Patents

Literature

51results about How to "No need for manual unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

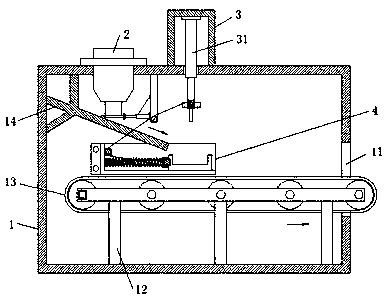

Efficient fertilizer mixing device

InactiveCN108404794AImprove the mixing effectUniform particle sizeTransportation and packagingRotary stirring mixersFertilizerEngineering

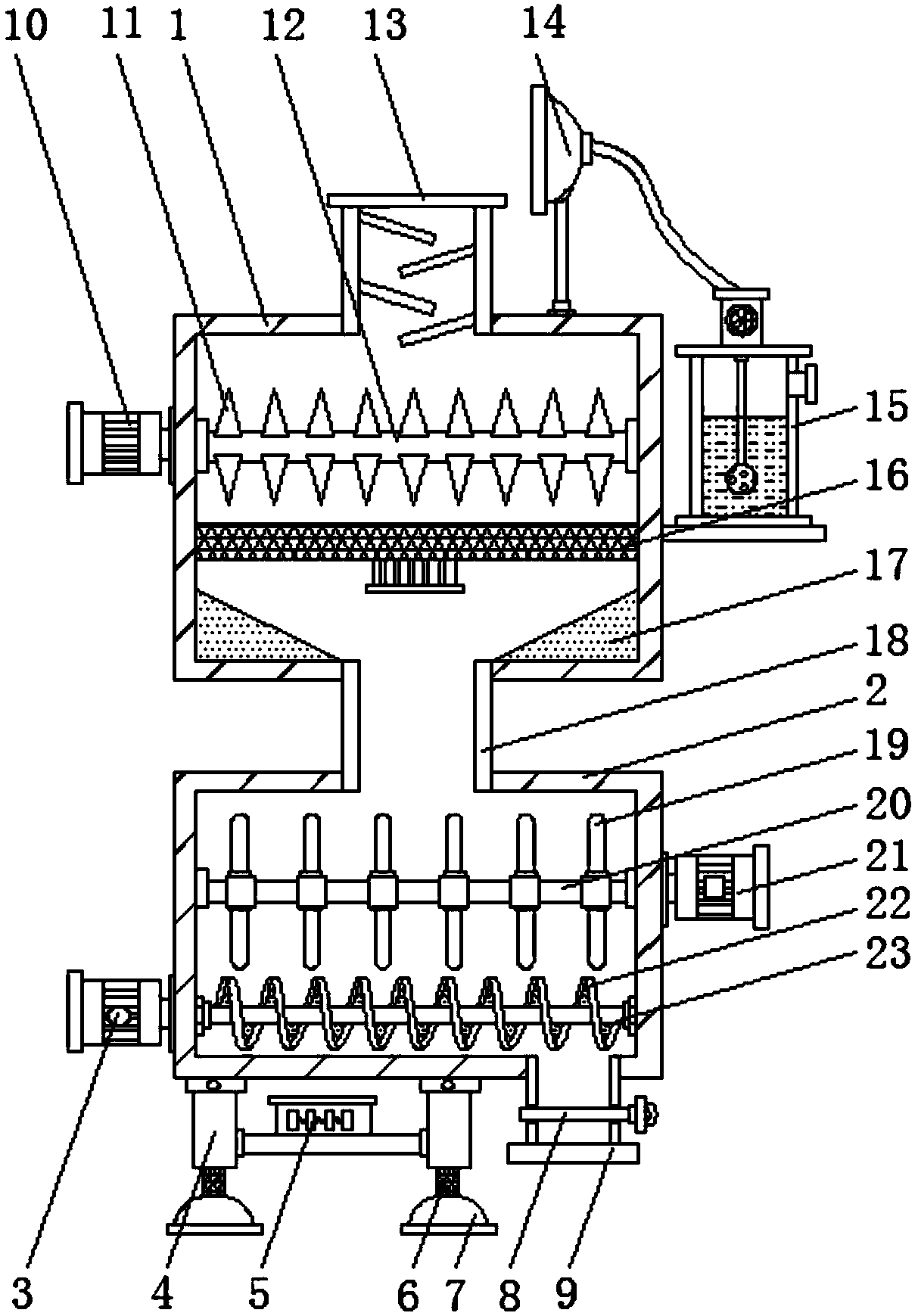

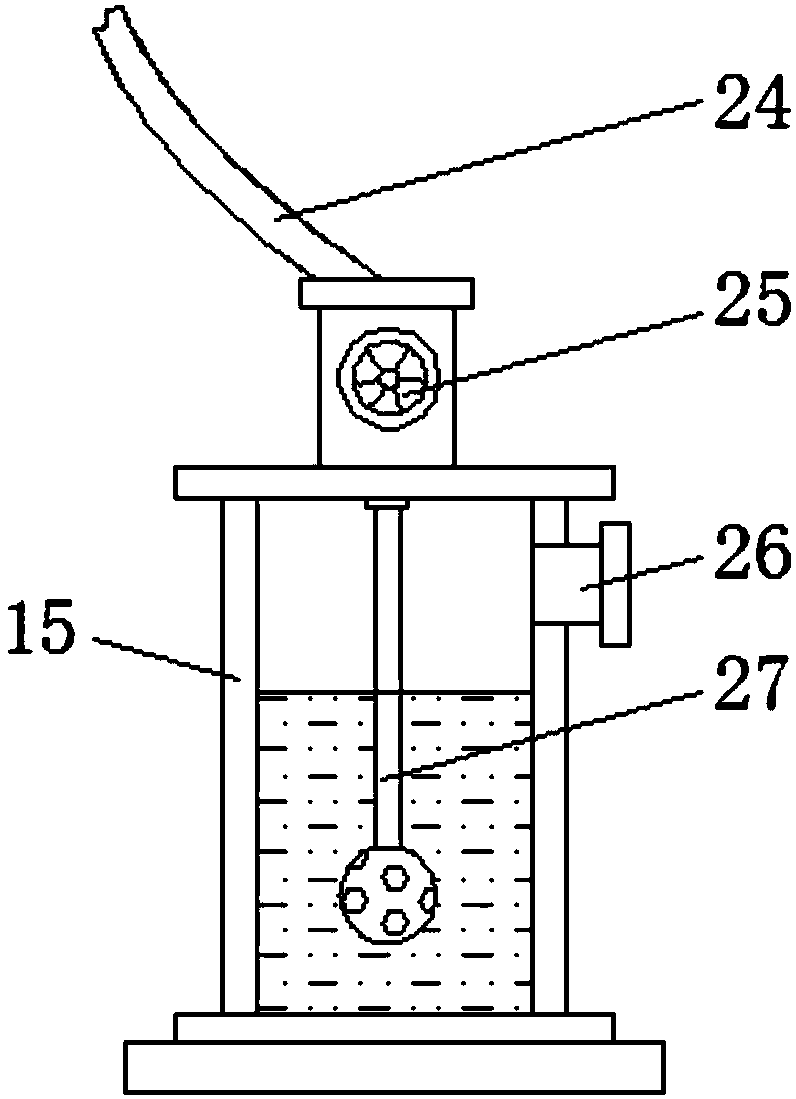

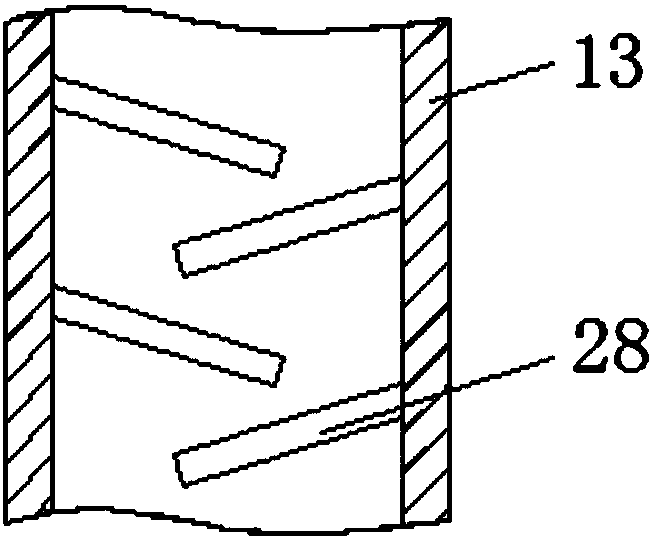

The invention discloses an efficient fertilizer mixing device which comprises a crushing box and a mixing box. A feeding hopper is arranged at the top of the crushing box, material guide inclined plates are arranged on the inner side wall of the feeding hopper in a staggered manner, a dust collection cover is arranged on the upper side of the feeding hopper, a water storage box is arranged on oneside of the crushing box, a dust collection pump is mounted at the top of the water storage box, a crushing motor is arranged on the side wall of the crushing box, the crushing box is communicated with the mixing box through a material guide pipe, and a stirring motor is arranged on the side wall of the mixing box. According to the mixing device, before fertilizers are mixed, hardened fertilizerscan be effectively crushed and thinned through crushing of crushing teeth in the crushing box, so that the fertilizers are more uniformly mixed, mixing effect of the fertilizers is improved, the device is simple in structure and convenient and efficient to use, volatile gas and dust generated in the mixing process of the fertilizers can be effectively removed, and environmental pollution is avoided.

Owner:安徽过湾农业科技有限公司

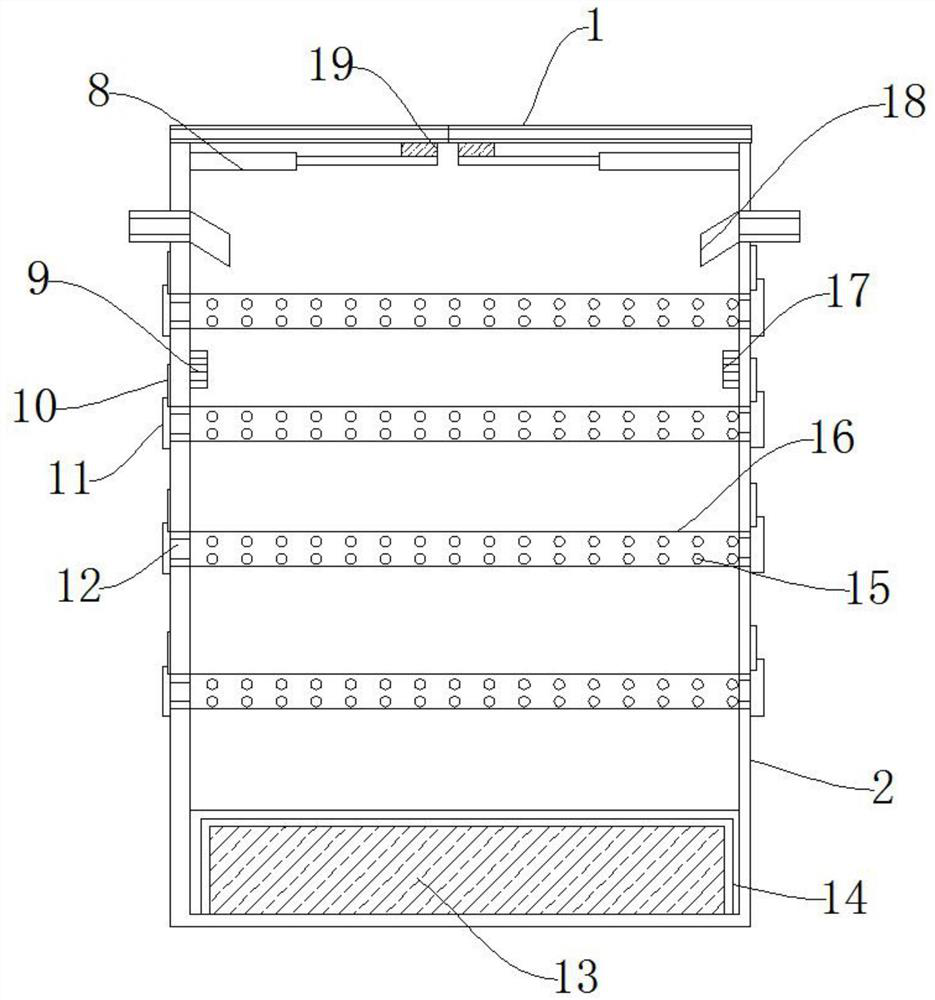

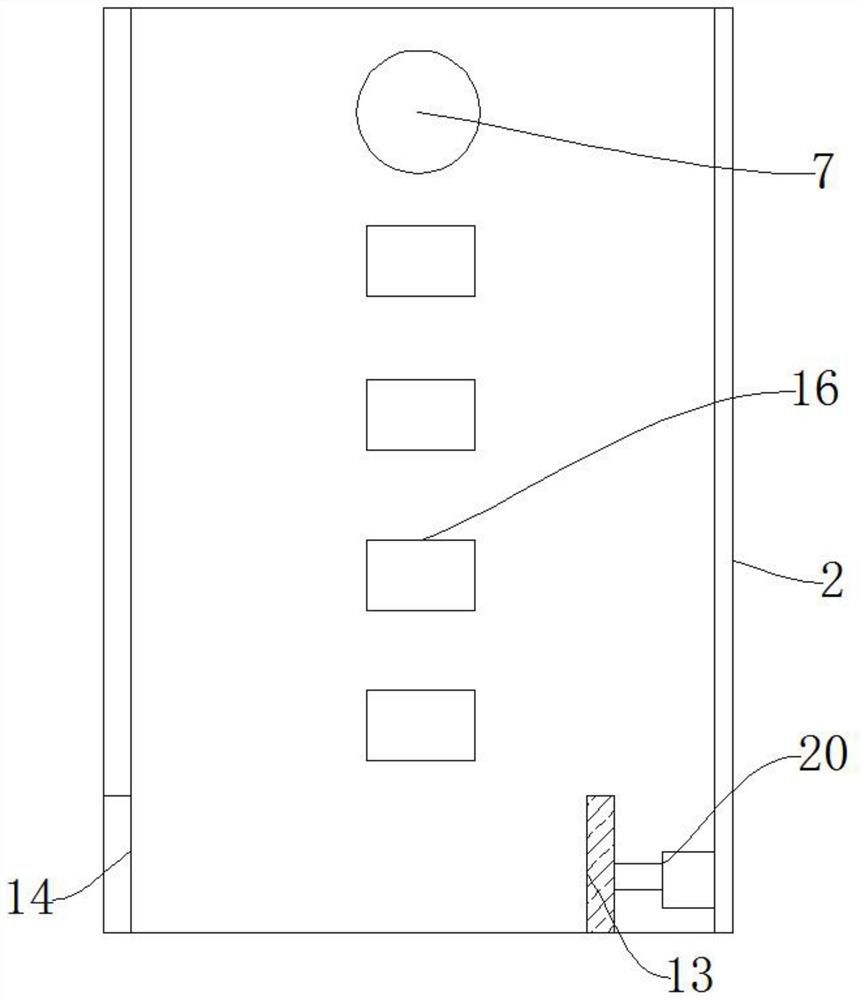

Graphite crusher

ActiveCN108176450AAvoid damageImprove crushing efficiencyGraphiteGranulation by powder suspensionImpellerGraphite

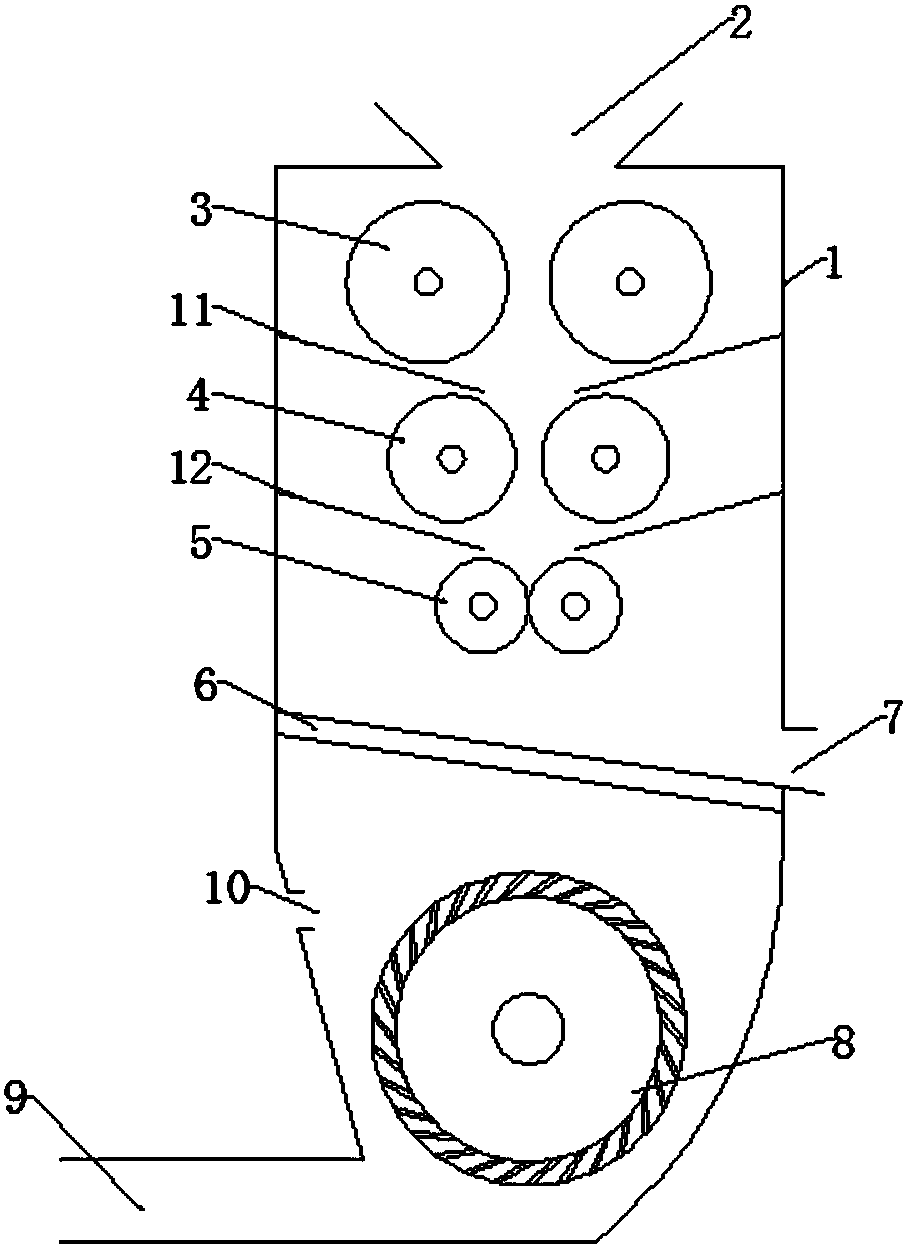

The invention discloses a graphite crusher. The graphite crusher comprises a shell body, a crushing assembly, a screen, a cross-flow fan impeller and a plurality of motors, wherein a feeding port is formed in the top end of the shell body; the crushing assembly is arranged in the shell body and comprises a pair of first crushing rollers, a pair of second crushing rollers and a pair of third crushing rollers; the screen is arranged below the pair of third crushing rollers, the edge of the screen is connected to the inner wall of the shell body, and a coarse material outlet is formed in the position, connected with the lowest edge of the screen, of the shell body; the cross-flow fan impeller is arranged in the shell body and is positioned below the screen, a fine material outlet is formed between the position, right opposite to one side of the circumferential surface of the cross-flow fan impeller, of the shell body and the position, right opposite to the other side of the circumferential surface of the cross-flow fan impeller, of the shell body, and an air inlet is formed in the upper part of the position, right opposite to one side of the circumferential surface of the cross-flow fan impeller, of the shell body; and the plurality of motors are used for correspondingly driving the pair of first crushing rollers, the pair of second crushing rollers, the pair of third crushing rollers and a cross-flow fan to rotate. According to the graphite crusher, the crushing effect and the spheroidization effect for graphite are excellent.

Owner:山东兴发炭素有限公司

Meat cleaning device for production of canned food

Owner:CHONGQING YUANXIANG FOOD

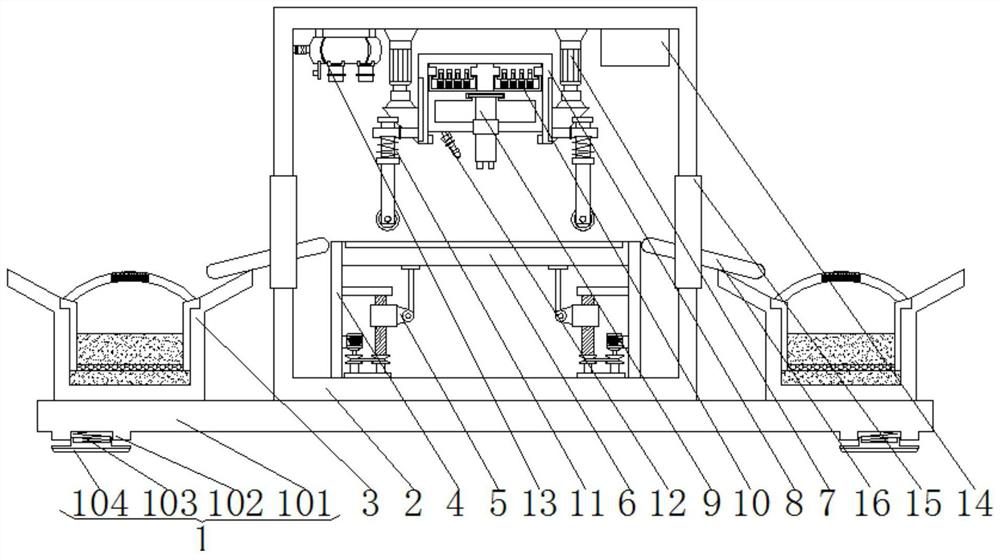

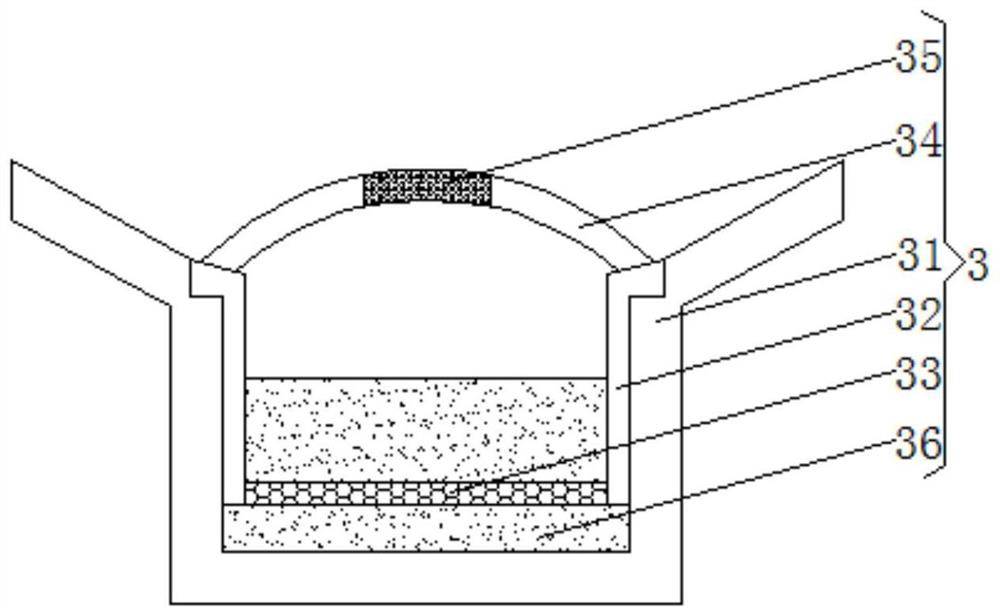

Unloading assisting device of liquefied natural gas

The invention relates to the technical field of an unloading assisting device and particularly relates to an unloading assisting device of liquefied natural gas. The unloading assisting device comprises two freight forklifts which are symmetrically fixed on a forklift portal frame; a second resetting spring is arranged between two baffles; two bearings are symmetrically arranged on the side wall, far away from one end of a limiting groove, of a horizontal blind hole; a rotary shaft is connected between inner rings of the two bearings; the middle axis of the rotary shaft is parallel to the middle axis of a through hole; the other end of a steel rope penetrates through the through hole and is connected with the two baffles and the rotary shaft; the baffle close to one end of a limiting groove is fixedly connected with the steel rope; and the baffle, far away from one side of the limiting groove, is movably connected with the steel rope. According to the unloading assisting device of the liquefied natural gas, manual unloading is not needed so that more labor is saved; a fuel gas tank does not swing greatly, so that unloading is safer; and when the forklift is used for unloading, a limiting plate is arranged on the forklift, so that unloading of the liquefied natural gas can be assisted better.

Owner:蚌埠启邦科技信息咨询有限公司

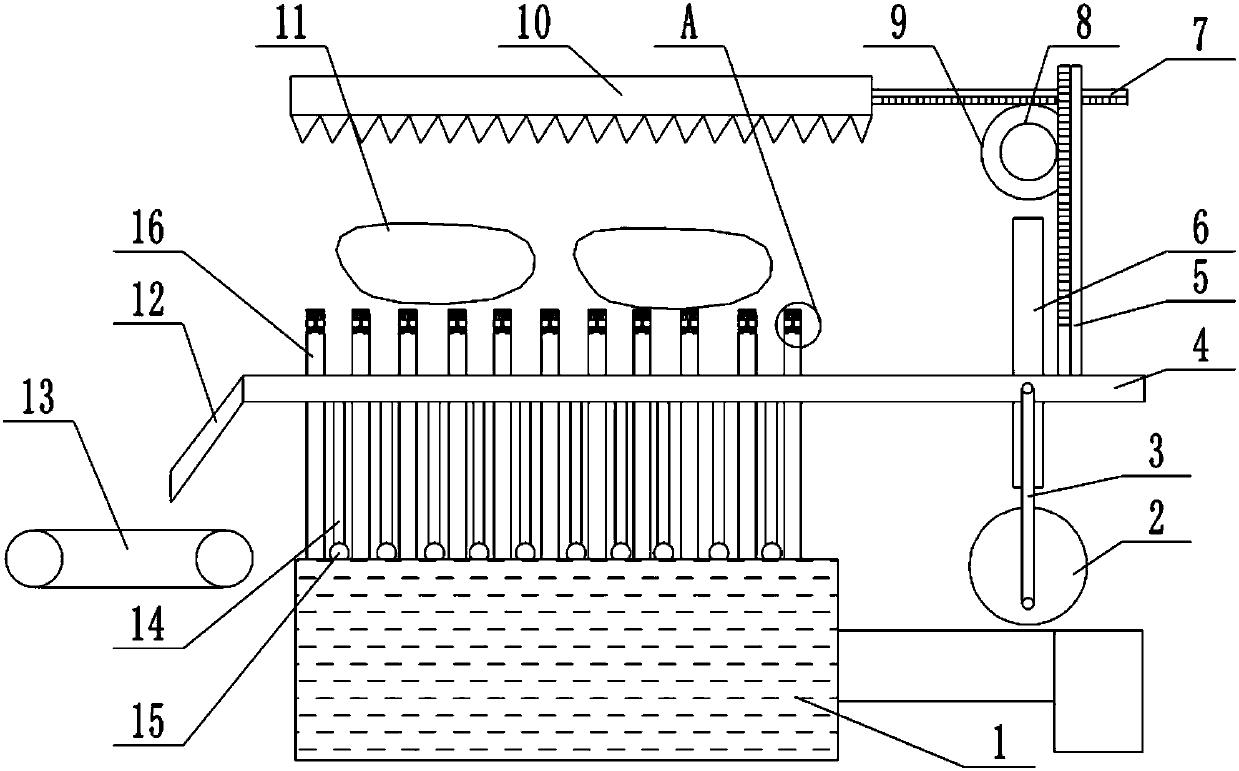

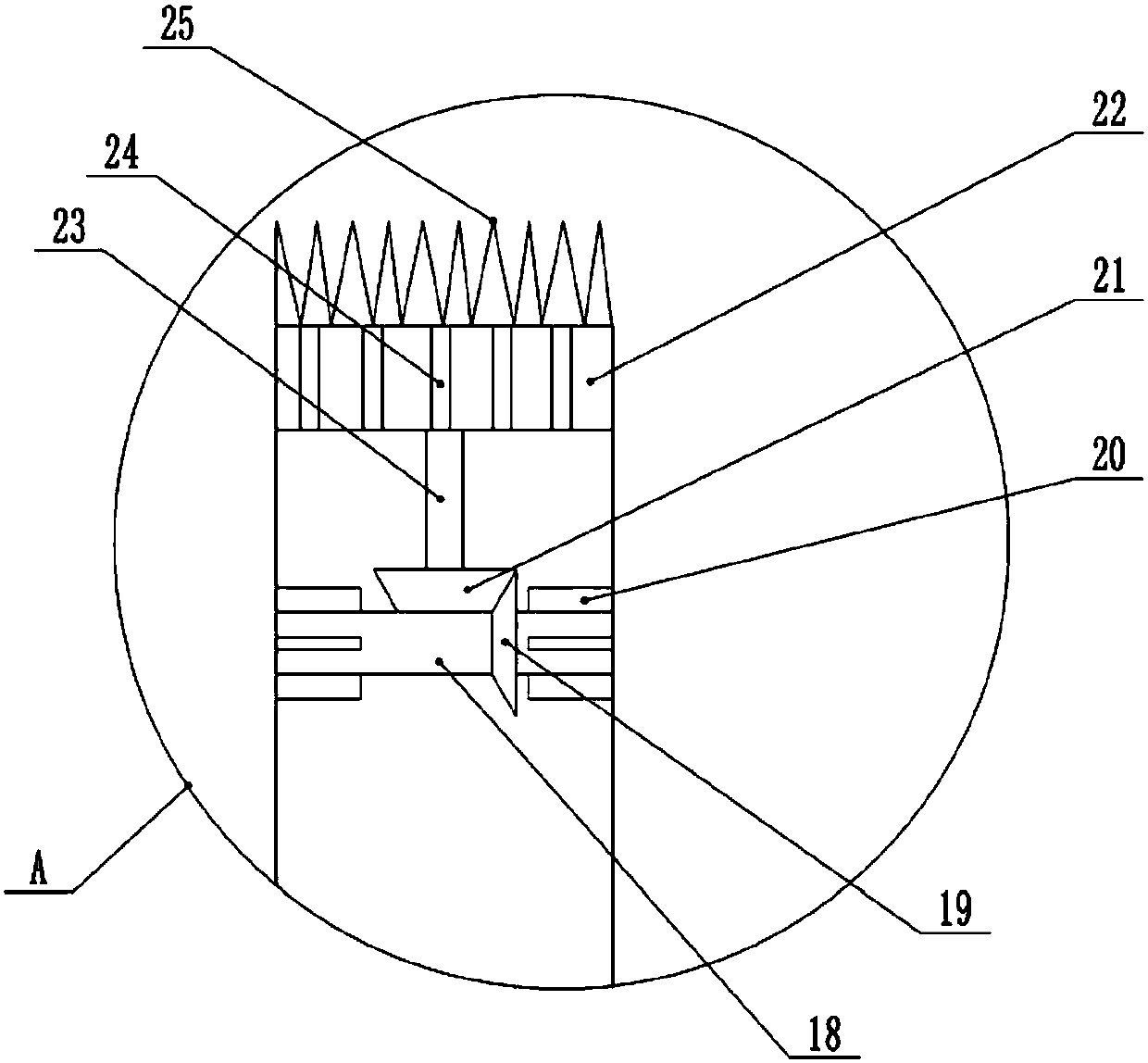

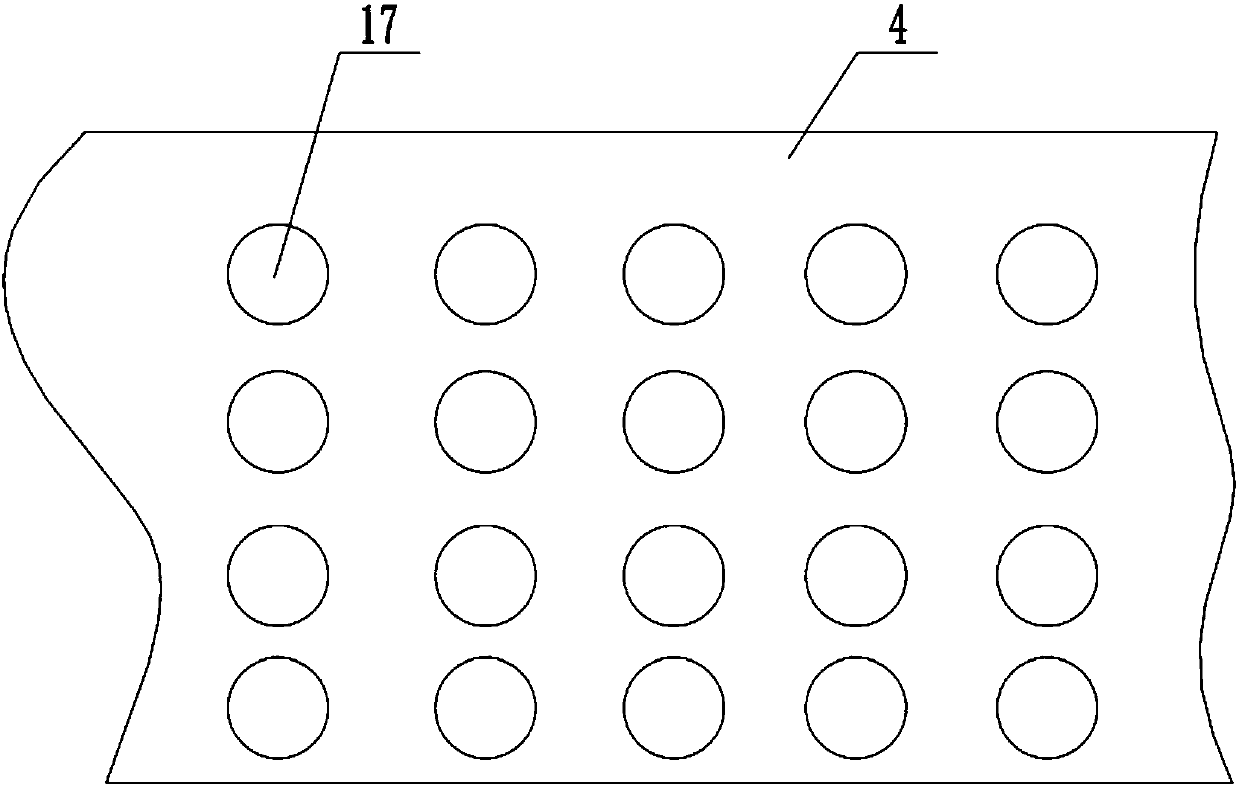

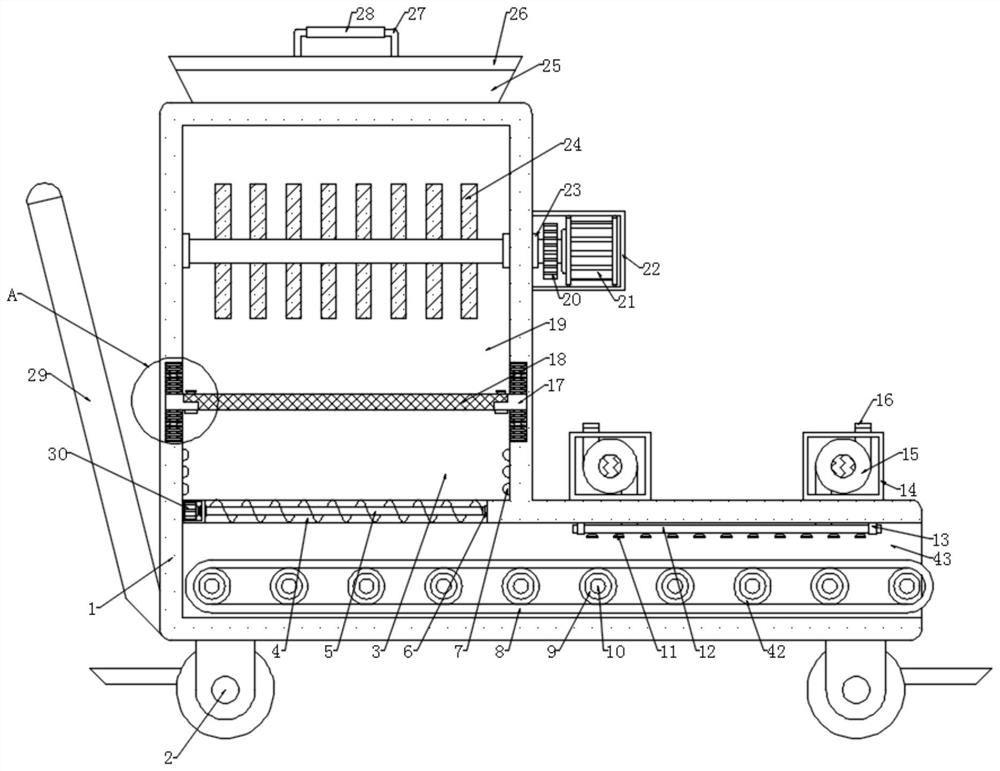

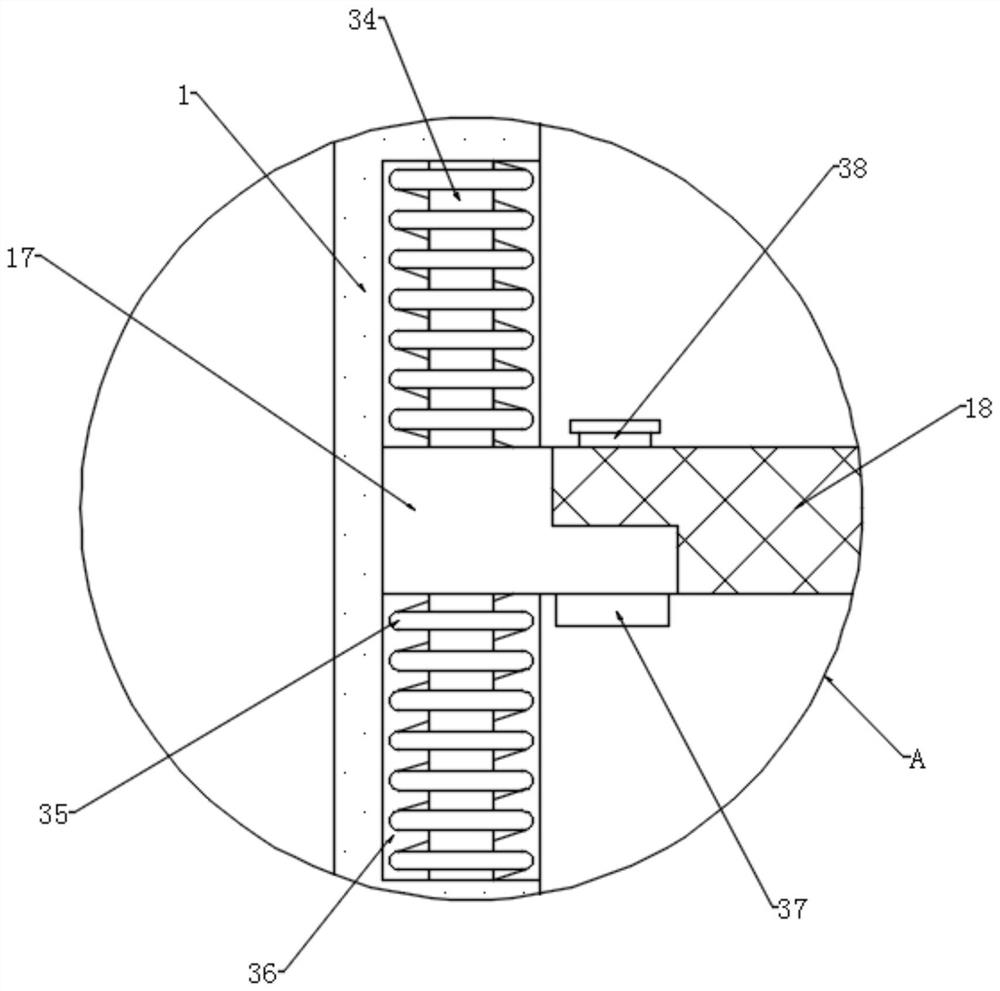

Movable multifunctional agricultural product processing equipment

InactiveCN112675996AAchieve the purpose of breakingTo achieve the purpose of drying treatmentSievingScreeningGear wheelAgricultural engineering

The invention discloses movable multifunctional agricultural product processing equipment, and belongs to the technical field of agricultural product processing. The equipment comprises a box body, the box body is internally provided with a crushing cavity, a sterilizing cavity and a conveying cavity, the side surface of the inner wall of the crushing cavity is fixedly connected with four third bearings, first crushing rods and second crushing rods are arranged in the four third bearings in a penetrating mode correspondingly, the first crushing rods mesh with the second crushing rods, and one ends of the first crushing rods and one ends of the second crushing rods penetrate through second bearings and are fixedly connected with a driving gear and a driven gear correspondingly. The equipment has the beneficial effects that a first motor works, the driving gear can be driven to rotate, then the driven gear can be driven to rotate, the first crushing rods and the second crushing rods can rotate in a meshing mode, and thus the purpose of crushing agricultural products is achieved; a drying pump works, external gas can be heated and then conveyed to a spray head through a pipeline, and thus the purpose of drying the agricultural products in the transportation process is achieved.

Owner:新化县日新农业发展有限公司

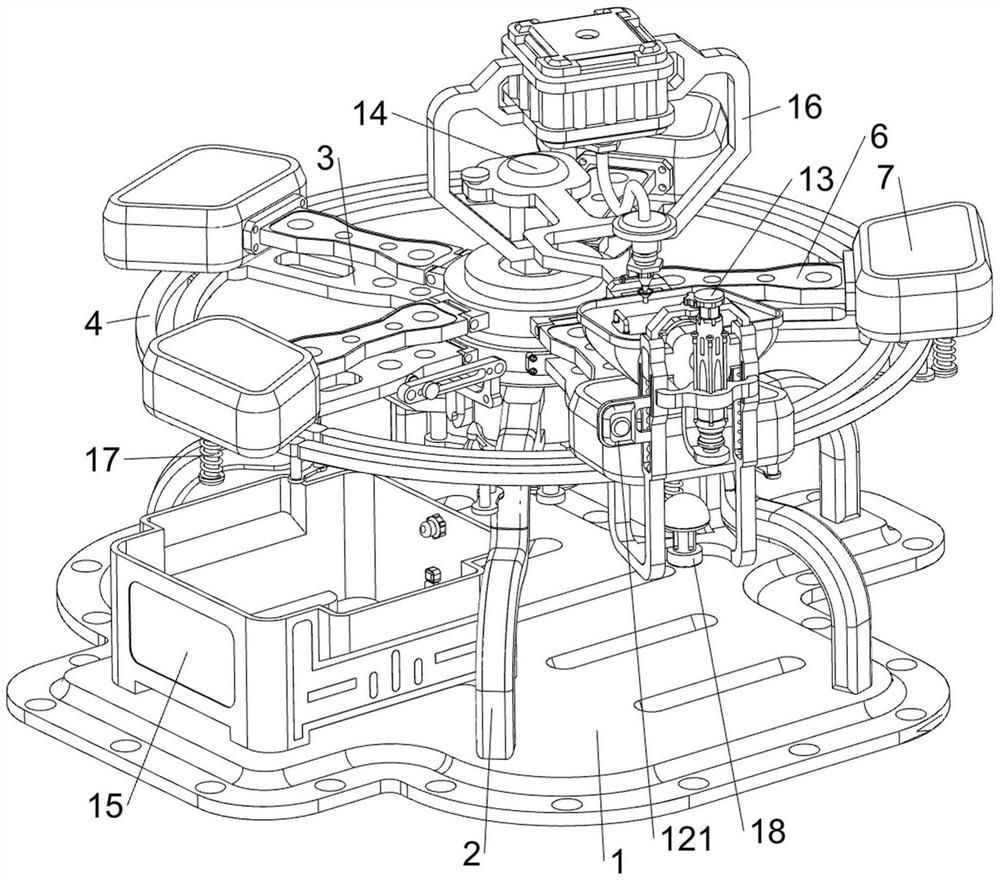

Unmanned mine car with induction function

InactiveCN112026620AAchieve steeringControl rotationSatellite radio beaconingItem transportation vehiclesMining engineeringStress sensors

The invention discloses an unmanned mine car with the induction function. The unmanned mine car specifically comprises a chassis, a functional table, a driver seat, a mine bucket and a limiting sleeve; the driver seat is installed in the middle of the top of the chassis, a storage battery is arranged in the driver seat, the functional table is fixed to one side of the top of the chassis, and the mine bucket is installed on the other side of the top of the chassis; hydraulic telescopic rods are arranged on the sides, close to the mine bucket, of the two ends of the driver seat, the output endsof the hydraulic telescopic rods are connected with the mine bucket, protective baffles are fixed to the two ends of the mine bucket through buffer springs, and ultrasonic radars are evenly installedat the tops of the two ends of the mine bucket. According to the unmanned mine car with the induction function, by arranging a pressure sensor and an ore loading hopper, minerals can be weighed whilebeing carried, and when the ore loading mass reaches a preset value, the device can send information to terminal control equipment to remind that ore loading is completed, the overload condition is avoided, and the use safety is higher.

Owner:DONGGUAN UNIV OF TECH

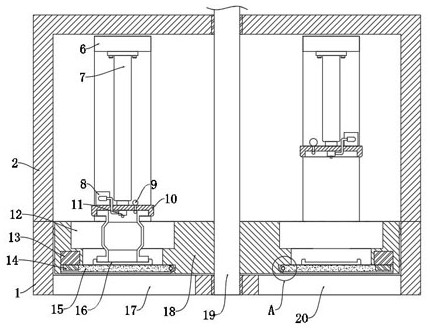

Filtering device for whey fermentation liquor processing and using method thereof

ActiveCN111389081AAvoid wastingImprove work efficiencyMoving filtering element filtersMilk SerumWater source

The invention relates to the technical field of food processing, in particular to a filtering device for whey fermentation liquor processing and a using method thereof. The device comprises a filtering tank and a supporting plate, the lower part of the outer side of a filtering tank is fixedly connected with fixed seats which are distributed left and right; the other end of the fixed seat is fixedly connected with the supporting plate; a discharging mechanism is fixedly connected to the interior of the lower end face of the filtering tank, a vibration mechanism is arranged above the discharging mechanism, the outer side of the vibration mechanism is fixedly connected with the filtering tank, a filtering device is arranged above the vibration mechanism, the outer side of the filtering device is slidably connected with the filtering tank, and a fixing plate is fixedly connected to the upper end face of the filtering device; through arrangement of a filtering motor, a rotating rod, a fixed block, a filtering net, a sliding ring and a flushing water pump, raw materials do not need to be cleaned and screened manually, the working efficiency is greatly improved, the labor cost is reduced, profits are increased, a water source can be recycled, waste of the water source is avoided, and good use value is achieved.

Owner:SYNBIOTECH BIOTECHNOLOGY YANGZHOU CO LTD

Automobile inner and outer mirror shell production mold

InactiveCN114228057ANo manual push requiredAutomation saves effortDomestic articlesEngineeringControl switch

The invention relates to a die, in particular to a die for producing inner and outer mirror shells of an automobile. According to the technical aims, the production mold for the inner and outer mirror shells of the automobile is high in working efficiency and capable of automatically cooling a formed mirror shell. According to the technical scheme, the automobile inner and outer mirror shell production mold comprises a bottom plate, a first supporting frame, first connecting rods, an annular block, a rotating shaft and the like, the first supporting frame is arranged at the top of the bottom plate, the four first connecting rods are annularly connected to the upper side of the first supporting frame in the circumferential direction, and the annular block is connected between the outer sides of the four first connecting rods; a rotating shaft is rotationally arranged in the middle of the top of the first supporting frame. An operator presses the control switch, the electric push rod works to drive the compaction module to move downwards to make contact with the shaping mold, the operator can inject molten liquid into a gap between the compaction module and the shaping mold for forming, the compaction module does not need to be manually pushed through the operation, and the operation is more stable and accurate.

Owner:YINGTAN KSD ELECTRONICS PLASTIC

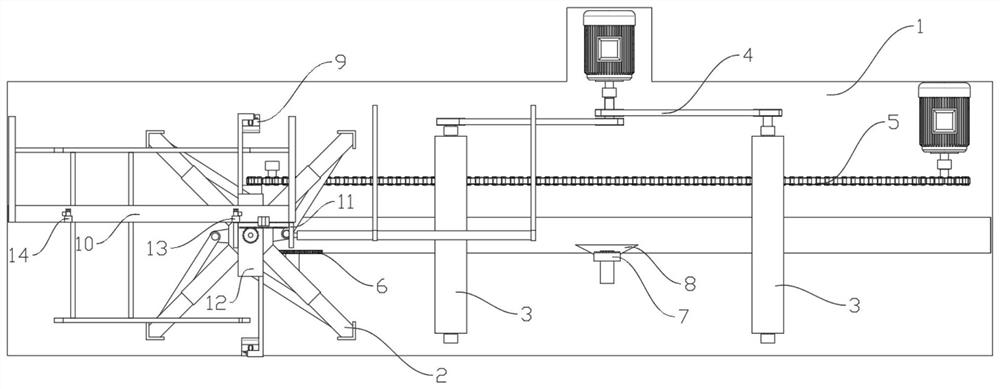

Factory valve detecting, screening and classifying equipment

ActiveCN113695263ASave human effortNo need for manual inspectionSortingFluid-tightness measurement using fluid/vacuumRapid detectionStructural engineering

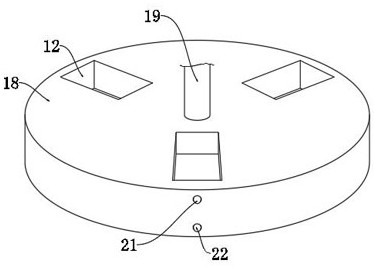

The invention discloses a factory valve detecting, screening and classifying equipment which comprises a base. The base is of a basin-shaped structure, a mounting cover is fixedly connected to the upper end of the base, a feeding opening is formed in the side wall of the mounting cover, and a rotatable rotating seat is arranged at the inner side of the base; a rotating column fixedly connected with the rotating seat vertically penetrates through the center of the rotating seat, the lower end of the rotating column is rotationally connected to the inner bottom of the base, the upper end of the rotating column penetrates out of the top of the mounting cover and is rotationally connected with the mounting cover, and three detection grooves are formed in the upper end face of the rotating seat at equal intervals in the circumferential direction; and a detection mechanism is installed above each detection groove, and a material supporting mechanism is arranged below each detection groove. According to the factory valve detecting, screening and classifying equipment, automatic and rapid detection and screening of valves are achieved, manual observation and detection are not needed, the overall detection and screening efficiency is greatly improved, meanwhile, automatic discharging is achieved, manual discharging is not needed, and manpower is saved.

Owner:南通金武锻造有限公司

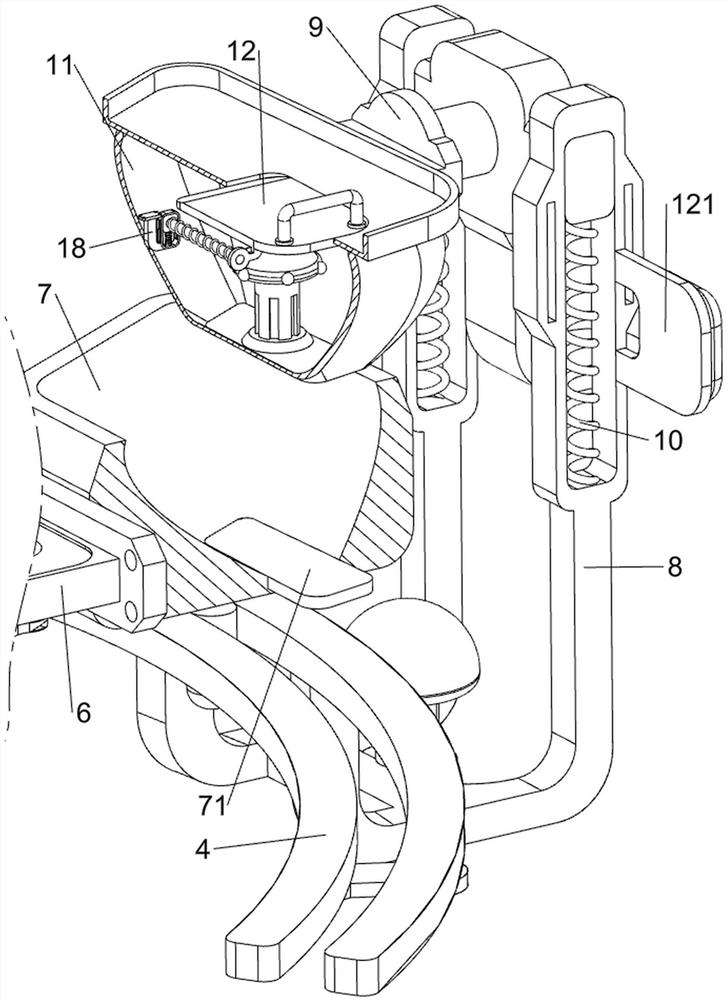

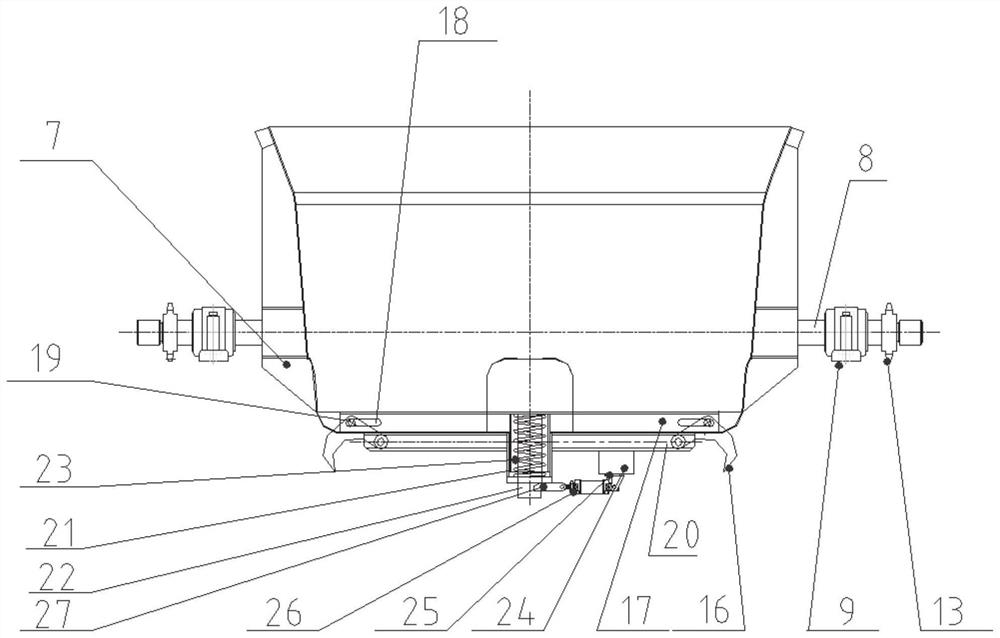

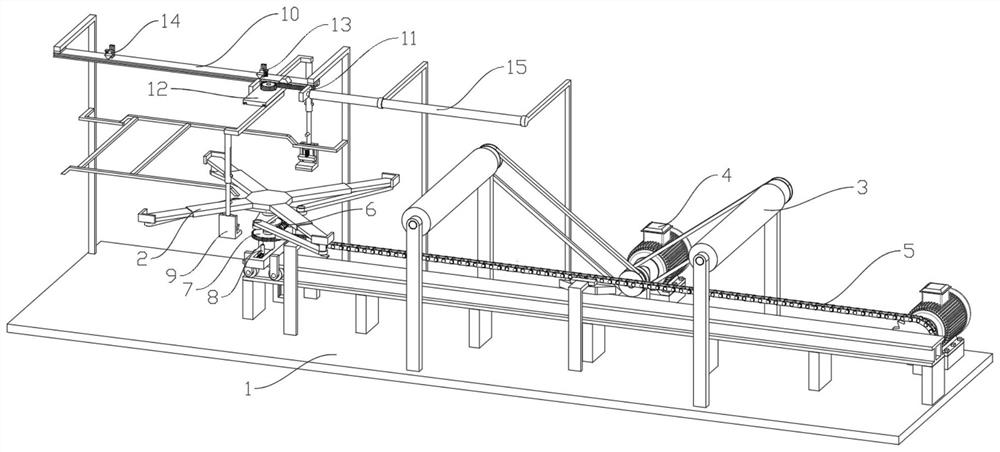

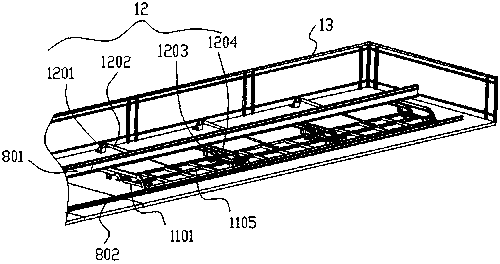

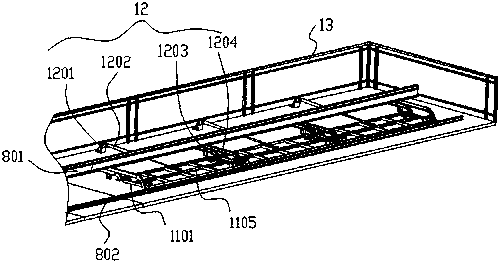

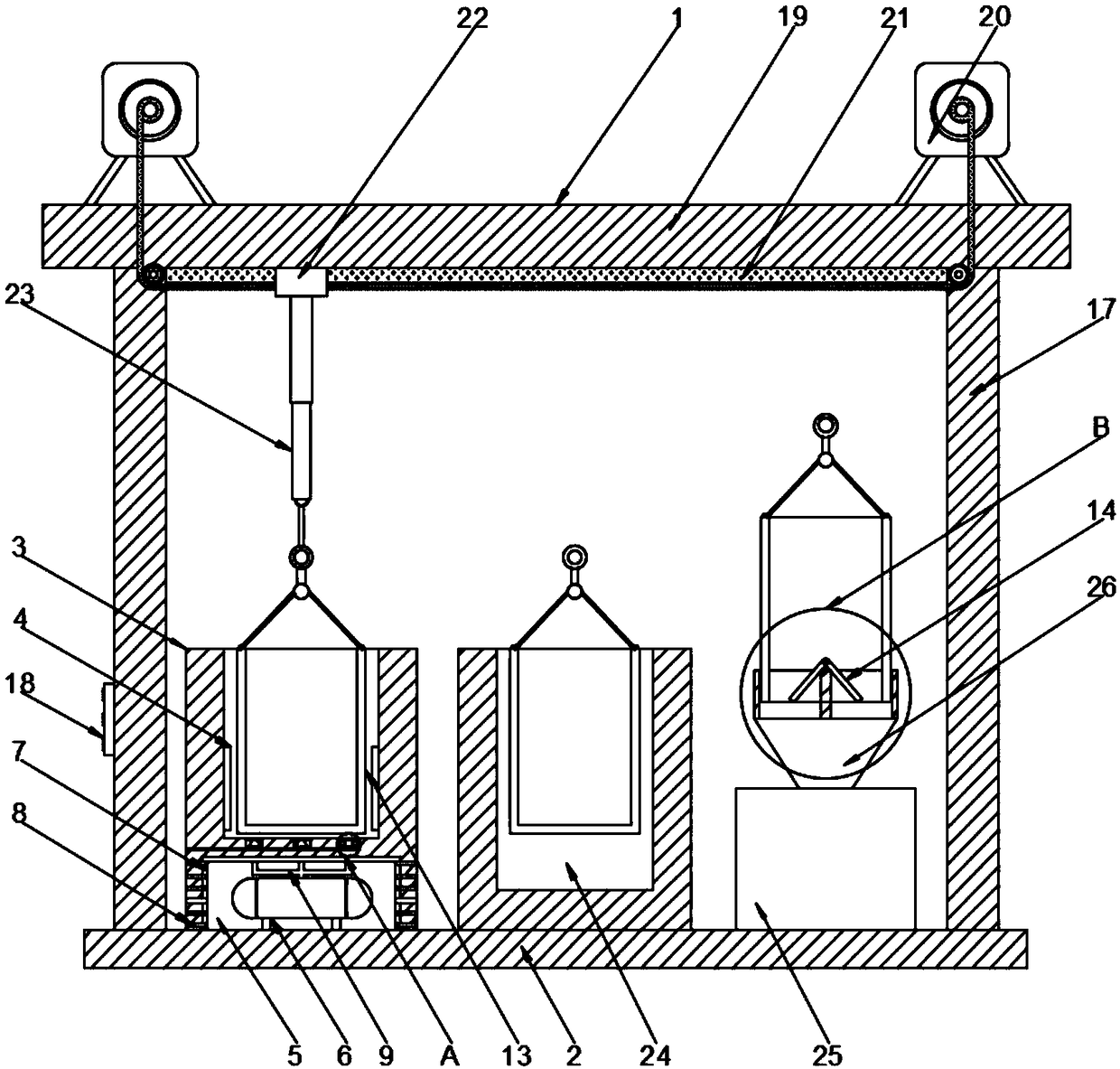

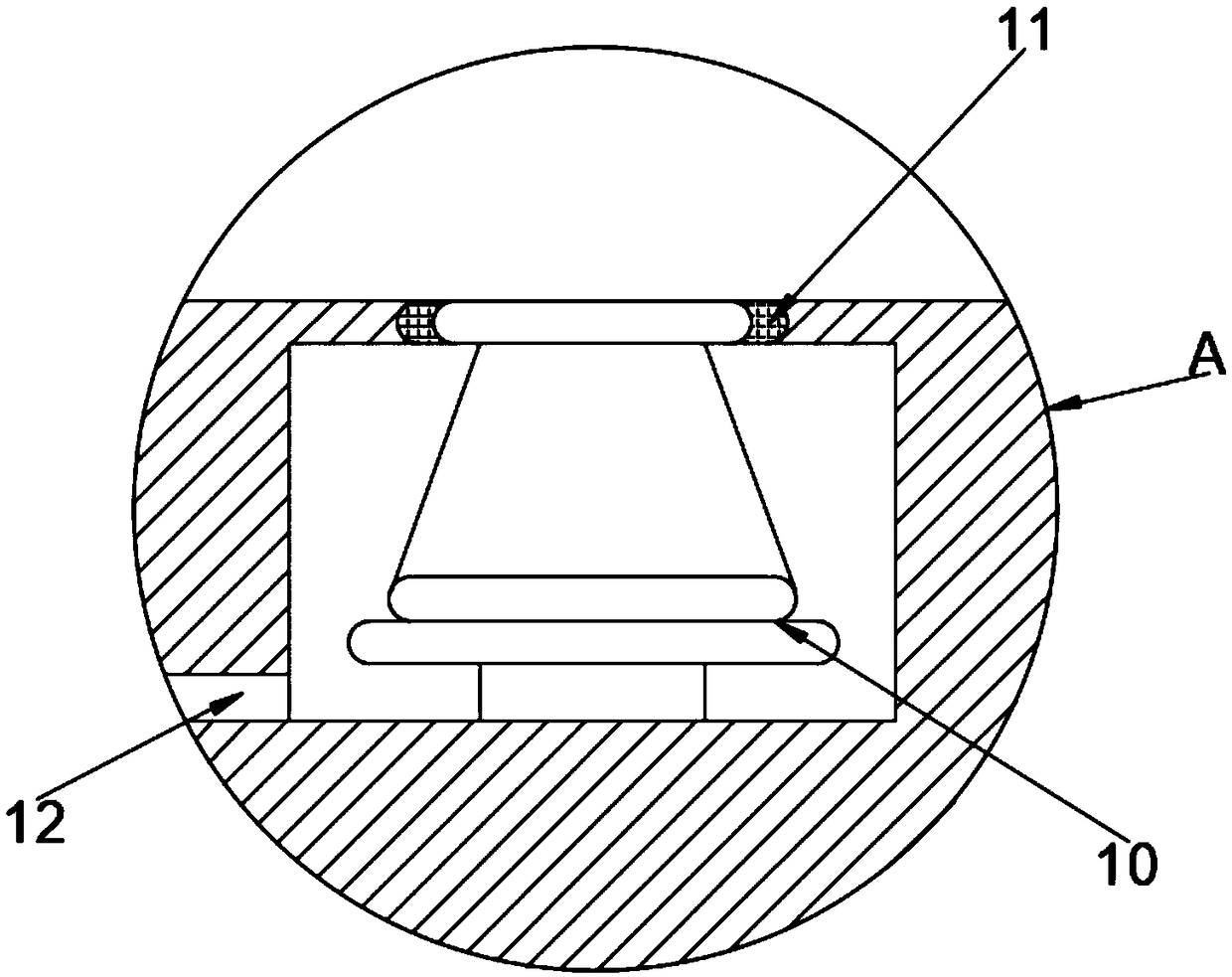

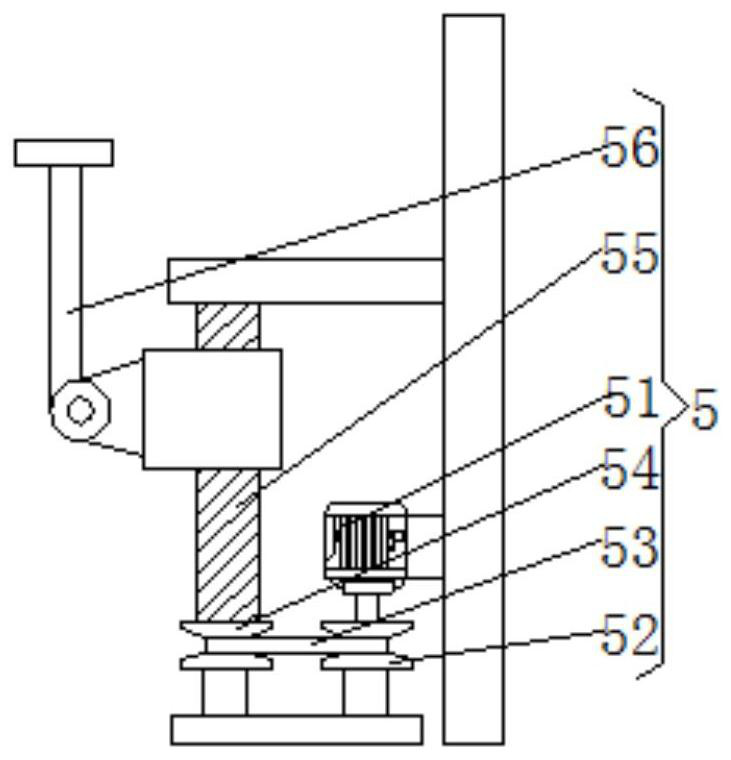

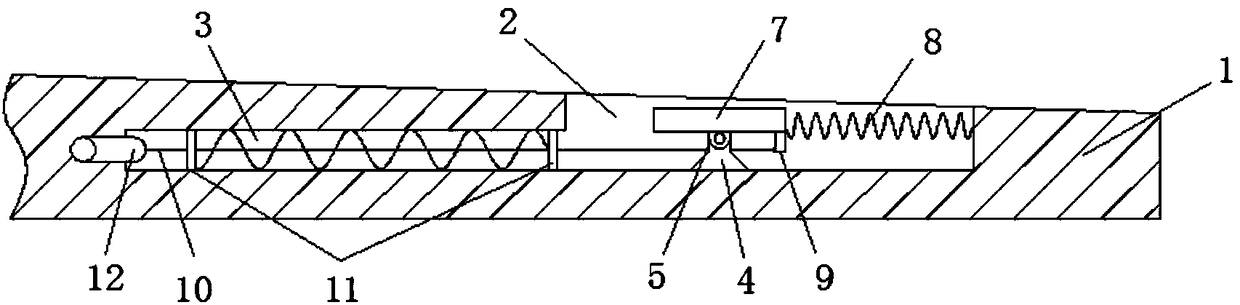

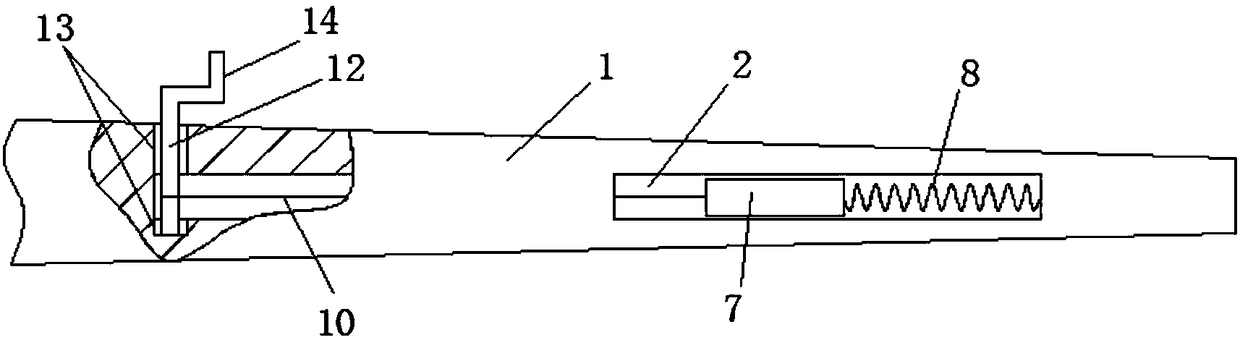

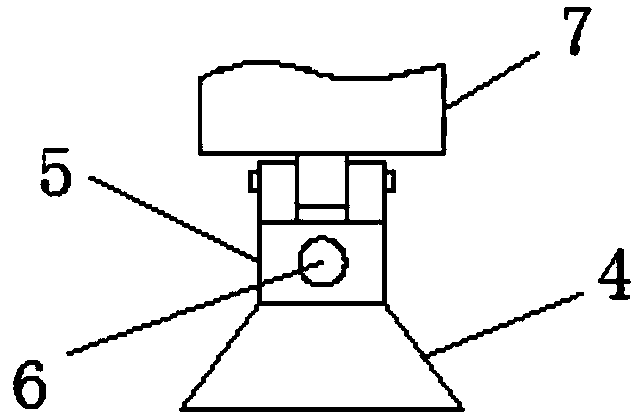

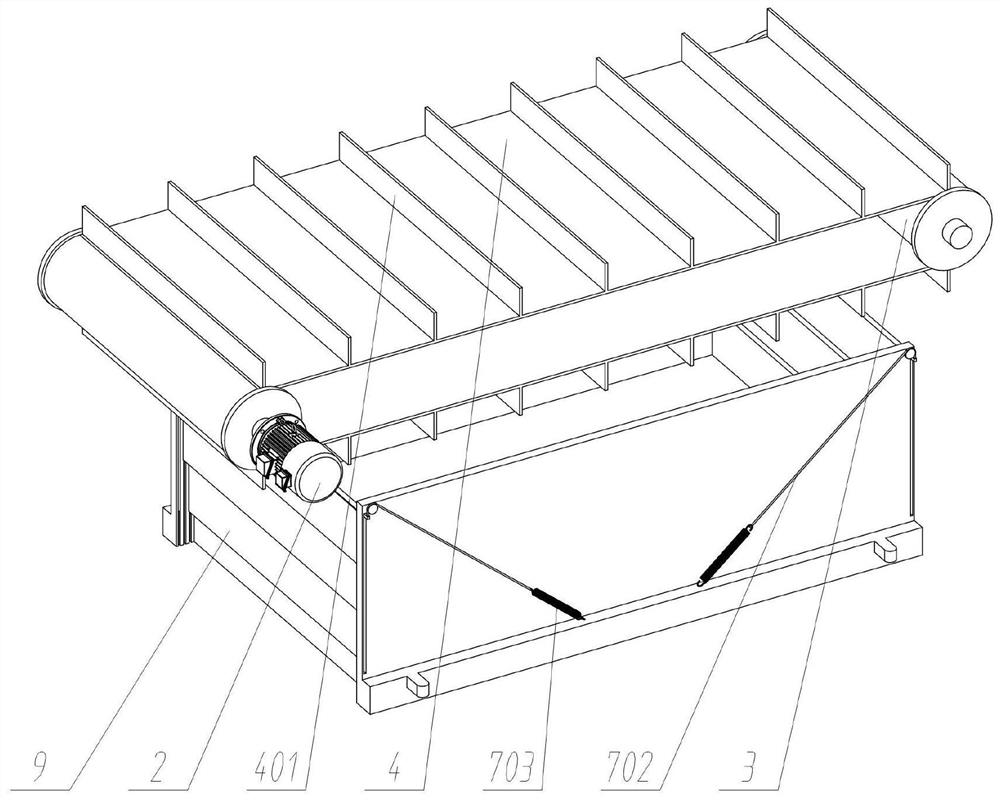

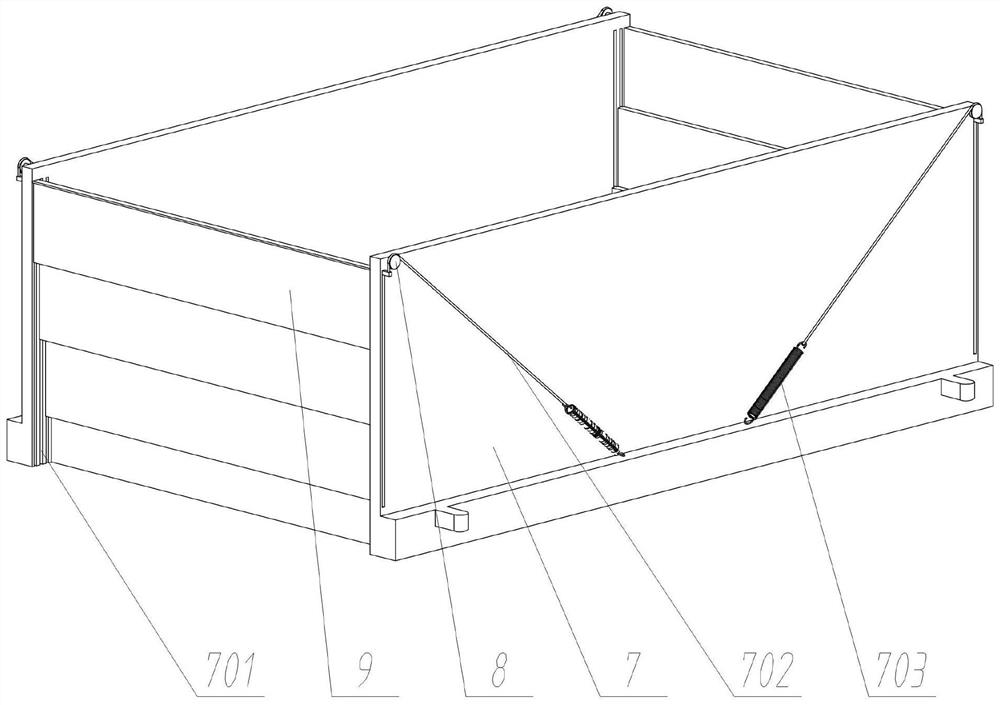

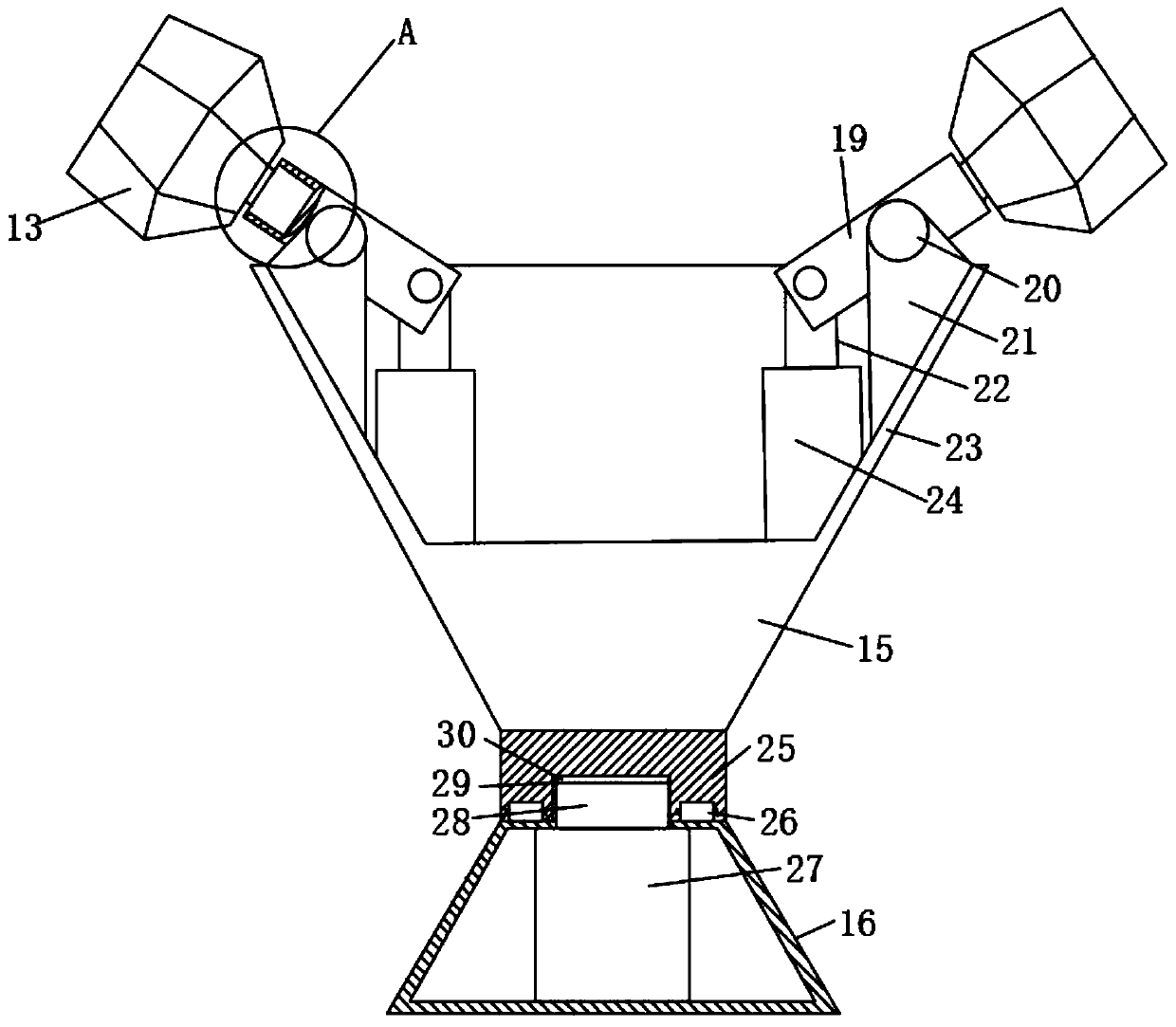

Automatic unpacking, unloading and recycling device for ton bags and working method

PendingCN111994400AImprove work efficiencyReduce labor intensityFlexible bulk container emptying systemsMechanical engineeringSuspender belt

The invention relates to an automatic unpacking, unloading and recycling device for ton bags and a working method. The automatic unpacking, unloading and recycling device comprises a lifting mechanism, wherein the lifting mechanism is connected with a lifting vehicle; the lifting vehicle is rotatably connected with a charging barrel; the charging barrel is connected with a turnover driving mechanism arranged on the lifting vehicle; a hook driving mechanism is arranged on the bottom of the charging barrel; the hook driving mechanism is connected with a hook; the hook can hold a hanging belt arranged on the bottom of a ton bag; a hopper is arranged below the tail end of the lifting mechanism; a guide grate which is arranged in an inclined mode is arranged in the hopper; a material conveyingmechanism is arranged below a discharge hole of the hopper; and a ton bag packing machine is arranged at one side of the tail end of the guide grate. The automatic unpacking, unloading and recycling device is high in working efficiency, is low in labor intensity, and avoids resource waste.

Owner:山东森烨生态工程有限公司

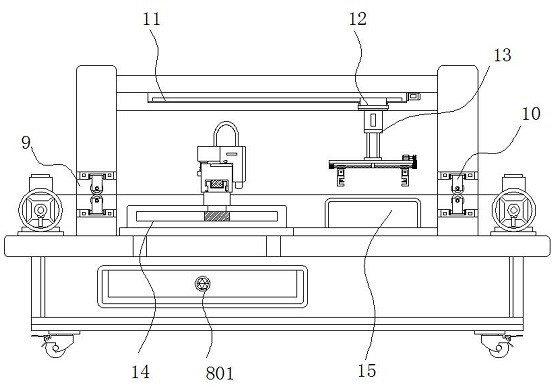

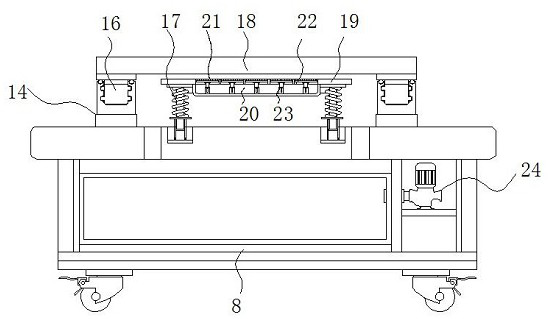

Automatic discharging device for leather carving type flexible decorative material

ActiveCN112025525ARealize automatic unloadingAchieve transshipmentPolishing machinesGrinding drivesHydraulic cylinderIndustrial engineering

The invention discloses an automatic discharging device for a leather carving type flexible decorative material, and relates to the technical field of leather carving type flexible decorative materialproduction processes. The automatic discharging device comprises two clamps and a second guide rail, wherein a pushing assembly is slidably arranged on the second guide rail, the pushing assembly comprises a third rack slidably arranged on the second guide rail, a first pushing block is fixedly connected to one end of the third rack, a second pushing block is fixedly connected to the other end ofthe third rack, the pushing assembly is driven by a hydraulic cylinder arranged on a machine frame, a linkage assembly is arranged between the pushing assembly and the two clamps, and the linkage assembly comprises a folding linkage unit and a lifting linkage unit. According to the automatic discharging device for the leather carving type flexible decorative material, through cooperation of the pushing assembly, the linkage assembly, a second locking mechanism, a third locking mechanism and the clamps, the leather carving type flexible decorative material loosened on a clamping mechanism canbe moved away from the clamping mechanism, automatic discharging is achieved, the leather carving type flexible decorative material is transferred to a downward moving processing procedure place or aconveying belt, manual discharging is not needed, and the discharging efficiency is high.

Owner:富晶智造(东莞)科技有限公司

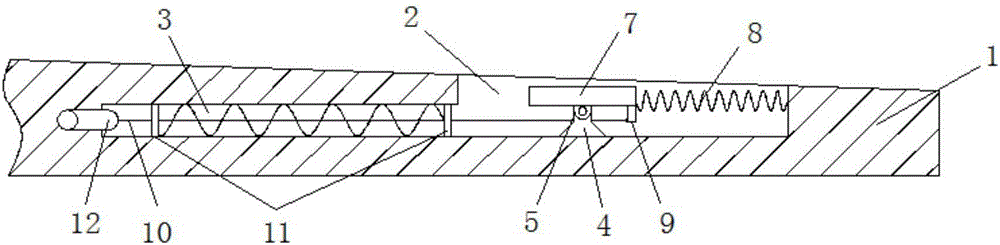

Cutting device for plastic tableware production

InactiveCN109202983AImprove cutting efficiencyEasy to operateMetal working apparatusEngineeringMechanical engineering

The invention discloses a cutting device for plastic tableware production. The cutting device includes a device body, and the device body is internally provided with a conveying mechanism, an efficient pressing cutting mechanism located on the upper part of the conveying mechanism and a feeding mechanism matched with the efficient pressing cutting mechanism; the efficient pressing cutting mechanism comprises a cutting platform, a first driving device and a linkage device, the cutting platform is suspended and fixed between the inner walls on both sides through a mounting plate, the cutting platform is internally and slidably provided with a discharging plate, one side of the discharging plate is provided with a fixing plate, one side of the fixing plate is connected with a guiding rod flushing with the discharging plate, and the guiding rod is sleeved with a spring; and a bottom piston rod of the first driving device is provided with a cutting blade, the linkage device is composed of four rotating guiding wheels and a transmission rope, and the transmission rope is connected to the four rotating guiding wheels in series. According to the cutting device for plastic tableware production, design is smart, manual feeding and discharging are not required, the degree of automation is high, the cost is saved, and the cutting efficiency of plastic tableware is effectively improved.

Owner:安徽森德自动化工业股份有限公司

Marking device of bolt

The invention discloses a marking device of a bolt. The marking device comprises a rack, and a conveying mechanism and a clamping mechanism are arranged on the rack; the conveying mechanism comprisesa slide rail and a pushing cylinder; a first groove is formed in the slide rail; the pushing cylinder is positioned at one end of the slide rail; a marking table is arranged at the other end of the slide rail; a marking cylinder is arranged above the marking table; a marking head is fixedly connected to the marking cylinder; a discharge clearance is formed between the marking table and the slide rail; a guide plate is arranged below the discharge clearance; a collection box is connected to the bottom end of the guide plate; a vertical second groove is formed in the marking table; the clampingmechanism comprises a sliding rod and a fixed block; a pressing block is arranged above the fixed block; a pressing switch used for controlling the marking cylinder is arranged on the pressing block;the sliding rod is connected to the fixed block in a sliding manner; a clamp is arranged at one end of the sliding rod; a reciprocating moving mechanism is arranged at the other end of the sliding rod; the end, away from the pushing cylinder, of the slide rail right faces the clamp; and a pressing rod capable of pressing the pressing block is fixedly connected to the clamp. According to the marking device, automatic conveying and marking of the bolt are achieved.

Owner:宁波隆锐机械制造有限公司

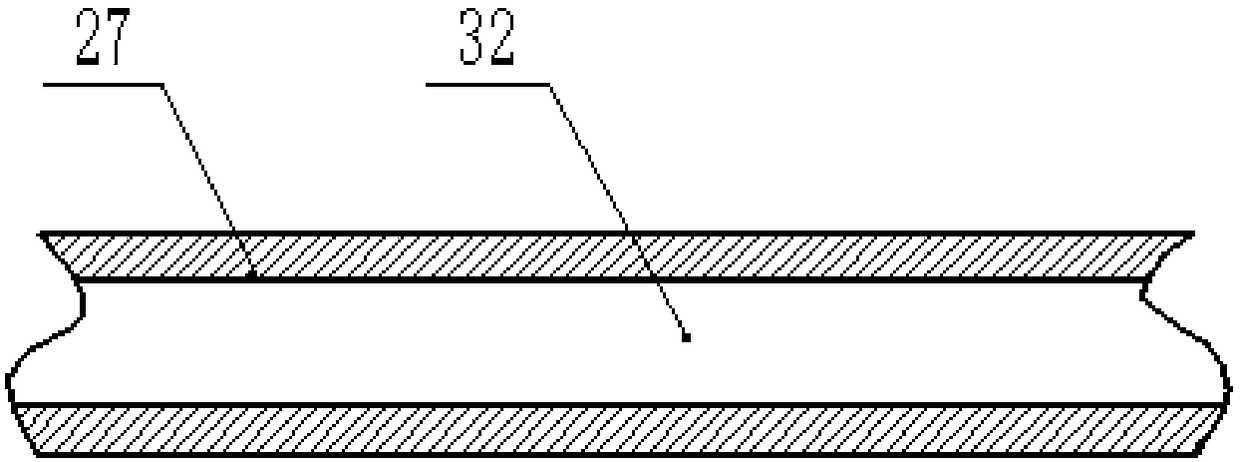

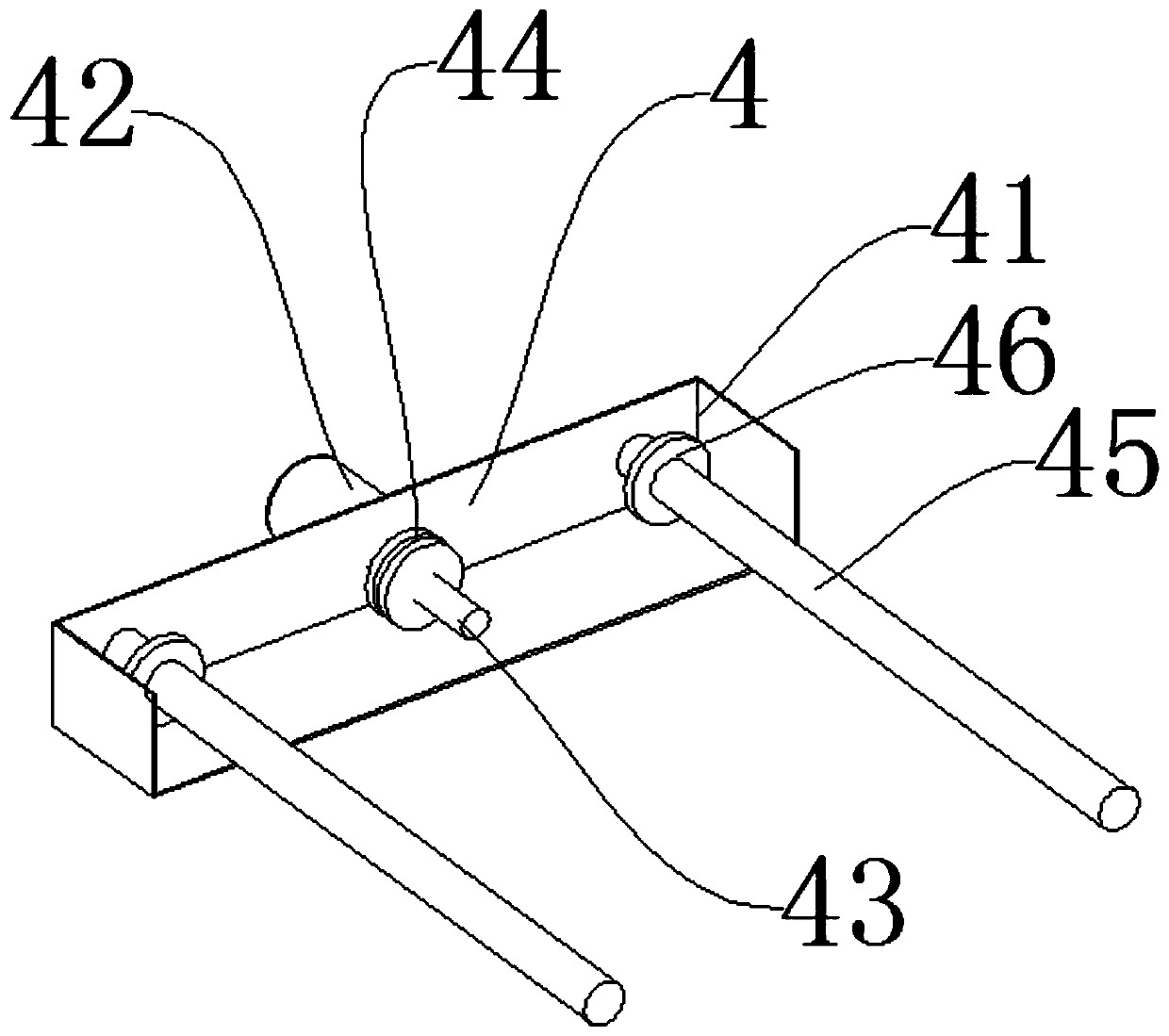

Processing fixture for milling plane of upper cover plate

InactiveCN110153757AImprove stabilityEasy to processWork clamping meansMetal working apparatusEngineeringMechanical engineering

The invention relates to a processing fixture for a milling plane of an upper cover plate. The processing fixture for the milling plane of the upper cover plate comprises a base, a support table and two groups of clamping assemblies, wherein the support table is arranged in the center of the base and is used for placing the upper cover plate; the two groups of clamping assemblies are horizontallyand slidably arranged on the base and are symmetrically arranged on two sides of the support table; and the two groups of clamping assemblies are close to each other or away from each other under theaction of an external force so as to clamp or loosen the upper cover plate. The processing fixture for the milling plane of the upper cover plate provided by the invention has the beneficial effects that the requirement on clamping two structures of the upper cover plate can be met at the same time, the applicability is high, the milling plane of the upper cover plate is favorably processed, the production efficiency is improved, and the production cost is reduced.

Owner:HUBEI FANCHAO AUTOMOTIVE IND

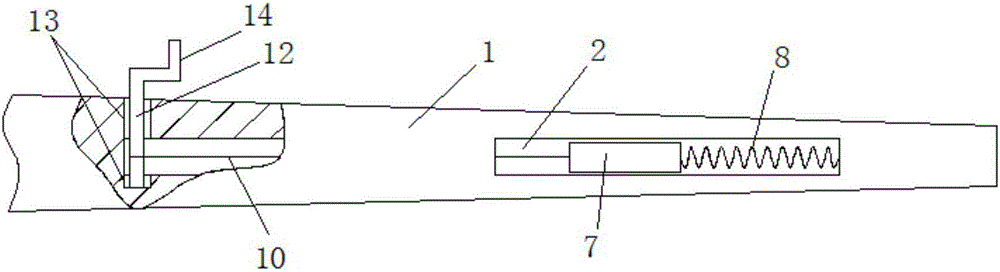

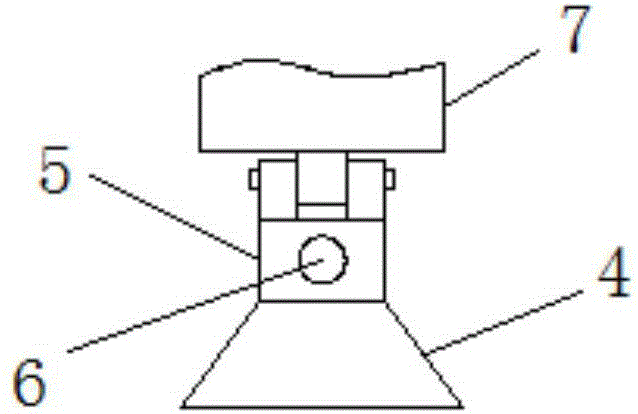

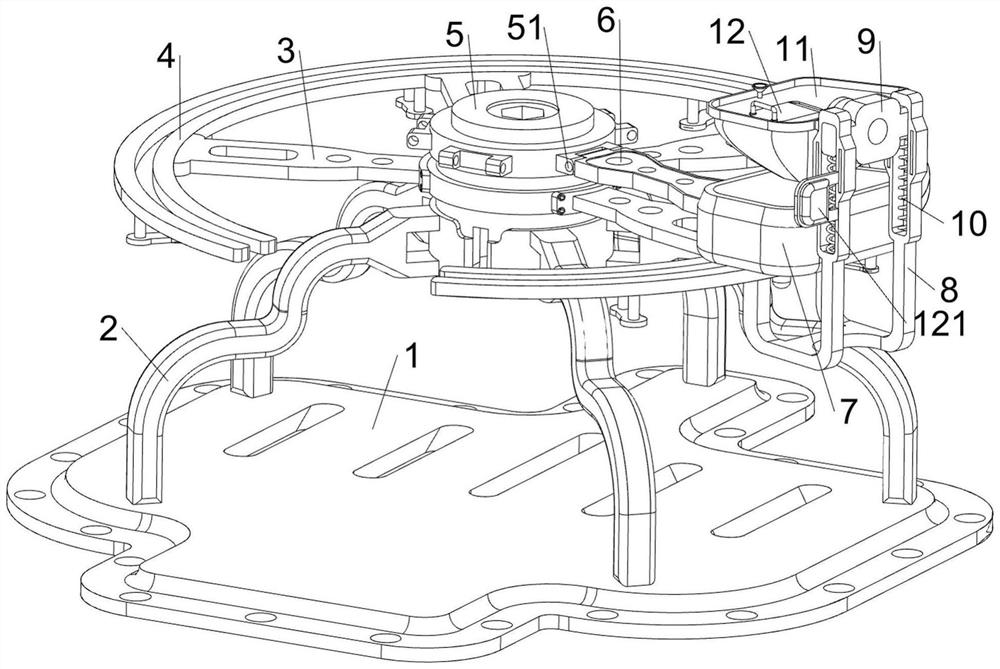

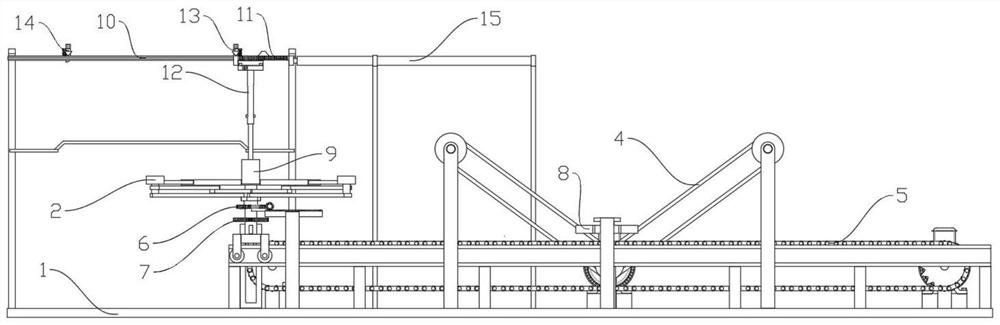

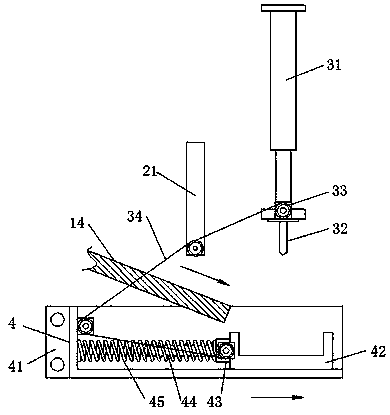

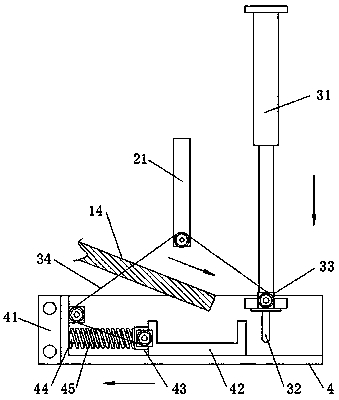

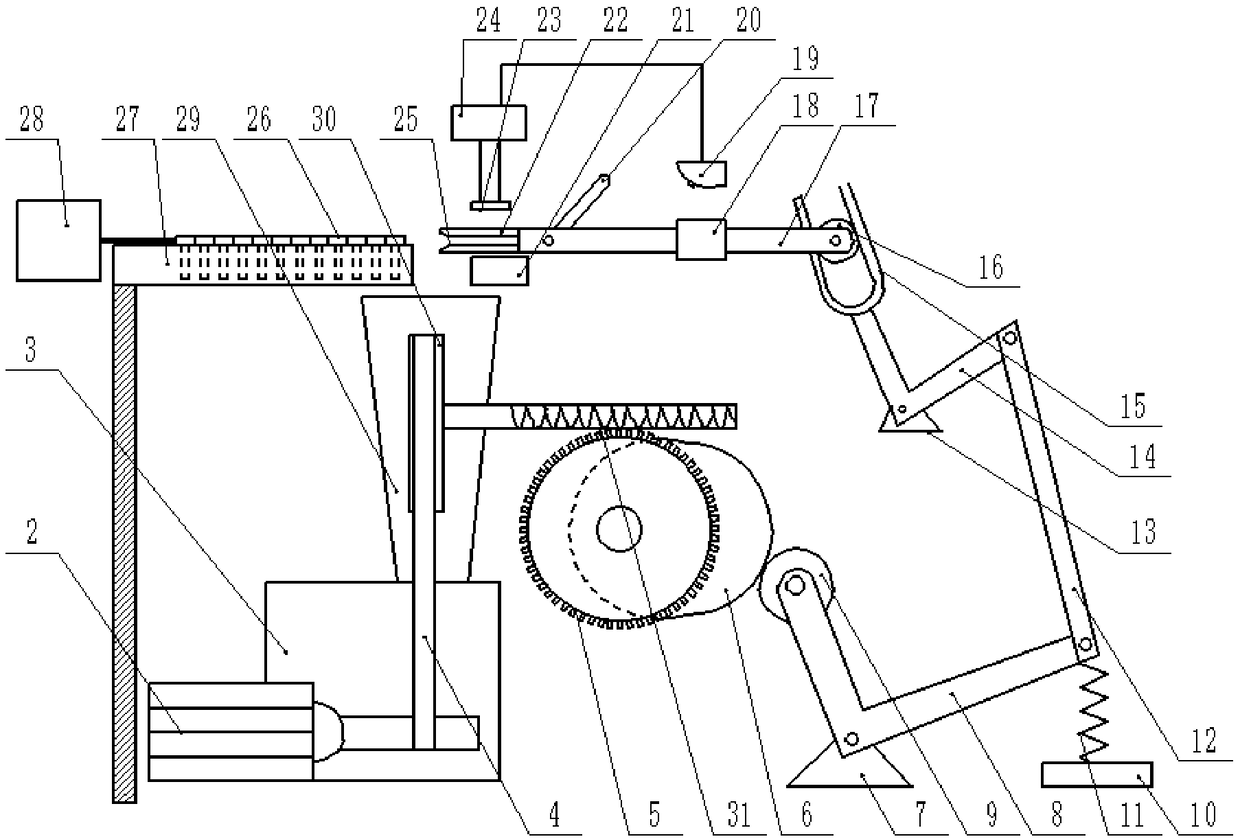

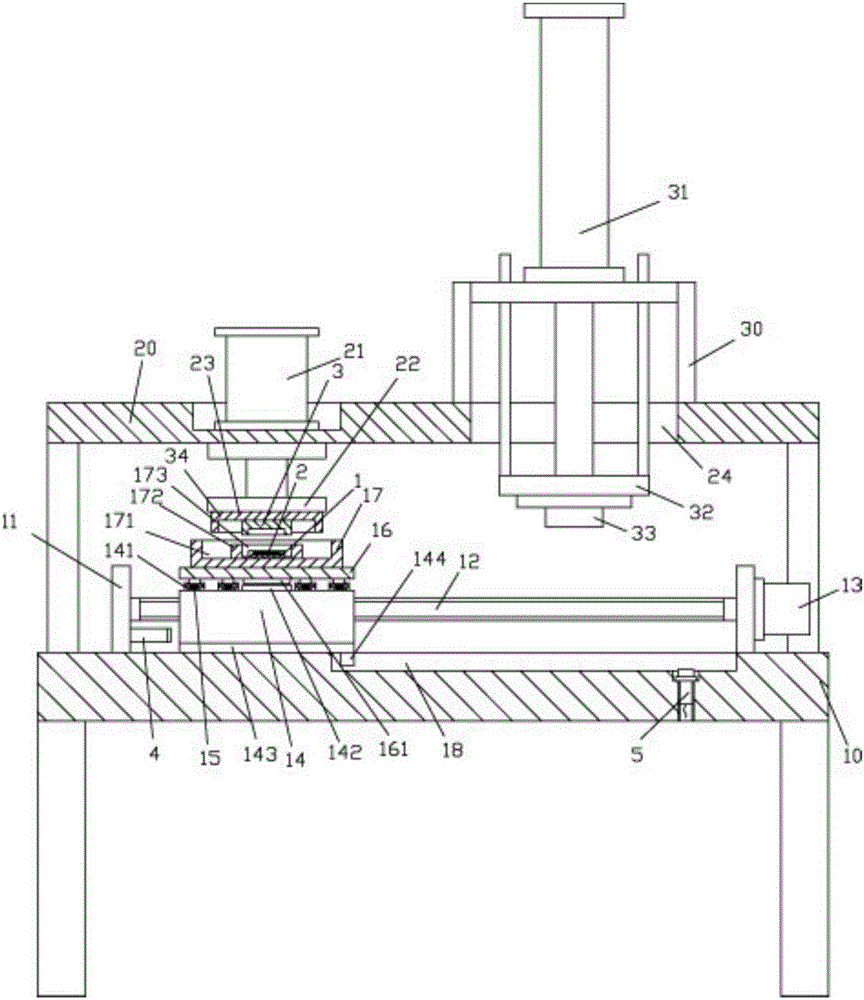

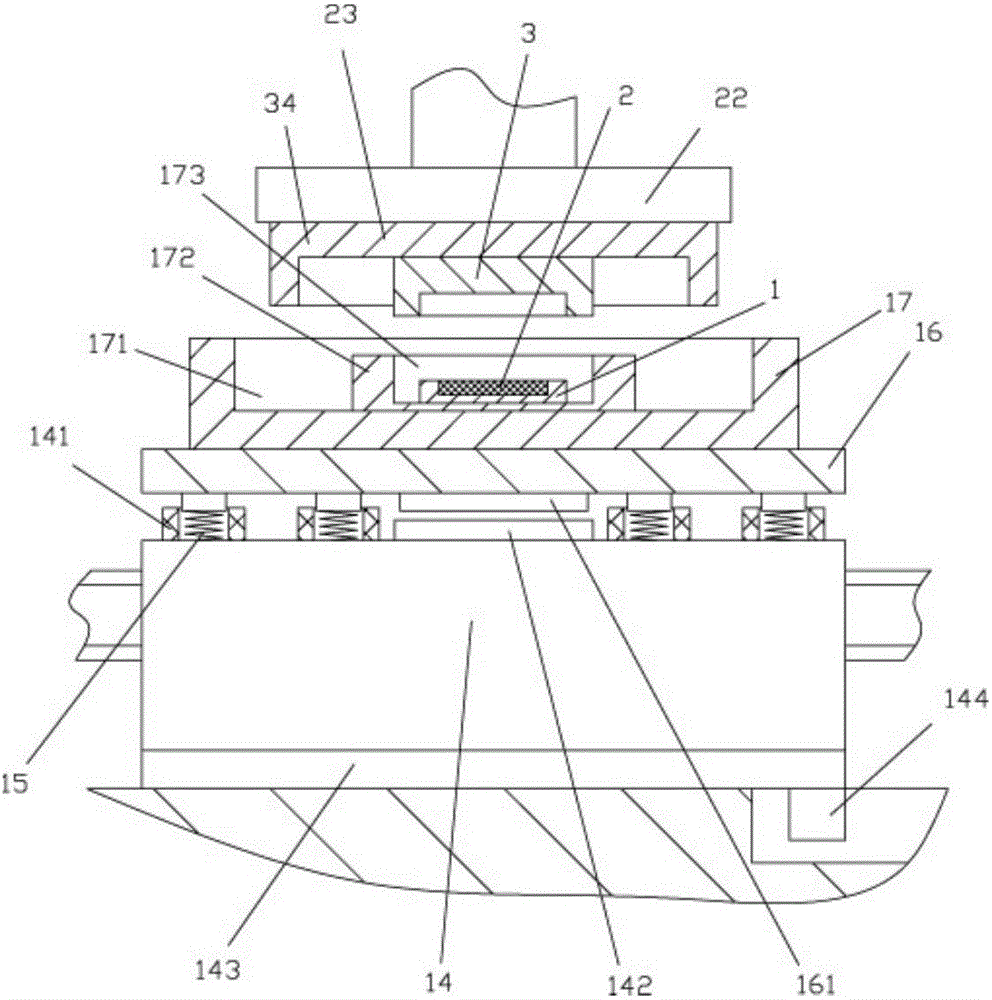

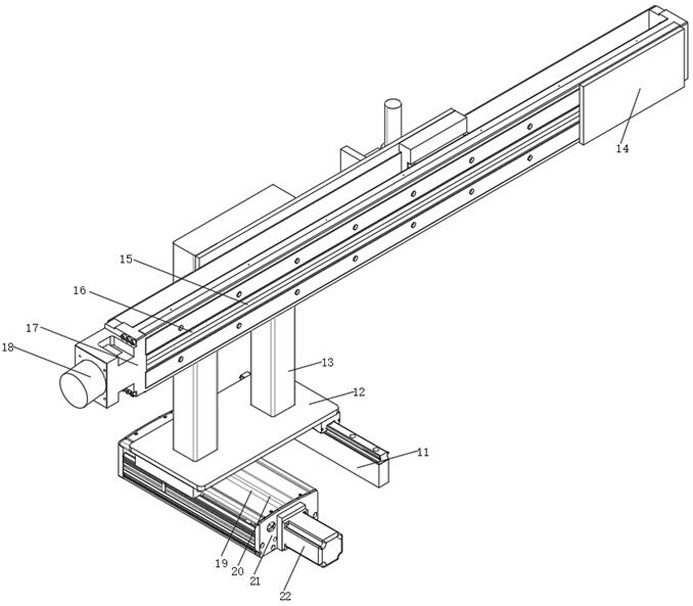

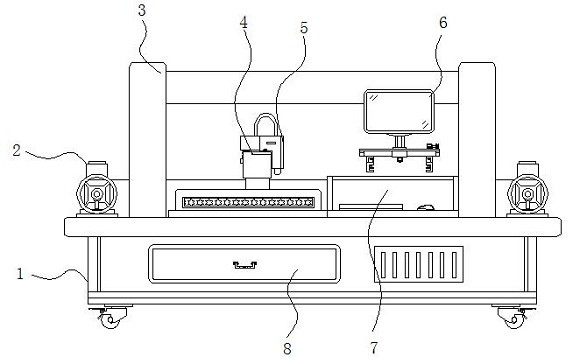

Stamping and grasping mechanism for small automobile parts

The invention discloses a stamping and grasping mechanism for small automobile parts. The stamping and grasping mechanism comprises a rack. An upper supporting frame is fixed to the upper portion of a top plate of the rack, vertical plates are fixed to the two sides of the top plate of the rack, the two ends of a transmission screw are hinged to the two vertical plates, a driving motor is fixed to the outer side wall of one vertical plate, an output shaft of the driving motor is a spline shaft, the spline shaft is inserted into a spline hole formed in one end of the transmission screw in a sleeved manner, and a movable block is in screw joint with the interior of the transmission screw. Multiple buffer springs are fixed to the side portion of the top face of the movable block, the upper ends of the buffer springs are fixed to an upper stamping supporting plate, a bottom stamping supporting block is fixed to the top face of the upper stamping supporting plate, an installing groove is formed in the middle of the top face of the bottom stamping supporting block, an installing block is fixed to the middle of the bottom face of the installing groove, and an installing trough is formed in the middle of the top face of the installing block. The stamping and grasping mechanism is simple in structure, small in size, suitable for small-batch products, good in safety and good in effect, and meanwhile automatic unloading can be achieved without manual unloading.

Owner:嵊州市高新技术发展有限公司

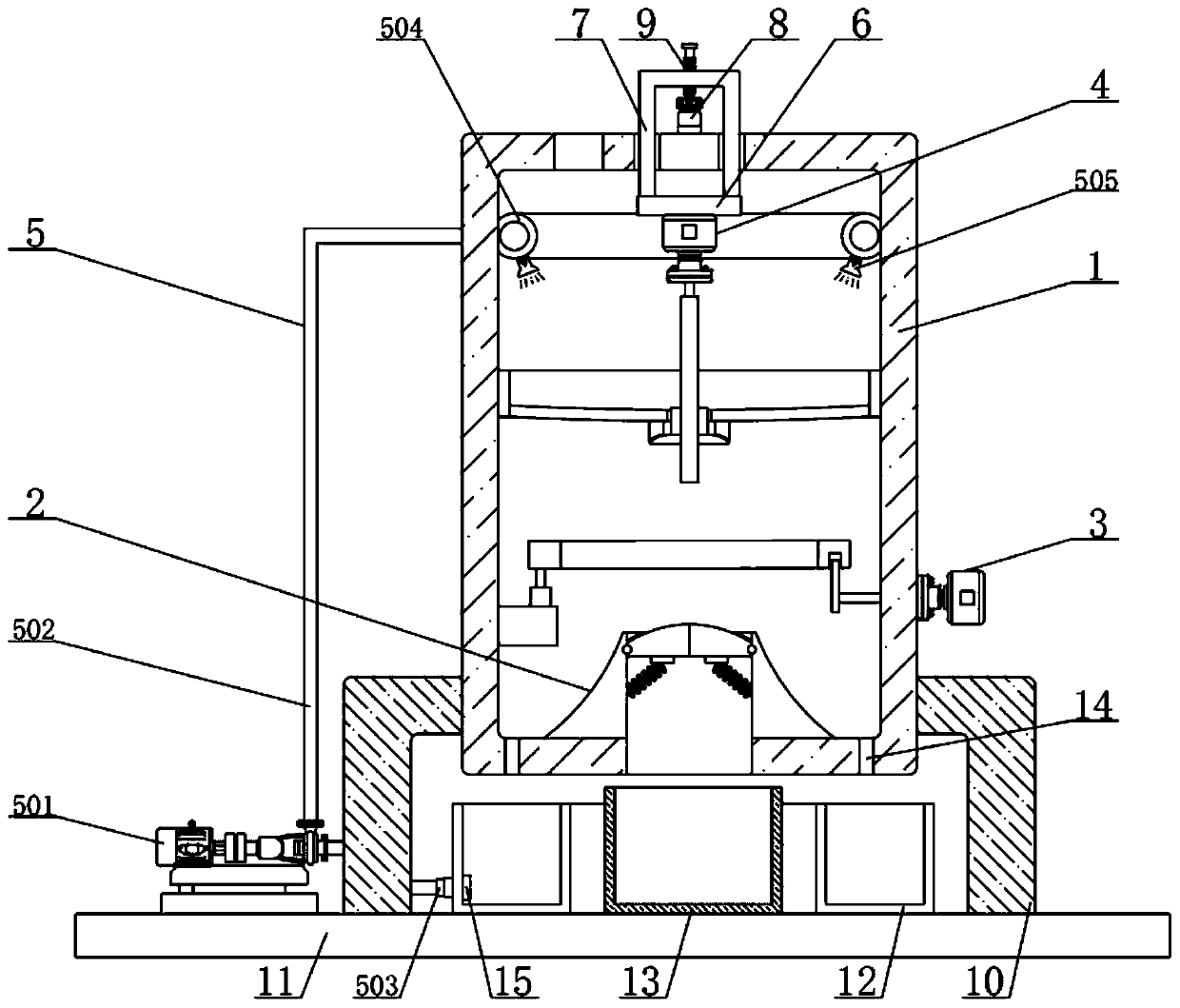

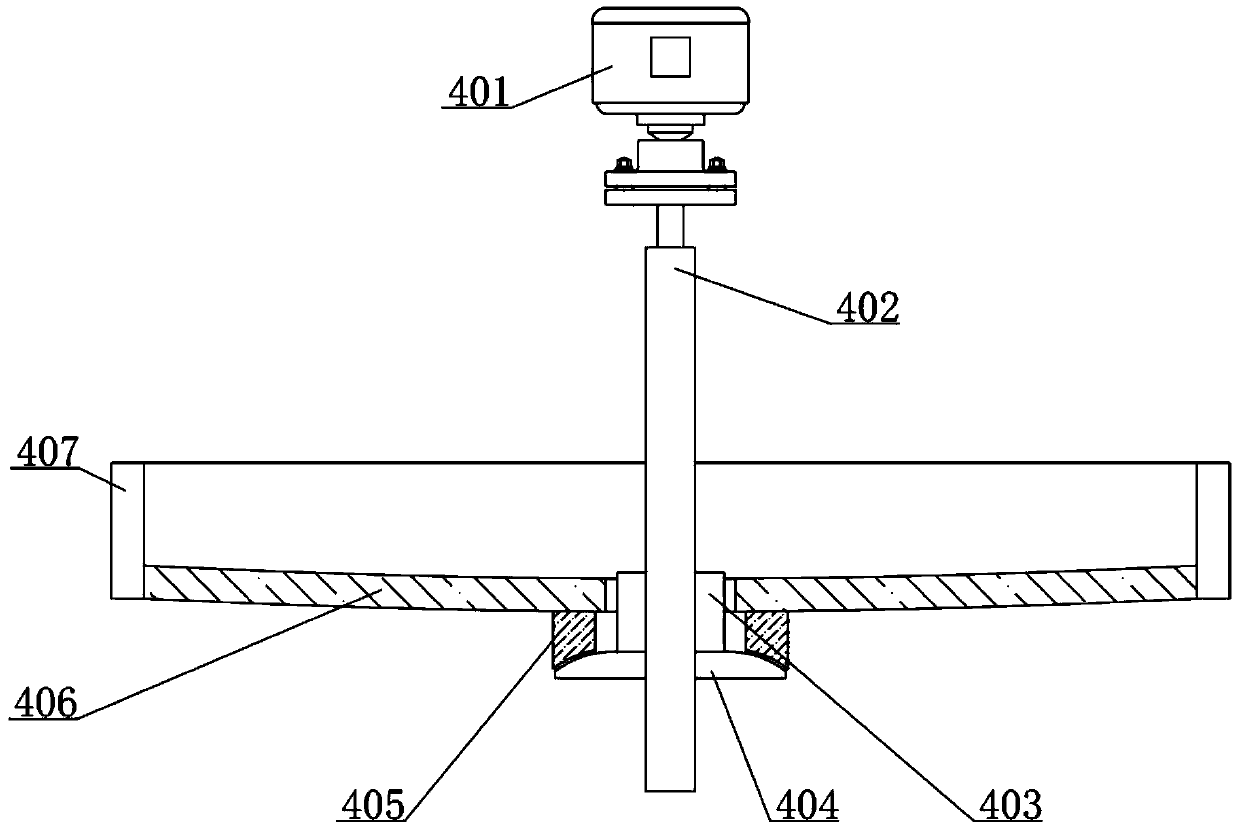

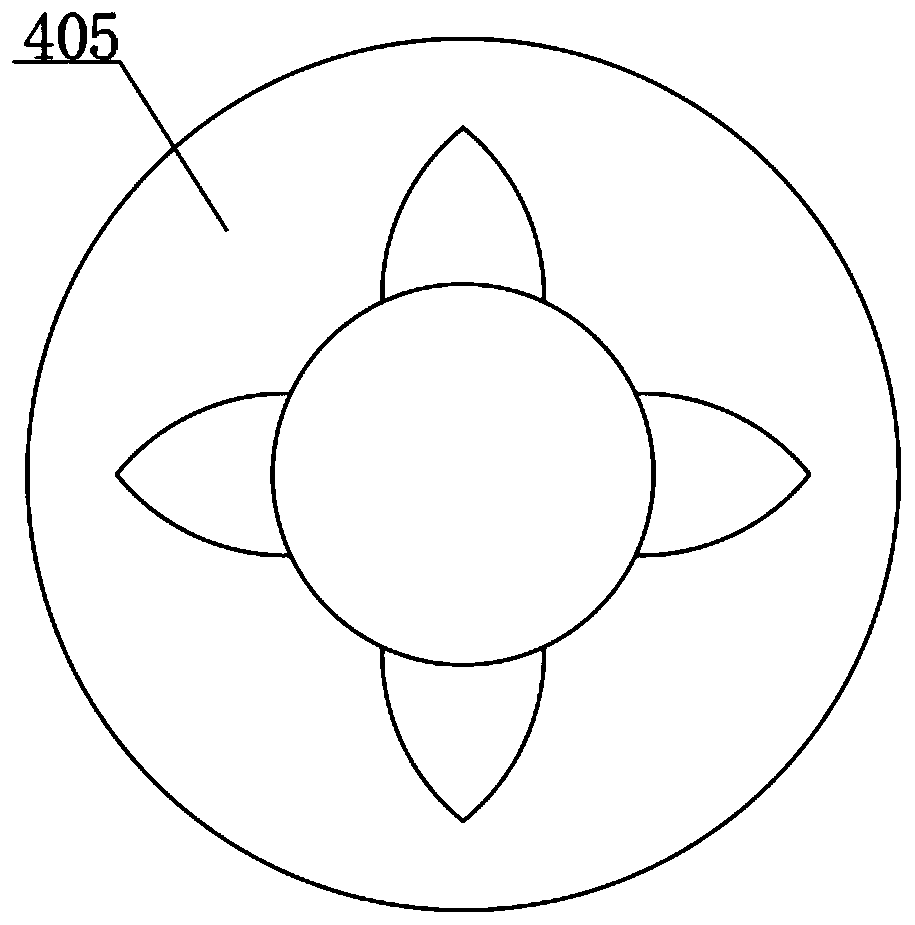

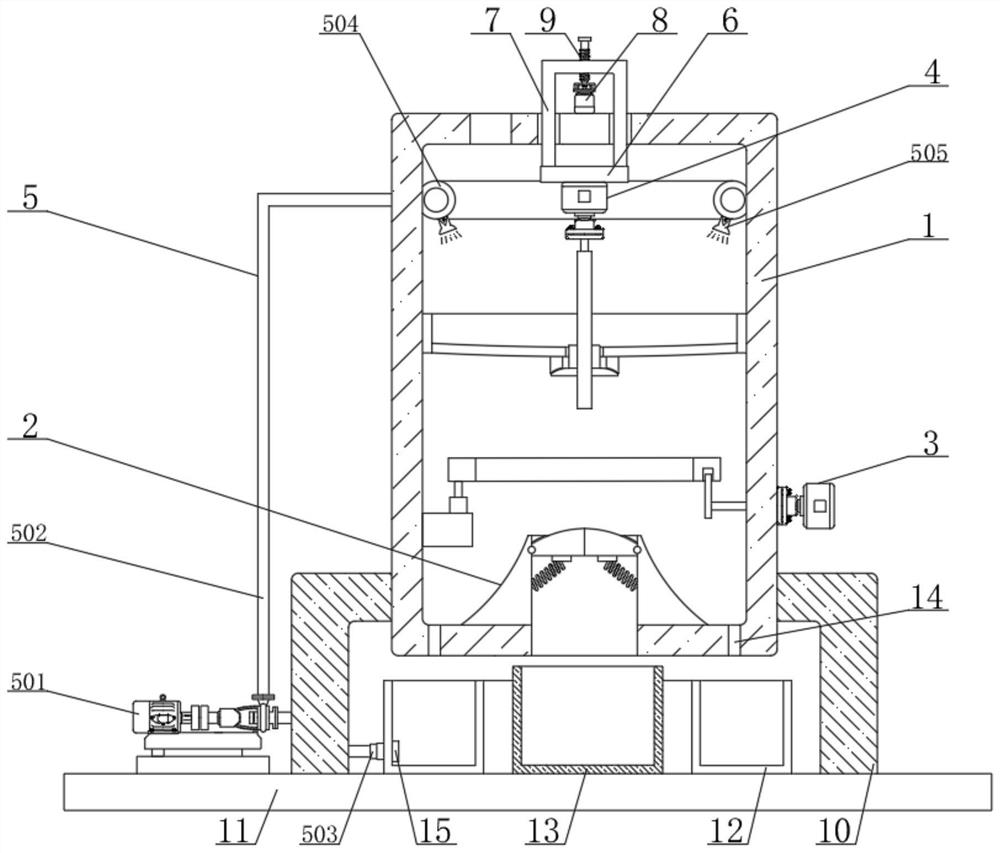

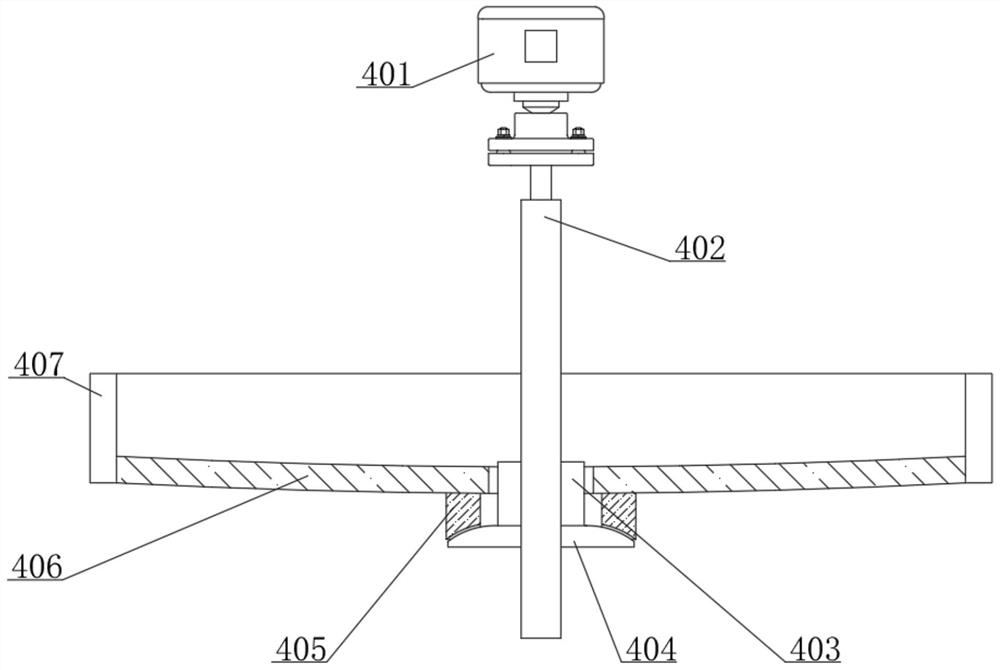

Welding surface detection device based on machine vision and detection method thereof

PendingCN112858316ARealize multi-directional movementEasy to moveOptically investigating flaws/contaminationMachine visionElectric machinery

The invention discloses a welding surface detection device based on machine vision and a detection method thereof. The welding surface detection device comprises a first bottom box, a second bottom box is fixedly connected to one side of the first bottom box, a welding structure is fixedly installed on one side of the top of the first bottom box, and three first sliding ways are formed in the other side of the top of the first bottom box; two motor mounting plates and two cover frames are fixedly mounted at the top of the first bottom box, a first driving motor is fixedly mounted at the top of each motor mounting plate, and a first threaded rod is fixedly connected to the driving end of each first driving motor. According to the welding surface detection device based on machine vision and the detection method thereof, automatic discharging of welded materials is achieved, welded workpieces are made to be away from a welding area, meanwhile, material clamping, namely welding surface detection of the workpieces is achieved, direct classified transportation is achieved after detection is completed, manual transfer is not needed, welding, unloading and detection are completed in one step, the process flow is reduced, and then the working efficiency is improved.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

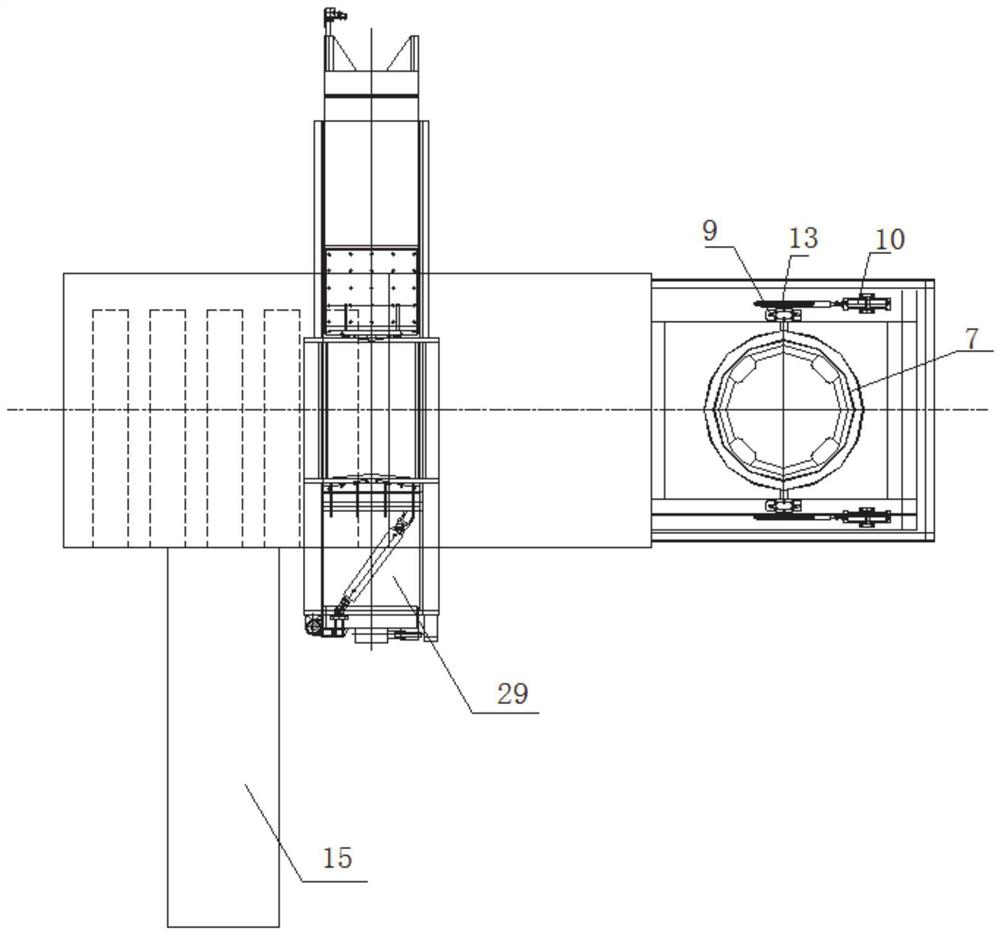

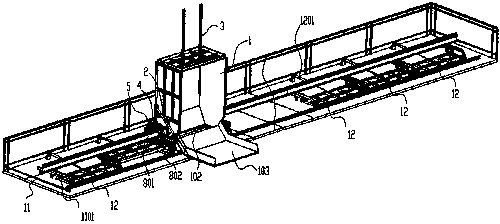

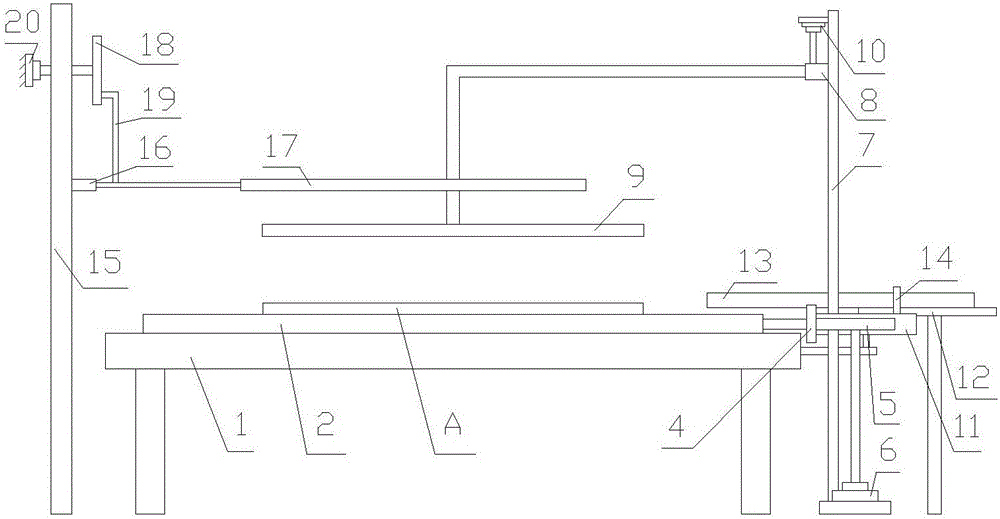

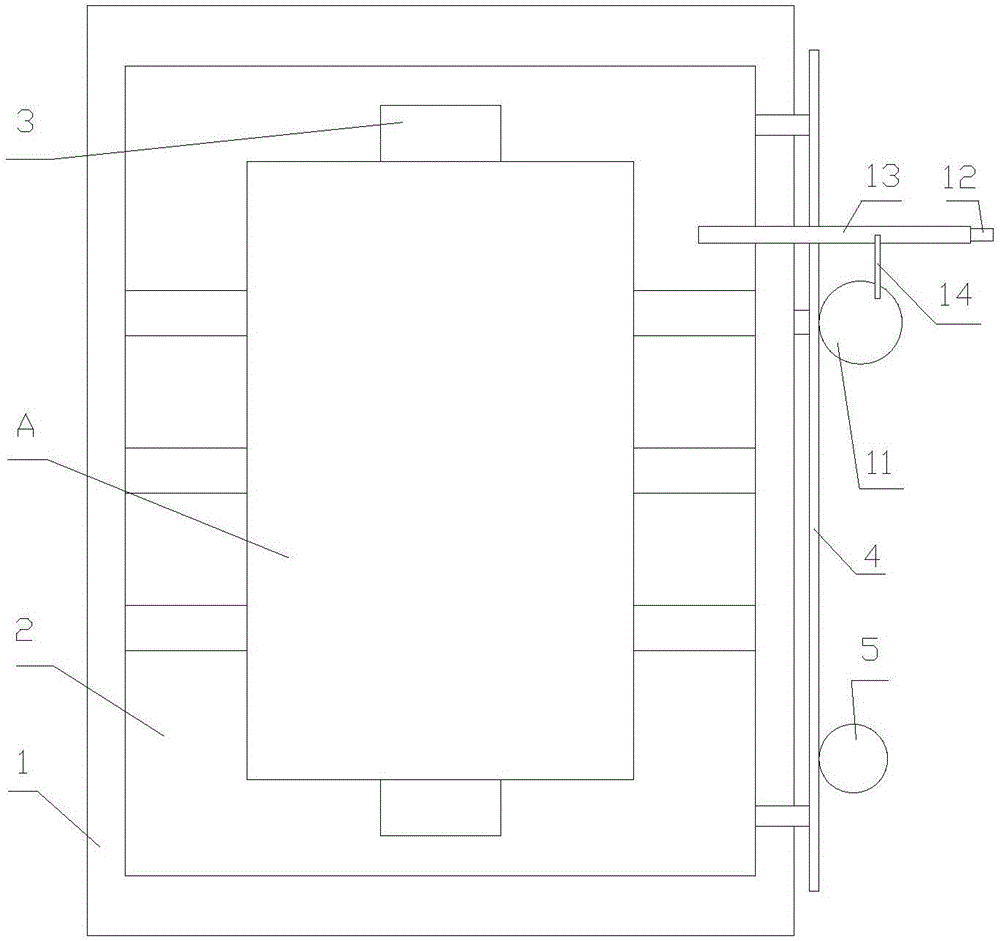

Automatic feeding system of large garbage incinerator

The invention discloses an automatic feeding system of a large garbage incinerator. The automatic feeding system is arranged above the incinerator, a plurality of incinerator door openings are linearly arranged on an incinerator top plate on the upper part of the incinerator, incinerator door systems are cooperatively arranged on the incinerator door openings, a driving rail is arranged above theincinerator door systems, and a vehicle body used for dumping garbage is cooperatively arranged above the driving rail. According to the automatic feeding system of the large garbage incinerator, feeding of the garbage incinerator is convenient, and thus leakage of the garbage can be avoided; and moreover, flexible control can be facilitated, and the risk of operating workers can be reduced.

Owner:王志斌

Peach kernel manufacturing device and working method thereof

InactiveCN108936441AReduce noiseDischarge in timeFood shapingVegetable peelingGas compressorSpray nozzle

The present invention discloses a peach kernel integrated manufacturing device and a working method thereof. The device comprises an air compressor, a high-pressure air transmission pipeline, high-pressure air spray nozzles, a feeding port and an unloading plate; the high-pressure air transmission pipeline is arranged above the air compressor; the high-pressure air spray nozzles are arranged at one end of the high-pressure air transmission pipeline; and the unloading plate is arranged at the middle part above the feeding port. The device is scientific and reasonable in structure and safe and convenient to use, is provided with the air compressor, the high-pressure air transmission pipeline and the high-pressure air spray nozzles, can effectively realize the stirring of the peaches in boiling water, not only realizes the full stirring of the peaches, enables the peaches to be heated uniformly in the boiling water so as to facilitate later treatment, but also can effectively avoid the collision between a stirring frame and the peaches when the peaches are stirred by using the stirring frame, wherein the collision results in peach surface damage and esthetic effection; and the deviceis provided with a folded plate and the unloading plate, can effectively unload the peaches inside a transportation basket, does not need manual unloading, and greatly reduces the waste of manpower.

Owner:南京致中生物科技有限公司

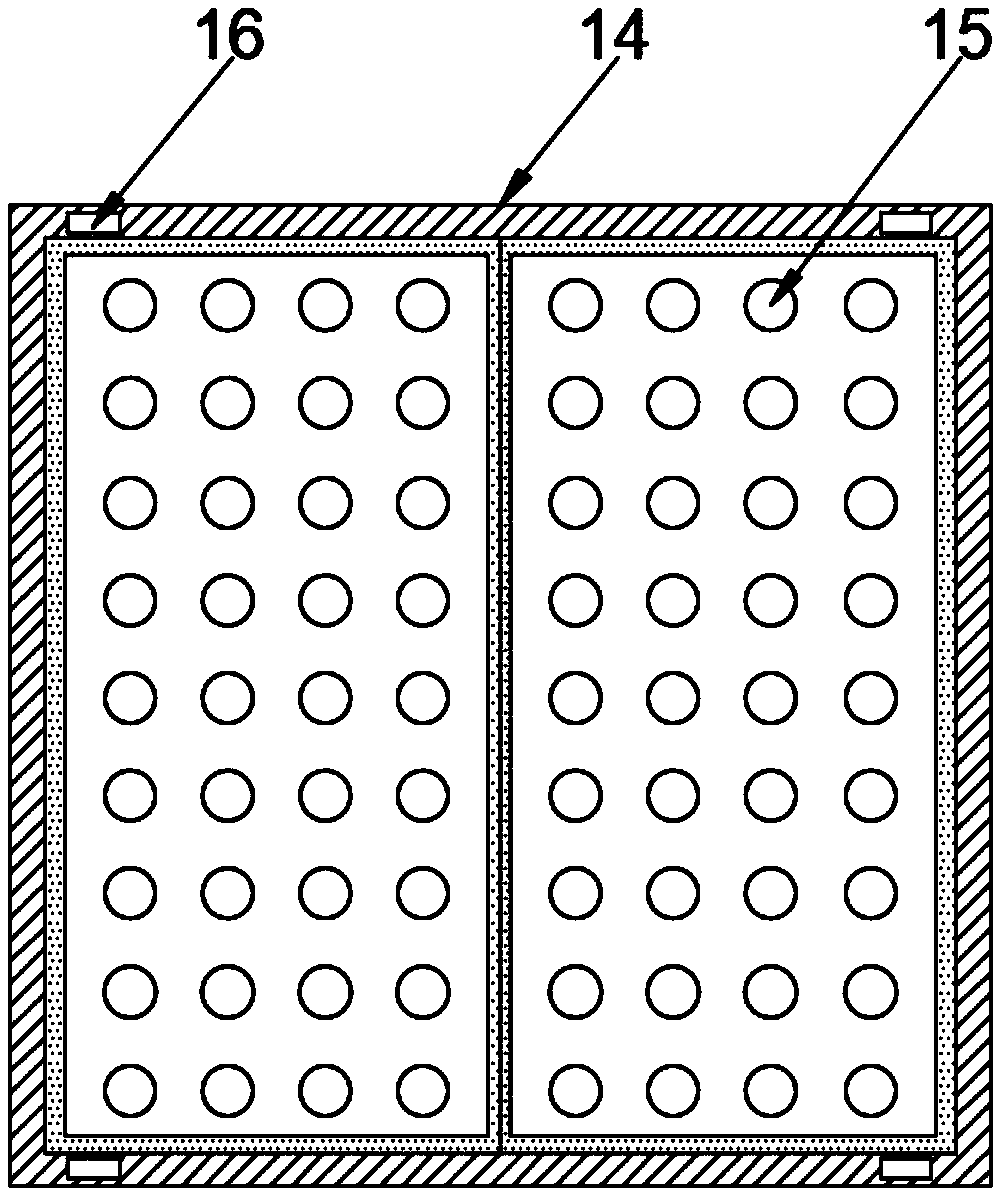

Air conditioner filter screen cutting device capable of performing positioning cutting according to size of filter screen

The invention discloses an air conditioner filter screen cutting device capable of performing positioning cutting according to the size of a filter screen. Specifically, the device comprises a workbench, feeding mechanisms, a discharging mechanism and a cutting table, wherein a frame body is mounted at the middle position of the top end of the workbench, the feeding mechanisms are mounted at the two sides of the top of the workbench respectively, an electromagnetic sliding rail is mounted at the middle position of the top end in the frame body, the discharging mechanism is fixed to the bottomend of the electromagnetic sliding rail, laser guide rails are mounted at the two ends of one side of the top of the workbench below the frame body, and a positioning sliding rail is mounted between the laser guide rails. According to the air conditioner filter screen cutting device capable of performing positioning cutting according to the size of the filter screen, the cutting table provided with a storage bin is arranged, the cutting table is divided into a plurality of partition grooves, a top plate is arranged in each partition groove, the top plates in a proper quantity can be selected according to the specifications and size of the filter screen to perform jacking, and therefore the device can automatically unload filter screens with different sizes and specifications.

Owner:东莞市固德智能科技有限公司

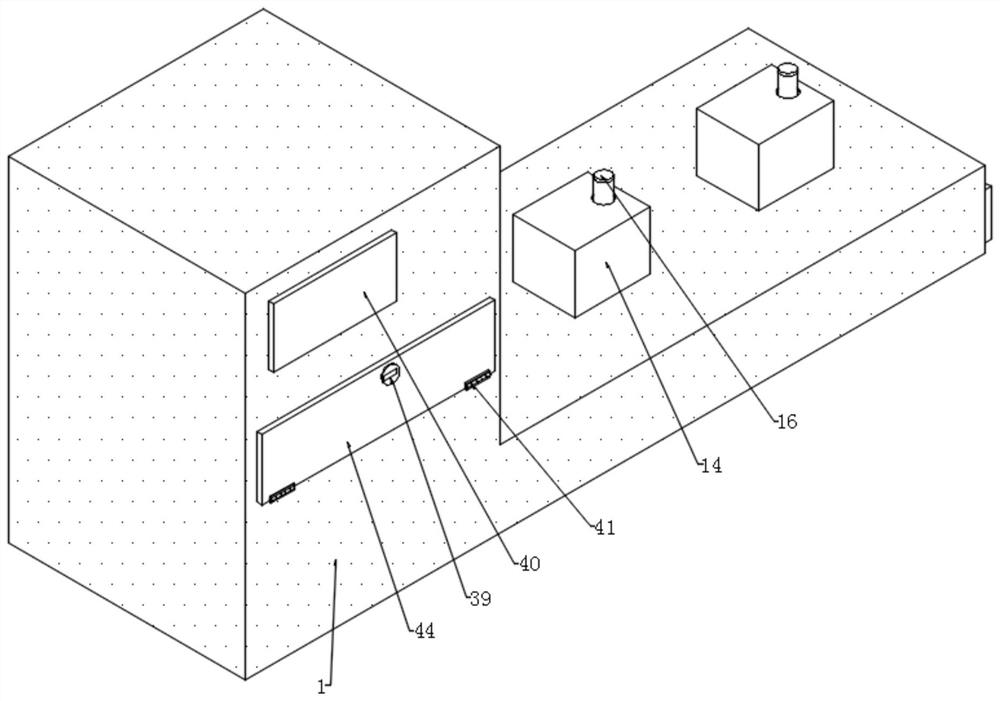

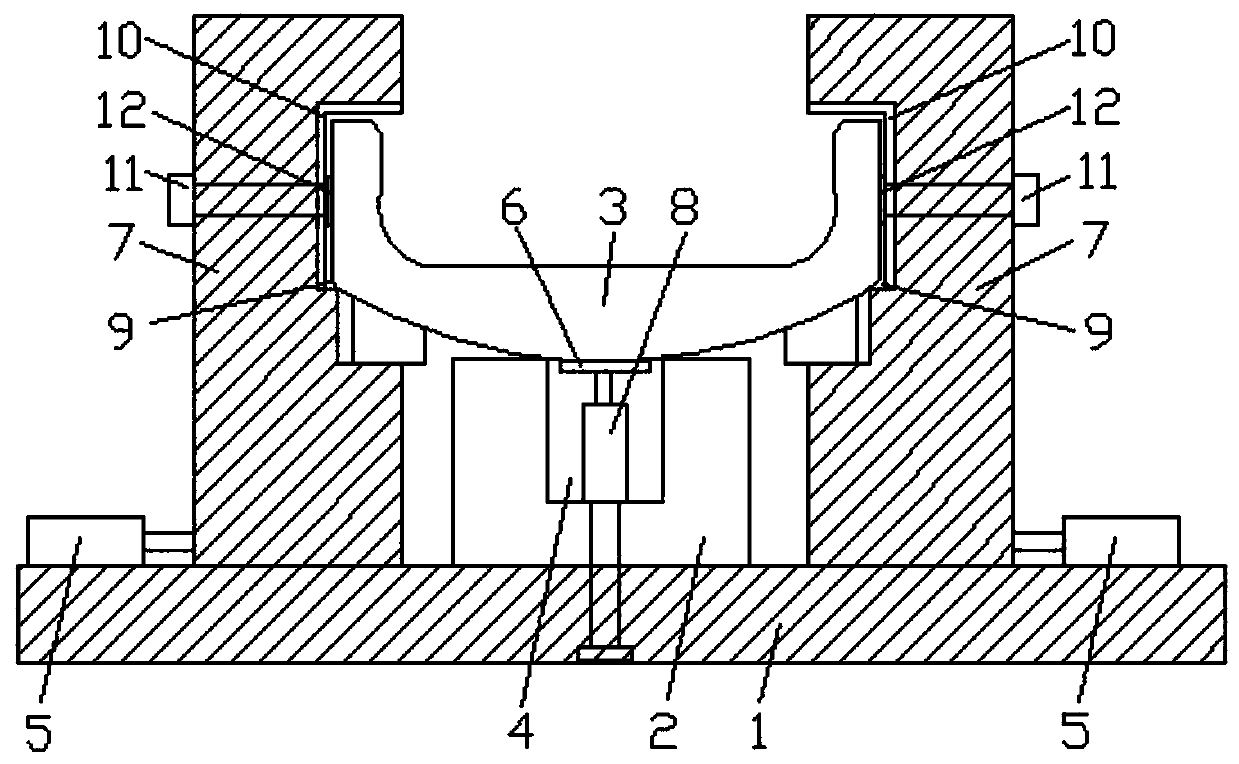

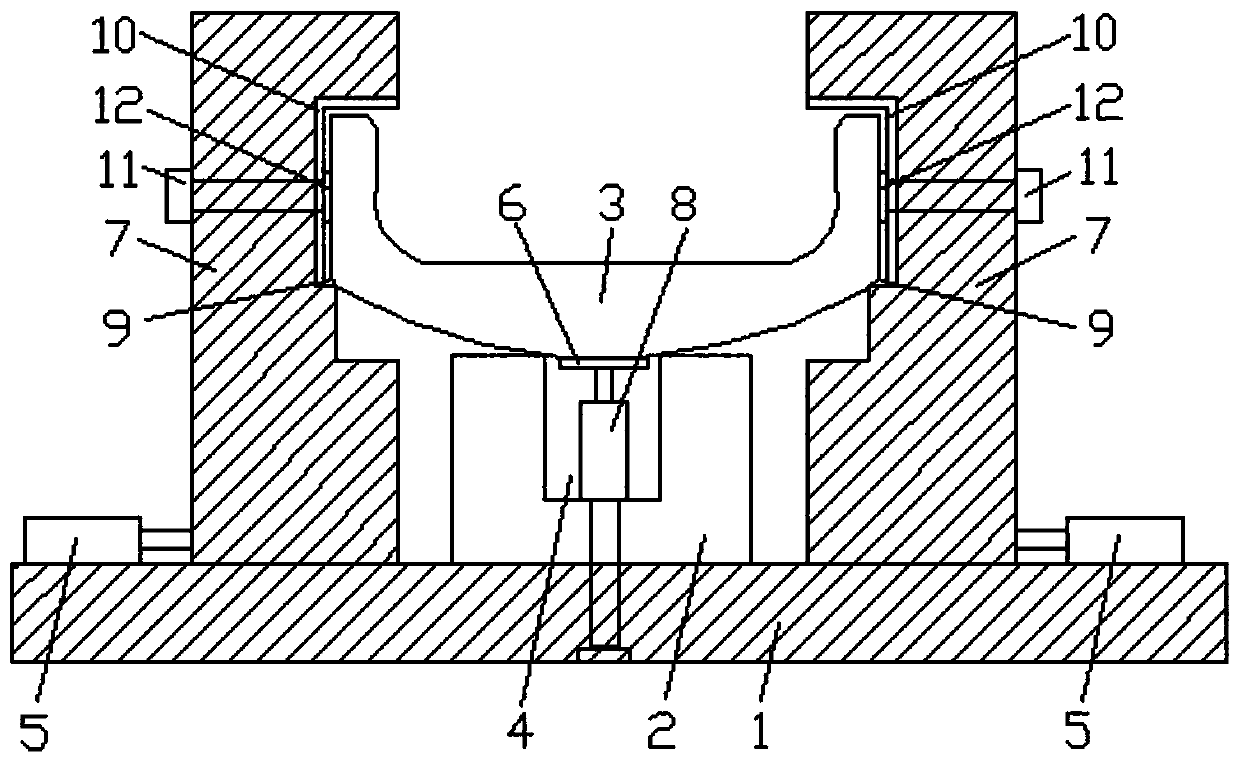

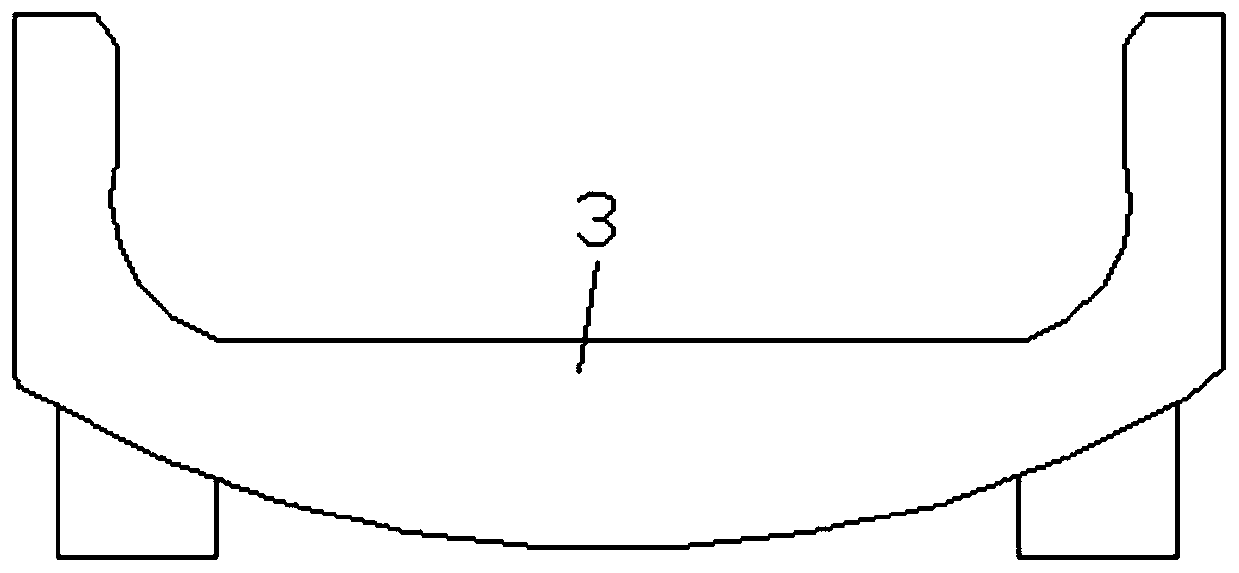

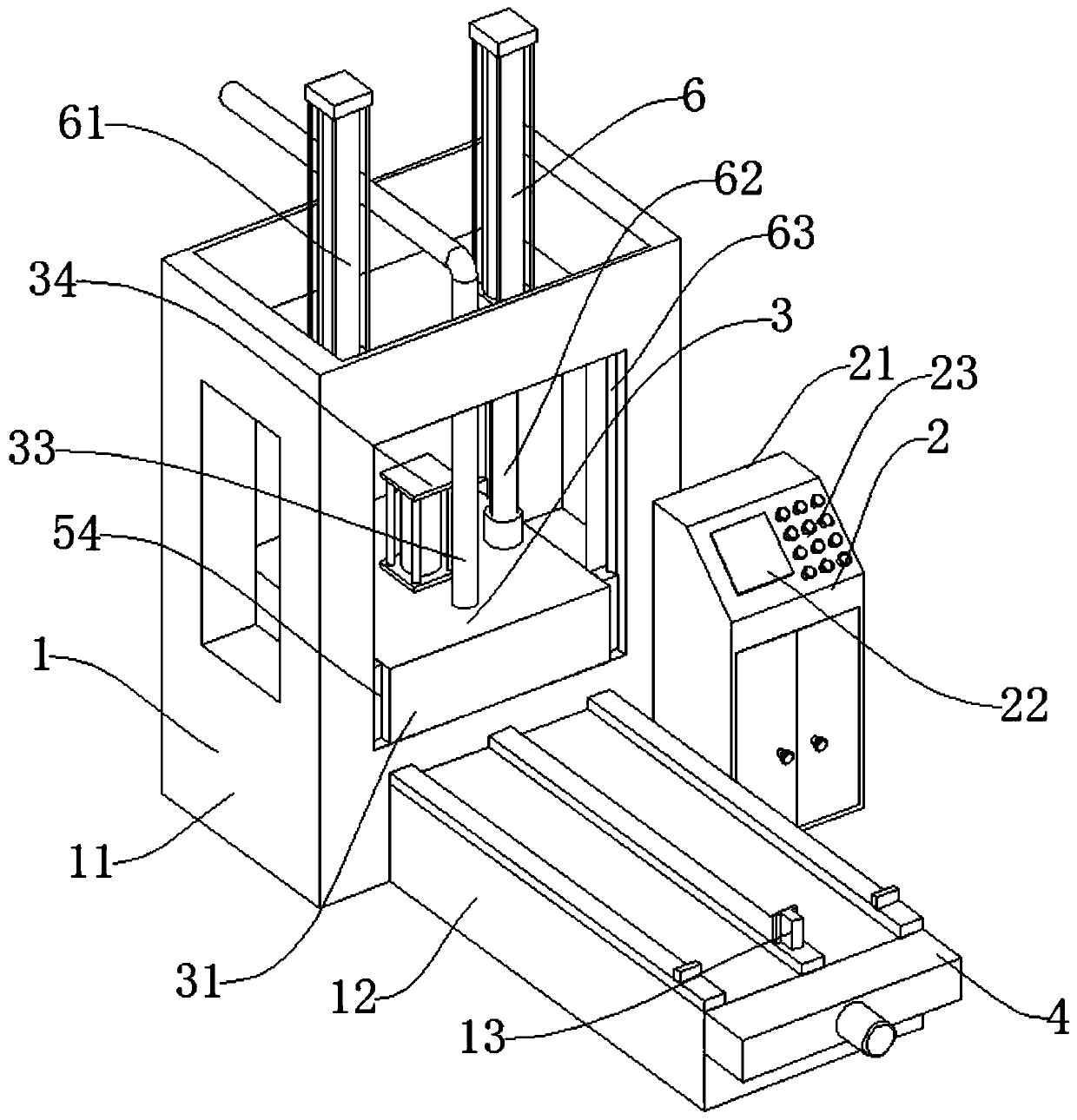

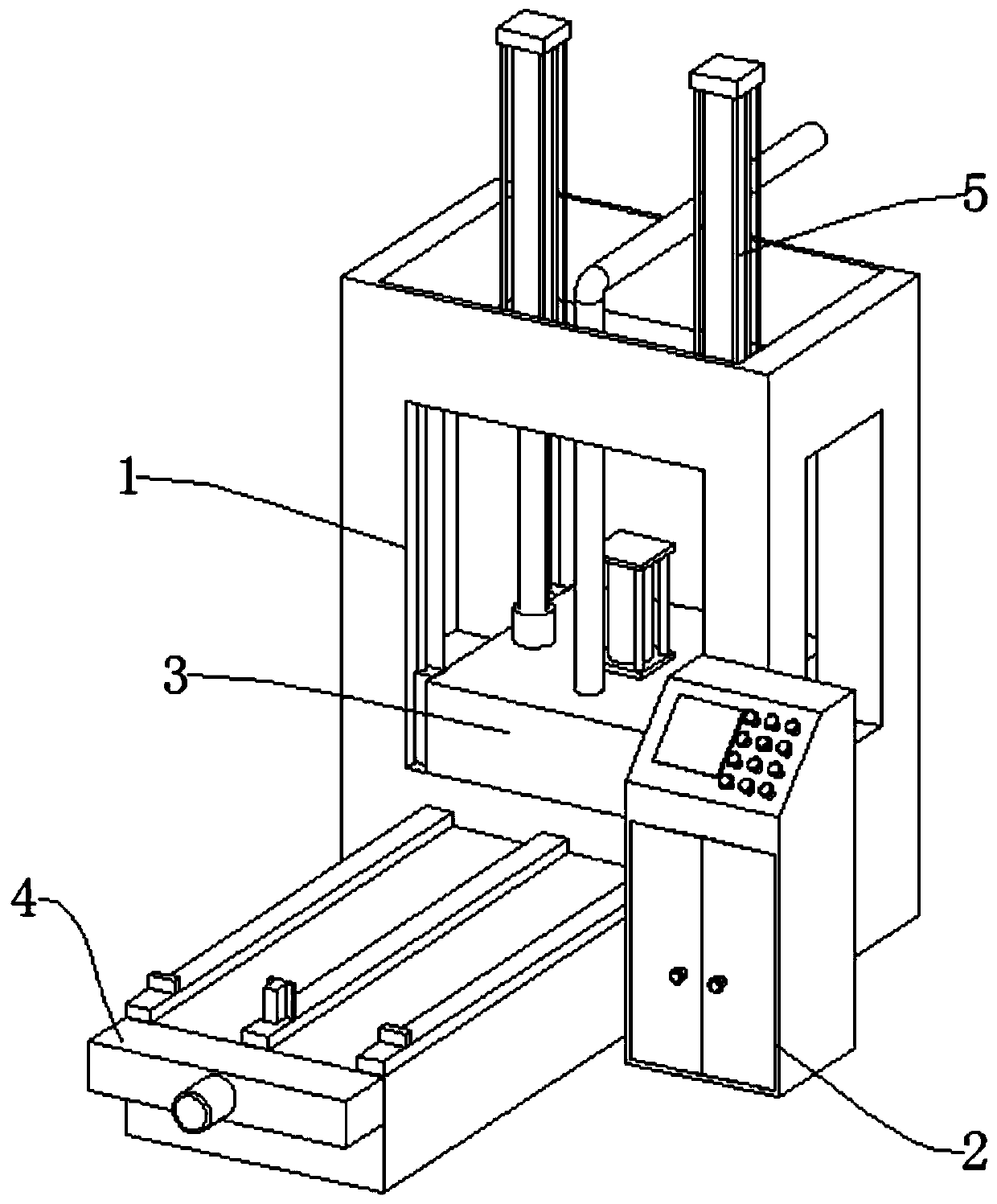

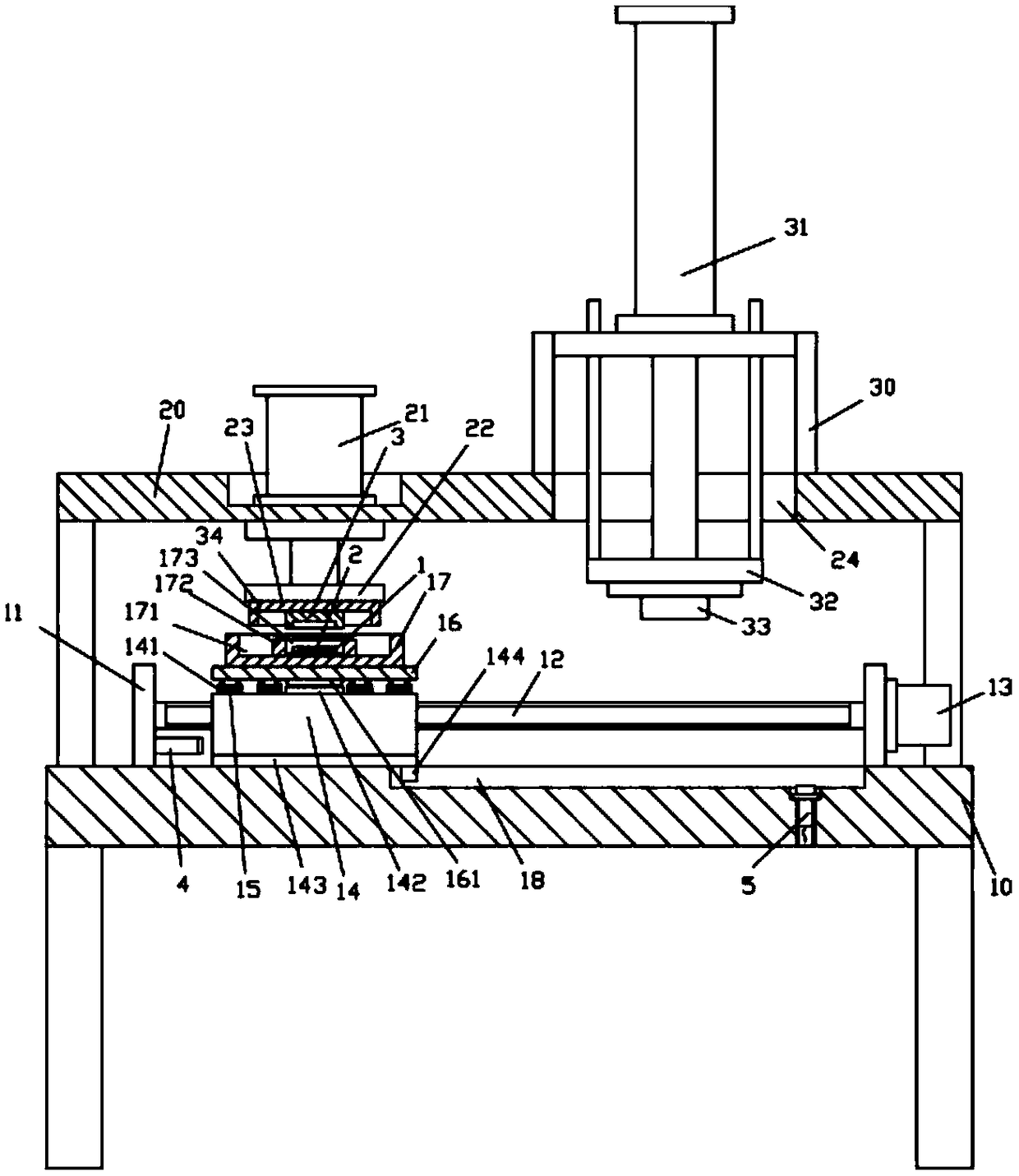

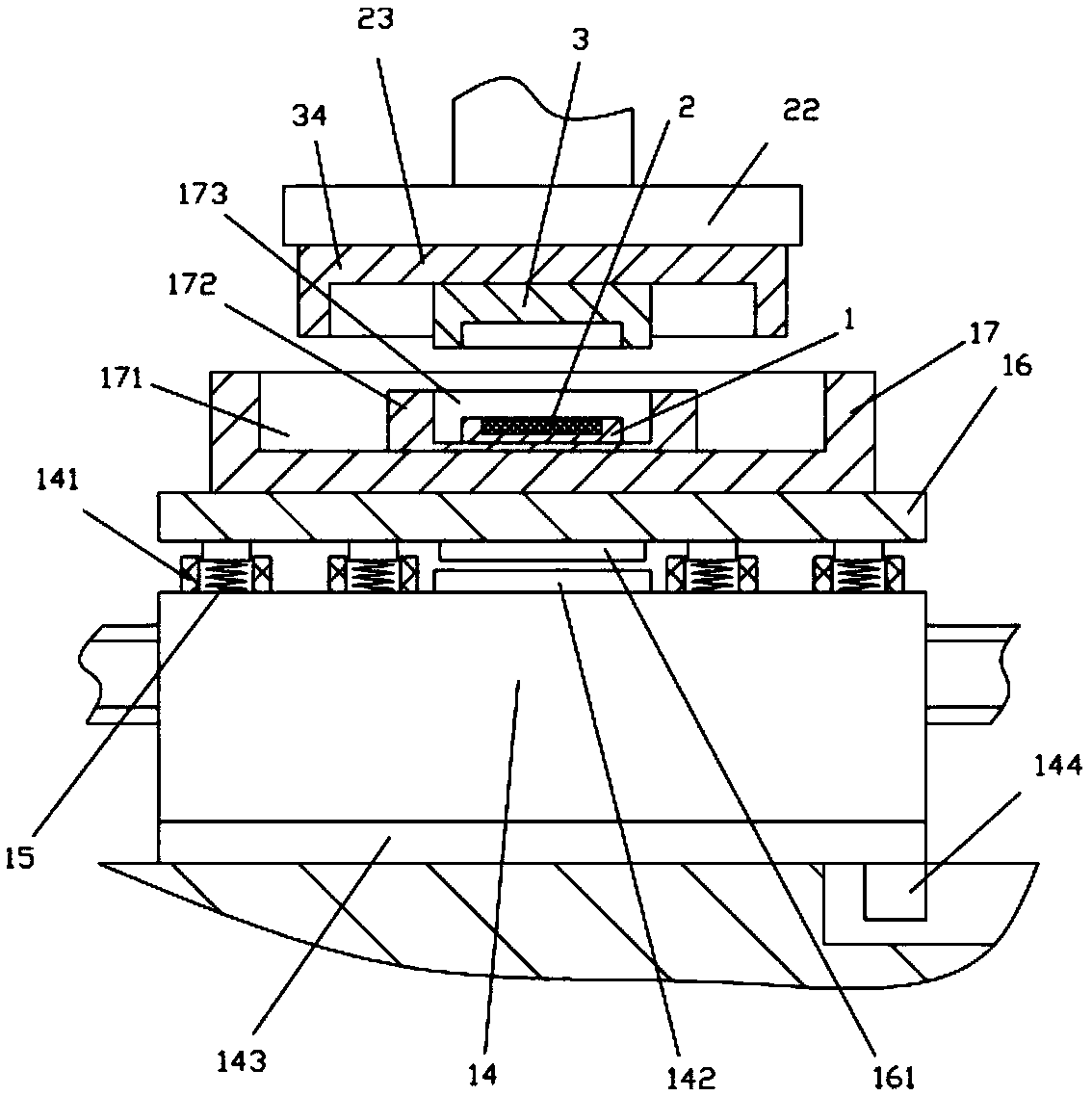

Mold pressing forming device used for producing base of power distribution cabinet and using method thereof

InactiveCN111002519AReasonable structureEasy to operateSwitchgearMechanical engineeringIndustrial engineering

The invention discloses a mold pressing forming device used for producing a base of a power distribution cabinet and a using method thereof. The mold pressing forming device comprises a supporting mechanism, a control structure, a mold pressing mechanism and a lifting mechanism. The control structure is arranged on one side of the supporting mechanism. The mold pressing mechanism is arranged at the upper end of the supporting mechanism. The lifting mechanism is arranged at the upper end of the mold pressing mechanism. The mold pressing forming device further comprises a pushing mechanism usedfor retreating materials and a power mechanism used for driving the pushing mechanism to operate. The mold pressing forming device is reasonable in structure and easy to operate, the device pushes theformed base of the power distribution cabinet by utilizing the hooking or pushing manner of the pushing mechanism, the mold pressing forming device is high in practicality and high in safety, the power mechanism and the pushing mechanism are utilized for cooperation, the automatic discharging manner is used, manual discharging is not needed, and safety is improved.

Owner:广州市顺承电气设备有限公司

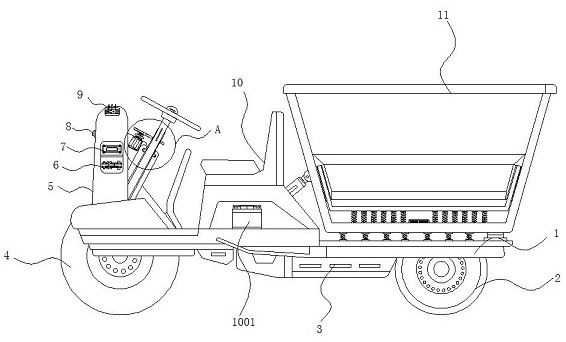

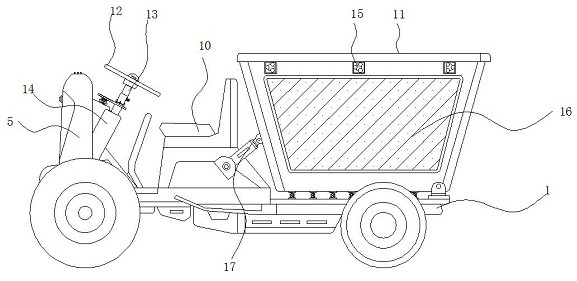

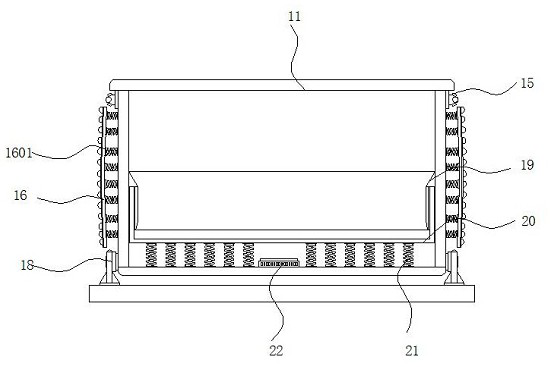

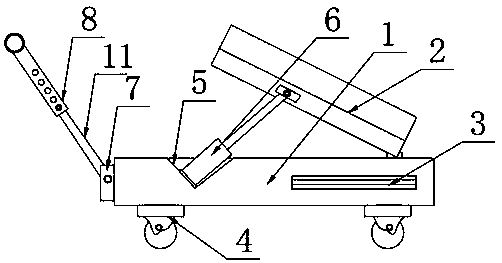

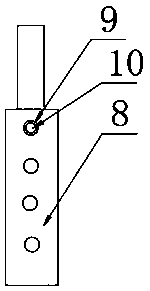

Handling device used for processing of electric three-wheeler parts

InactiveCN109572776ABig angleMeet the needs of useHand carts with multiple axesHand cart accessoriesEngineeringMechanical engineering

The invention discloses a handling device used for the processing of electric three-wheeler parts. The handling device comprises a base, wherein a placement plate is arranged on the outer wall of thetop end of the base; one end of the bottom of the placement plate is hinged to the top end of the base; the outer walls of two sides of the base are both provided with reflective stickers; swivel wheels are fixed at four corners of the outer wall of the bottom end of the base by screws; a mounting groove is formed on the outer wall of one side of the base; a cylinder is hinged to the interior of the mounting groove; the output end of the cylinder is hinged to the outer wall of one side of the placement plate; a hinge column is arranged in the middle of the outer wall of one side of the base; the base is connected with an inner tube through the hinge column; and an adjustment support tube is arranged on the outer side of one side of the base. By starting the cylinder, the handling device used for the processing of the electric three-wheeler parts enables the placement plate to turn over under the pushing of a piston rod of the cylinder so as to increase the angle between the placement plate and the base, thereby directly unloading the parts by erecting the placement plate without the need for manual unloading, and greatly improving the unloading speed.

Owner:LUYUAN ELECTRIC VEHICLE JIANGSU CO LTD

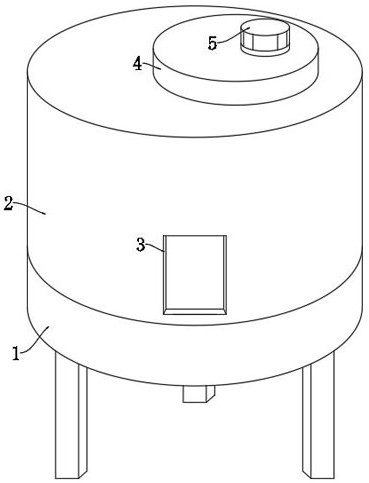

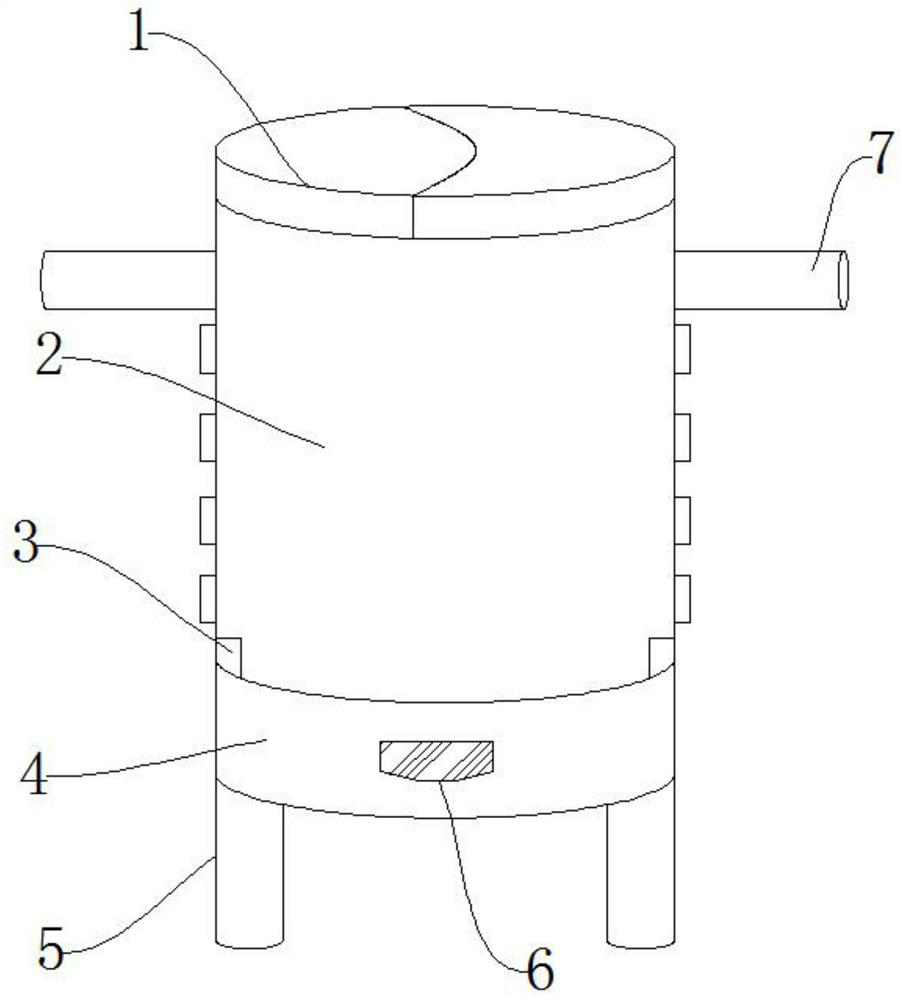

Composting pool

ActiveCN111925243AReduce labor costsImprove practicalityBio-organic fraction processingOrganic fertiliser apparatusProcess engineeringMechanical equipment

The invention discloses a composting pool which comprises a stock bin, a bin cover, supporting legs and a composting pipe, an electric push rod is arranged at the upper end of the inner wall of the stock bin, a connecting block is arranged on one side of the electric push rod, and the bin cover is arranged at the upper end of the connecting block. Beneficial effects are that: the stock bin, the composting pipe and the vent hole are arranged, the labor cost, the construction cost and the occupied area of the device can be saved, and the interior of the device can be ventilated without electrical equipment and mechanical equipment, organic matters in the device can be subjected to aerobic fermentation and the device practicability is improved; a temperature sensor and a humidity sensor are arranged, the temperature sensor can detect the temperature in the device in real time, the humidity sensor can detect the humidity in the device in real time, when the temperature or humidity in the device is not adaptive to the temperature and the humidity of organic matter fermentation, corresponding adjusting measures can be taken in time, the fermentation effect of organic matter is guaranteed, and the functionality of the device is improved.

Owner:肖金来

Welding device for sheet metal processing

ActiveCN110653471BNo need for manual unloadingAccurateResistance welding apparatusEngineeringPhysics

The invention discloses a welding device for sheet metal processing, comprising a support base, the top of the support base is fixedly connected with protective material guide devices on both sides of the welding box, and the middle position of the bottom of the inner cavity of the welding box is fixedly connected with a support frame An adjustment device is fixedly connected to the bottom of one side of the support frame close to each other, and a welding platform is fixedly connected to the side of the adjustment device away from the bottom of the inner cavity of the welding box, and the outer walls on both sides of the welding protection box are located between the front and the front of the electric telescopic rod. The symmetrical positions on the back are slidingly connected with fastening and positioning devices. The bottom of the welding protection box is located on the left side of the welder and is fixedly connected with a nozzle. The top of the inner cavity of the welding box is located on the left side of the electric telescopic rod. gold technology field. Effective positioning, and suitable for sheet metal parts of different thicknesses, without manual unloading, convenient, fast, accurate, conducive to personal safety protection, and automatic cleaning, can effectively prevent debris from endangering equipment safety.

Owner:HUZHOU LONGHAO AUTO PARTS

A liquefied natural gas unloading auxiliary device

The invention relates to the technical field of an unloading assisting device and particularly relates to an unloading assisting device of liquefied natural gas. The unloading assisting device comprises two freight forklifts which are symmetrically fixed on a forklift portal frame; a second resetting spring is arranged between two baffles; two bearings are symmetrically arranged on the side wall, far away from one end of a limiting groove, of a horizontal blind hole; a rotary shaft is connected between inner rings of the two bearings; the middle axis of the rotary shaft is parallel to the middle axis of a through hole; the other end of a steel rope penetrates through the through hole and is connected with the two baffles and the rotary shaft; the baffle close to one end of a limiting groove is fixedly connected with the steel rope; and the baffle, far away from one side of the limiting groove, is movably connected with the steel rope. According to the unloading assisting device of the liquefied natural gas, manual unloading is not needed so that more labor is saved; a fuel gas tank does not swing greatly, so that unloading is safer; and when the forklift is used for unloading, a limiting plate is arranged on the forklift, so that unloading of the liquefied natural gas can be assisted better.

Owner:蚌埠启邦科技信息咨询有限公司

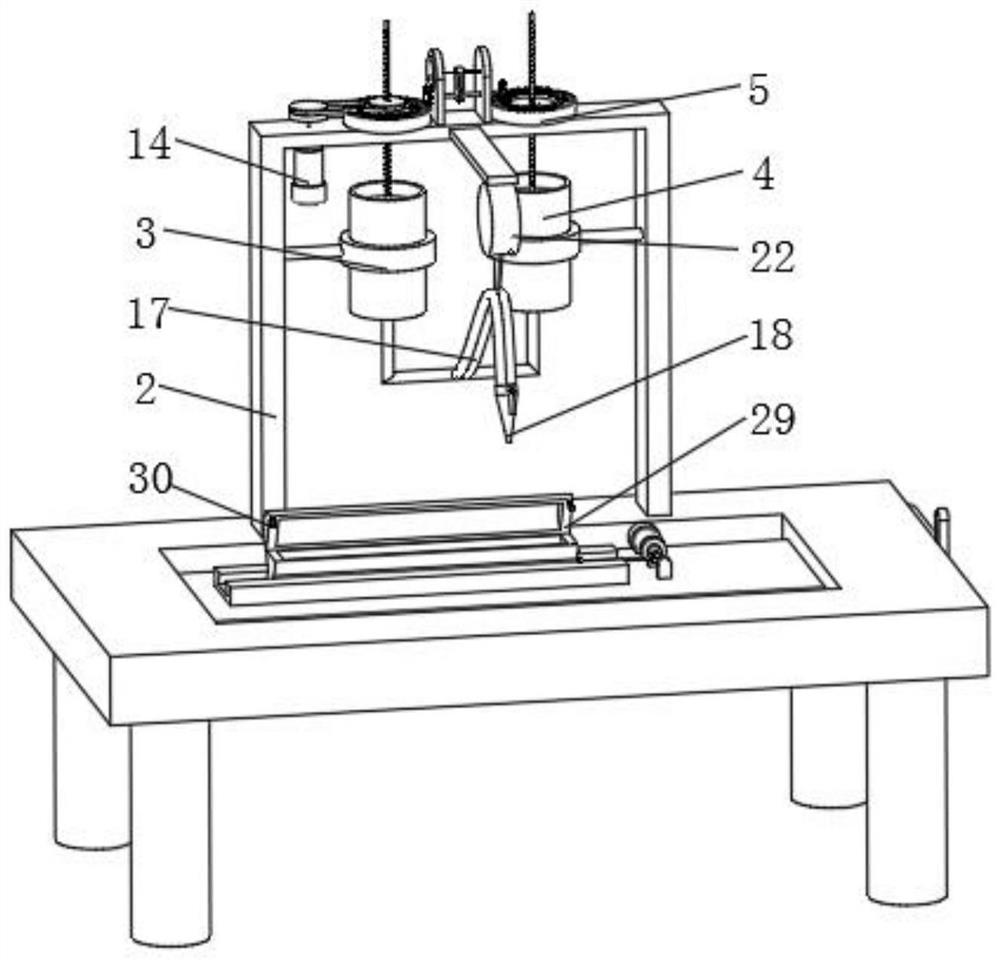

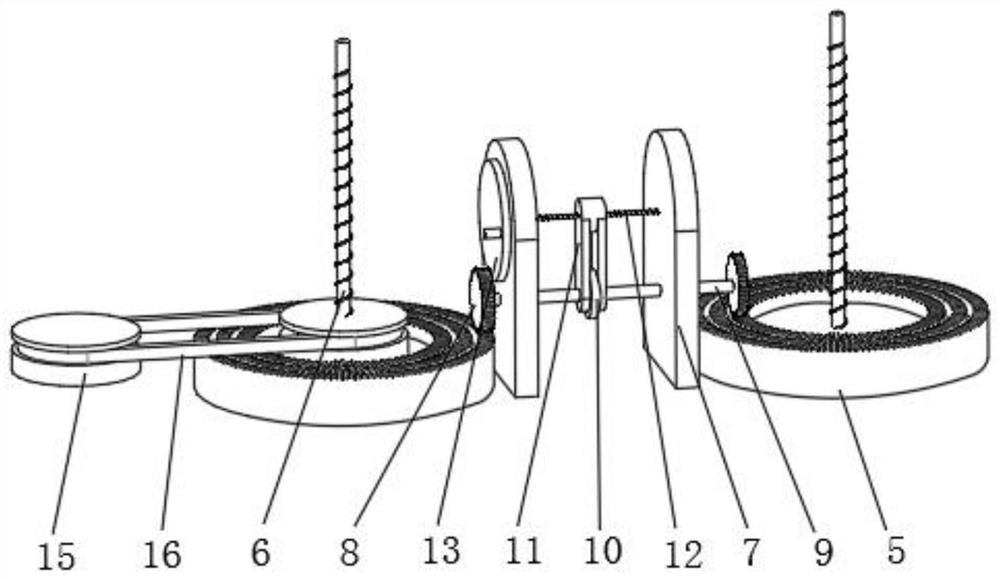

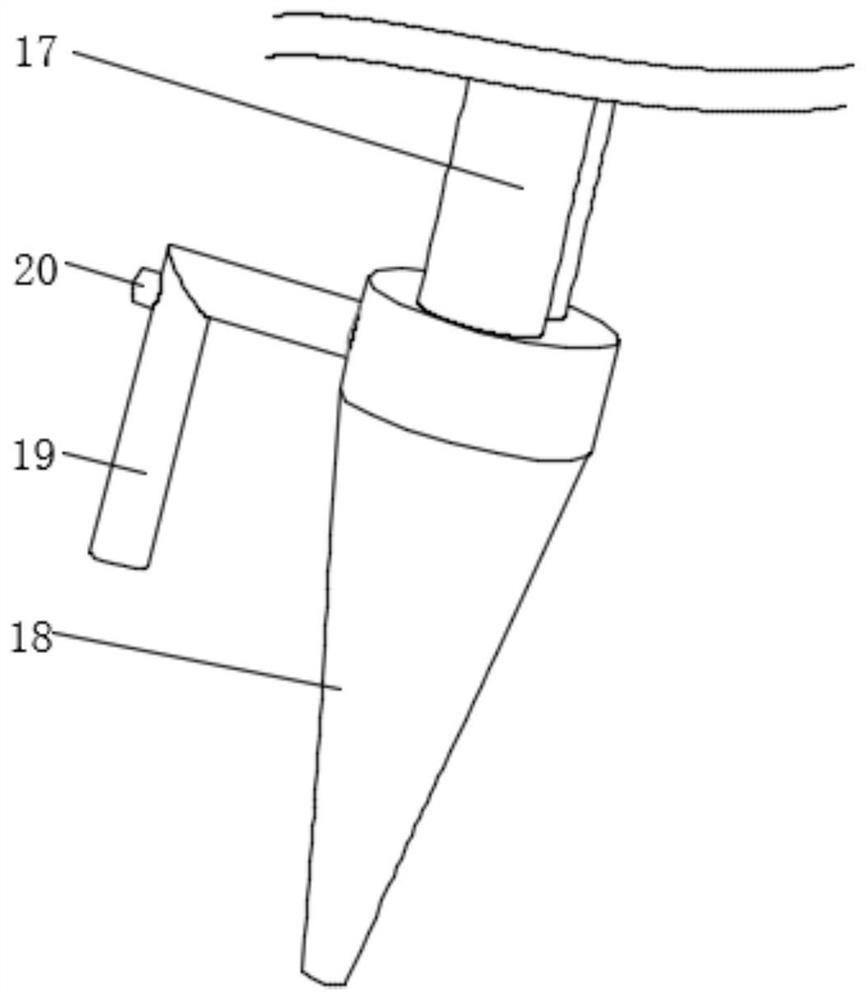

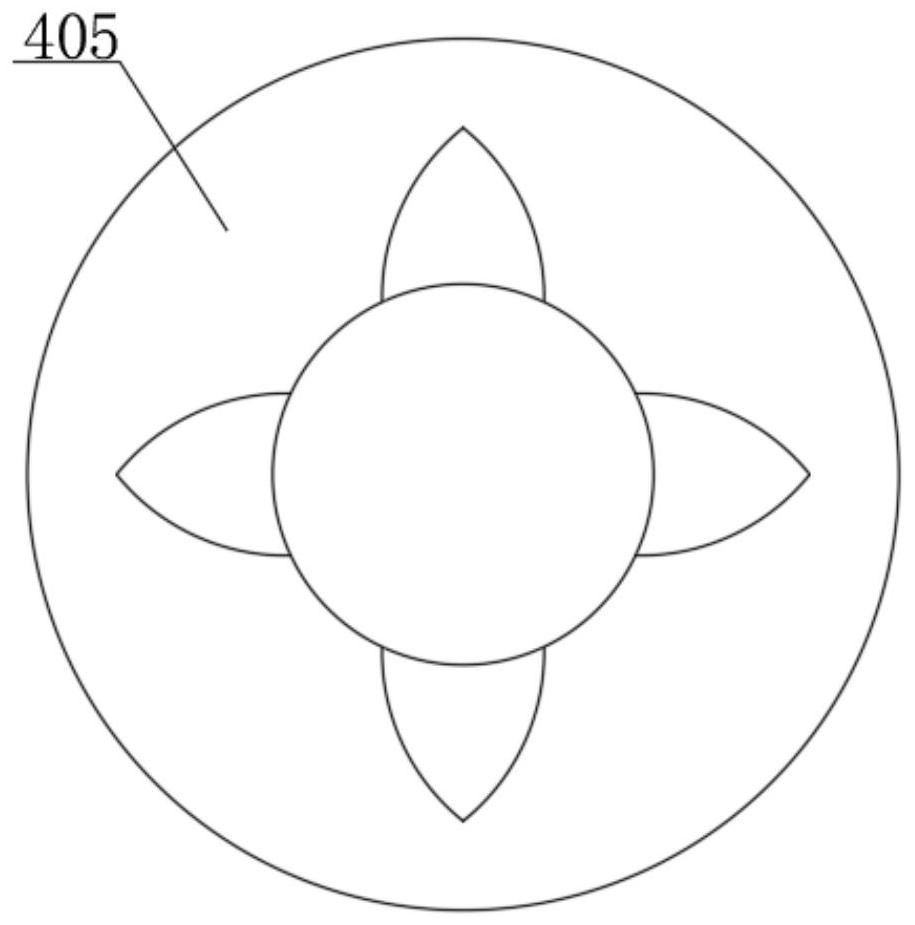

Foaming equipment for producing polyurethane foam plastic and production process

The invention discloses foaming equipment for polyurethane foam plastic production and a production process, and relates to the field of polyurethane foam. The foaming equipment comprises a workbench, a mounting frame is fixedly mounted on the top side of the workbench, and two multi-layer gear rings are rotatably mounted on the top side of the mounting frame; circular shafts are fixedly mounted on the inner walls of the two sides, away from each other, of the mounting frame correspondingly, and fixing rings are fixedly mounted at the ends, close to each other, of the two circular shafts correspondingly. A rotating disc is rotated to drive an adjusting lead screw to rotate, the adjusting lead screw rotates to drive a U-shaped block to move, the U-shaped block moves to drive a lantern ring to move, the lantern ring moves to drive two gears to slide on the two multi-layer gear rings through a rotating shaft, and therefore injection proportion of two raw materials is adjusted by adjusting transmission ratio of rotation of the two multi-layer gear rings, the best foaming effect can be achieved by finely adjusting the proportion according to different shapes, strengths and functions of foaming forming, foaming effect of the foaming equipment is good, and performance of the formed polyurethane foam plastic is good.

Owner:HUIZHOU YUANAN NEW MATERIALS

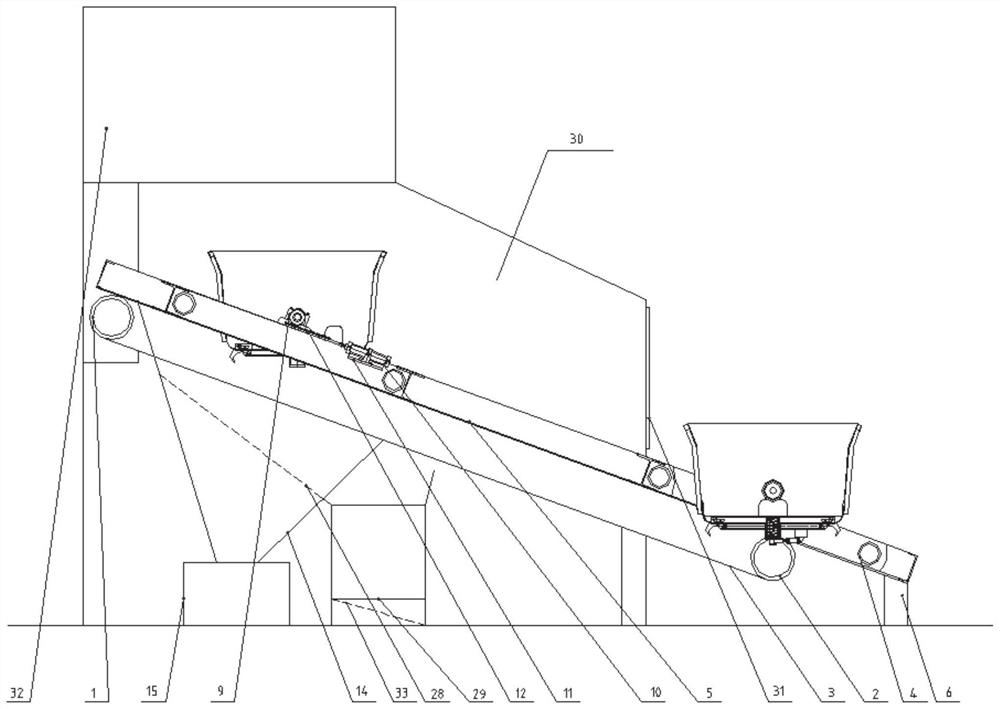

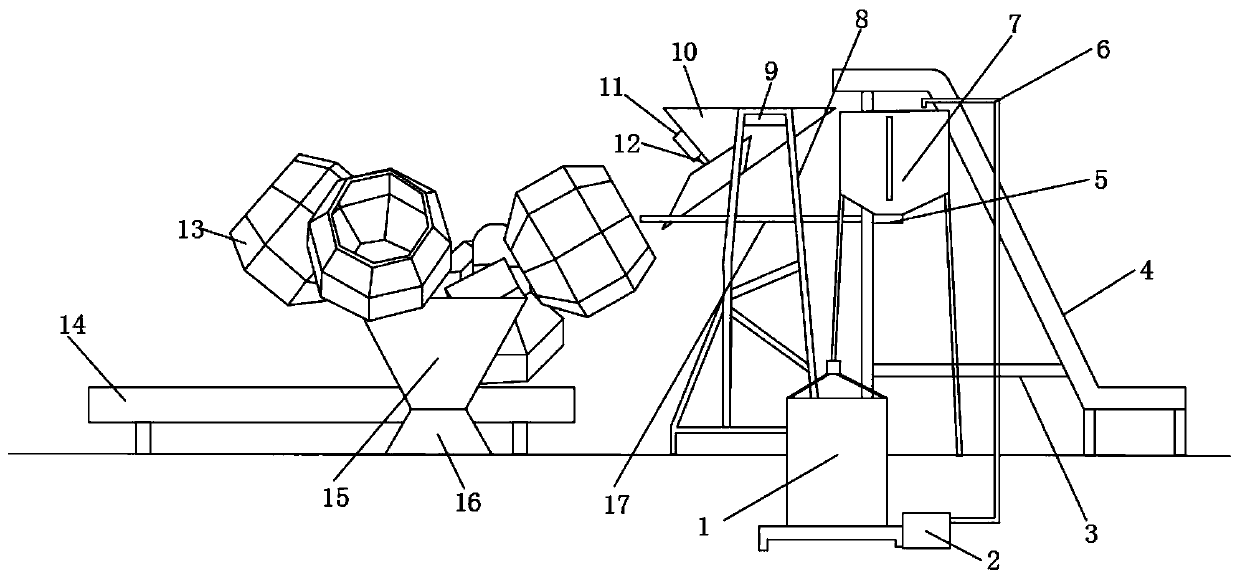

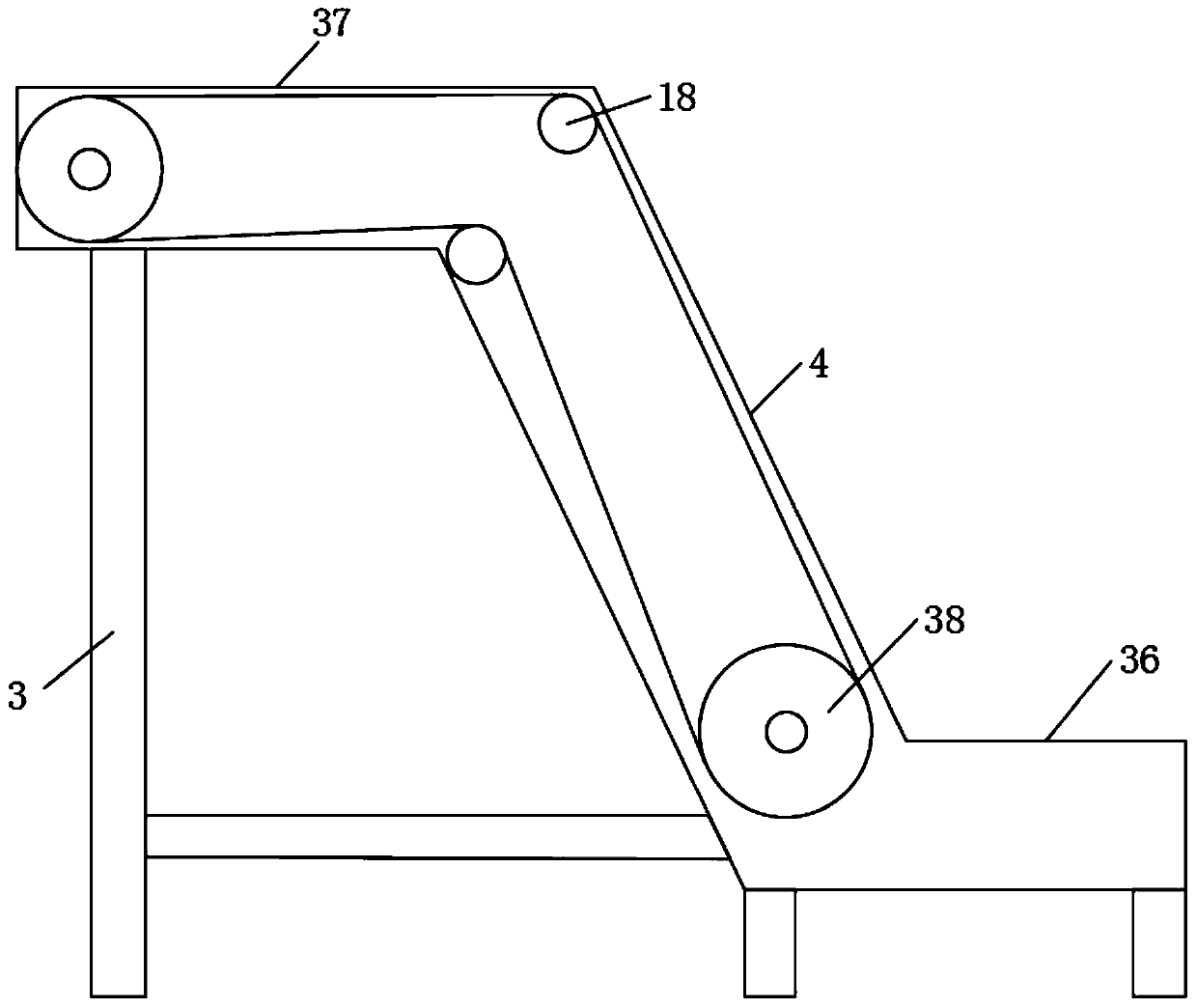

Extension type construction feeding device for building construction

InactiveCN112942830AReduce labor intensityStable unloadingConveyorsBuilding material handlingArchitectural engineeringWinch

The invention discloses an extension type construction feeding device for building construction, and relates to the technical field of building construction. The problems that when an existing construction feeding device is used, a worker needs to carry out materials in a bearing part, operation is troublesome, the labor amount of the worker is large, the discharging speed is high, the amount can only be fixed every time during discharging, and discharging cannot be flexible according to the requirement are solved. The automatic discharging device comprises a mounting seat, a group of discharging driving pieces are fixedly connected to the front end surface of the mounting seat; a group of discharging driven roller shafts are rotationally connected with the right side of the top of the mounting seat; and a group of lifting winches are fixedly connected to the left side and the right side of the front end surface and the rear end of the mounting seat. According to the extension type construction feeding device for building construction, materials are lifted, meanwhile, the materials can be automatically discharged in the lifting process, manual unloading is not needed, the labor intensity of workers is reduced, discharging is more stable, the discharging speed is high, the discharging amount and the discharging speed can be controlled according to needs, and using is more convenient and flexible.

Owner:纪蕾

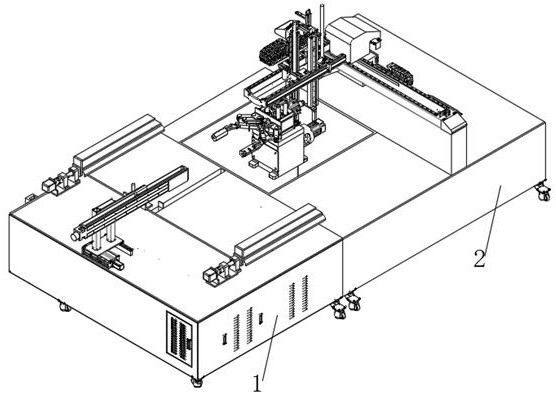

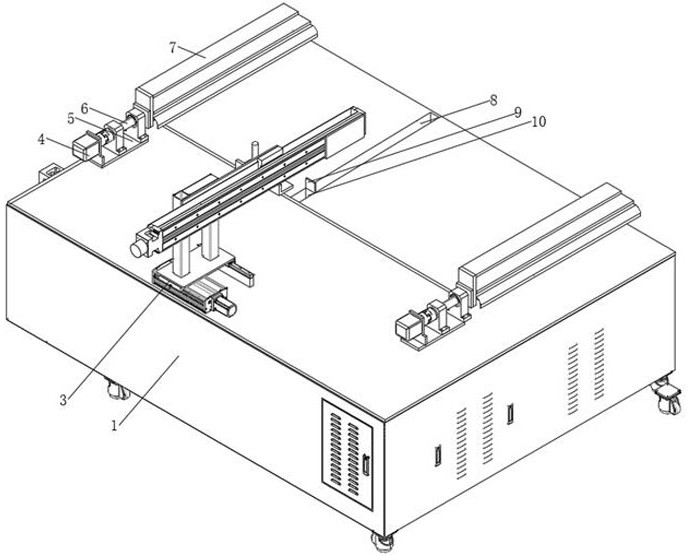

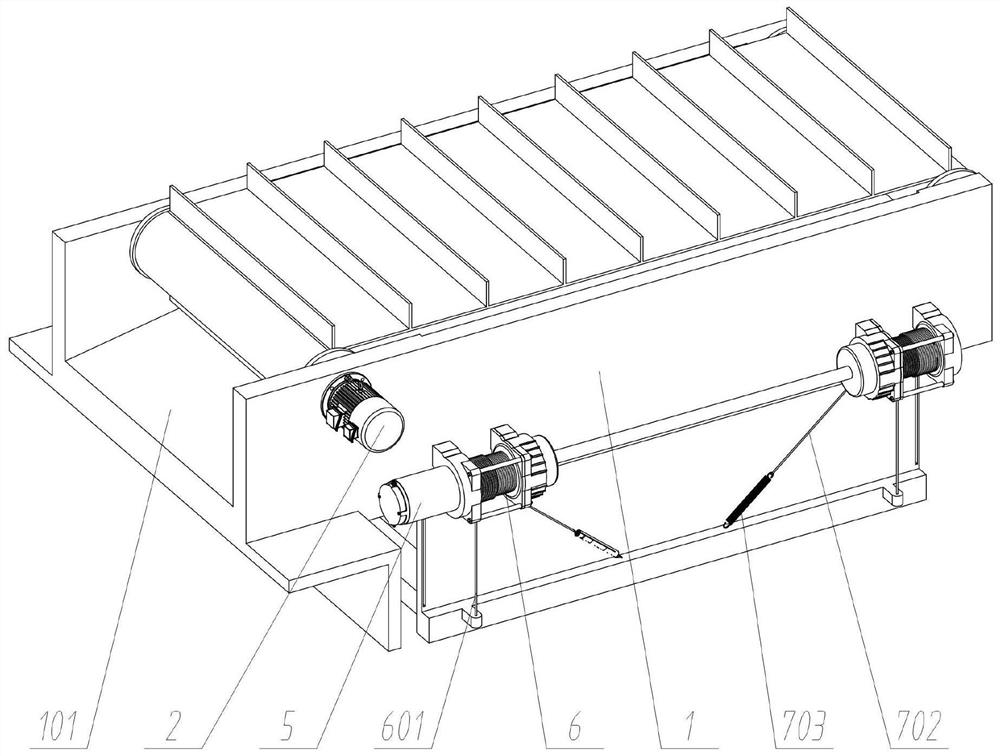

PVC slot plate processing equipment

PendingCN106695922AImprove cutting accuracyAvoid human interferenceMetal working apparatusEngineeringGear tooth

The invention discloses PVC slot plate processing equipment which comprises a processing table, a processing plate, a power mechanism, a cutting mechanism and an unloading mechanism, wherein the processing table is equipped with a guide rail in the length direction of the processing table; the processing plate can be movably mounted on the guide rail; an accommodating slot used for accommodating a PVC slot plate is formed in the upper surface of the processing plate; the accommodating slot is formed in the length direction of the processing table; a plurality of cutting channels are further arranged on the upper surface of the processing plate, are uniformly distributed in the length direction of the processing table, and the length direction of the cutting channels is perpendicular to that of the processing stable; the power mechanism comprises a rack, a rotary wheel and a plurality of sections of gear teeth; the power unit and the rack are mounted on the processing plate; the length direction of the rack is parallel to that of the processing stable; the rotary wheel is arranged at one side of the rack; the multiple sections of gear teeth are uniformly distributed on the outer peripheral surface of the rotary wheel in a spaced mode; the gear teeth are matched with the rack; and the power unit is used for driving the rotary wheel to rotate. The PVC slot plate processing equipment disclosed by the invention is high in processing precision.

Owner:安徽优丽普科技有限公司

A Stamping and Grabbing Mechanism for Small Automobile Parts

Owner:嵊州市高新技术发展有限公司

A filter device for processing whey fermentation liquid and its application method

ActiveCN111389081BAvoid wastingImprove work efficiencyMoving filtering element filtersMilk SerumWater source

Owner:SYNBIOTECH BIOTECHNOLOGY YANGZHOU CO LTD

A kind of candied fruit intelligent adding and mixing device and using method thereof

ActiveCN110921250BReduce laborNo need for manual weighingRotating receptacle mixersConfectioneryControl engineeringAgricultural engineering

The invention discloses an intelligent seasoning device for candied fruit, which comprises a feeding box and a mounting frame. The feeding fixed frame on one side is provided with an auxiliary material tank, which drives the second output shaft to rotate through the output end of the second motor, and then makes the mixing box rotate, and the mixing process of the candied fruit raw materials in the box, due to the mixing box Place it at an angle to improve the stirring effect, so that the candied fruit raw materials are stirred more evenly, and then control the rotation of the round seat. When the mixing box rotates the position of the discharge conveyor belt, the second piston rod is controlled by the second hydraulic cylinder to move upward. The second piston The rod pushes one end of the horizontal plate on the top to move upward, so that the opening of the mixing box is downward, and the stirred candied fruit is dumped on the discharge conveyor belt, and then conveyed out of the device, which is convenient for the next processing process and does not require manual unloading , Improve the efficiency of candied fruit processing.

Owner:GUANGDONG JIABAO GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com