Light-transmitting LED (light-emitting diode) waterproof lamp group and manufacturing method thereof

A technology of LED waterproof lamps and LED lamp groups, which is applied in the direction of gas-proof/waterproof devices, light sources, electric light sources, etc., can solve the problems of light source failure, damage, yellowing, etc., achieve good UV resistance, reduce production costs, and prolong use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

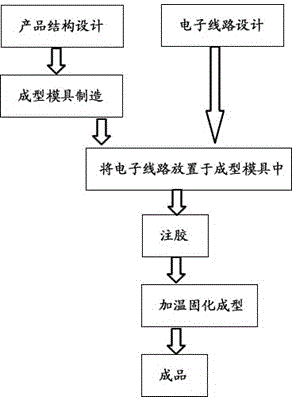

Method used

Image

Examples

Embodiment 1

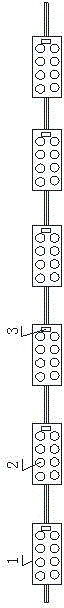

[0017] Embodiment 1: with reference to attached figure 1 . A light-transmitting LED waterproof lamp group. A plurality of LED lamps 1 are connected in series to form an LED lamp group. The light source of the one or more LED lamps 1 is composed of one or more LED2 arrays. The plurality of LED lamps are covered with PVC paste. It is sealed and wrapped into a light-transmitting and waterproof lamp group, and a gap-free sealing structure is formed between the LED light source and the PVC paste. One or more LED2 series packaged finished products. The manner and structure of one or more LEDs 2 arranged to form the LED light source are prior art, and will not be described here. The drive circuit 3 used to drive the LED light source is a prior art, and will not be described here. The air-gap-free sealing structure means that there may be a peeling gap between the PVC paste and the coated device (LED light source, drive circuit, control chip, etc.), but the peeling gap is a sealed ...

Embodiment 2

[0018] Embodiment 2: On the basis of Embodiment 1, the LED lamp itself includes an LED driving circuit and is sealed and covered by PVC paste.

Embodiment 3

[0019] Embodiment 3: On the basis of Embodiment 1, the LED lamp itself includes an LED driving circuit and a control chip and is sealed and covered by PVC paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com