Method of continuous edge processing of plates and edge processing device

An edge processing and edge technology, which is applied in the field of continuous edge processing of boards, can solve problems such as inability to round corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

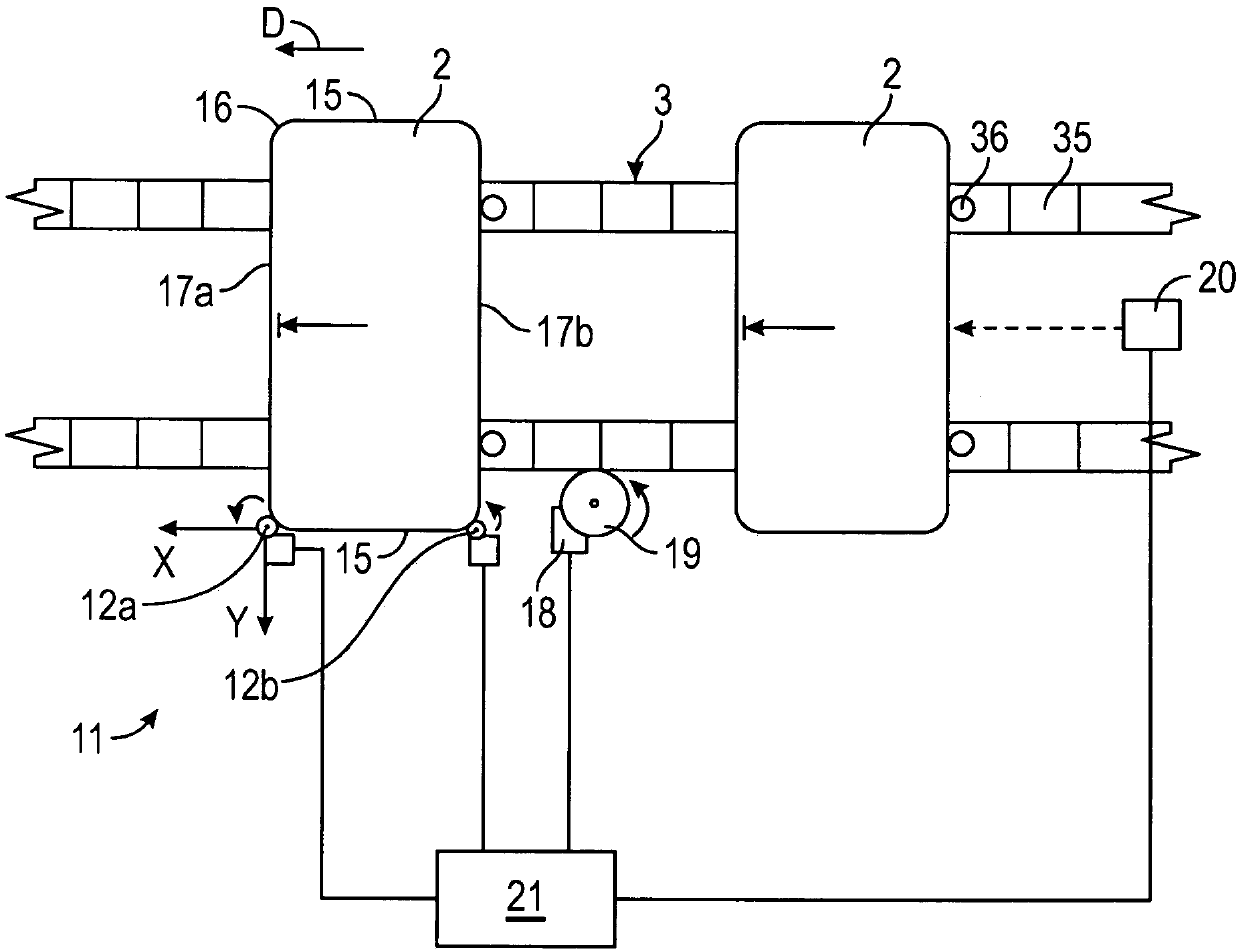

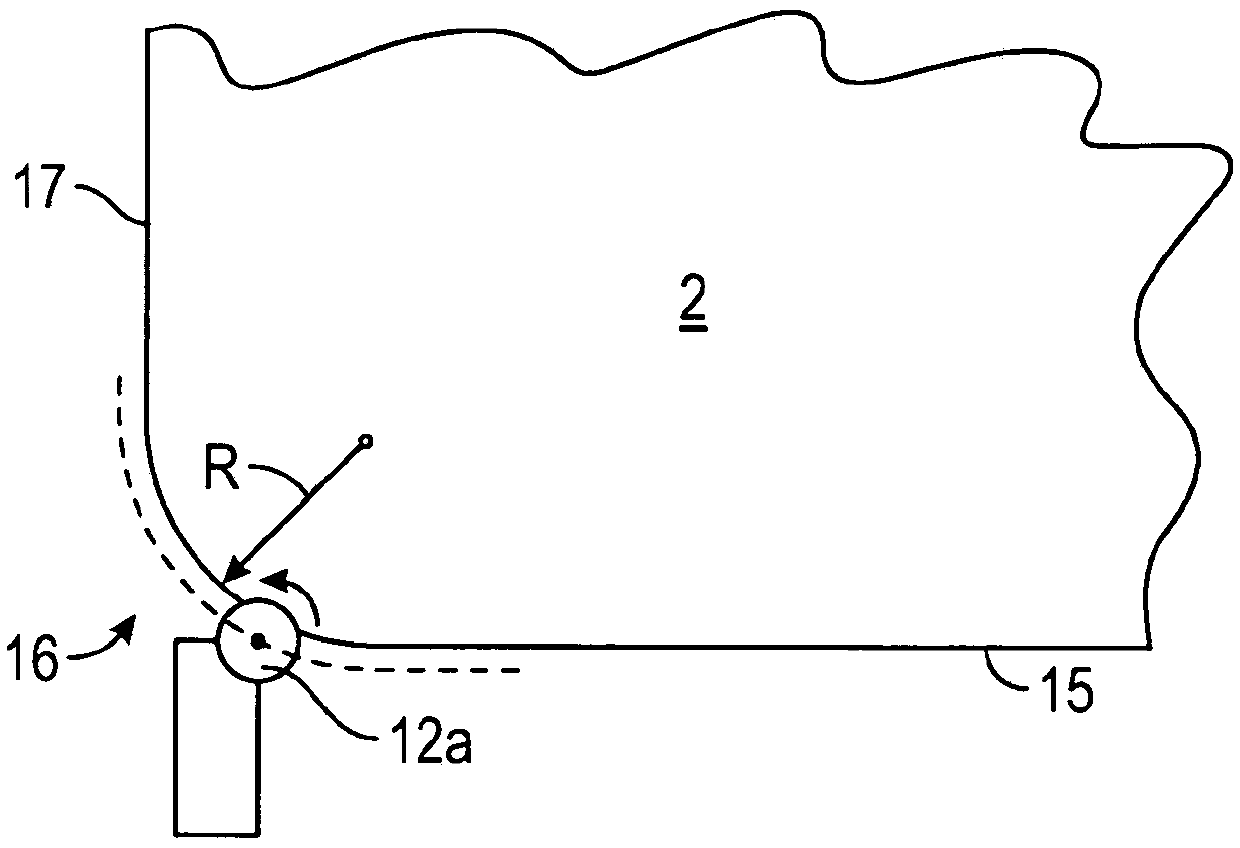

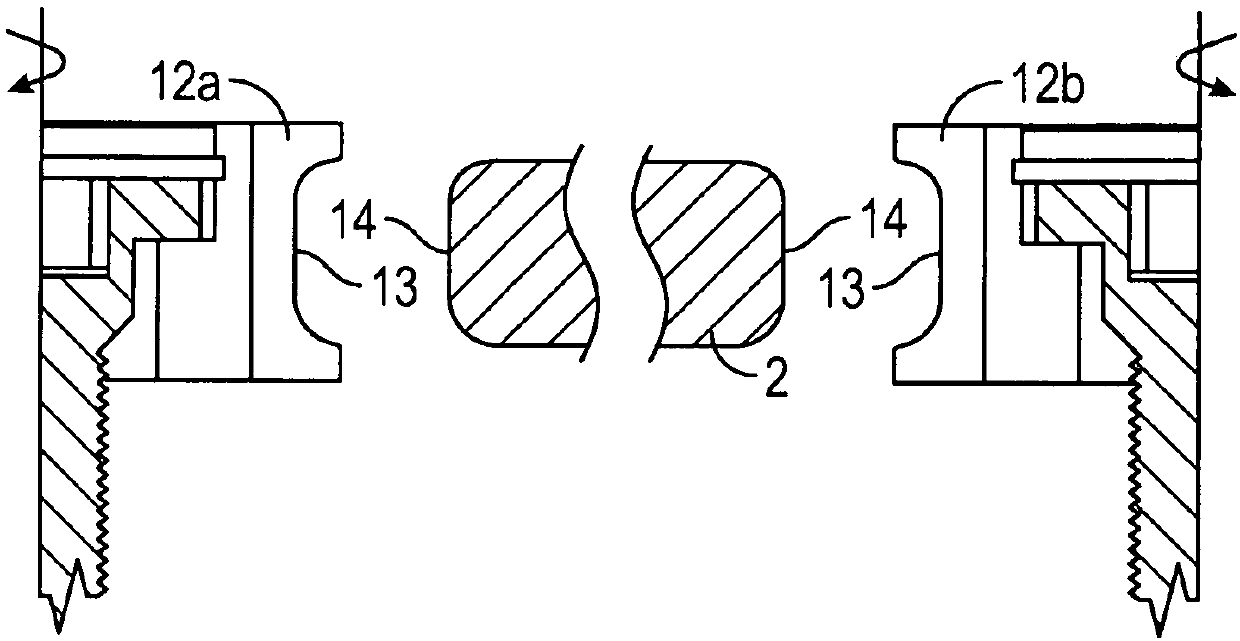

[0072] Figure 8 A complete continuous edge processing line is shown comprising a continuous edge processing device for edge processing of boards according to the invention.

[0073] The continuous edge treatment device according to the invention can treat any kind of board or strip in order to provide these items with an edge profile along their longitudinal edges and around the corners. Preferably, the same edge profiles are provided along the longitudinal edges and around the corners; however, these profiles may differ. Figure 8 The complete continuous edge processing line shown in is suitable for processing the edges of boards in order to provide them with edge profiles along all sides and corners.

[0074] allowable Figure 8 Any kind of board is processed in the complete continuous edge processing line shown; however, the line is especially suitable for processing porous materials such as MDF boards (MDF is Medium Density Fibreboard), HDF (High Density Fibreboard), Me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com