Panel feeding, rotary-cutting and stacking integrated device

A sheet and stacking technology, applied in the field of sheet feeding, rotary cutting and stacking integrated devices, can solve the problems of time-consuming and laborious, high risk, low work efficiency, etc., and achieve the effect of solving high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

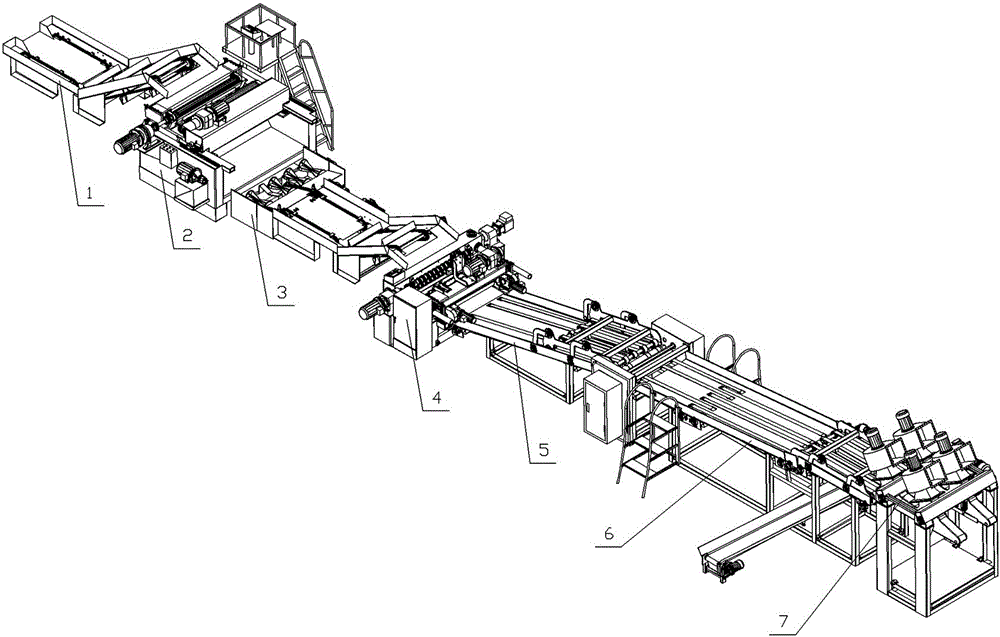

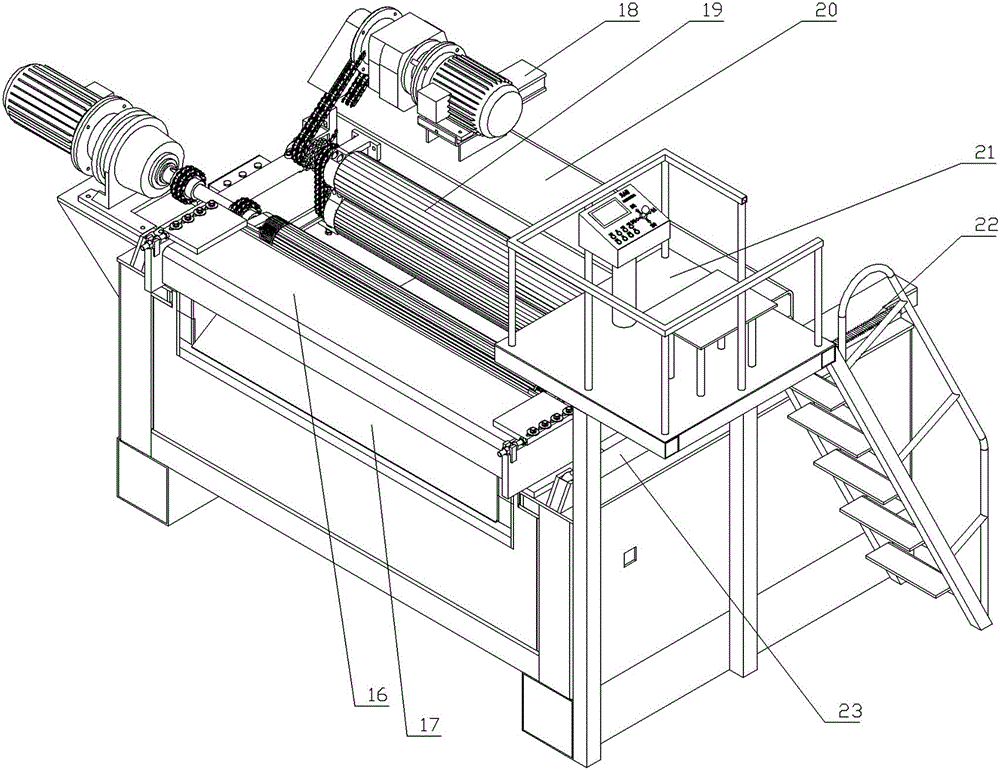

[0027] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 with Figure 11 , invent a kind of plank feeding, rotary cutting and stacking integrated device, it comprises rounding machine 2 and rotary cutting machine 4, the feeding end of described rounding machine 2 is provided with feeding device 1, and the discharging end is provided with There is a wood proofreading machine 3; the back of the proofreading machine 3 is connected with the rotary cutter 4 through a feeding device; the discharge end of the rotary cutter is provided with a conveying frame 5; Automatic board receiving machine 7 connection;

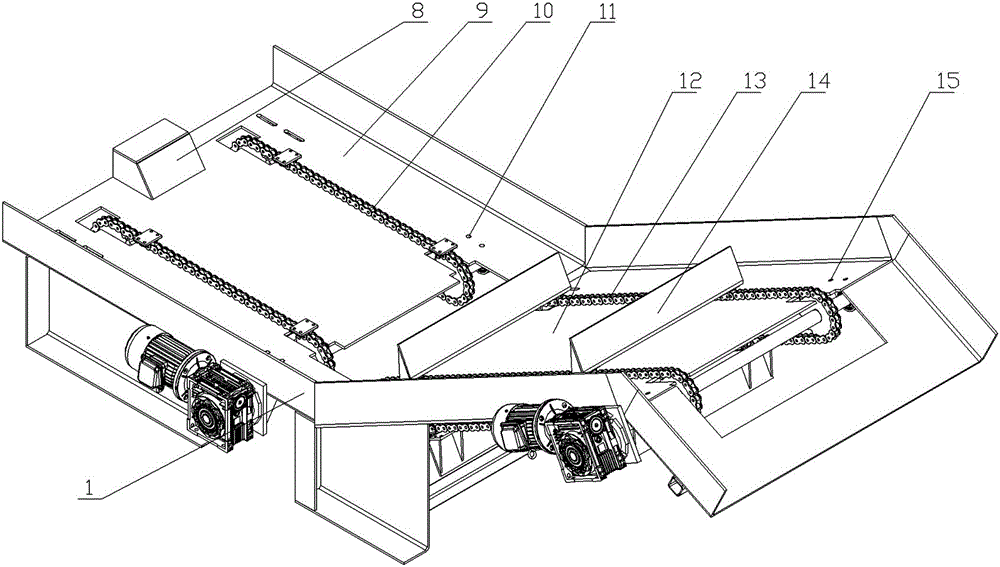

[0028] The feeding device 1 includes a conveying platform 9 and a feeding platform 12, and the conveying platform and the feeding platform are welded at an angle of 45° as one; the conveying platform is provided with a transmission chain 10; the front of the conveying chain An induction probe I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com