Simultaneous movement mechanism and equipment provided with simultaneous movement mechanism

A technology of synchronous movement and rotating shaft, applied in the direction of pivot connection, etc., can solve the problems of stuck, different friction of the intermediate guide body, etc., to achieve the effect of smooth transmission, better processing cost, and no risk of stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

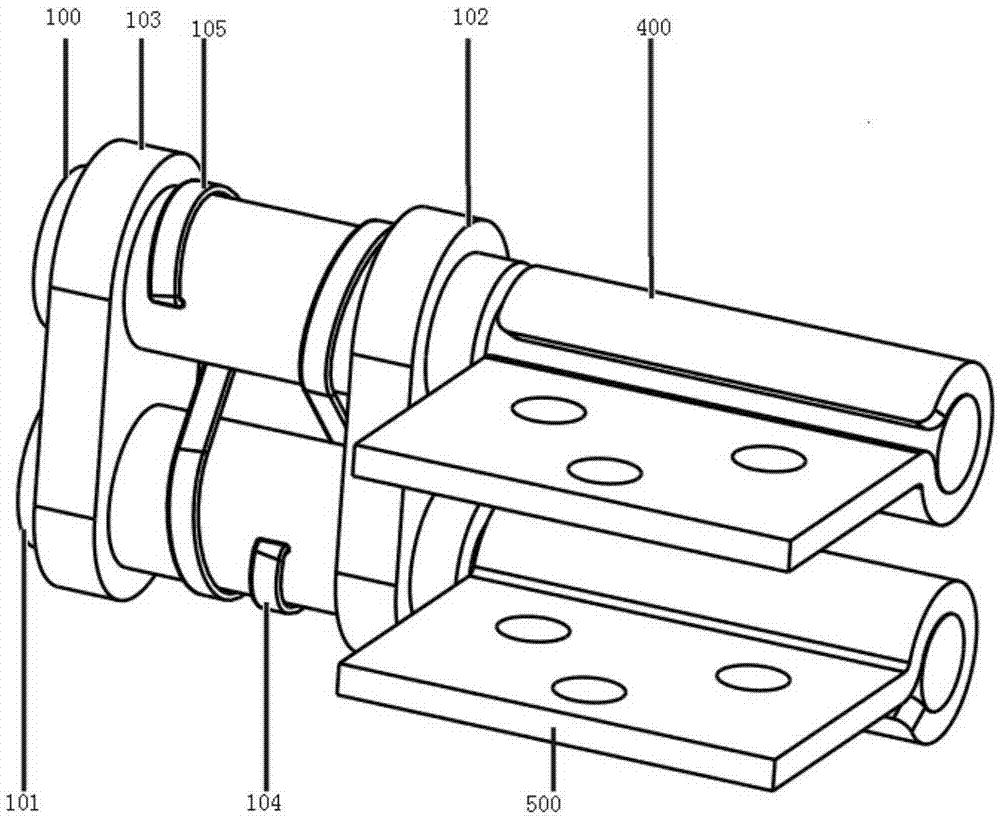

[0026] Such as Figure 1-5 As shown, the synchronous movement mechanism of this embodiment includes a first rotating shaft 100 , a second rotating shaft 101 , a first guide 102 , a second guide 103 , a first elastic member 104 , and a second elastic member 105 .

[0027] The first rotating shaft 100 is sequentially sleeved with the first guide member 102, the first elastic member 104, the second elastic member 105, and the second guide member 103, and the second rotating shaft 101 is sequentially sleeved with the first guide member 102, the first elastic member 104, The second elastic member 105 , the second guide member 103 , the first elastic member 104 and the second elastic member 105 are oppositely fixed on the first rotating shaft 100 and the second rotating shaft 101 respectively.

[0028] The first elastic member 104 and the second elastic member 105 have the same structure and are S-shaped elastic steel belts. In other embodiments, elastic fibers or chains with a larg...

Embodiment 2

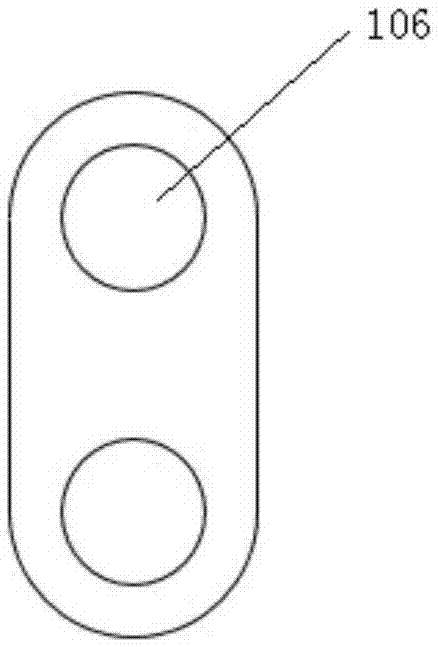

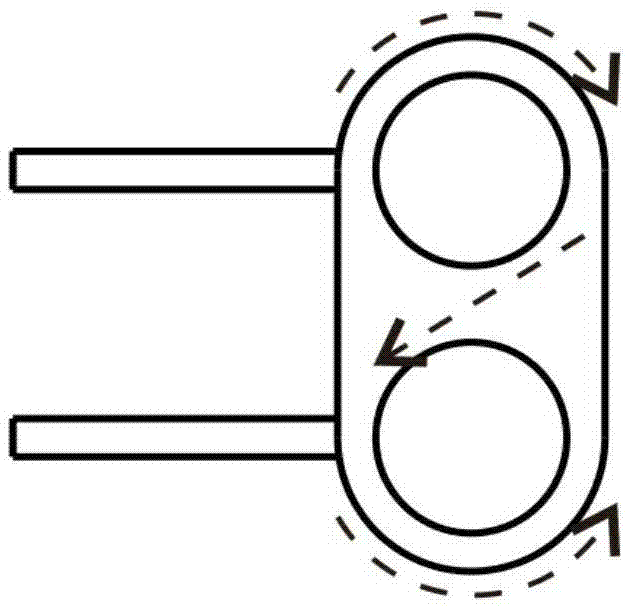

[0036] In this embodiment, the fixed points of the first elastic member and the second elastic member on the second rotating shaft coincide, so the elastic component 114 in this embodiment is Figure 6 and Figure 7 In the structure shown, the ends of the two S-shaped elastic members are integrally fixed on the second rotating shaft, and the other two head ends are respectively fixed on the first rotating shaft.

[0037] Other implementations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com