Foaming equipment for producing polyurethane foam plastic and production process

A foamed plastic and foaming equipment technology, applied in the field of polyurethane foam, can solve the problems of unmatched fine-tuning to achieve the best foaming effect, poor foaming effect of foaming equipment, poor performance of polyurethane foam, etc. Good foaming effect, improving foaming effect and speeding up foaming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

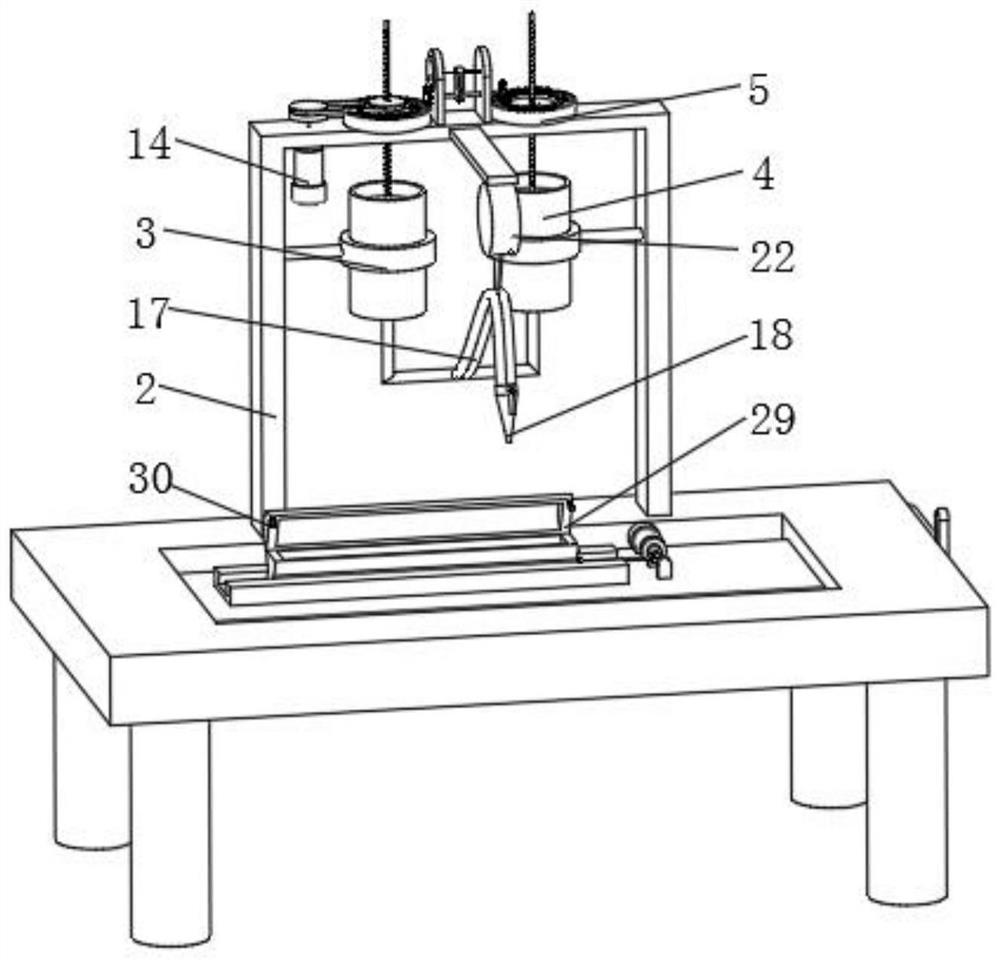

[0045] Example: Reference Figure 1-9 The shown foaming equipment for polyurethane foam production includes a workbench 1 . The workbench 1 can be any base structure in the prior art, such as a metal plate body.

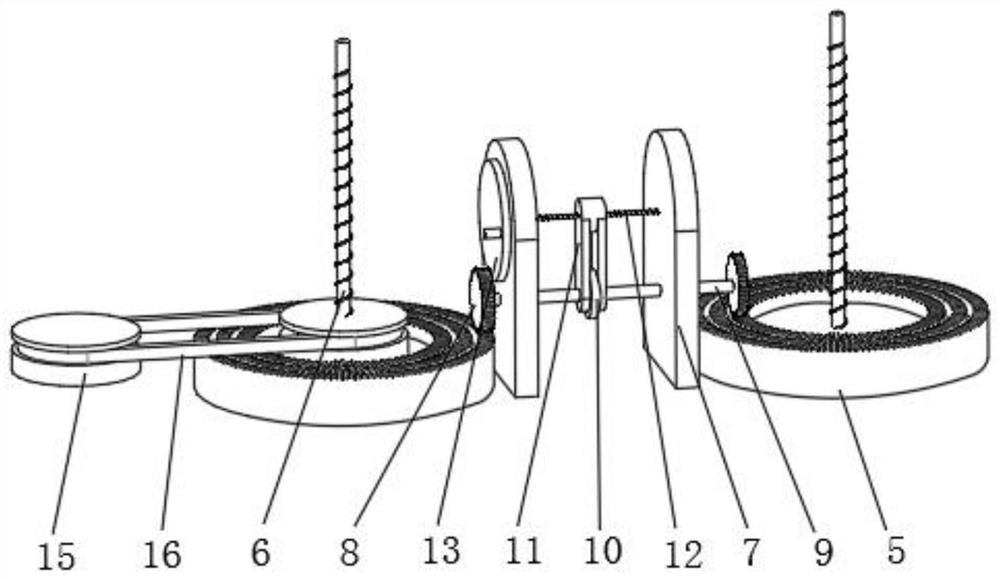

[0046] An installation frame 2 is fixedly installed on the top side of the workbench 1, and the installation frame 2 may be any frame structure in the prior art, and two multi-layer ring gears 5 are rotatably installed on the top side of the installation frame 2.

[0047] Both sides of the installation frame 2 are far away from each other and are fixed with round shafts on the inner walls, and one end of the two round shafts is fixed with a fixed ring 3, and the fixed ring 3 can be any metal ring in the prior art. Reagent cartridges 4 are fixedly sleeved inside the fixing rings 3, and the reagent cartridges 4 may be any kind of cartridge mechanism in the prior art, such as metal cartridges.

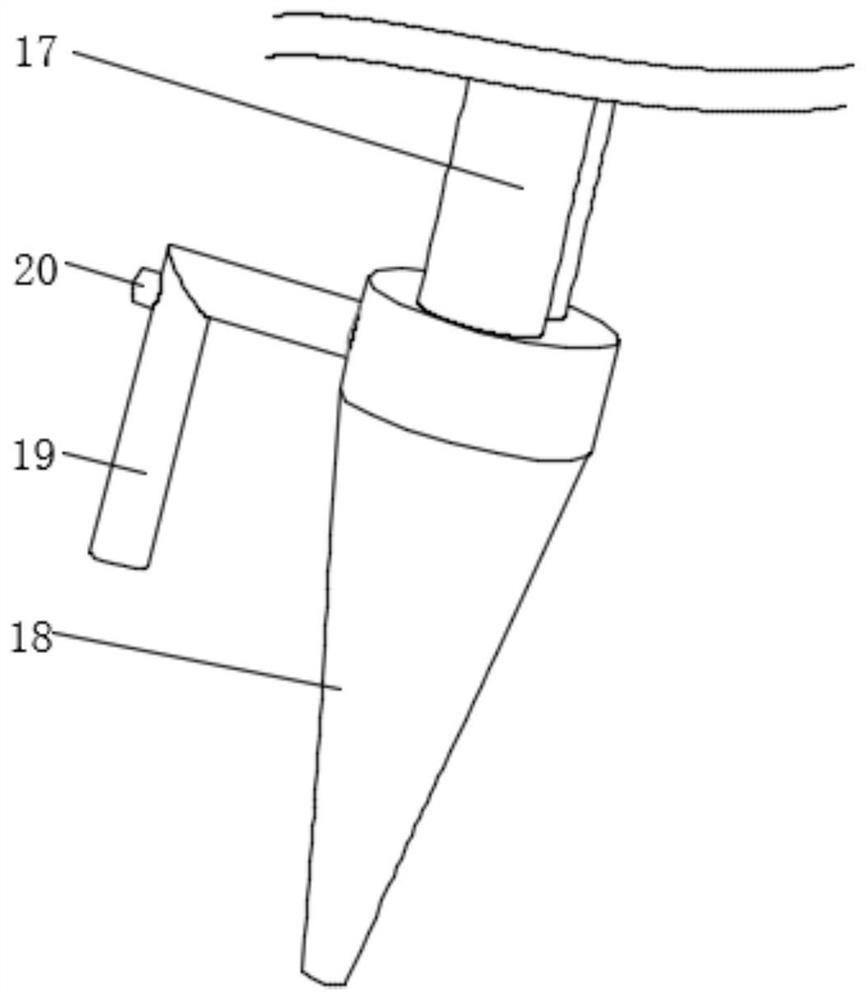

[0048] Pistons are movably socketed in the two reagent cylinders 4, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com