Automobile inner and outer mirror shell production mold

A technology for molds and automobiles, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as affecting work efficiency and inability to cool the mirror casing, and achieve the effect of improving work efficiency, automation and labor saving, and beautiful mirror casings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

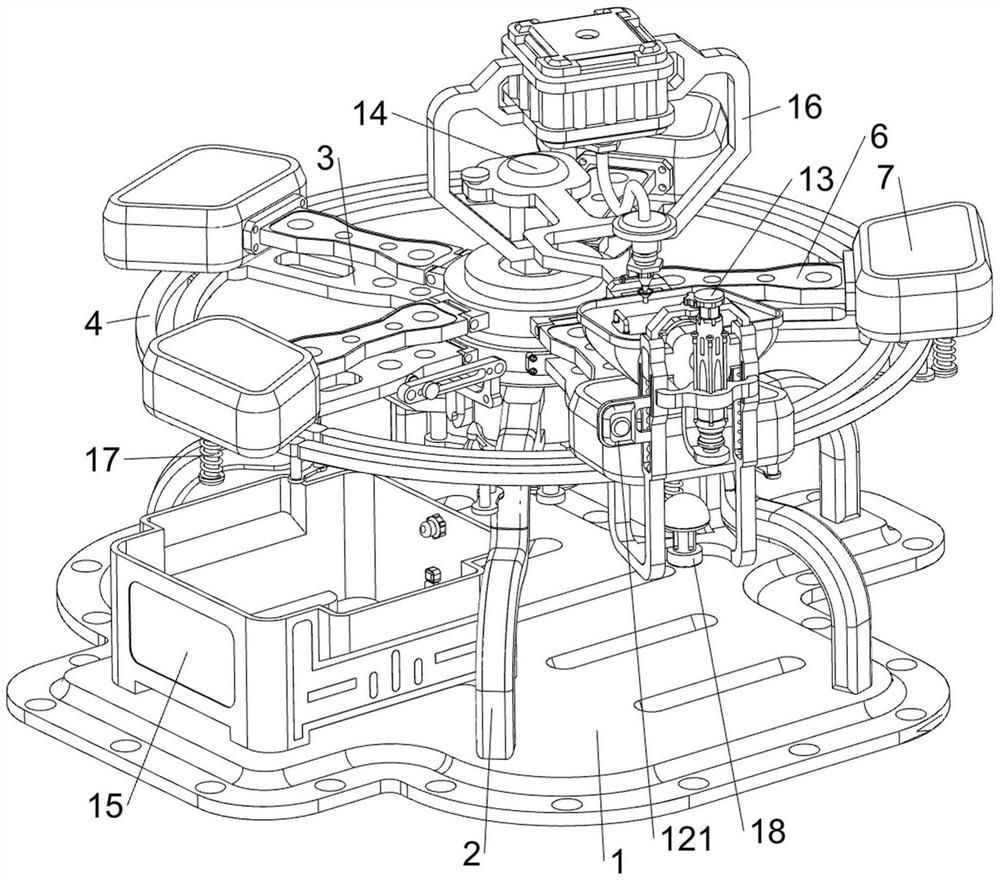

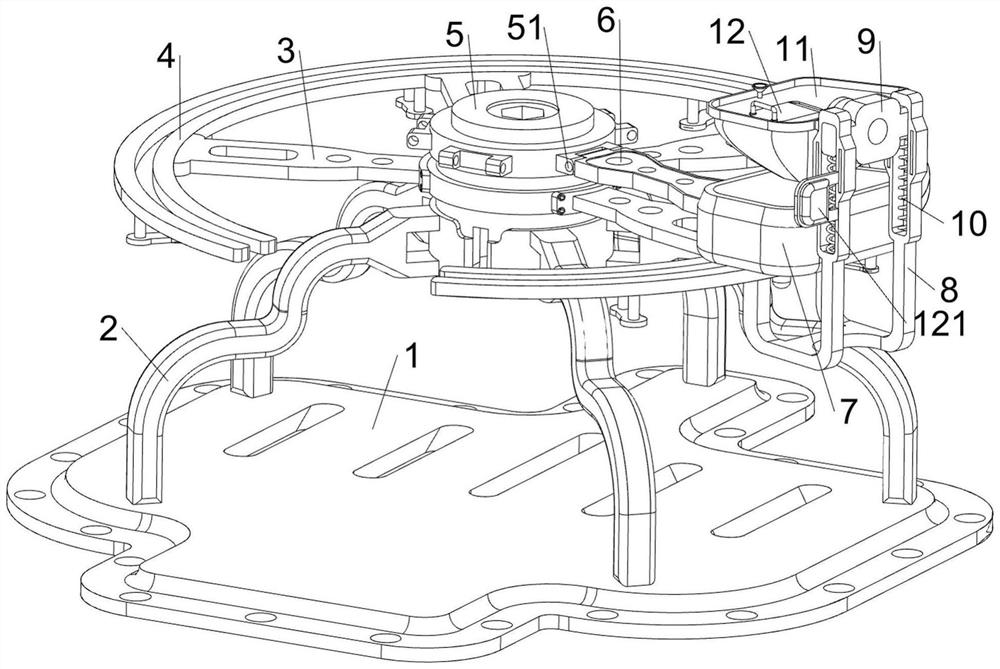

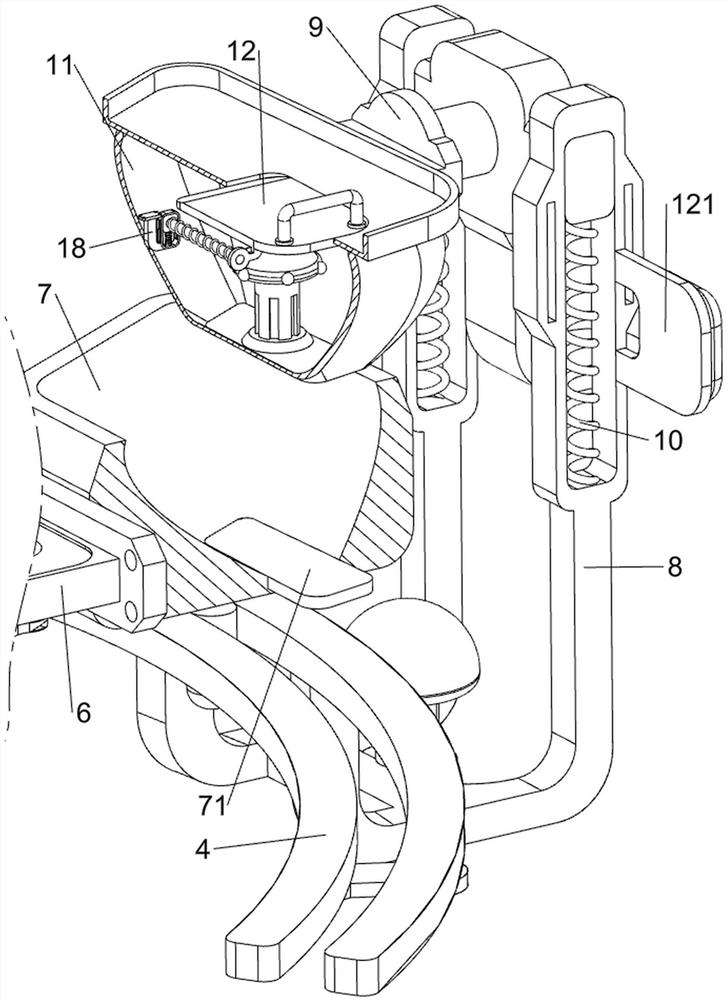

[0039] A production mold for the interior and exterior mirror shells of automobiles, in Figure 1-3 As shown in , it includes a bottom plate 1, a first support frame 2, a first connecting rod 3, an annular block 4, a rotating shaft 5, a first connecting shaft 51, a second connecting rod 6, a molding die 7, a push plate 71, a limiter Position frame 8, first slider 9, return spring 10, compacting module 11, baffle plate 12, control panel 121, lifting mechanism 13, rotating mechanism 14 and cooling mechanism 15, the top of bottom plate 1 is provided with first support frame 2, The upper side of the first support frame 2 is annularly connected with four first connecting rods 3 along the circumferential direction, and an annular block 4 for guiding is connected between the outer sides of the four first connecting rods 3 , and the top of the first support frame 2 is rotated in the middle. Rotating shaft 5 is arranged, and the outer side of rotating shaft 5 is connected with five fir...

Embodiment 2

[0045] On the basis of Example 1, in figure 1 and Figure 10As shown in the figure, it also includes an injection molding mechanism 16, and the injection molding mechanism 16 includes a third support frame 160, a charging box 161, an electric heating pipe 162, a support block 163, a nozzle 164, a booster pump 165, a delivery pipe 166 and a first pressure Sensor 167, the middle part of the third connection block 144 is connected with a third support frame 160 by bolt connection, the third support frame 160 is provided with a charging box 161 for storing the melt, and the four sides of the outer wall of the charging box 161 are provided with There are three electric heating tubes 162 for heating the melt, a support block 163 is provided on the right side of the top of the third connecting block 144, and a nozzle 164 for spraying the melt is arranged on the support block 163, and the nozzle 164 is in contact with the feeding pipe And aligned, the right side of the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com