Wood rod forming equipment for wood processing

A technology for forming equipment and wooden sticks, which is applied to wood processing equipment, manufacturing of wooden sticks, forming/shaping machines, etc., can solve the problems of hard texture and ring cutter stuck in the wood, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

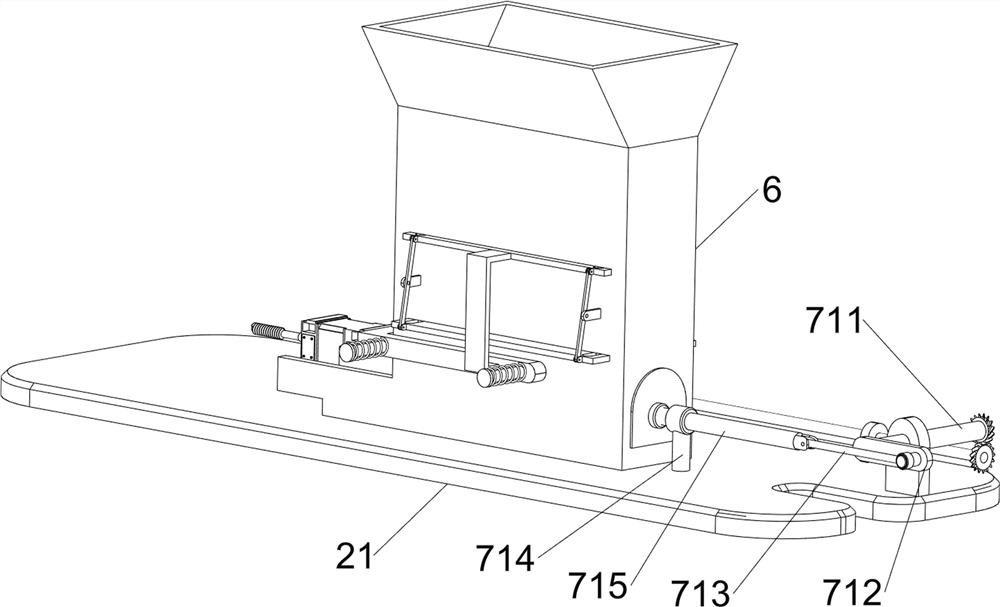

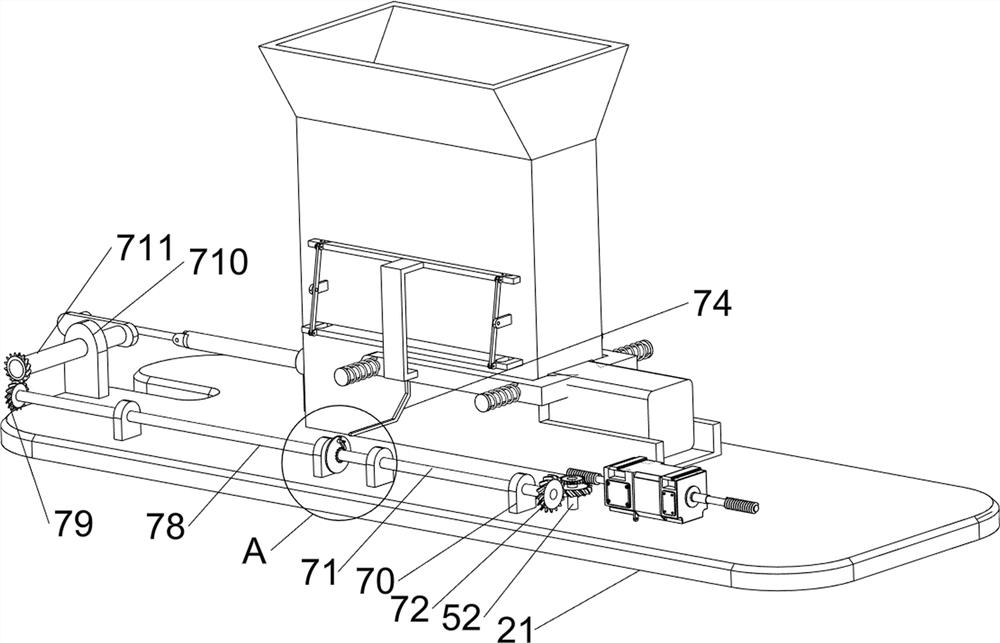

[0061] A wood rod forming equipment for wood processing, such as figure 1 As shown, it includes a bottom plate 1, a support mechanism 2 and a circle cutting mechanism 3. The top of the bottom plate 1 is provided with a support mechanism 2, and the support mechanism 2 is provided with a circle cutting mechanism 3.

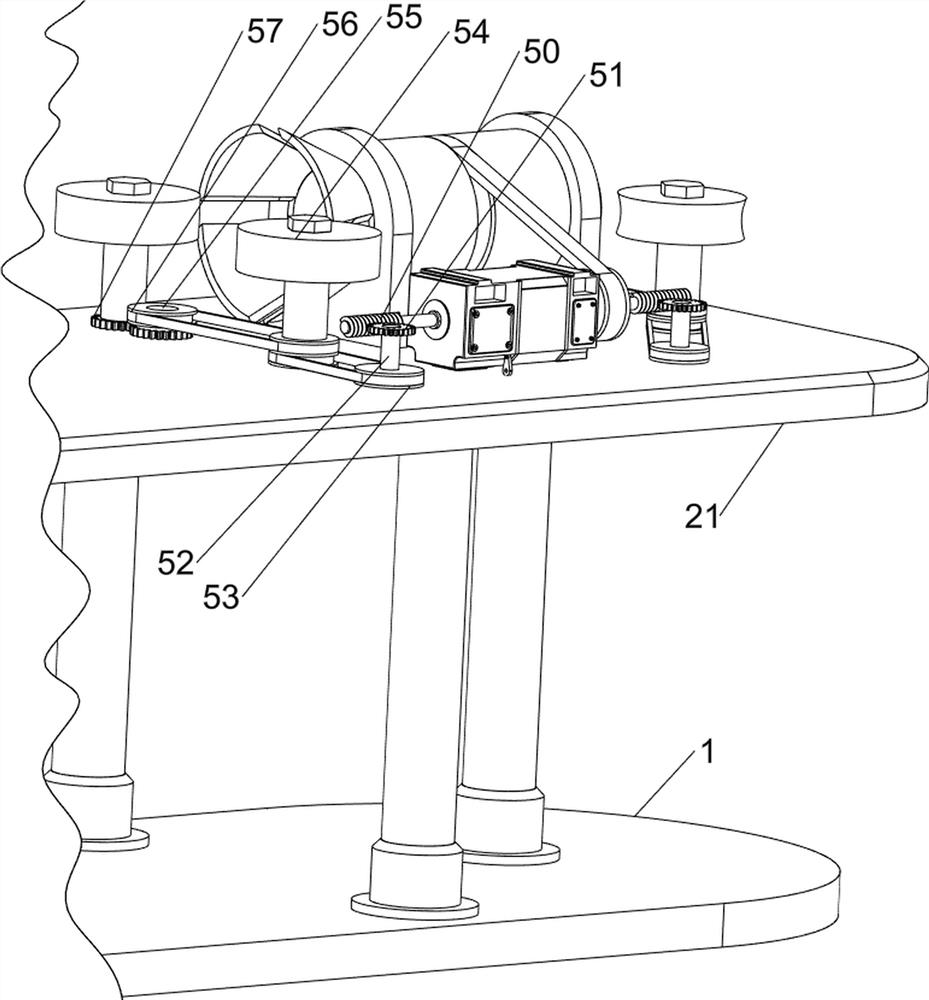

[0062] Such as figure 2 As shown, the support mechanism 2 includes a support column 20 and an installation platform 21 , three support columns 20 are provided on the left and right sides of the top of the bottom plate 1 , and the installation platform 21 is connected between the tops of the support columns 20 .

[0063] Such as figure 2As shown, the circle cutting mechanism 3 includes a mounting plate 30, a motor 31, a rotating cylinder 32, the first pulley group 33 and a rotary cutter 34, and the left and right sides of the top of the mounting table 21 are symmetrically provided with the mounting plate 30, and the right side of the mounting table 21 top right A...

Embodiment 2

[0066] On the basis of Example 1, such as figure 2 As shown, a discharge mechanism 4 is also included, and the discharge mechanism 4 includes a first rotating shaft 40, a first worm 41, a first turbine 42, a second pulley set 43, a discharge wheel 44, a second rotating shaft 45, a third The belt pulley set 46 and the first gear set 47, the top right side of the mounting table 21 is provided with a first rotating shaft 40, the upper side of the first rotating shaft 40 is provided with a first turbine 42, and the output shaft on the right side of the motor 31 is provided with a first worm 41 , the first worm 41 is meshed with the first worm gear 42, the front and rear symmetrical rotation of the top right side of the installation platform 21 is provided with a discharge wheel 44, the rotation of the right rear side of the top of the installation platform 21 is provided with a second rotating shaft 45, and the front side discharge wheel 44 and the first rotating shaft 40 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com