Patents

Literature

51results about "Rounding machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Round stick processing machinery

InactiveCN103692500AExpand the scope of processingEliminate gap wobbleRounding machinesMechanical engineeringEngineering

The invention discloses round stick processing machinery, wherein a processing cutter is fixed on the axle center position of a three-jaw chuck, a material passing hole matched with the diameter of a round stick is formed in the center, cutter teeth are arranged on the front end, feeding and clamping rollers are a pair of rollers provided with 90-degree V-shaped grooves located in the front end of the processing cutter and are used for conveying a batten to be processed, a material shifting wheel is located on the rear end of the processing cutter and is used for outputting a processed round stick, and material brackets used for supporting the batten to be processed and the processed round stick are respectively arranged on the front end of each feeding and clamping roller and on the rear end of the material shifting wheel. According to the round stick processing machinery disclosed by the invention, the processing cutter does not need to be adjusted, and processing cutters with different specifications are directly changed to process round sticks with different specifications. The round stick processing machinery disclosed by the invention can be used for processing a round stick with a minimal diameter of only 1 mm.

Owner:山西晟龙木雕模型艺术有限公司

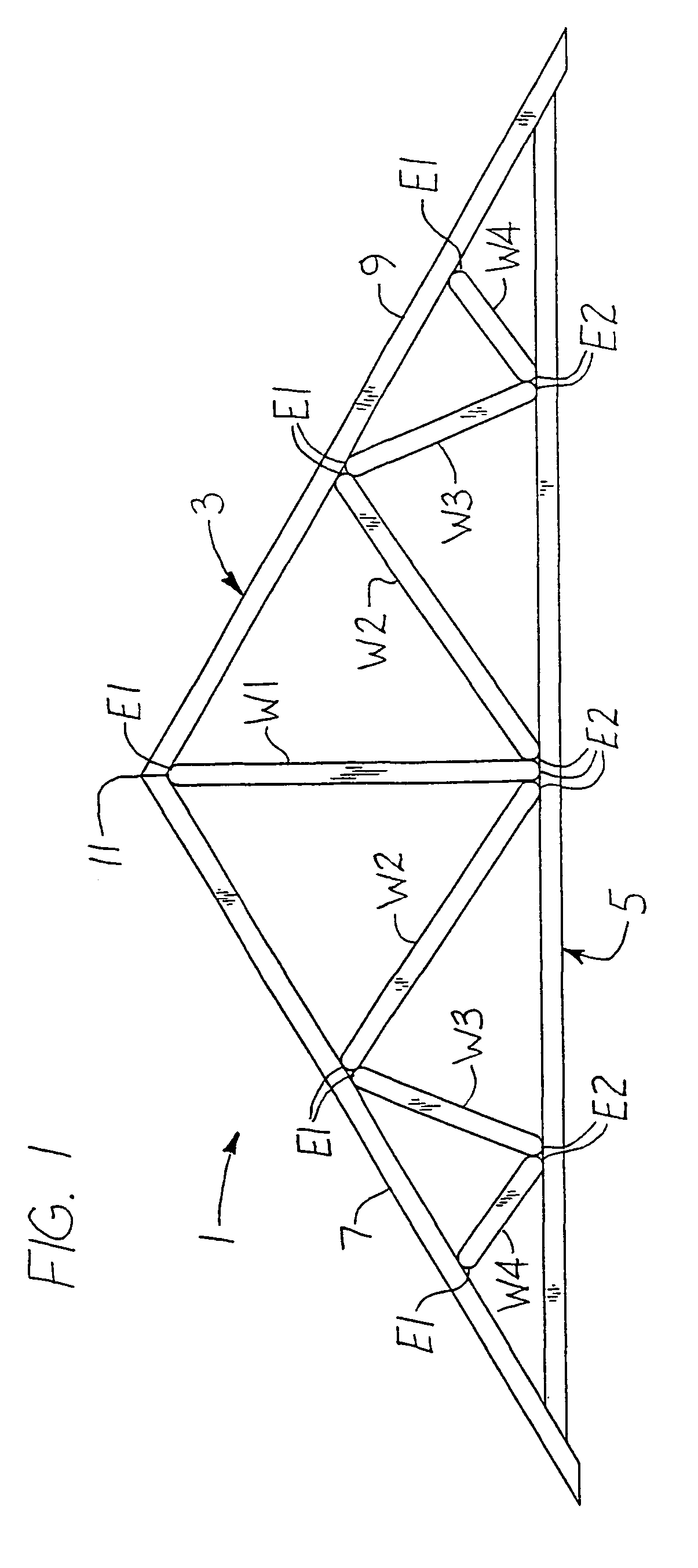

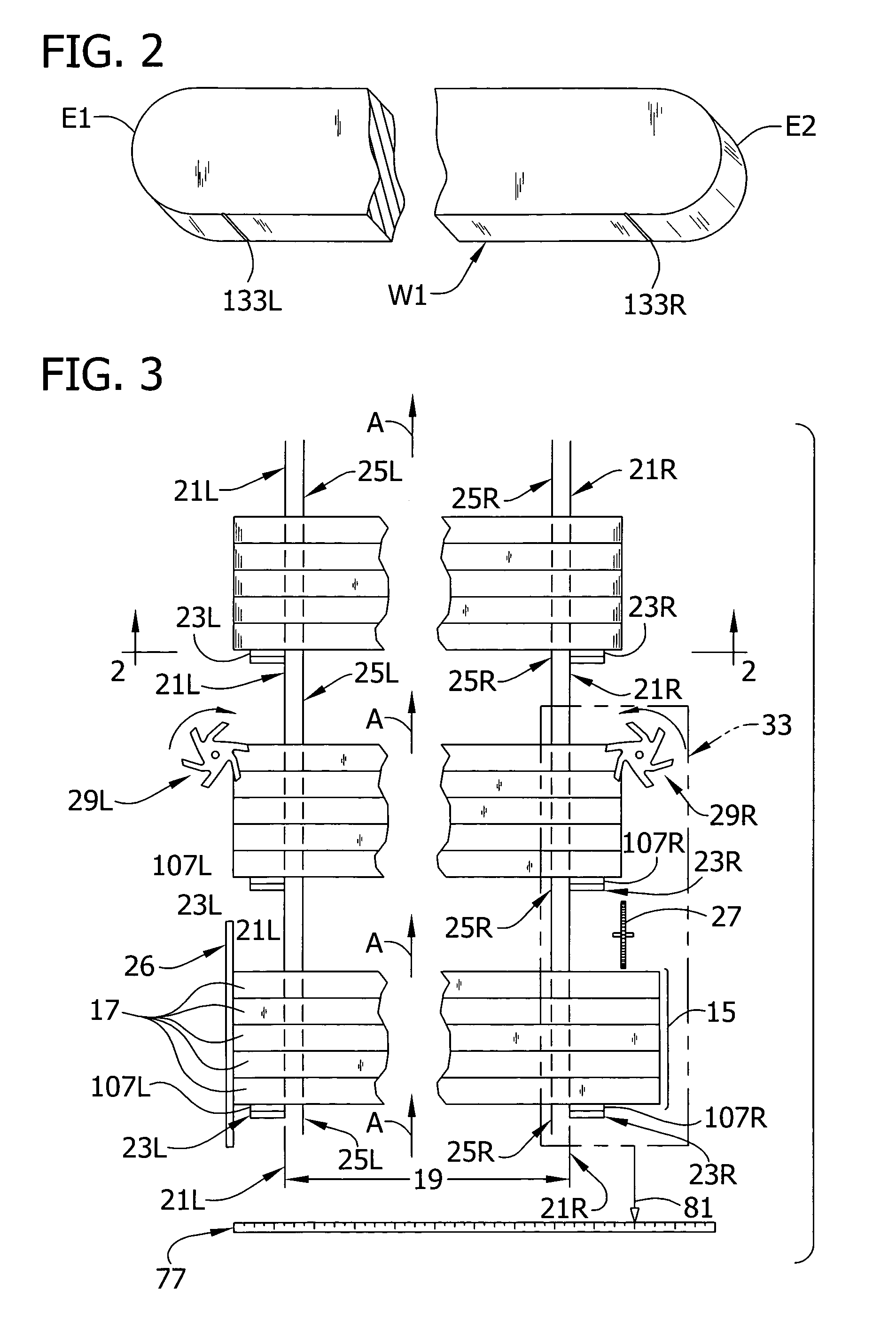

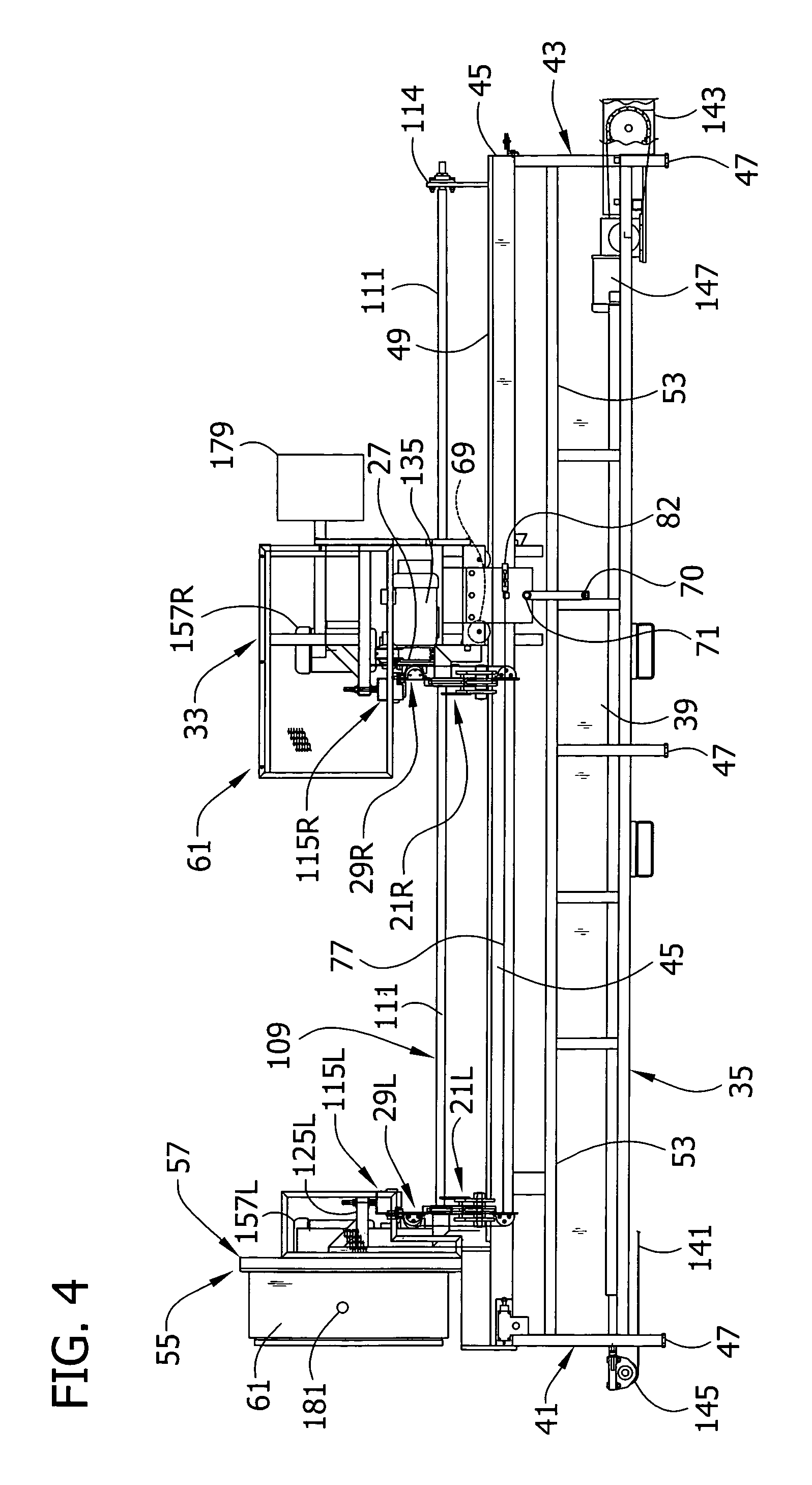

Method of and apparatus for forming timbers with rounded ends

InactiveUS7093628B2Improve productivityReduce labor costsMulti-purpose machinesWood mortising machinesTimber roof trussEngineering

The method of forming timbers especially for use as webs in timber roof trusses comprising feeding timbers in a predetermined path with the timbers extending transversely to the direction of feed and, as the timbers are so fed, shaping the ends thereof to rounded form, and apparatus for carrying out said method comprising conveyors for feeding the work, a saw for cutting the timbers to length, and cutters for the end shaping.

Owner:MITEK HLDG INC

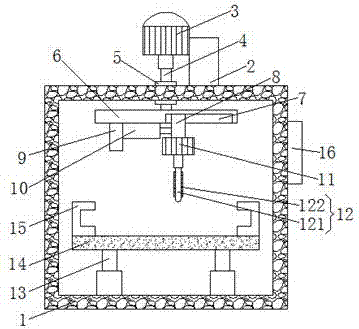

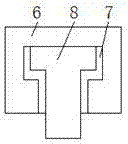

Manufacturing device of round wood plate

InactiveCN107322707ARegular shapeHigh speedStationary drilling machinesRounding machinesManufactured apparatusEngineering

The invention discloses a circular wooden board manufacturing device, which comprises a casing, the upper surface of the casing is fixedly connected with the fuselage of a first motor through a fixing block, and the output shaft of the first motor is fixed to the top end of the rotating shaft. connection, the outer surface of the rotating shaft is sleeved with a bearing, and the bearing is clamped on the upper surface of the housing, the bottom end of the rotating shaft is fixedly connected with the upper surface of the connecting plate, and the lower surface of the connecting plate is provided with a chute , the inside of the chute is slidably connected with a slider, the lower surface of the connecting plate is fixedly connected with the upper surface of the connecting block, the right side of the connecting block is fixedly connected with one end of the first electric push rod, the The other end of the first electric push rod is fixedly connected with the left side of the slide block. The manufacturing device of the circular wooden board can ensure that the shape of the circular wooden board is kept regular by using the cutting device to make the circular wooden board, and can make circular wooden boards with different diameters, which improves the speed of the producer to make the circular wooden board.

Owner:扬州市大悦信息科技有限公司

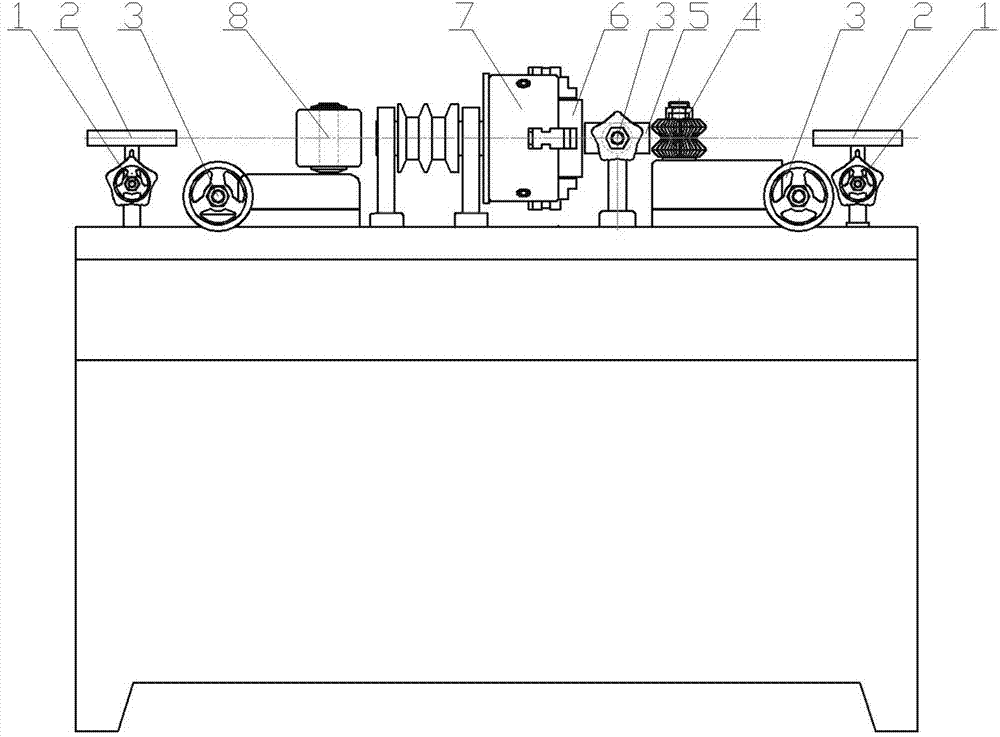

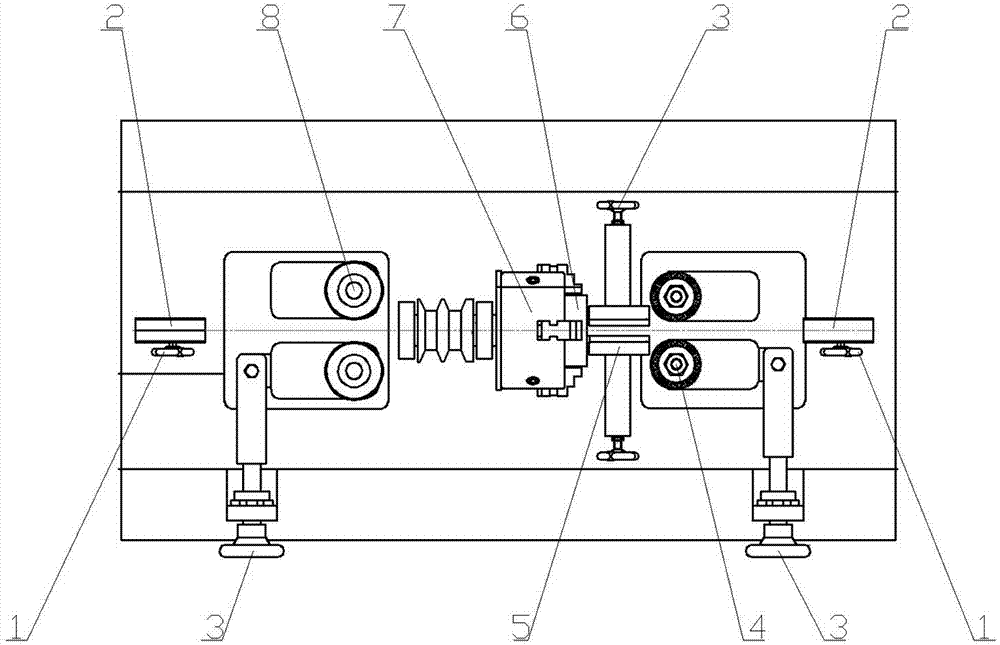

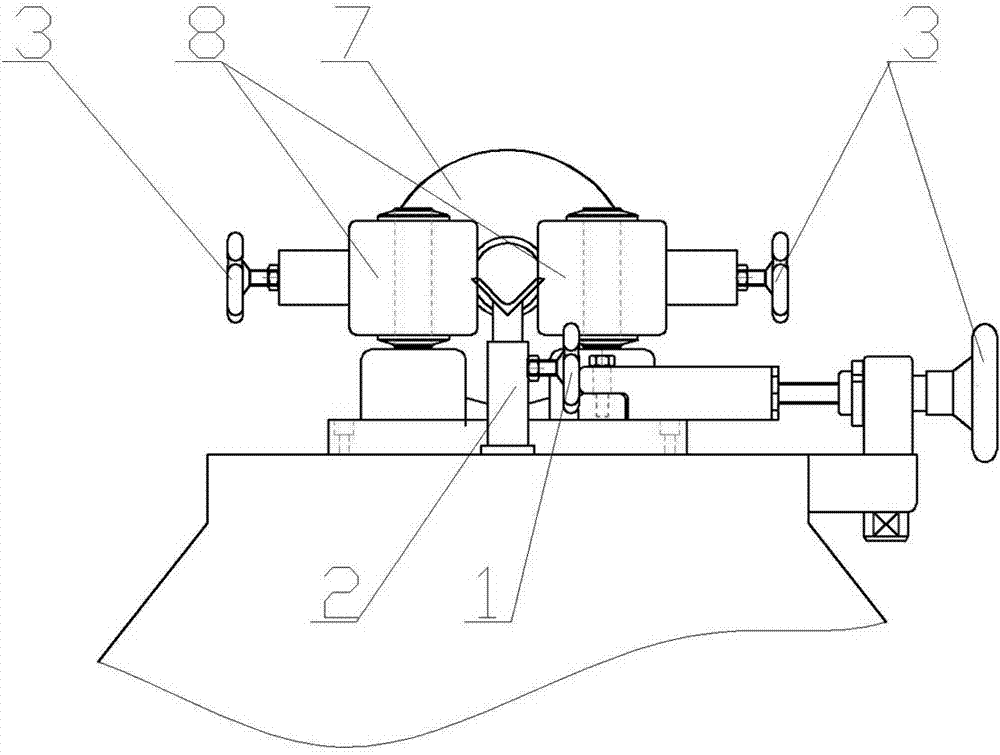

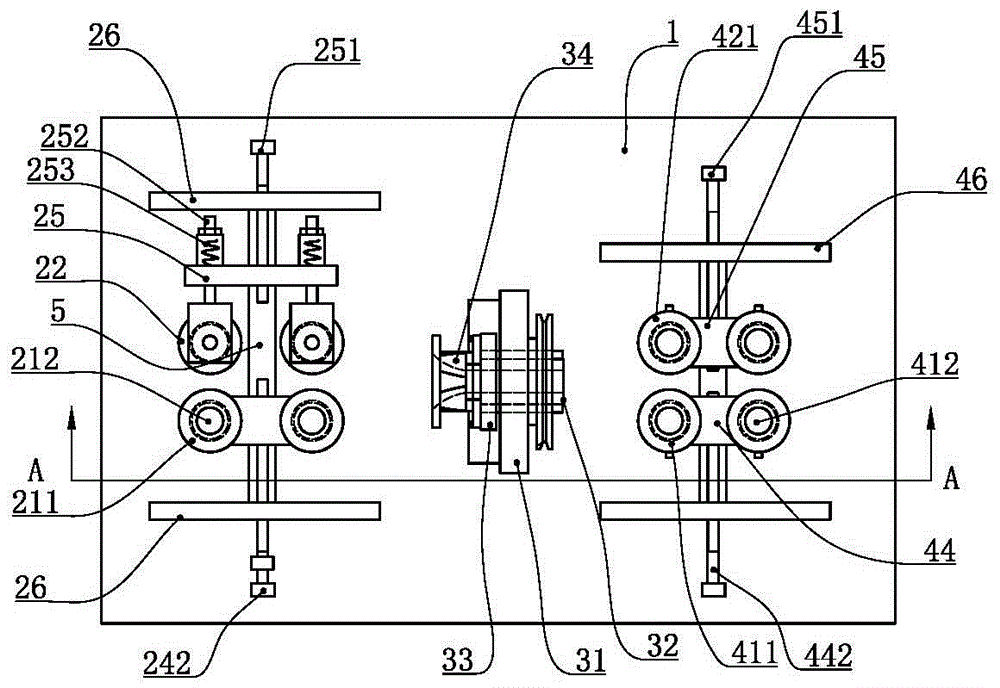

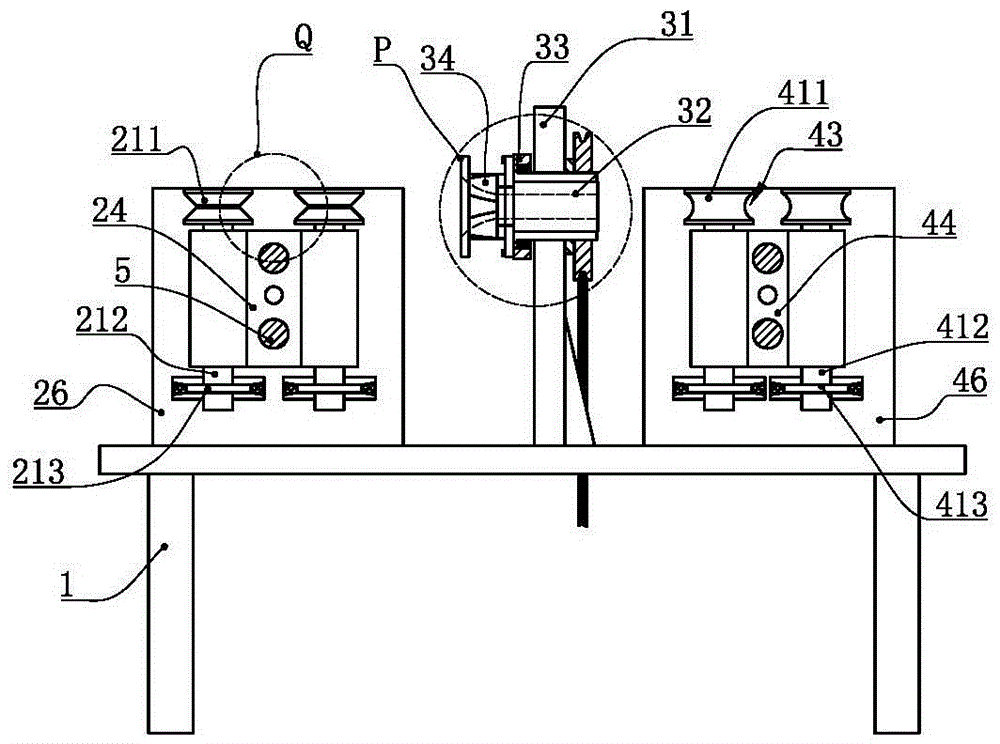

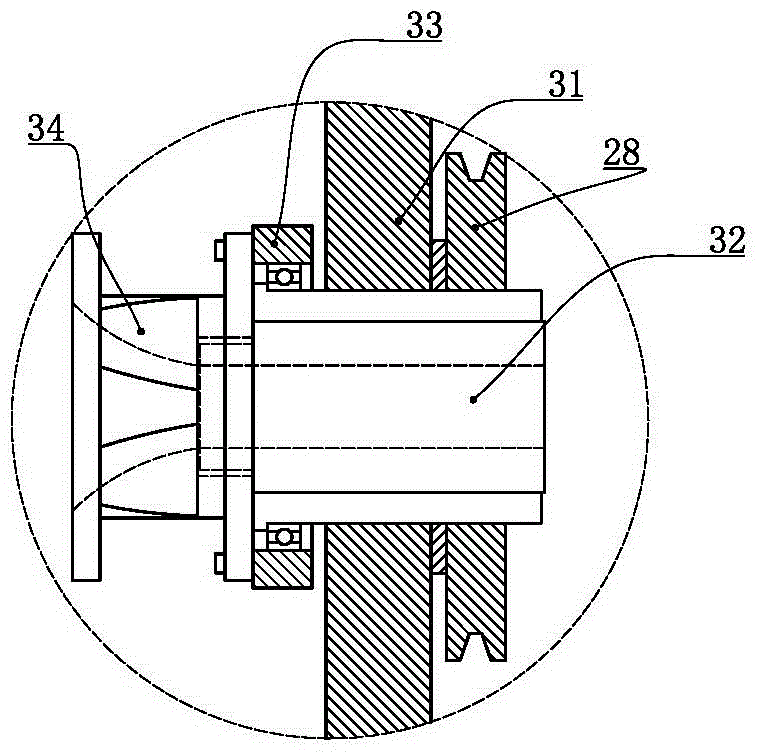

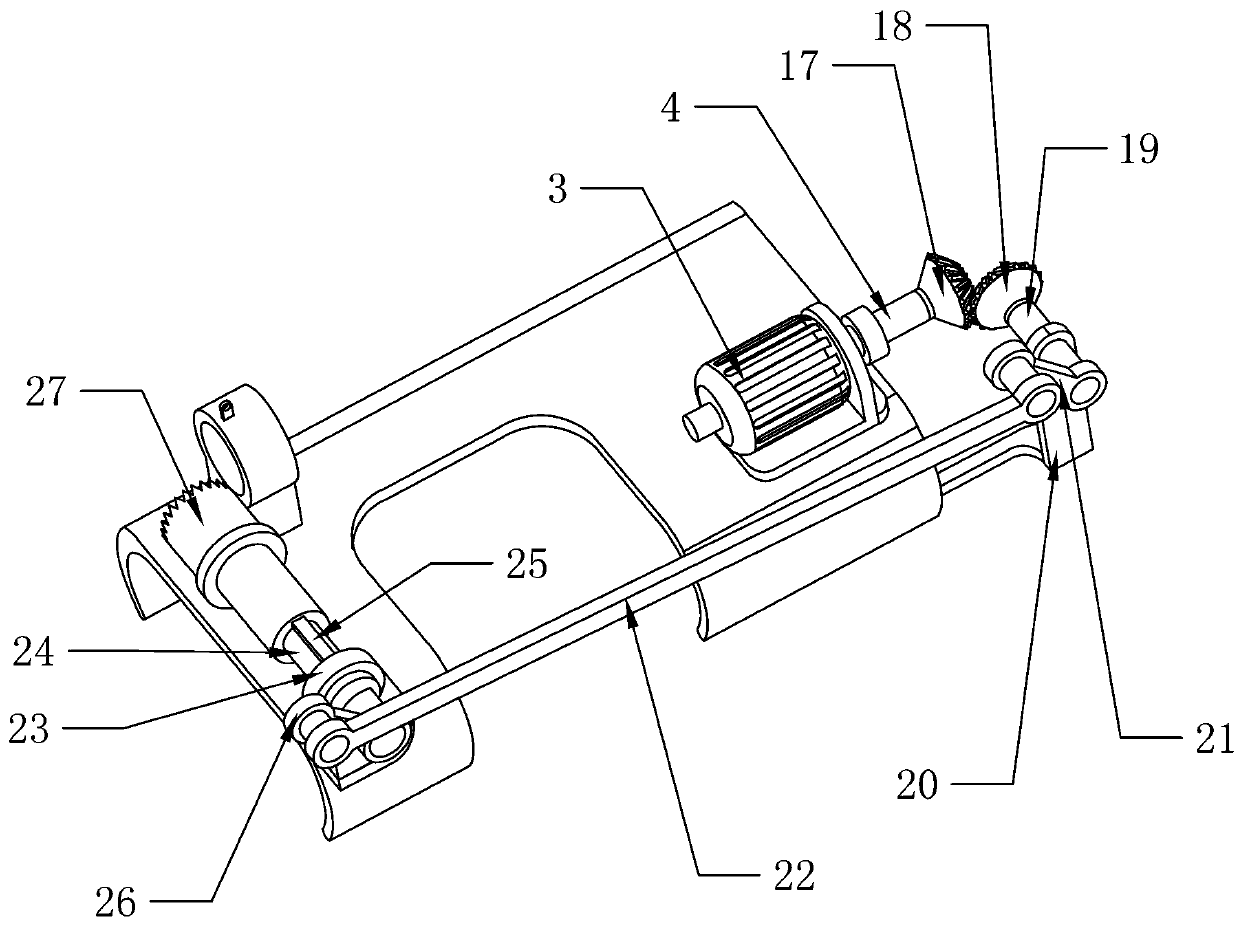

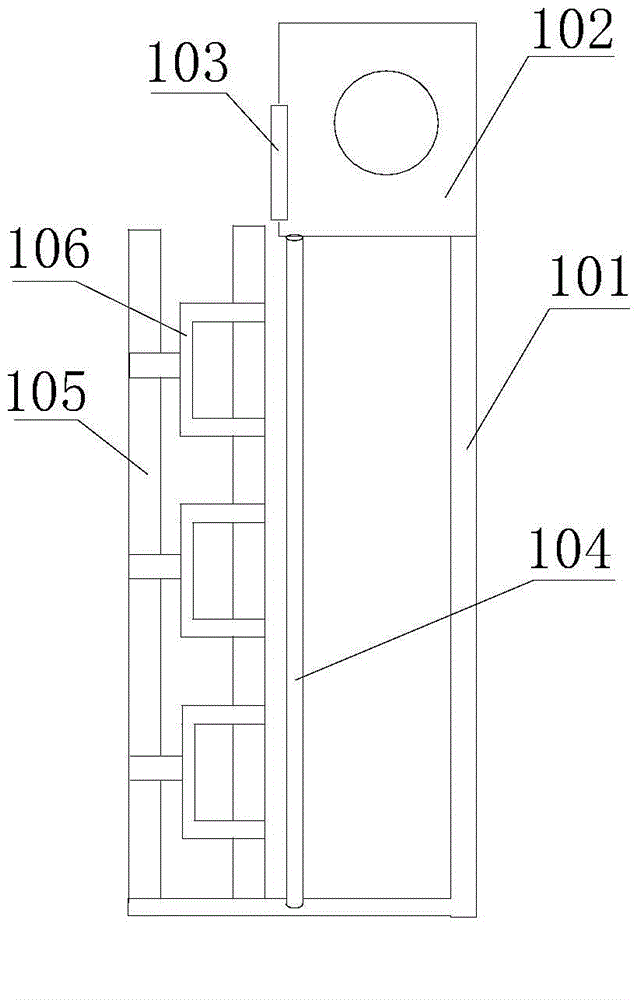

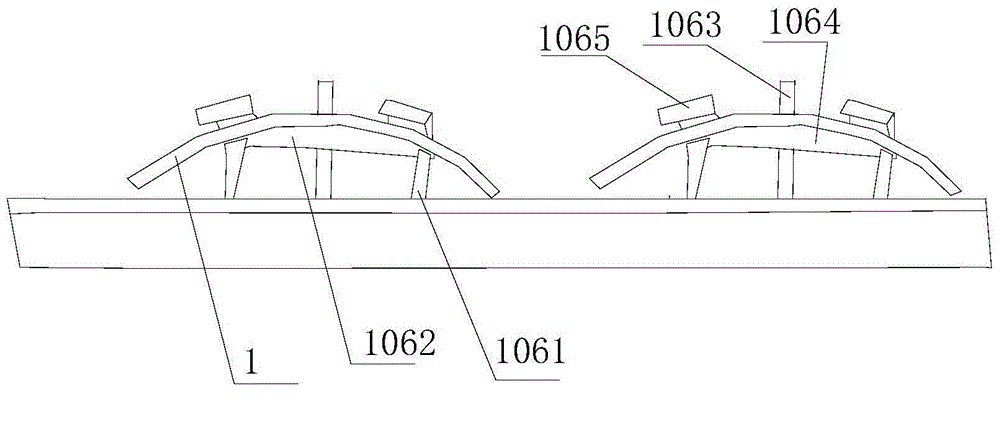

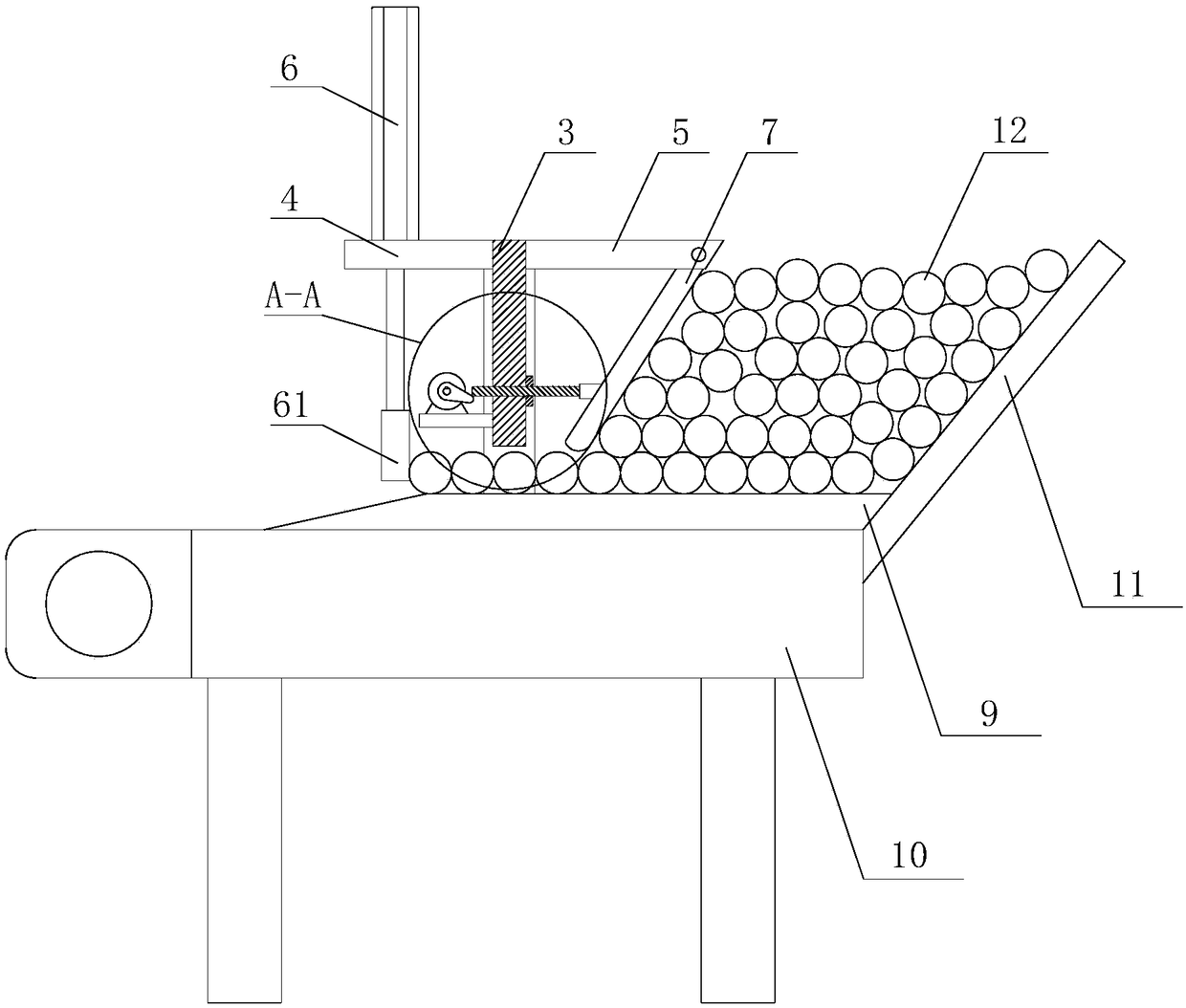

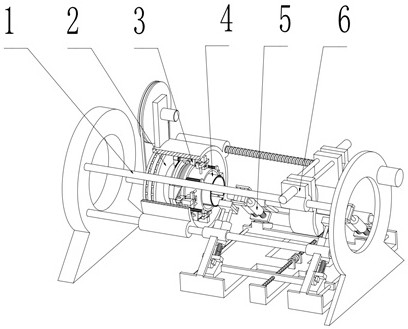

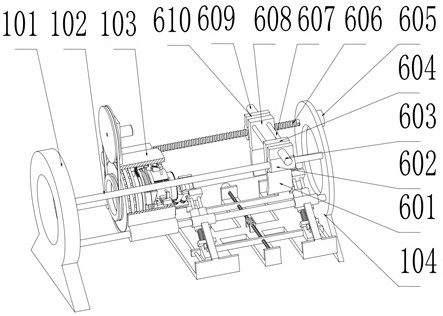

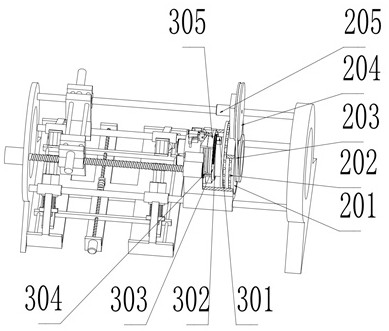

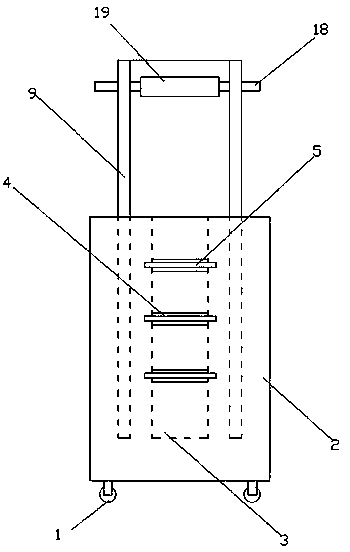

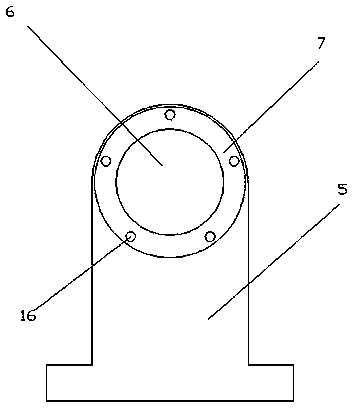

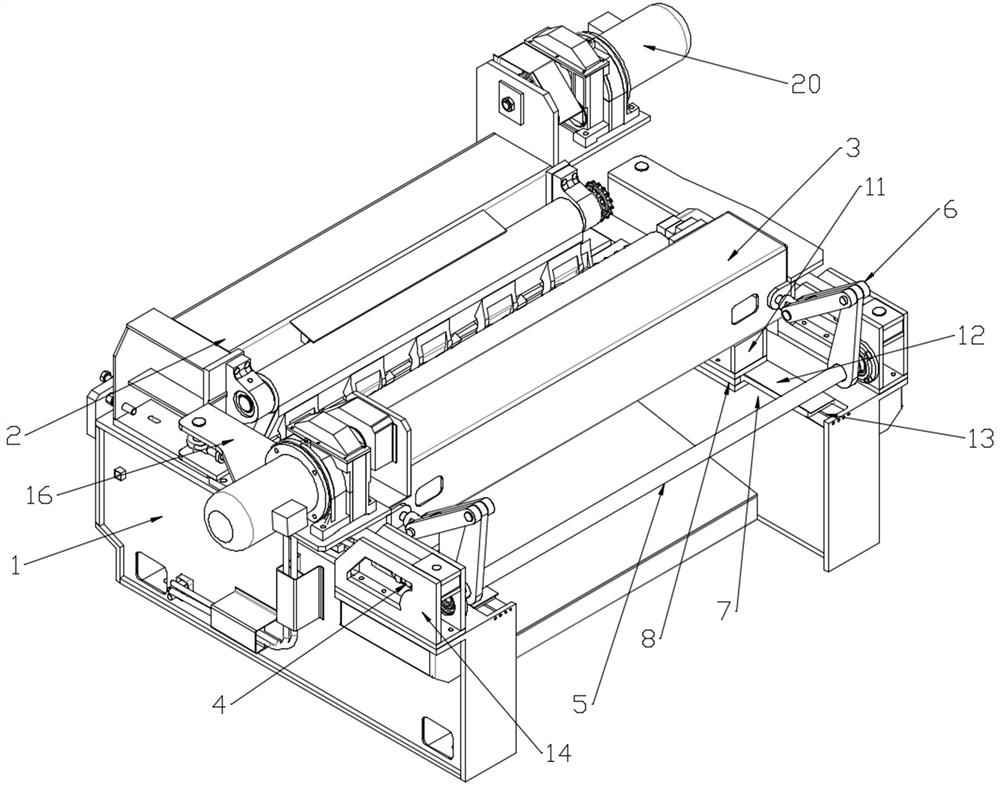

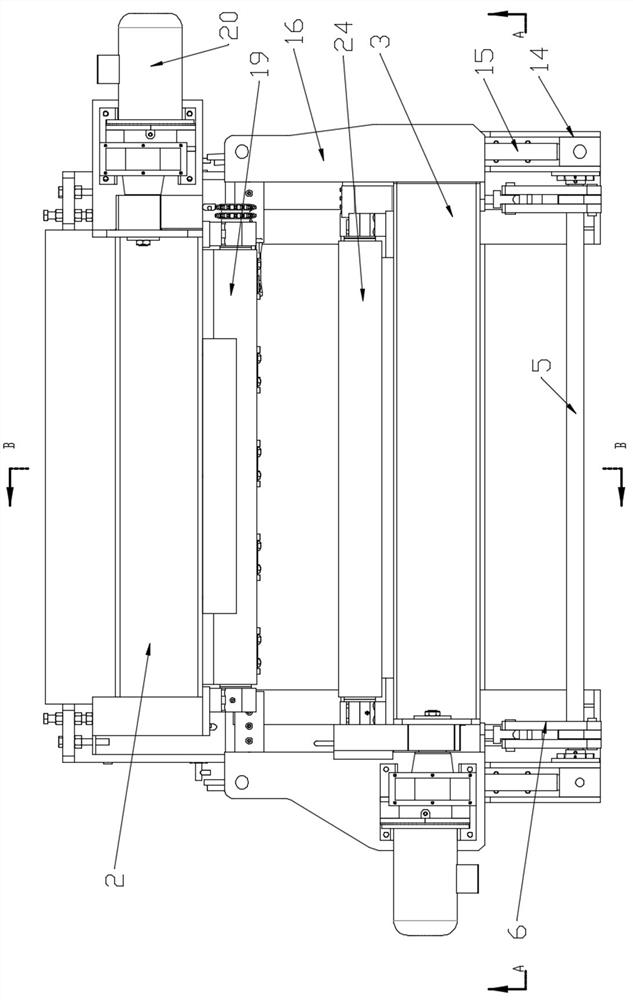

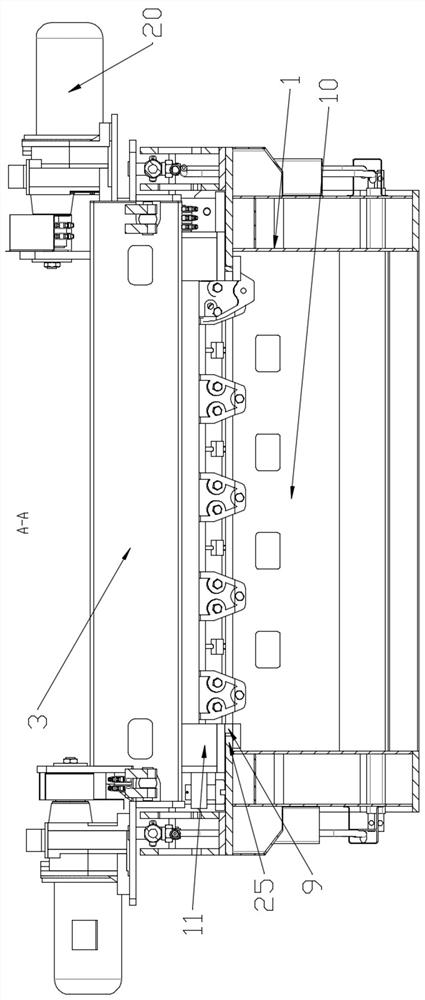

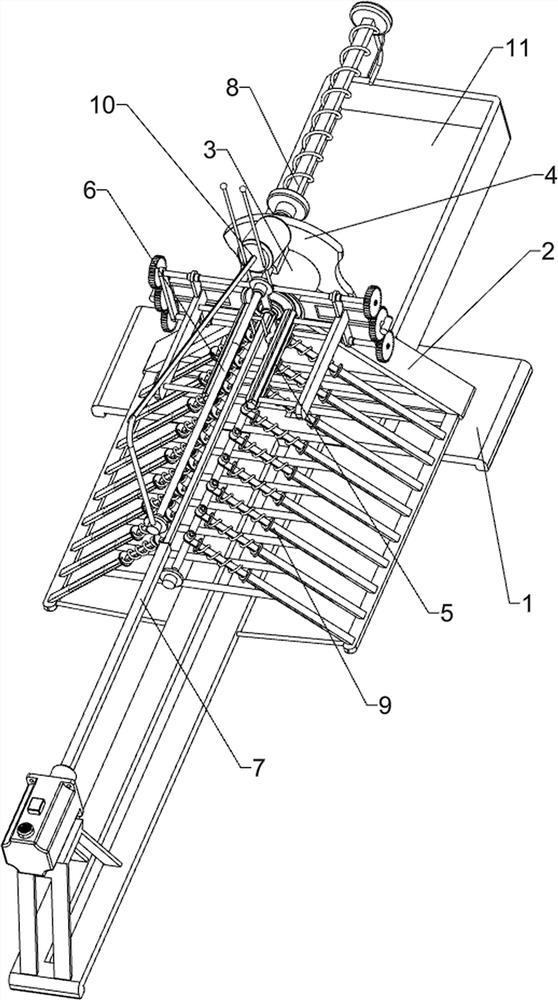

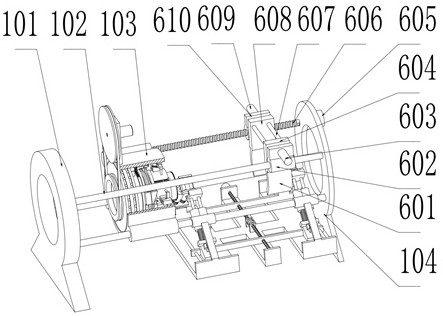

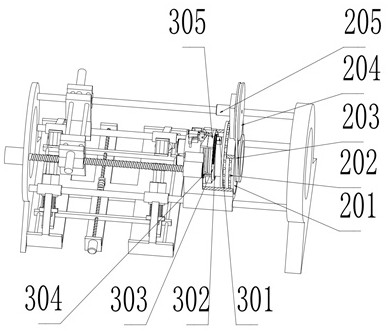

Round bar molding machine

The invention belongs to the technical field of wood processing, and discloses a round bar molding machine which comprises a frame. A feeding mechanism, a milling mechanism and a discharging mechanism are arranged on the frame in sequence from back to front. The feeding mechanism comprises at least two feeding roller groups. In each feeding roller group, driving feeding rollers and driven feeding rollers are arranged in pairs. Right-angled V-shaped grooves are processed in the circumferential surfaces of all the feeding rollers. Small circular grooves are formed in the bottoms of the right-angled V-shaped grooves. The discharging mechanism comprises at least two discharging roller groups. In each discharging roller group, driving discharging rollers and driven discharging rollers are arranged in pairs. Large circular grooves are processed in the circumferential surfaces of all the discharging rollers. The milling mechanism comprises a main tool rest and a milling tool component arranged on the main tool test. The small circular grooves are formed in the bottoms of the right-angled V-shaped grooves of the feeding rollers, so that the radial positioning precision of bars is improved, and the off center problem caused in bar processing is solved.

Owner:浙江千束家居用品有限公司

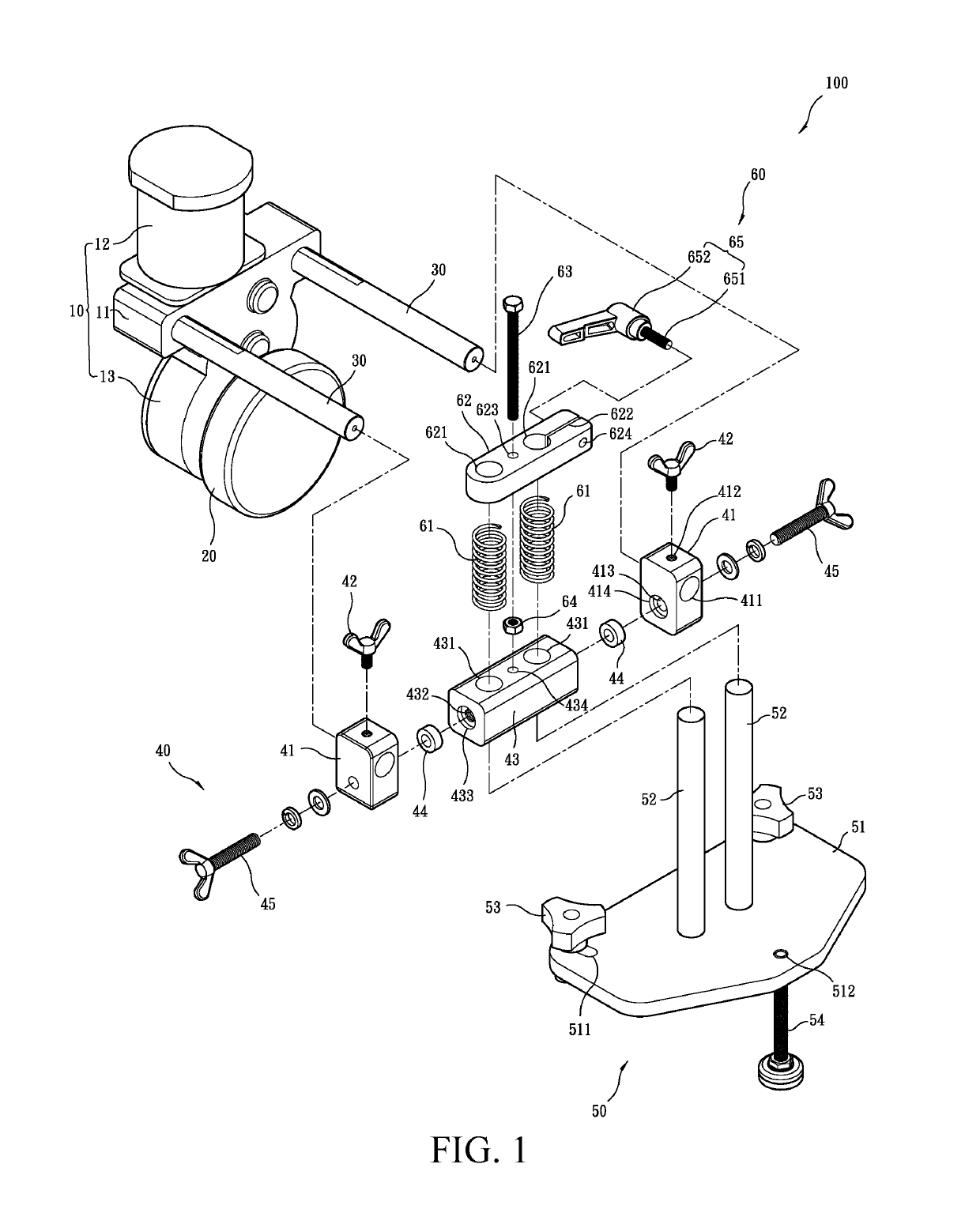

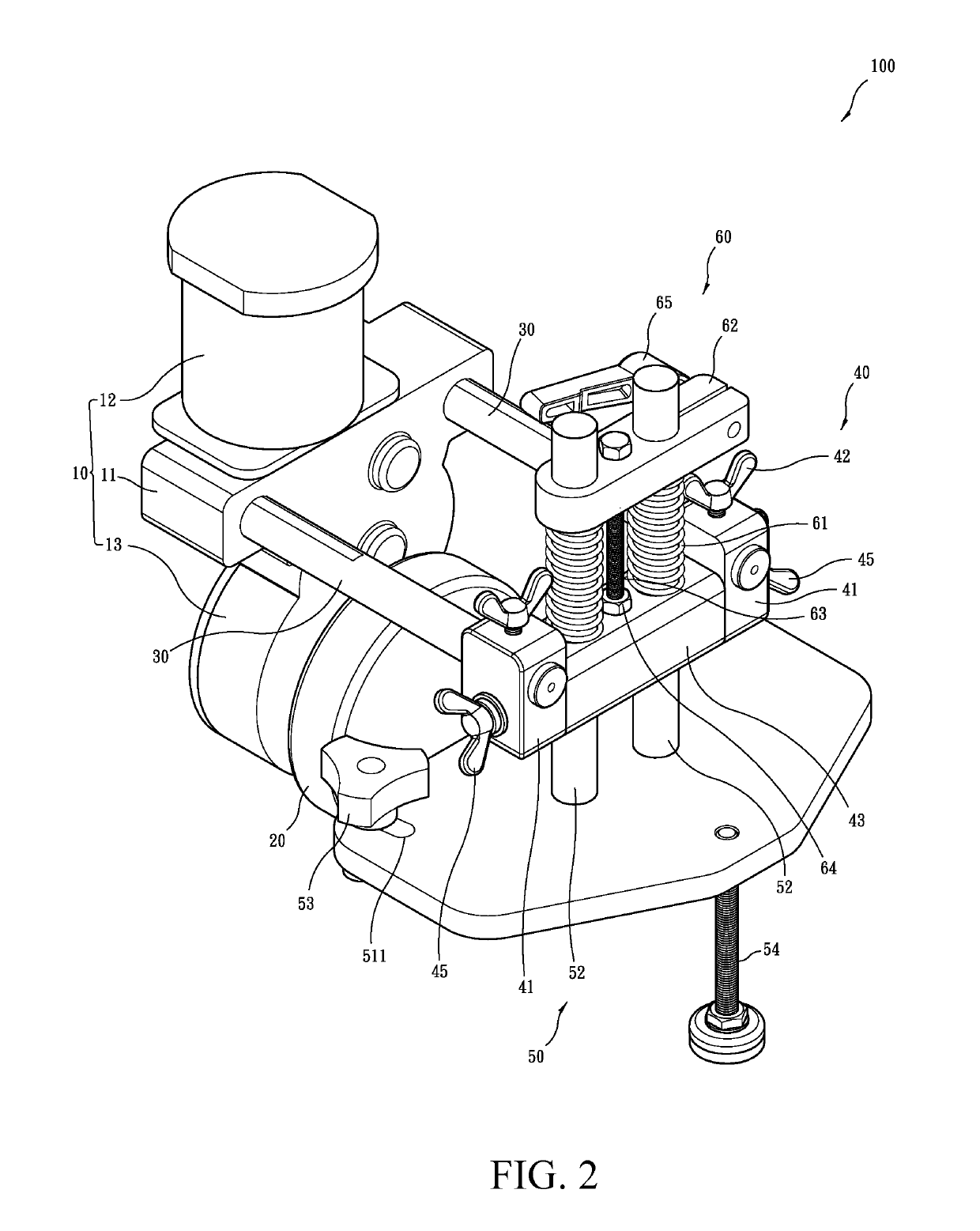

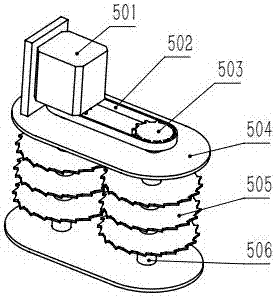

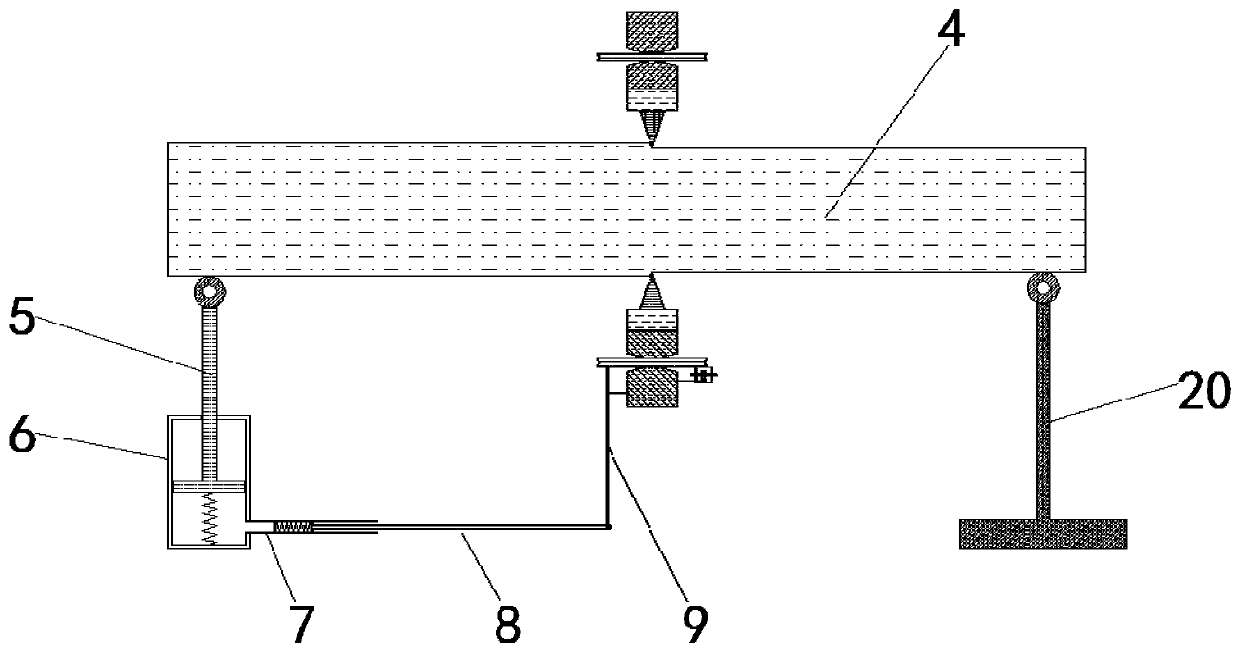

Structure of power carpentry feeder machine

ActiveUS20190210243A1Improve adaptabilityMaterial safetyWood feeding arangementsGuide fencesElectric powerWoodworking

A power carpentry feeder machine includes a power source; a rotary wheel operatively coupled to the power source; horizontal guide rods horizontally coupled to the power source; a horizontal movement unit including two movable blocks having horizontal guide holes to receive the horizontal guide rods therein, locking members attached to the movable blocks, a connection block interposed between the two movable blocks and including vertical guide holes, and jointing members jointing the movable blocks to the connection block; a mounting base including a base board and vertical guide rods vertically coupled to the base board and extending through the vertical guide holes; and a vertical movement unit including springs encompassing the vertical guide rods to set the connection block under the springs and a clamp block having clamping holes to receive the vertical guide rods to extend therethrough so as to set the clamp block on the springs.

Owner:YU BEN

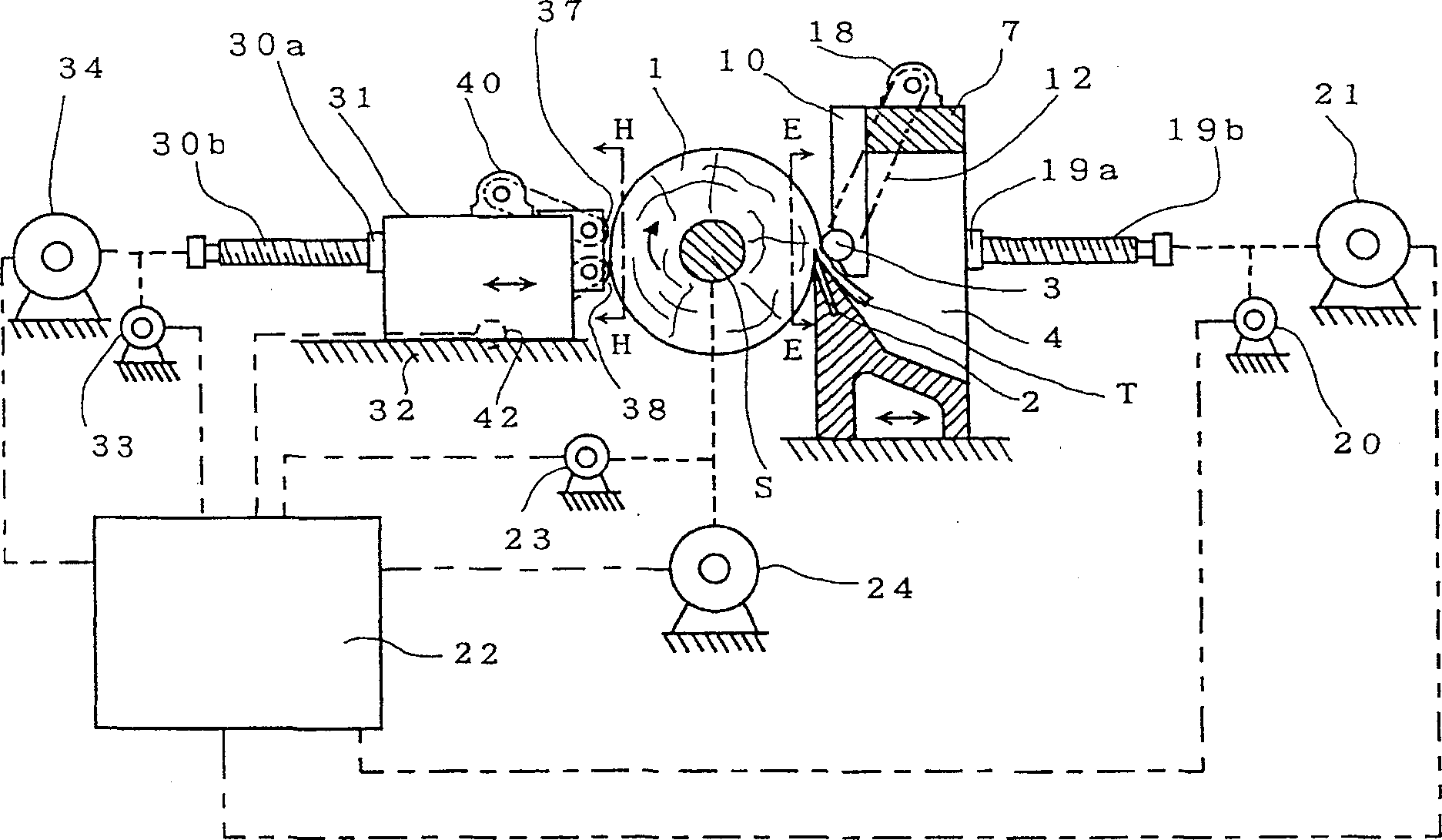

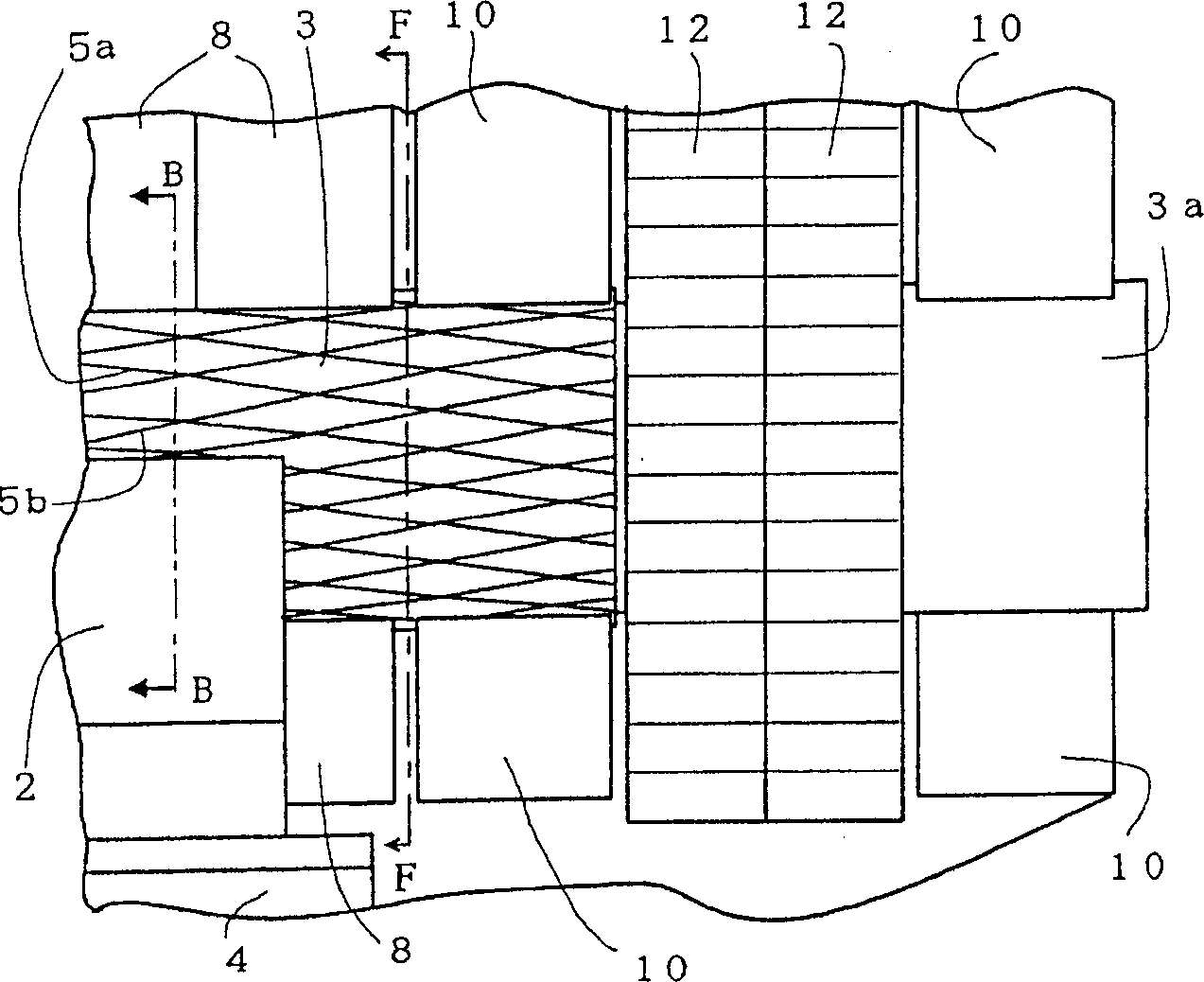

Rotary cutting machine

InactiveCN1375385AEasy to break awayReduce the numberRounding machinesVeneer manufactureEngineeringMachine tool

The invention provides a rotary cutting machine, which can be driven to obtain a cut veneer, and the veneer can be used as a plywood surface without residual scars. The technical solution adopted to solve this technical problem is that the rotary cutting machine drives the tool to pressurize the log peripheral surface at the upstream side of the log rotation direction, and the tool is fixed on the planer table to cut the rotating log; (3) A plurality of grooves are formed on the peripheral surface, and the shape of the grooves (5a) in the section perpendicular to the axis centerline of the roller rod (3) is such that at the upstream side in the direction of rotation of the roller rod, the corner (3e) The angle formed by the tangent of the tangent and the outwardly protruding line (3b) is 130 to 160 degrees, and the angle (3e) is formed by the outer peripheral line (3d) of the rolling bar (3) and the side extending outward from the centerline of the rolling bar (3) shaft. The outgoing line (3b) constitutes.

Owner:MEINAN MASCH WORKS INC

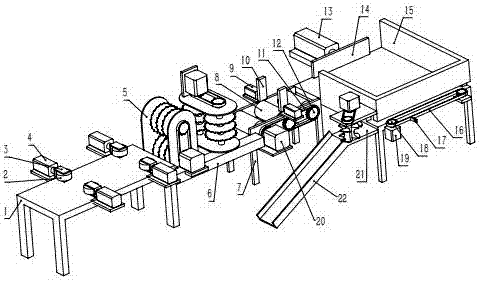

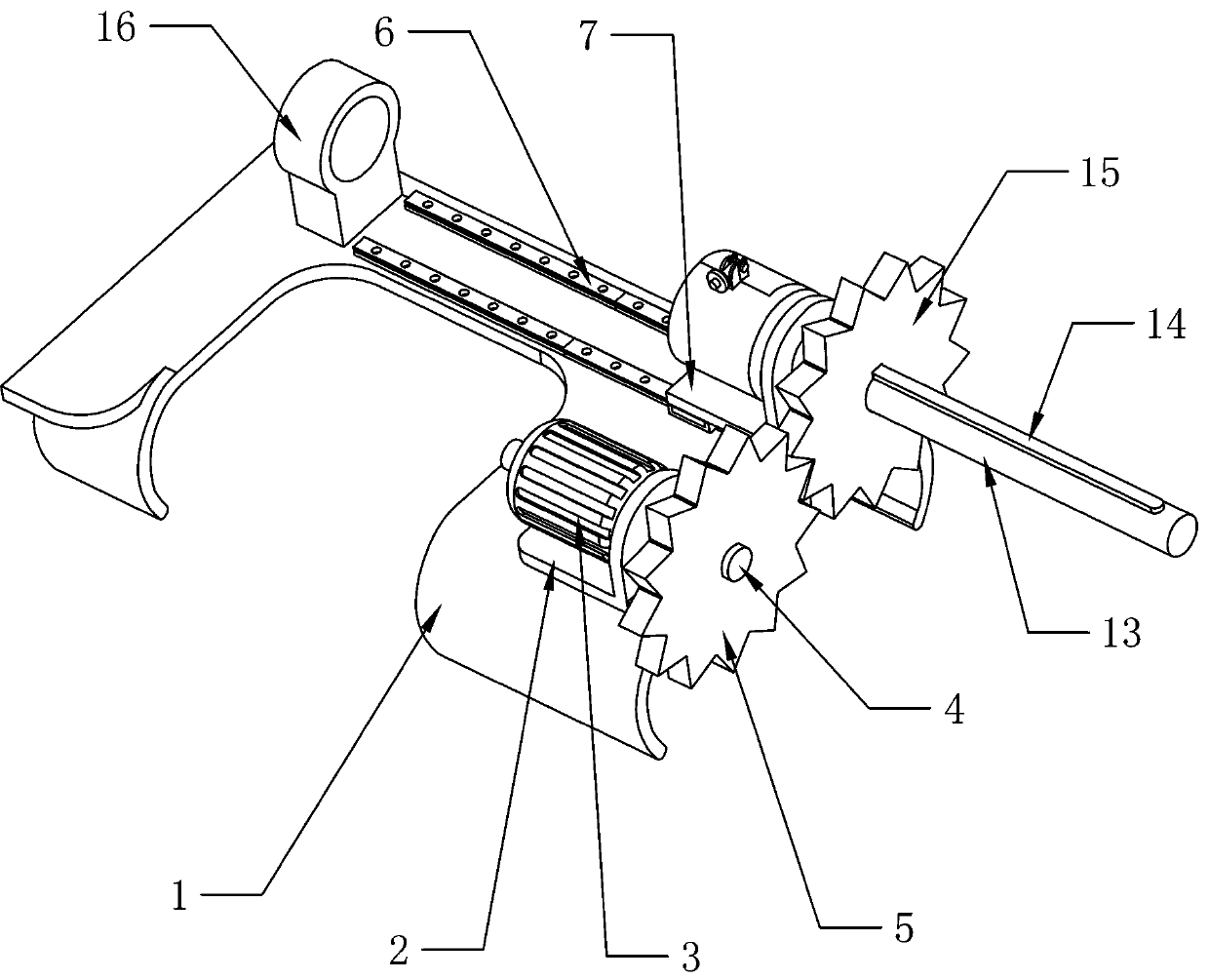

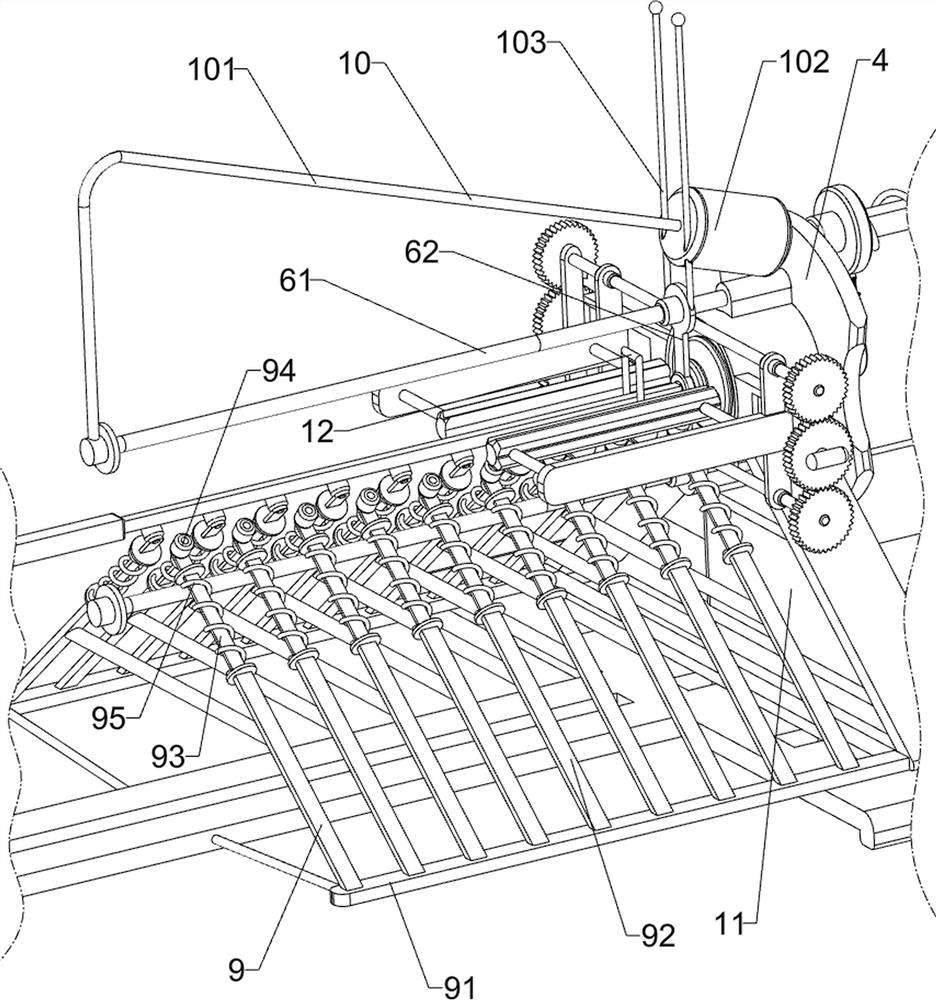

Intelligent round wood bar machining robot

ActiveCN106956329ARealize intelligenceIncrease productivityRounding machinesProfiling/shaping machinesEngineeringFour-slide

An intelligent round wood bar machining robot comprises a first workbench, four sliding wheels, four sliding wheel frames, four first electric cylinders, two saw disc sets, a first support, a second support, three roll shafts, two second electric cylinders, two baffles, a first chain, three first tooth discs, a third electric cylinder, a push plate, a second workbench, a second chain, a push rod, two second tooth discs, a second stepping motor, a first stepping motor, a wood bar machining set and a round wood bar outlet. The intelligent round wood bar machining robot has the following beneficial effects that the structure is compact, safety and reliability are achieved, operation is simple, intelligent and batched round wood bar machining can be achieved, a worker only needs to place a panel into the intelligent round wood bar machining robot so that a round wood bar can be obtained, the round wood bar production efficiency is improved, and the labor force is greatly liberated.

Owner:TIANJIN JINHANG COMP TECH RES INST

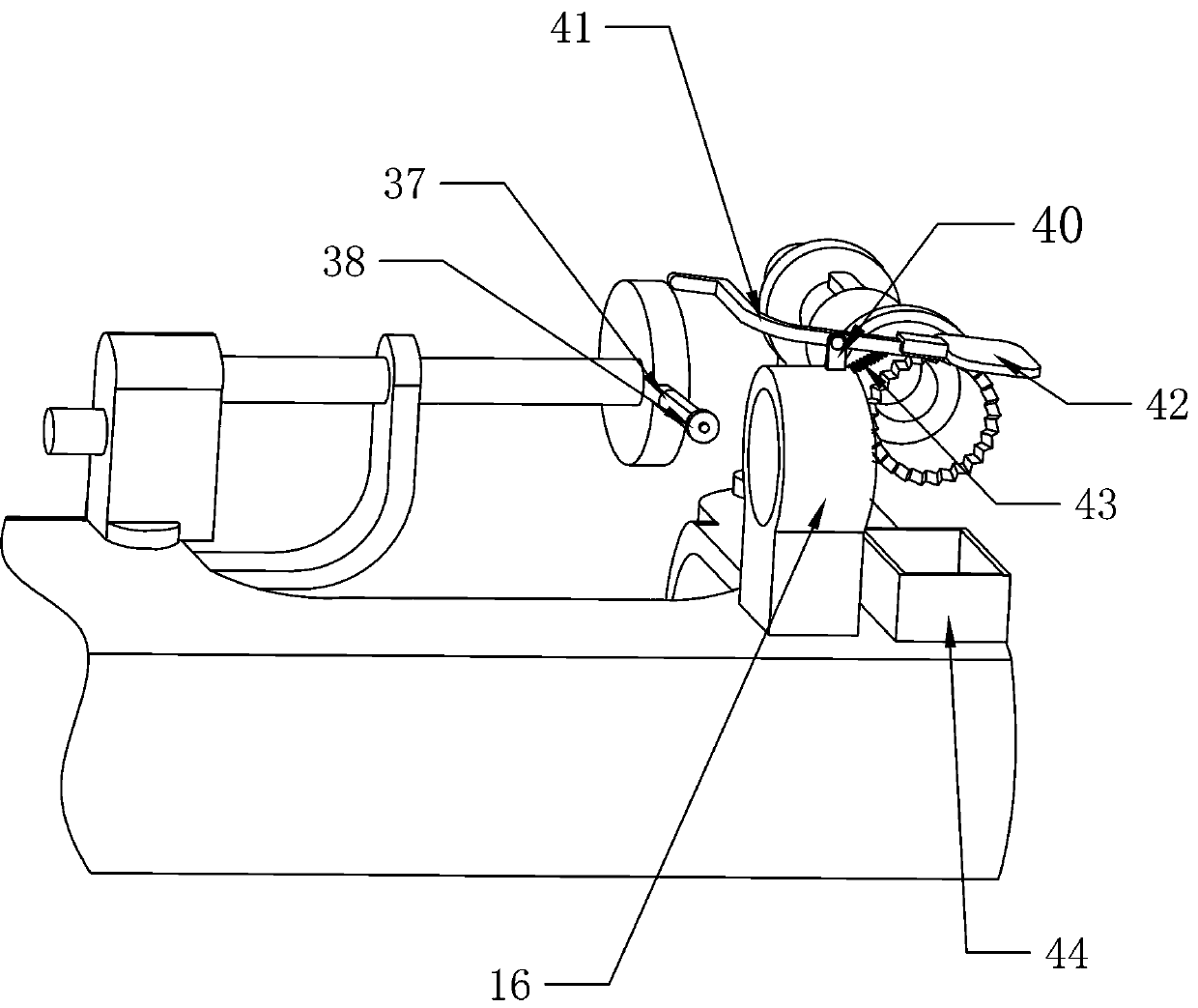

Progressive wooden bead manufacturing device

ActiveCN111391037AAvoid risk of injuryEasy to processRounding machinesGlass productionElectric machineryStructural engineering

The invention relates to a manufacturing device, in particular to a progressive wooden bead manufacturing device. The technical problem of the progressive wooden bead manufacturing device is how to provide a progressive wooden bead manufacturing device which can automatically cut wood and further automatically beat a cut wood ball down. The progressive wooden bead manufacturing device comprises abottom plate, a transmission mechanism and a locking mechanism, wherein a motor seat is fixedly connected to the bottom plate, and a biaxial motor is mounted on the motor seat; the transmission mechanism is fixedly connected to the bottom plate, and the biaxial motor is connected to the transmission mechanism; and the locking mechanism is fixedly connected to the transmission mechanism. The progressive wooden bead manufacturing device is driven by the motor, can automatically rotate a wooden cylinder, the motor drives a cutting knife to rotate, automatic cutting of the wooden cylinder is realized, the tedious processing procedure is simplified, and no using the hand-held cutting knife is further required.

Owner:临沂临港国有资产运营集团有限公司

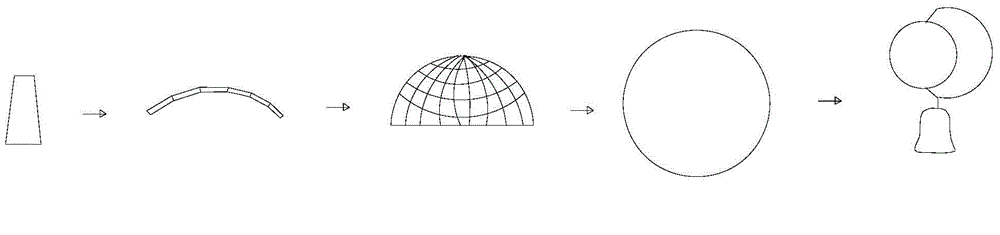

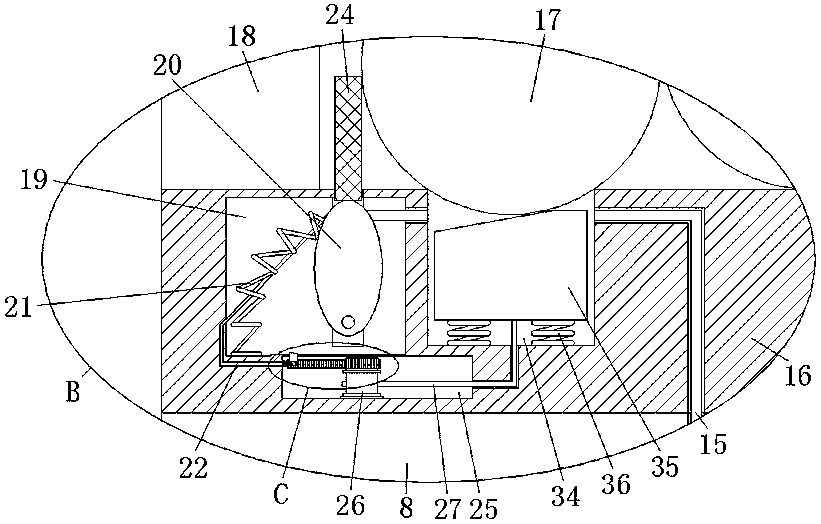

Tellurion producing device with automatic milling cutter device

InactiveCN104626316AWarm appearanceReduce releaseRounding machinesProfiling/shaping machinesSolid woodHazardous substance

The invention discloses a tellurion producing device with an automatic milling cutter device. The tellurion producing device comprises a saw blade device for cutting a flat plate into saw sections, a trimming device for sawing away redundant leftover materials on the saw sections, the automatic milling cutter device for trimming a ball blank into a smooth ball and a semiautomatic milling cutter device for manufacturing a frustum-shaped base. The tellurion producing device is easy to manufacture and convenient to use, an excellent tellurion can be manufactured and is made of solid wood, released hazardous substances are extremely few, and the device is beneficial to health and environment. Meanwhile, the made tellurion is mild in appearance, high in overall grade and dignified.

Owner:安徽爱乐门窗系统工程有限公司

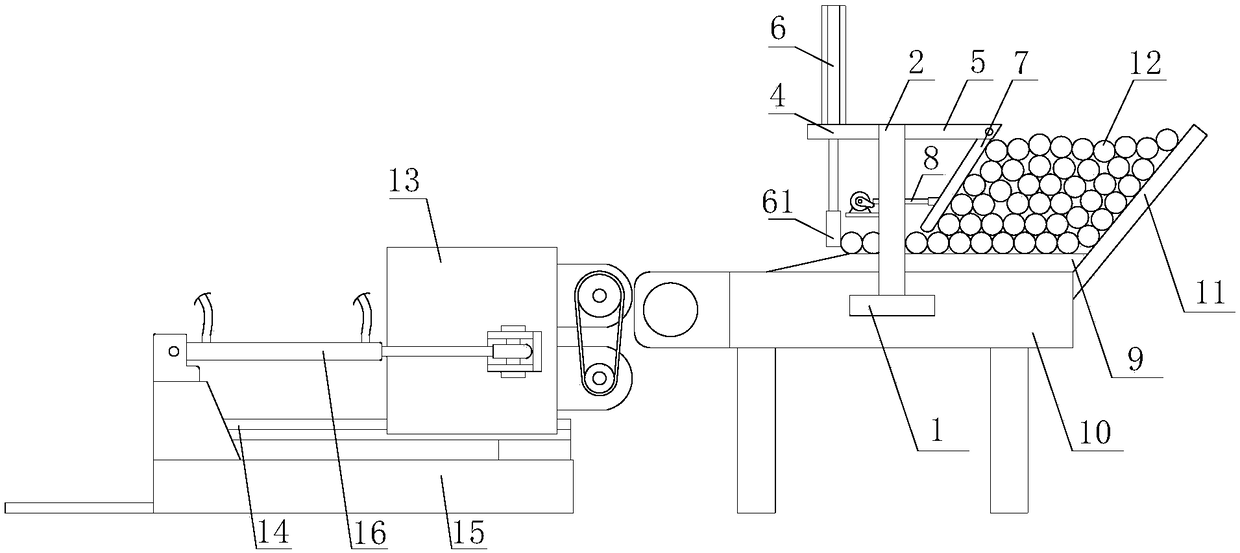

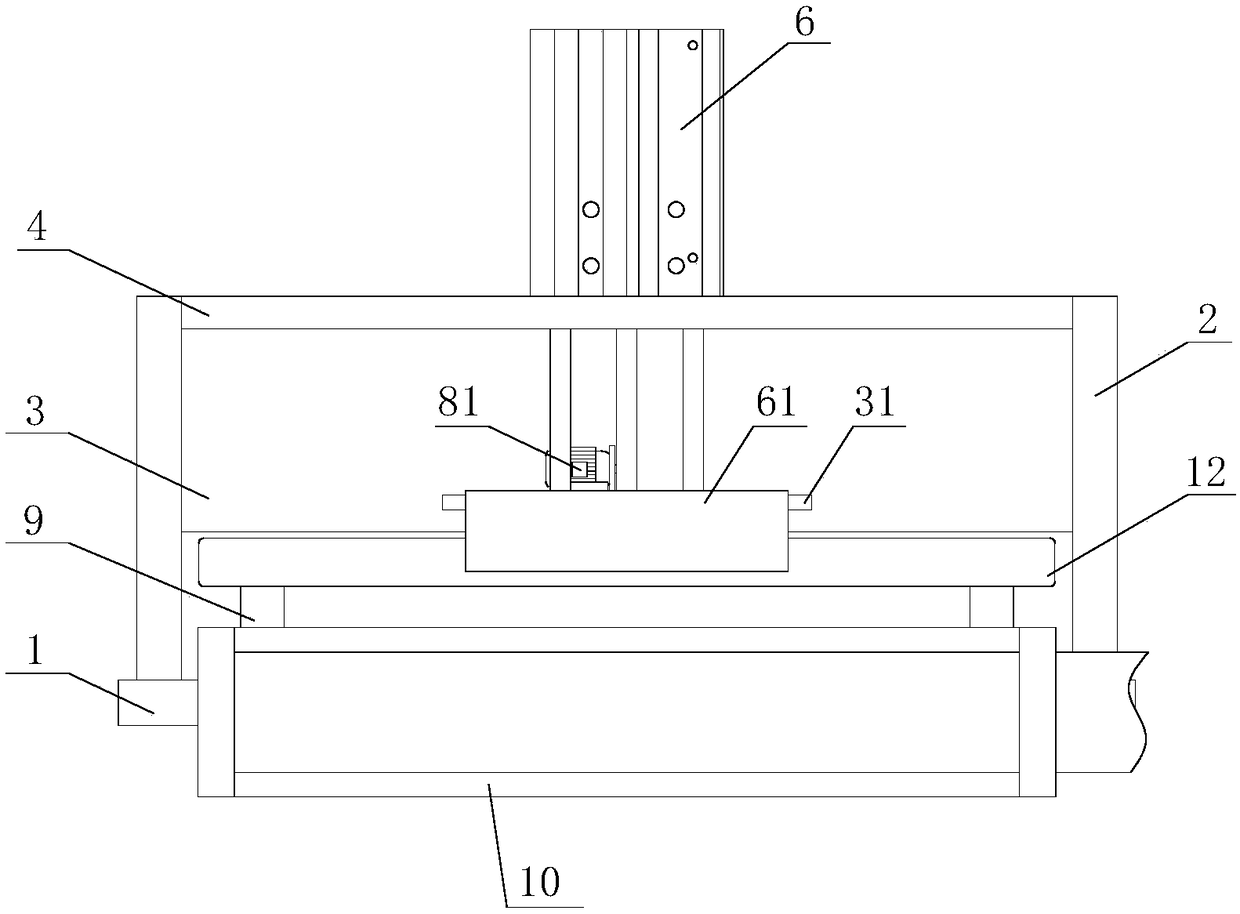

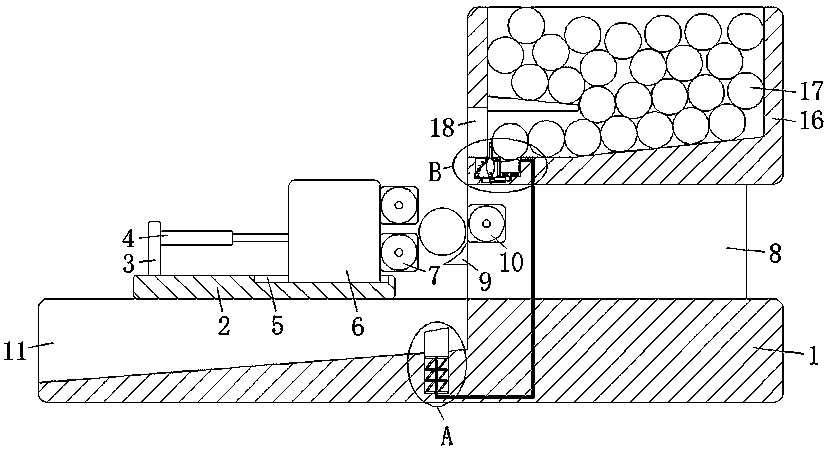

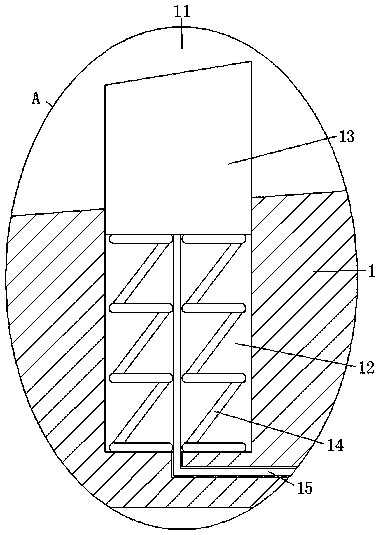

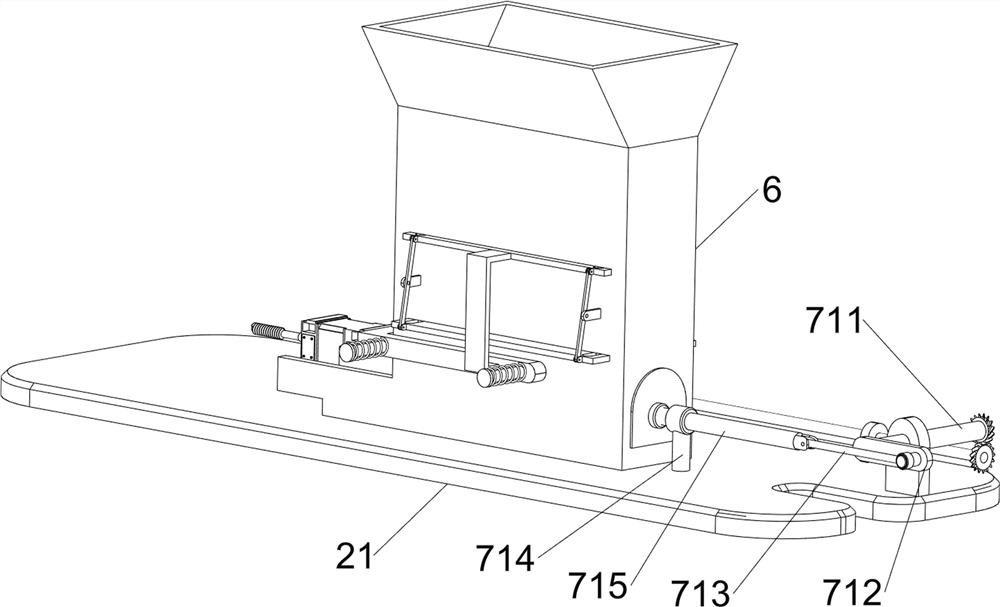

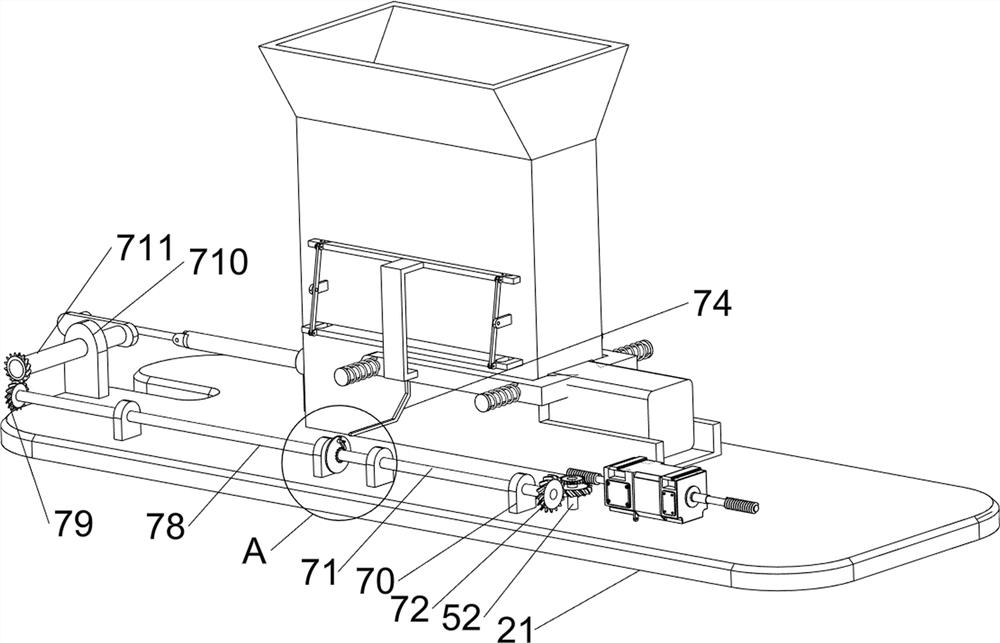

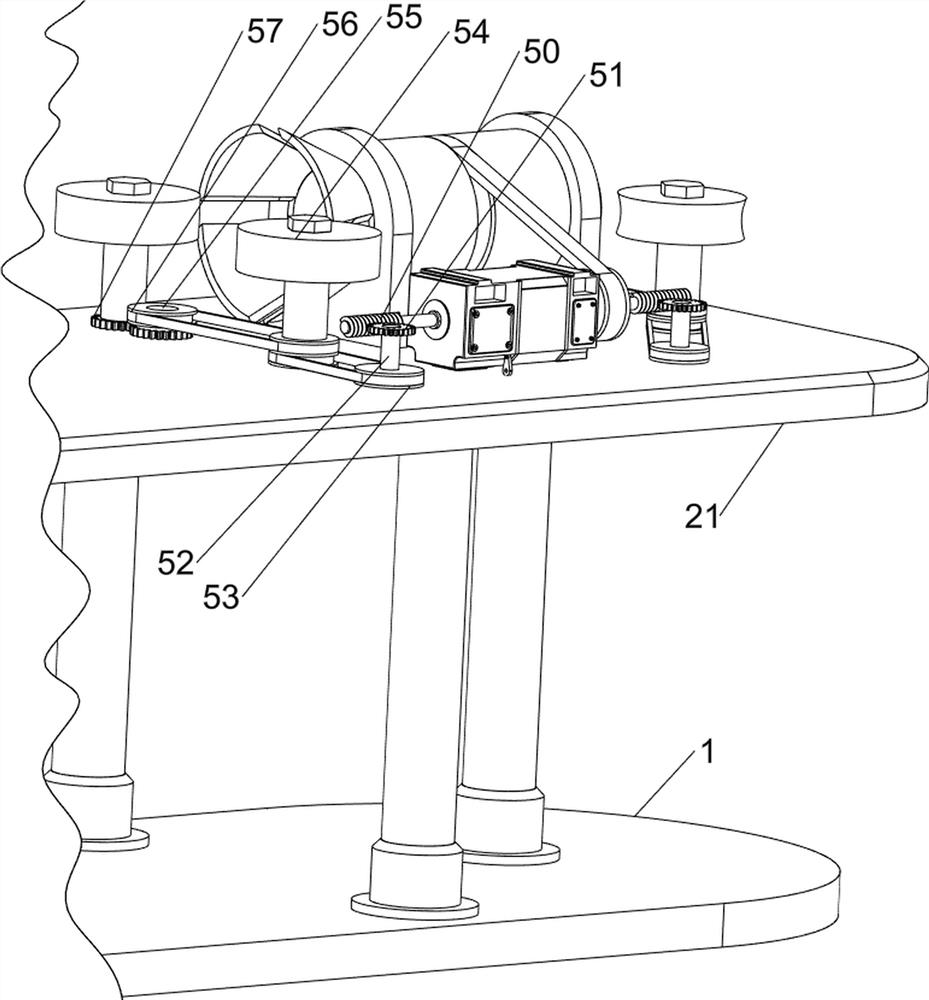

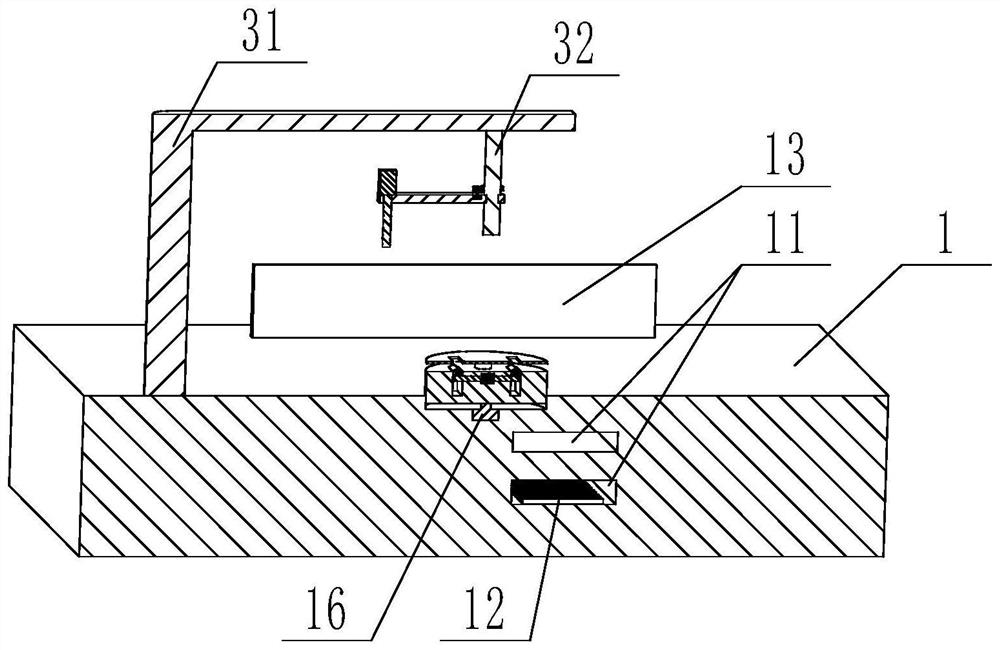

Feeding device of wood rounding machine and operation method of feeding device

The invention device discloses a feeding device of a wood rounding machine and an operation method of the feeding device. The feeding device comprises bottom plates, vertical plates, a drive air cylinder, a movable baffle and a loosening device. A first upper plate is vertically provided with the drive air cylinder, and an output rod of the drive air cylinder penetrates one end of the first upperplate to be fixedly connected with a check block. A second upper plate is connected with the obliquely-arranged movable baffle in a hinged manner. The movable baffle is connected with the loosening device. The tail end of a feeding platform is connected with a fixed baffle in a welded manner. The loosening device comprises a motor, a cam, a push rod and a limiting plate. A rotating shaft of the motor is provided with the cam through a spline. The cam is connected with the push rod in a contact manner, the push rod movably penetrates a middle plate, the other end of the push rod is fixedly connected to the movable baffle, and the push rod is fixedly sleeved with a limiting plate. According to the feeding device of the wood rounding machine and the operation method of the feeding device, collapsing of accumulated wood bars is prevented, safety is improved, the situation that workers are physically hurt and equipment is damaged is avoided, and the problem that no protection measures are taken to the accumulated wood bars during existing manual feeding, and consequently dangerousness is great large is solved.

Owner:MAANSHAN RUNMA MACHINERY MFG

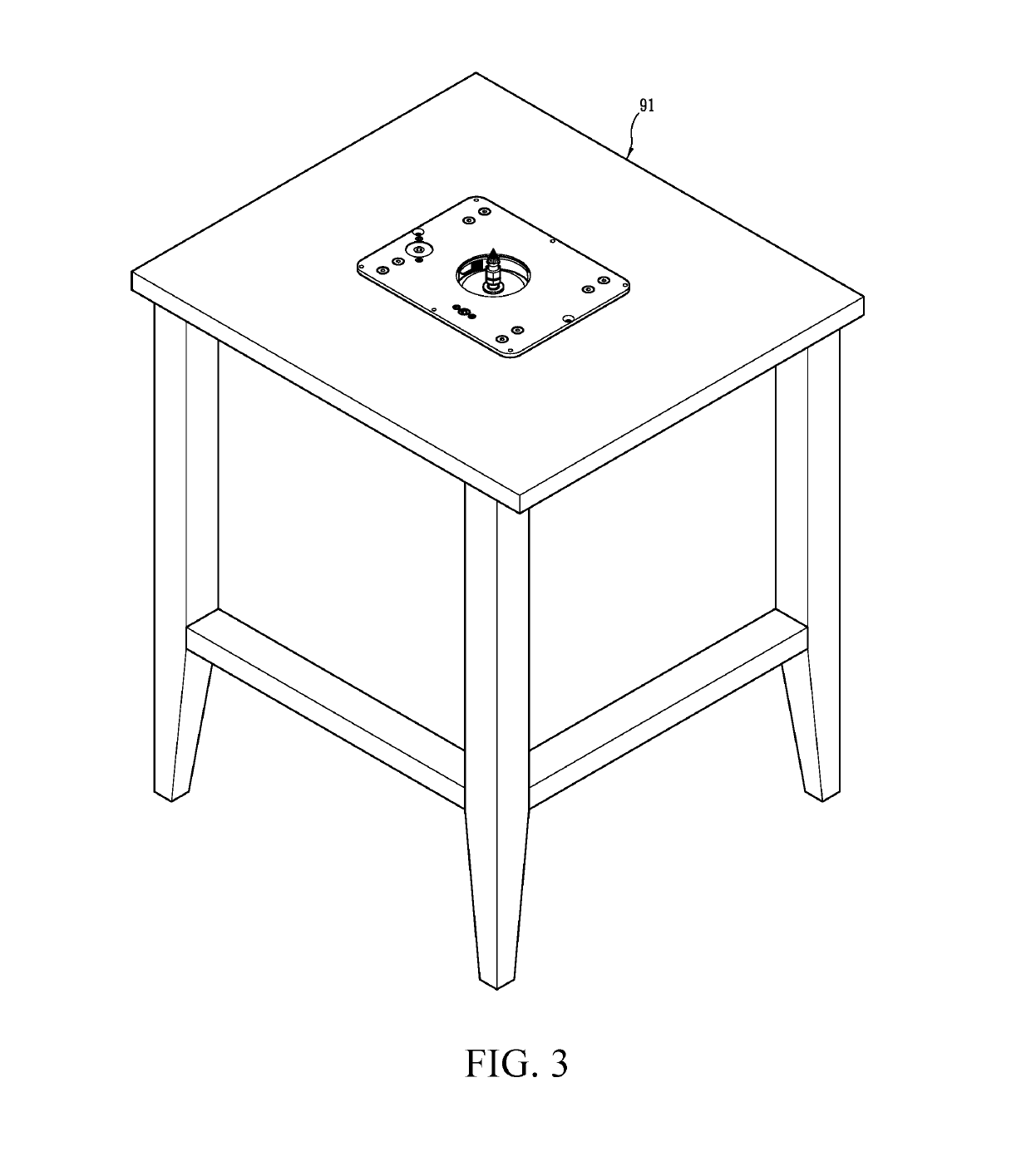

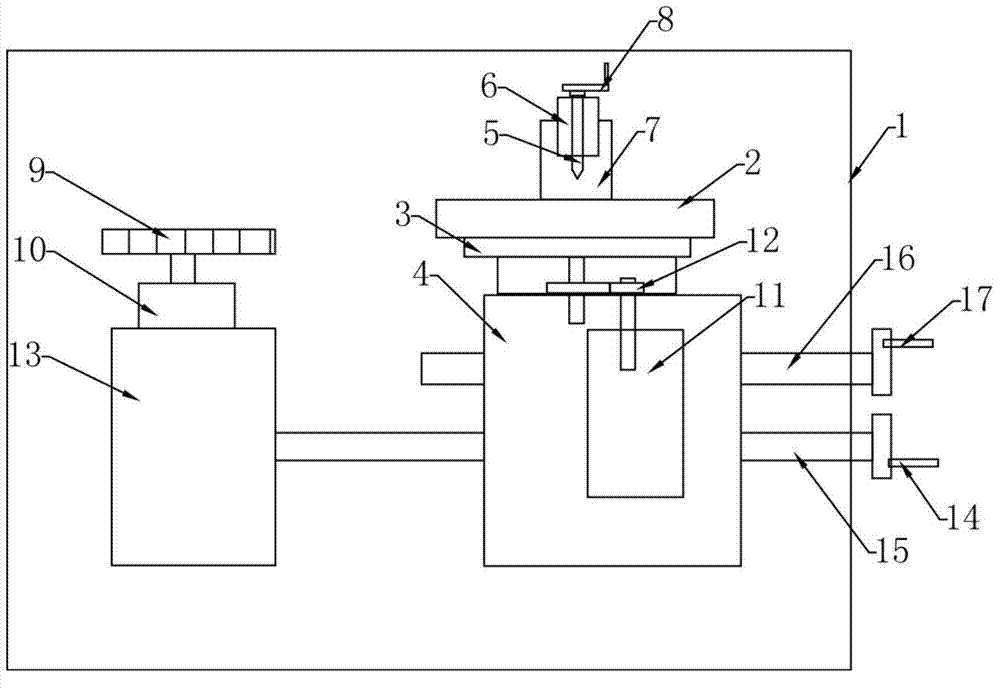

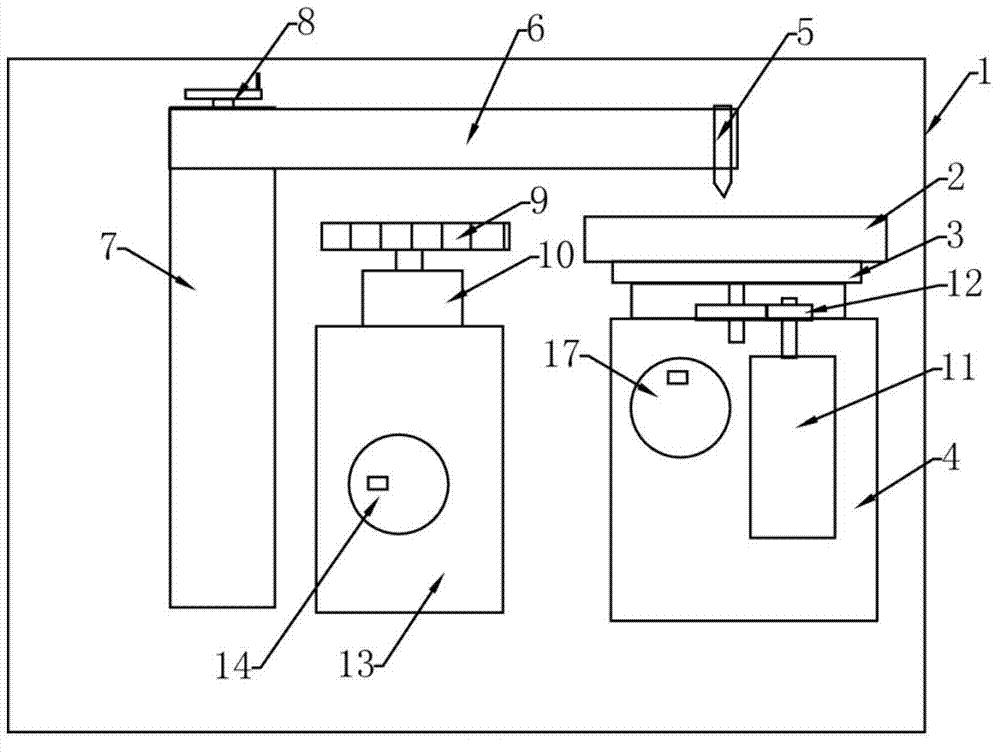

Chopping board round edge processing machine and chopping board round edge processing method

ActiveCN104325521AOvercome cumbersomeOvercome efficiencyRounding machinesMilling cutterCircular motion

The invention relates to the technical field of chopping board processing, and discloses a chopping board round edge processing machine and a chopping board round edge processing method. The chopping board round edge processing machine comprises a bracket, a locating device and a cutter device; the bracket comprises a tray used for placing a chopping board and a tray bracket used for supporting the tray; the locating device comprises an ejector pin and an ejector pin lifting mechanism; the ejector pin is arranged above the tray; the ejector pin lifting mechanism is connected with the ejector pin and is used for driving the ejector pin to move up and down; the cutter device comprises a milling cutter and a milling cutter rotating mechanism used for driving the milling cutter to rotate around the self center axis; the milling cutter is arranged at one side of the tray, at least one out of the milling cutter and the tray can translate relative to the other one; when the round edge of the chopping board is processed, the milling cutter makes circular motion along the horizontal direction around the tray, and / or the tray rotates around the self center axis. The chopping board round edge processing machine is capable of automatically cutting the round edge of the chopping board, the problems that the existing manual chopping board round edge processing method is complicated in process, low in efficiency and poorer in product quality can be solved, and the working efficiency is greatly improved.

Owner:泰州市海鑫高新技术投资发展有限公司

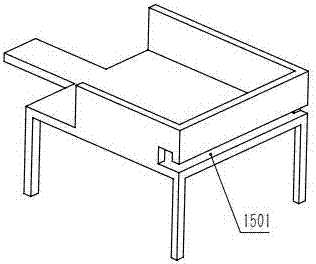

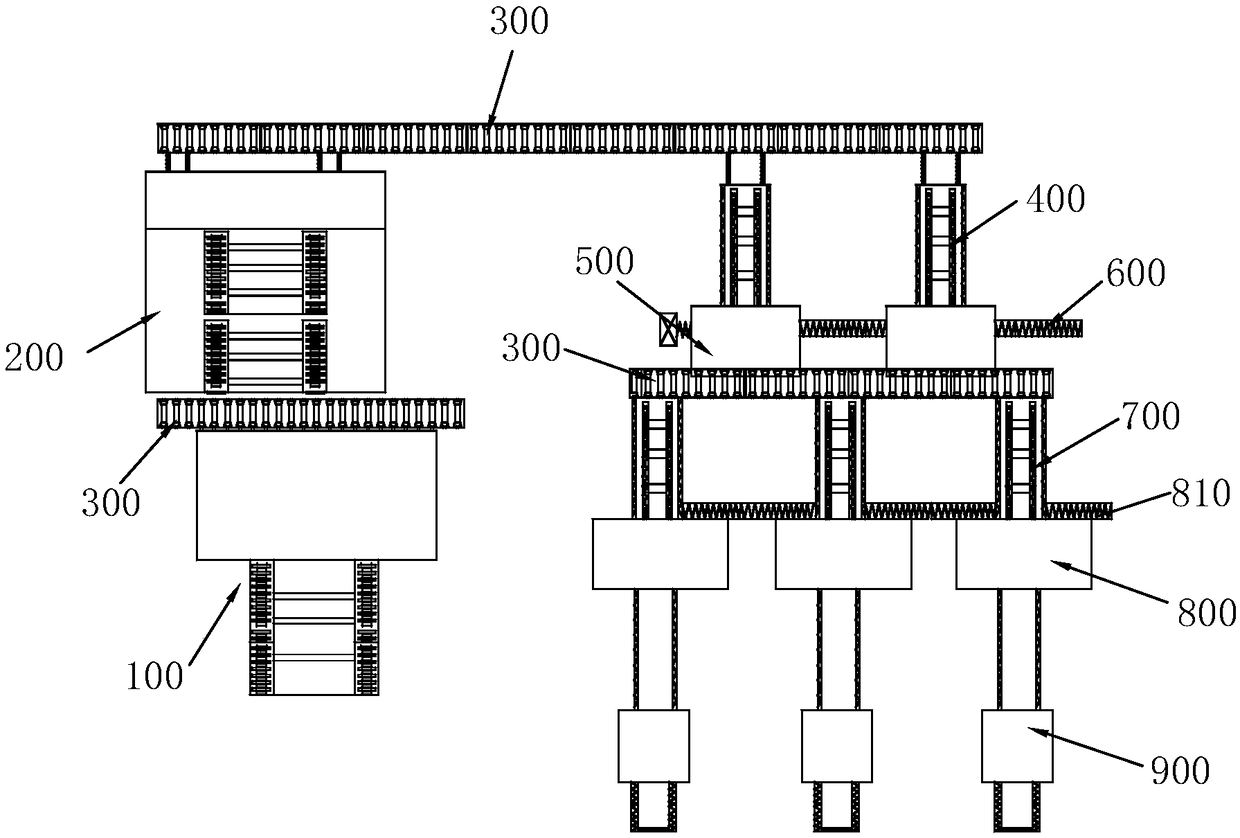

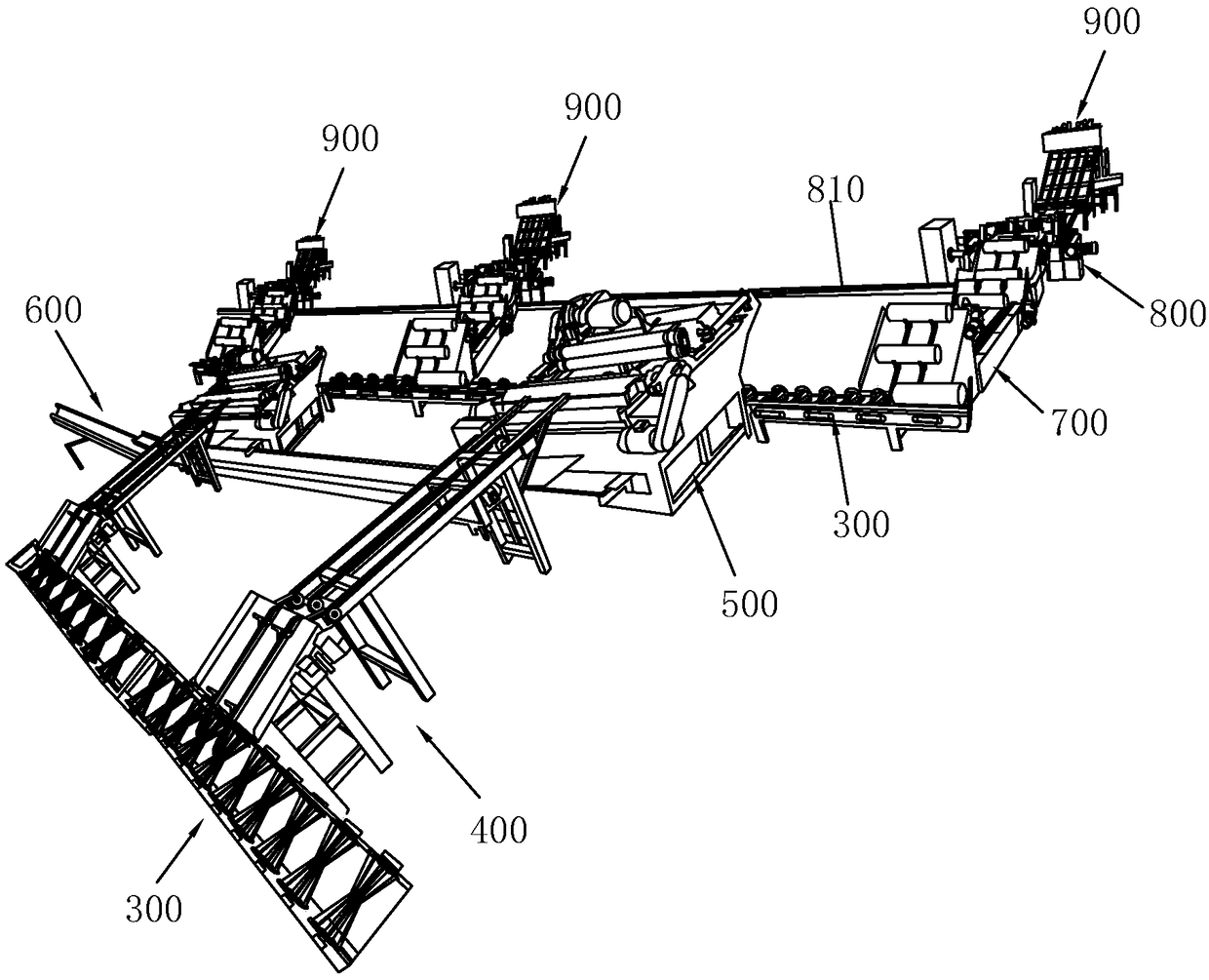

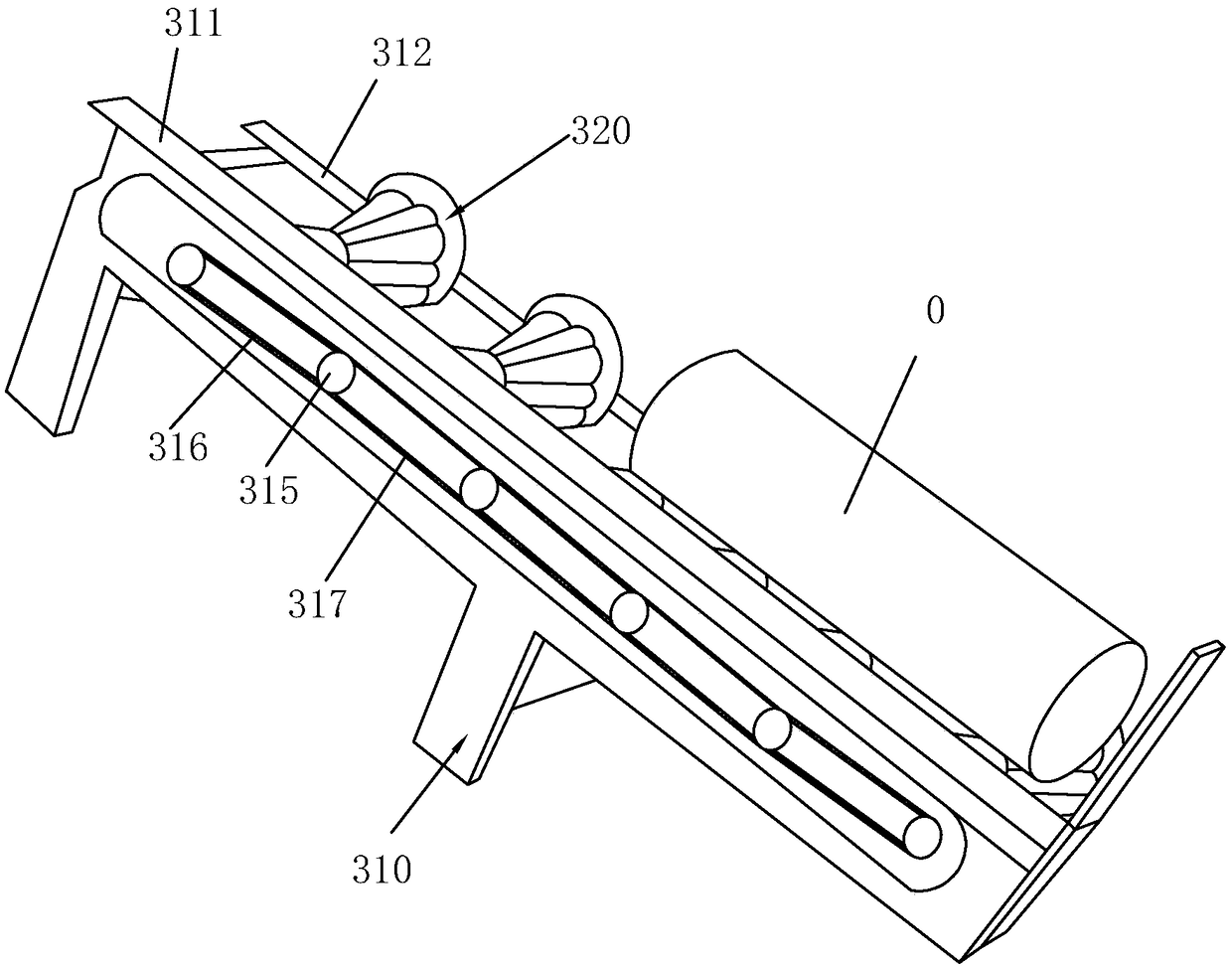

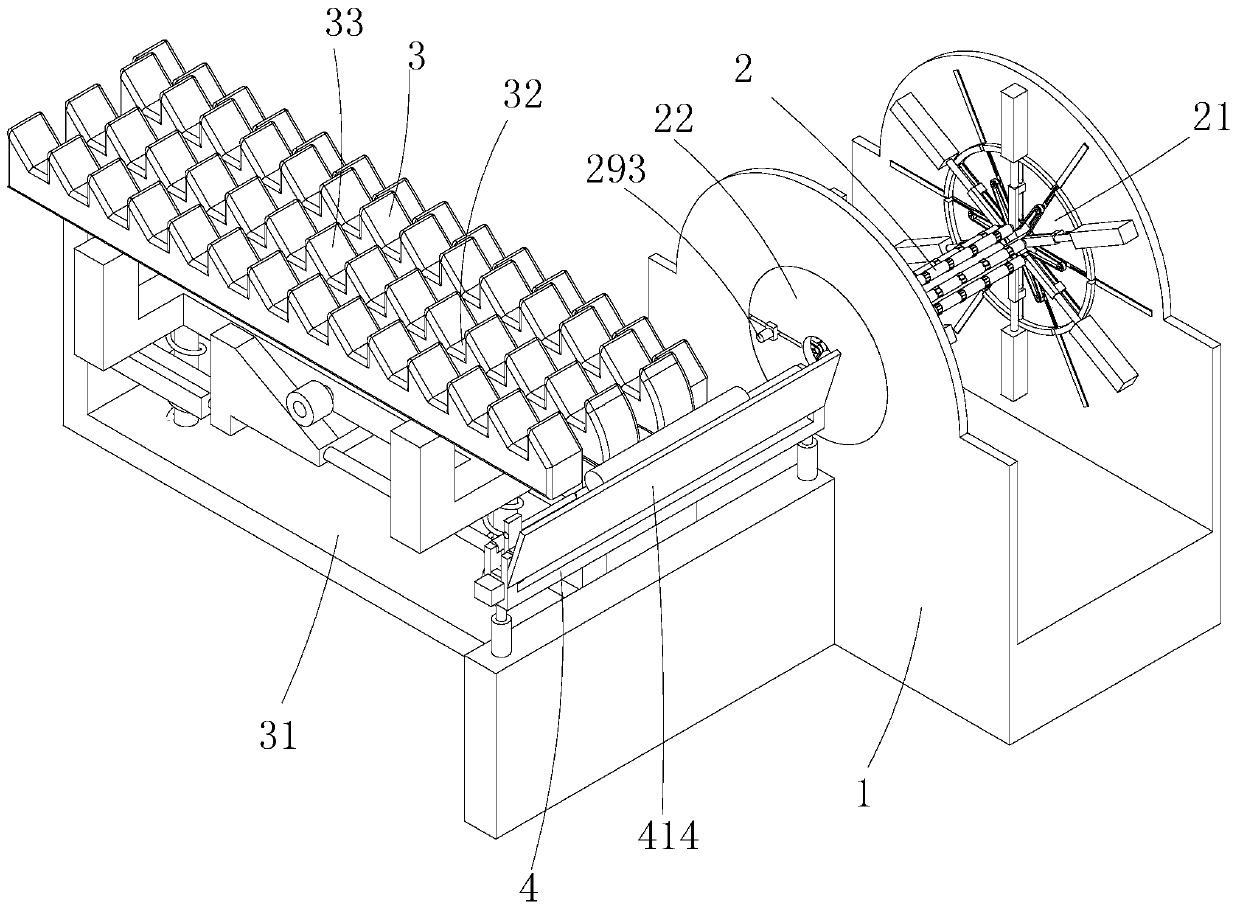

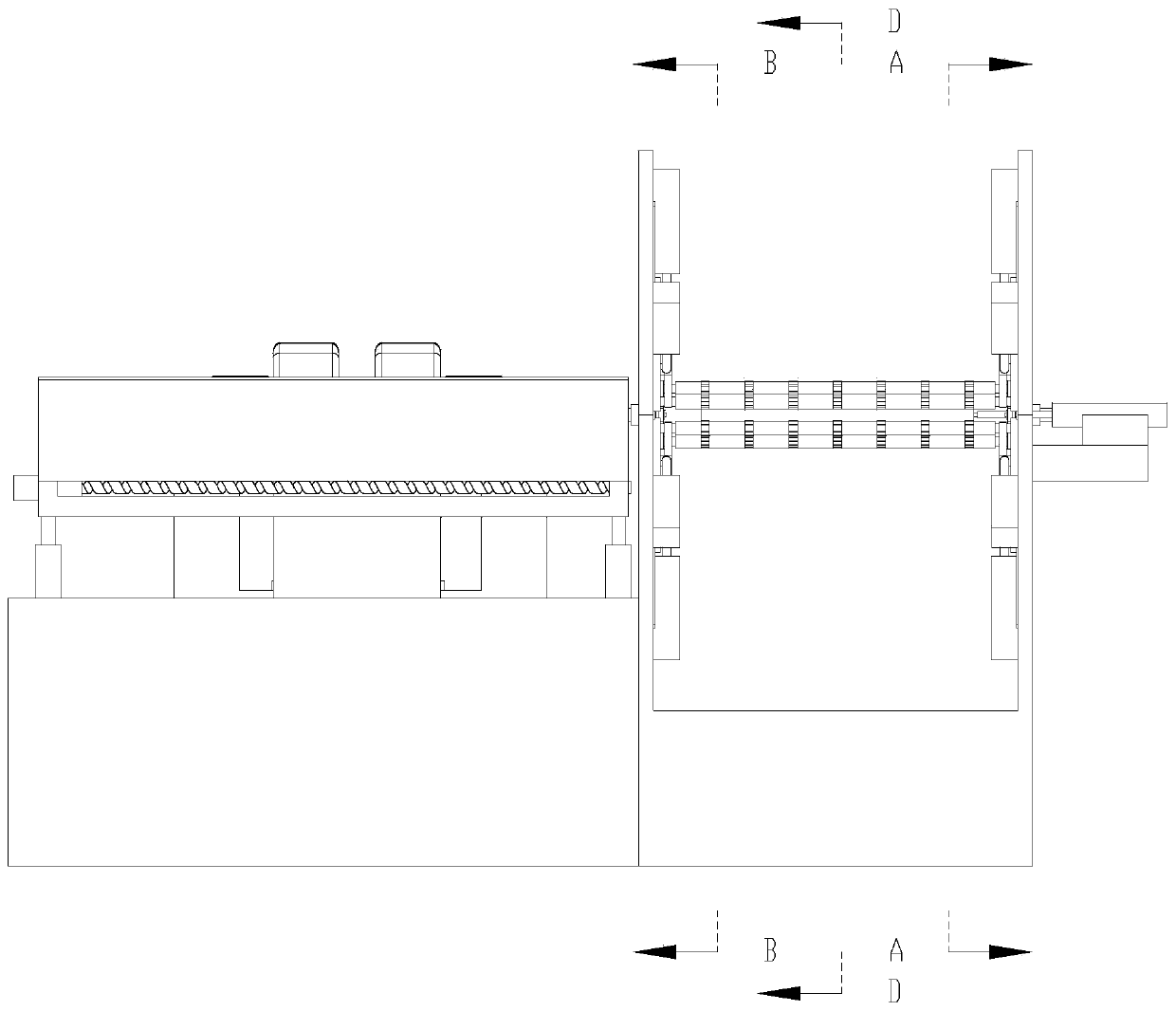

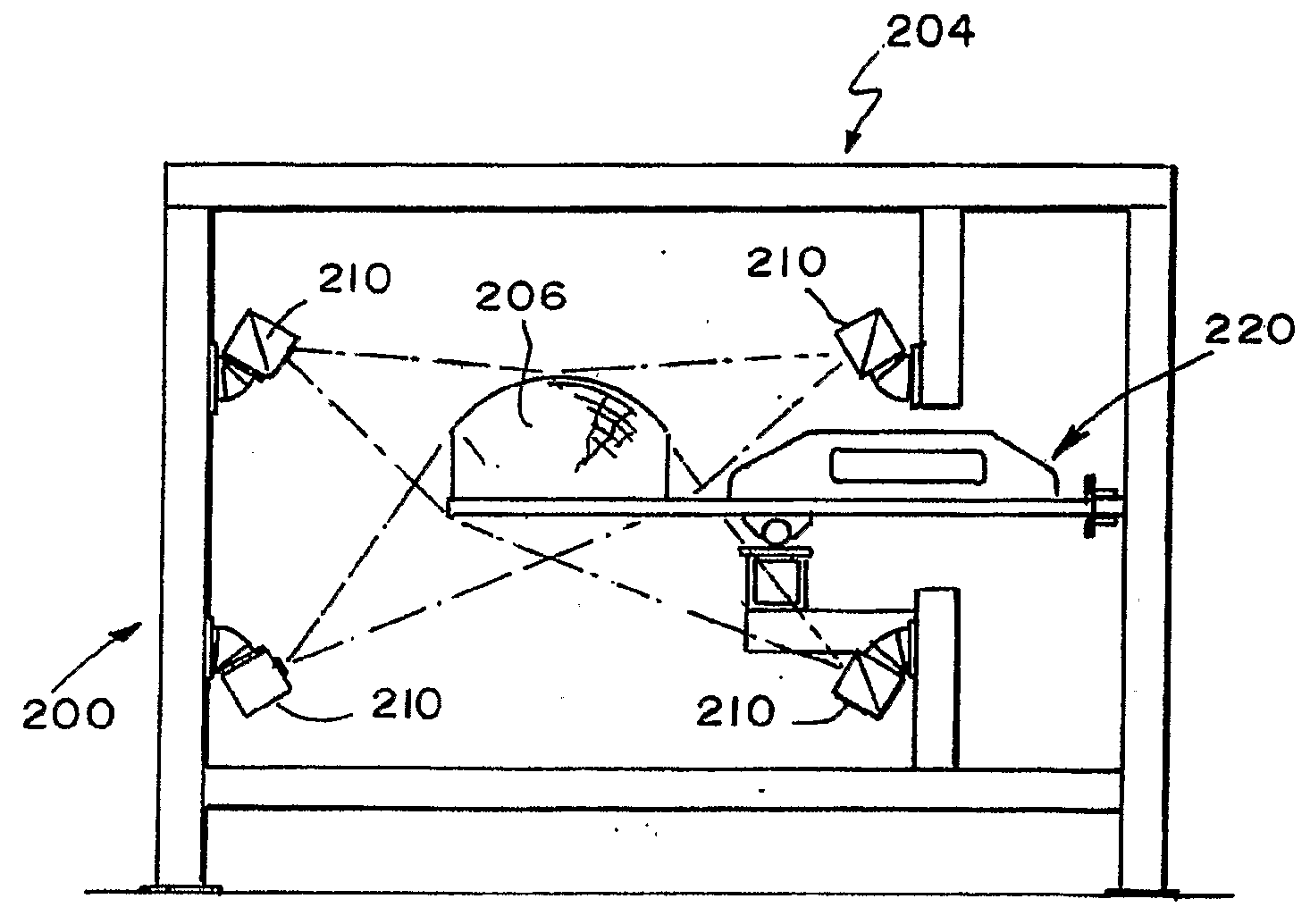

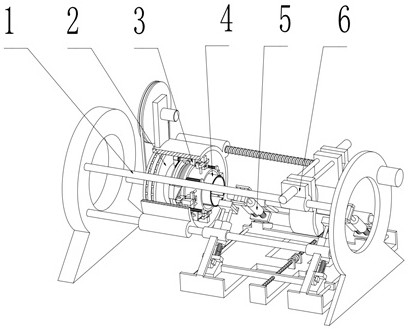

Integral wood processing system

PendingCN109203116AReduce manufacturing costIncrease productivityFeeding devicesRounding machinesPulp and paper industryWood processing

The invention relates to the technical field of wood processing equipment, and especially relates to an integral wood processing system. Compared with the prior art, the integral wood processing system is composed of a round timber loading device, a sorting and cutting device, an impeller type timber conveying device, a transportation linking device, a polishing and rounding device, a waste lifting device, a wave type loading device, a high speed rotation slicing device, and a waste removing and plate receiving device. The whole process comprises sorting, cutting, conveying, station transmitting, rounding, waste discarding, slicing, and plate receiving and is automatically controlled, the number of operators is reduced, the production cost is greatly reduced, the production efficiency is improved, and the product quality is improved.

Owner:福建善诚木业科技有限公司

Bruting machine for furniture processing, and processing method thereof

InactiveCN111516061AGuarantee normal progressSave human resourcesRounding machinesTree debarkingProcess engineeringMachine

The invention discloses a bruting machine for furniture processing. The bruting machine for furniture processing comprises a base and a piece to be bruted, wherein a first drive mechanism is fixedly connected to the upper end of the base; a second drive mechanism opposite to the first drive mechanism is fixedly connected to the upper end of the base; an inclined discharge hole is formed in the upper end of the base; a sliding mechanism is arranged on the inner bottom part of the discharge hole; a storage tank is fixedly connected to the upper end of the second drive mechanism; the piece to bebruted is placed in the storage tank; a discharge chute is arranged on the side wall of the storage tank in a penetrating way; an inclined guide plate is fixedly connected to the inner side wall of the storage tank; an abutting mechanism abutted against the piece to be bruted is arranged on the storage tank; and the free end of the sliding mechanism is fixedly connected with the side wall of the abutting mechanism. The bruting machine for furniture processing is reasonable in structure design, capable of automatically loading pieces to be bruted one by one, and beneficial to saving the manpower resource and guaranteeing the working efficiency.

Owner:苟明

Round log trimming device

The invention discloses a log trimming device which comprises a rack, a rotating component, a radial adjusting component, a trimming component, a concentric adjusting component and a clamping and conveying component. An inlet is formed in a second rack base, concentric adjustment is conducted through the concentric adjusting component, and the trimming circle center of wood is made to be the sameas the rotating circle center of a trimming tool; the clamping and conveying component is used for clamping and conveying wood, and continuous trimming action is conducted; through belt rotation, a rotary drum is made to rotate, and the trimming tool is made to rotate; and the rotation radius of the trimming tool is adjusted through the radial adjusting component, and the trimming radius of the trimming tool is changed. The log trimming device is novel in structure, uneven parts on the wood are trimmed, and the working efficiency is high.

Owner:华琳琳

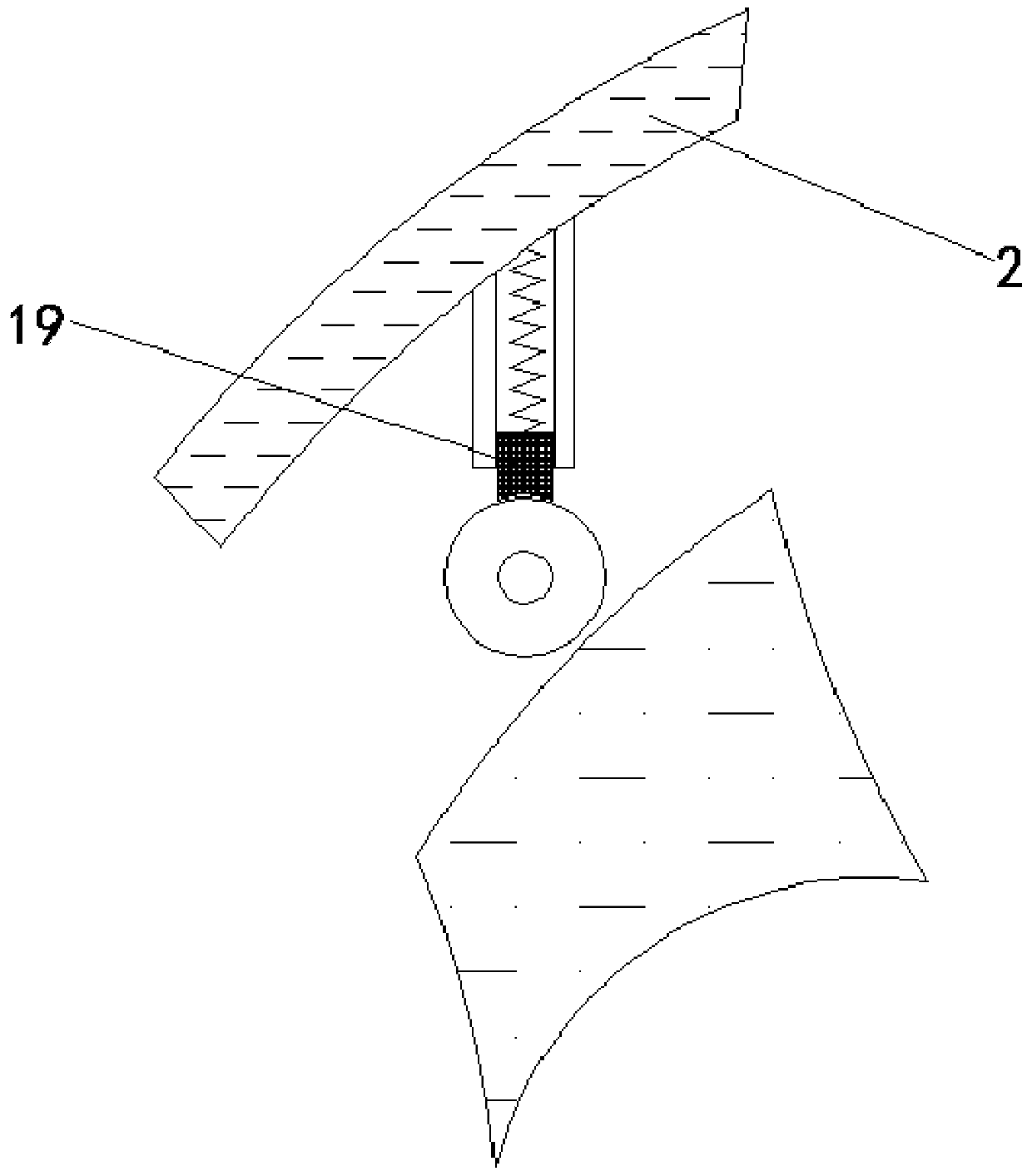

Rope molding jig

A stock-shaping machine is operable to shape elongated stock and includes a powered machine and a jig. The powered machine includes a feed mechanism shiftably mounted relative to a frame so as to feed stock through the machine. The machine also includes a shaping device supported relative to the frame to shape the stock during feeding thereof. The elongated jig orients the stock so that an axis of the stock is at least generally parallel to a jig axis. The jig permits rotation of the stock relative to the jig about the stock axis and longitudinal sliding of the stock along the jig. The jig is mounted with the jig axis at an oblique angle relative to a machine feed axis so that shifting of the feed mechanism causes rotation and longitudinal sliding of the stock.

Owner:WOODMASTER TOOLS

Columnar wood machining device

InactiveCN109352745AFast processingReasonable designWooden sticks manufactureRounding machinesWood machiningAnnular cutter

The invention discloses a columnar wood machining device. The device comprises a seat body provided with rolling wheels, and is structurally characterized in that a columnar blind groove which extendsdownwards from the top surface is formed in the seat body, at least three inserting openings communicating with the columnar blind groove are formed in the side wall of the seat body, and the three inserting openings are linearly arranged from top to bottom; each inserting opening is internally provided with a cutting frame in an inserted mode; a round opening with the same diameter as the columnar blind groove is formed in each cutting frame, and an annular cutter is arranged on each round opening; and an annular groove which is coaxial with the columnar blind groove is formed in the seat body, threads are arranged in the wall of the annular groove, and a wood fixing cylinder provided with external threads is cooperatively arranged. Compared with the prior art, the device has the beneficial effects that the design is reasonable, the structure is simple, and column-shaped woods can be quickly machined; and in addition, the coaxiality can be guaranteed during machining, eccentric machining is avoided, so that the machining quality is guaranteed.

Owner:泗阳县联吉木业有限公司

Wood rod forming equipment for wood processing

PendingCN112621956ANo manual push requiredSave human effortWooden sticks manufactureRounding machinesAgricultural engineeringWood machining

The invention relates to wood rod forming equipment, in particular to wood rod forming equipment for wood processing. According to the wood rod forming equipment for wood processing, a cutter does not need to be manually used for cutting wood, and the wood is mechanically cut into wood rods. According to the technical scheme, the wood rod forming equipment for wood processing comprises a bottom plate and a circle cutting mechanism, and a supporting mechanism is arranged at the top of the bottom plate; and the circle cutting mechanism is arranged on the supporting mechanism. Through cooperation of the supporting mechanism and the circle cutting mechanism, after a worker puts wood well, a motor is started to work, and meanwhile, the wood is pushed to move rightwards to be cut into the wood rod; and through the cooperation of a discharging mechanism and a feeding mechanism, after the worker puts the wood rods well, the wood can be moved to be cut without manual pushing, and the worker only needs to continuously put the wood to be cut well.

Owner:蔡宦翼

Wood product machining equipment

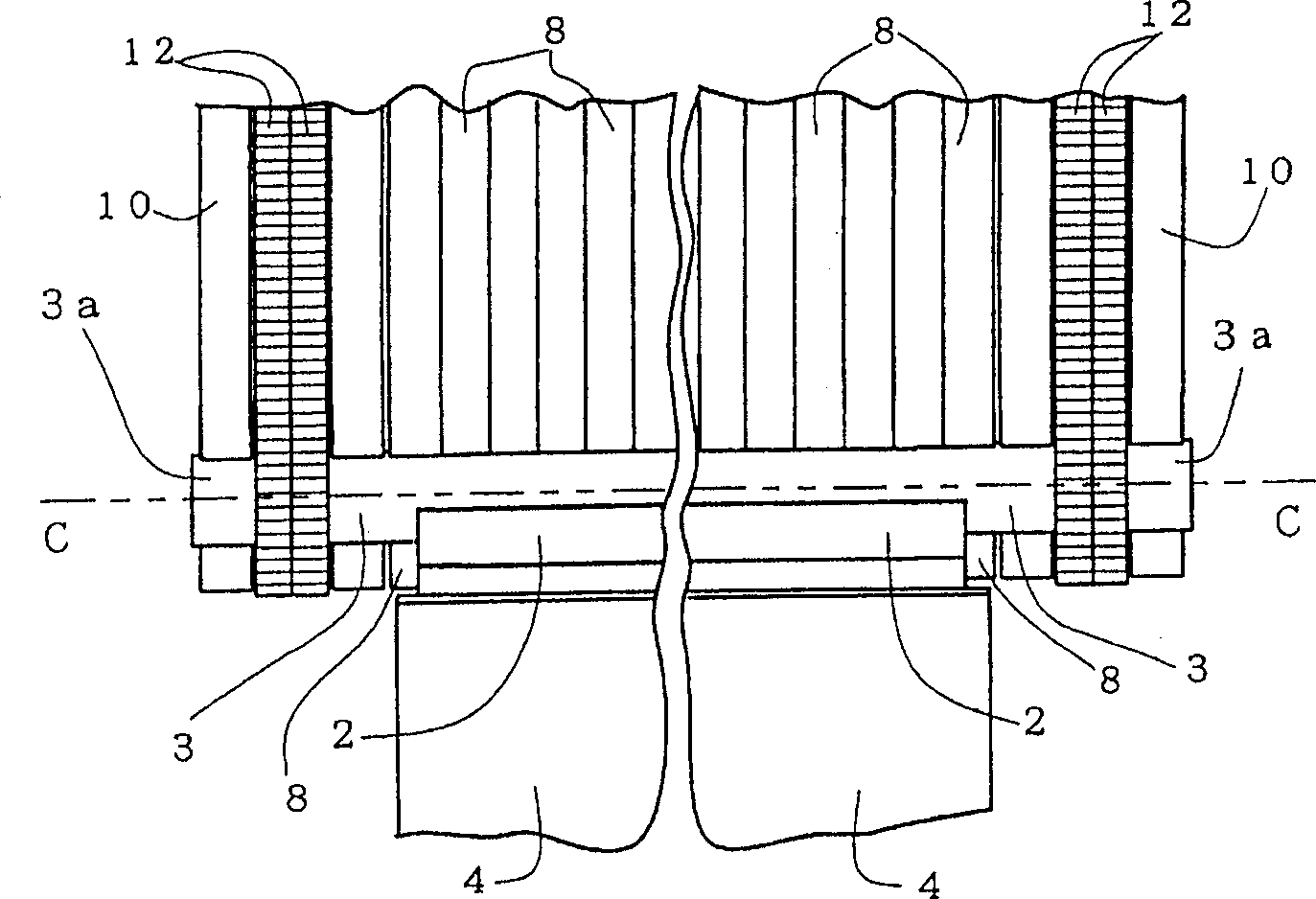

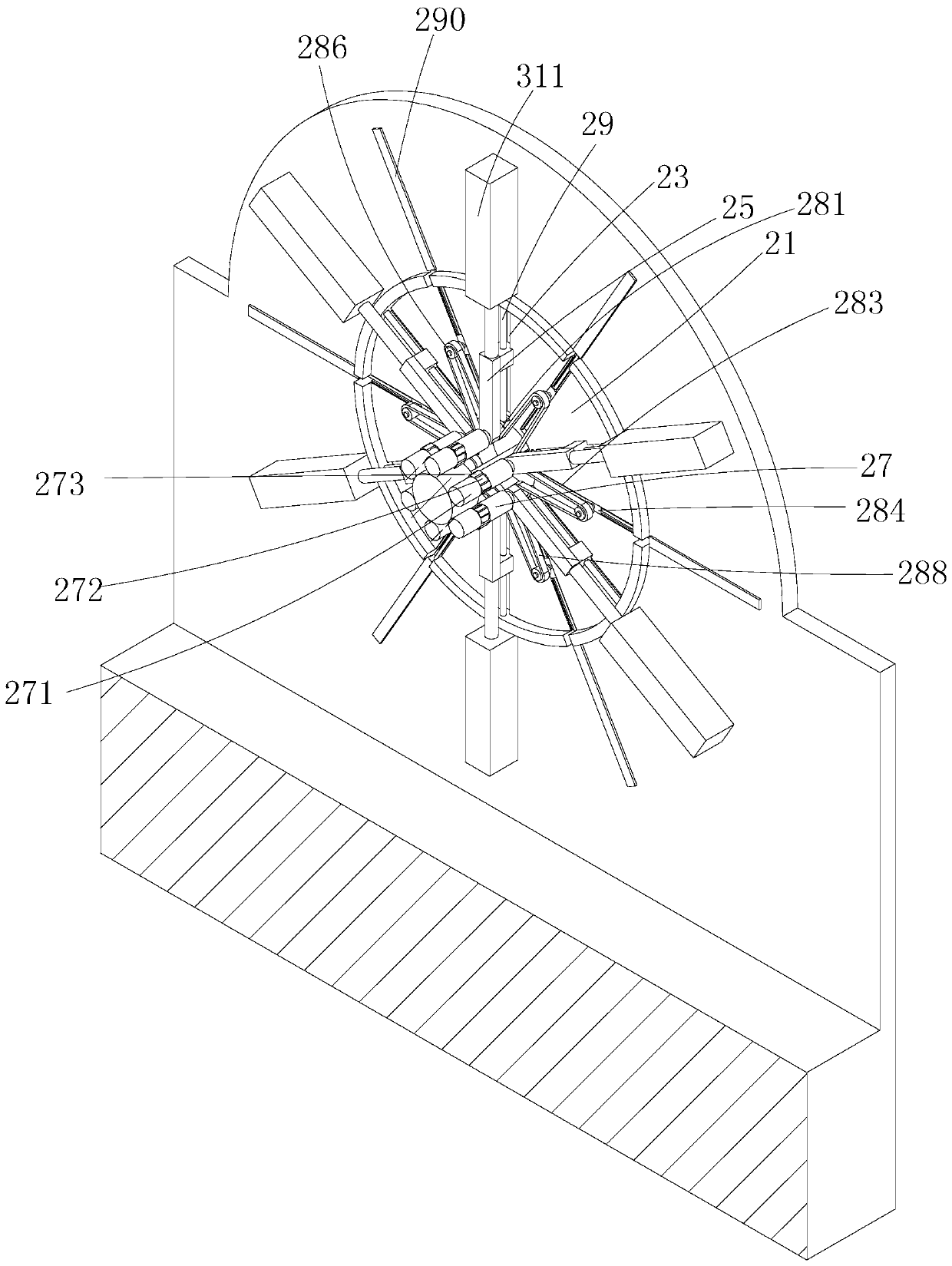

ActiveCN111571750ARotary cutting holdGuaranteed to move normallyRounding machinesVeneer manufactureHydraulic cylinderMachine

The invention discloses wood product machining equipment. The wood product machining equipment comprises a machine body, a transmission device arranged on the machine body and used for rotating logs,a conveying device used for conveying the logs and pushing devices arranged at the two ends of the transmission device, wherein the transmission device comprises a first base, a second base, a plurality of first sliding grooves annularly distributed in the first base at equal intervals, a plurality of second sliding grooves annularly distributed in the second base at equal intervals, a plurality of first sliding bases movably arranged on the plurality of first sliding grooves respectively, a plurality of second sliding bases movably arranged on the plurality of second sliding grooves respectively, a plurality of driving rollers with the two ends rotationally arranged on the plurality of first sliding bases and the plurality of second sliding bases correspondingly, a driving assembly for driving the plurality of driving rollers to rotate in the same direction, a plurality of first hydraulic cylinders for driving the plurality of first sliding bases to move and a plurality of second hydraulic cylinders for driving the second sliding bases to move. According to the wood product machining equipment, waste of the logs can be greatly reduced, and the rotating efficiency of the logs and the surface quality of veneers obtained after rotary cutting are ensured.

Owner:浙江景宁华寅工艺品有限公司

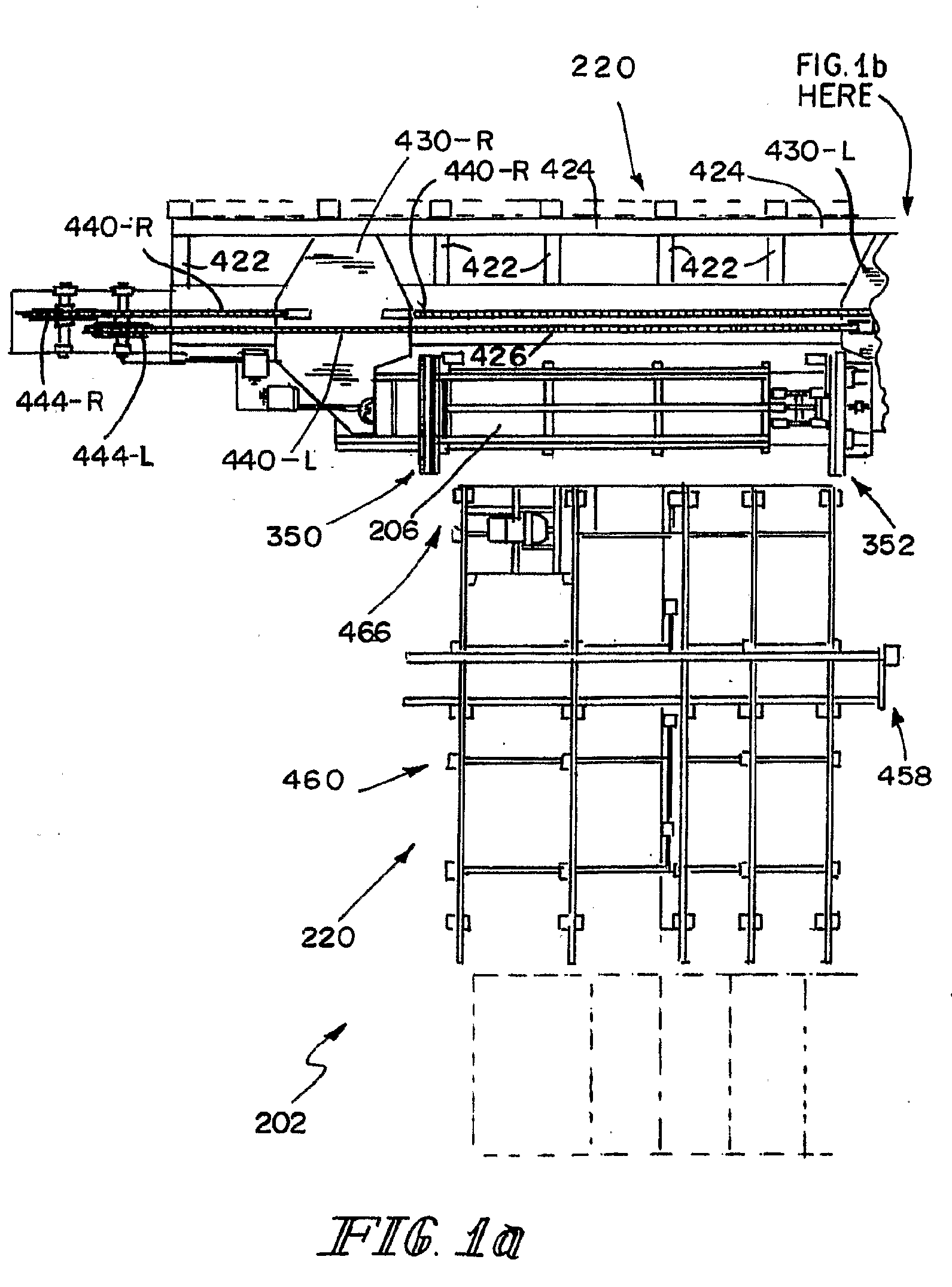

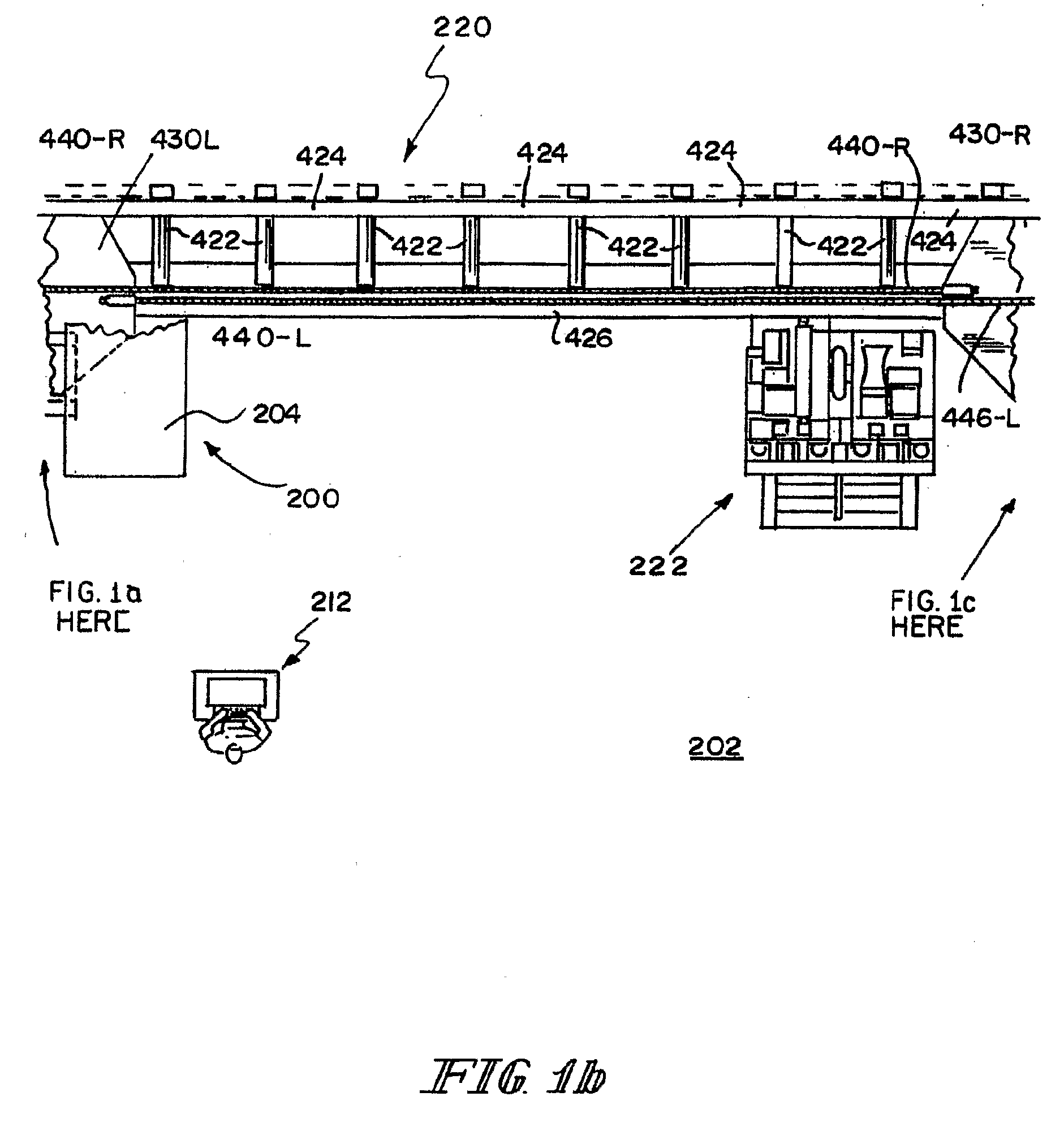

Flitch planer

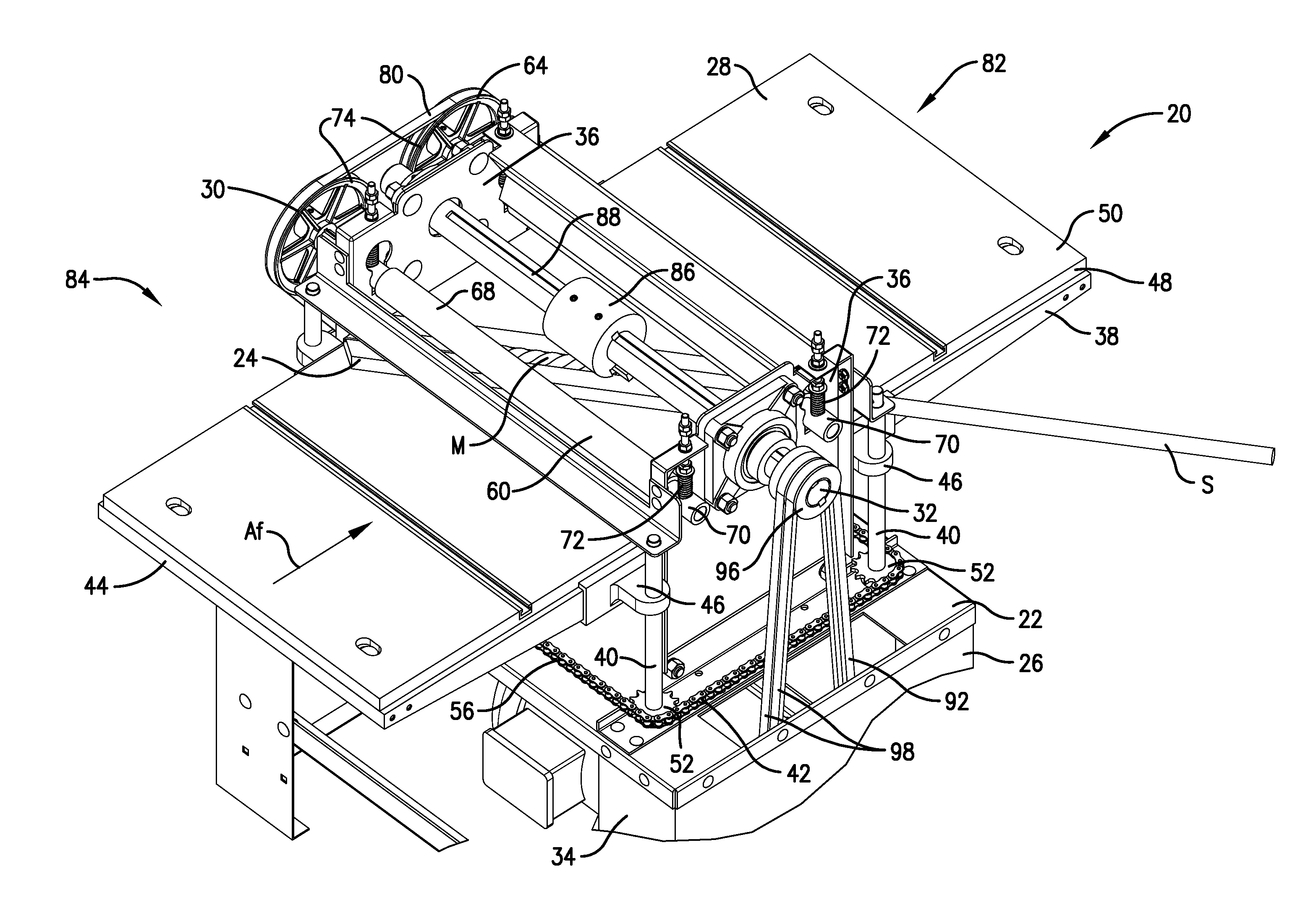

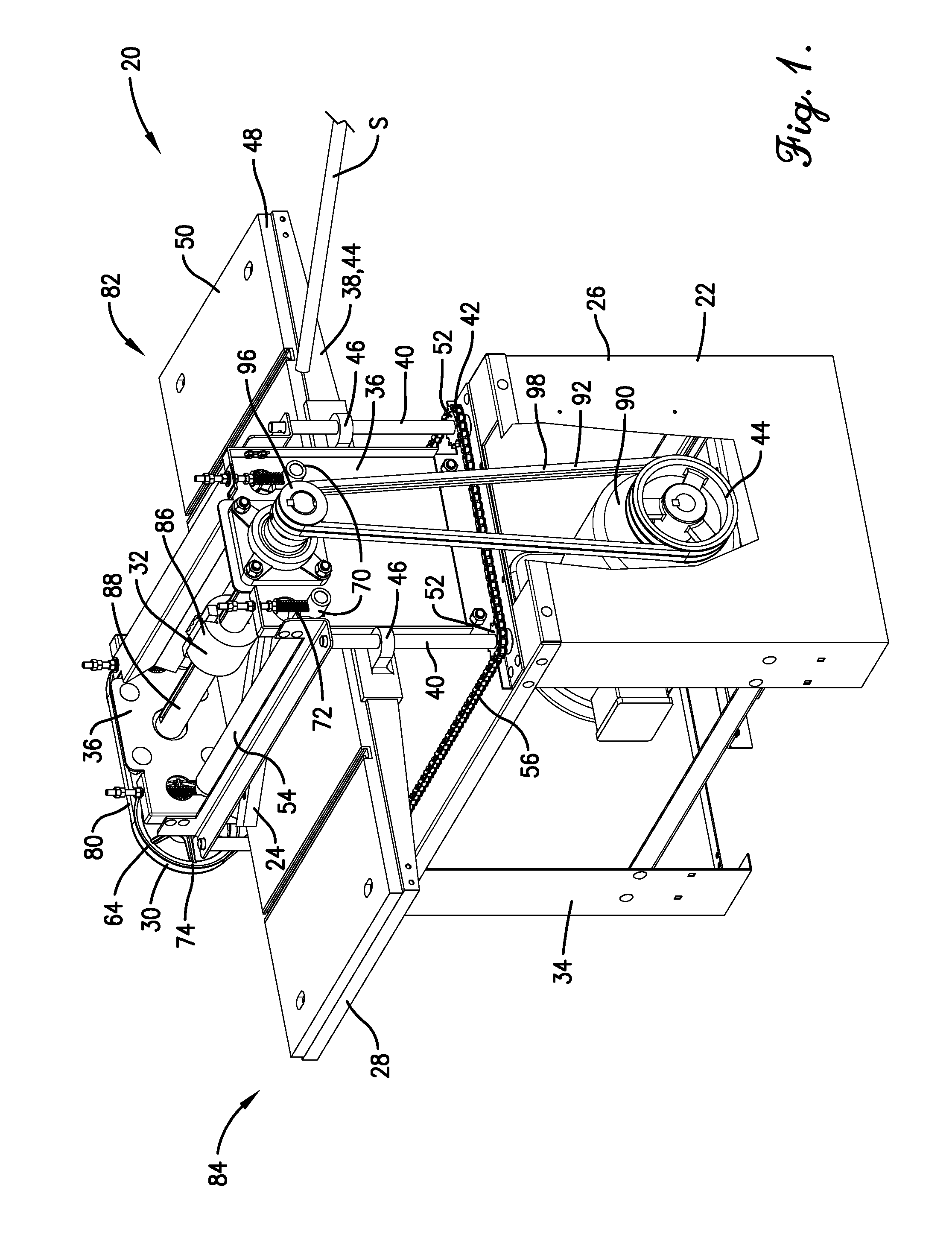

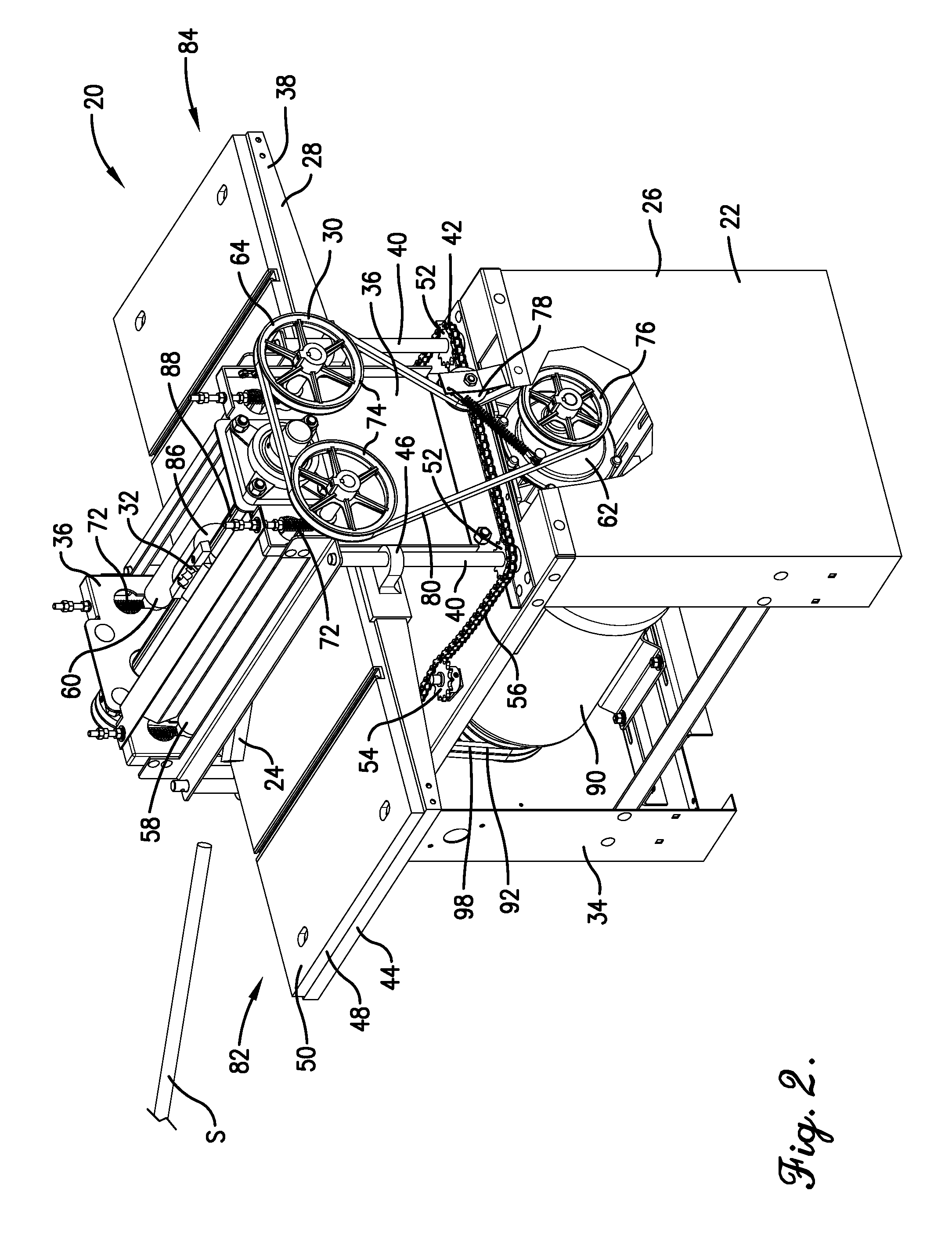

InactiveUS20090173411A1Wood feeding arangementsAutomatic control devicesEngineeringMechanical engineering

Apparatus for shaping a flitch includes an upper shaping head assembly for shaping an upper surface of the flitch, a lower shaping head assembly for shaping a lower surface of the flitch, and a groover assembly for placing at least one groove in a surface of the flitch. The apparatus further includes at least one centering arm and chain runner assembly. The at least one centering arm and chain runner assembly includes a chain runner assembly for conveying the flitch toward a transverse center of the centering arm and chain runner assembly, and a centering arm assembly for positioning the flitch. A flitch transport conveyor includes a conveyor frame, a first dogger arm assembly for engaging a first end of the flitch, and a second dogger arm assembly for engaging a second end of the flitch.

Owner:PADANA

Wood rounding equipment based on furniture manufacturing

InactiveCN111590696AGuaranteed to be verticalAvoid misalignmentRounding machinesStructural engineeringWater pipe

The invention discloses wood rounding equipment based on furniture manufacturing. The wood rounding equipment comprises a shell, wherein a cutting ring is rotationally connected into the shell, cutting knifes are fixedly connected to the inner wall of the cutting ring, a log is arranged in the cutting ring, an ejector rod is slidably connected into an air cylinder, an extrusion rod is fixedly connected to the right side of the shell, a wire is arranged on the side face of a conductive box in a penetrating mode, a water pipe is fixedly connected to the side face of the wire, an insulating plateis slidably connected into the water pipe, a liquid pushing plate is arranged below the insulating plate, a two-section rod is rotationally connected to the bottom of the liquid pushing plate, and atransmission rod is connected to the bottom of the log and located on the right side of the ejector rod in a rolling mode. According to the wood rounding equipment based on furniture manufacturing, through cooperative use of the ejector rod and the air cylinder, the effects that once wood inclines during wood rounding, a cutting mechanism is automatically adjusted, so that the cutting mechanism inclines synchronously, and dislocation of the wood during cutting is prevented are achieved.

Owner:临沂辰腾商贸有限公司

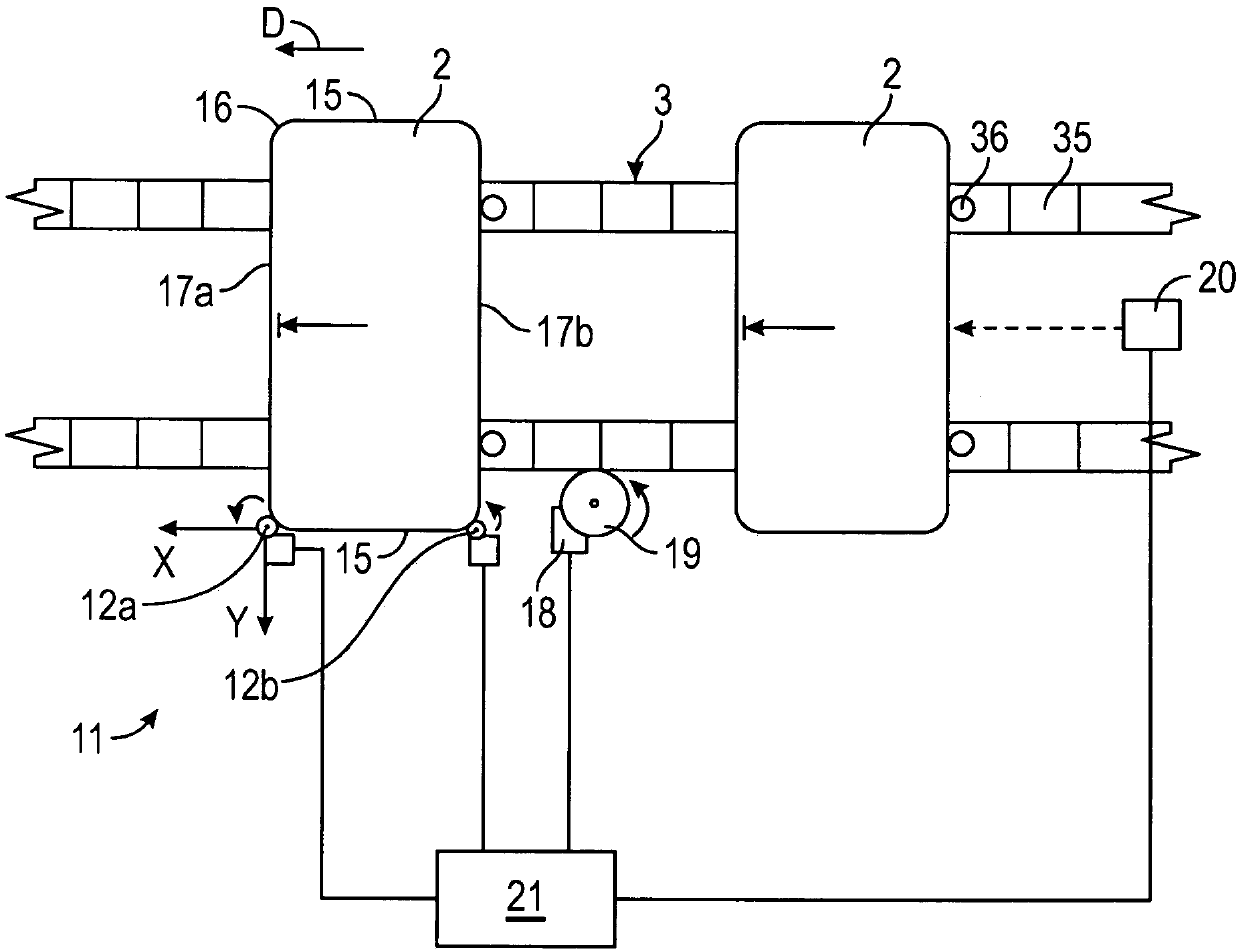

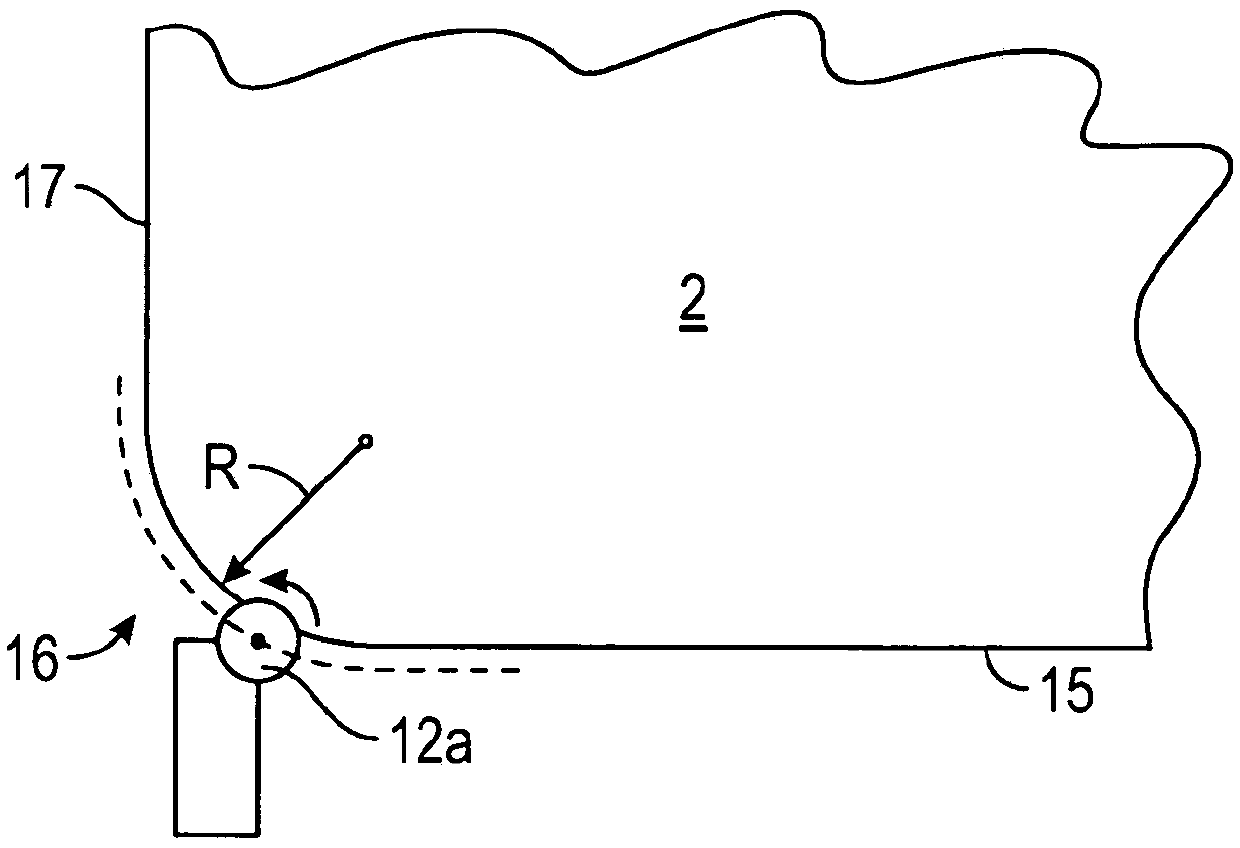

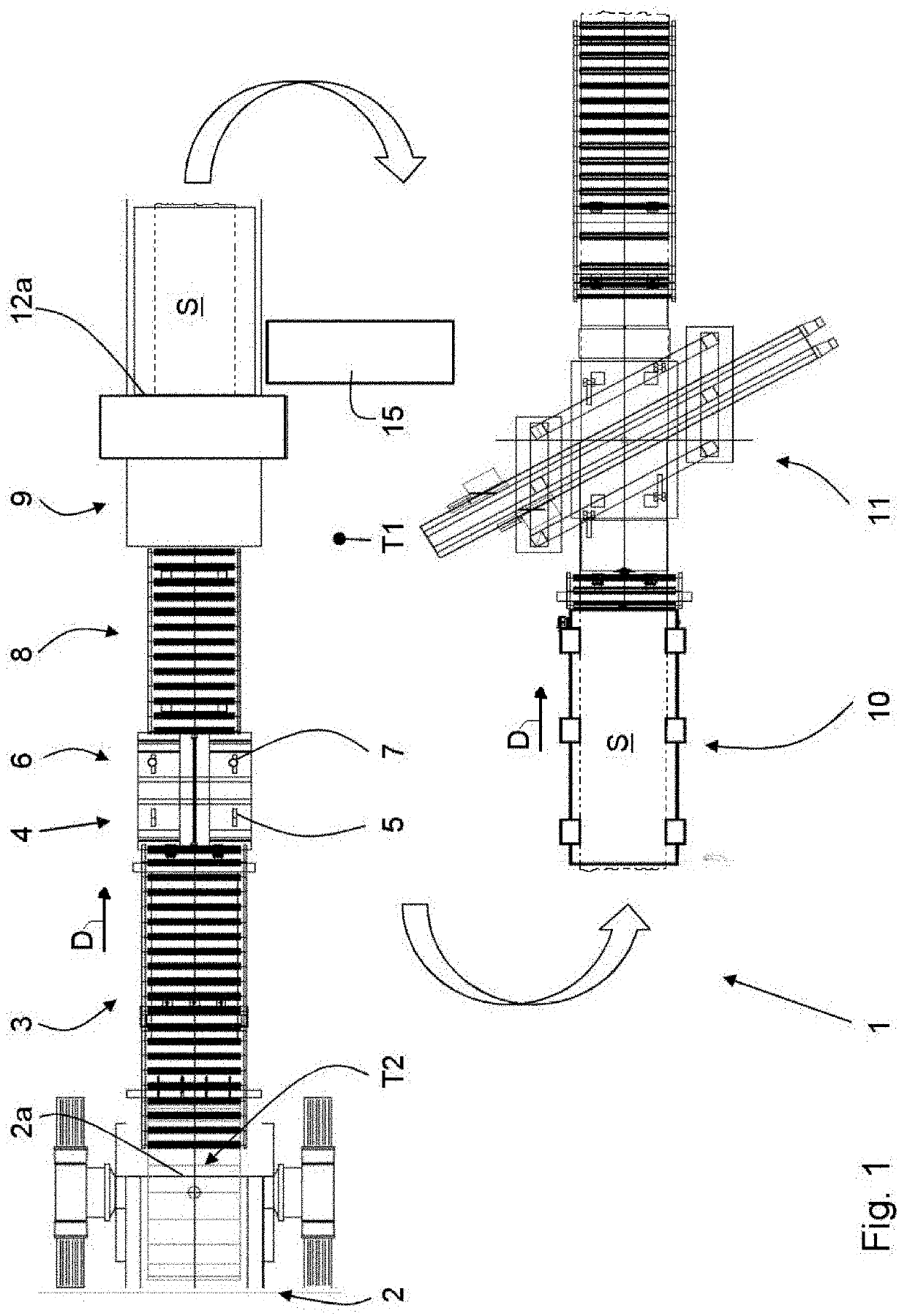

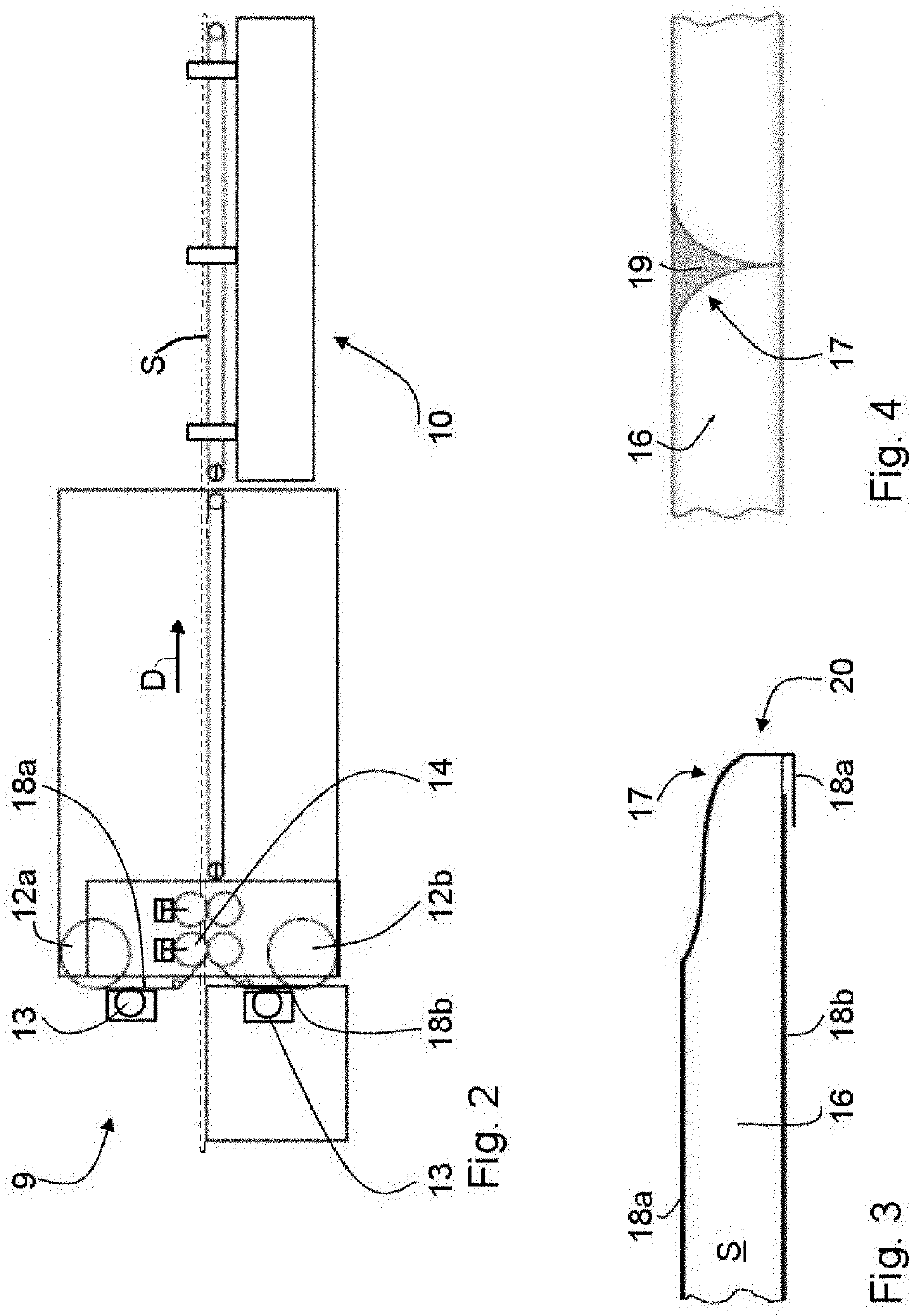

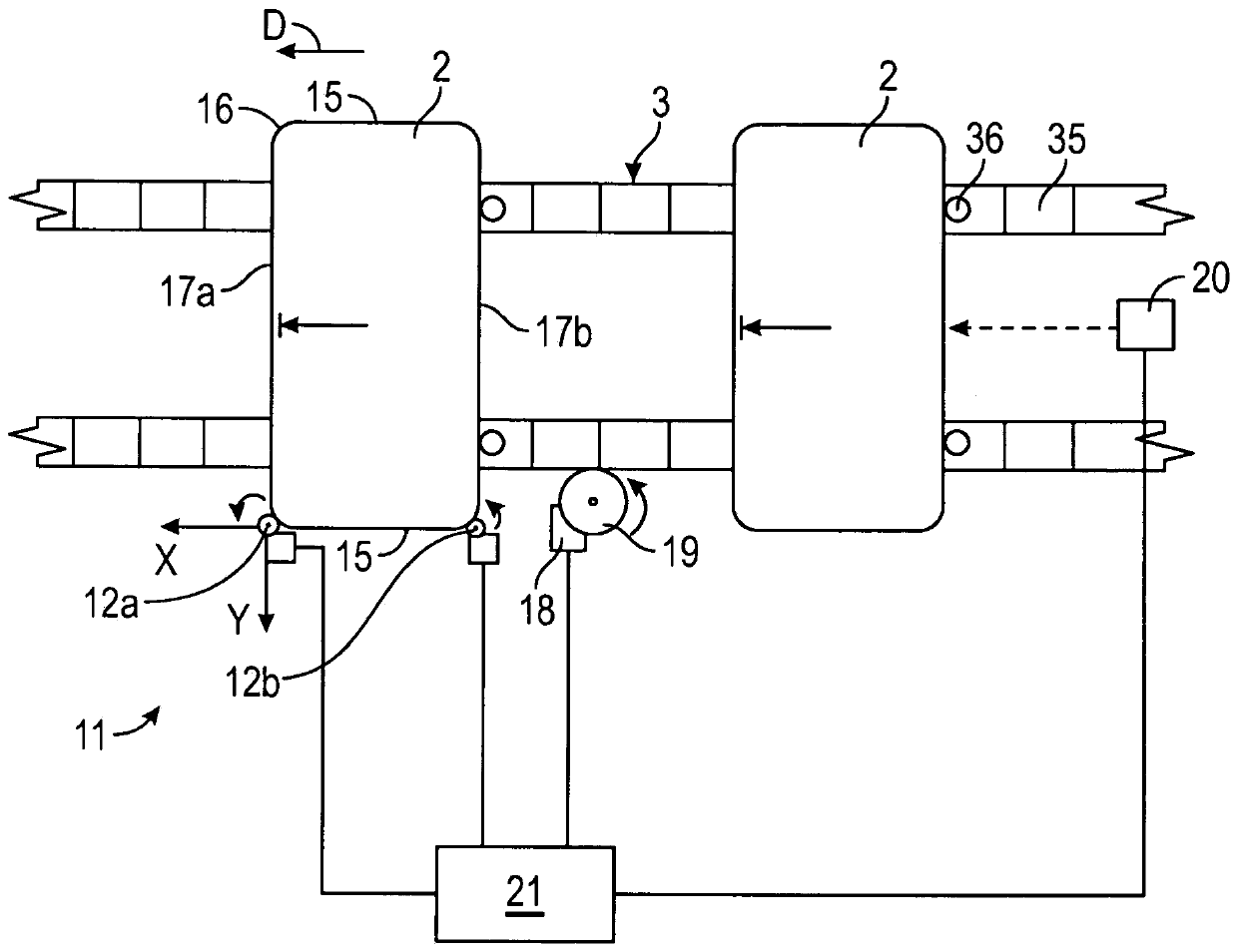

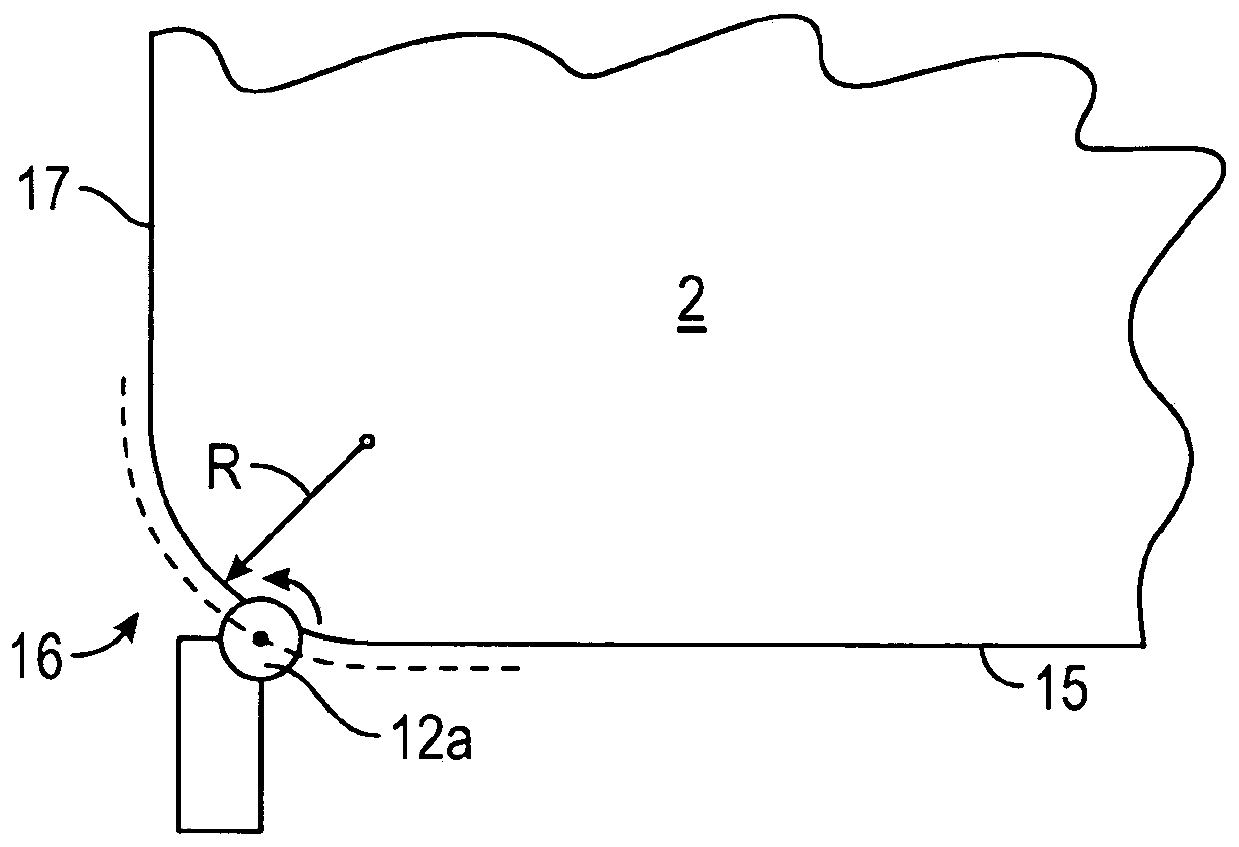

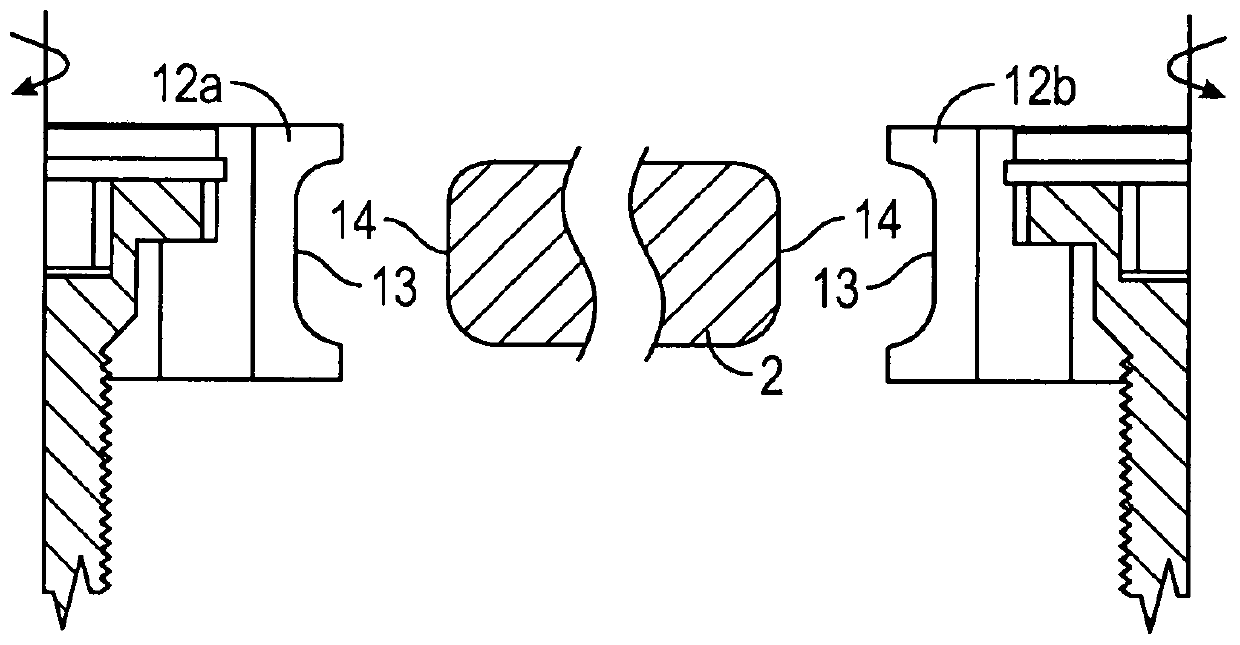

Method of continuous edge processing of plates and edge processing device

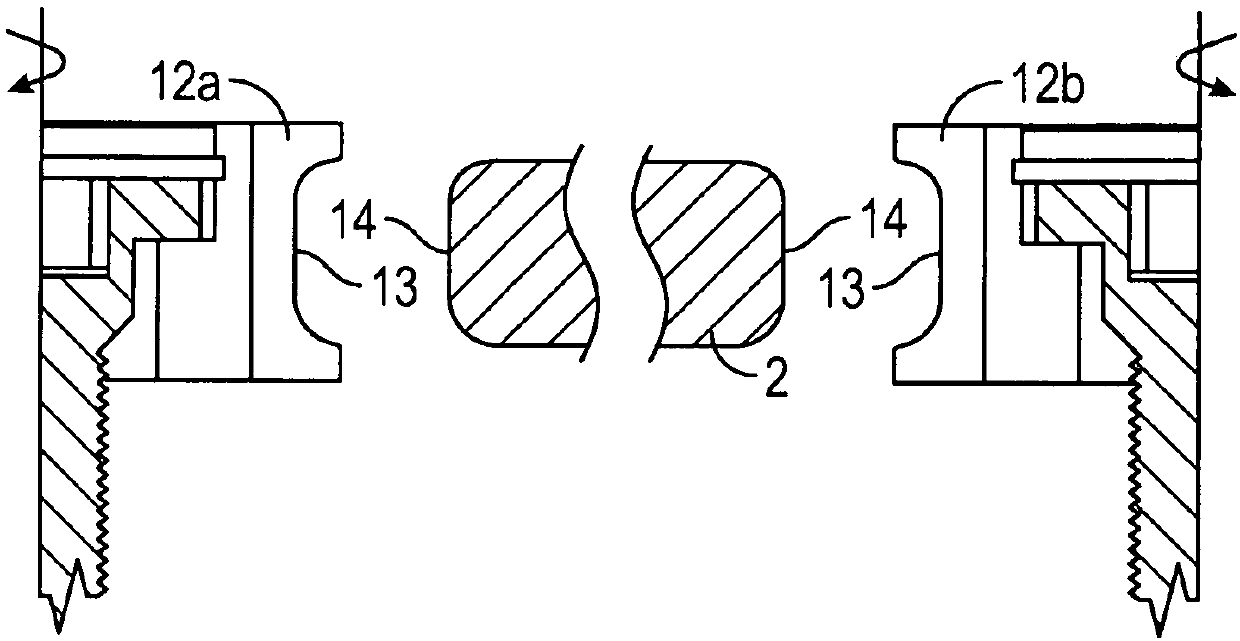

The invention discloses a method of continuous edge processing of plates and an edge processing device. According to the invention, plates (2;) are conveyed continuously in a conveying direction, whereby at least a first edge (15) of a plate Is provided with an edge profile by means of a rotating edge milling tool. A corner (16) connecting, the first edge and a second edge (17) of the plate is rounded at least partly by means of a rotating milling tool (12a, 12b) having a peripheral profile corresponding to a desired comer edge: profile of the plate. The rotating corner milling tool is controlled to be displaced along the continuously moving plate so if) at the rotating garner milling tool moves next to a corner to: he mimdeel1 and Is subsequently controlled to fee displaced simultaneouslyin the conveying direction (D) and m a transverse direction to Hie conveying, direction so that if follows a trajectory describing at least a part of: a desired rounding of the corner in a coordinatesystem fixed to the continuously moving plate.

Owner:ULMADAN R D APS

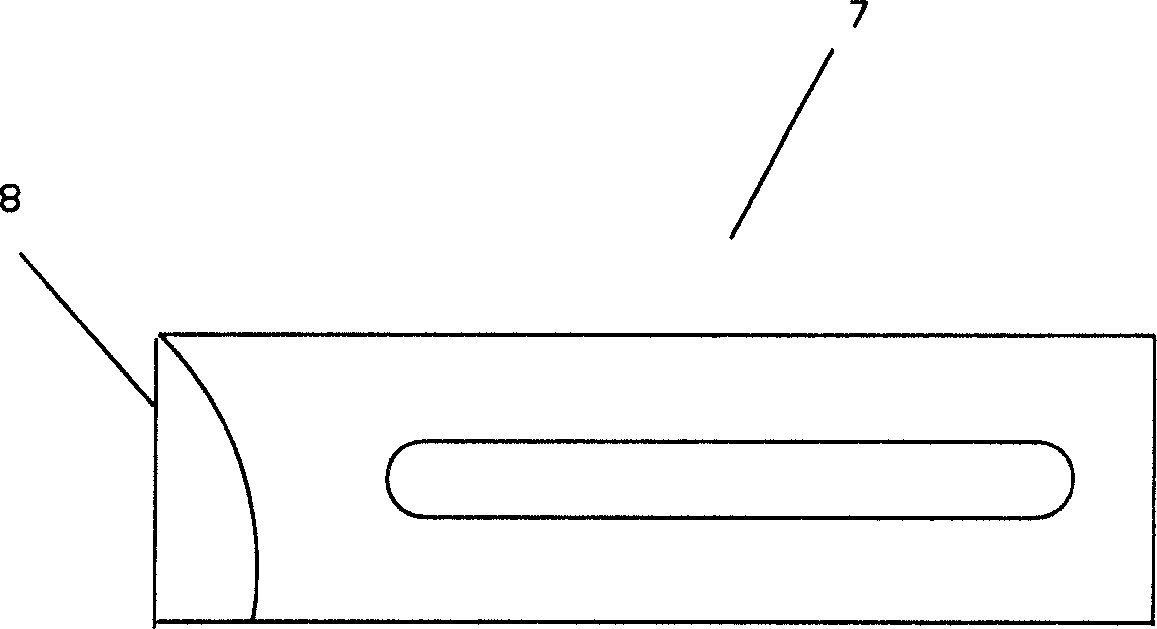

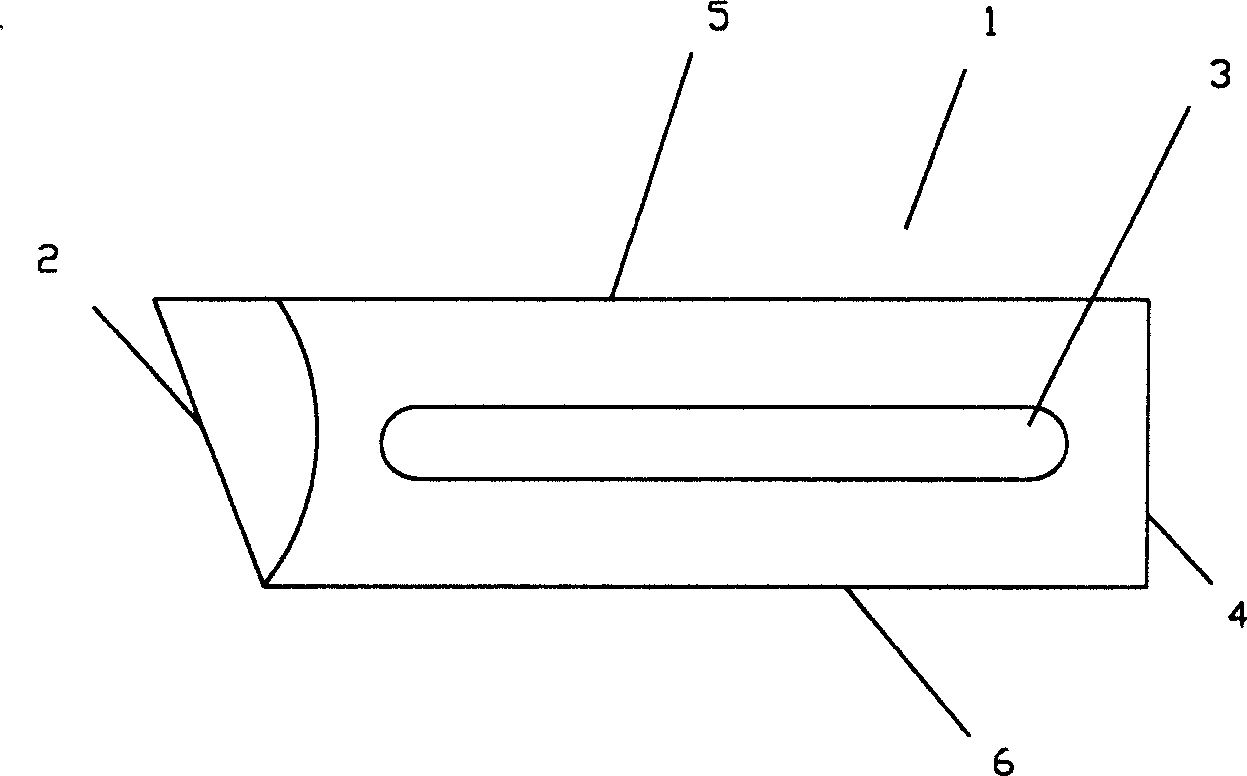

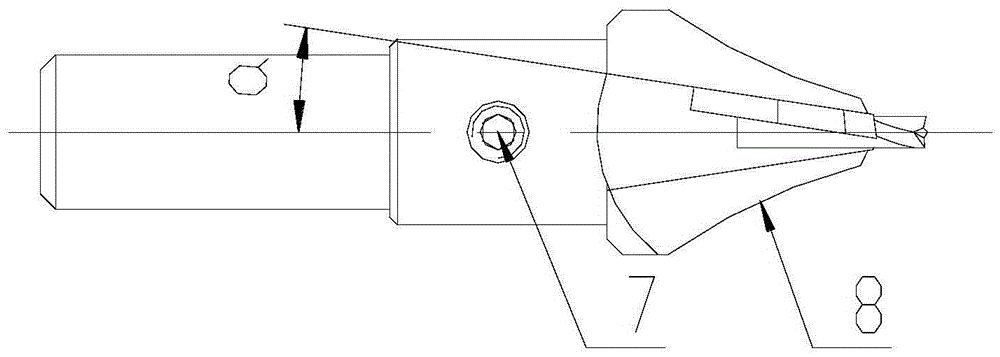

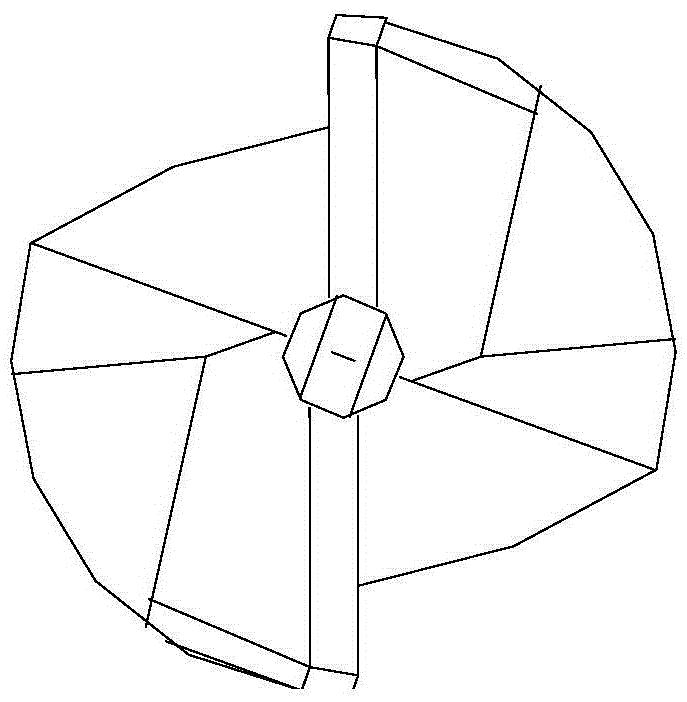

Rod rounding machine cutter

InactiveCN1706604AImprove smoothnessGood lookingRounding machinesRotary cutting toolsAcute angleEngineering

The rod rounding machine cutter includes cutter body and angled edge formed through wire electrode cutting, and the edge is in an acute angle to the bottom plane of the cutter body. During cutting circular rod, the edge of the cutter has dot-line contact with the machined rod, and this results in less cutting resistance, raised production efficiency, and high smoothness of machined rod.

Owner:梁志权

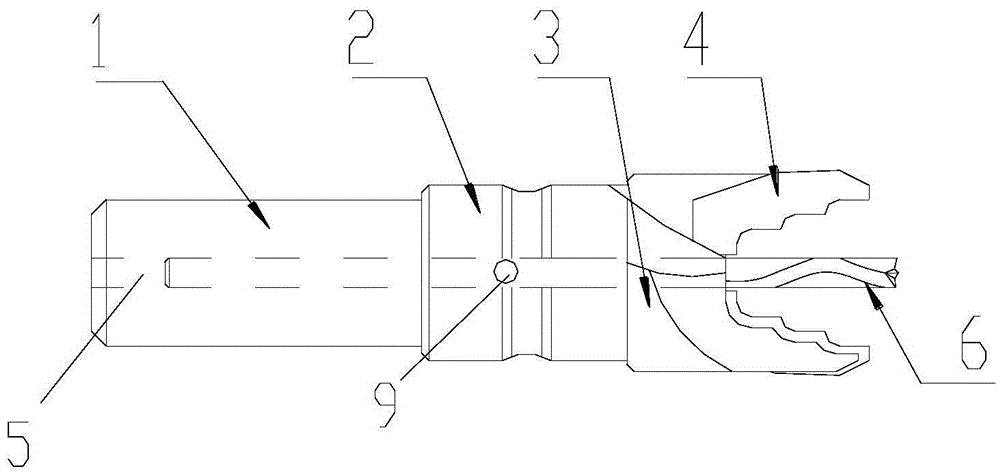

Cutter for tower-shaped and bottle-gourd-shaped Buddhist prayerbeads and processing method

The invention relates to a cutter for tower-shaped and bottle-gourd-shaped Buddhist prayer beads and a processing method and aims to provide a cutter which can produce products with uniform size and good surface quality and is high in processing speed, good in wear resistance and high in precision for the tower-shaped and bottle-gourd-shaped Buddhist prayer beads and a processing method. The cutter comprises a handle, a step and a cutter body, wherein the handle is connected with the step which is connected with the cutter body; the cutter body comprises a cutting blade and a drilling core, the cutting blade is welded on the cutter body, the drilling core adopts an auger bit, a round hole matched with the drilling core is formed in the cutter body, a screw hole for fixing the drilling core is formed in the step, a lock screw matched with the screw hole is arranged in the screw hole, an included angle is formed between the cutting blade and the horizontal plane and ranges from 5 degrees to 15 degrees, and tooth back is arranged on the back of the cutter body.

Owner:ZHEJIANG LANGCHAO PRECISION MACHINERY

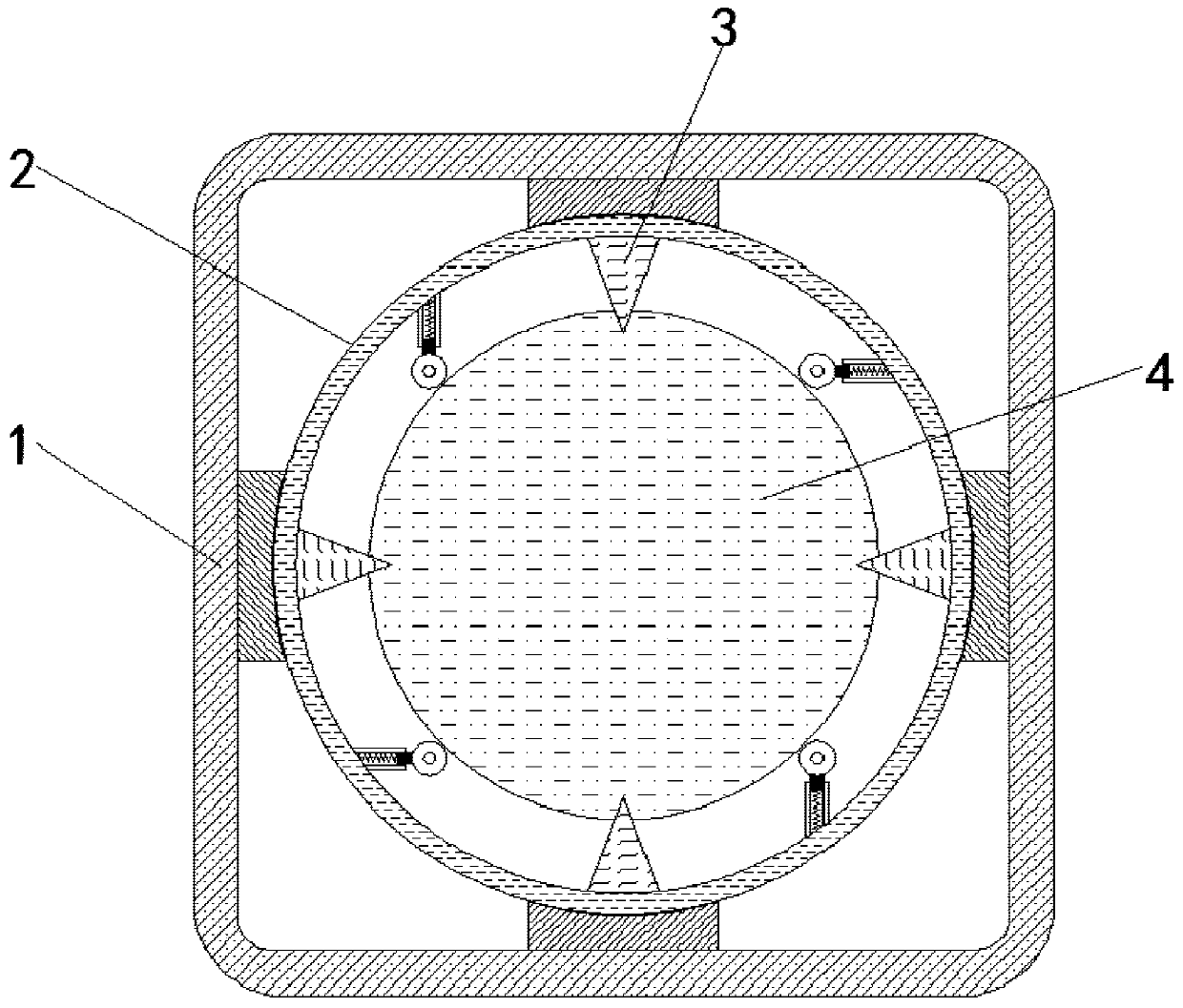

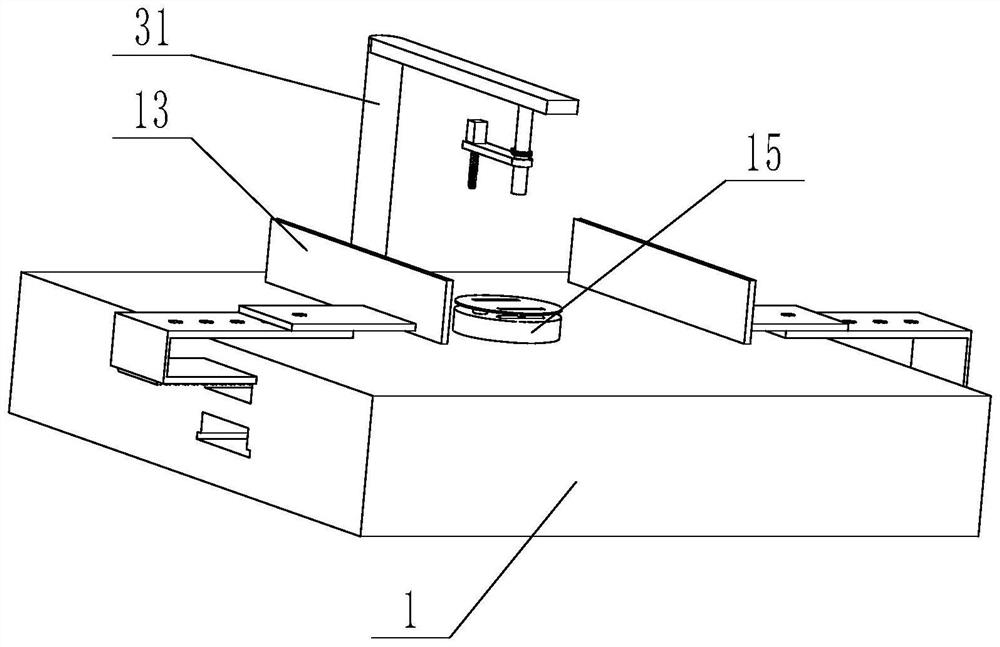

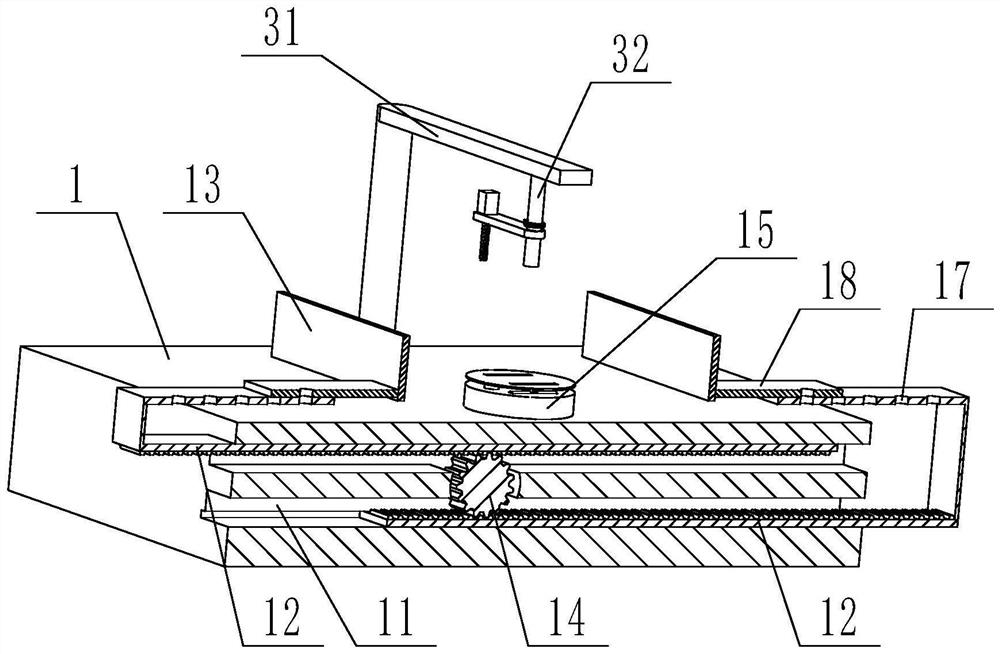

Positioning machining device for intelligent manufacturing

ActiveCN114347187ALarge diameterSolve efficiency problemsRounding machinesProfiling/shaping machinesGear wheelElectric machinery

The invention discloses a positioning machining device for intelligent manufacturing, and belongs to the technical field of machining. The positioning machining device for intelligent manufacturing comprises a base table, two racks, a driving gear and a rotary table, two parallel penetrating holes are formed in the base table, and the two penetrating holes communicate with each other through a first through hole; the two racks are slidably connected into the two penetrating holes respectively, the tooth surfaces of the two racks are opposite, the ends, away from each other, of the two racks are fixedly connected with the vertical plates respectively, and the two vertical plates are parallel to each other; the driving gear is arranged in the first through hole, the driving gear is meshed with the two racks, the driving gear is fixedly connected to an output shaft of a driving motor, and the driving motor is arranged in the base table; the rotary table is fixedly connected with an output shaft of a rotating motor which is fixed to the base table. The invention discloses a positioning machining device for intelligent manufacturing. By means of the positioning machining device, the maximum diameter of a machined circular plate of a plate can be achieved, and the problems that the efficiency is low and errors are large in the process of manually finding the center of the plate by people are solved.

Owner:ZHENGZHOU UNIV OF IND TECH

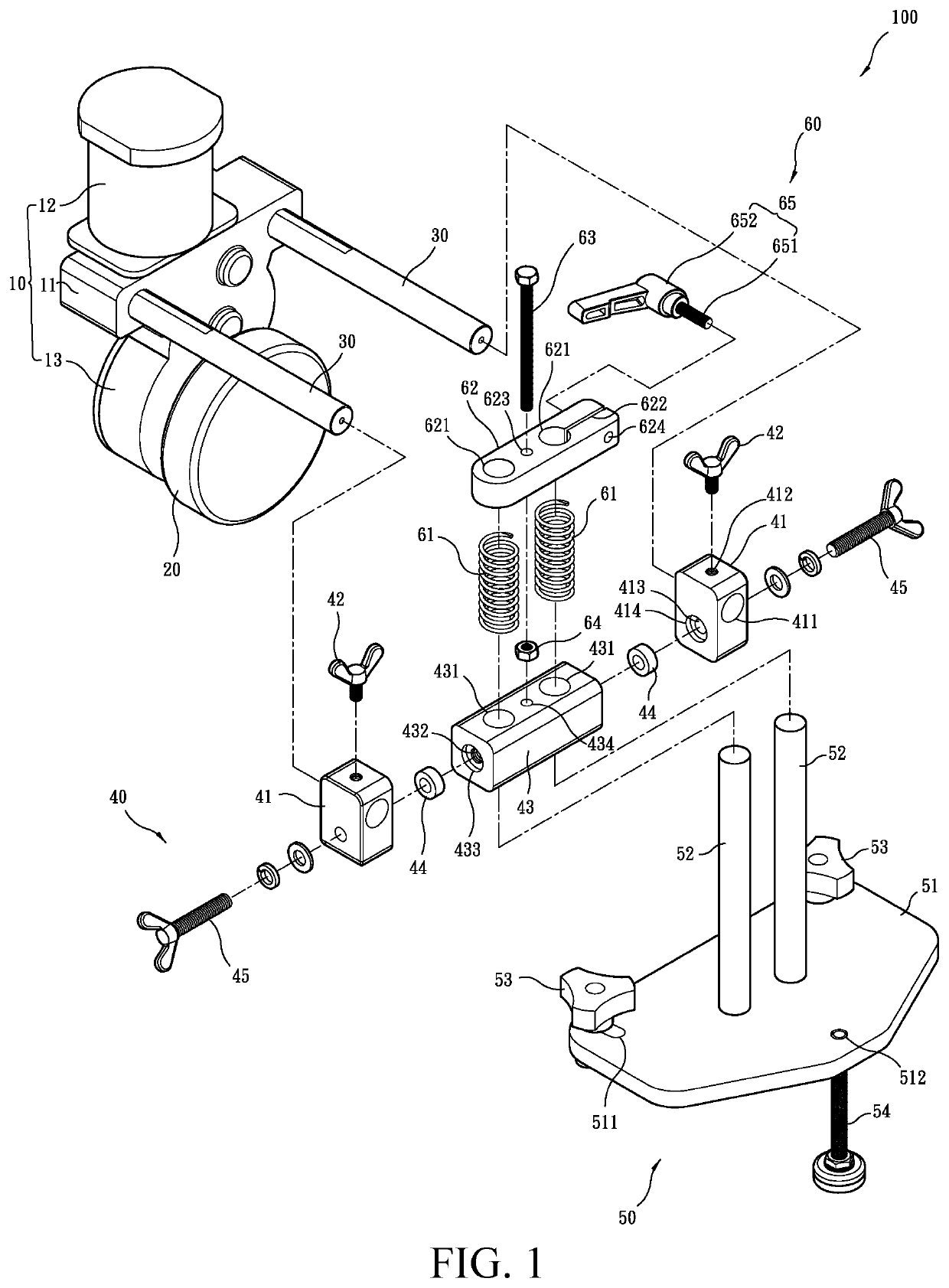

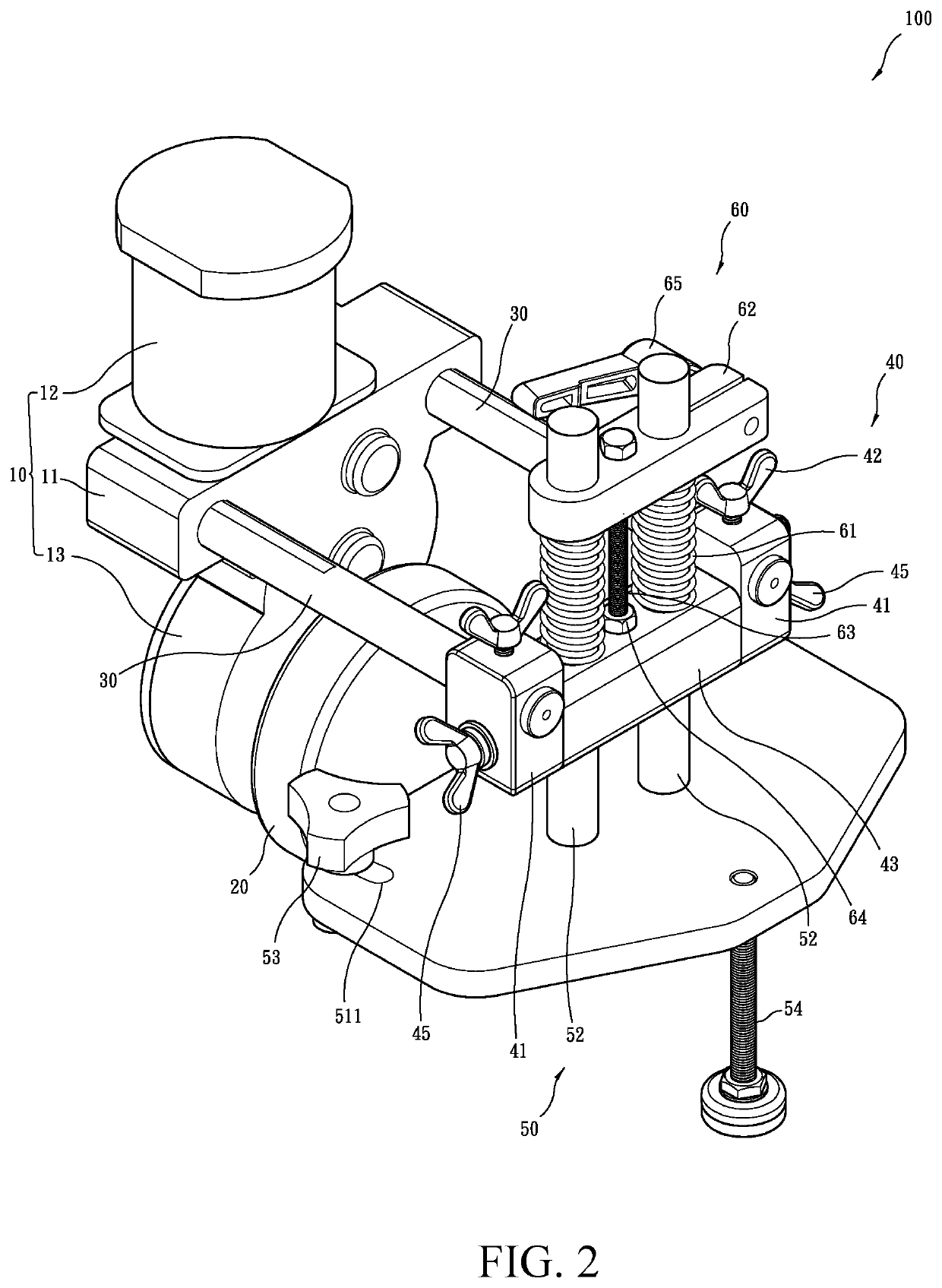

Structure of power carpentry feeder machine

ActiveUS10518434B2Material safetySmoothness securityWood feeding arangementsGuide fencesEngineeringWoodworking

A power carpentry feeder machine includes a power source; a rotary wheel operatively coupled to the power source; horizontal guide rods horizontally coupled to the power source; a horizontal movement unit including two movable blocks having horizontal guide holes to receive the horizontal guide rods therein, locking members attached to the movable blocks, a connection block interposed between the two movable blocks and including vertical guide holes, and jointing members jointing the movable blocks to the connection block; a mounting base including a base board and vertical guide rods vertically coupled to the base board and extending through the vertical guide holes; and a vertical movement unit including springs encompassing the vertical guide rods to set the connection block under the springs and a clamp block having clamping holes to receive the vertical guide rods to extend therethrough so as to set the clamp block on the springs.

Owner:YU BEN

Swinging self-adaptive adjustment type spindle-free rotary cutter and working method thereof

ActiveCN114851316AHigh yieldQuality improvementRounding machinesVeneer manufactureStructural engineeringFixed Beam

The invention provides a swing self-adaptive adjustment clamping-shaft-free rotary cutter and a working method thereof.The swing self-adaptive adjustment clamping-shaft-free rotary cutter comprises a working table, a fixed beam and a movable beam, the fixed beam is fixedly connected to the working table, and the movable beam is slidably connected to the working table corresponding to the fixed beam. Driving mechanisms used for driving the movable beam to move are installed at the positions, at the two ends of the movable beam, of the workbench, a balance rod is rotationally connected between the two driving mechanisms, and the two ends of the movable beam are connected with the two ends of the balance rod through connecting rod structures. The device is reasonable in design, easy to operate, convenient to use, high in log outturn percentage and good in log quality, specialized production is facilitated, and the production efficiency is improved.

Owner:福州三木三森机械有限公司

Making profile-edge construction board

PendingUS20220143863A1Other plywood/veneer working apparatusPlywood pressesEngineeringMechanical engineering

Owner:SIEMPELKAMP MASCH & ANLAGENBAU GMBH & CO KG

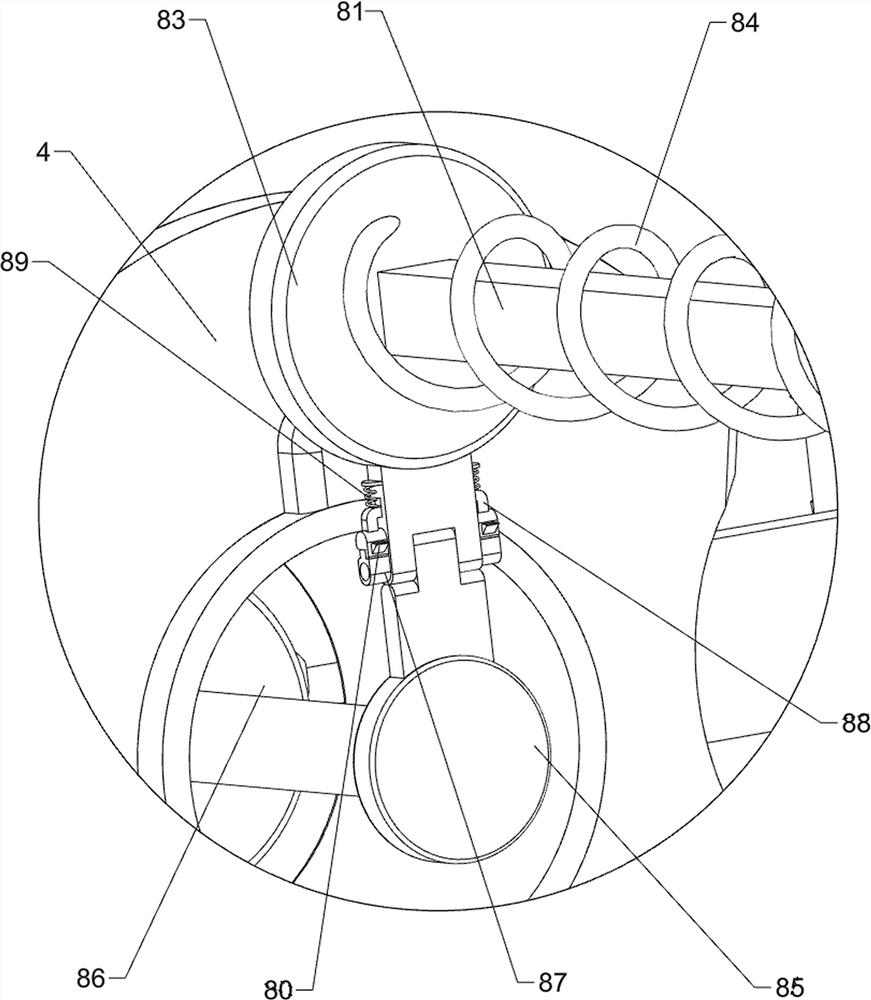

Rounding equipment for cylindrical blank of wooden toy

ActiveCN112265071ATo achieve the effect of roundingSave human effortRounding machinesProfiling/shaping machinesStructural engineeringMechanical engineering

The invention relates to rounding equipment, and in particular relates to rounding equipment for a cylindrical blank of a wooden toy. The technical problem to be solved by the invention is how to design the rounding equipment for the cylindrical blank of the wooden toy, which is simple to operate, can improve the working efficiency and saves manpower. In order to solve the technical problem, the rounding equipment for the cylindrical blank of the wooden toy comprises a bottom plate, a connecting sleeve, a mounting plate, a rounding mechanism, a pushing mechanism, a transmission mechanism and aclamping mechanism, wherein wedge-shaped plates are connected to the two sides of the top of the bottom plate, and the connecting sleeve is connected between the wedge-shaped plates on the two sides;the mounting plate is connected to the connecting sleeve, and the rounding mechanism is arranged on the connecting sleeve; the pushing mechanism is arranged on the connecting sleeve, and the transmission mechanism is arranged on the bottom plate and is in transmission connection with the pushing mechanism; and the clamping mechanism is arranged on the mounting plate. According to the rounding equipment, the rounding mechanism, the pushing mechanism, the transmission mechanism and the clamping mechanism are matched to operate to round the cylindrical blank, and therefore the effect of roundingthe cylindrical blank is achieved.

Owner:朱宜根

Continuous edge processing method and edge processing device for board

The plates (2) are continuously conveyed in the conveying direction, wherein at least a first edge (15) of the plates is provided with an edge profile by a rotary edge milling tool. The corner (16) connecting the first and second edges (17) of the plate is at least partially rounded by means of a rotary angle milling tool (12a, 12b) whose outer peripheral profile corresponds to the desired corner edge profile of the plate. The rotary angle milling tool is controlled to be displaced along the continuously moving plate such that the rotary angle milling tool is moved adjacent to the corner to be rounded and is subsequently controlled to move simultaneously in the conveying direction (D) and transversely to the conveying direction is displaced in a direction such that it moves along a trajectory describing at least a portion of the desired rounding of the corner in a coordinate system fixed to the continuously moving plate.

Owner:ULMADAN R D APS

A log trimming device

The invention discloses a log trimming device, comprising a frame, a rotating part, a radial adjusting part, a trimming part, a concentric adjusting part, and a clamping and transmitting part; an inlet is provided on the second frame base, and the concentric adjusting part is used for concentric adjustment, Make the trimming center of the wood the same as the rotating center of the trimming tool, use the gripping and conveying parts to clamp and convey the wood, and carry out continuous trimming action. The component adjusts the radius of rotation of the dressing tool and changes the dressing radius of the dressing tool. The invention has novel structure, trims the uneven parts on the wood, and has high work efficiency.

Owner:华琳琳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com