Progressive wooden bead manufacturing device

A production device and progressive technology, which is applied in the field of progressive wooden bead production devices, can solve the problems of cumbersome, slow procedures, and worker injuries, and achieve the effects of simplifying processing procedures, improving processing efficiency, and avoiding injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

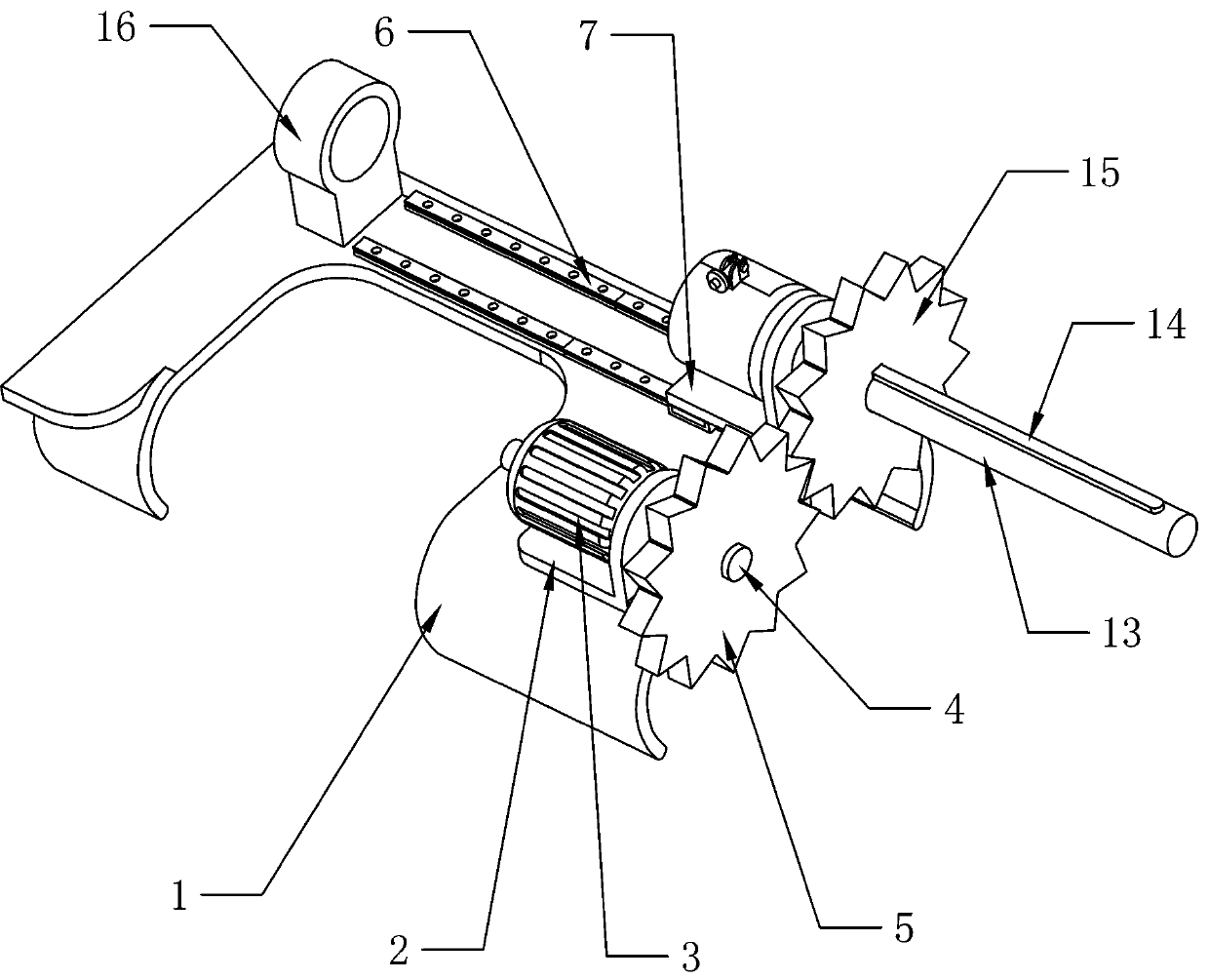

[0023] A progressive wooden bead making device, such as Figure 1-2 As shown, it includes a base plate 1, a motor base 2, a biaxial motor 3, a transmission mechanism and a locking mechanism. The upper side of the right part of the base plate 1 is fixedly connected with a motor base 2, and the upper side of the motor base 2 is installed with a biaxial motor 3. The base plate 1. A transmission mechanism is fixedly connected to the upper side of the right part, and the biaxial motor 3 is connected to the transmission mechanism, and a locking mechanism is fixedly connected to the transmission mechanism.

[0024] Such as Figure 1-2 As shown, the transmission mechanism includes a rotating rod 4, a first gear 5, a linear slide rail 6, a moving seat 7, a rotating shaft 13, a long key bar 14, a second gear 15, a gear mounting seat 151 and a first slideway 16, The output shaft of the biaxial motor 3 is fixedly connected with a rotating rod 4, and the rotating rod 4 is located on the r...

Embodiment 2

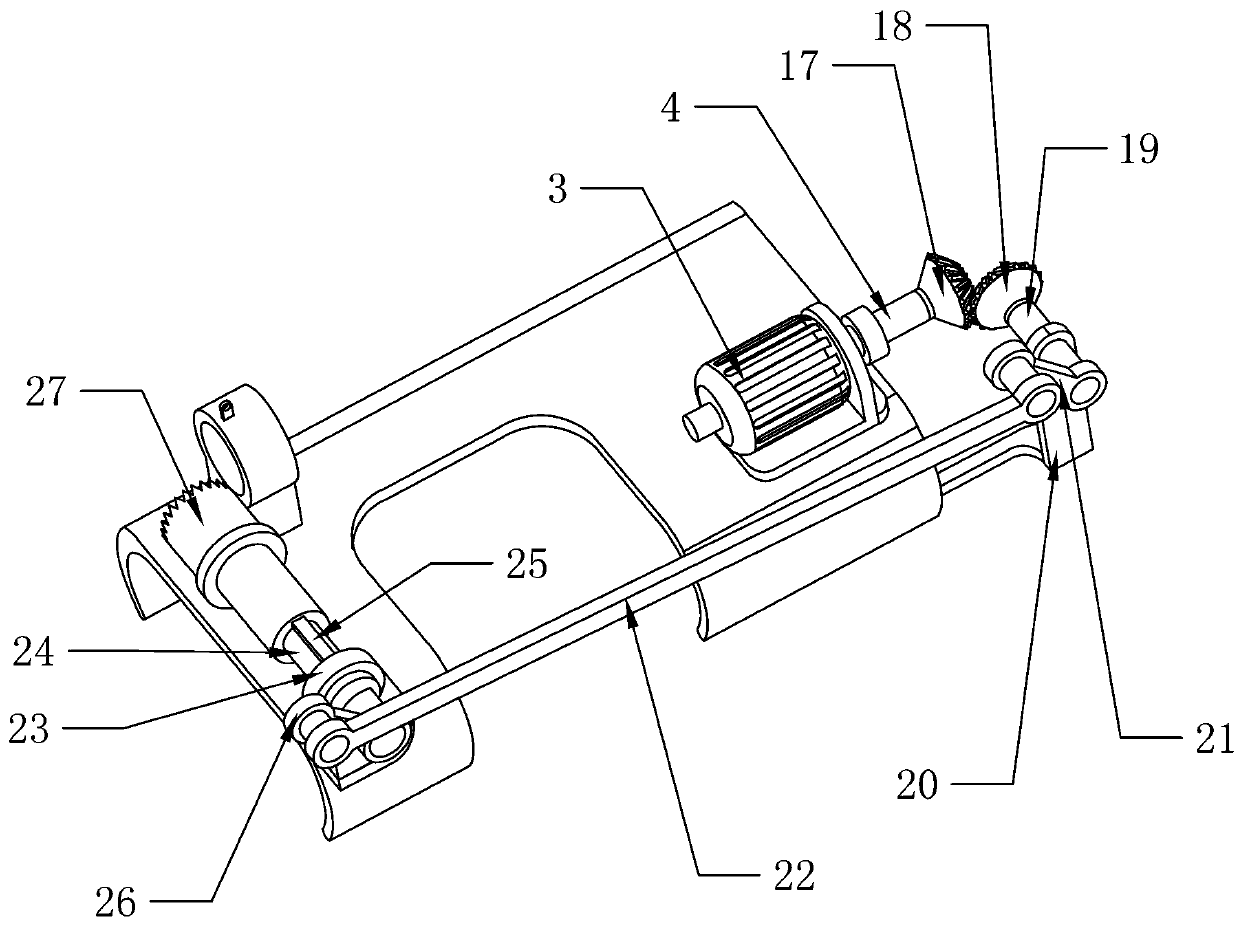

[0030] On the basis of Example 1, such as Figure 4As shown, it also includes a first helical gear 17, a second helical gear 18, a connecting shaft 19, a welding plate 20, a first rocker arm 21, a long rod 22, a bearing seat 23, a sliding shaft 24, a short key bar 25, the first Two rocking arms 26 and cutter 27, the first helical gear 17 is installed on the right end of the rotating rod 4, the front part of the right side of the bottom plate 1 is fixedly connected with a welding plate 20, the upper end of the welding plate 20 is rotatably connected with a connecting shaft 19, and the connecting shaft 19 rear ends The second helical gear 18 is fixedly connected, the front end of the connecting shaft 19 is fixedly connected with the first rocker arm 21, the second helical gear 18 meshes with the first helical gear 17, the front end of the first rocker arm 21 is connected with a long rod 22 for rotation, and the bottom plate 1 A bearing seat 23 is fixedly connected to the upper s...

Embodiment 3

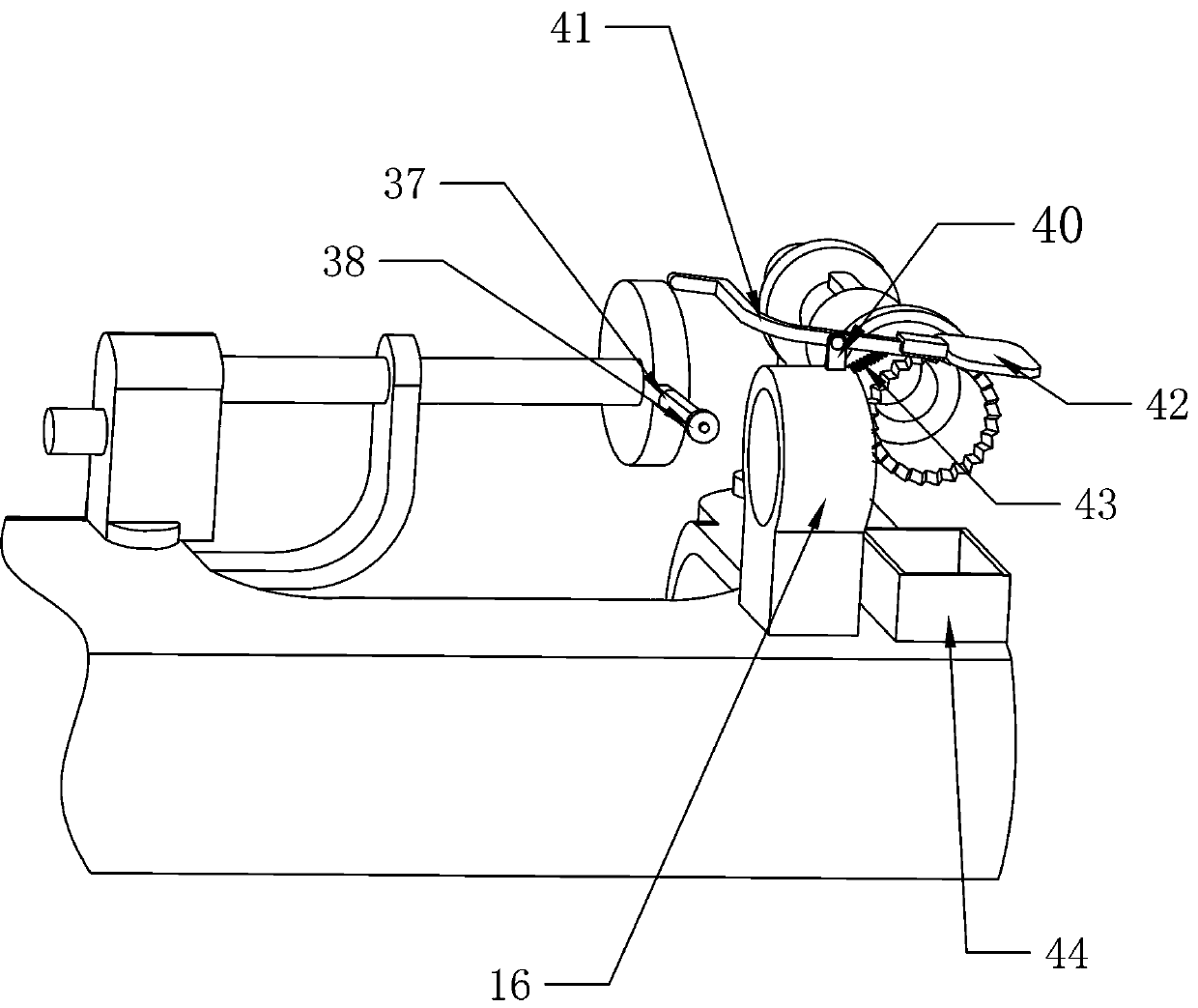

[0033] On the basis of Example 2, such as Figure 5 Shown, also include reducer 28, connecting plate 29, rotating shaft 30, cam 31, offset seat 32, connecting rod 33, second slideway 34, first roller 35 and spring 36, bottom plate 1 right upper side A reducer 28 is fixedly connected, the output shaft on the left side of the biaxial motor 3 is fixedly connected to the input shaft of the reducer 28, the lower side of the bottom plate 1 is fixedly connected with a connecting plate 29, and the upper part of the connecting plate 29 is pierced with a rotating shaft 30, and the rotating shaft 30 is connected to the The bottom plate 1 is parallel, the right end of the rotating shaft 30 is fixedly connected to the output shaft of the reducer 28, the left end of the rotating shaft 30 is fixedly connected with a cam 31, the middle part of the cutting knife 27 is provided with an offset seat 32 through a bearing sleeve, and the right side of the offset seat 32 is fixedly connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com