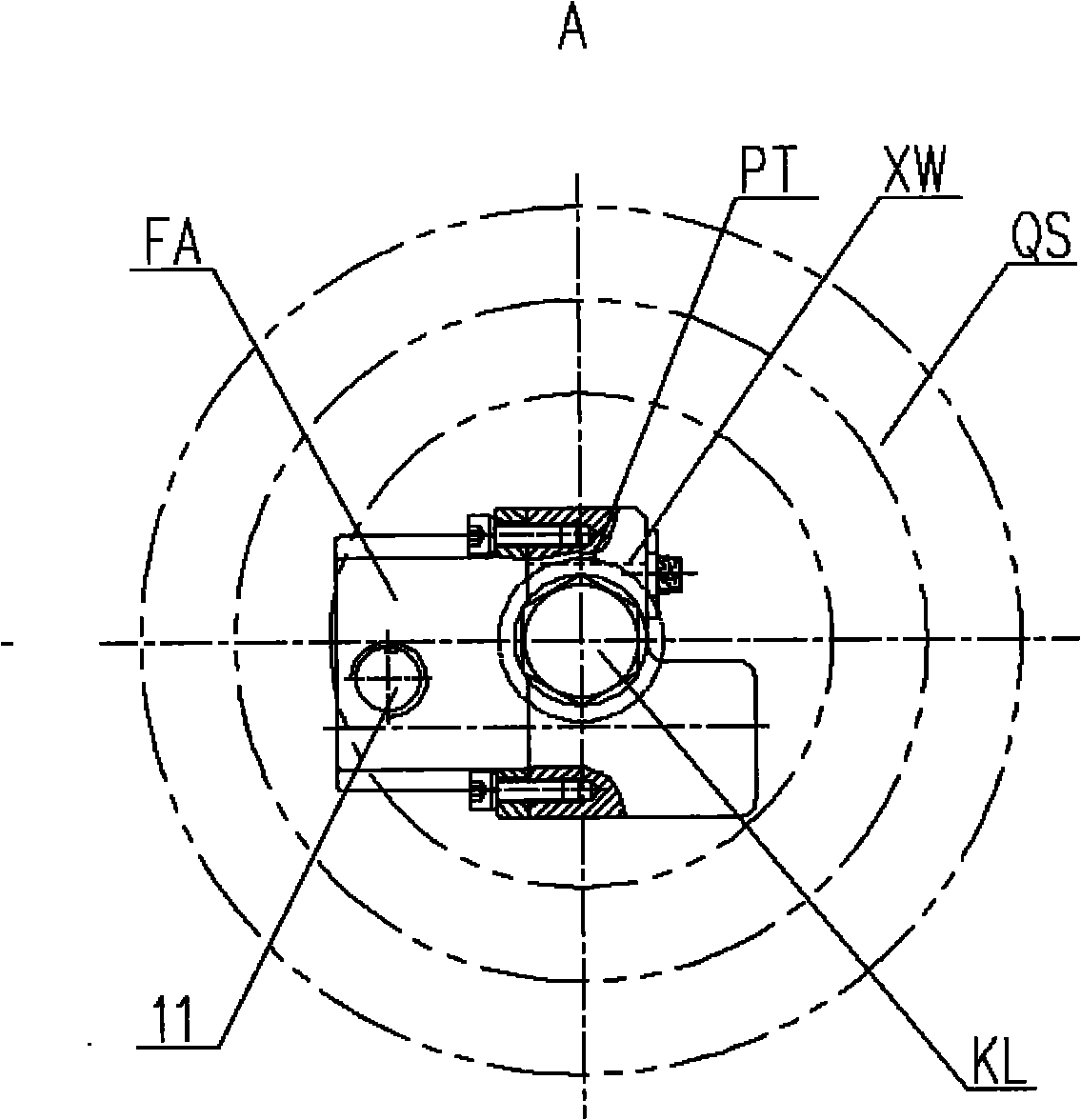

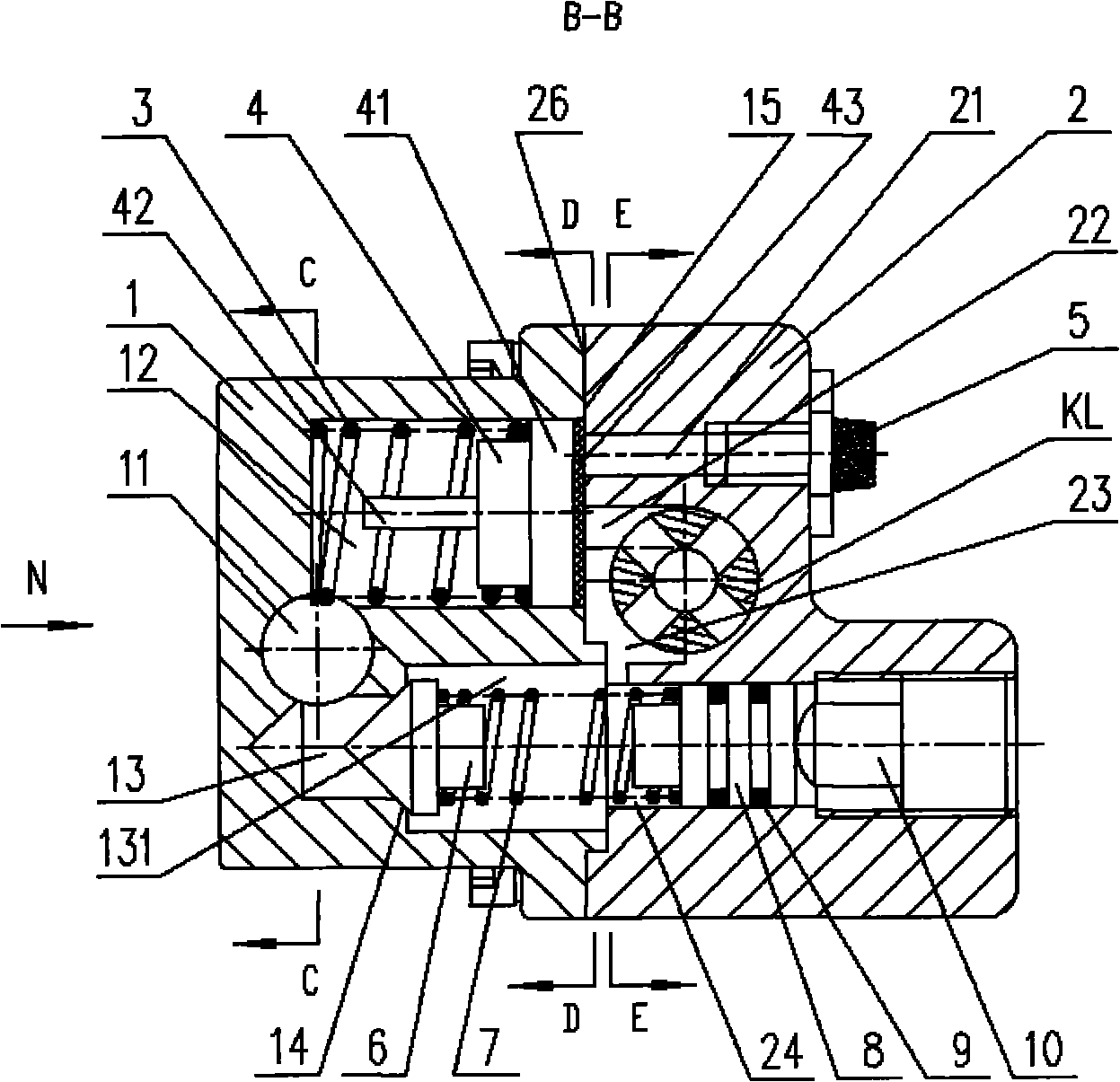

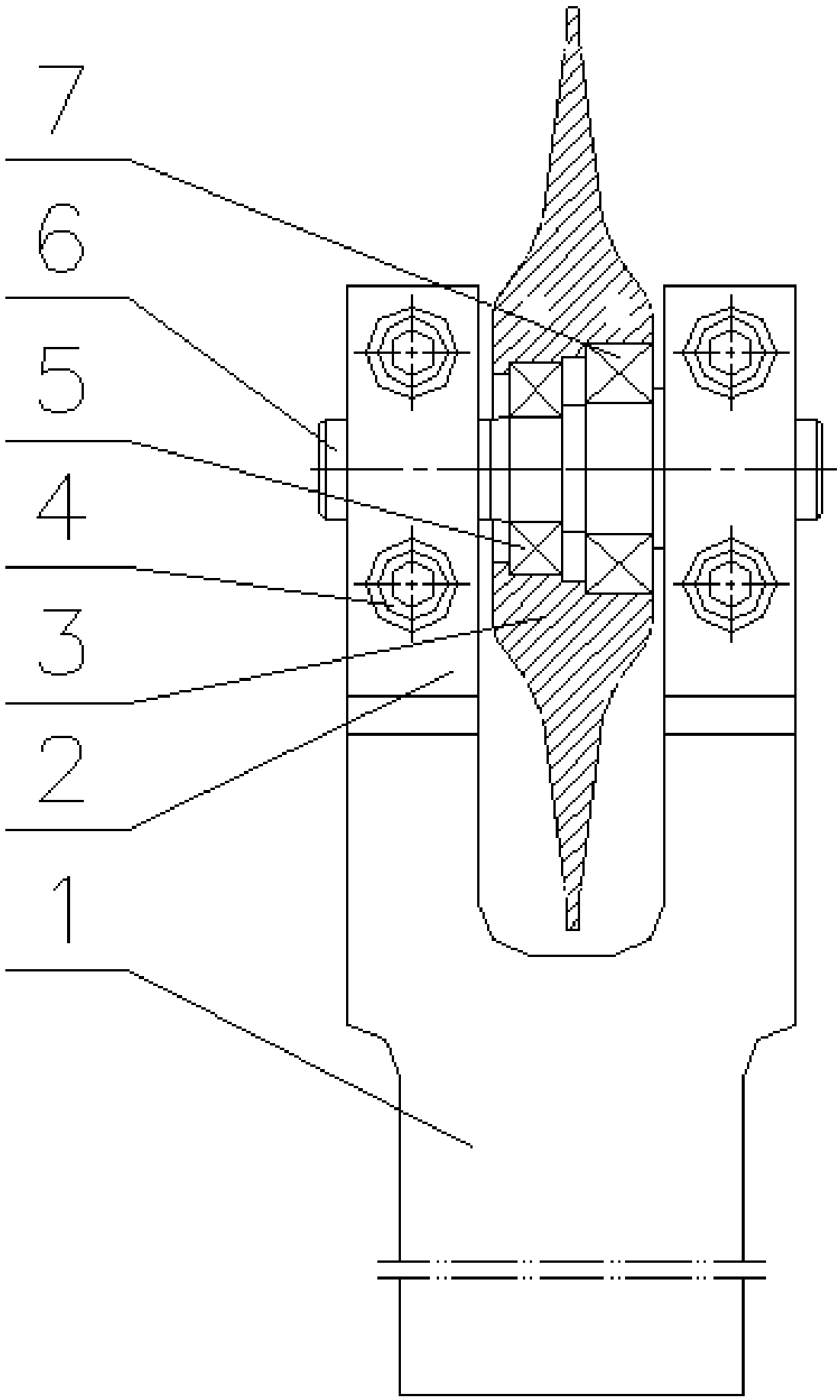

One-way pressure-regulating quick release valve

InactiveCN102371990AReduce processing costsGood processing costEqualizing valvesSafety valvesRepair timeHigh pressure

The invention discloses a one-way pressure-regulating quick release valve, which has the functions that: when high-pressure gas flows from an inlet of the one-way pressure-regulating quick release valve, the opening time and the outlet pressure of the one-way pressure-regulating quick release valve can be controlled by adjusting the opening pressure of a pressure-regulating valve core of the one-way pressure-regulating quick release valve; and when the high-pressure gas finishing work reversely backflows form an outlet of the one-way pressure-regulating quick release valve, the pressure-regulating valve core of the one-way pressure-regulating quick release valve is closed, a one-way valve core is opened and the high-pressure gas is quickly exhausted to the atmosphere from a quick release hole of the one-way pressure-regulating quick release valve. The one-way pressure-regulating quick release valve is especially suitable for an air-pressure brake pipeline system of an automobile; the one-way pressure-regulating quick release valve is arranged in the brake pipeline, the adjustment of brake forces of a left wheel and a right wheel is realized by adjusting the one-way pressure-regulating quick release valve, and thereby the brake deviation is effectively solved; meanwhile, the problems of non-uniformity in heating and wear of a brake and the like can be effectively solved, and thus the service life of the brake is effectively prolonged and the maintenance and repair times of the brake are reduced; the one-way pressure-regulating quick release valve has a quick release function, so that the one-way pressure-regulating quick release valve can replace a general quick release valve; and the one-way pressure-regulating quick release valve is arranged on a brake air chamber, so that the exhaust distance is shortened and shorter exhaust time and quicker brake response are obtained.

Owner:施霞

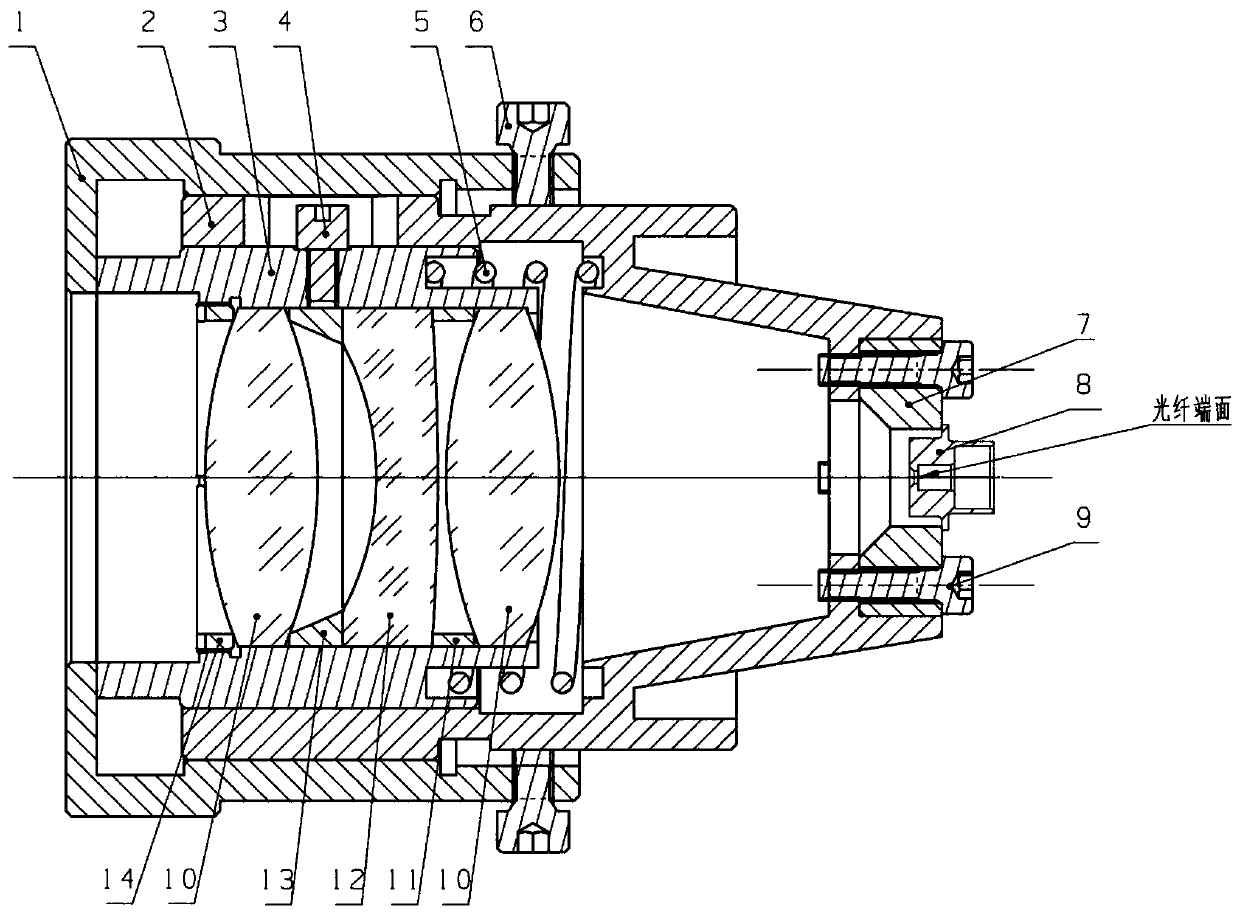

Laser coupling focusing mechanism

InactiveCN110515165AThe principle is simpleHigh focusing precisionCoupling light guidesCouplingEngineering

The invention discloses a laser coupling focusing mechanism and relates to the field of optical instruments. The device is technically characterized by comprising a fine adjustment sleeve, a main lenscone, a coupling lens group lens cone, a guide rod, a compression spring, multiple locking screws, an optical fiber connector seat, an optical fiber connector, a fixing screw, a pair of lenses A, a space ring A, a lens B, a space ring B and a pressing ring, wherein the main lens cone is arranged in the fine adjustment sleeve, the coupling lens group lens cone is arranged on the main lens cone, aleft end surface of the interior of the fine tuning lens cone is attached to a left end surface of the coupling lens group lens cone, a surface of the main lens cone is provided with a guide chute, the guide rod is sleeved in the guide chute on the main lens cone, the guide rod is fixed on an outer cylindrical surface of the coupling lens group lens cone through threads, a right end of the lens coupling lens group lens cone is provided with a spring mounting groove of the compression spring, a right end of a larger inner hole of the main lens cone is provided with a spring mounting groove, andthe compression spring is arranged between the two spring mounting grooves. The device is advantaged in that the structure is simple, machining cost is low, and adjustment is convenient.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

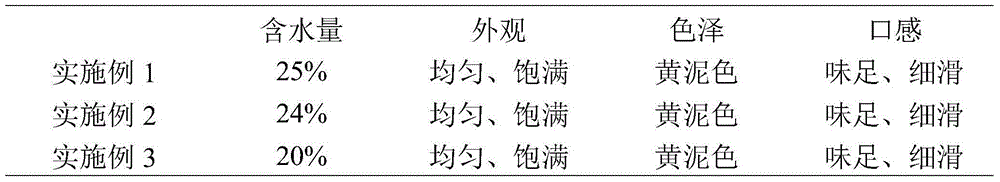

Processing method of dried litchi chinensis

The present invention belongs to the field of litchi chinensis processing and relates to a processing method of dried litchi chinensis, which comprises the following steps in sequence: selecting fresh litchi chinensis with thick flesh and small kernels, and cleaning, peeling, and removing the kernels of the litchi chinensis to obtain the litchi chinensis fruit pulp; soaking the litchi chinensis fruit pulp in an aqueous solution of 0.2% NaHSO3 , 0.1% citric acid, and 0.2% CaCl2 for 2-3 hours; blanching the hardened the litchi chinensis fruit pulp in a hot water at 90-100 DEG C for 2-3 min; then placing the litchi chinensis fruit pulp in a cold storage at -20 to 0 DEG, rapidly decreasing the water activity of the litchi chinensis fruit pulp to be less than 0.6 and the moisture content to be lower than 50% by using a dehumidifier; and finally putting the litchi chinensis fruit pulp in a drying oven, hot air drying at 50 DEG C for 8-10 hours with a hot air flow rate of 1-2 m / s until the moisture content is lower than 25%, and then cooling and packaging. The present invention provides a processing method of dried litchi chinensis with full appearances and good color, and the processing method has low processing costs.

Owner:钟兴欢

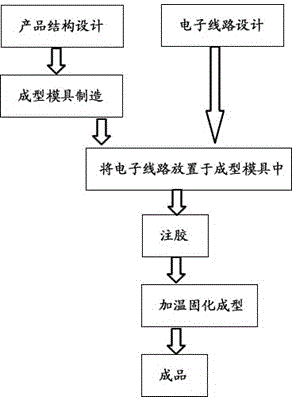

Light-transmitting LED (light-emitting diode) waterproof lamp group and manufacturing method thereof

PendingCN103822118AAvoid destructionExtended service lifePoint-like light sourceElectric lightingWeather resistanceUltraviolet

The invention relates to a light-transmitting LED (light-emitting diode) waterproof lamp group and a manufacturing method thereof. The light-transmitting LED waterproof lamp group is provided with a good ultraviolet resisting function and an excellent weather resistance performance, can serve as an LED light source shell independently and can work outdoors and underwater for a long time without moisture permeation. The light-transmitting LED waterproof lamp group is formed by a series of connection of a plurality of LED lamps. Light sources for the one or a plurality of the LED lamps are formed by one LED or arrangement of a plurality of LEDs, and the one or a plurality of the LED lamps are hermetically coated by a PVC (polyvinyl chloride) thickener to form the light-transmitting LED waterproof lamp group. The light-transmitting LED waterproof lamp group has the advantages that 1, the PVC thickener serving as a shell of the LED light source is good in ultraviolet resistance, low temperature resistance and weather resistance and can reach V-2 to V-0 grades in flame retardance; 2, material cost and production cost of products are reduced, and the light-transmitting LED waterproof lamp group is low in processing cost, short in producing period and high in processing efficiency; 3, the shape of the light-transmitting LED waterproof lamp group can be formed differently according to different needs of users, and a technical bias that technicians in the field consider that the PVC thickener cannot serve as an LED lamp group forming material for a long time is basically changed.

Owner:徐松炎

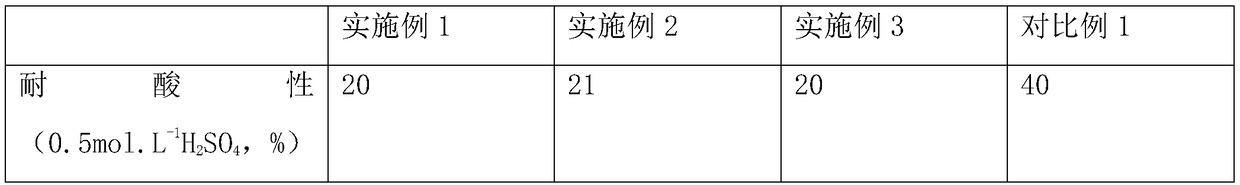

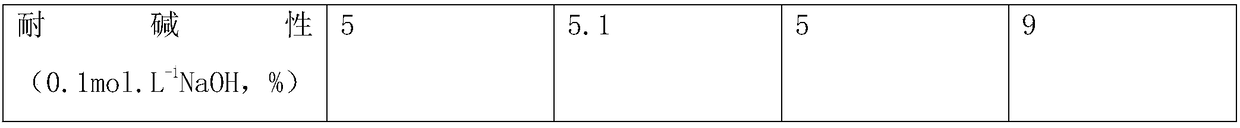

Glass fiber and processing technology thereof

The invention discloses a glass fiber which comprises the following raw materials in parts by weight: 30-50 parts of SiO2, 6-10 parts of Al2O3, 1-4 parts of CaF2, 10-14 parts of ZrO2, 11-16 parts of Ln2O3, 4-6 parts of TiO2, 60-70 parts of H2O and 50-70 parts of H3BO3. The glass fiber is mainly prepared by the following steps: mixing the raw materials, melting, drawing, pickling and performing heat setting treatment. The glass fiber disclosed in the invention has the beneficial effects that (1) the glass fiber disclosed in the invention is excellent in acid resistance, low in molding temperature and low in cost, and the production efficiency is improved; (2) the glass fiber disclosed in the invention is excellent in high temperature resistance, can be applicable to a temperature of 1000 DEG C or less for a long time, and has excellent ablation property, excellent high temperature resistance and chemical resistance; (3) the processing technology of the glass fiber is low in cost, simpleto operate and suitable for more small and medium-sized enterprises.

Owner:旌德县源远新材料有限公司

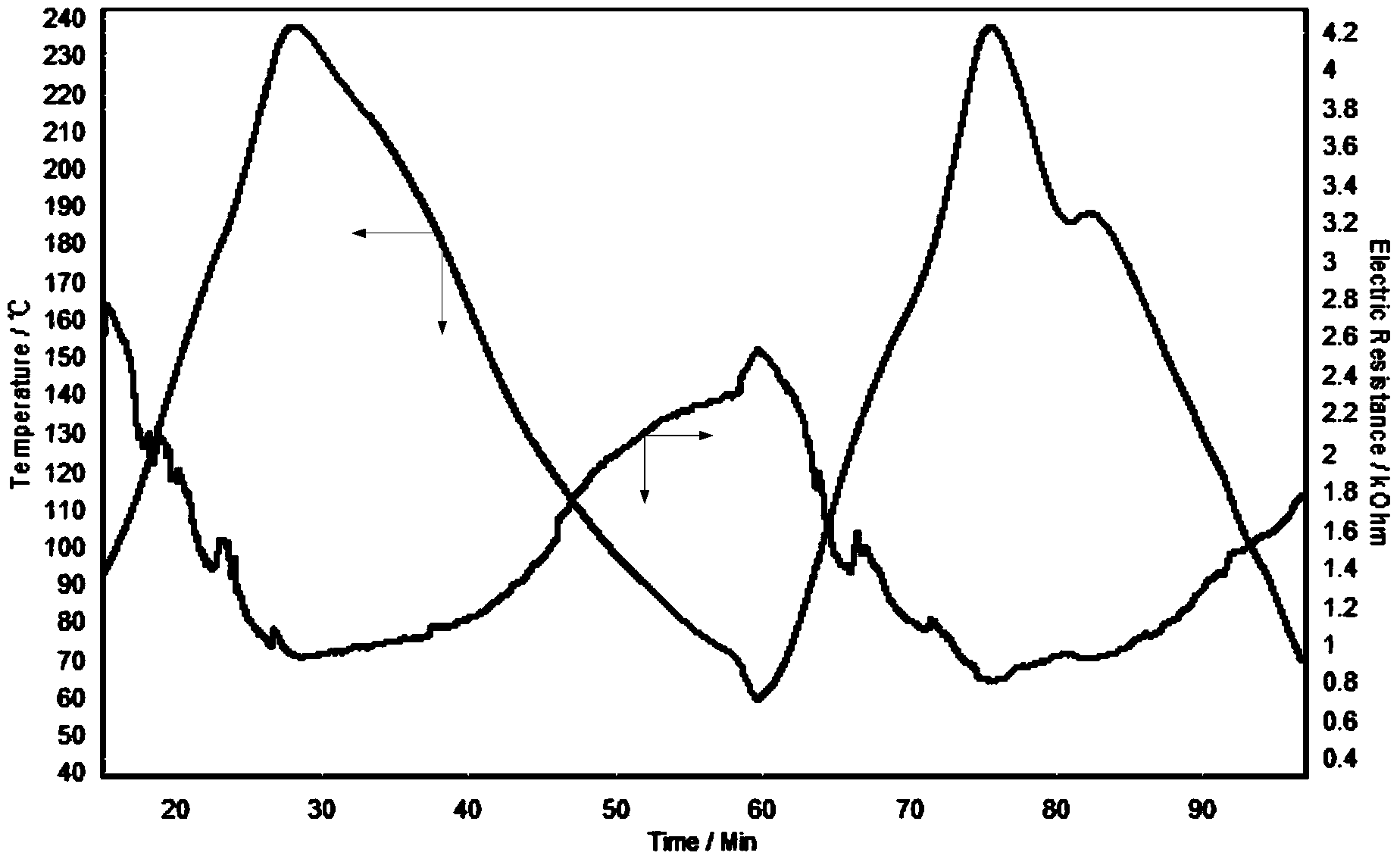

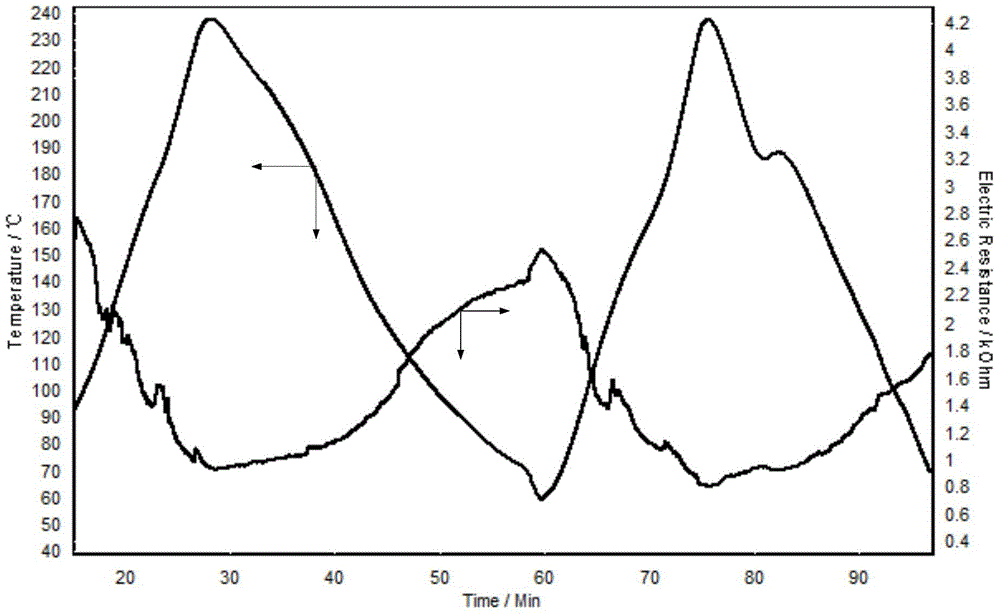

Preparation method for gas-sensitive element for hydrocarbon gas detection

ActiveCN104132987AThe synthesis method is simpleHigh sensitivityMaterial analysis by electric/magnetic meansChemistryFilm-coated tablet

The invention relates to a preparation method for a gas-sensitive element for hydrocarbon gas detection, and is mainly used for solving the problems of complicated synthesis technology, relatively high operating temperature and relatively high processing cost in the prior art. The preparation method for the gas-sensitive element for the hydrocarbon gas detection comprises the following steps of (1) pretreating a base body: treating the base body through acid and alkali in sequence, and drying the base body to obtain a pretreated base body; (2) preparing tin dioxide: adding SnCl2.2H2O into ethyl alcohol to obtain tin dioxide solution; (3) preparing a tin dioxide thin film: putting the obtained pretreated base body into the tin dioxide solution for film coating, and then performing drying and baking to obtain a base body coated by a tin oxide precursor; (4) performing thermal treatment: heating, roasting and cooling the base body coated by the tin oxide precursor to obtain the tin oxide thin film gas-sensitive element. According to the technical scheme, the problems in the prior art are well solved; the gas-sensitive element can be used for the hydrocarbon gas detection.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

Ventilation steel channel, manufacturing method of ventilation steel channel, ventilation structure and motor

ActiveCN104578483AImprove cooling effectThe overall thickness is thinMagnetic circuit rotating partsMagnetic circuit stationary partsAgricultural engineeringConductor Coil

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Special carp feed

InactiveCN104137955AReduce gastroenteritisEnhance immune functionFood processingClimate change adaptationDiseaseBiotechnology

The invention is a special carp feed comprising the following raw materials by weight: 10-25 parts of broken rice, 10-20 parts of rapeseed cake, 10-15 parts of wheat bran, 10-15 parts of dry potato powder, 7-20 parts of rice bran, 1-3 parts of yeast, 0.1-0.6 part of salt, 0.5-2 parts of sesame powder, 0.3-0.5 part of sucrose, 0.1-0.4 part of dry garlic powder and 0.3-0.6 part of a probiotic preparation. The main production method of the feed is as follows: first, weighing the raw materials in the ratio, crushing the raw materials, then stirring and mixing the raw materials, and finally preparing the mixture to obtain the pellet feed, namely the special carp feed finished product. The pellet feed is rich in nutrition, can enhance the carp disease prevention and disease resistance, and provides pollution-free healthy beneficial product carps to the market.

Owner:赵亲文

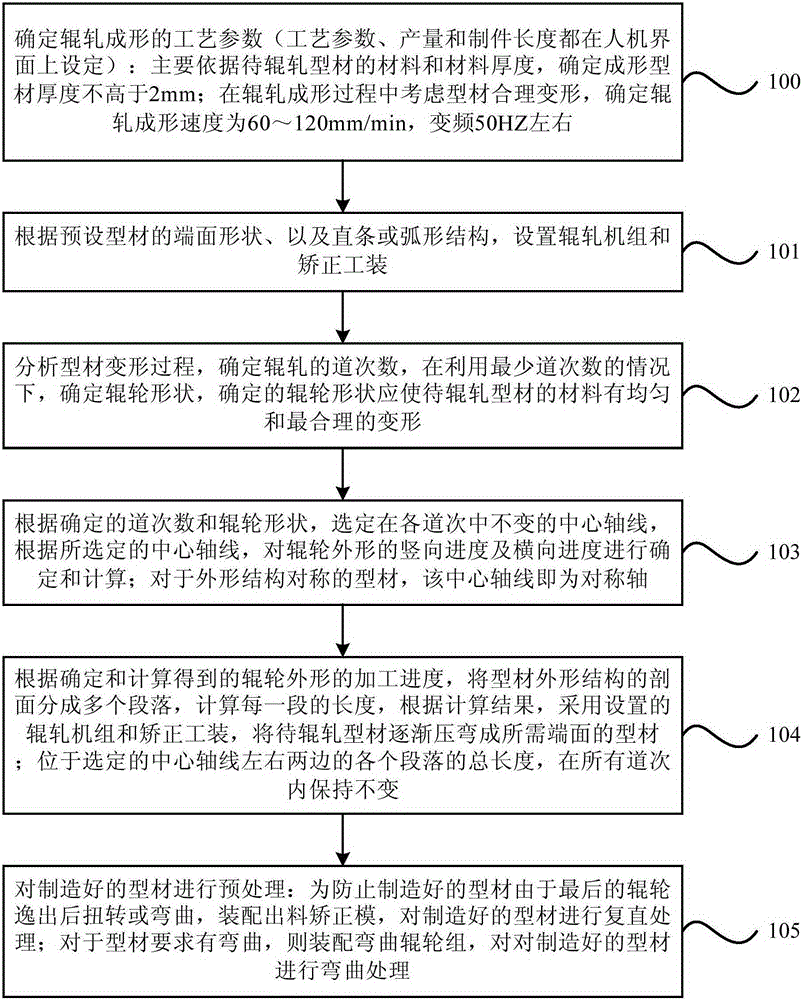

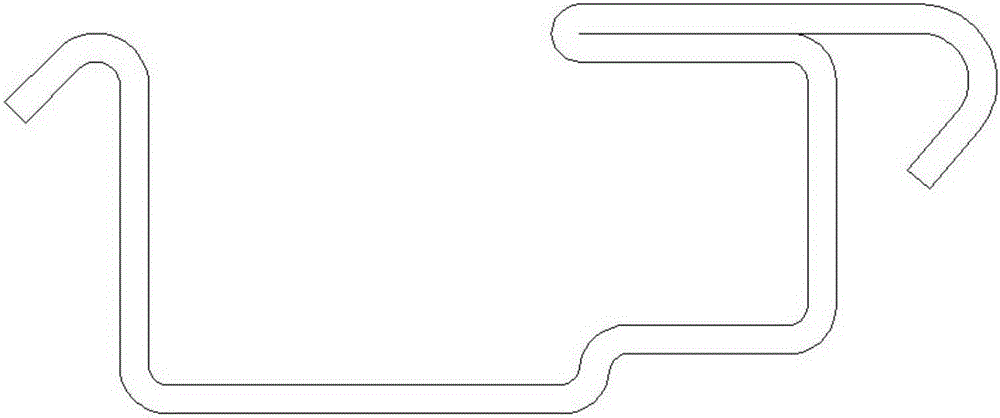

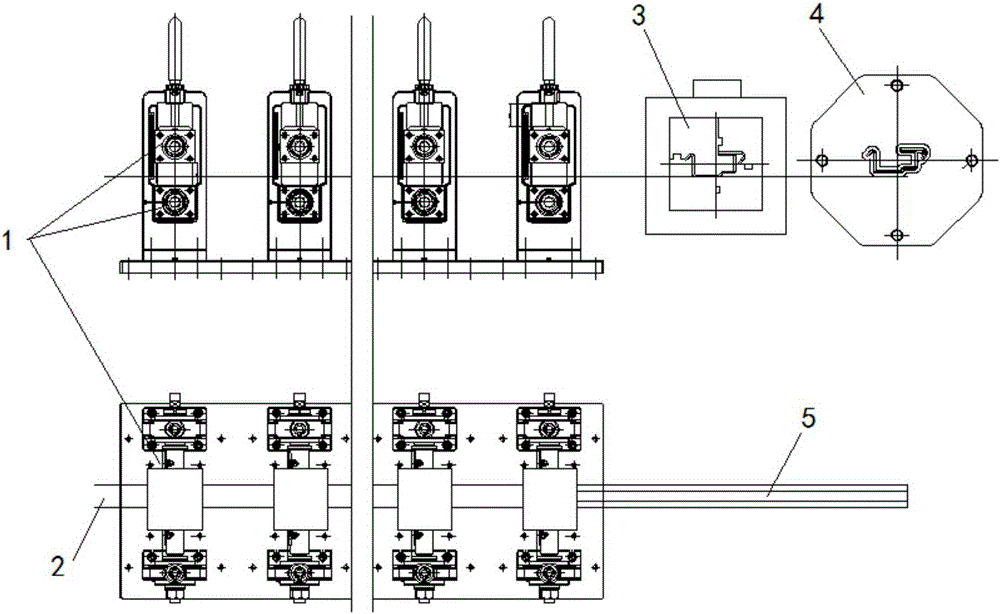

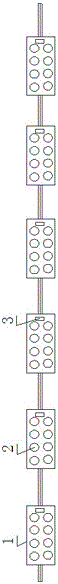

A kind of roll forming method of elongated shaped bar

Owner:LIUZHOU SHUXIN AUTO PARTS

Light-transmitting led outdoor lamp group and its manufacturing method

ActiveCN103822131BImproves UV resistanceImprove low temperature resistanceElectric lightingOutdoor lightingWeather resistancePolyvinyl chloride

The invention relates to a light-transmitting outdoor LED (light-emitting diode) lamp group and a manufacturing method thereof. The light-transmitting outdoor LED lamp group is provided with a good ultraviolet resisting function and an excellent weather resistance performance, can serve as an LED light source shell independently and can work outdoors and underwater for a long time without moisture permeation. The light-transmitting outdoor LED lamp group is formed by a series of connection of a plurality of LED lamps. Light sources for the one or a plurality of the LED lamps are formed by one LED or arrangement of a plurality of LEDs, and the one or a plurality of the LED lamps are hermetically coated by a modified PVC (polyvinyl chloride) thickener to form the light-transmitting outdoor LED lamp group. The light-transmitting outdoor LED lamp group has the advantages that 1, the PVC thickener serving as a shell of the LED light source is good in ultraviolet resistance, low temperature resistance and weather resistance and can reach V-2 to V-0 grades in flame retardance; 2, material cost and production cost of products are reduced, and the outdoor light-transmitting LED lamp group is low in processing cost, short in producing period and high in processing efficiency; 3, the shape of the light-transmitting outdoor LED lamp group can be formed differently according to different needs of users, and a technical bias that technicians in the field consider that the PVC thickener cannot serve as an LED lamp group forming material for a long time is basically changed.

Owner:徐松炎

Processing method for press roll-shaped structural parts

The invention discloses a processing method for press roll-shaped structural parts, which includes the following steps: according to a fixed support to be cast, a casting mold is arranged, and the needed fixed support is casted in the casting mold; after being calcined and cooled with water, the cast fixed support is polished, and a blower is then used for blowing off polishing dust on the surface of the fixed support; a press roll-shaped structural part and the fixed support are respectively connected with both ends of a V-shaped elastic strip; the whole body which is composed of the press roll-shaped structural part, the V-shaped elastic strip and the fixed support undergoes foreign matter removal, cleaning and drying treatment; after a preset mold passes check, the press roll-shaped structural part, the V-shaped elastic strip and the fixed support are put into the preset mold as a whole, and by adopting a continuous steel casting method, molten metal which is prepared in advance is poured into the preset mold to cast the press roll-shaped structural part, the V-shaped elastic strip and the fixed support together through a casting machine. The processing method for press roll-shaped structural parts has the advantages of high production efficiency, high product quality and low processing cost.

Owner:WUXI YANGGONG MACHINERY MFG

Manufacturing method of hardware structure part

The invention discloses a manufacturing method of a hardware structure part. The manufacturing method of the hardware structure part includes: tightly pressing the hardware structure part which needs a support on a fixing support to be casted through a Z-shaped positioning piece; respectively connecting the hardware structure part and the fixing support with two ends of the Z-shaped positioning piece; placing the hardware structure part, the Z-shaped positioning piece and the fixing support into a preinstalled mold as a whole, and pouring melting metal liquid prepared in advance into the preinstalled mold so as to cast the melting metal liquid together with the hardware structure part, the Z-shaped positioning piece and the fixing support through a casting machine by using a mold casting method; enabling a fusion point of the Z-shaped positioning piece to exceed a fusion point of the melting metal liquid prepared in advance; performing mechanical steel releasing when no bubble emerges in a steel bottle used to contain the melting metal liquid prepared in advance after casting is completed, and then recycling residues in the steel bottle; performing polishing and antirust coat spraying treatment on the hardware structure part cooled to room temperature after the hardware structure part completely casted is cooled to the room temperature. The manufacturing method of the hardware structure part is high in production efficiency, good in product quality and low in manufacturing cost.

Owner:WUXI YANGGONG MACHINERY MFG

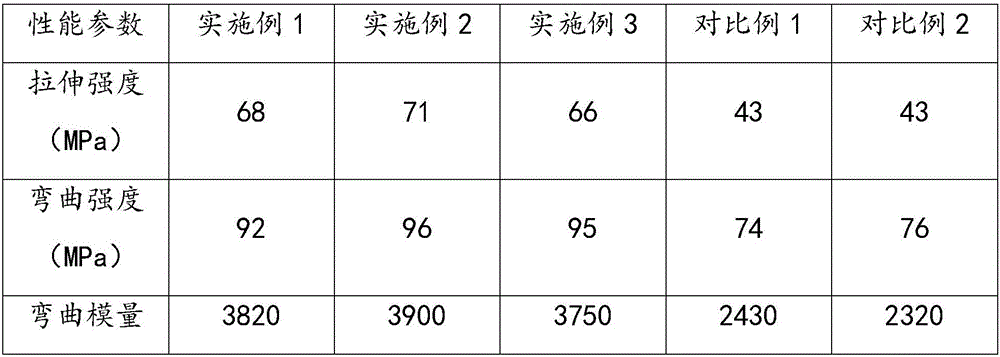

PP-PA alloy and preparation method thereof

The invention belongs to the field of organic polymeric compounds, and especially relates to a PP-PA alloy and a preparation method thereof. The PP-PA alloy comprises PP, PA, red mud, wollastonite, glass beads, hydrotalcite, a silane coupling agent, a flexibilizer, graphite and a compatilizer. The preparation method comprises the following steps: uniformly mixing the PP, the PA, red mud, wollastonite, glass beads, hydrotalcite, the silane coupling agent, the flexibilizer, graphite and the compatilizer, and extruding the obtained mixture through a double screw extruder to obtain the PP-PA alloy. The PP-PA alloy prepared in the invention has excellent mechanical performances, and the preparation method is simple.

Owner:四川锦泰佳环保建材有限公司

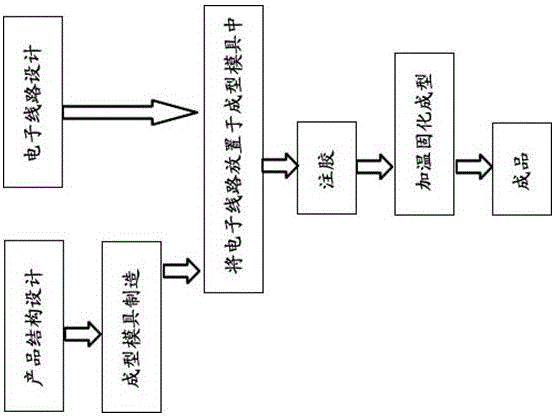

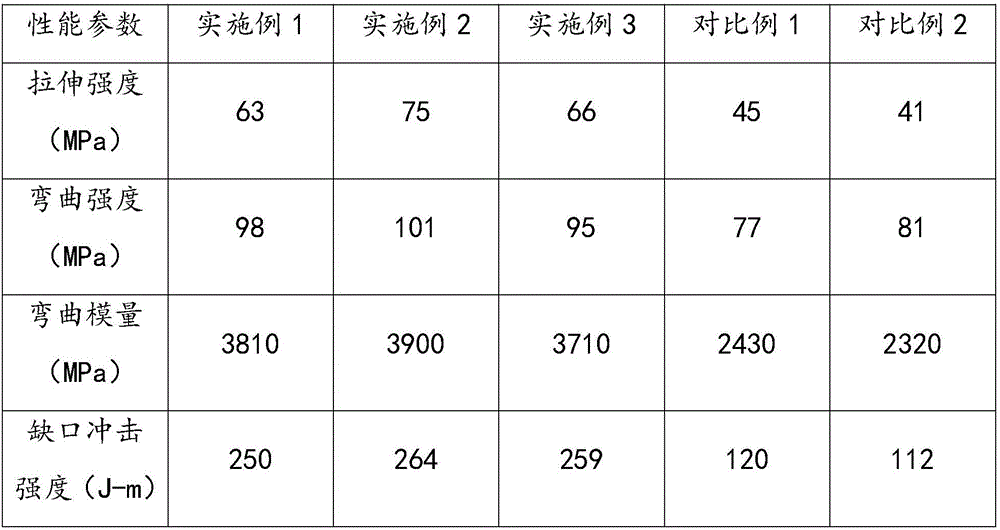

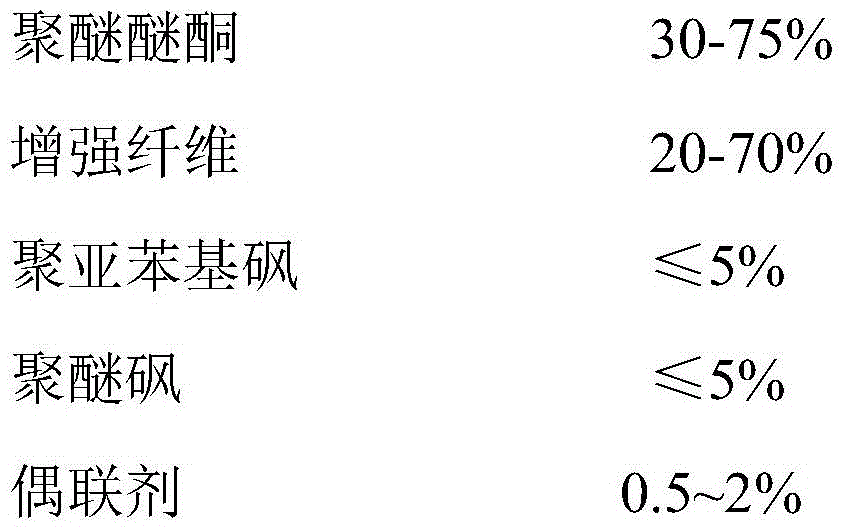

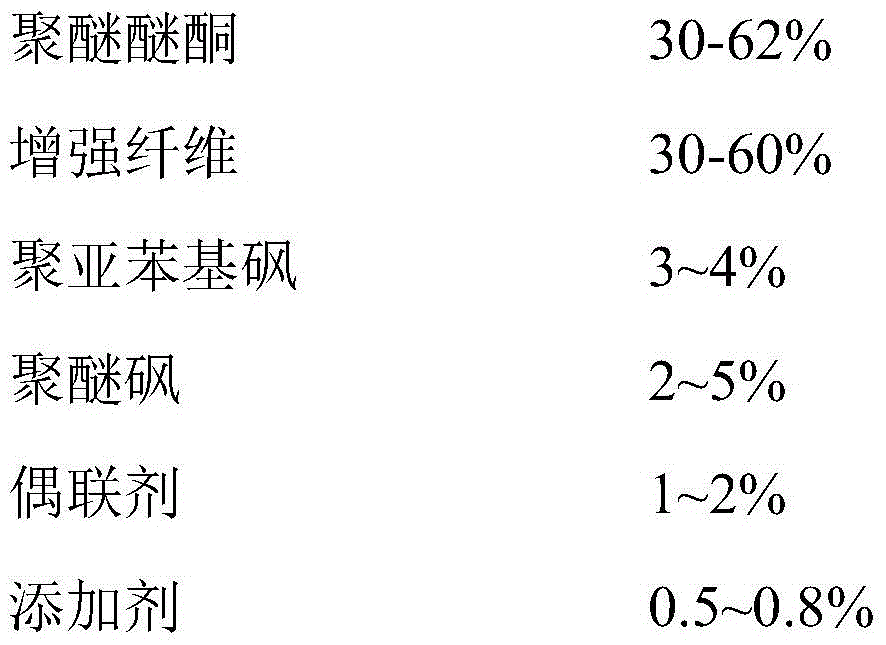

Engineering plastics, preparation method and application for preparing surgical operating instrument

InactiveCN105641752AImprove corrosion resistanceGood dimensional stabilitySurgeryFiberEngineering plastic

The invention discloses engineering plastics, a preparation method and application for preparing a surgical operating instrument. The engineering plastics is prepared from, by weight, 30-75% of polyether-ether-ketone, 20-70% of reinforced fiber, not larger than 5% of polyphenylene sulfone, not larger than 5% of polyether sulfone, 0.5-2% of a coupling agent and 0.1-3% of an additive. The engineering plastics can be used for preparing the surgical operating instrument. The engineering plastics has the advantages that the obtained surgical operating instrument is good in corrosion resistance, high in dimensional stability, excellent in dyeability, and capable of performing sterilization in various conventional sterilization modes including high-temperature and high-pressure steam, ethylene oxide, low-temperature plasma, gamma rays and the like; the surgical operating instrument can be prepared through an injection molding method, rapid production can be achieved, the processing cost is low, the good anticoagulant activity is achieved when the surgical operating instrument makes contact with blood, the ISO 10993 certification is met, no rejection is produced when the surgical operating instrument marks contact with human tissue organs for a short or middle period of time in a surgery, and the enough chemical stability and physiological inertia are achieved.

Owner:SHANGHAI XUEFENG PRECISION MACHINERY CO LTD

Ventilation channel steel, its manufacturing method, ventilation structure and motor

ActiveCN104578483BImprove cooling effectThe overall thickness is thinMagnetic circuit rotating partsMagnetic circuit stationary partsAgricultural engineeringConductor Coil

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

PP-PE alloy and preparation method thereof

The invention belongs to the field of an organic high-molecular compound, and particularly relates to a PP(Propene Polymer)-PE(Poly Ethylene) alloy and a preparation method thereof. The PP-PE alloy is prepared from the following raw materials including PP, PE, titanium dioxide, rectorite, thiourea, wood fiber, a titanate coupling agent, sulfonated zinc polystyrene and maleic anhydride-glycidyl methacrylate bimonomer grafting high-density polyethylene. The preparation method comprises the following steps of A, weighing the titanium dioxide, the rectorite, the thiourea and the wood fiber according to the weight parts; putting the materials into a high-speed mixing machine; performing dispersion and mixing; and obtaining a mixture A; B, adding the titanate coupling agent and the sulfonated zinc polystyrene into the mixture A obtained in the step A in a spraying way to obtain a mixture B; and C, adding the mixture B obtained in the step B into an extrusion machine, and performing plasticization, fusion, compounding, machine head extrusion, strip pulling, cooling, pelletizing, drying and packaging to obtain the PP-PE alloy. The prepared PP-PE alloy has excellent mechanical performance, and the preparation method is simple.

Owner:四川锦泰佳环保建材有限公司

Machining technology of hardware structural part

The invention discloses a machining technology of a hardware structural part. The machining technology comprises the steps that rubber materials are adopted, and a fixed support to be cast is provided with a fixed support rubber accessory in a matched manner; the fixed support rubber accessory is used for coating the fixed support after being cooled so as to protect the fixed support, and transportation is facilitated; the hardware structural part and the fixed support are connected to the two ends of a Z-shaped elastic sheet respectively; after a preset mold is detected to be qualified, the hardware structural part, the Z-shaped elastic sheet and the fixed support are placed in the preset mold as a whole; and through a casting machine, molten metal prepared in advance is poured into the preset mold to be cast together through a mold casting method. The machining technology of the hardware structural part is high in production efficiency, good in product quality and low in machining cost.

Owner:南京中配橡塑制品有限公司

A kind of preparation method of gravel-carrying filter pipe

A method for preparing a gravel-carrying filter pipe. A gravel-carrying water filter pipe, including a water pipe made of polymer materials, uniformly slit on the pipe wall in the axial direction of the water pipe, that is, the length direction, the width of the slit is 0.25-0.80mm, and the two ends of the water pipe are internal and external threaded structures. The length of the interval is 80-150cm; the outer side of the slit of the water pipe is covered with a filter screen, and there is a uniform granular filter material between the filter screen and the wall of the water pipe. Shaped fixing bracket, in which the covering filter screen is fixed between the two fixing brackets, the gap formed by the inner fixing bracket is filled with granular filter material, the thickness of the powder filter material is 20‑30mm, and the gap between the two fixing brackets The distance is 10-60cm.

Owner:江阴市星宇塑胶有限公司

Roll-formed structural part manufacturing method

The invention discloses a roll-formed structural part manufacturing method. The roll-formed structural part manufacturing method comprises the steps that a pouring die is arranged on the basis of a fixed support to be poured, and a required fixed support is obtained in a pouring mode through the pouring die; the fixed support obtained in the pouring mode is polished after being calcinated and water-cooled, and then an air blower is used for blowing off polished dust on the surface of the fixed support; the matching fixed support and an S-shaped locating plate are selected according to a roll-formed structural part which needs to be provided with a support; the roll-formed structural part which needs to be provided with the support is compressed on the fixed support to be poured through the S-shaped locating plate; the roll-formed structural part and the fixed support are connected to the two ends of the S-shaped locating plate respectively; the roll-formed structural part, the S-shaped locating plate and the fixed support are placed into the prearranged die as a whole, and prepared molten metal is poured into the prearranged die for joint pouring through a casting machine by the adoption of a continuous steel injection method. By means of the roll-formed structural part manufacturing method, production efficiency is high, product quality is good, and machining cost is low.

Owner:WUXI YANGGONG MACHINERY MFG

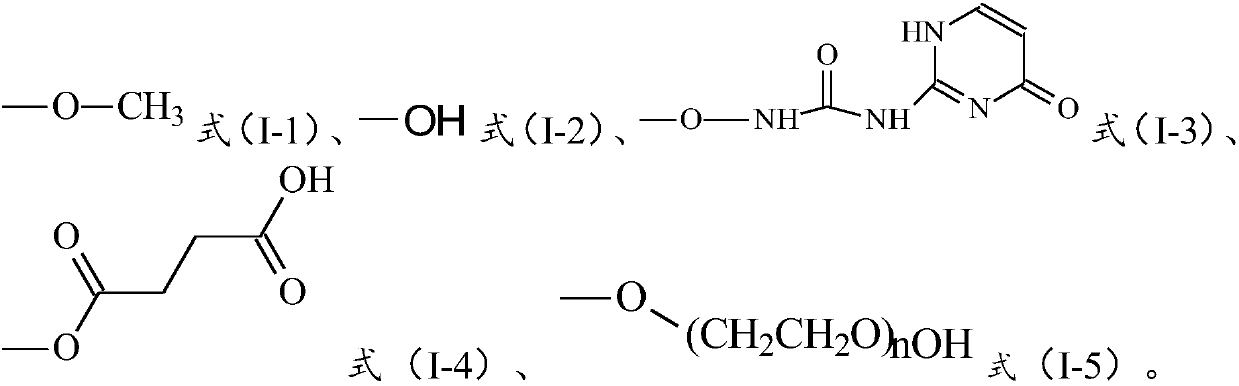

Pressure-sensitive compound, pressure-sensitive material, preparation method thereof and pressure-sensitive film

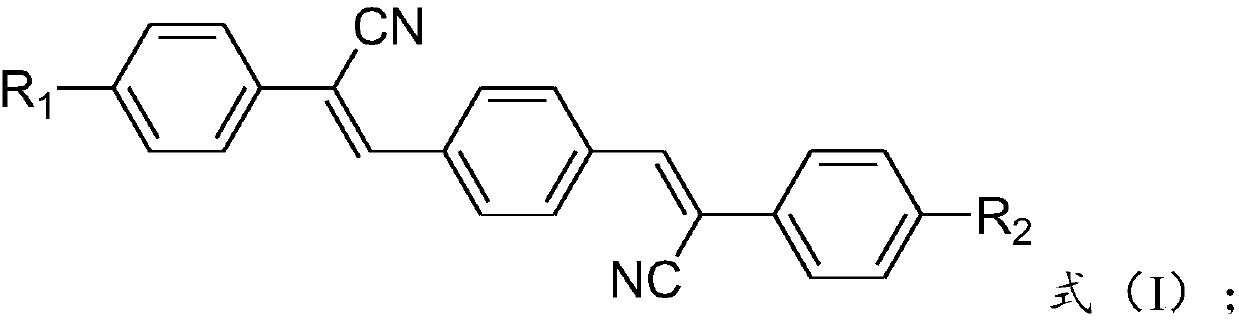

ActiveCN107817066AWide usable temperature rangeImprove mechanical propertiesForce measurement by measuring optical property variationCoatingsPressure senseApplication areas

The invention provides a pressure-sensitive compound, a pressure-sensitive material, a preparation method thereof and a pressure-sensitive film. The pressure-sensitive compound provided by the invention can form a compound of another structure after being pressed. Before and after the compound is pressed, two compounds are different in color, so that a color difference is formed. The larger the pressure, the larger the color difference. Based on the color difference, the size of the pressure can be judged. The pressure-sensitive compound is large in applicable temperature range and can be applied to the pressure sensing tests of various electronic consumer products, batteries and the like. The compound is high in mechanical performance, convenient to use and good in mechanical sensitivity.The compound can be applied to the pressure measurement of products in the low-pressure industry, and the application field of pressure measurement materials is expanded.

Owner:郭庚汶

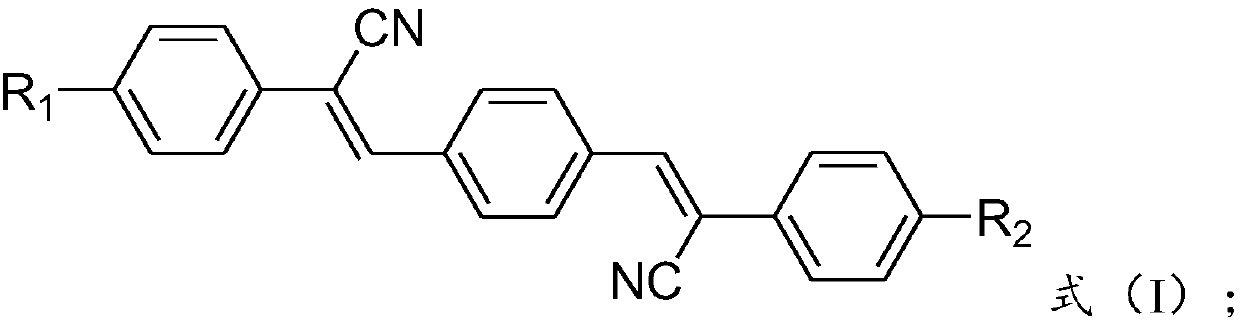

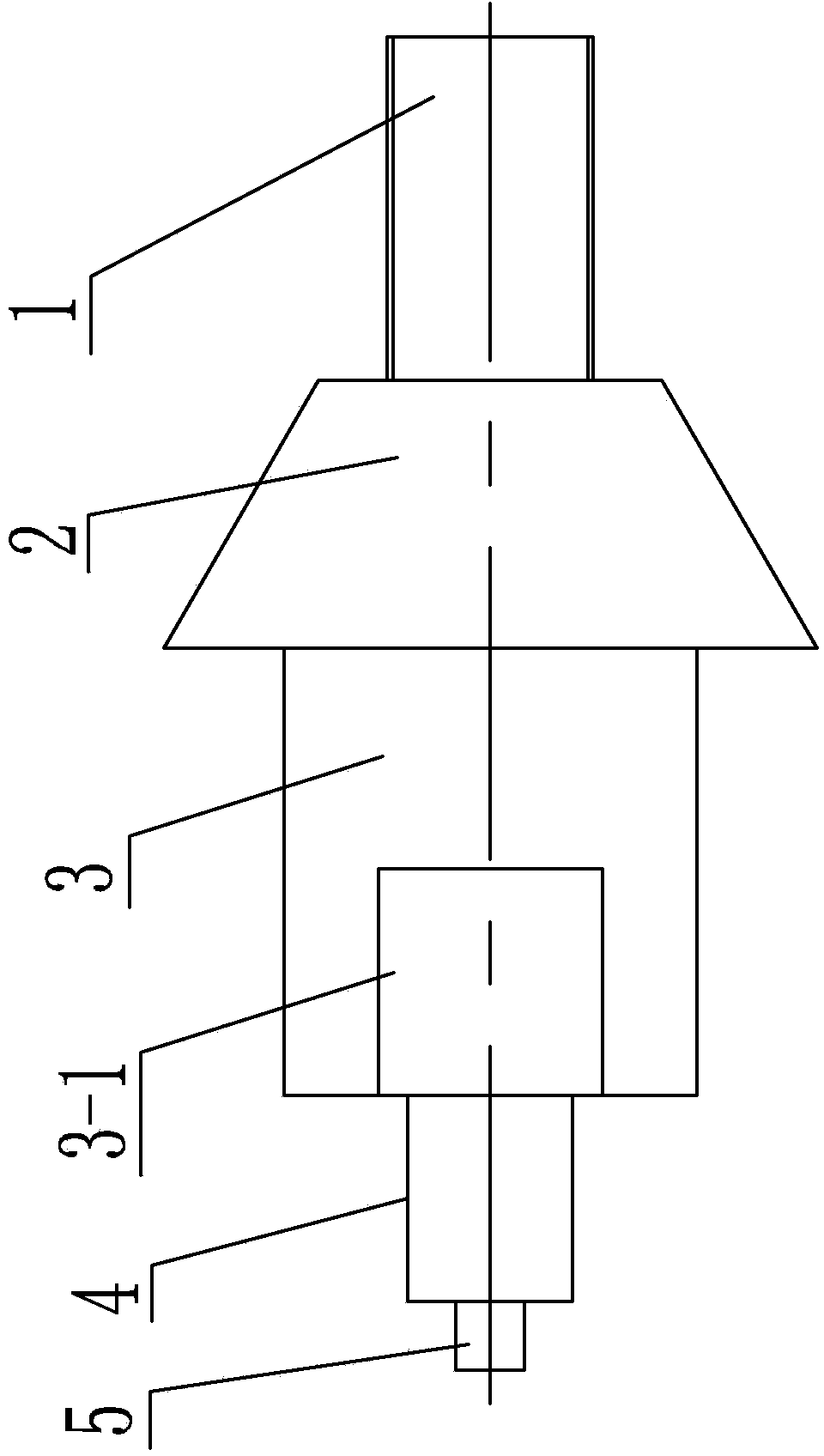

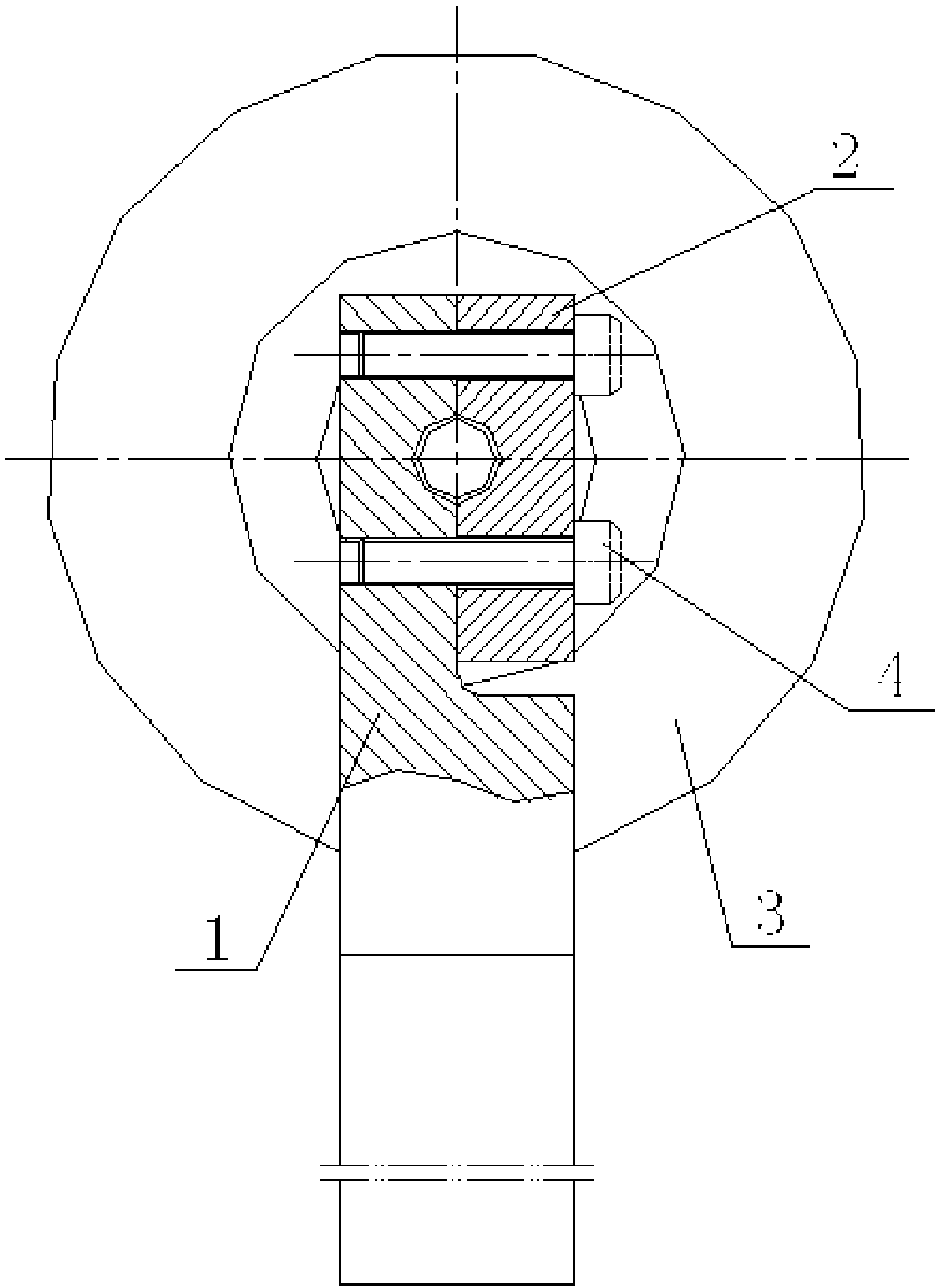

Connecting device for rotors and indexing monitoring equipment for machining wheel grooves of rotors of steam turbines

ActiveCN103465095ASimple structureReduce volumeMaintainance and safety accessoriesSteam turbine rotorElectrical and Electronics engineering

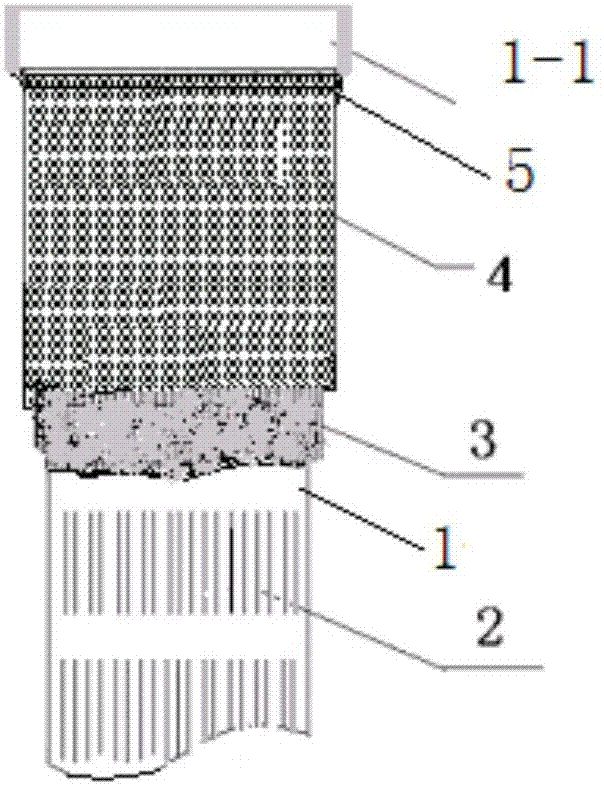

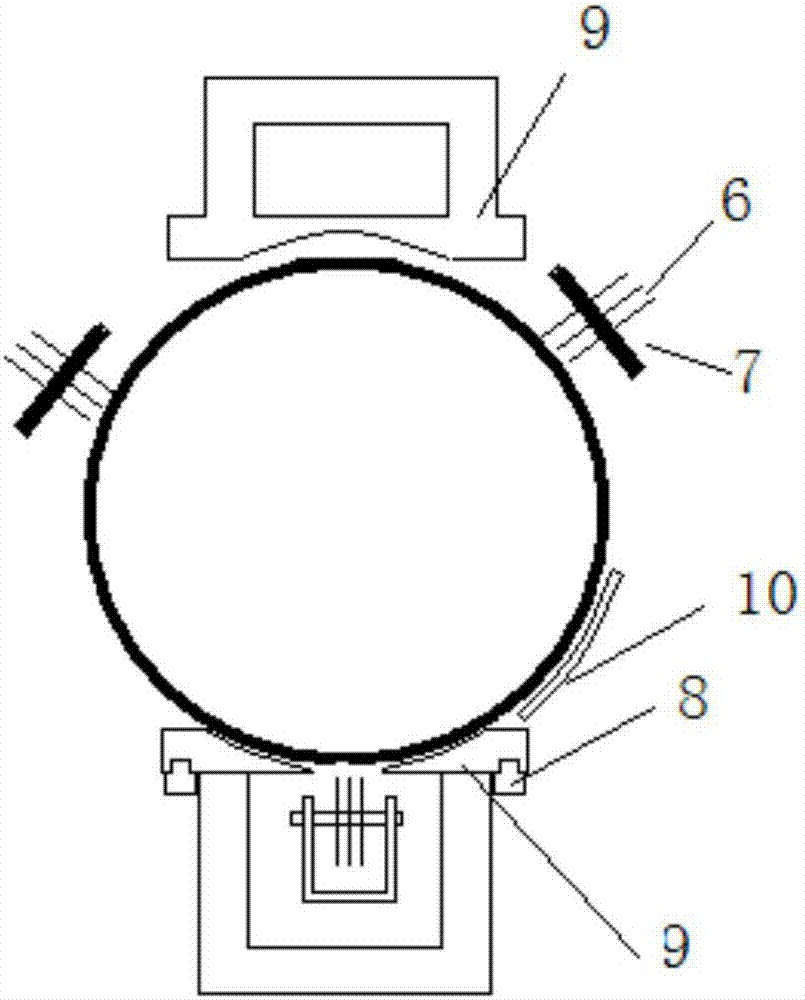

The invention discloses a connecting device for rotors and indexing monitoring equipment for machining wheel grooves of the rotors of steam turbines, and relates to a connecting device. The connecting device is used for solving problems of long time consumption and high labor consumption and service cost of an existing indexing disc during usage. The connecting device comprises a first cylinder section (1), a circular truncated cone section (2), a second cylinder section (3), a fourth cylinder section (4) and a fifth cylinder section (5) which are axially, sequentially and fixedly integrated. One end of the first cylinder section (1) is fixedly connected with a small end of the circular truncated cone section (2), one end of the second cylinder section (3) is fixedly connected with a large end of the circular truncated cone section (2), external threads are machined on the first cylinder section (1) along the length direction of the first cylinder section (1), and two rectangular platforms (3-1) are symmetrically machined on the second cylinder section (3). The connecting device is used for connecting the rotors with the indexing monitoring equipment for machining the wheel grooves of the rotors of the steam turbines.

Owner:HARBIN TURBINE

Preparation method of gas sensor for hydrocarbon gas detection

ActiveCN104132987BHigh sensitivityGood reproducibilityMaterial analysis by electric/magnetic meansTin dioxideProcessing cost

The invention relates to a preparation method of a gas sensitive element used for hydrocarbon gas detection, which mainly solves the problems of complex synthesis process, high operating temperature and high processing cost in the prior art. The present invention comprises the following steps by adopting a method for preparing a gas sensitive element used for hydrocarbon gas detection: (1) pretreatment of the substrate: successively treating the substrate with acid and alkali and then drying to obtain the pretreated substrate; 2) Preparation of tin dioxide: adding SnCl to ethanol 2 2H 2 O, to obtain tin dioxide solution. (3) Preparation of tin dioxide film: put the obtained pretreated substrate into the tin dioxide solution to coat the film, then dry and dry to obtain the substrate coated with the tin oxide precursor. (4) Heat treatment: the technical solution of heating, roasting and cooling the substrate coated with the tin oxide precursor to obtain the tin oxide thin film gas sensor better solves the above problems and can be used in hydrocarbon gas detection.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

Bolt bar part circular groove rolling strengthening method and rolling strengthening device for turning lathe

The invention discloses a bolt bar part circular groove rolling strengthening method and a rolling strengthening device for a turning lathe. When a surface of a bolt bar part circular groove is rolledand strengthened, the turning lathe is adopted for rolling strengthening on the bolt bar part circular groove, one end of a bolt needing to be rolled and strengthened is clamped on a chuck of the turning lathe, the other end of the bolt is tightened by a centre of the turning lathe, then the rolling strengthening device for the turning lathe is arranged on a tool holder of the turning lathe, a rolling wheel capable of pressing the bolt bar part circular groove is arranged on the rolling strengthening device for the turning lathe, after the rolling wheel is aligned at and ejects the bolt bar part circular groove needing to be rolled and strengthened, the chuck of the turning lathe drives the bolt to rotate, and a friction force generated when the rolling wheel ejects the bolt bar part circular groove can drive the rolling wheel to rotate together, so that the bolt bar part circular groove is rolled and strengthened through the rolling wheel. The bolt bar part circular groove rolling strengthening method and the rolling strengthening device for the turning lathe provided by the invention have the beneficial effects of high processing efficiency, low cost, good quality, the simple structure, convenience in use and the like.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

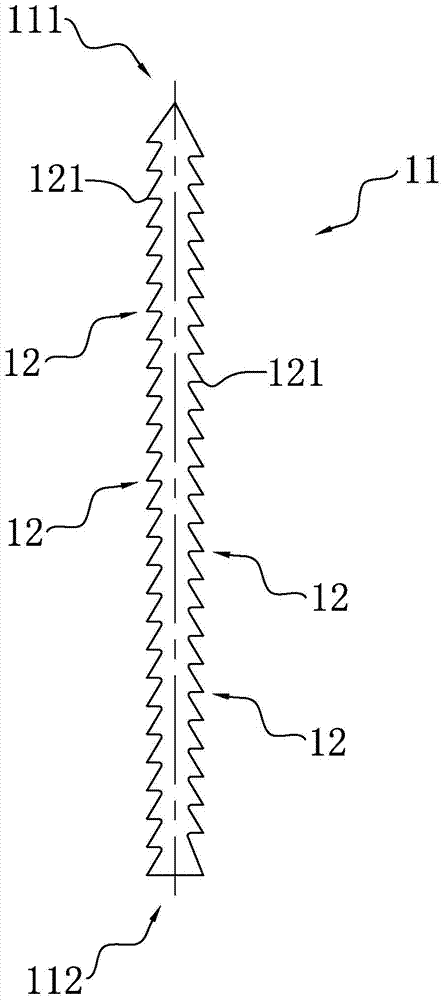

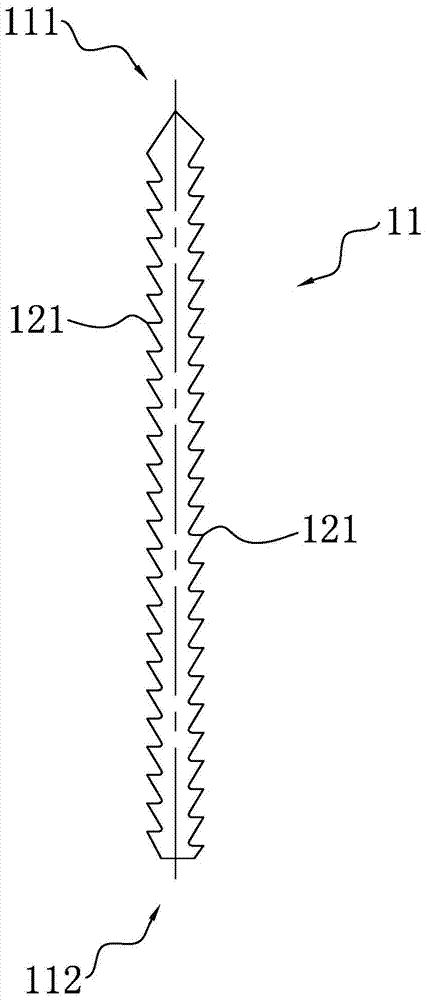

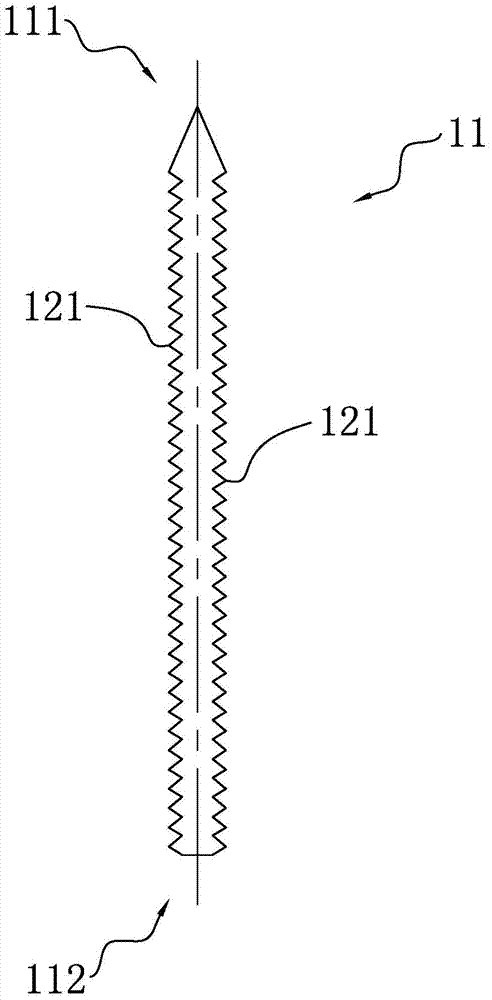

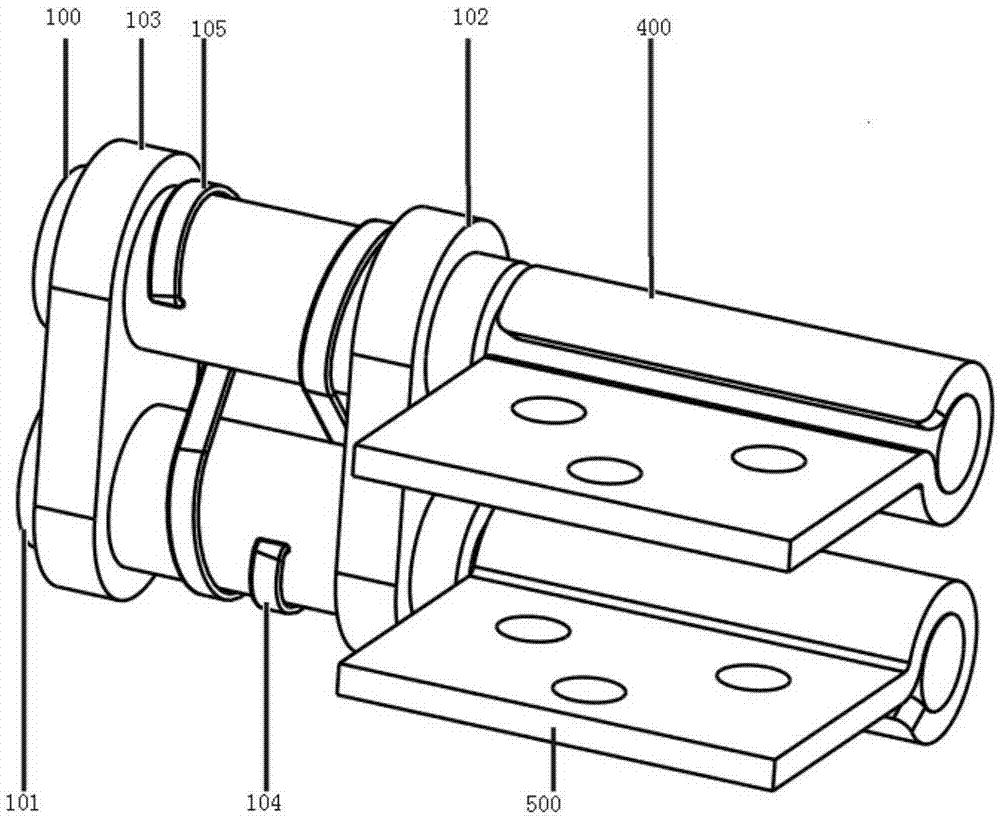

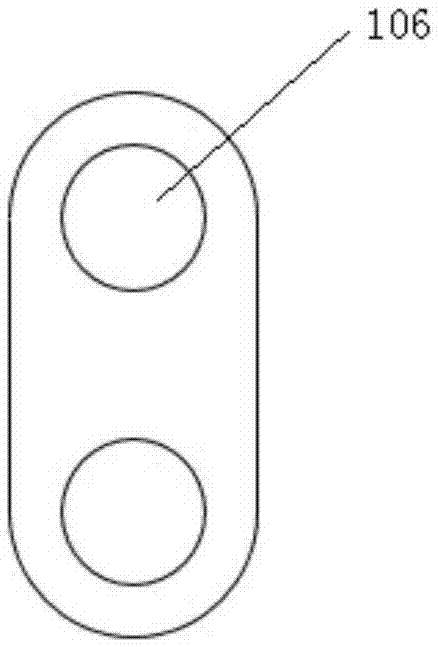

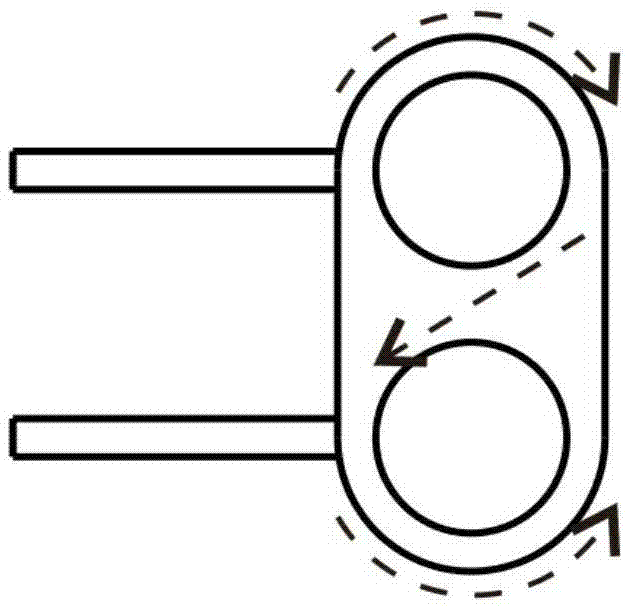

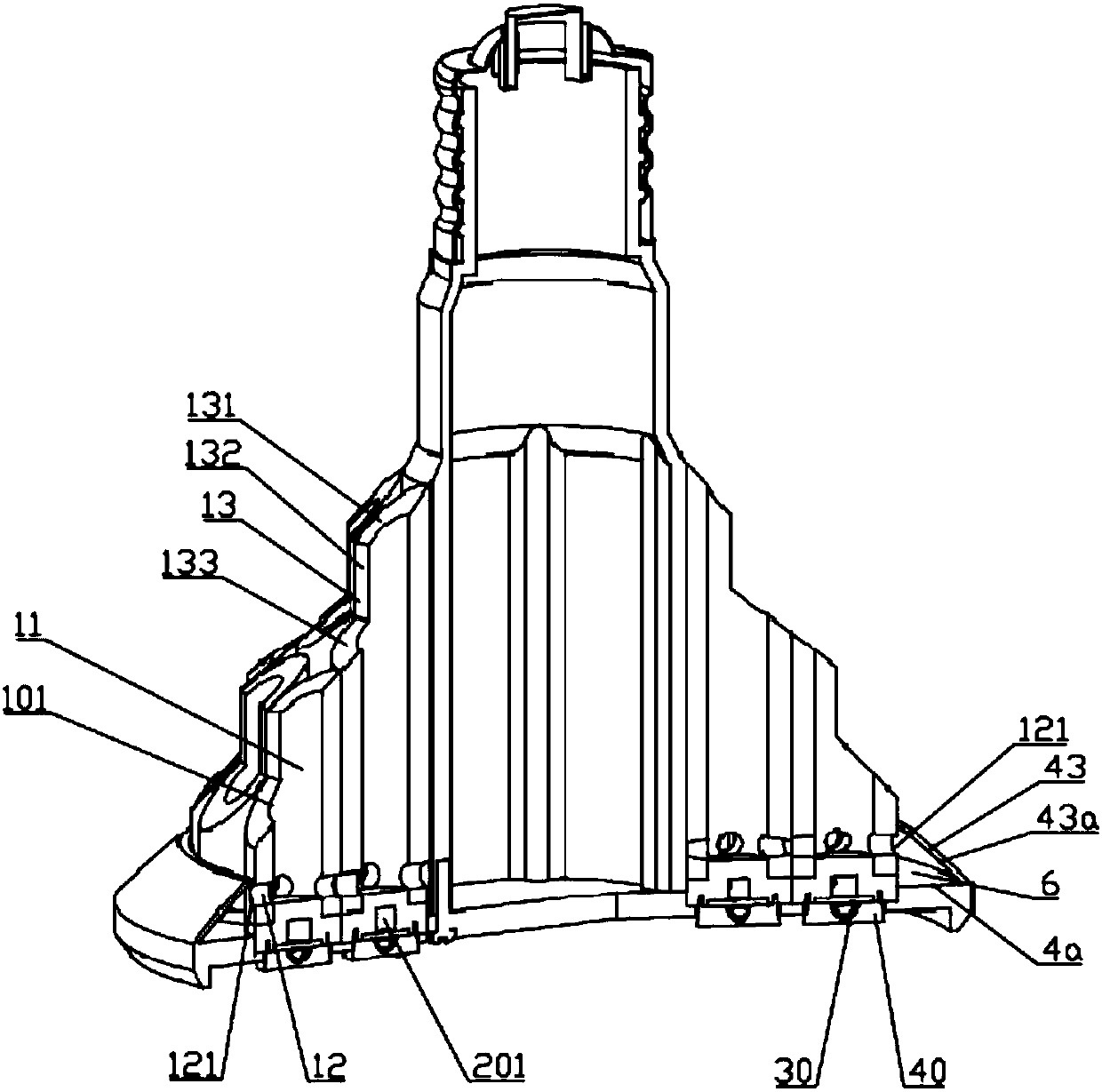

Simultaneous movement mechanism and equipment provided with simultaneous movement mechanism

InactiveCN106855079ASmooth transmissionGood processing costPivotal connectionsElastic componentEngineering

The invention discloses a synchronous movement mechanism and equipment using the mechanism, comprising at least one set of elastic components, the elastic components including at least two elastic parts, the first end of the first elastic part is fixed on the first rotating shaft, The end is fixed on the second rotating shaft after passing through the axis line connecting the first rotating shaft and the second rotating shaft, the head end of the second elastic member is fixed on the second rotating shaft, and the end passes through the connecting line connecting the axes of the first rotating shaft and the second rotating shaft Finally, it is fixed on the first rotating shaft; the projections of the first elastic member and the second elastic member on the cross-section of the first rotating shaft and the second rotating shaft have an intersection point; the first rotating shaft and the second rotating shaft are respectively sleeved on the on the guide. Using the synchronous transmission mechanism of the present invention, the synchronous rotation of the two rotating shafts can be smoothly realized, the processing cost is better, and there is no risk of jamming at the same time, the transmission is stable, and the elastic members are fixed on the rotating shaft in opposite directions so that the two rotating shafts can move in opposite directions. turn.

Owner:江苏东方滤袋股份有限公司

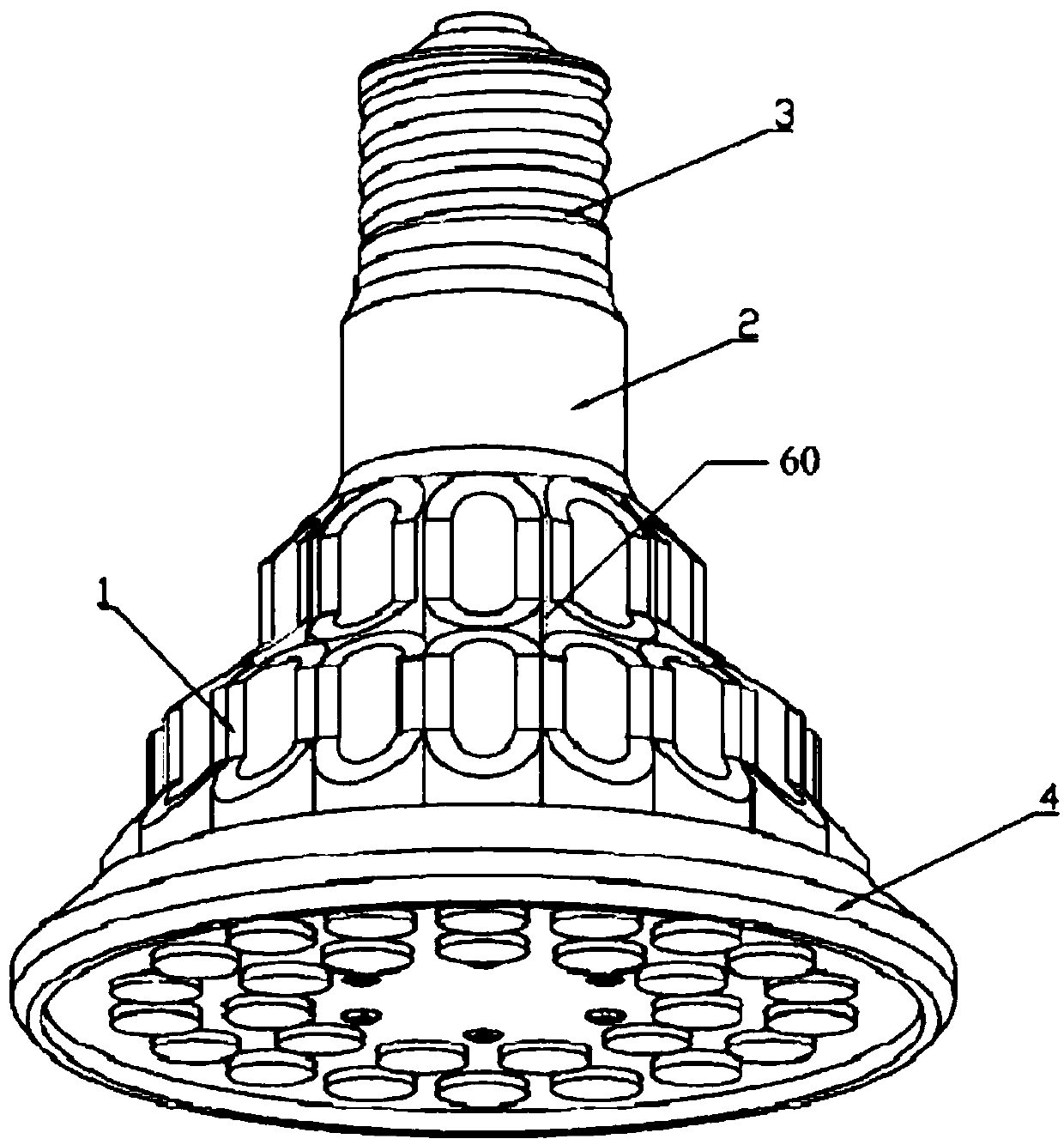

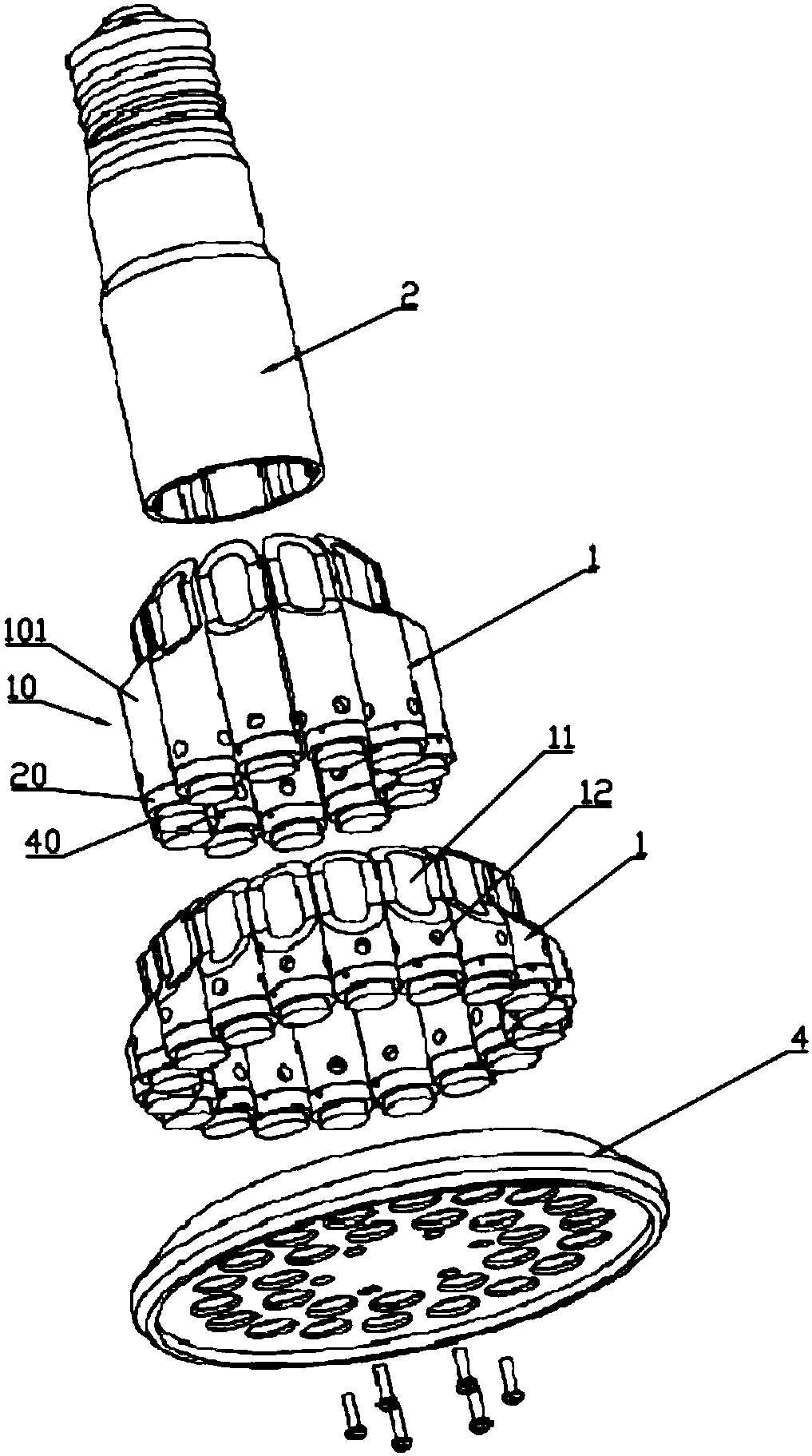

Radiator for LED module, LED module and LED lamp

PendingCN107642696AImprove cooling effectReduce heat dissipationLighting heating/cooling arrangementsLight fasteningsEngineeringLED lamp

The invention discloses a radiator for an LED module. The radiator for the LED module includes a radiator body. A through hole penetrating through the radiator body is arranged on the radiator body, and a hole is formed in the radiator body. The hole is communicated with the through hole, and the open end of the hole is exposed on the side wall of the radiator body. The radiator for the LED modulehas small heat dissipation volume, good heat dissipation effect, and low processing cost. The LED module adopting the radiator has the advantages of small size and good heat dissipation effect.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

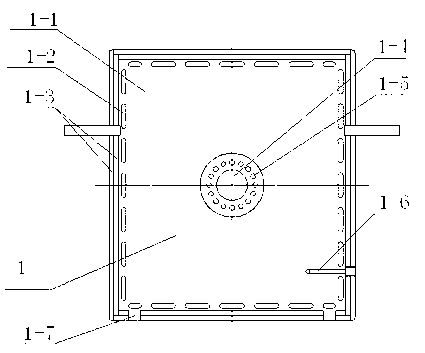

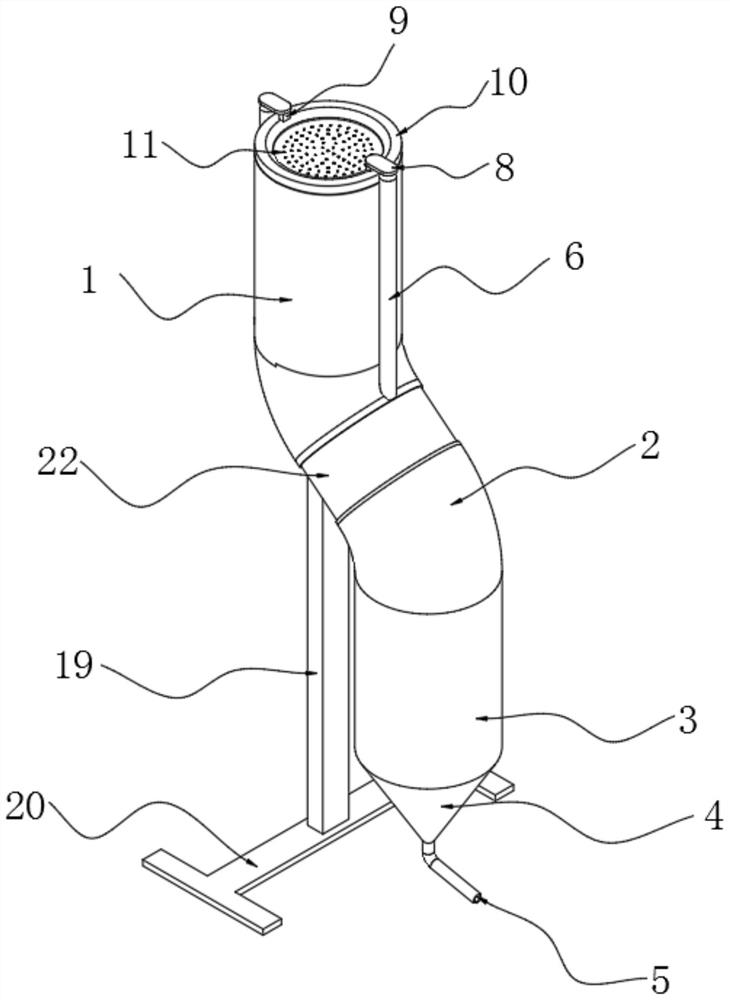

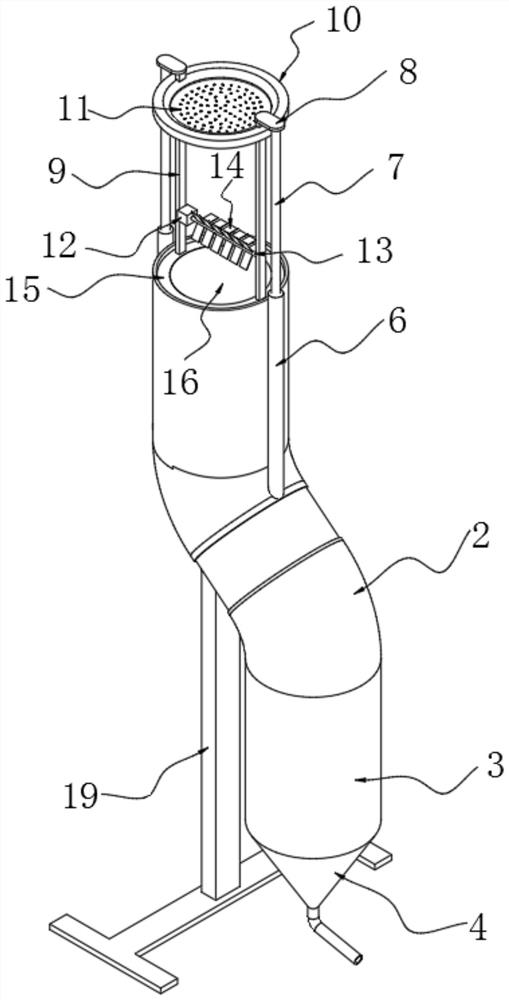

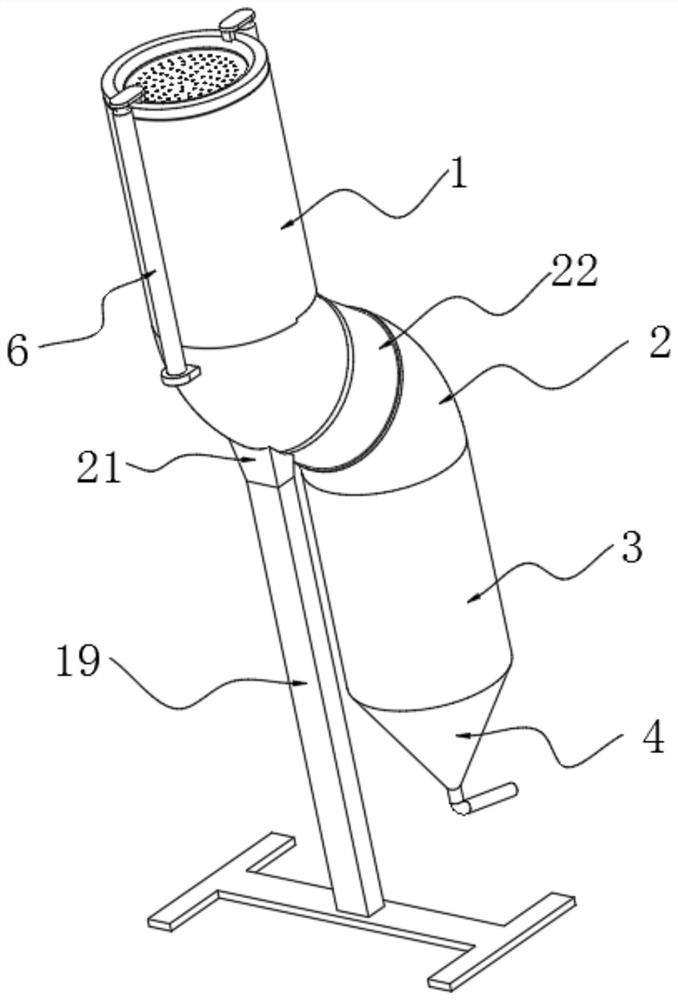

Equipment for adsorbing heavy metal elements

PendingCN113816510AGood processing costReduce processing costsWater contaminantsTreatment involving filtrationMicrowell PlateSewage

The invention provides equipment for adsorbing heavy metal elements, and belongs to the technical field of sewage treatment. The equipment for adsorbing the heavy metal elements comprises a treatment channel which comprises a first treatment channel, an arc-shaped treatment channel, a second treatment channel and a conical connecting pipe; the first treatment channel, the arc-shaped treatment channel, the second treatment channel and the conical connecting pipe are sequentially communicated from top to bottom, a recoverable adsorption mechanism is arranged in the first treatment channel, and the recoverable adsorption mechanism comprises two electric telescopic rods. The whole device is reasonable in structural arrangement, ingenious in conception, convenient to use, and suitable for batch adsorption or batch treatment of heavy metal elements in sewage, the treatment efficiency is high, the effect is good, the adsorbed heavy metal elements can be extracted through the device, operation is convenient, a flow guide mechanism in the device prevents the heavy metal elements from blocking the microwell plate, and the whole treatment channel is compact in structure, low in machining cost and high in practicability .

Owner:INSPECTION & QUARANTINE TECH CENT SHANTOU CIQ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com