A rhinestone turning and inversion device

A technology of rhinestones and flipping arms, which is applied in the direction of used abrasive processing devices, metal processing equipment, manufacturing tools, etc., and can solve the problems of affecting the effect of drilling and plastic absorption, unsatisfactory results, and low success rate. Good plastic effect, convenient drilling and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

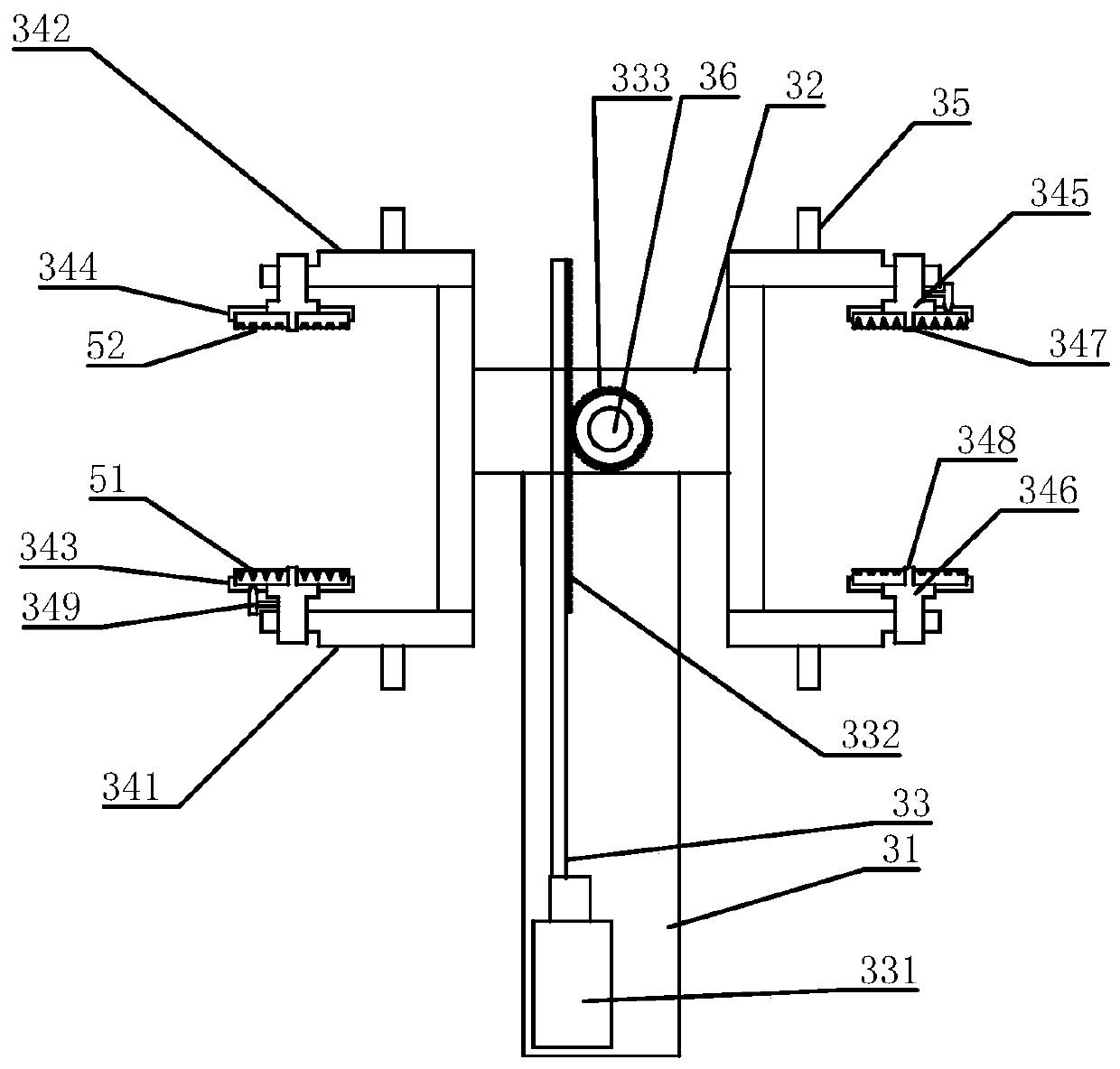

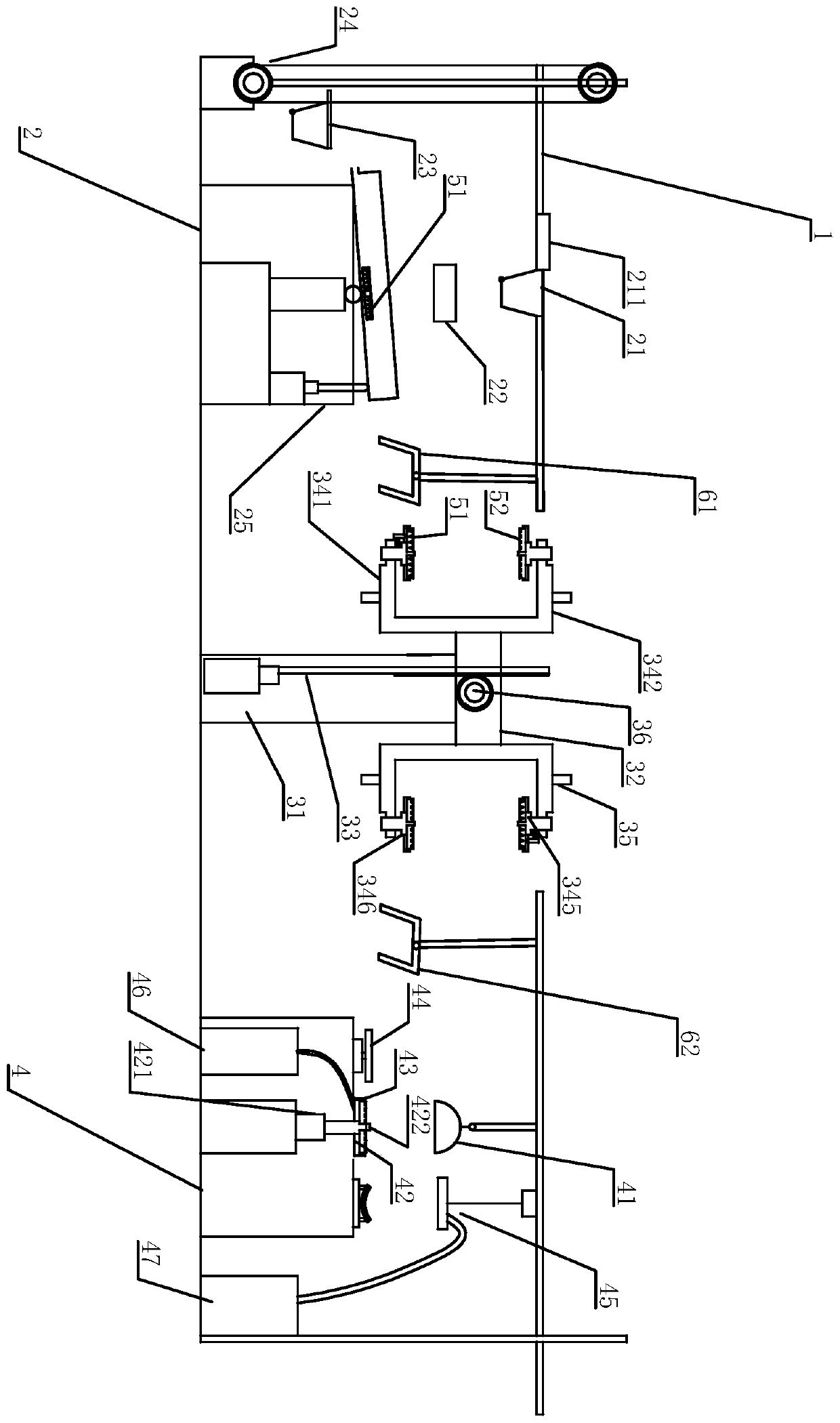

[0019] see figure 1 , figure 2 The turning and inversion mechanism includes a turning bracket 31, a turning arm 32, a turning driving device 33, a buckling part and a buckling power unit 35, the middle part of the turning arm 32 is arranged on the turning bracket 31 through a rotating shaft 36, and the turning driving device 33 drives the turning The arm 32 is overturned, and the overturning arm 32 can be stationary in a horizontal position through a limiting device; both ends of the overturning arm 32 are provided with fastening parts, and the fastening part is composed of a first fastening arm 341 and a second fastening arm 342, The first positioning plate 345 is installed on the first fastening arm 341 for fixing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com