Patents

Literature

57results about How to "Overcome quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

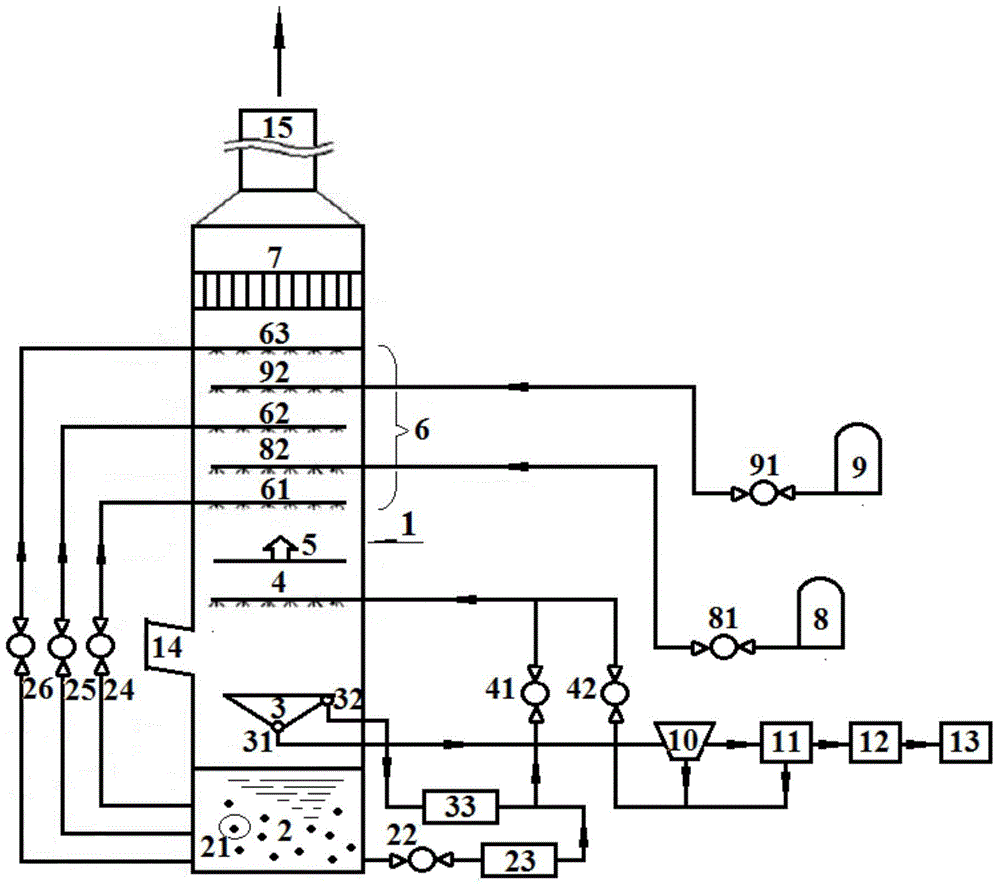

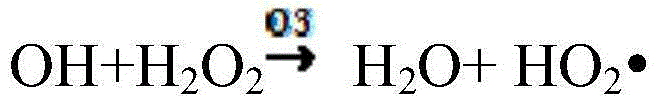

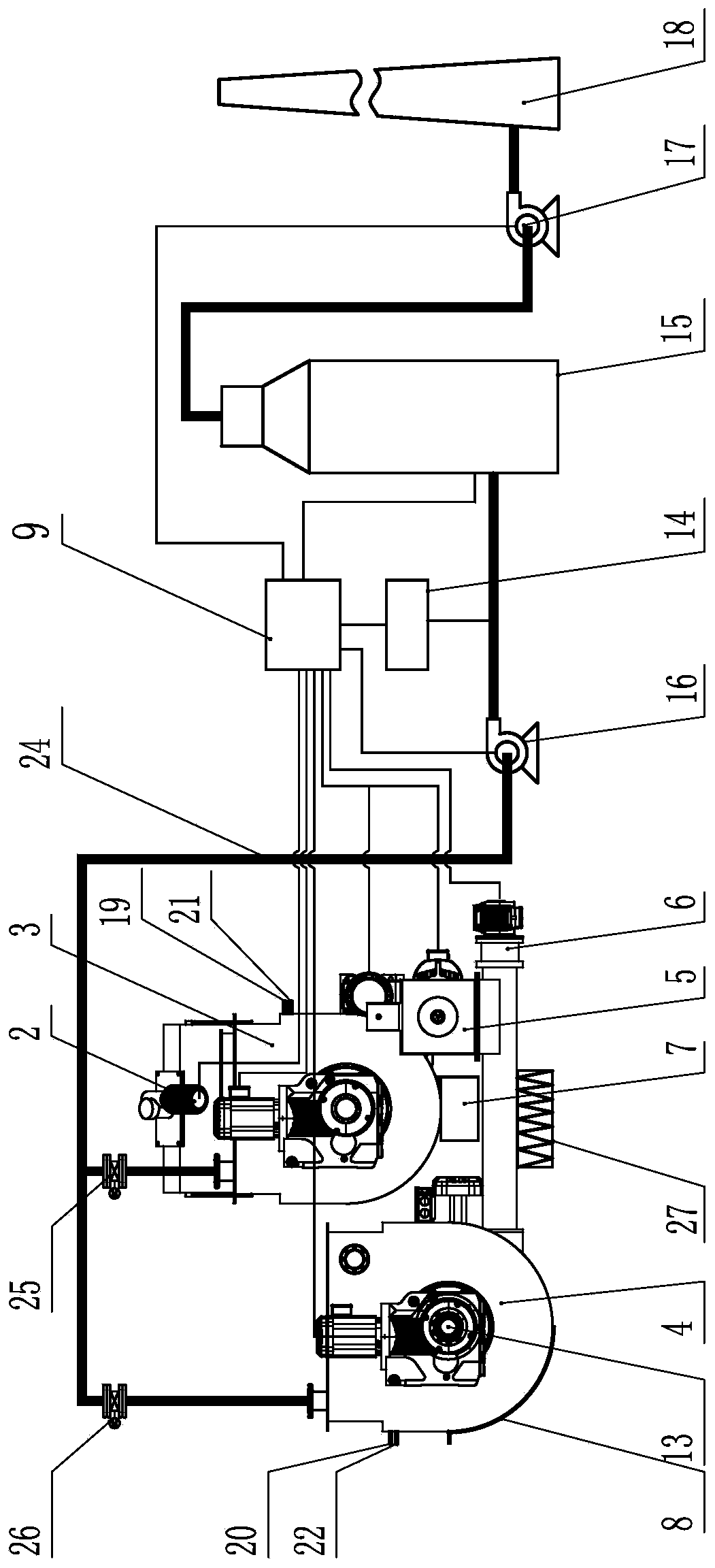

Integrated flue gas treatment device and method

ActiveCN104857835ARealize resource utilizationReduce wateringCombination devicesMagnesium nitratesLiquid wasteReaction layer

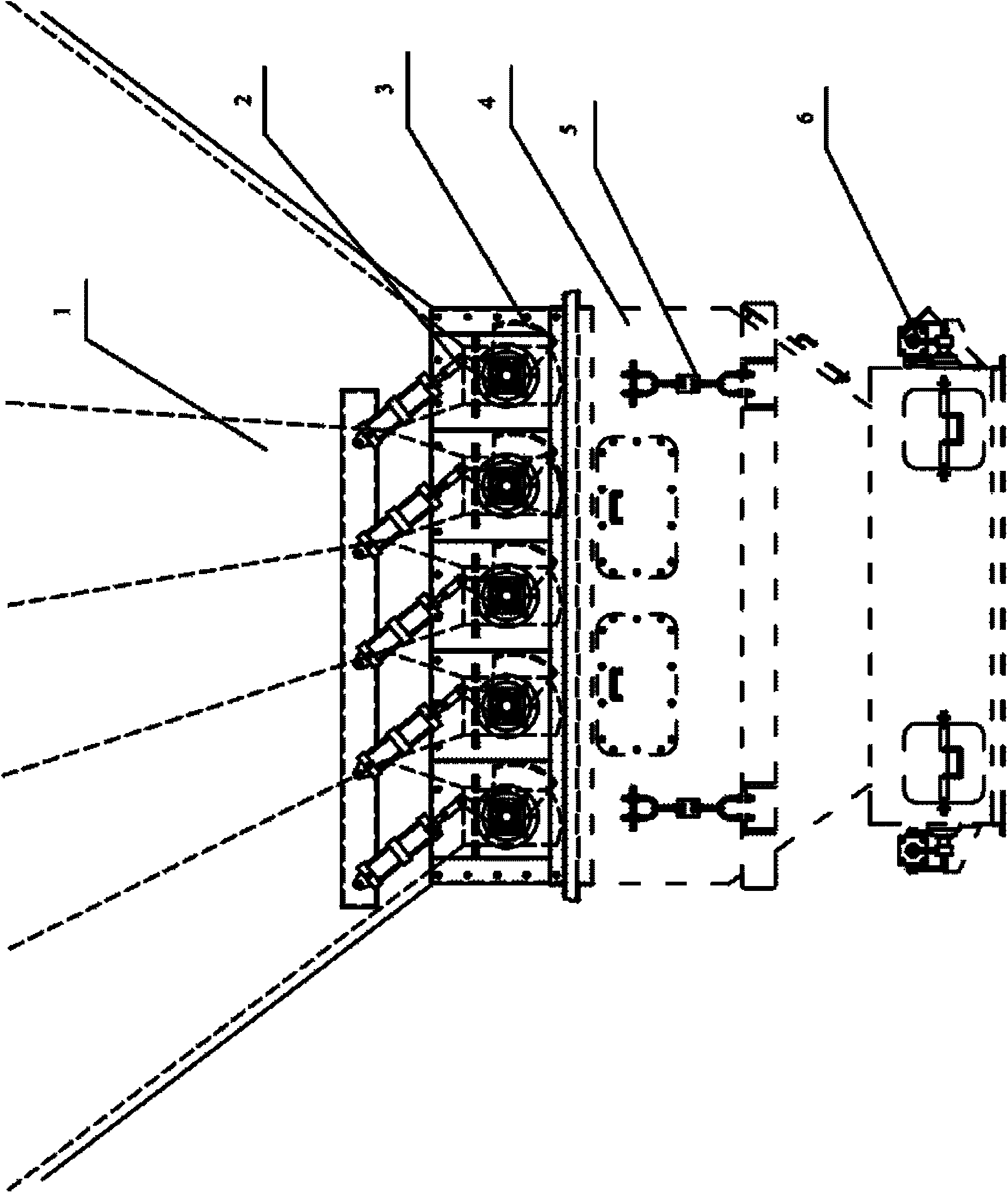

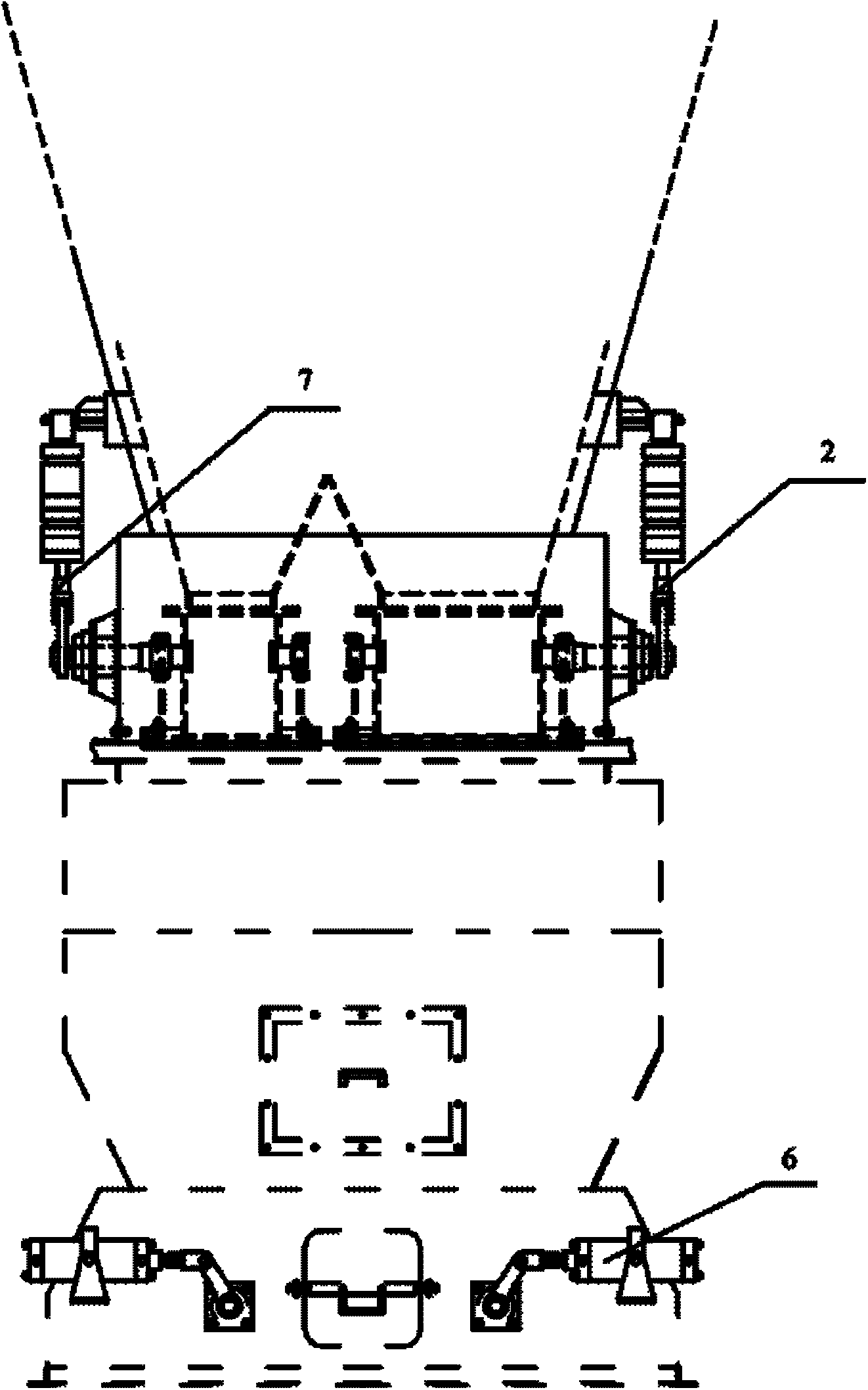

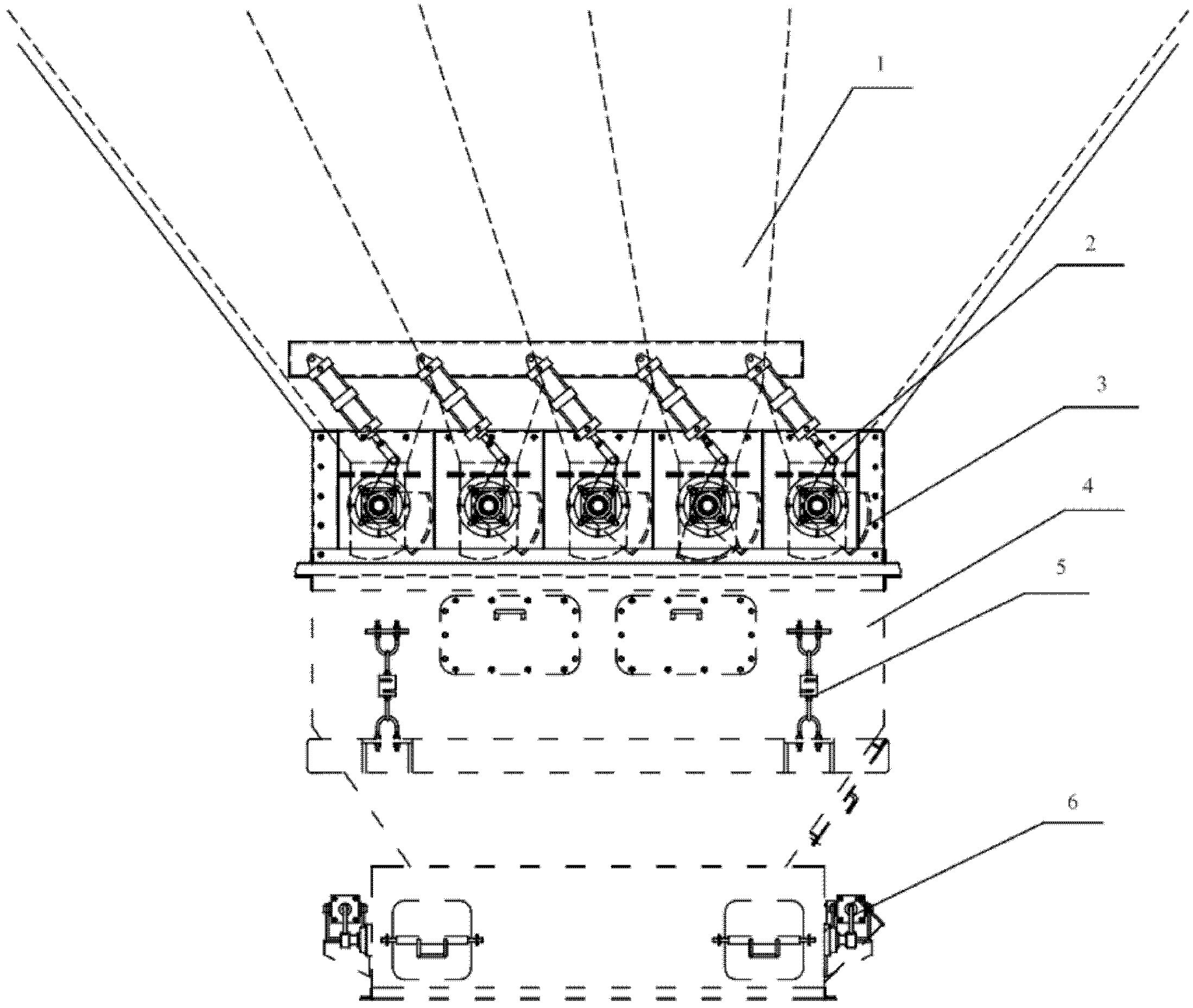

The invention discloses an integrated flue gas treatment device and method. The device comprises flue gas treatment equipment, ozone supply equipment, hydrogen peroxide supply equipment, evaporation and concentration equipment, cyclic sedimentation equipment and the like, wherein the flue gas treatment equipment comprises an ozone spray oxidation reaction layer, a hydrogen peroxide spray oxidation reaction layer, an absorber spray area, a slurry circulation area and a dust and mist removal area; both the ozone spray oxidation reaction layer and the hydrogen peroxide spray oxidation reaction layer are arranged in the absorber spray area; the dust and mist removal area is positioned above the absorber spray area; both the evaporation and concentration equipment and the cyclic sedimentation equipment are arranged in the flue gas treatment equipment. The device and the method disclosed by the invention are suitable for comprehensive treatment of flue gas containing SO2, NOX, Hg and dust and resource utilization of liquid waste in coal fired boilers, iron and steel sintering machines, pellets, industry kiln stoves and the like.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

Production method for ready-to-eat instant nutritive edible fungus soup

The invention discloses a production method for ready-to-eat instant nutritive edible fungus soup, which belongs to the technical field of deep processing of agricultural products. The production method mainly comprises the steps of selecting, cleaning, precise cutting, mixed boiling, spreading, pre-freezing and microwave vacuum freeze drying on screened raw materials such as edible fungi, thus obtaining the product which is subjected to nitrogen-filled packaging after being taken out of storage. The raw materials of the edible fungus soup is dewatered by a microwave vacuum freeze drying technology according to a modern food nutrition principle, so that the original color, aroma, taste and nutrients of the product are kept to the hilt, and compared with those of a conventional process, the drying efficiency is remarkably improved, the production cycle is shortened, the production cost is effectively reduced, and the special sterilizing effect of microwaves further guarantees the product quality at the same time. The edible fungus soup produced by the method is flat in shape, bright in color and luster, rich in nutrition, good in water regaining effect and long in storage time, and a feasible new way is provided for deep processing and utilization of the edible fungi.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

Pickled carrot preparing process

InactiveCN105211804AImprove qualityAdd flavorFood preparationFood ingredient as mouthfeel improving agentCentrifugationPre treatment

The invention discloses a pickled carrot preparing process and belongs to the technical field of preparation of the fermented food pickles. The process comprises the steps of A, carrot preprocessing; B, pickling water I and pickling water II preparation; C, circulating fermentation, wherein the processed vegetable obtained in the step A is fermented in the pickling water I obtained in the step B, after the 4n time of fermentation, centrifugation, dewatering, pickling water II supplement, gaofuji paolemei lactic acid bacteria powder adding, detection and adjustment are conducted on pickling water obtained after the 4n time of fermentation in sequence, and then the pickling water is continued to be used for fermenting the processed vegetable obtained in the step A; D, finished product processing. By controlling carrot preprocessing, pickling water preparation, circulating fermentation and finished product processing, especially addition of gaofuji paolemei lactic acid bacteria powder to the pickling water and control over various parameters and indexes during the circulating fermentation process, pickled carrot preparation time is shortened greatly, the quality and taste of pickled carrots are improved, large-scale production is facilitated, the development of the pickle industry is promoted, and economical benefits are high.

Owner:SICHUAN GAOFUJI BIOLOGICAL TECH

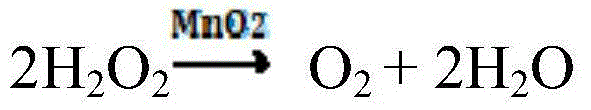

Combined drying method for improving dehydration efficiency of maize

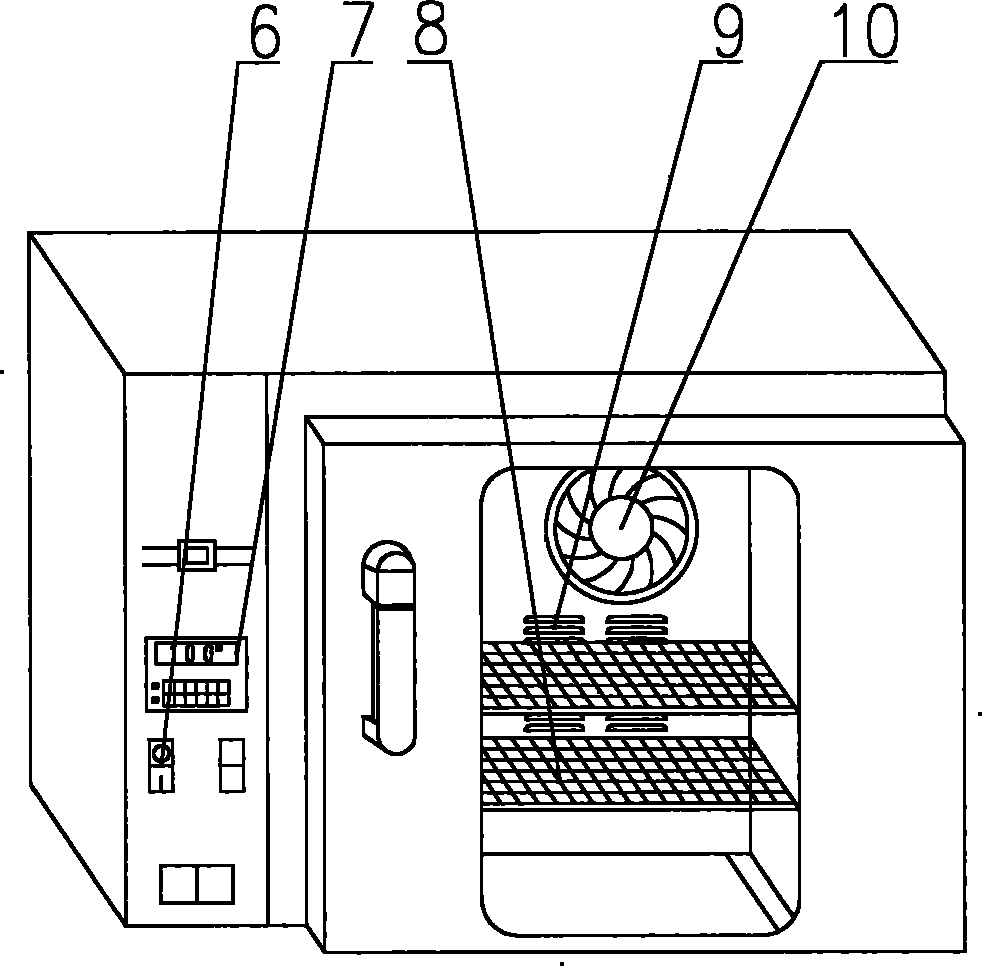

InactiveCN101803631ARetain qualityLow drying temperatureSeed preservation by dryingMicrowave ovenThree stage

The invention relates to a crop drying technology, in particular to a combined drying method for improving the dehydration efficiency of maize, which aims at solving the problems of long drying time, low drying efficiency, serious pollution and the like in the prior drying technology. The drying technology consists of two / three stages, in the front stage, a hot air / microwave drying is adopted and changed into microwave drying to the end point when drying to certain water content. The equipment used by a drying technology is a hot air dryer and a microwave oven; and by using the heating characteristic of microwave, the invention solves the problems of long drying time of crops, low drying efficiency, serious pollution and the like in the prior drying technology.

Owner:JILIN UNIV

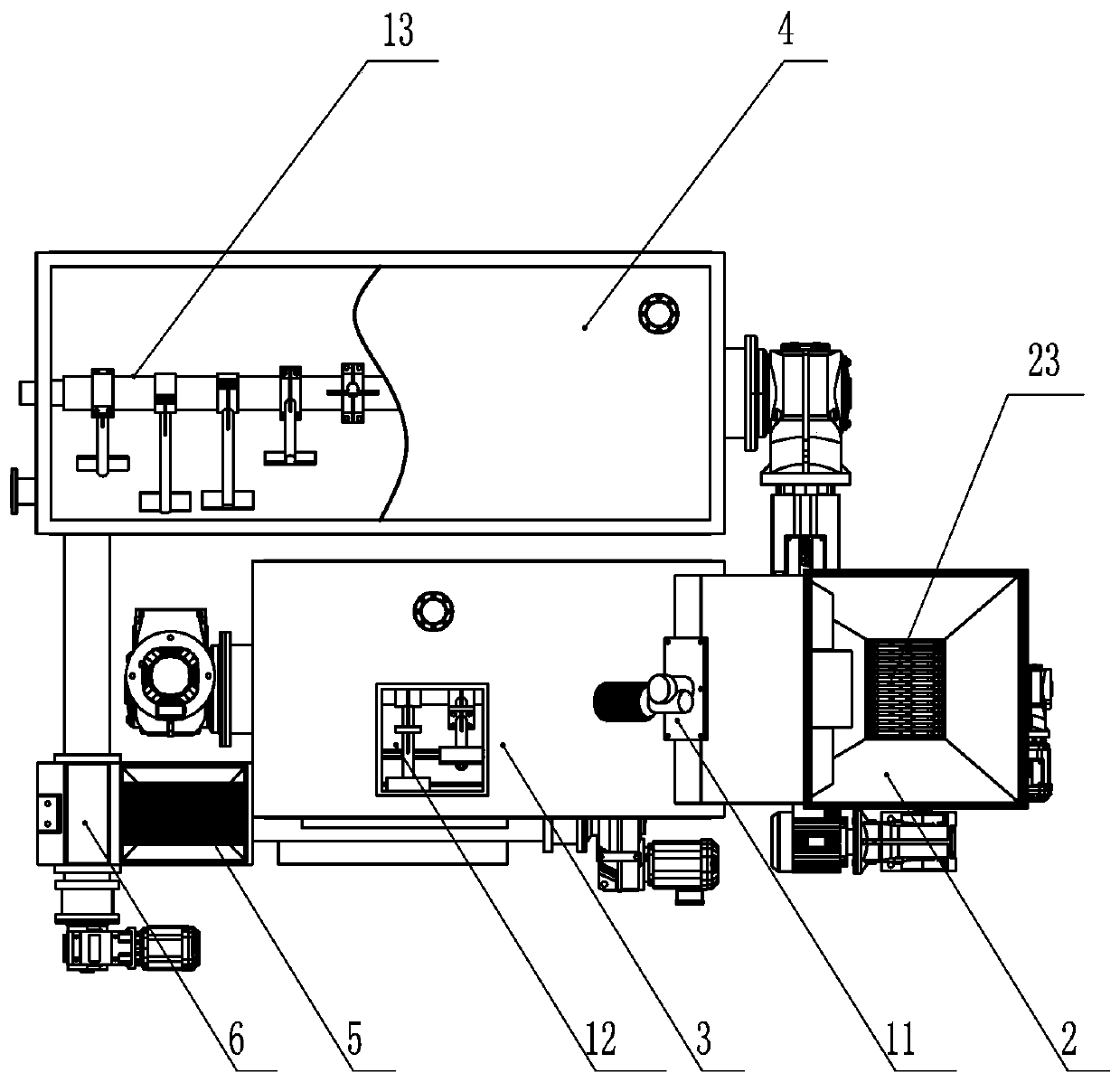

Aggregate weighing system for asphalt mixture

The invention discloses an aggregate weighing system for an asphalt mixture, which comprises a plurality of aggregate bin assemblies which are arranged in parallel at intervals. An aggregate weighing hopper is arranged below each aggregate bin assembly. Weighing sensors are arranged in the aggregate weighing hoppers. Aggregate weighing hopper door opening cylinders are arranged below the aggregate weighing hoppers. Each aggregate bin is provided with a big batching door and a small batching door. A big batching door control cylinder is arranged in the big batching door. A small batching door control cylinder is arranged in the small batching door. Due to the adoption of the aggregate weighing system for the asphalt mixture, which is disclosed by the invention, the defects of low weighing accuracy, poor product quality and the like in the prior art can be overcome, so that the advantages of high weighing accuracy and high product quality are realized.

Owner:WUXI XUETAO GROUP

Morchella box-type stereoscopic efficient cultivation method

InactiveCN109997605AReduce morbidityImprove land utilizationCultivating equipmentsMushroom cultivationDiseaseLand resources

Owner:XUZHOU INST OF AGRI SCI IN JIANGSU XUHUAI DISTRICT (JIANGSU XUZHOU SWEETPOTATO CENT)

Method for preparing silkworm eggs for transgene of eggs of bivoltine silkworm varieties

InactiveCN101703035ASolve the problem of low injection hatching rateOvercoming the low amount of cocoon silkVector-based foreign material introductionAnimal husbandryEmbryoTransgene

The invention relates to the field of insect bioengineering, in particular to a method for transgene of eggs of bivoltine silkworm varieties. In the method, early activated eggs are obtained by utilizing combination of protection temperature and light system in a parent generation silkworm egg hatching period, and artificial hatching treatment on the silkworm eggs before offspring fertilization; and then the early activated eggs are subjected to micro-injection and screening so as to obtain transgenic silkworm eggs. The method can solve the problems that the artificial hatching treatment after the diapaused eggs of the bivoltine silkworm varieties are subjected to transgenic injection causes damage to the silkworm eggs and the silkworm eggs cannot be hatched, also can solve the problem of low hatching rate due to transgenic injection after the early hydrochloric acid hatching treatment on the diapaused eggs of the bivoltine silkworm varieties, and also solves the problems that embryo robustness is poor and larva survival rate is low for offspring non-diapause eggs of the bivoltine silkworm varieties obtained by the hydrochloric acid hatching treatment on the diapaused eggs of the bivoltine silkworm varieties and low-temperature and dark hatching conditions for the parent generation silkworm eggs.

Owner:SUZHOU UNIV

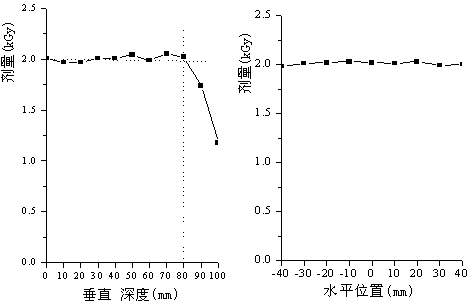

Processing method for controlling microbes of dehydrated spices through combining irradiation of high-energy electron beams with hot-air drying

ActiveCN104013069AImprove drying efficiencyKeep the flavorFood preservationFood dryingHigh energyTissue fluid

The invention provides a processing method for controlling microbes of dehydrated spices through combining irradiation of high-energy electron beams with hot-air drying, and belongs to the technical field of deep processing of farm products. The processing method comprises the following processes that: fresh spices are subjected to selection, cleaning and water draining; high-energy electron beam irradiation is carried out; and phased atmospheric pressure hot-air drying is carried out after the irradiation. The processing method has the advantages that the irradiation of the high-energy electron beams on the fresh spices has the effects that: 1, partial microbes in raw materials can be directly killed, and the number of the microbes is reduced; and 2, through the penetration effect of the high-energy electron beams, cell structures in the fresh spices can deform, shrink or crack and the like, so tissue fluid in cells is easier to exude or lose, and the free water content is increased; and the water is favorably diffused out during the drying, and the drying efficiency is improved. The phased hot-air drying has the effects that: 1, the water in the raw materials is evaporated to obtain dried products; and 2, through the irradiation effect on the microbes, the physiological functions of the microbes in the spices are damaged to different degrees and cannot be restored during the drying; the microbes in the spices can be effectively killed with a low dose of irradiation; and the hot-air drying efficiency is improved.

Owner:SHANGHAI ACAD OF AGRI SCI +1

Immersion non-woven fabrics and method for producing artificial boards by coating films

InactiveCN101591862AGuarantee product qualityTemperature heat conduction balanceWood veneer joiningTextiles and paperPolyurethane adhesiveWear resistant

The invention relates to immersion non-woven fabrics and a method for producing artificial boards by coating films on the immersion non-woven fabrics. The ration of the non-woven fabrics is between 50 and 500 g / m and the thickness is between 0.5 and 5 mm; and a resin adhesive is a phenolic resin adhesive, a melamine resin adhesive or a polyurethane adhesive. The resin content of the immersion non-woven fabrics is between 28 and 36 percent, the volatile content is between 8 and 9 percent, and the pre-cure degree is between 30 and 55 percent. The method for producing the artificial boards by coating films on the immersion non-woven fabrics comprises the following steps: immersing the non-woven fabrics in the resin adhesive, and drying; and coating the films on the surfaces of the artificial boards through hot pressing, wherein the hot-pressing temperature is between 85 and 150 DEG C, the time is between 5 and 10 min, and the pressure is between 0.5 and 1 Mpa. The artificial boards produced by the method are wear-resistant, fire-retardant, neat, rich in color, low in cost, and environment-friendly.

Owner:邱天祥

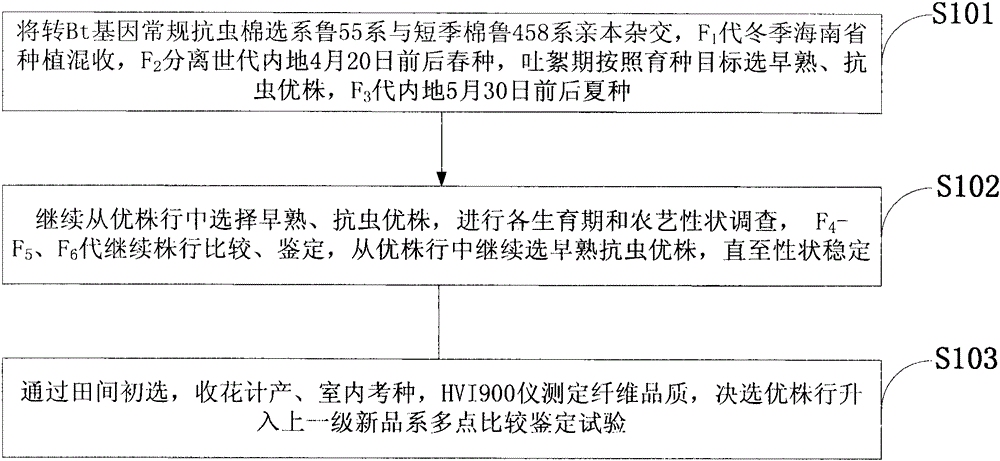

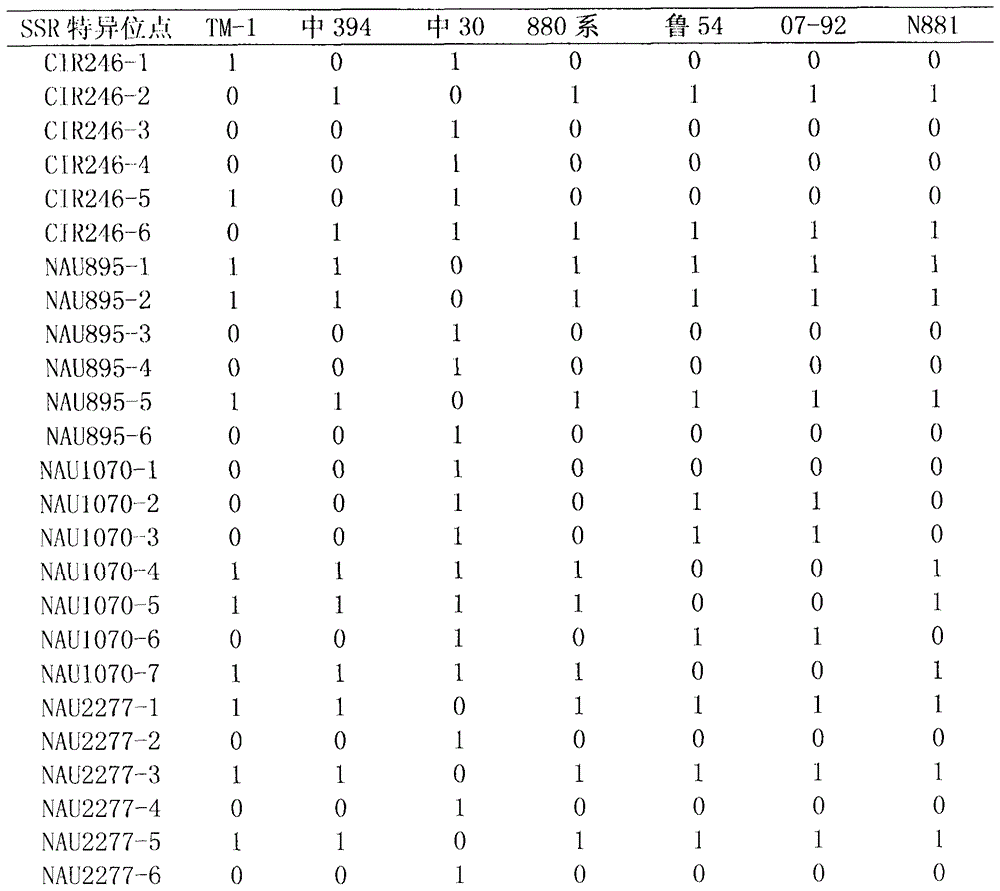

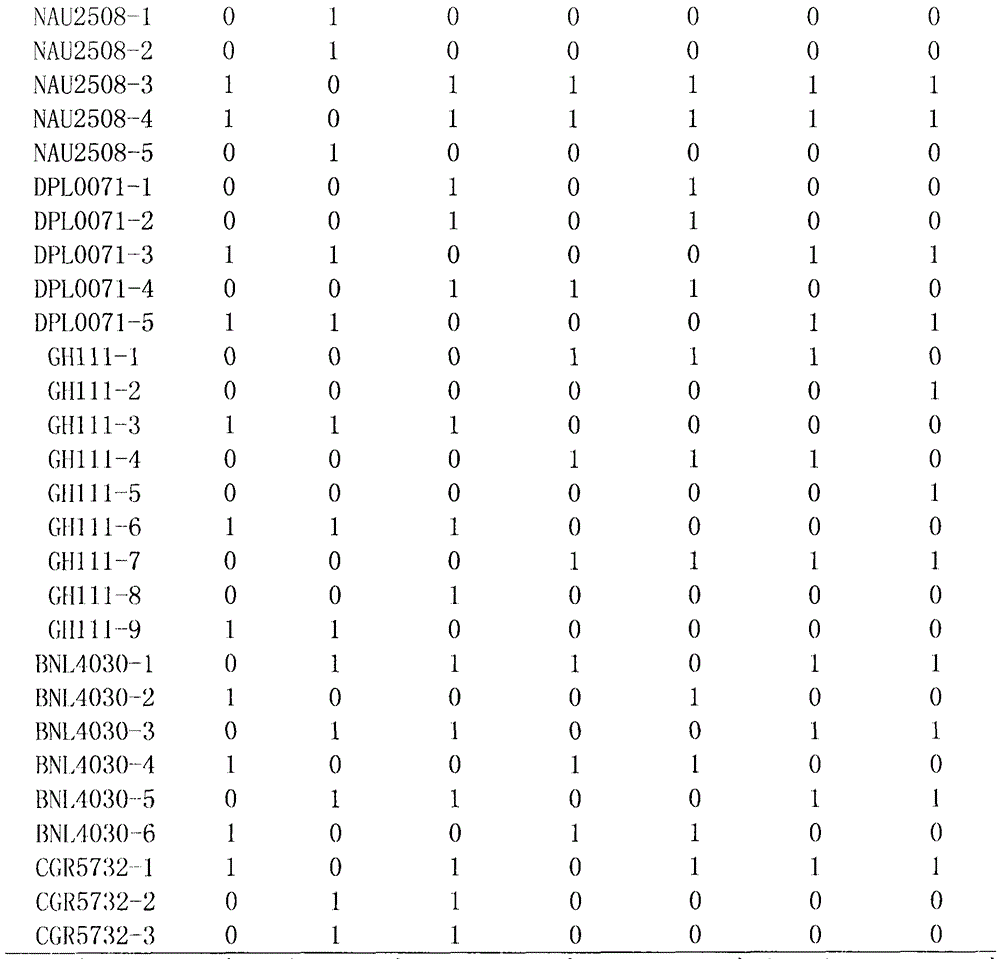

Insect-resistant short-season cotton new variety selection breeding method

InactiveCN105123494ABroaden the scope of germplasm resource utilizationShort reproductive periodPlant genotype modificationFiberAgricultural science

The invention discloses an insect-resistant short-season cotton new variety selection breeding method comprising following steps: 1) hybridizing a transgenic Bt cotton regular insect-resistant cotton inbred line Lu-55 with a short-season cotton line Lu-458 as parents; 2) planting an F1 generation in Hainan Province in winter, mixed-harvesting the F1 generation, spring-sowing an F2 separated generation in mainland at about 20th, April, selecting early-maturing and insect-resistant superior plants according to breeding objects, and summer-sowing an F3 generation in mainland at about 30th, May; 3) continuously selecting early-maturing and insect-resistant superior plants from superior plant rows, performing inspection of various growth periods and agricultural characters; 4) continuously performing plant row comparison and identification to F4-F5 generations and an F6 generation, selecting early-maturing and insect-resistant superior plants from the superior plant rows until the characters are stable; 5) testing the quality of fibers through primary selection in field, cotton harvesting and yield calculation and inner seed inspection; and 6) finally selecting a superior plant row, and raising the superior plant row to the next level new strain and performing multipoint comparison identification test. The selection breeding method broadens utilization range of germplasm resources of short-season cotton, overcomes a negative relationship of early maturity to yield and quality characters, and can be used for selecting new varieties, which are shorter in growth period, are insect-resistant, are high in yield and are high in quality, of the short-season cotton.

Owner:SHANDONG COTTON RES CENT

Production method of starch-based oil-fried food with low oil content

InactiveCN107333854AUnique linear molecular structureExcellent hydrophilic film-forming propertiesDough treatmentDeep-fried productsWater bathsPullulan

The invention discloses a production method of starch-based oil-fried food with low oil content. The production method of the starch-based oil-fried food with low oil content comprises the following steps: (1), respectively weighing 85-95 parts of wheat flour, 5-15 parts of pullulan, 55-82 parts of water, and 10-20 parts of seasonings; (2), making dough, namely preparing raw dough; (3), steaming the raw dough over boiling water bath so as to obtain pre-steamed dough; and (4), putting the pre-steamed dough into a pan containing oil when the dough is still hot so as to carry out oil-frying, and then, draining oil, and carrying out cooling and packaging so as to obtain the final oil-fried food with low oil content. The production method disclosed by the invention is capable of producing starch-based oil-fried foods with low oil contents; moreover, the production method is capable of realizing nutrition enhancement of dietary fiber while improving edible quality of the foods and reducing oil content.

Owner:JIANGNAN UNIV

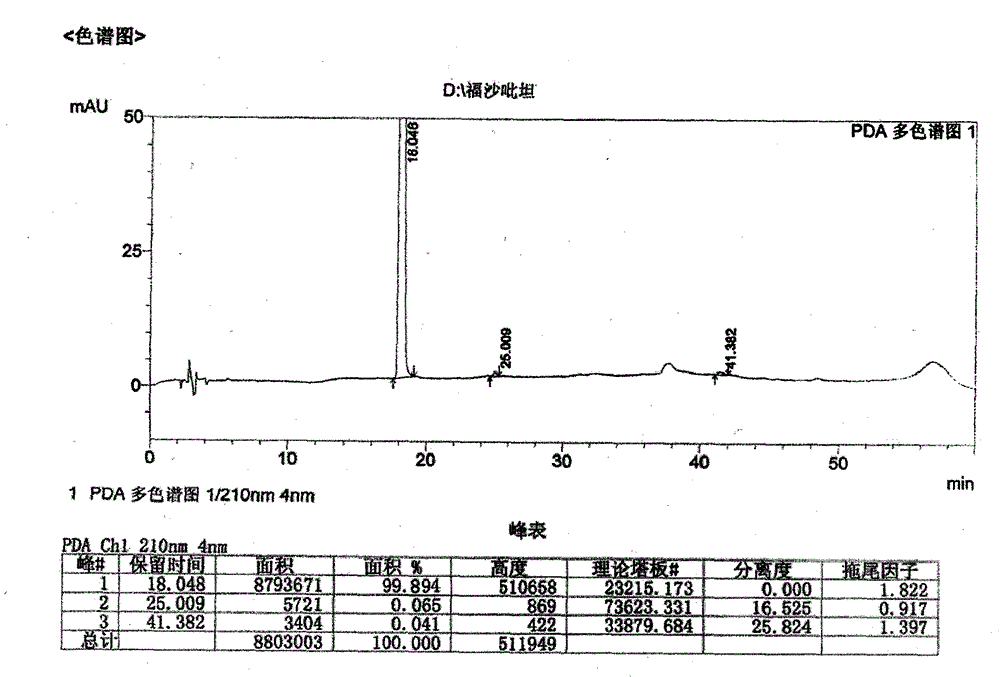

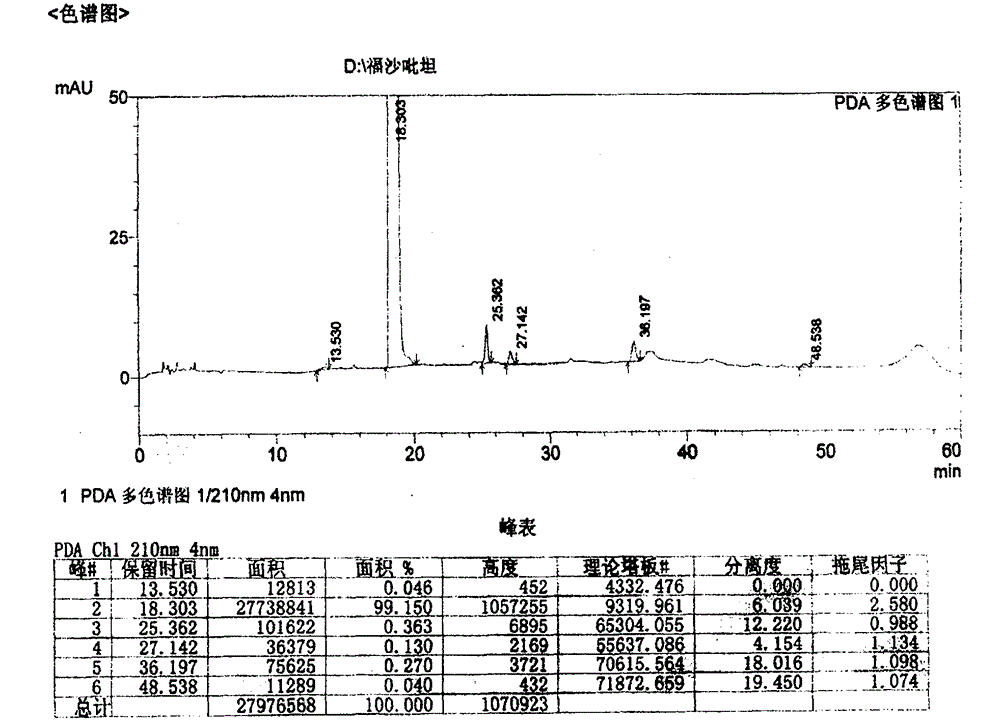

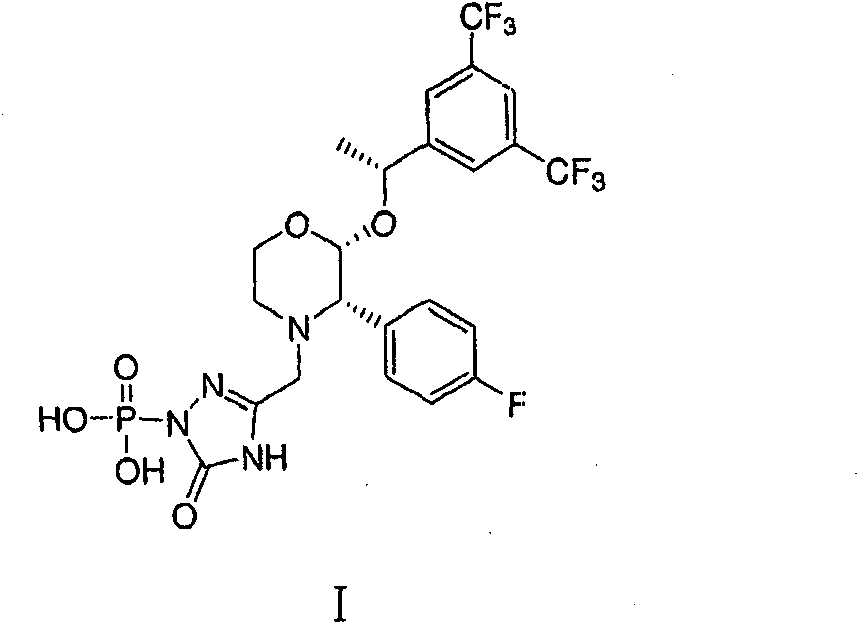

New preparation method for fosaprepitant and pharmaceutically acceptable salt thereof

ActiveCN105254668AOvercome costsOvercome qualityGroup 5/15 element organic compoundsBulk chemical productionPhosphateChemistry

The present invention provides a new preparation method for fosaprepitant and a pharmaceutically acceptable salt thereof. The method comprises: adopting aprepitant dibenzyl phosphate as a raw material, carrying out catalytic hydrogenation in the absence of counter ions and supercritical fluids to prepare fosaprepitant, and forming the pharmaceutically acceptable salt with an alkali after separation or without separation. According to the present invention, the method has characteristics of good product quality, low production cost, simple operation and short reaction period, and is suitable for industrial production.

Owner:海南金泰药业有限公司

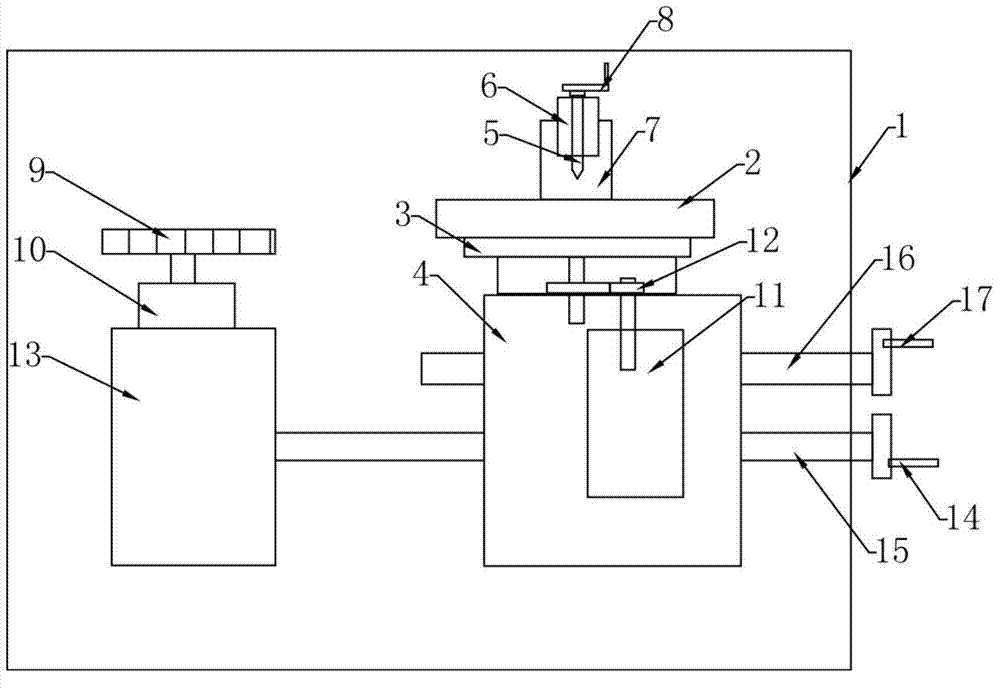

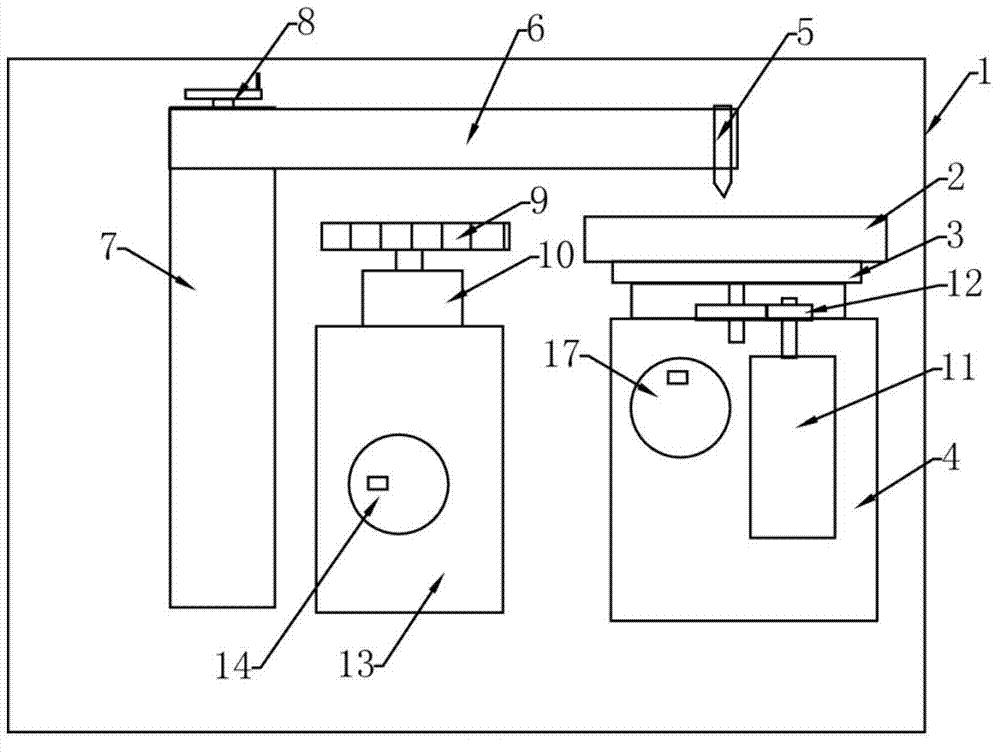

Chopping board round edge processing machine and chopping board round edge processing method

ActiveCN104325521AOvercome cumbersomeOvercome efficiencyRounding machinesMilling cutterCircular motion

The invention relates to the technical field of chopping board processing, and discloses a chopping board round edge processing machine and a chopping board round edge processing method. The chopping board round edge processing machine comprises a bracket, a locating device and a cutter device; the bracket comprises a tray used for placing a chopping board and a tray bracket used for supporting the tray; the locating device comprises an ejector pin and an ejector pin lifting mechanism; the ejector pin is arranged above the tray; the ejector pin lifting mechanism is connected with the ejector pin and is used for driving the ejector pin to move up and down; the cutter device comprises a milling cutter and a milling cutter rotating mechanism used for driving the milling cutter to rotate around the self center axis; the milling cutter is arranged at one side of the tray, at least one out of the milling cutter and the tray can translate relative to the other one; when the round edge of the chopping board is processed, the milling cutter makes circular motion along the horizontal direction around the tray, and / or the tray rotates around the self center axis. The chopping board round edge processing machine is capable of automatically cutting the round edge of the chopping board, the problems that the existing manual chopping board round edge processing method is complicated in process, low in efficiency and poorer in product quality can be solved, and the working efficiency is greatly improved.

Owner:泰州市海鑫高新技术投资发展有限公司

Preparing technology for fresh pickle

The invention discloses a preparing technology for fresh pickle and belongs to the technical field of preparation of pickle in fermentation food. The technology comprises the steps that firstly, vegetables are pretreated; secondly, soaking water I and soaking water II are prepared; thirdly, circulation fermentation is carried out, wherein the soaking water I in the second step is used for fermenting the vegetables treated in the first step, the soaking water obtained after the 4nth fermentation is subjected to centrifugation and discarding sequentially when fermentation is carried out for the 4nth time, the soaking water II is used for supplementation, Gaofuji pickle agent Paolemei lactic acid bacterial powder is added, and the mixture continues to be used for fermenting the vegetables treated in the first step after detection and adjusting treatment; fourthly, a finished product is treated. According to the technology, the steps of vegetable pretreatment, soaking water preparation, circulation fermentation and finished product treatment are controlled, and especially, the Gaofuji pickle agent Paolemei lactic acid bacterial powder is added in the soaking water and various parameters and indexes in the circulation fermentation process are controlled, so that the preparing time of the fresh pickle is greatly shortened, the quality and the taste of the fresh pickle are improved, and the preparing technology is suitable for large-scale production, promotes the development of the pickle industry and achieves good economic benefits.

Owner:SICHUAN GAOFUJI BIOLOGICAL TECH

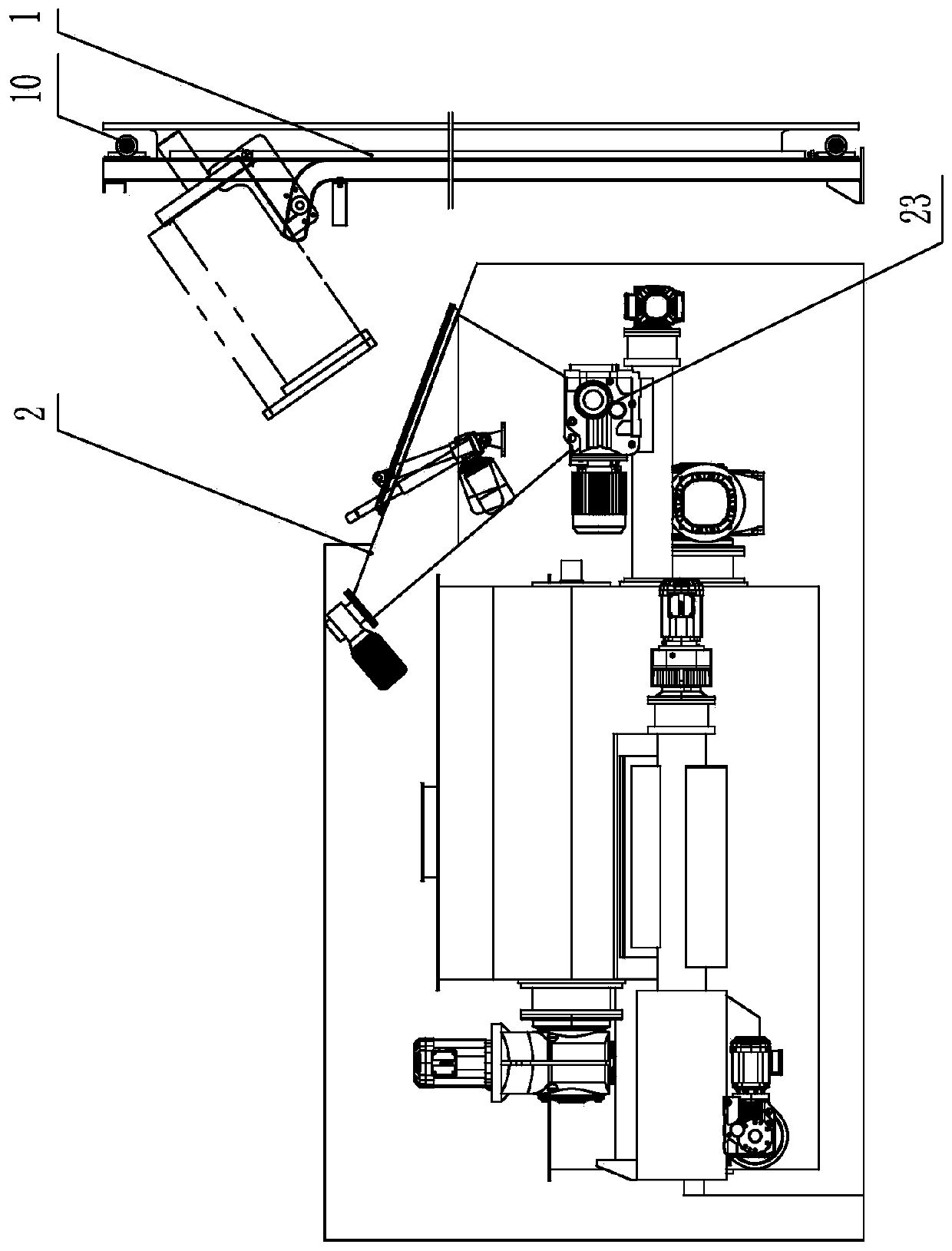

Kitchen garbage distributed rapid degradation integrated device and process thereof

PendingCN111454084AOvercome timeOvercoming pollutionClimate change adaptationOrganic fertilisersMicroorganismDecomposition

The invention discloses a kitchen garbage distributed rapid degradation integrated device and a process thereof, the device comprises a decomposition bin for degrading kitchen garbage by means of microorganisms, a receiving hopper arranged above the decomposition bin, and a lifting chain wheel rack arranged on one side of the receiving hopper, the decomposition bin is communicated with decomposition curing bin through a dehydration screw and a conveying screw, a crushing knife group is arranged below the receiving hopper and is positioned above the decomposing bin, a decomposition bin air outlet valve is arranged on the decomposition bin, a decomposition bin air outlet valve is arranged on the decomposition bin, the decomposition bin air outlet valve and the decomposition bin air outlet valve are connected with a first-stage ozone deodorizer through a first exhaust fan, an outlet of the first-stage ozone deodorizer is connected with an inlet of a second-stage spray tower, an outlet ofthe second-stage spray tower is connected with an inlet of the second exhaust fan, and an outlet of the second exhaust fan is connected with an exhaust chimney.

Owner:北京舞鹤环境工程设计有限公司

Preparation technology of fresh pickled cowpea

The invention provides preparation technology of fresh pickled cowpea. The technology comprises the following steps: step A, preparing pickle liquid I and pickle liquid II for later use, wherein the difference between the pickle liquid I and the pickle liquid II is that Gaofuji Paolemei Lactobacillus Powder is added in the pickle liquid I while no Gaofuji Paolemei Lactobacillus Powder is added in the pickle liquid II; step B, circulation fermentation, namely fermenting vegetable cowpea by the pickle liquid I prepared in step A, so that the fresh pickled cowpea is obtained; when performing the 4n times of fermentation, the pickle liquid after the 4n-time fermentation is used again for fermenting the cowpea after sequential processes such as centrifugation, water-losing and the like, wherein the n is selected from continuous positive integers; and the fermentation is carried on at 20-24 DEG C for 40-65 hours. According to the technology, the pickle liquid preparation and the circulation fermentation control are utilized, especially the addition of the Gaofuji Paolemei Lactobacillus Powder into the pickle liquid and the controls to the parameters and indexes in the circulation fermentation process are performed, so that the preparation time of the fresh pickled vegetables is shortened and the quality and taste of the fresh pickled vegetables are improved; thus, the technology is suitable for large-scale production and promotes development of the pickled-vegetable industry; moreover, the technology is relatively good in economic benefit.

Owner:SICHUAN GAOFUJI BIOLOGICAL TECH

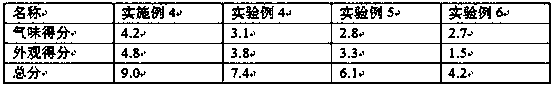

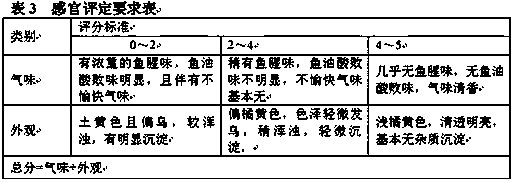

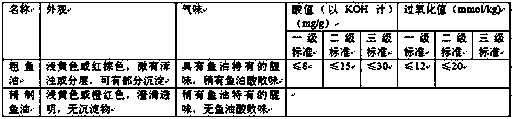

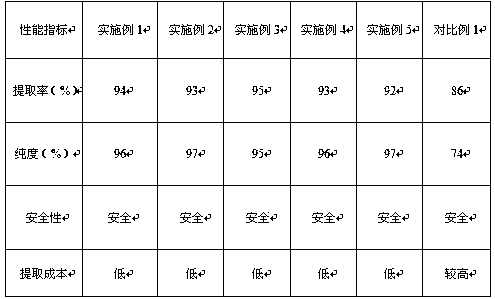

Preparation method of salmon viscus fish oil

ActiveCN110982854AOvercoming incomplete extractionOvercome qualityFatty-oils/fats productionFermentationFisheryFish oil

The invention discloses a preparation method of salmon viscus fish oil. The preparation method comprises the steps of raw material pretreatment, first-stage enzymolysis and second-stage enzymolysis, wherein the first-stage enzymolysis is mainly lipase enzymolysis, an autolytic enzyme enzymolysis process is assisted and enhanced at the same time, and calcium chloride is added in the process; and the second-stage enzymolysis is protease enzymolysis. The method can significantly shorten fish oil extraction time and obviously improve fish oil extraction rate; meanwhile, the prepared crude viscus fish oil is orange yellow, bright and clear in color, basically free of fishy smell and peculiar smell and remarkably improved in quality; the rancidity degree of the fish oil in the extraction processis effectively reduced; the acceptability of the viscus fish oil is improved; meanwhile, the application way of the viscus fish oil is expanded, and the processing applicability of the viscus fish oil is improved.

Owner:SHANDONG ORIENTAL OCEAN SCI TECH

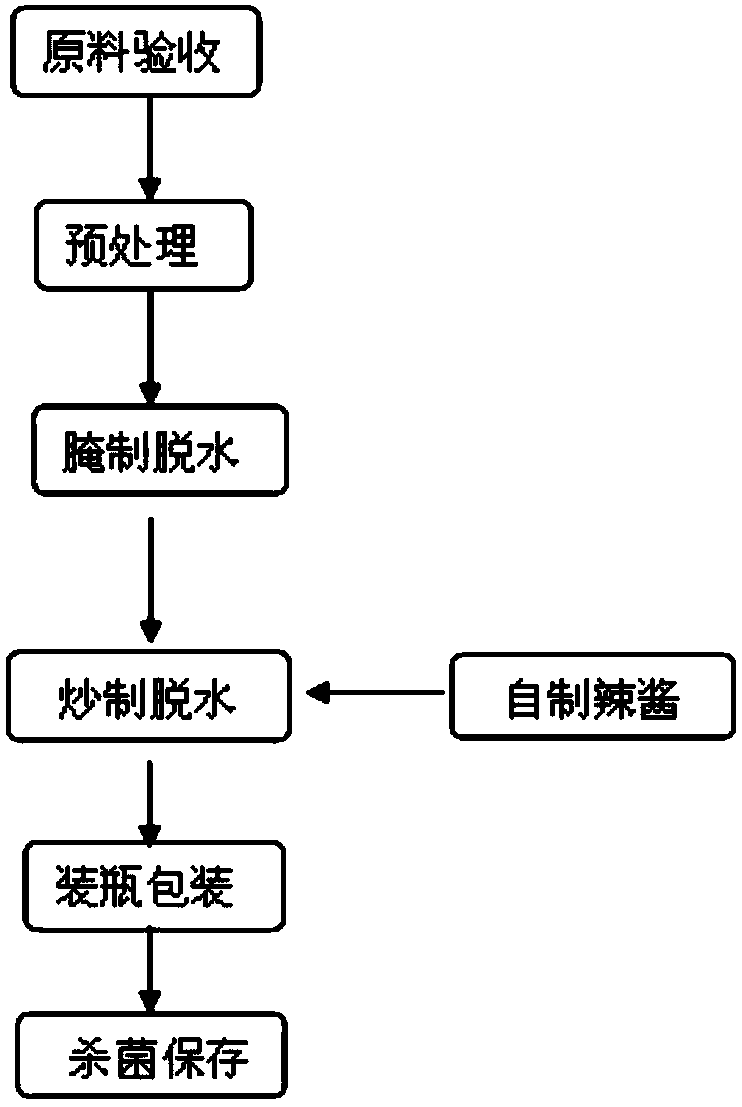

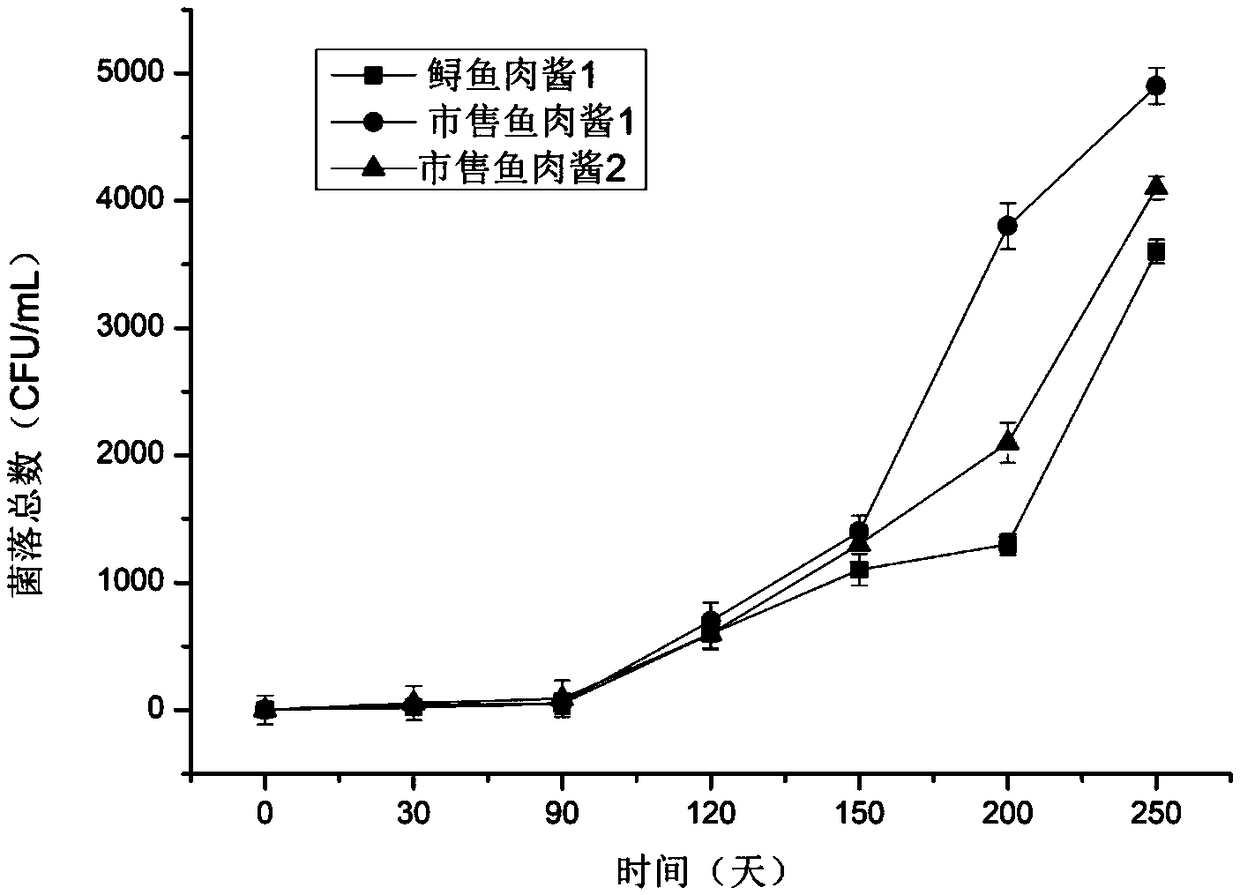

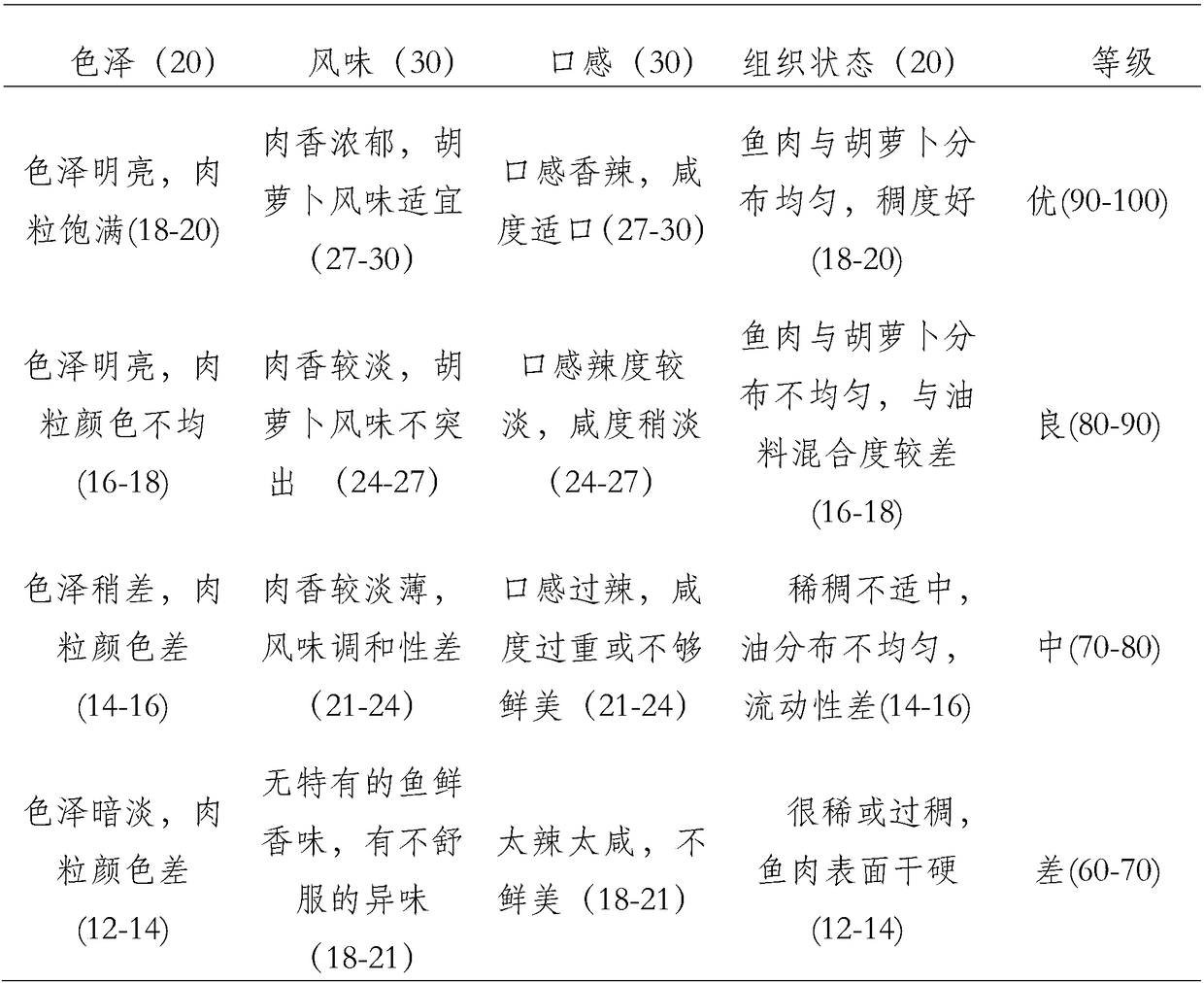

Method for processing instant fish sauce

PendingCN109090506AImprove overall utilizationRich varietyFood ingredient functionsAquatic productRapeseed

The invention discloses a method for processing an instant fish sauce. The method includes placing fish pieces in a deodorization liquid for curing and then mixing and frying rapeseed oil, garlic, fermented soya beans, chili powder, shiitake mushroom, peanut and bean paste to obtain a homemade hot sauce; adding the homemade hot sauce to the fish pieces subjected to deodorization curing, then adding oil, carrot, red pepper and the homemade hot sauce for mixing and then frying for dehydration to obtain the fish sauce. According to the method, the problem that aquatic products are soft in textureafter cured by high salt is solved by means of the synergistic effect of raw material pretreatment, frying dehydration, canning and sterilization, the product texture quality is improved, and the fish umami taste is maintained to the largest extent. Carrot raw materials are added to the product, and the effect of improving eyesight and nurturing the soul can be improved if a user eats the fish sauce frequently. The instant canned product is convenient to eat and carry, spicy in taste and rich in nutrient.

Owner:JIANGNAN UNIV

Circuit layer and aluminum base conduction process

InactiveCN108513457AImprove the level of manufacturing technologyReduce manufacturing costPrinted element electric connection formationState of artCopper

The invention discloses a circuit layer and aluminum base conduction process. A production method comprises the steps as follows: a blind hole is drilled to an aluminum substrate from a circuit layerthrough a dielectric layer on the aluminum substrate, the blind hole is filled with conductive resin ink and the ink covers a copper sheet of the circuit layer at the same time, so that the copper sheet of the circuit layer and an aluminum base are conducted through the conductive ink. According to the circuit layer and aluminum base conduction process, the production process level of the aluminumsubstrate and the product structure are improved, the production cost is reduced, the quality of a product is stable and controllable, and the problems that the process is complicated, the productioncost is high and the quality of the product cannot be easily ensured in the prior art are solved.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

Machining method for press roller support

The invention discloses a machining method for a press roller support. The machining method includes the steps that a pouring die is arranged on the basis of a fixed support to be poured, and the needed fixed support is obtained through pouring of the pouring die; the fixed support obtained through pouring is calcined, cooled with water, grinded and polished, and grinding dust on the surface of the fixed support is blown away through a blower; a press roller needing to be provided with the support is pressed on the fixed support to be poured through a U-shaped positioning piece and a pressing block; the press roller and the fixed support are connected to the two ends of the U-shaped positioning piece and the two ends of the pressing block respectively; the pressing block is a metal pressing block arranged to be in magnetic attraction with the U-shaped positioning piece; the press roller, the U-shaped positioning piece and the pressing block are pressed and put into a preset die together with the fixed support as a whole, and molten metal liquid prepared in advance is poured into the preset die to be poured together through a pouring machine by adopting a die pouring method. The machining method for the press roller support has the advantages of being high in production efficiency, good in product quality and low in machining cost.

Owner:WUXI YANGGONG MACHINERY MFG

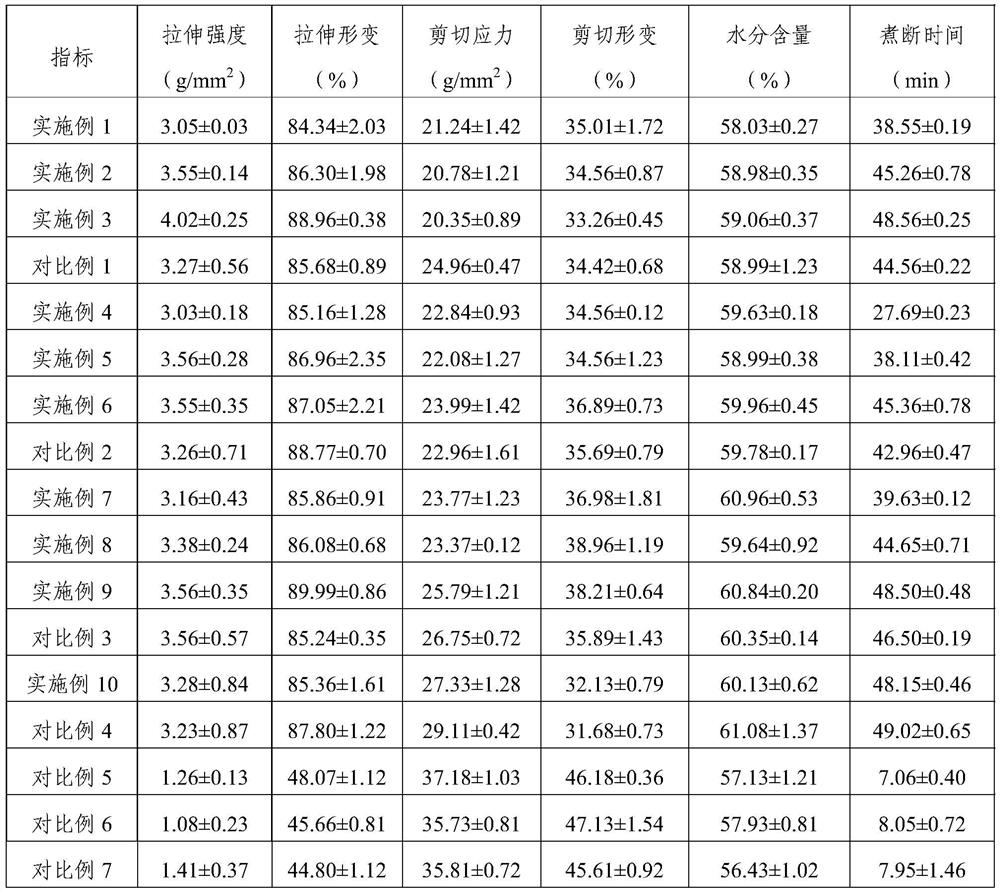

Alum-free fresh and wet potato vermicelli and preparation method thereof

ActiveCN112704219AHigh tensile strengthGood cooking resistanceInorganic compound food ingredientsBiotechnologyFood grade

The invention relates to the technical field of food processing, in particular to alum-free fresh and wet potato vermicelli and a preparation method thereof. The alum-free fresh and wet potato vermicelli is prepared from the following raw materials in parts by weight: 60-95 parts of potato starch, 0.05-2.5 parts of mineral salt and water, wherein the weight ratio of the water to the other raw materials is (60-100): 100; and the mineral salt is selected from one or more of food-grade calcium salt, food-grade potassium salt and food-grade magnesium salt. The fresh and wet potato vermicelli has the characteristics of high tensile strength, long boiling-off time and the like on the premise that alum is not added, and is rich in mineral elements.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

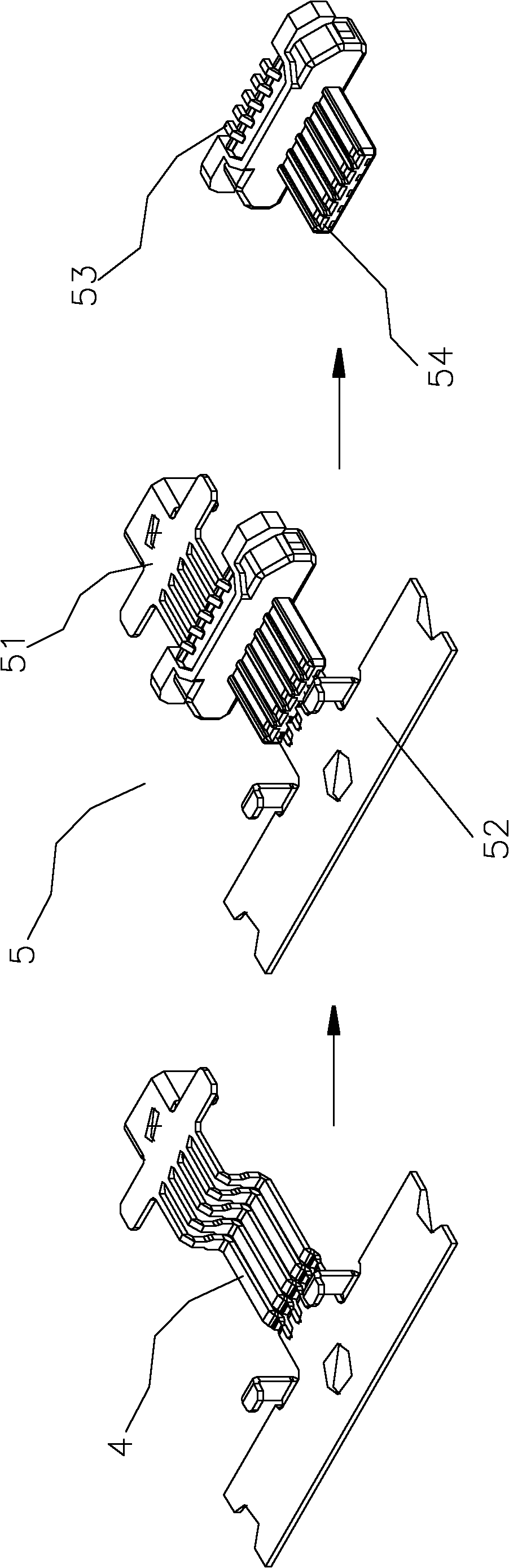

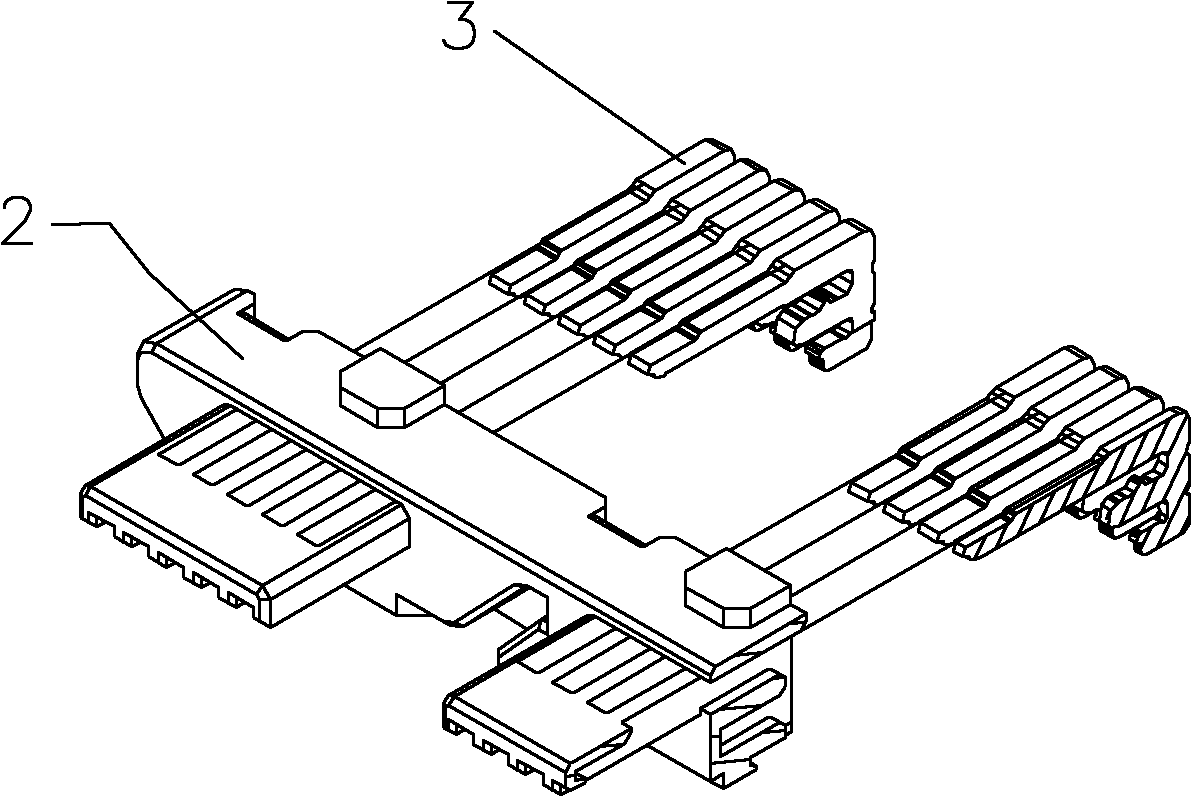

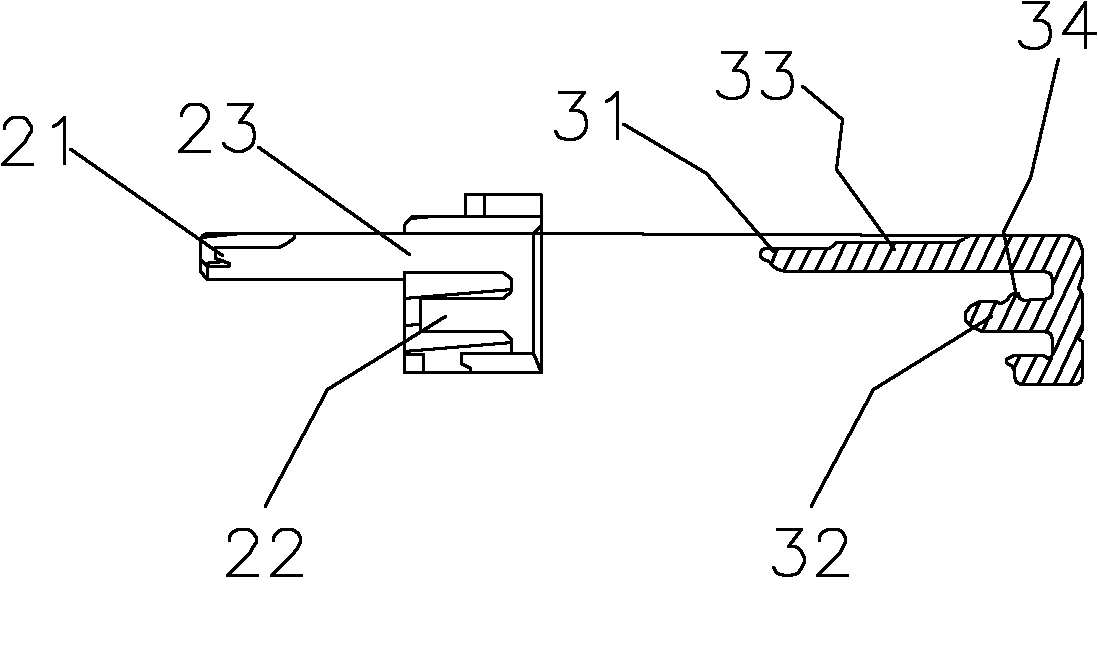

Improved MicroUSB (universal serial bus) interface and manufacturing method thereof

ActiveCN102136646AOvercome costsOvercoming Process ComplexityLine/current collector detailsCoupling contact membersEngineeringColloid

The invention discloses an improved MicroUSB (universal serial bus) interface and a manufacturing method thereof. The interface comprises a colloid and a plurality of terminals, wherein the colloid is formed by injection molding; the colloid is provided with a plurality of cavities for a terminal to insert in, and each cavity is provided with two main cavities; the plurality of terminals are flat-type terminals; each terminal is provided with a terminal contact crossbeam and a terminal clamp crossbeam, and is inserted into the colloid in parallel; each terminal contact crossbeam is inserted into one main cavity of the colloid; each terminal clamp crossbeam is arranged in the other main cavity of the colloid; and the colloid is subjected to injection molding by an injection molding machine, then the terminal is assembled in the cavity corresponding to the colloid, and finally the terminal is pressed in place by a laminated jig. The assembling manner has a simple process, and makes the adoption of automatic assembly possible; the capacity can reach 60-65K per day after automatic assembly; the terminal is in flat type and has high strength, and the weld leg is not easy to deform; thehead of the terminal dose not need to be connected with a conveying feed belt, thus effectively avoiding the damage of colloid after the material is broken.

Owner:翊腾电子科技(昆山)有限公司

Spicy ice cream and preparation method thereof

InactiveCN111919958ADigest resourcesGood health effectFrozen sweetsFood ingredient functionsMonosodium glutamateAmomum tsaoko

The invention relates to a preparation method of the spicy ice cream comprising the following steps: step 1, cleaning dry red peppers, cutting the cleaned dry red peppers into crisps, adding the crisps, flour, glutinous rice flour, monosodium glutamate, chicken essence, edible edible salt, white sugar, fennel, sesame seeds, fructus amomi, the pepper and the fruit of caoguo into mineral water, anduniformly performing stirring; filling a container with the mixture, performing sealing with a preservative film, and performing fermenting for 3-10 hours for later use; step 2, heating oil to raise the temperature to 260 DEG C, and then reducing the temperature to 160 DEG C; frying the raw materials obtained in the step 1 in a fryer until the raw materials are crispy, immediately taking the raw materials out of the fryer, and performing spin-drying oil; performing cooling for 30 minutes, crushing the cooled materials into small particles, and putting the processed materials into the containerfor later use; step 3, putting yoghourt, unsalted butter and milk into the container, and uniformly performing stirring for later use; step 4, putting the raw materials obtained in the step 3 into the container filled with the small granular raw materials in the step 2, uniformly performing stirring, performing fermenting for 3-5 hours again, and performing boiling with soft fire for later use; and step 5, loading the raw materials obtained in the step 4 with egg rolls, performing shaping, putting the shaped raw materials in a freezer at a temperature of -30 DEG C, and performing freezing for4 hours.

Owner:GUIZHOU ZUNYI COUNTY GUISANHONG FOOD

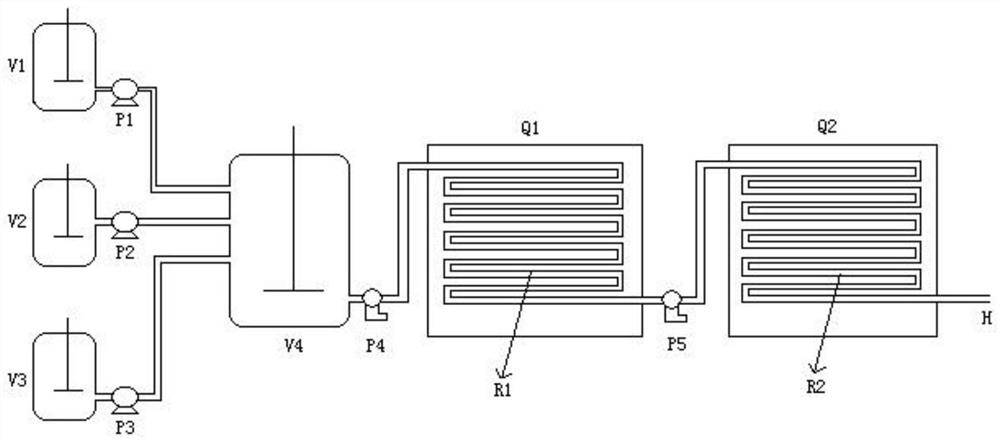

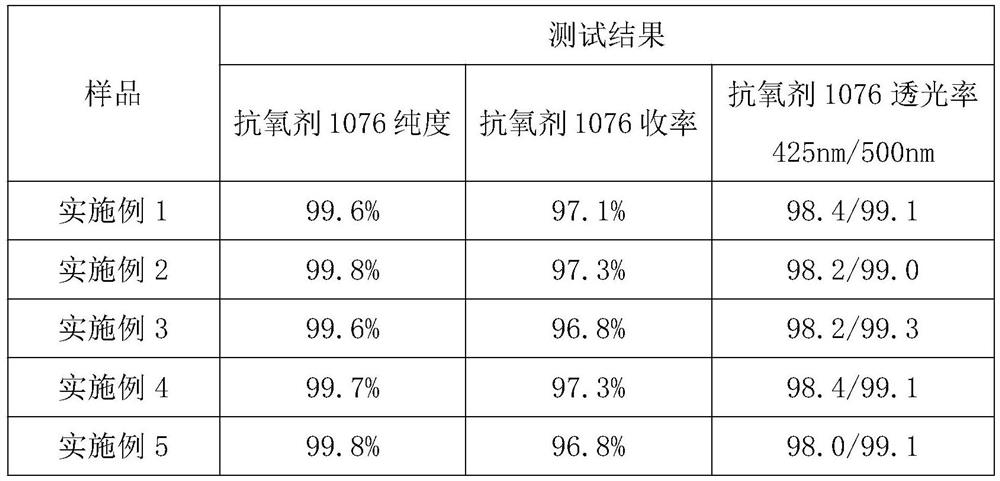

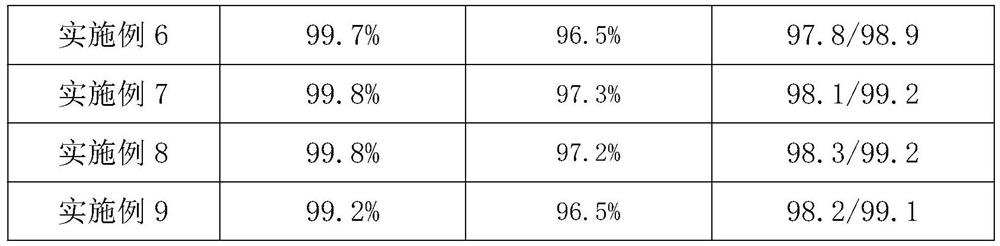

Continuous preparation method of antioxidant 1076

PendingCN114790140AOvercome stabilityOvercome qualityPreparation by ester-hydroxy reactionOrganic compound preparationPropanoic acidPtru catalyst

The invention relates to a continuous preparation method of an antioxidant 1076, and belongs to the technical field of antioxidant production. The method comprises the following steps: respectively dissolving beta-(3, 5-di-tert-butyl-4-hydroxyphenyl) methyl propionate, octadecanol and a catalyst in a material preparation kettle, sequentially adding the dissolved materials into a material mixing kettle according to a ratio through a flow pump, mixing, reacting through two groups of tubular reactors, setting different temperatures for a first tubular reactor and a second tubular reactor, and carrying out high-temperature crystallization to obtain the beta-(3, 5-di-tert-butyl-4-hydroxyphenyl) methyl propionate. According to the present invention, the antioxidant 1076 can be continuously produced, the problems of unstable parameters and mass difference between batches of the traditional intermittent production process are avoided, the method has characteristics of short reaction time, less by-products, high yield and the like, the product yield is more than 96.5%, the production cost is low, and the method is suitable for industrial production. And the purity of the product reaches 99.8% or above.

Owner:陕西艾科莱特新材料有限公司

Manufacture method for apple seed essential oil

InactiveCN105349247AOvercome qualityOvercome the problem of low oil yieldFatty-oils/fats refiningFatty-oils/fats productionFlavorOil phase

A manufacture method for apple seed essential oil is disclosed and comprises crushing apple seed and shelling, so as to obtain apple seed kernel powder; then performing hydraulic squeezing on the apple seed kernel, so as to obtain crude oil; heating the crude oil, dropwise adding a sodium hydroxide solution into the crude oil with stirring, continuing stirring after dropwise adding is finished, so as to performing sufficient alkali refining on the crude oil; then standing at a constant temperature, and filtering, so as to obtain an oil phase; and washing the oil phase with water to be neutral, and finally performing decoloring and filtering, so as to obtain the apple seed essential oil. The method employs a chemical process for performing alkali refining on apple seeds, the oil yield is up to 12% or more on the basis of guaranteeing the oil quality, and the method is suitable for industrialized production. According to the method, the processes of hydraulic squeezing and refining are employed for obtaining the apple seed essential oil, various nutrients and the flavor of the apple seed oil are kept to a great degree, and also the apple seed essential oil prepared by employing the method possesses unique flavor, no solvent residue and abundant nutrients.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

Method for preparing pectin through double-effect combined extraction technology

The invention discloses a method for preparing pectin through a double-effect combined extraction technology. The method integrates respective advantages of inorganic acid extraction and resin ion exchange technology extraction, overcomes the disadvantages of long production cycle, low yield, low quality and difficult process control of traditional pectin, has the advantages of high extraction efficiency, energy saving, high yield, small destroys to the molecular chain and the gelling degree of pectin, and simple production control, and is very suitable for large-scale and industrialized production.

Owner:安徽亿源生物工程有限公司

Preparation technology of fresh pickled onions

InactiveCN105433313AOvercome the tasteOvercome qualityFood scienceLactic acid bacteriumEconomic benefits

The invention provides a preparation technology of fresh pickled onions. The technology comprises the following steps of A, pretreating onions; B, preparing pickling water I and pickling water II which are different for standby application, wherein Gaofuji paolemei lactic acid bacterium powder is added in the pickling water I and is not added in the pickling water II; C, using the pickling water I prepared in the step B for fermenting the onions treated in the step A so as to obtain fresh pickled onions, when the onions are fermented for the 4n time, sequentially performing centrifuging, water drainage and the like on the pickling water after being fermented for the 4n time, and fermenting the onions treated in the step A with the treated pickling water, wherein n is sequentially taken from continuous positive integers; and D, treating finished products: sequentially performing cutting, seasoning, packaging, and disinfection on the fresh pickled onions obtained by fermentation each time in the step C so as to obtain finished products. According to the preparation technology disclosed by the invention, the preparation time of the fresh pickled onions is shortened, the quality and the mouth feel of the fresh pickled onions are improved, and the preparation technology is suitable for mass production. The development of trade of pickles is promoted, and the preparation technology has good economic benefits.

Owner:SICHUAN GAOFUJI BIOLOGICAL TECH

Method for extracting food natural pigment from green plum pericarps

InactiveCN107903656AImprove extraction efficiencyExtract fitNatural dyesFood ingredient functionsPectinaseMicrowave

The invention provides a method for extracting a food natural pigment from green plum pericarps. The method comprises the following steps: selecting and washing fresh green plums; heating the fresh green plums by adopting microwaves and dissolving into oversaturated table salt; adding a complex enzyme composed of cellulase and pectinase and carrying out enzymolysis; crystallizing and separating out at low temperature by adopting the dissolved table salt; then extracting the pigment by adopting an ultrasonic extraction manner. According to the method provided by the invention, the extraction efficiency and the extraction rate of the pigment are effectively improved and the pigment has extremely high food safety. The problems that a product produced by a traditional natural pigment extraction method has poor quality, low concentration, undesirable odor and residual solvent are overcome.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Active dry yeast capable of improving fermentation rate, and preparation method thereof

InactiveCN105002101AOvercoming slow growthOvercoming activityFungiOn/in organic carrierBiotechnologyFiber

The present invention discloses active dry yeast capable of improving fermentation rate, and a preparation method thereof, wherein the raw materials comprise, by weight, 32-38 parts of manihot esculenta crantz powder, 23-26 parts ofshrimp bran powder, 10-14 parts of taro stem powder, 7-9 parts of green bamboo leaf powder, 1-2 parts of common vladimiria root powder, 1-1.5 parts of a mucor seed liquid, 0.3-0.6 part of malt extract, 0.2-0.4 part of flax protein powder, 0.2-0.4 part ofmung bean mud, 0.1-0.3 part of a yeast seed liquid, 2-3 parts of a artemisia desertorum glue, 1-2 parts of carboxymethyl starch, 0.5-1 part of nanometer vermiculite powder, 2-3 parts of rice bran fibers, and 1-2 parts of cuttlefish bone powder. The active dry yeast of the present invention has characteristics of yeast fermentation rate improving, yeast activity increase, fermentation period shortening, fermentation process simplifying, yeast contamination resistance enhancing, fermentation process controllability enhancing, fermented product quality and flavor improving during the fermentation process, and fermentation product palatability and nutrition content improving.

Owner:HEFEI LAISI BIOLOGICAL ENG

Machining method of roller structural part

The invention discloses a machining method of a roller structural part. The machining method comprises the following steps: the roller structural part required to be provided with a bracket is tightly pressed on a fixed bracket to be cast through an S-shaped elastic piece; the roller structural part and the fixed bracket are respectively connected to the two ends of the S-shaped elastic piece; after a preset mold is qualified, the roller structural part, the S-shaped elastic piece and the fixed bracket are put into the preset mold as a whole, and prepared molten metal is poured into the preset mold for casting together through a casting machine by a continuous steel casting method; the melting point of the S-shaped elastic piece is higher than the melting point of the prepared molten metal; and when the casting is finished, and a steel bottle to accommodate the prepared molten metal has no bubbles, the mechanical steel lifting is performed, and residues in the steel bottle are recovered. The machining method of the roller structural part has high production efficiency, good product quality and low machining cost.

Owner:WUXI YANGGONG MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com