Patents

Literature

66results about How to "Prevent reverse movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

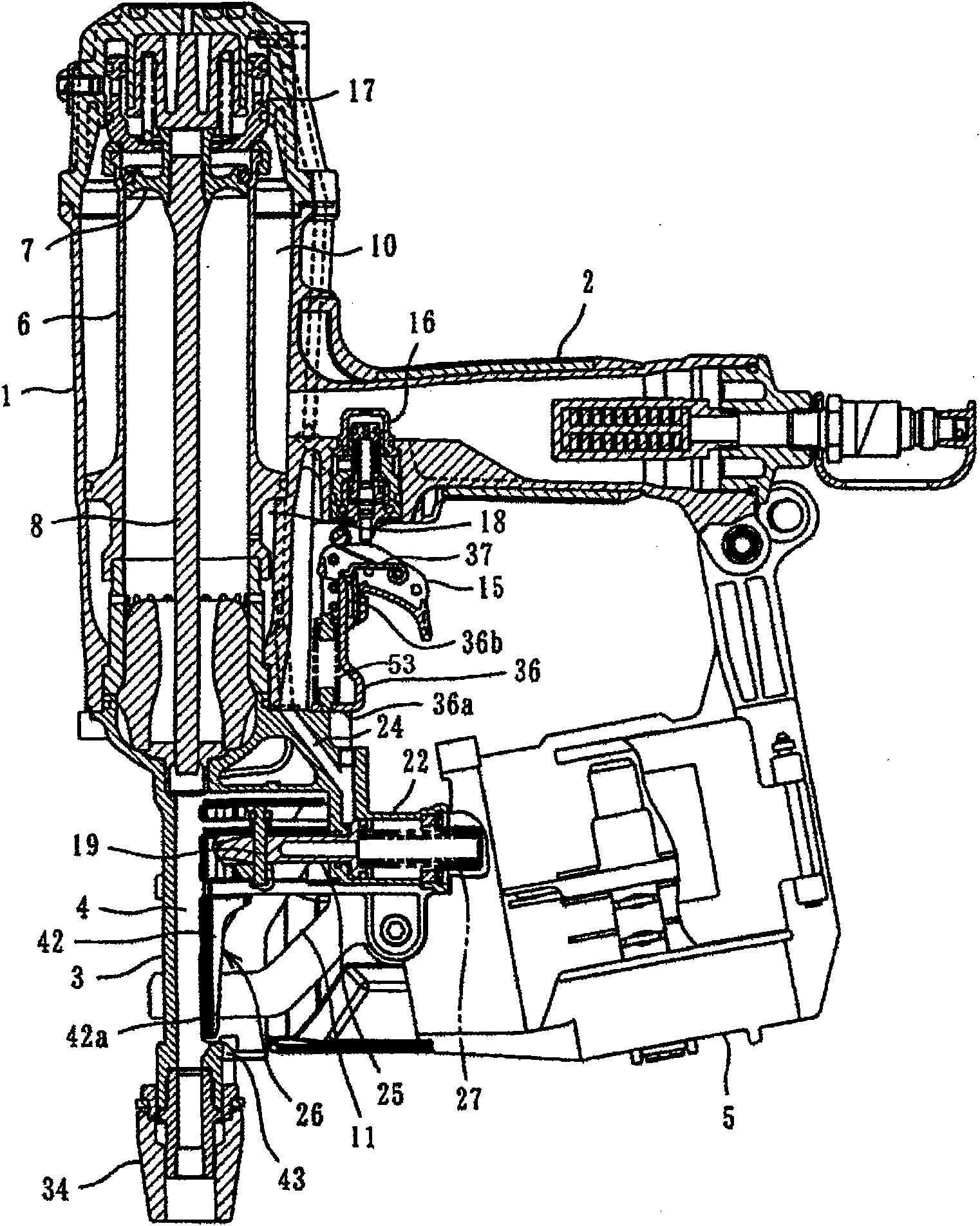

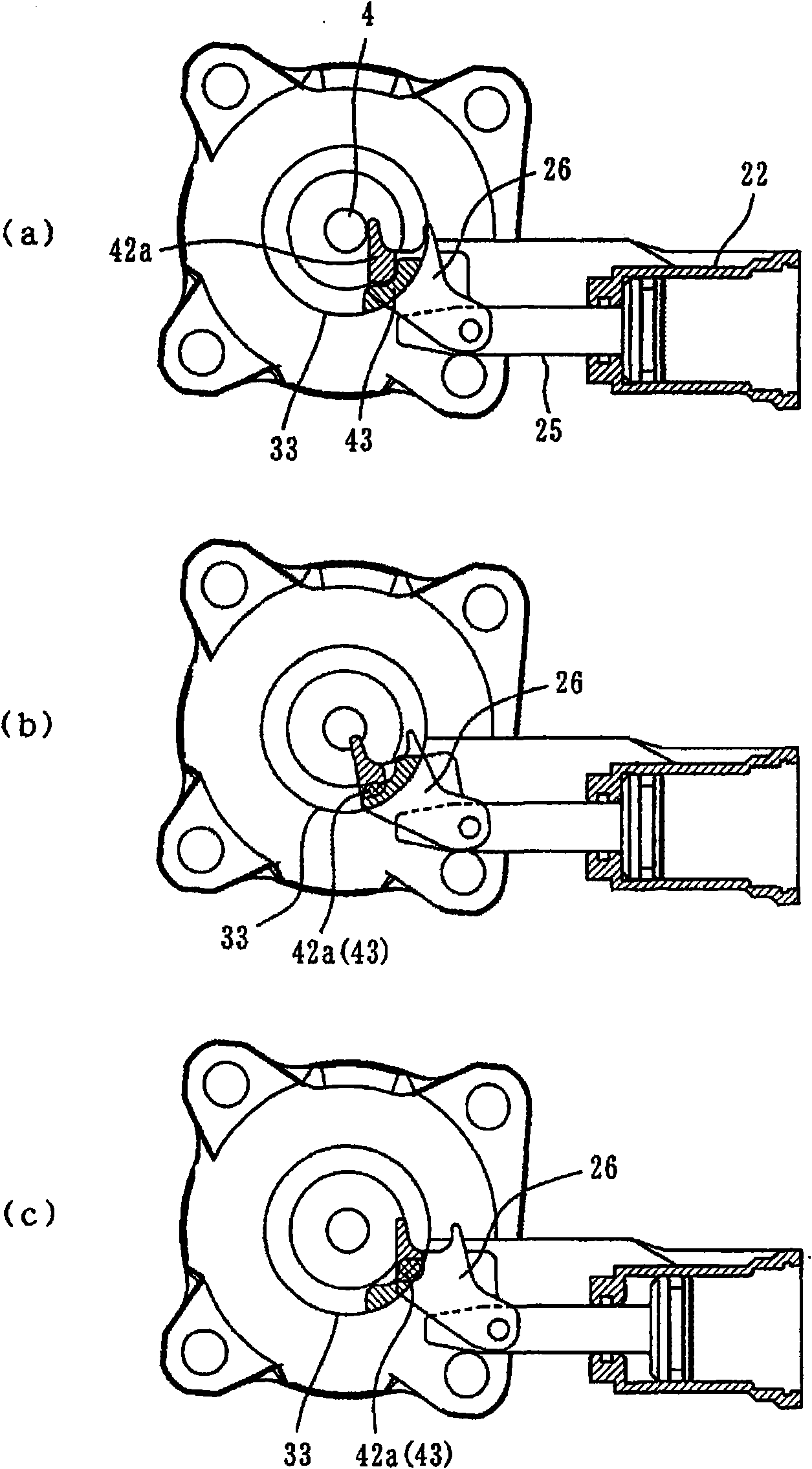

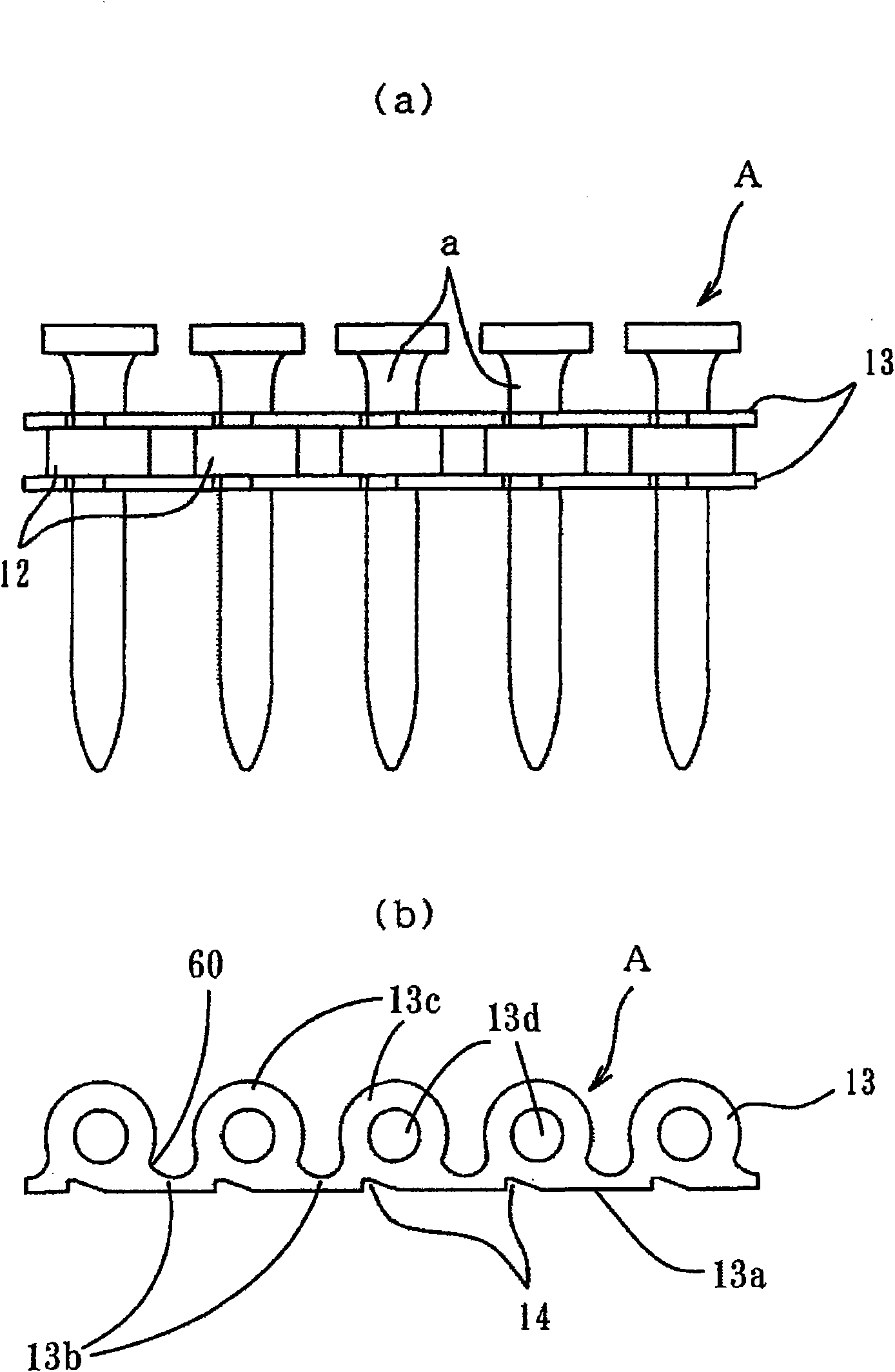

Fastener punching machine

A fastener punching machine is provided with the following components: a conveying passage which is provided with an opening at a machine head (3) for punching; a conveying pawl (26) which is jointed with a connecting fastener (A) and moves in a conveying direction for transporting the connecting fastener (A) to a shooting outlet (4); a touch unit (33) which is freely equipped slidably along the machine head (3) and is pressed to the punched material for moving relatively to a punching machine body (1) and validating a starting operation of punching the fastener; and jointing parts (43,52) which are set on the touch unit (33) and can be jointed with the conveying pawl (26). The conveying pawl (2) can retreat and rotate from the conveying passage (11). The conveying pawl (26) can load the connecting fastener (A) to the conveying passage (11) without causing the rotation of the conveying pawl (26). The touch unit (33) is pressed to the punched material at a state that the conveying pawl (26) retreats and rotates, and the jointing parts (43,52) of the touch unit (33) are jointed with the conveying pawl (26).

Owner:MAX CO LTD

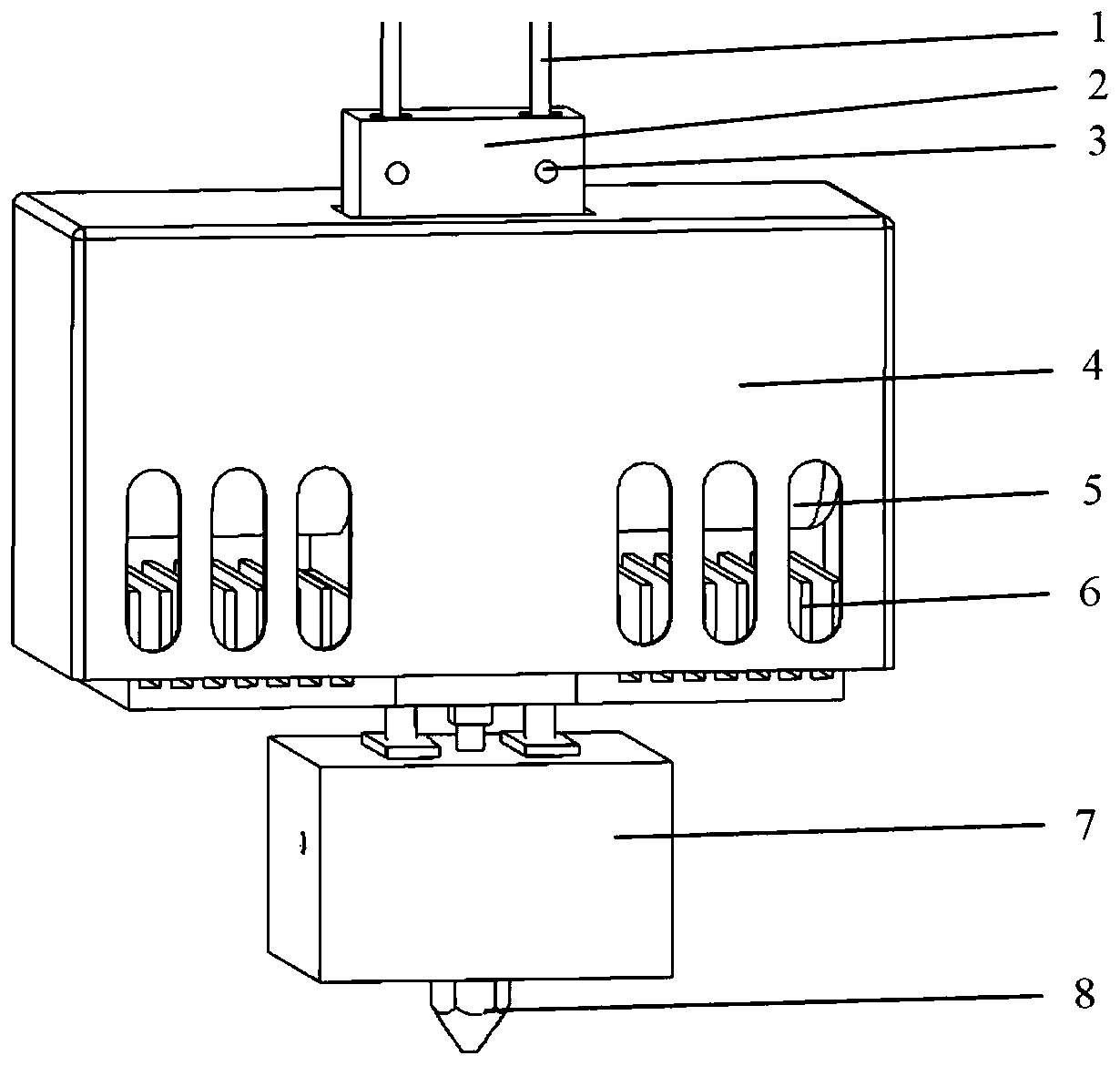

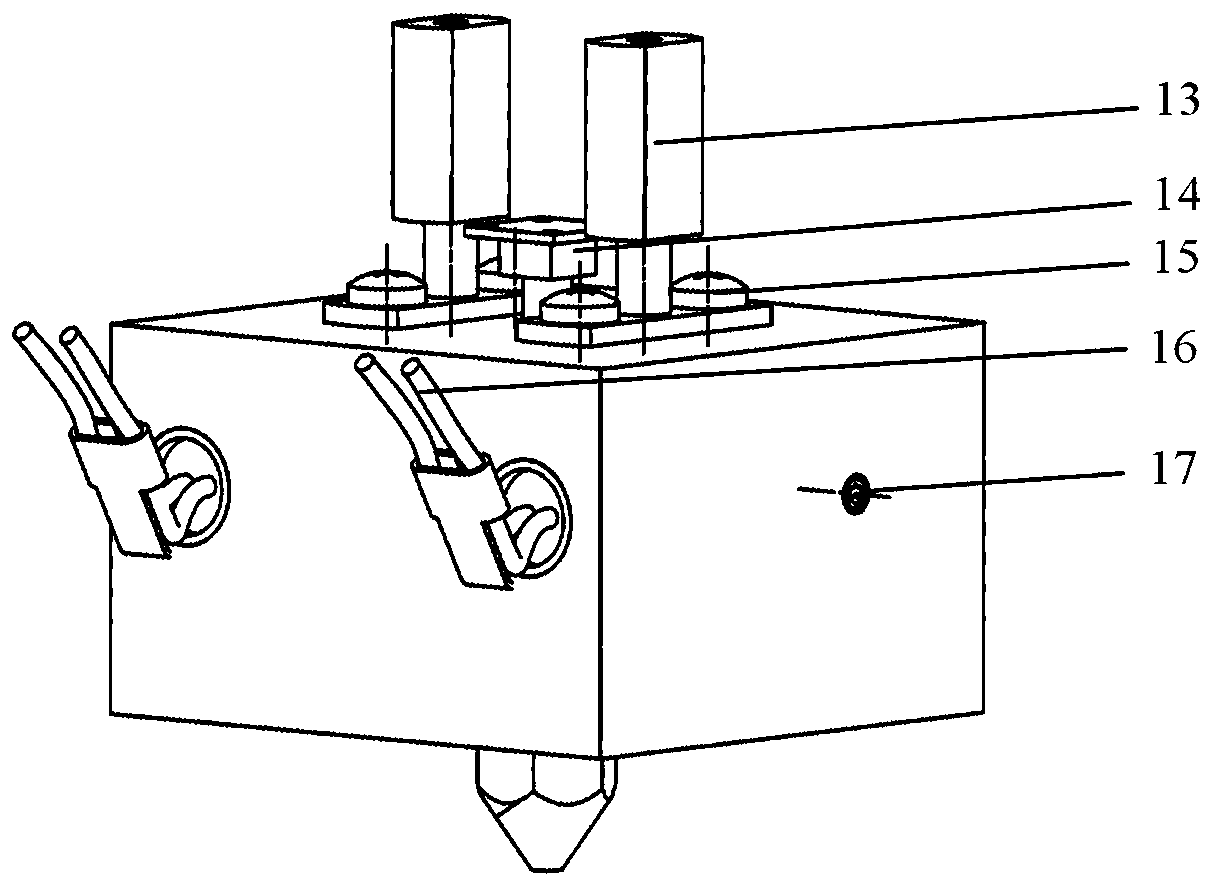

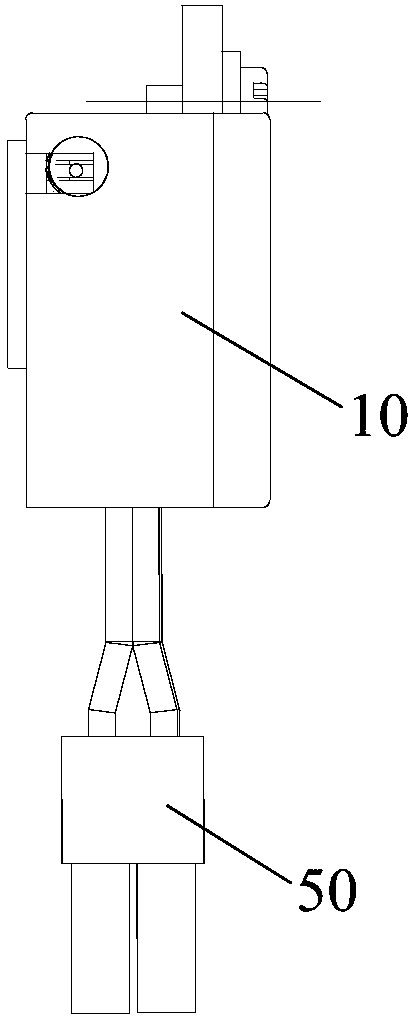

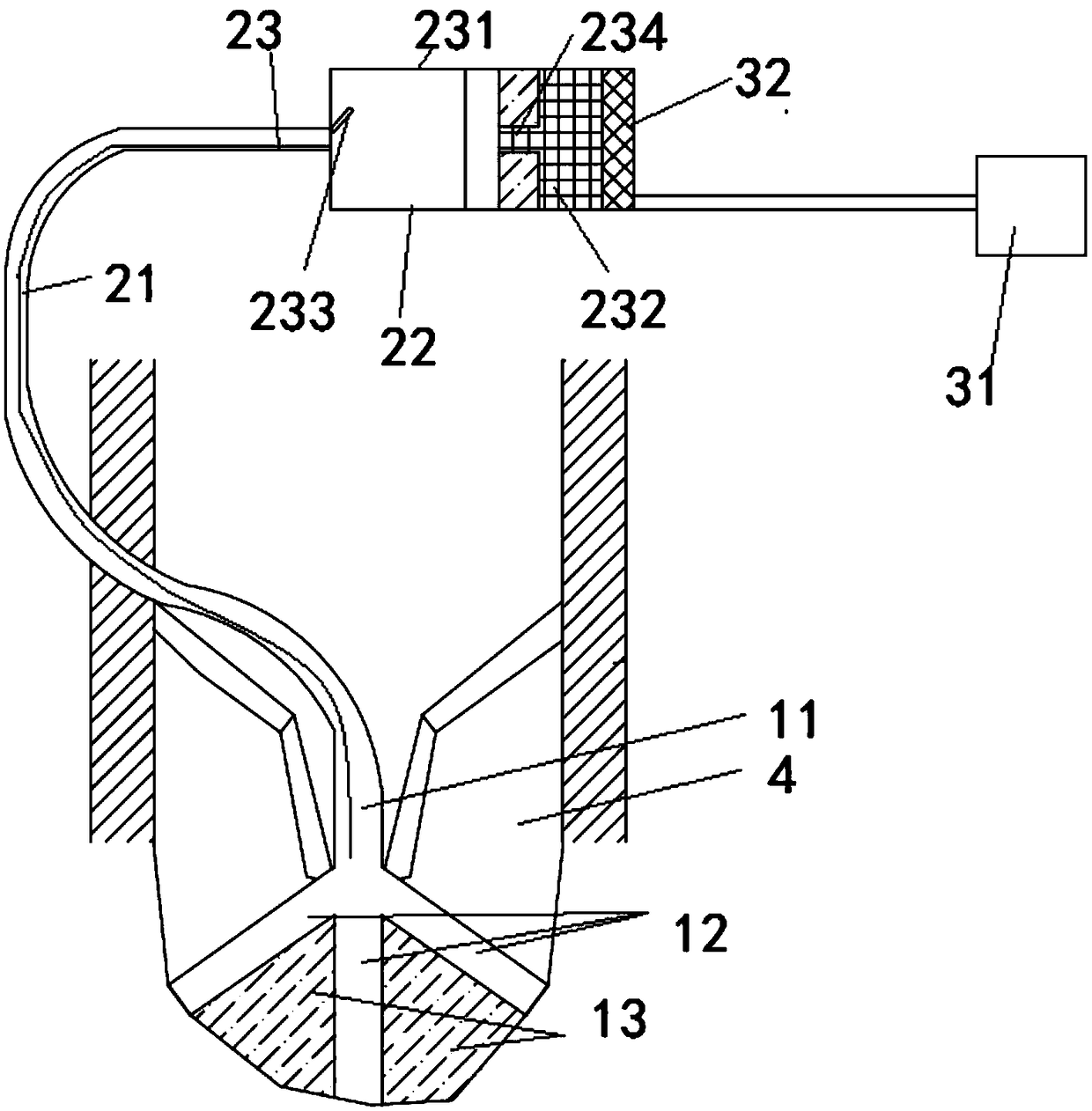

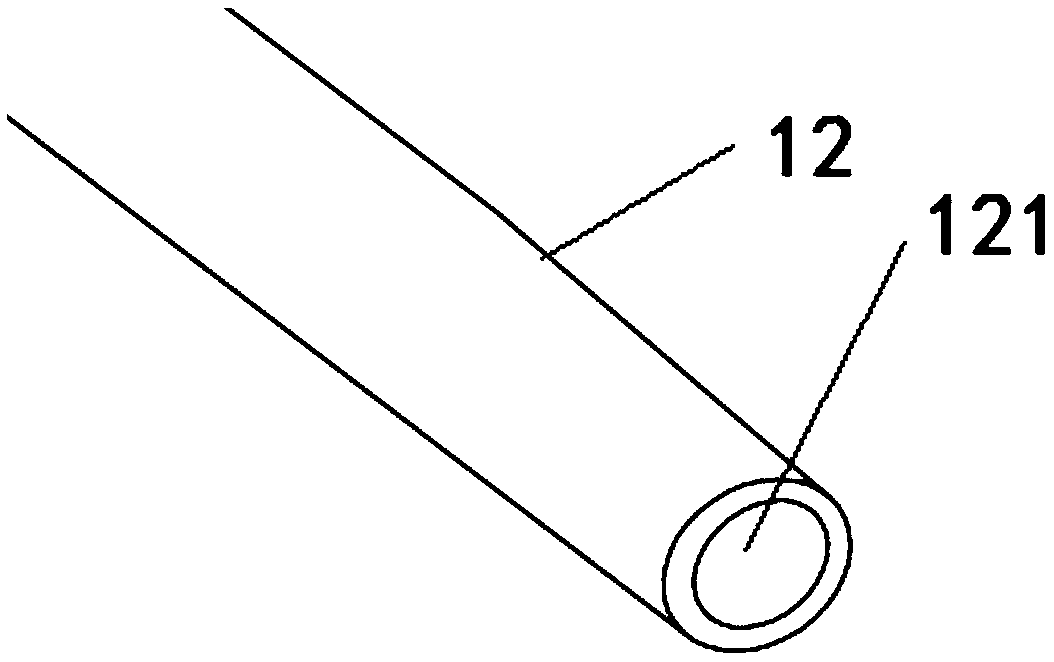

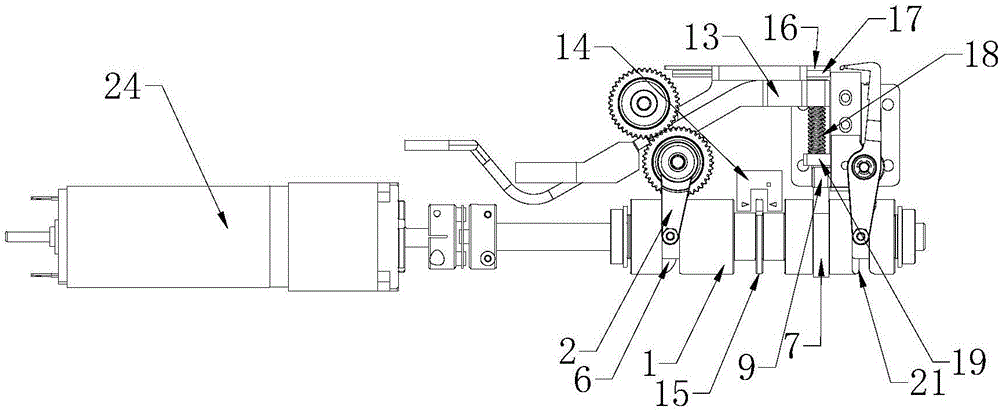

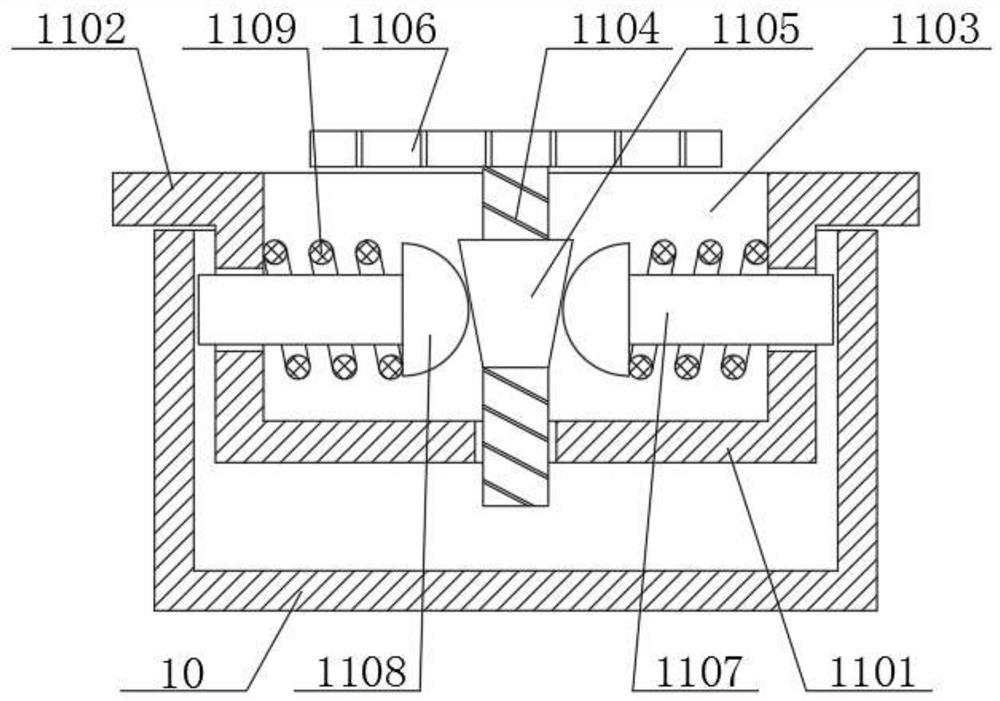

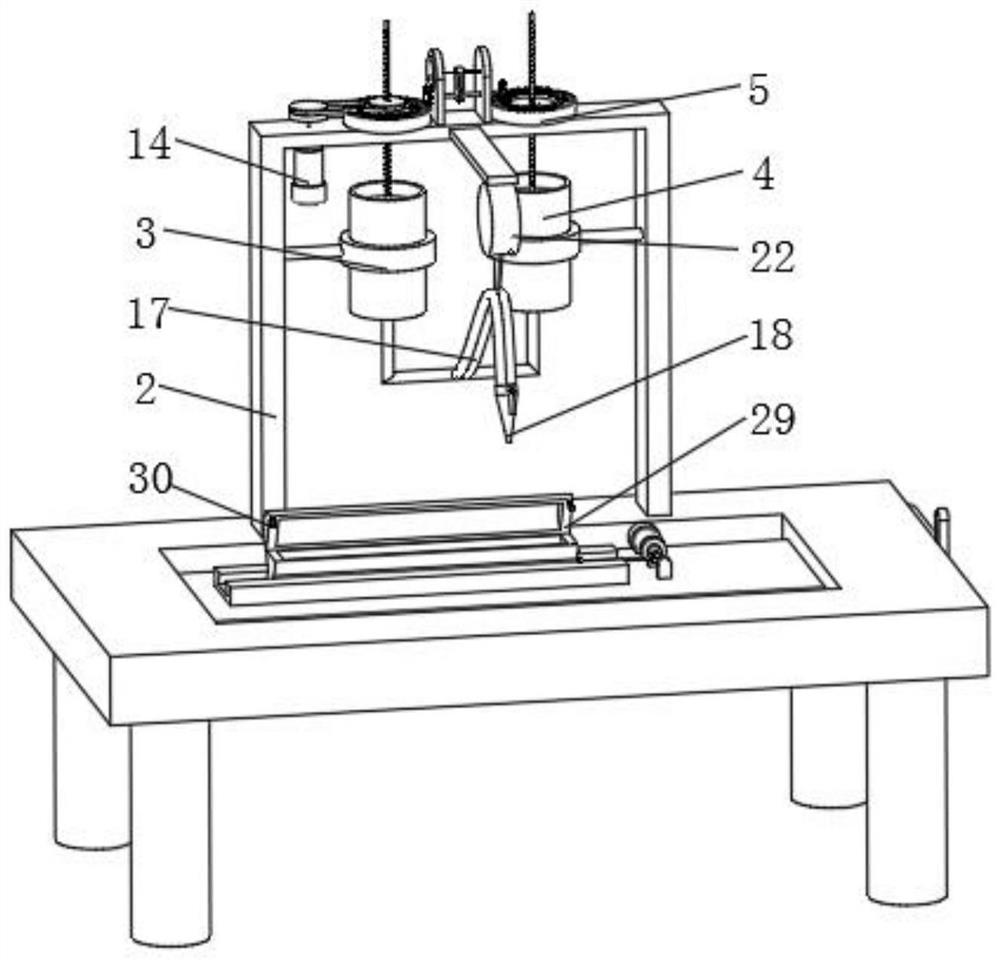

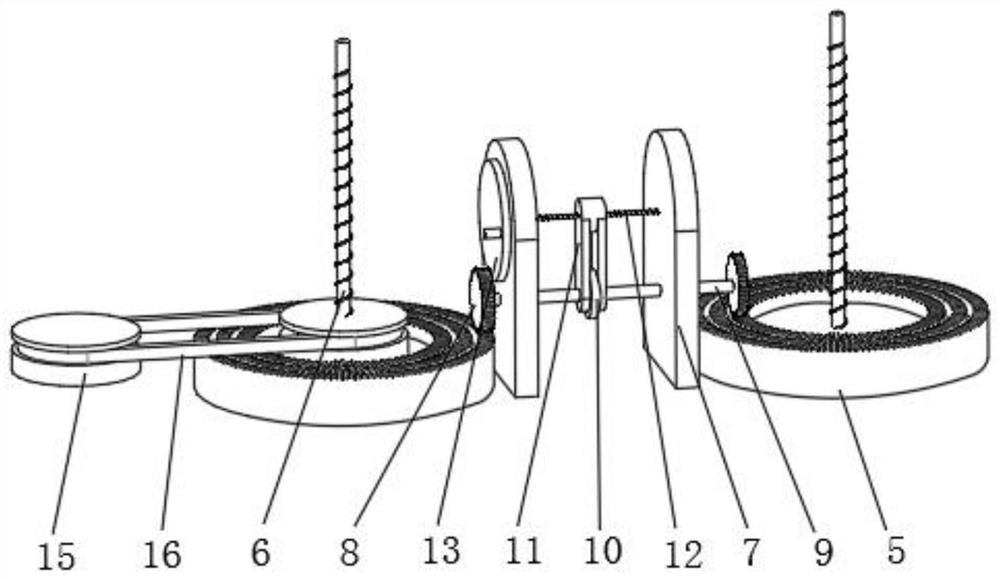

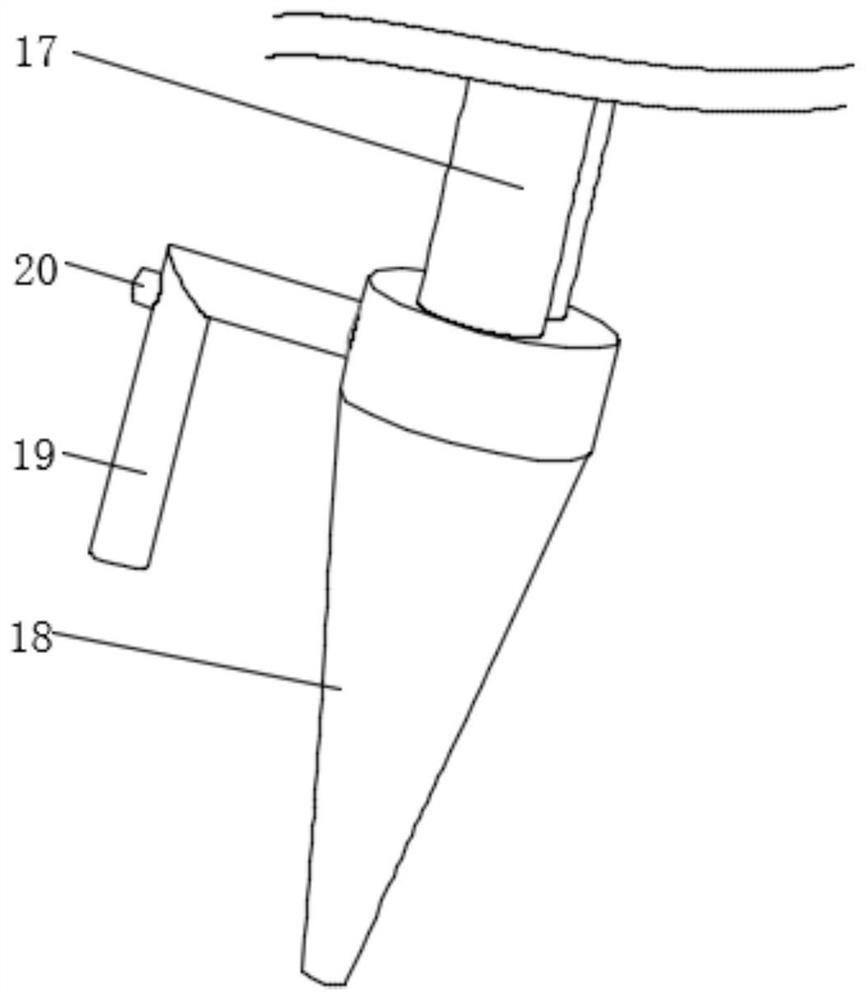

Color mixing 3D printing nozzle device based on FDM technology and discharging method thereof

InactiveCN110435145AIncrease profitEven color mixingManufacturing heating elements3D object support structuresYarnColor printing

The invention discloses a color mixing 3D printing nozzle device based on an FDM technology and a discharging method thereof. Color mixing printing can realize the color of a product and has more advantages compared with single-color printing. The color mixing 3D printing nozzle device based on the FDM technology comprises a feeding mechanism and a mixing heating mechanism. The feeding mechanism comprises a feeding shell, a feeding guide block and a feeding driving assembly. The feeding driving assembly comprises a feeding motor, a driving conveying wheel, an extruding conveying wheel, an extruding sliding block and an extruding spring. The mixing heating mechanism comprises a heating mixing block, a heating guide pipe, a color mixing stirrer, a nozzle, a cooling fin and a heating wire. The color mixing stirrer comprises a connecting shaft, a stirring fan and a stirring motor. According to the two-inlet-one-outlet type color mixing nozzle device, two thermoplastic wire yarns with different colors can be sent to a color mixing cavity of the heating mixing block for color mixing by controlling the mixing proportion of different color wire yarns or setting the change trend of the mixing proportion.

Owner:HANGZHOU DIANZI UNIV

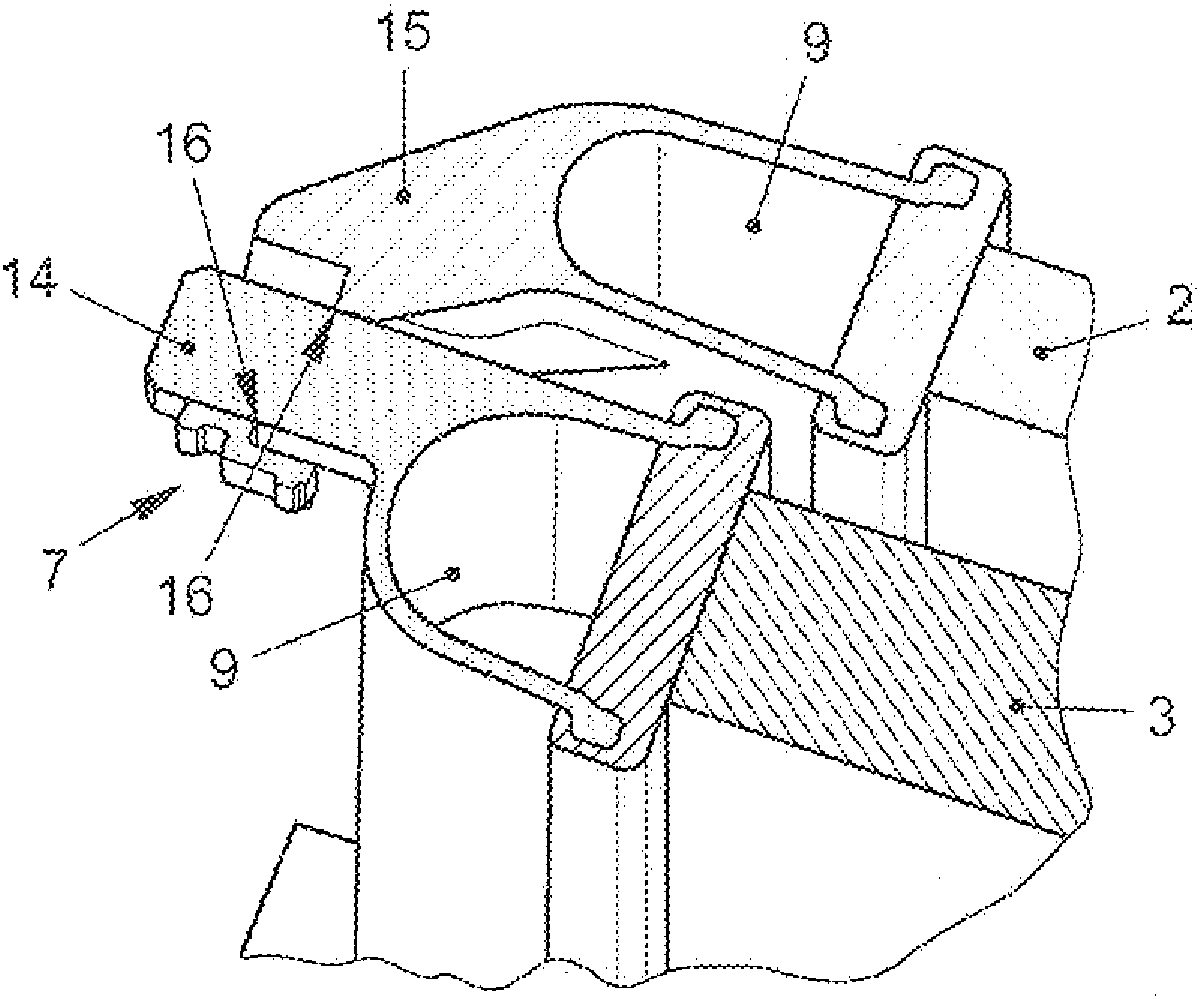

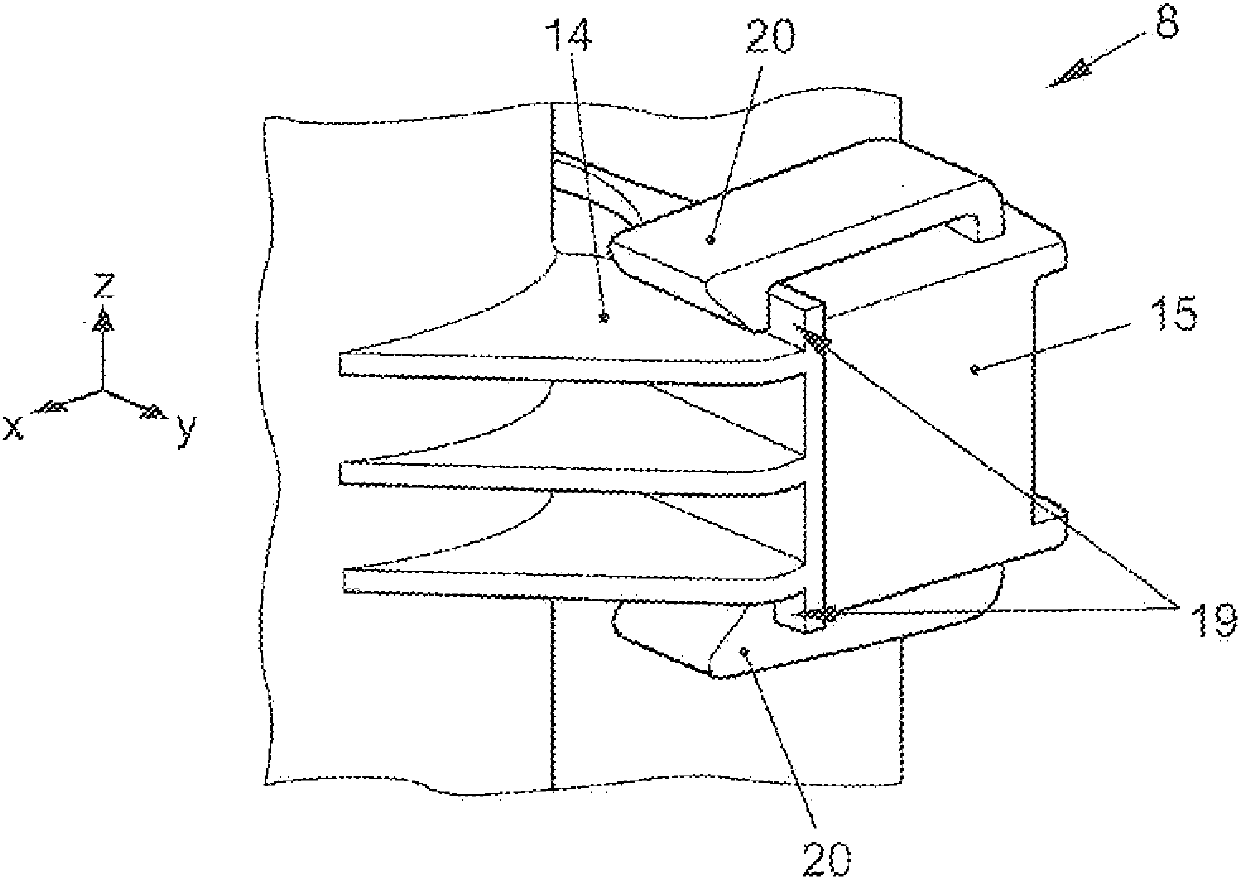

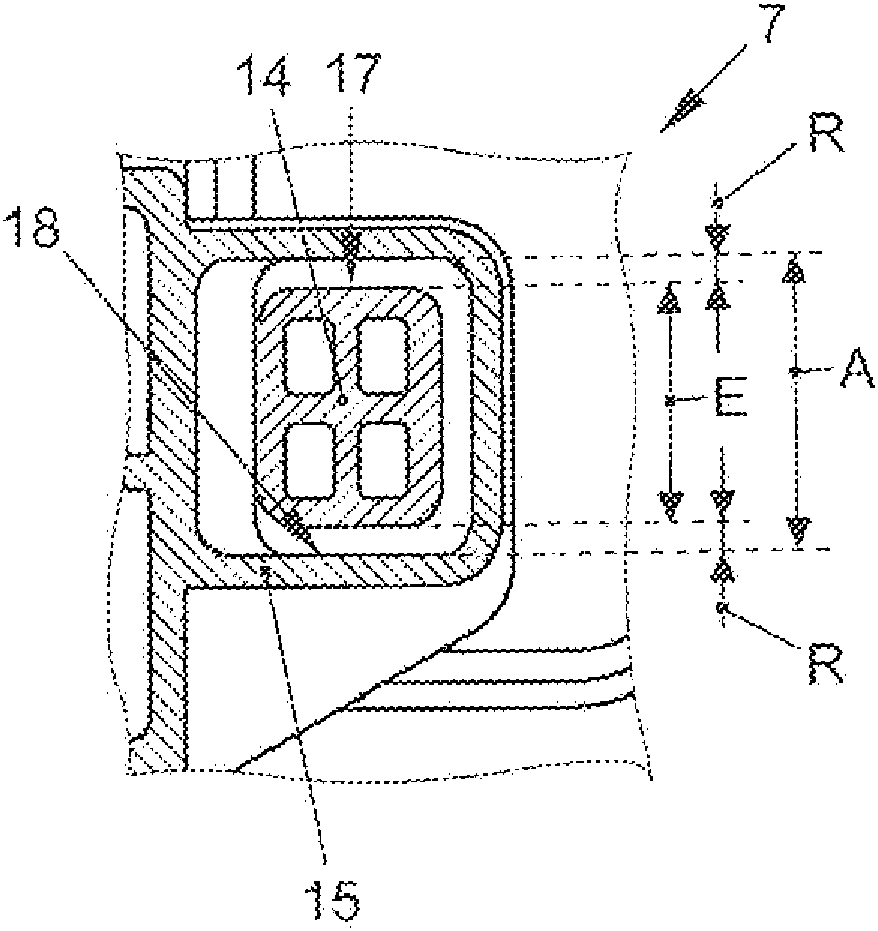

Cooling device for a motor vehicle

ActiveCN105008164ABalance Manufacturing TolerancesEasy to assembleVehicle heating/cooling devicesStationary conduit assembliesFixed positionElectrical and Electronics engineering

The invention relates to a cooling device for a motor vehicle, wherein the cooling device comprises at least two cooling elements (2, 3), which are arranged in succession in different, in particular parallel, planes so as to be permeable to supplied ambient air and which are interconnected by means of plug-in connections, wherein at least one first plug-in connection (7) is disposed so as to be displaceable along a first spatial axis during assembly and at least one second plug-in connection is disposed so as to be displaceable along a second spatial axis transversally to the first spatial axis during assembly, and the at least one of the first plug-in connections (7) is disposed so as to be limitedly displaceable in the direction of at least one spatial axis in its fixing position, which connects the cooling elements (2, 3), in the plane parallel to the cooling elements (2, 3) in each case. The at least one first plug-in connection (7) is arranged on a first edge, in particular on a first collecting device (9) of the cooling elements (2, 3), so as to form a floating bearing face, and the at least one second plug-in connection is arranged on a second edge lying opposite the first edge, in particular on a second collecting device (9), so as to form a fixed bearing face.

Owner:VOLKSWAGEN AG

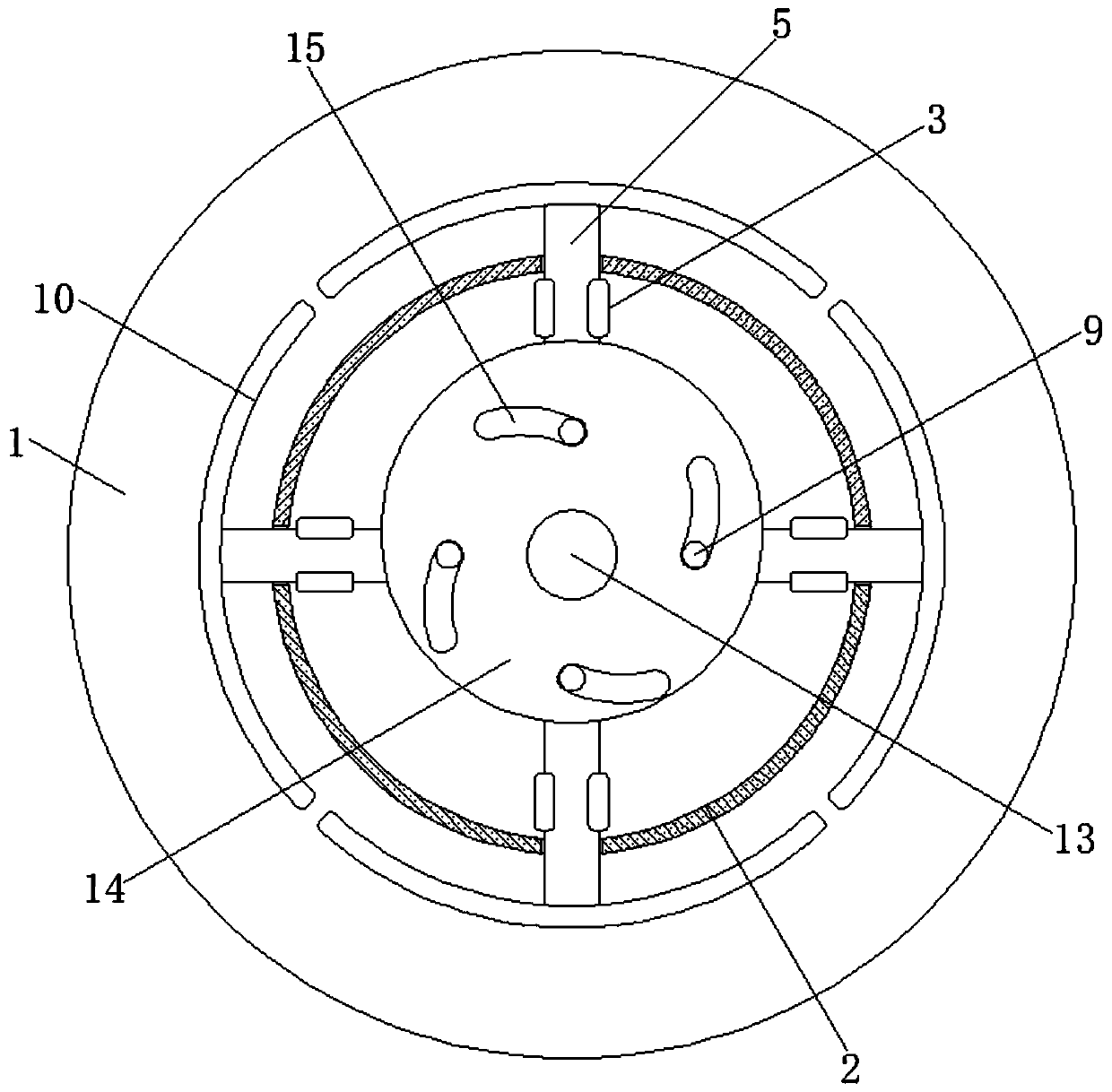

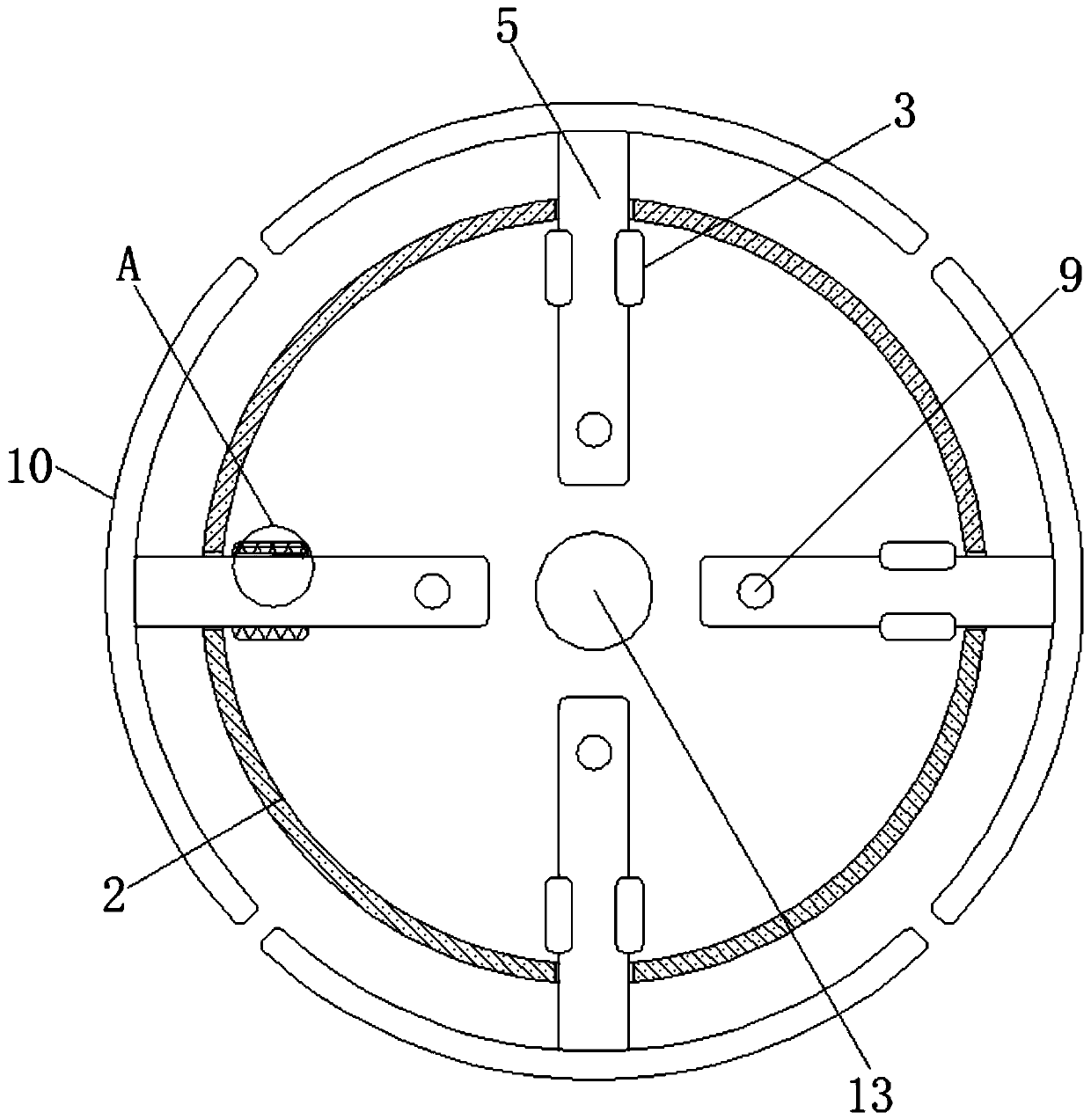

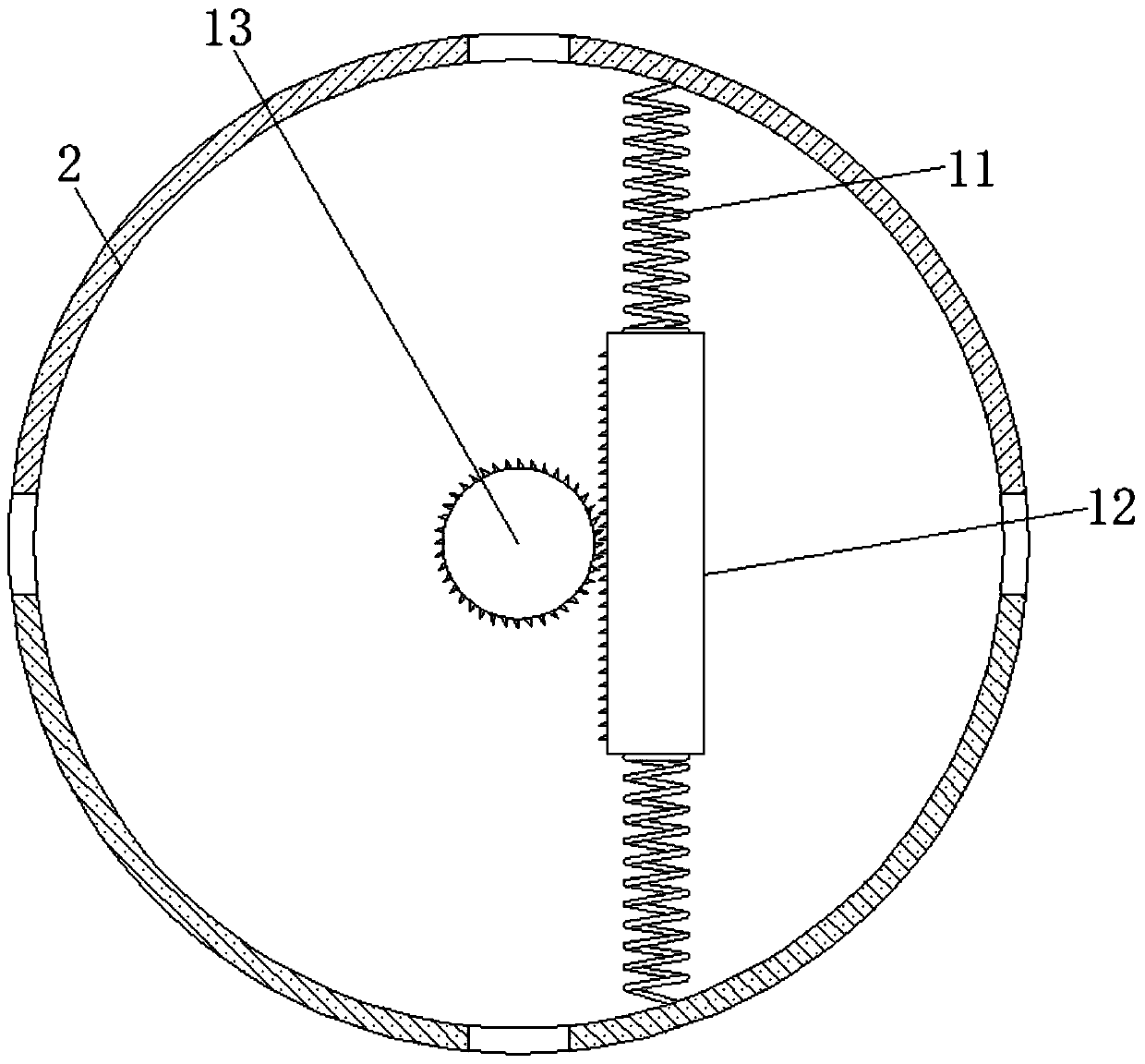

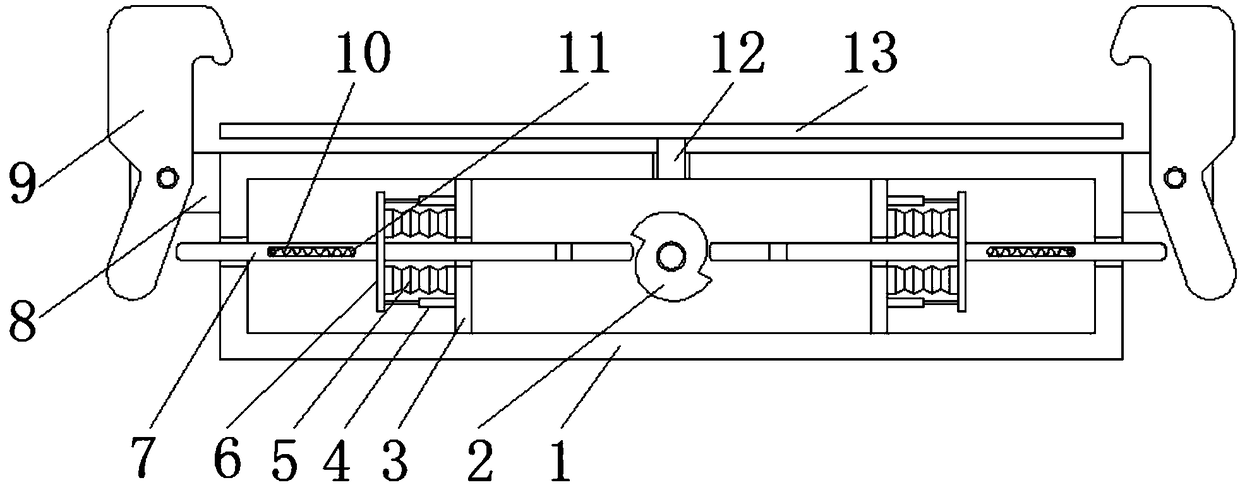

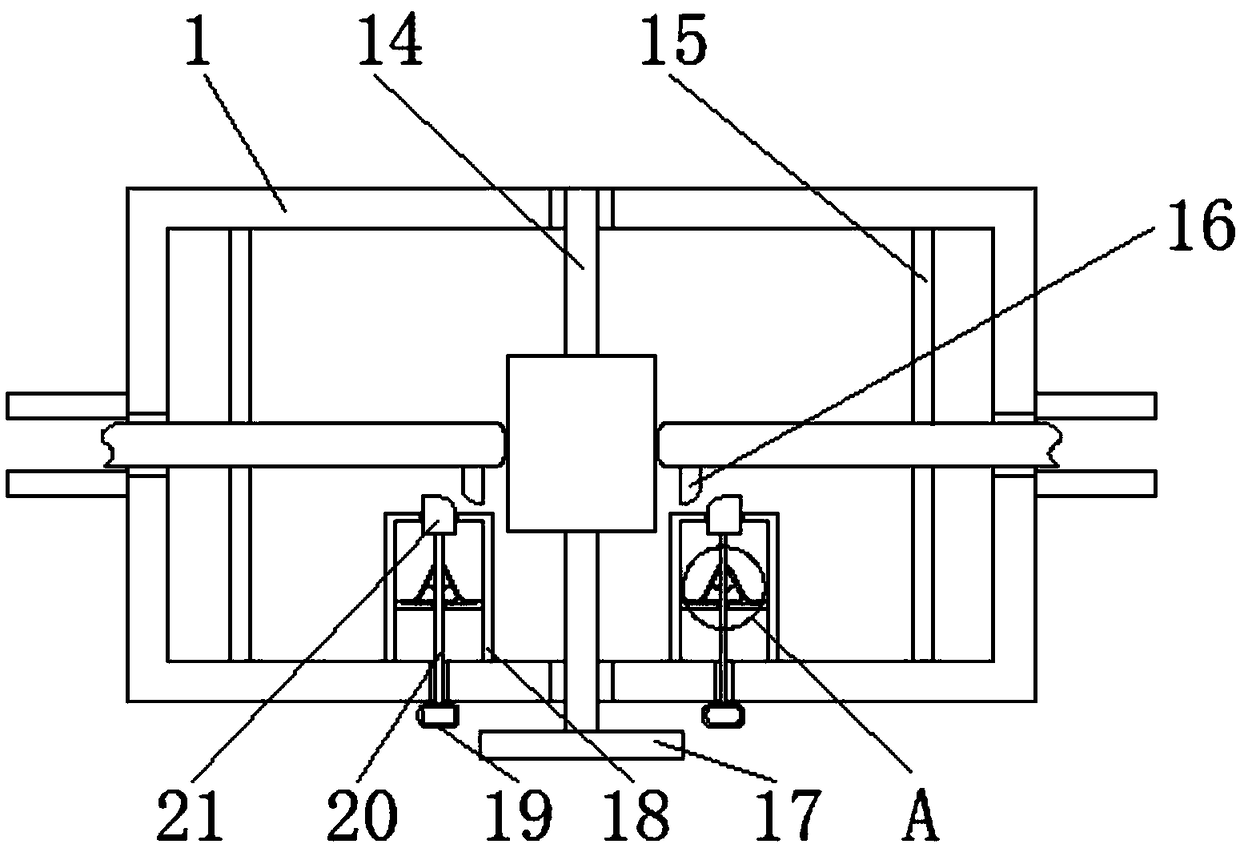

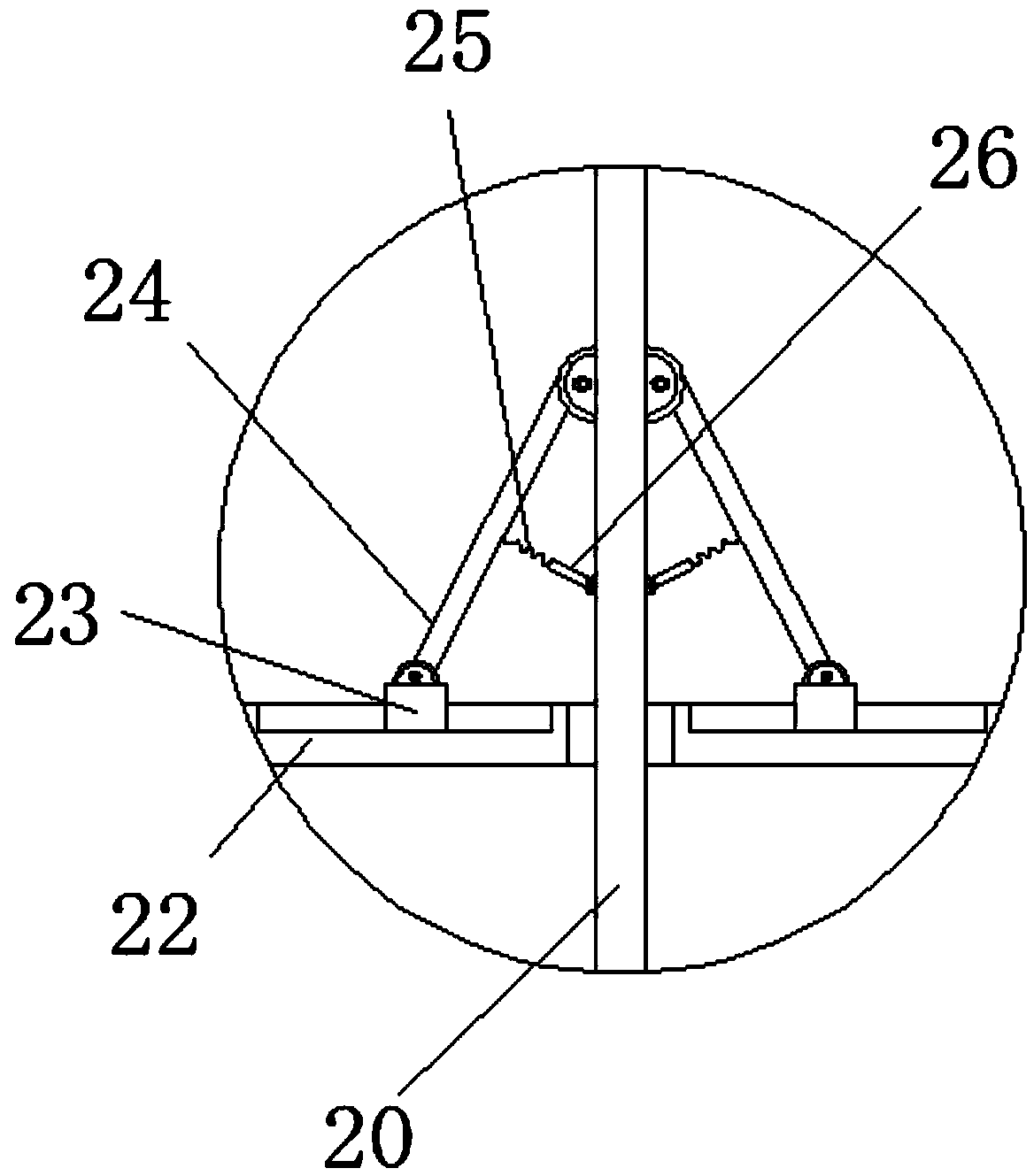

Anti-loosening device for steel wire winding barrel during transportation process

The invention relates to the technical field of transportation, and discloses an anti-loosening device for a steel wire winding barrel during a transportation process. The anti-loosening device comprises a side plate which can prevent a steel wire coil from slipping, an inner sleeve is welded at the inner side of the side plate, four openings are formed at the outer side of the inner sleeve, and four guide rails are welded at the inner side of the inner sleeve. According to the anti-loosening device for the steel wire winding barrel during the transportation process, the steel wire is wound ona winding plate, when a transport vehicle runs at a bumpy road section, a rack drives a rotating shaft to rotate, and the anti-loosening device is inoperative, and the rack is separated from the outer teeth of the rotating shaft, and when the wound steel wire loosens, the rack drives the rotating shaft to rotate clockwise, a sliding block is pushed away from the circle center of the rotating plate through the sliding groove, the sliding block drives the movable rod to extend outwards along the guide rail, so that the diameter of the winding plate is increased, the steel wire is tightened again, and accordingly the situation that during the transportation process, the steel wire coil is loosened due to the bumpy road conditions, and the subsequent carrying, storage and use are inconvenient, can be prevented.

Owner:杭州富阳锐明科技有限公司

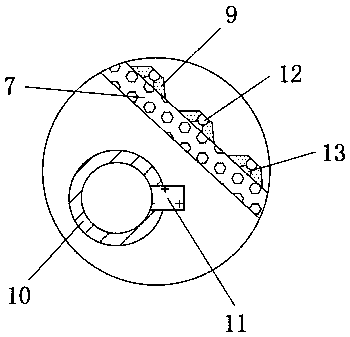

Sponge fixing base for processing

The invention discloses a sponge fixing base for processing. The sponge fixing base comprises a fixing base. A rotating shaft is arranged on the inner wall of the fixing base along the width center line. A bidirectional cam is welded to the outer surface wall of the rotating shaft and on the vertical central line of the fixing base. Fixing rods are equidistantly welded to the inner wall of the fixing base along the vertical direction and on two sides of the rotating shaft. The sponge fixing base has the advantages that round rings can be rotated, the bidirectional cam squeezes two push rods, two fixing clamps are driven by the push rods to rotate, and sponge is fastened; after the sponge is fastened, clamping blocks can quickly clamp limiting blocks, reverse movement of the push rods is prevented, and the sponge is stably fastened; when the sponge needs to be rotated, handles can be pulled, the push rods quickly return to original positions, and the bidirectional cam returns to the original position under the action of the push rods; at the moment, the fixing clamps can reset through their own gravity, and accordingly, the sponge is fastened and rotated rapidly, simply and conveniently.

Owner:ANQING RUIXIA MECHINERY CO LTD

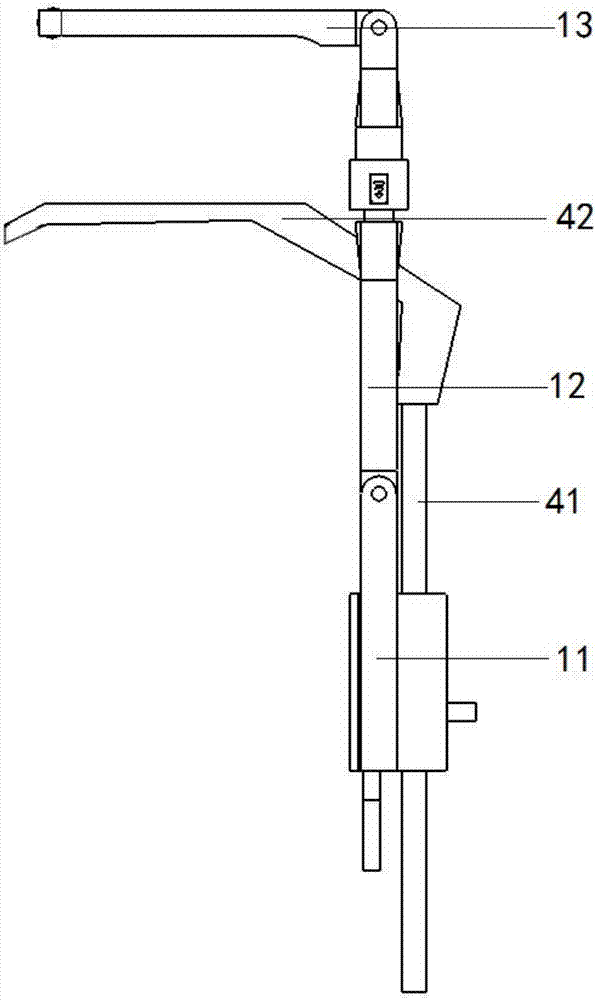

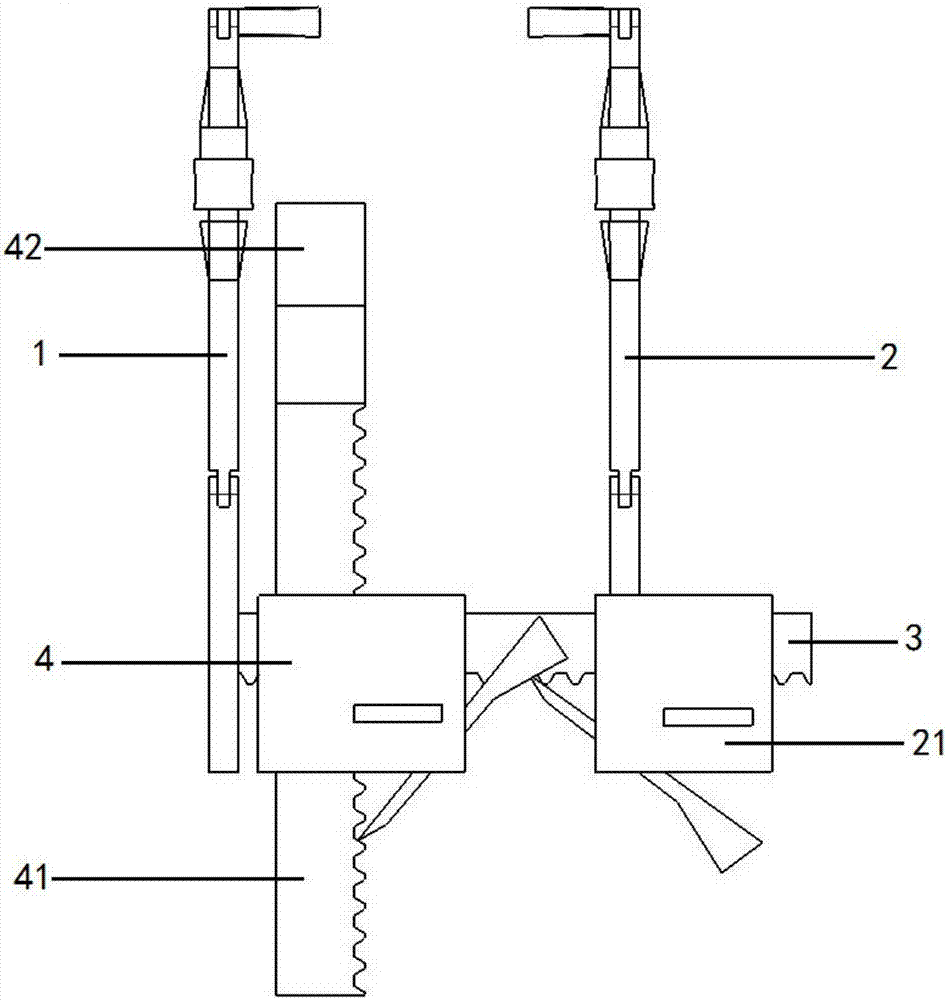

Multifunctional universal intervertebral distraction apparatus used for posterior lumbar interbody fusion technology

PendingCN107007311AImprove convenienceDoes not affect implant operationSurgerySpinal cagePhysical medicine and rehabilitation

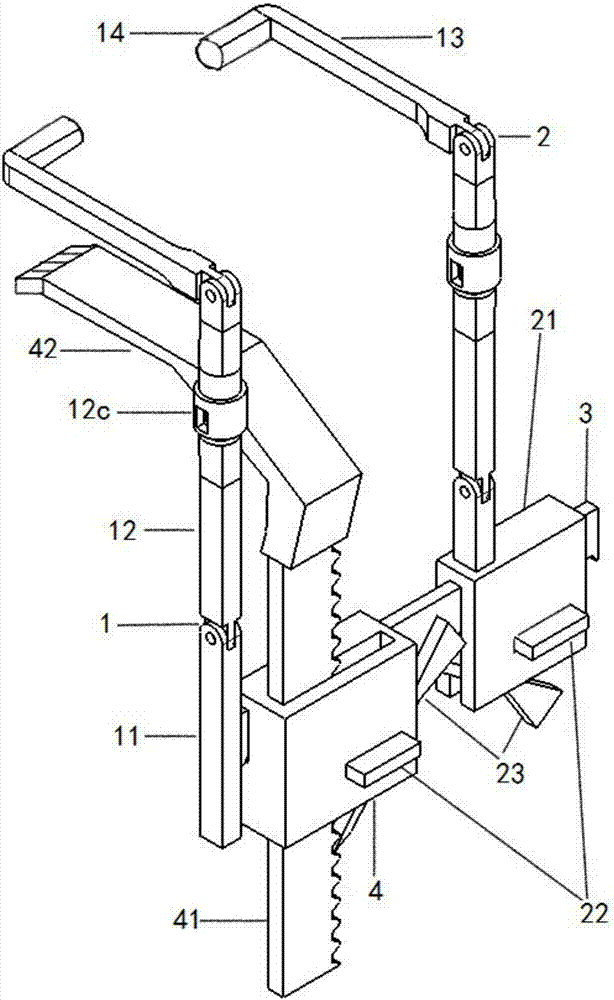

The invention discloses a multifunctional universal intervertebral distraction apparatus used for the posterior lumbar interbody fusion technology. The distraction apparatus comprises a first distraction arm, a second distraction arm and a distraction rack, and the second distraction arm is installed on the distraction rack through a slider and slides along the distraction rack along with the slider; the first distraction arm and the second distraction arm are both of a multi-section type structure, and each distraction arm comprises a rear distraction arm section, a middle distraction arm section, a front distraction arm section and a clamping section which are connected in sequence; each middle distraction arm section is divided into two segments, the close segment and the far segment of each middle distraction arm section are rotationally connected, and the rotational angle is locked through a locking mechanism. The clamping sections of the two distraction arms are placed in U-shaped grooves in the tail portions of adjacent pedicle screws, one of the distraction arms slides along the distraction rack, the intervertebral space is effectively distracted, and the implantation safety of an interbody fusion cage is improved. A pull hook is arranged between the two distraction arms, the erector spinae can be pulled to the outer side through the pull hook, the operation field is sufficiently exposed, and the operation convenience and safety are improved.

Owner:JIANGSU PROVINCE HOSPITAL

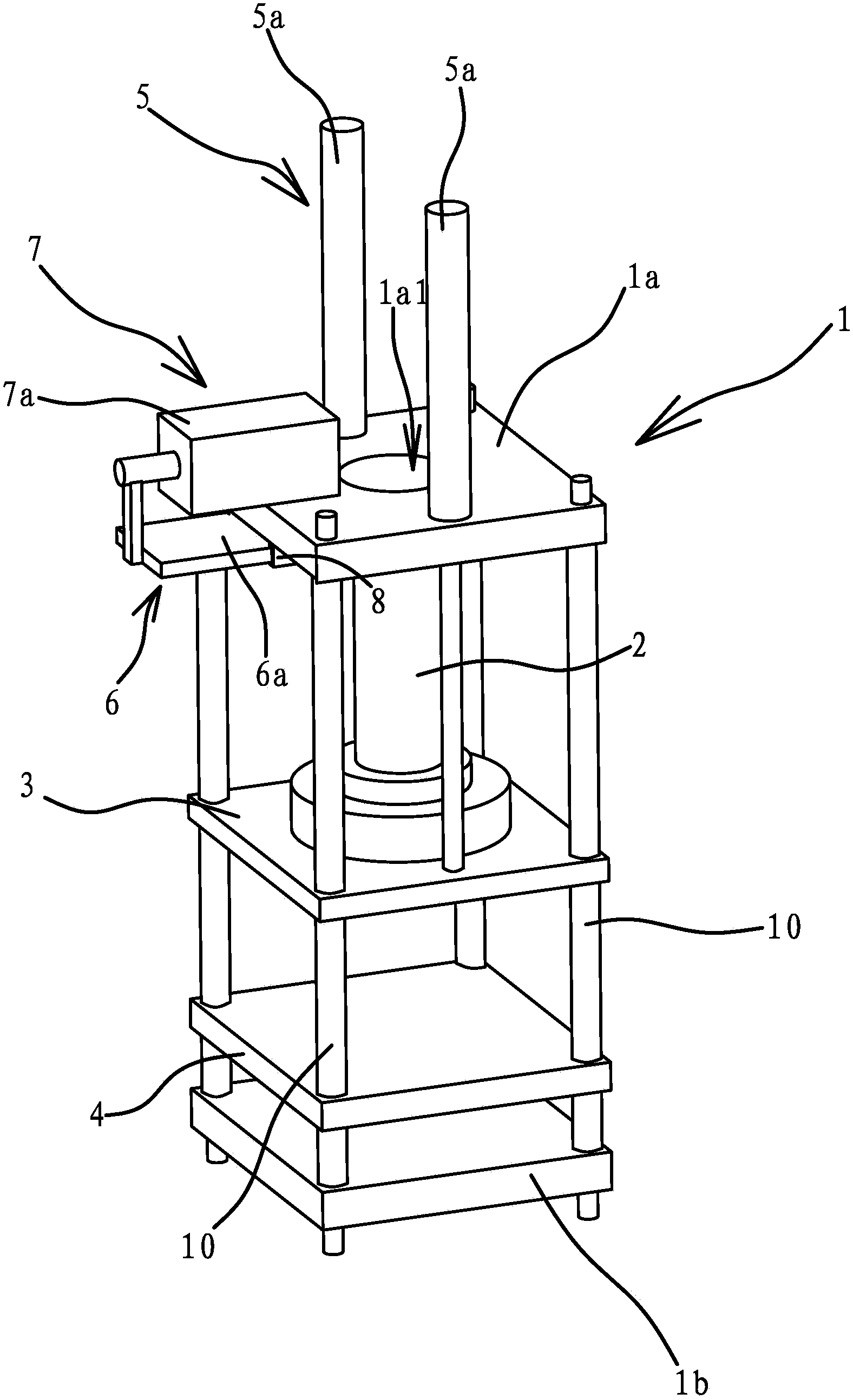

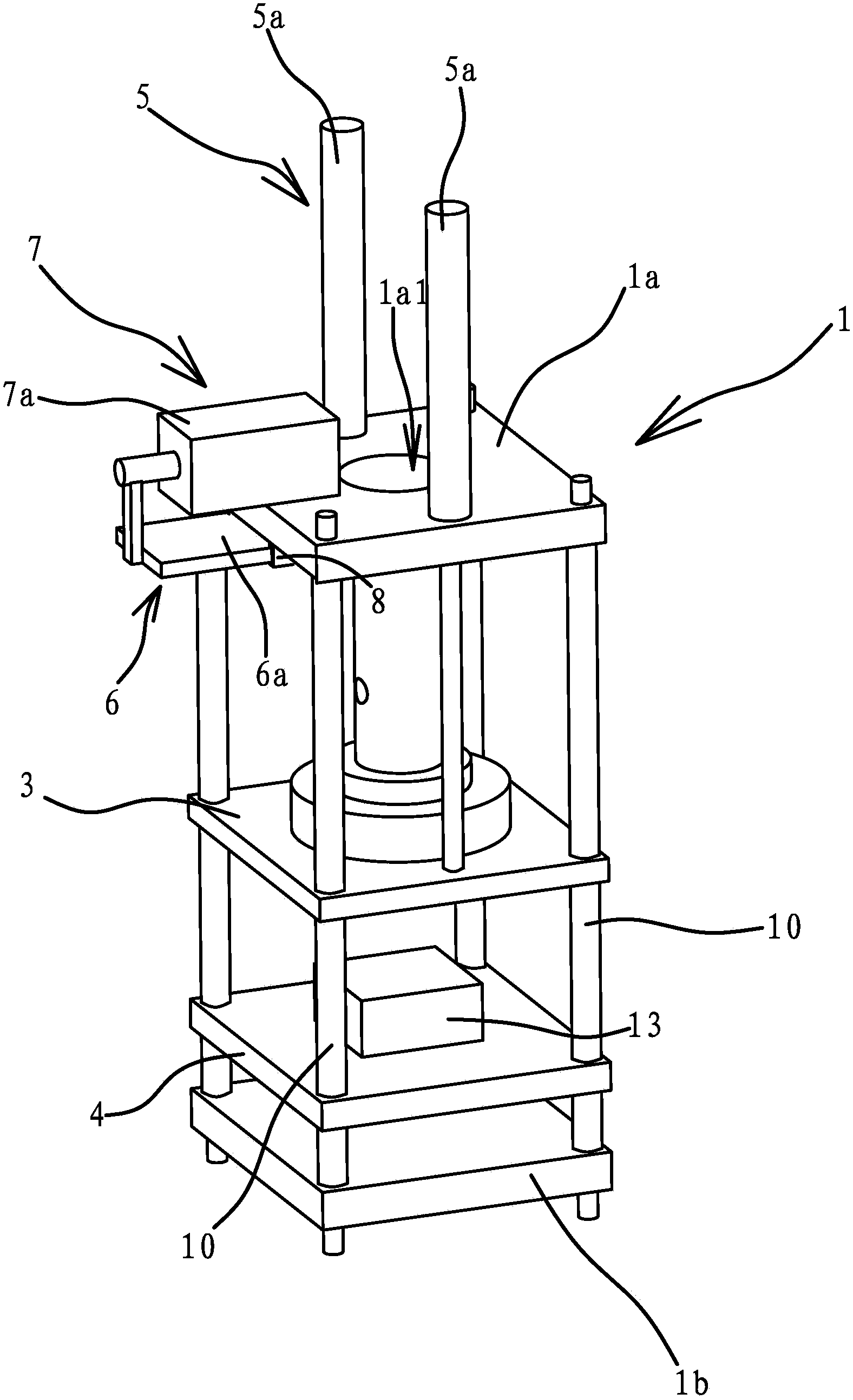

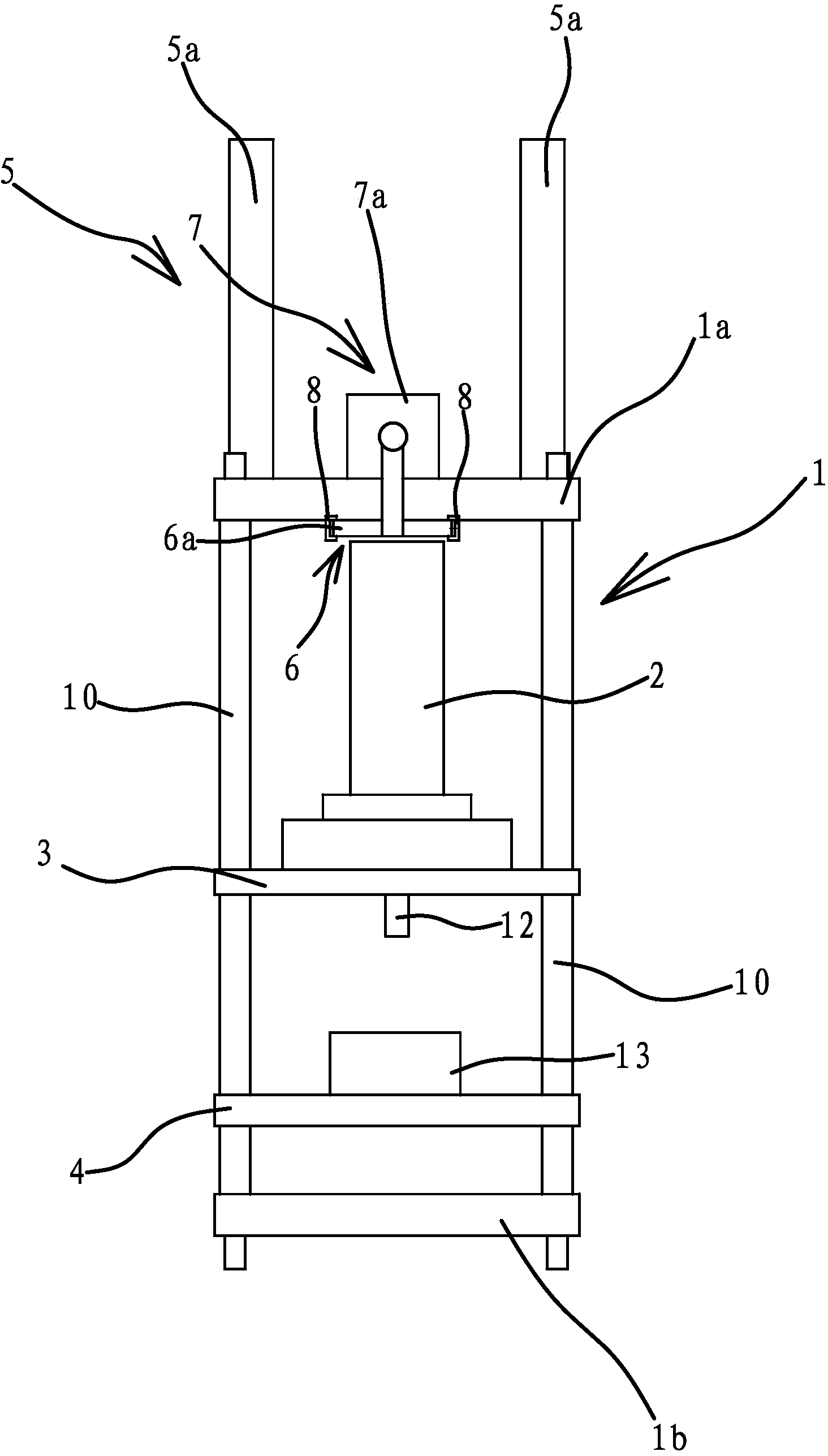

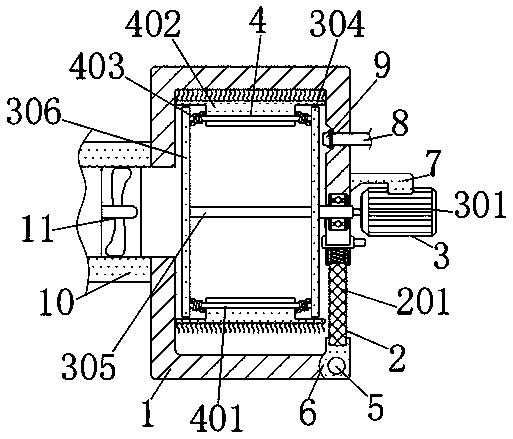

Die pressing mechanism of powder forming machine

InactiveCN103963339AImprove processing efficiencyImprove yieldShaping pressMolding machineEngineering

The invention provides a die pressing mechanism of a powder forming machine, and belongs to the technical field of mechanical equipment. The die pressing mechanism of the powder forming machine solves the problem that a die pressing mechanism of an existing powder forming machine is not ideal in pressing effect. The die pressing mechanism of the powder forming machine comprises a rack and a booster oil cylinder, the rack comprises an upper fixing plate and a lower fixing plate which is parallel and opposite to the upper fixing plate, an upper die plate and a lower die plate are arranged between the upper fixing plate and the lower fixing plate, a cylinder body of the booster oil cylinder is vertically and fixedly connected to the upper die plate, a piston rod of the booster oil cylinder faces down and penetrates through the upper die plate, the lower end of the piston rod of the booster oil cylinder can be fixedly connected with a die head, the cylinder body of the booster oil cylinder can penetrate through the upper fixing plate, the upper fixing plate is further provided with a lifting mechanism, the upper fixing plate is provided with a blocking piece and a driving mechanism, and the driving mechanism can drive the blocking piece to move horizontally so as to enable the upper end of the cylinder body of the booster oil cylinder to abut against the blocking piece. The die pressing mechanism of the powder forming machine has the advantage of being ideal in pressing effect.

Owner:苏光宝

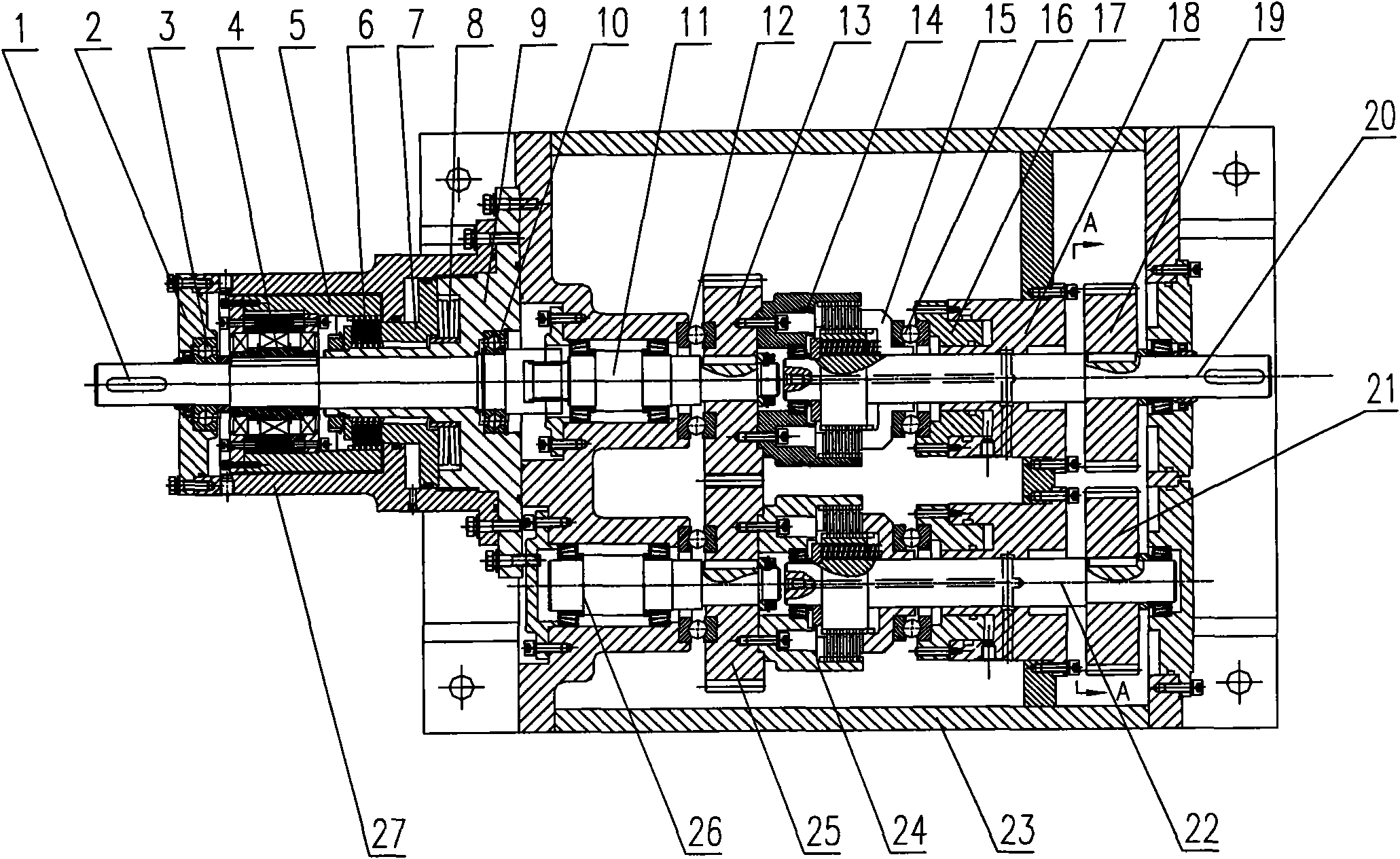

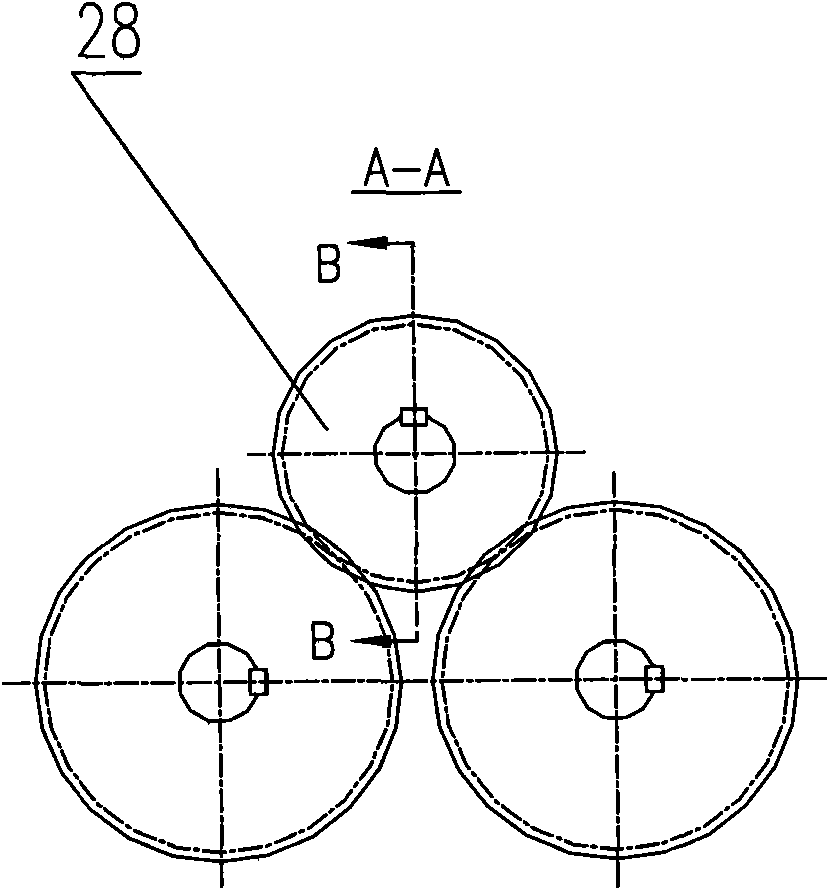

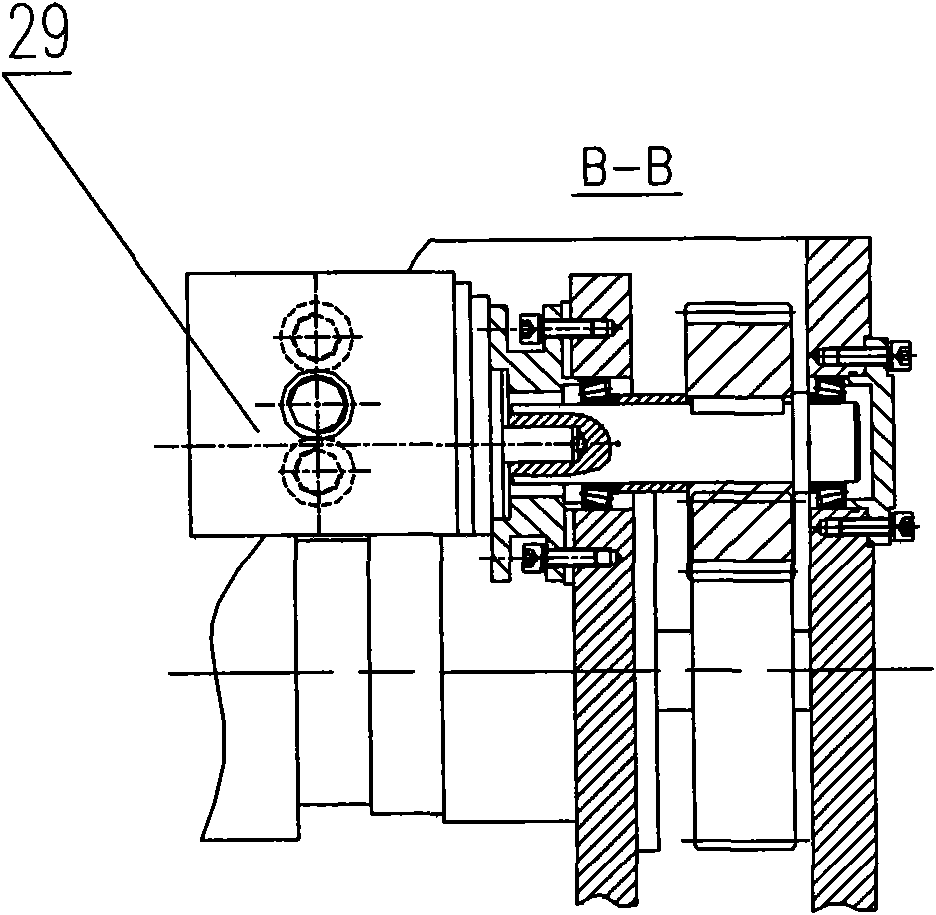

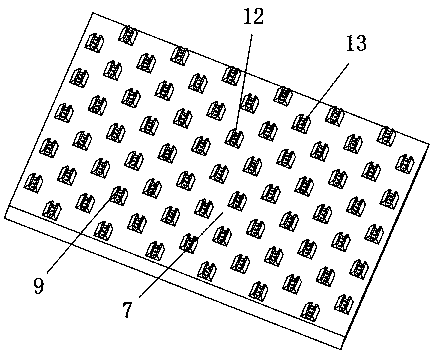

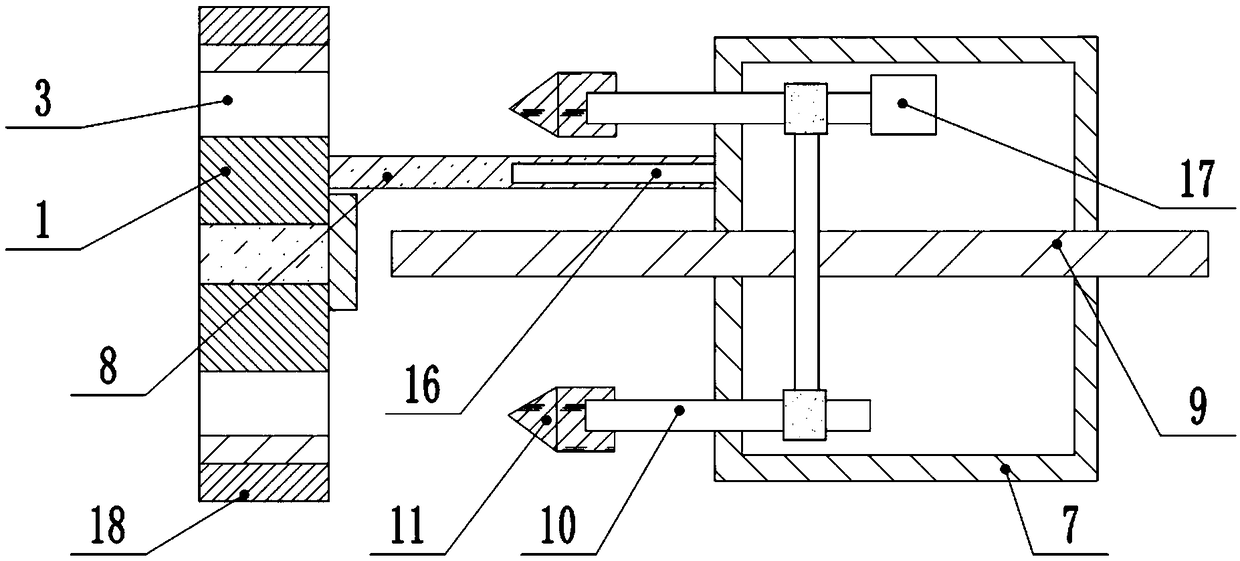

Tensioning winch transmission device of belt conveyer

InactiveCN101941580ARealize frequent switchingAvoid frequent switchingConveyorsToothed gearingsEngineeringWinch

The invention relates to a tensioning winch transmission device of a belt conveyer, which mainly comprises a box body, a main transmission mechanism, an auxiliary transmission mechanism and an output transmission mechanism which is arranged at the front end of the box body and connected with the main transmission mechanism, wherein the main transmission mechanism and the auxiliary transmission mechanism are arranged in the box body in parallel. In the invention, a gear pair comprising a main clutch, an auxiliary clutch and five gears is adopted to achieve the purpose that an input shaft of a winch rotates along one direction all the time while reeling off and rolling up so as follow the tensile force change of a conveyer belt and meet the requirement on the change of the conveyer belt within a larger range; dynamic braking can be directly carried out through a motor to limit the maximum reeling off speed so as to prevent safe accidents; and soft start during rolling up can be realized, thus impact force born by a steel wire rope and relevant components is reduced, and the service life of the components is prolonged. The device can be used for precisely controlling the tensioning force and is suitable for controlling the tensioning winch of the belt conveyer, particularly for a narrow space under a coal mine. The device has the advantages of simple structure, convenient maintenance, low manufacturing cost, strong generality and high reliability.

Owner:CHINA UNIV OF MINING & TECH +1

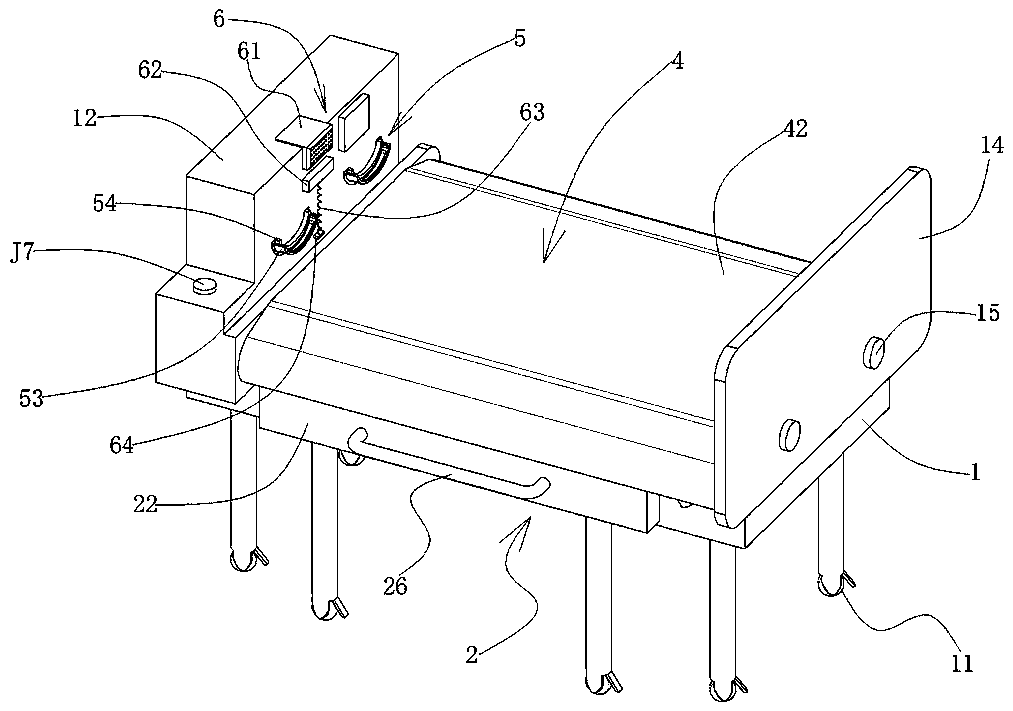

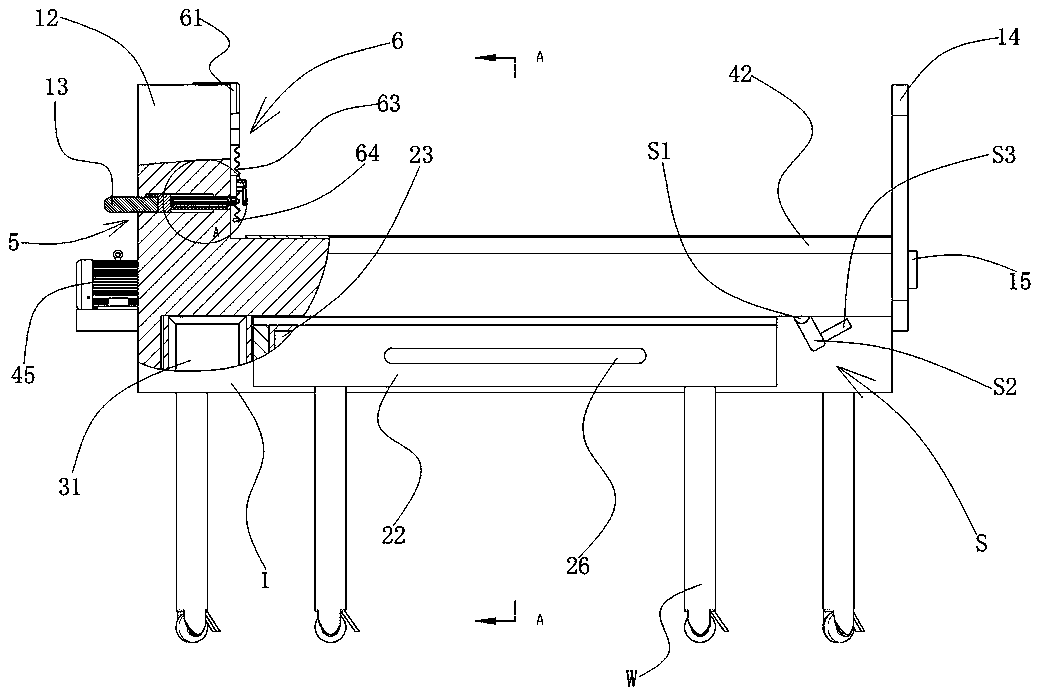

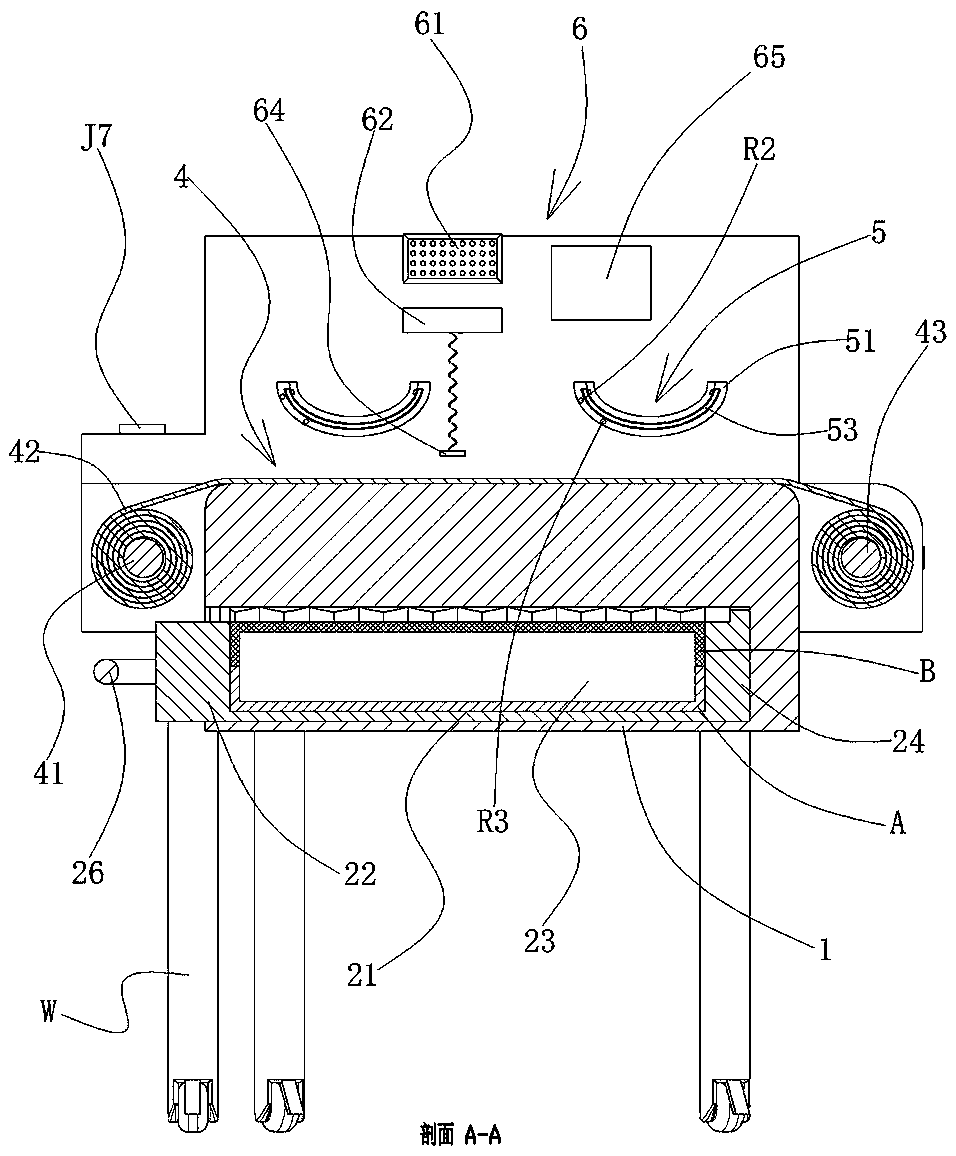

5G-monitored medical sickbed

ActiveCN110840673AConvenient restEasy to replaceDiagnosticsNursing bedsPhysical therapyBiomedical engineering

The invention provides a 5G-monitored medical sickbed, which comprises a main bed plate provided with universal wheels, wherein an inner main bed plate device is mounted below the main bed plate, andinflatable devices are symmetrically arranged at two ends of the inner main bed plate device; and a bed sheet changing device is arranged above the main bed plate, a first mounting plate is fixedly mounted at the tail end of the bed sheet changing device, symmetrically-distributed foot supporting plate devices are mounted on the first mounting plate, an adjusting screw is arranged on one side of each foot supporting plate device, a 5G monitoring device is arranged above the adjusting screws, a second mounting plate is arranged on the bed sheet changing device, and the second mounting plate isconnected with the main bed plate through fixing screws. According to the 5G-monitored medical sickbed, the bed sheet changing device can be used for quickly and simply replacing the bed sheet of thesickbed, and the adjusting screws can adjust the position of the foot supporting plate devices, so that the 5G-monitored medical sickbed is suitable for patients with foot injuries of different heights.

Owner:悦来湖(山东)数字经济产业园运营管理有限公司

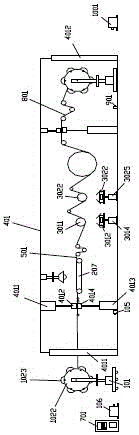

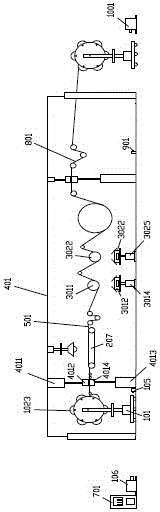

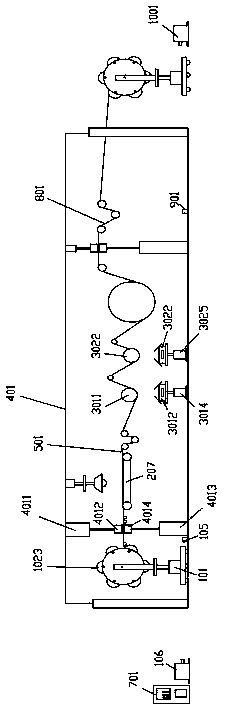

Vacuum coating equipment for processing metallic films

InactiveCN106435513AHigh degree of automationConvenience for feeding/receivingVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention discloses vacuum coating equipment for processing metallic films. The vacuum coating equipment comprises a vacuum chamber, a feeding mechanism, a coating mechanism and a winding mechanism, wherein the feeding mechanism, the coating mechanism and the winding mechanism are arranged inside the vacuum chamber; the feeding mechanism comprises a first lifting mechanism and a feeding device; a preheating mechanism is arranged between the feeding mechanism and the coating mechanism; a first movable plate assembly adjusting an opening of a first evaporation boat is arranged in the opening area of the top of the first evaporation boat; a second movable plate assembly adjusting an opening of a second first evaporation boat is arranged in the opening area of the top of the second evaporation boat; film limiting devices are arranged between the feeding mechanism and the coating mechanism as well as between the coating mechanism and the winding mechanism; the winding mechanism comprises a fifth lifting mechanism and a winding device; and an extension end of the fifth lifting mechanism is matched with the winding device to drive the winding device to move up and down. The vacuum coating equipment has the advantages that the automation degree is high, supplementing and collecting are convenient and timely, preheating is uniform, the preheating degree can be adjusted, the processing requirements of the films of various models can be met and the coating thickness can be adjusted.

Owner:铜陵市铜创电子科技有限公司

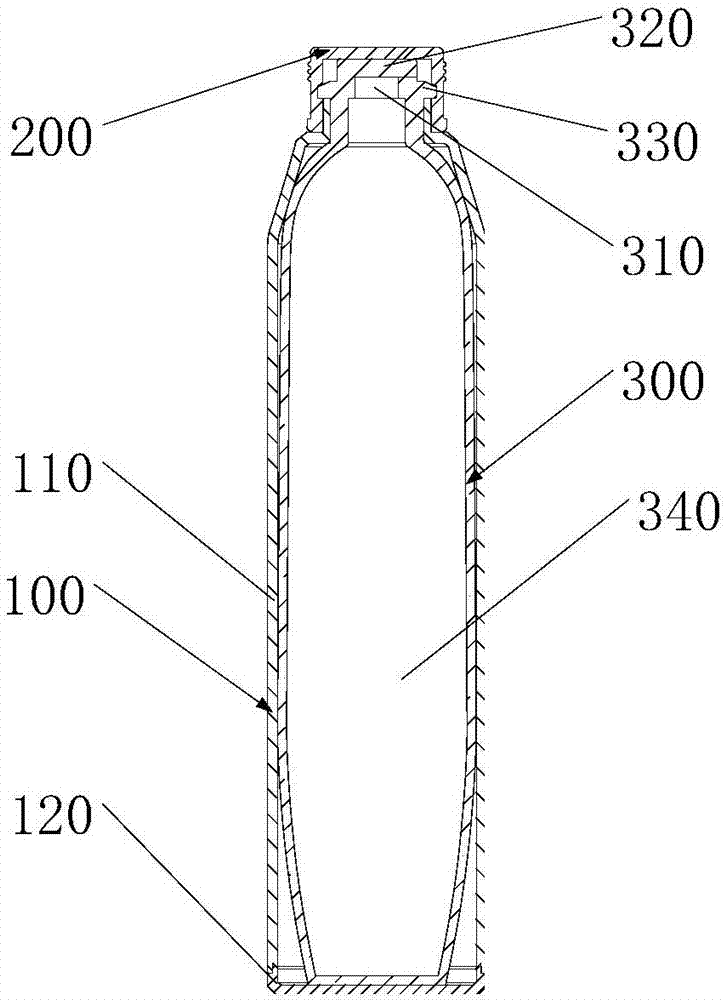

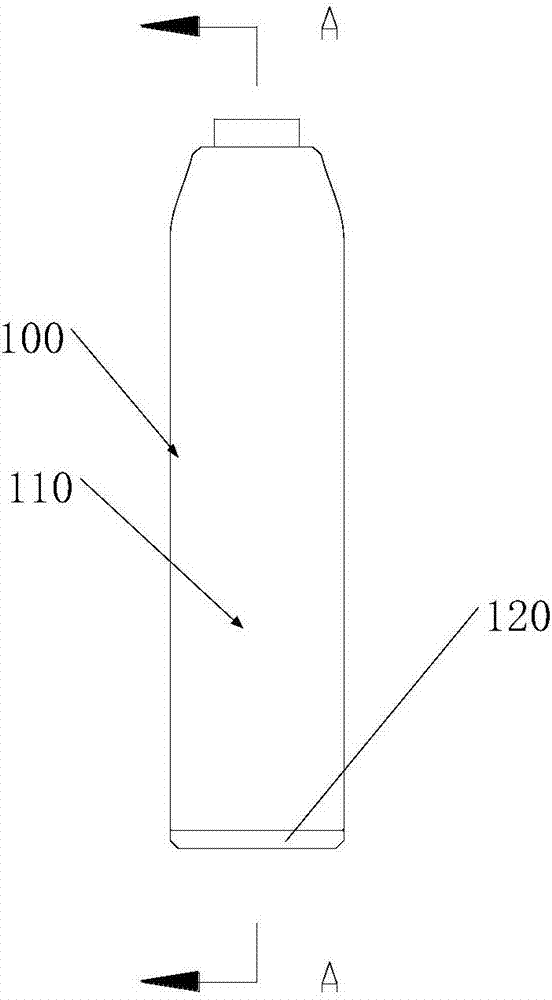

Toothpaste storage body, toothpaste body and toothbrush of integral structure

InactiveCN107007004AIncrease supplySimple structureBrush bodiesFlexible containersToothpasteEngineering

The invention relates to a toothpaste storage body, a toothpaste body and a toothbrush of an integral structure. The toothpaste storage body disclosed by the invention is suitable to be mounted in a storage chamber of the toothbrush of the integral structure, and the stored toothpaste is supplied to a brush head of the toothbrush of the integral structure. The toothpaste storage body disclosed by the invention comprises a soft capsule and a shell, wherein the soft capsule is used for storing the toothpaste and comprises a soft capsule opening used for adding and squeezing the toothpaste; the soft capsule opening can be connected to an inlet of a toothpaste supply channel of the toothbrush of the integral structure; the soft capsule is mounted inside the shell; and the shell can be detachably mounted in the storage chamber of the toothbrush of the integral structure. The toothpaste storage body and the toothpaste body are simple in structure and convenient to mount and replace, and the toothpaste can be conveniently supplied to the toothpaste supply channel of the toothbrush of the integral structure.

Owner:朱春生

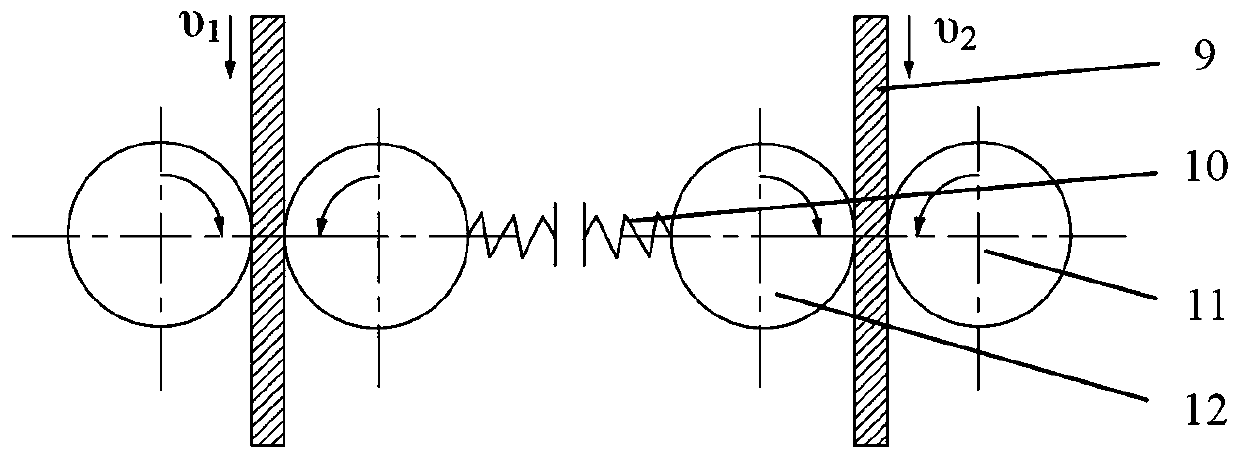

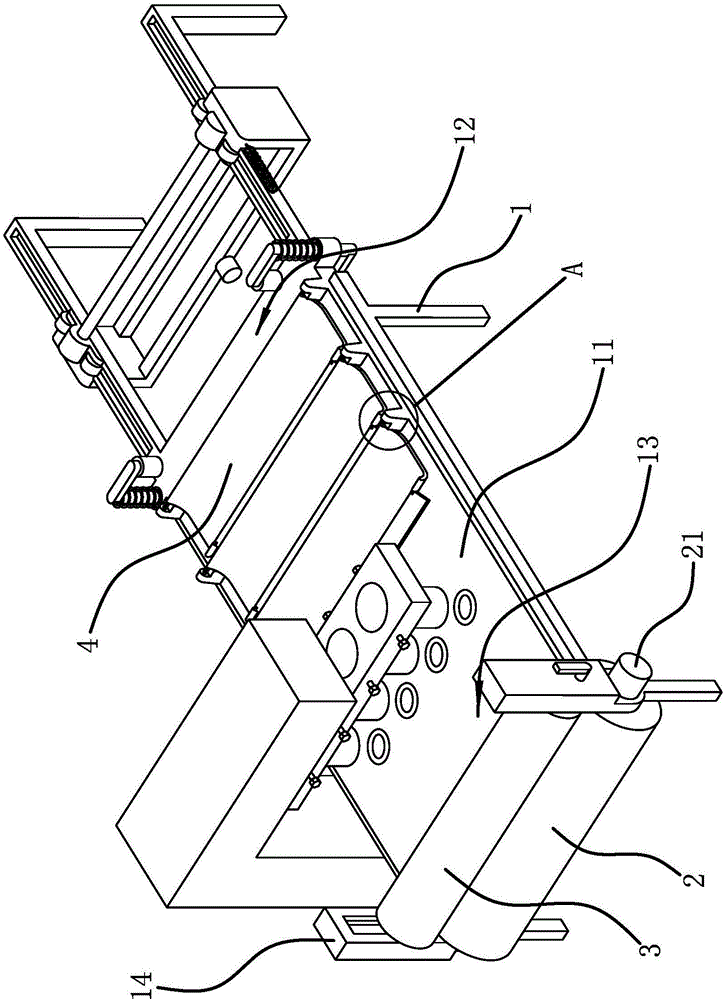

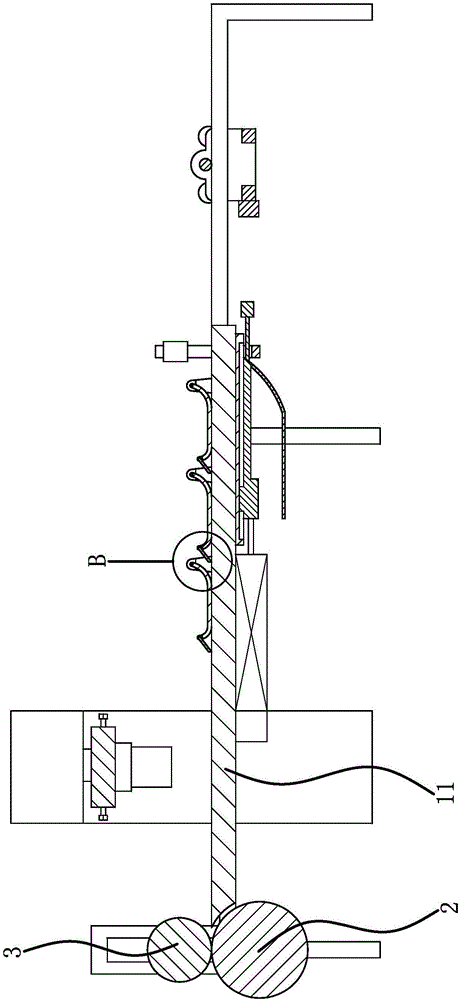

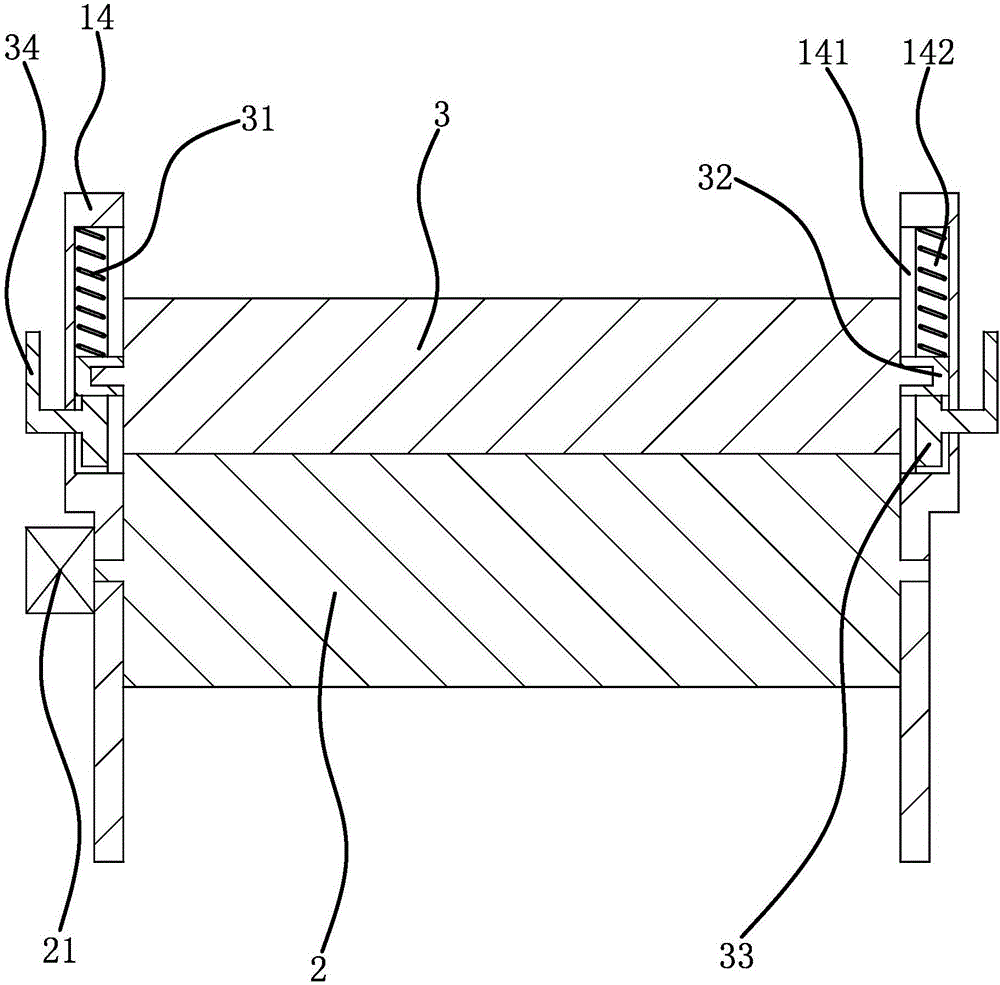

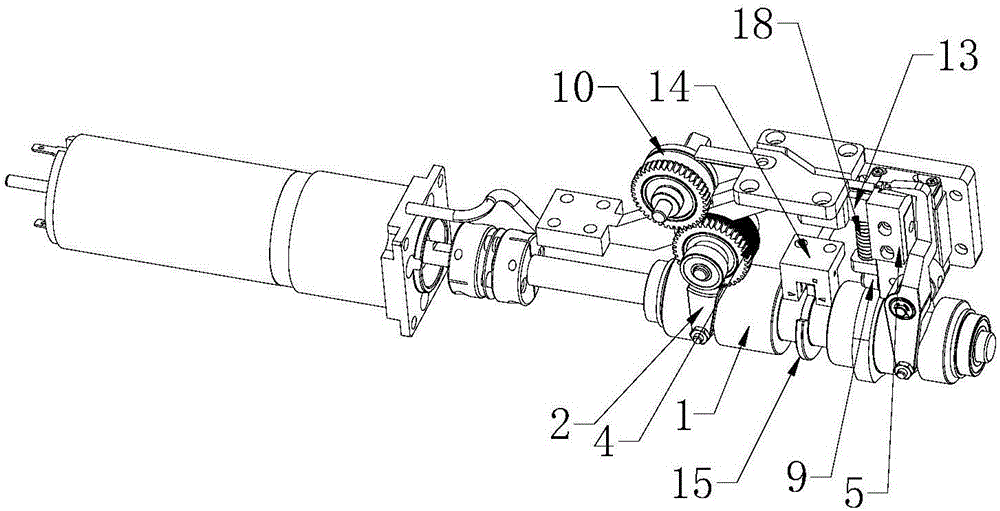

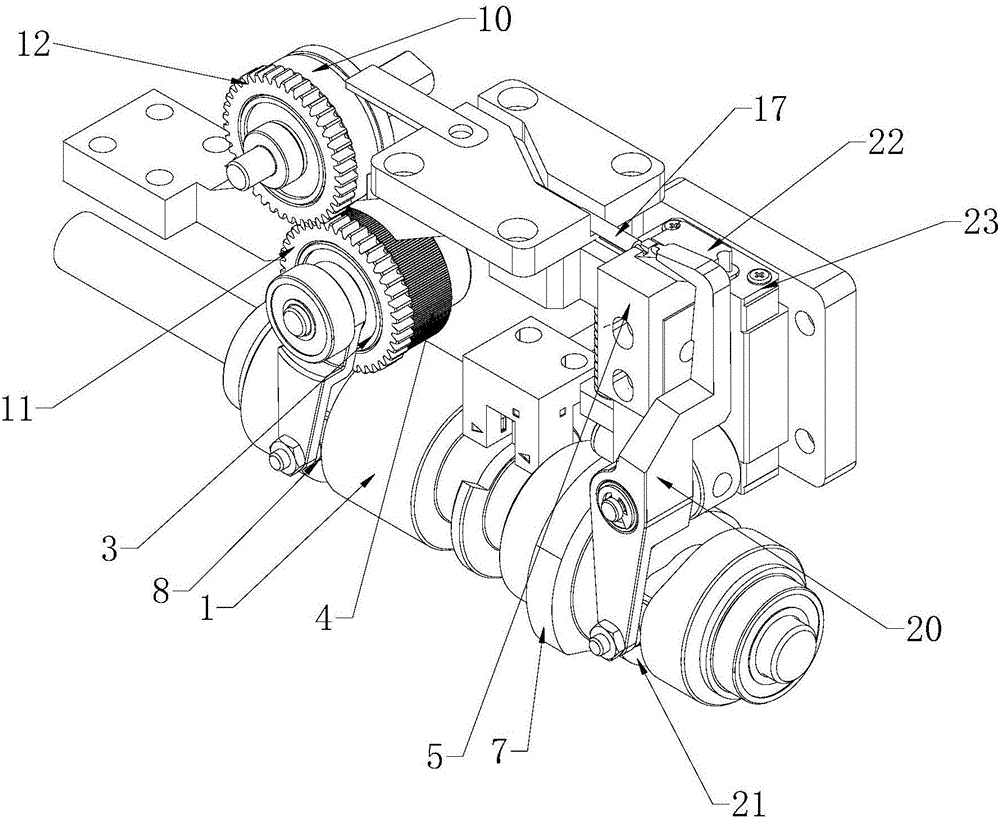

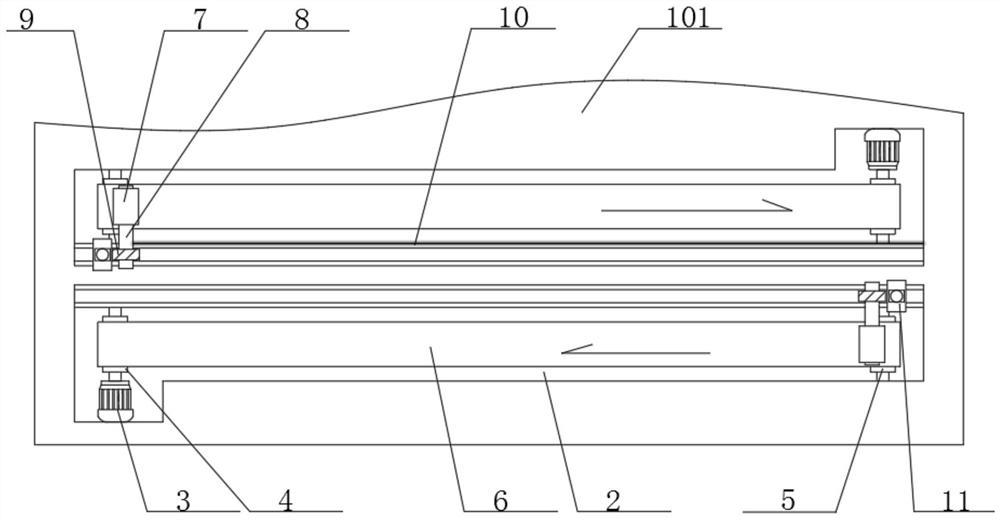

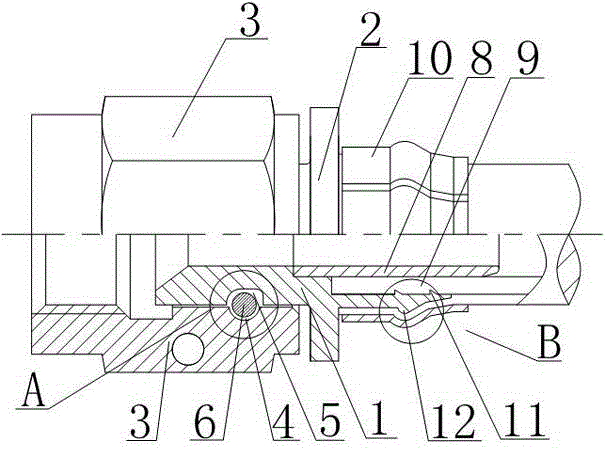

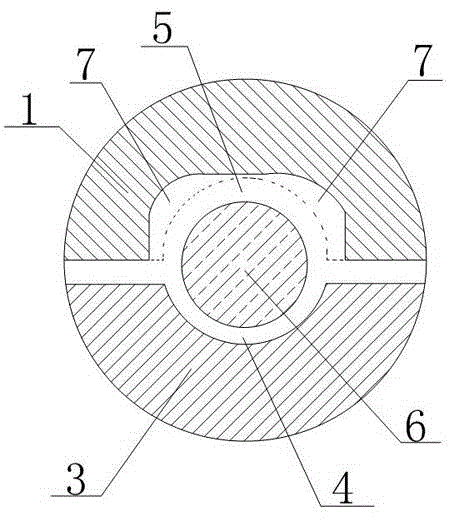

Feeding mechanism of punching machine

InactiveCN106738052AAccurate movement setting distancePrevent reverse movementMetal working apparatusPunchingEngineering

The invention provides a feeding mechanism of a punching machine and belongs to the technical field of mechanical equipment. The feeding mechanism of the punching machine solves the problem that the punching quality of an existing punching machine is low. According to the feeding mechanism of the punching machine, the punching machine comprises a rack, a punching platform is fixedly connected with the rack, the feeding mechanism comprises a rotary drum, and the outer peripheral wall of the upper portion of the rotary drum is flush with the upper side face of the punching platform; the portion, above the rotary drum, of the rack is rotatably connected with a pressing drum, and pressing springs capable of pressing the pressing drum onto the rotary drum are arranged on the rack; and the feeding end of the punching platform is further hinged to a plurality of pressing plates, and the free ends of the pressing plates face the discharging ends, and a top plate capable of preventing a felt from reverse shifting is connected with the free ends of the pressing plates. According to the feeding mechanism of the punching machine, accurate feeding can be conducted, and consequently the punching quality is improved.

Owner:海宁英和金属制品有限公司

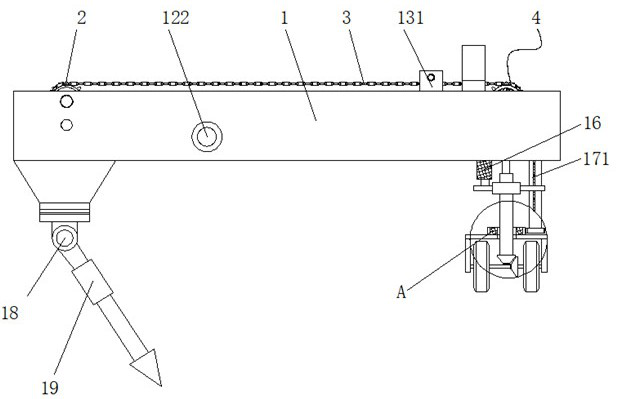

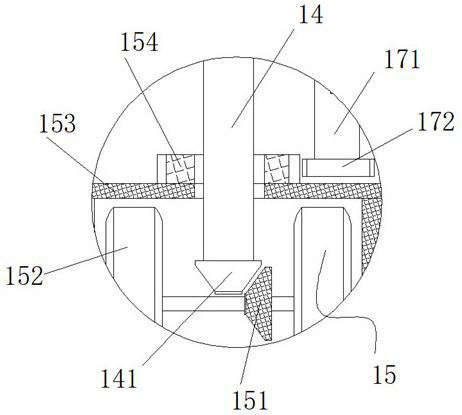

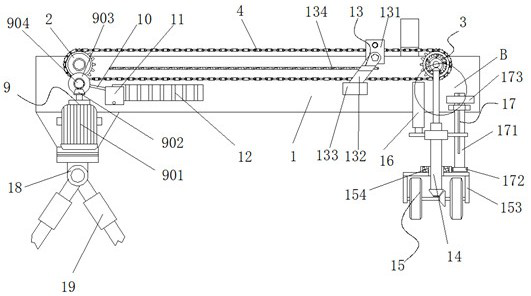

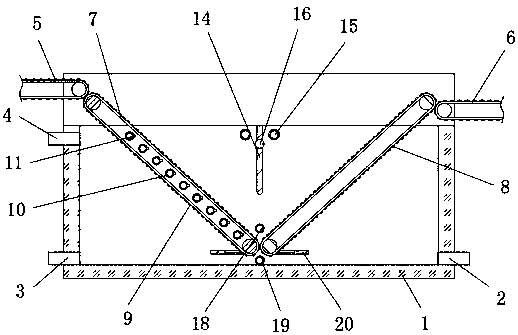

Ejection rack for unmanned aerial vehicle launching

InactiveCN111762333ASolve the problem of inconvenient movement and too complicated and laborious adjustmentPrevent reverse movementLaunching/towing gearRatchetGear wheel

The invention belongs to the technical field of unmanned aerial vehicles and relates to an ejection rack for unmanned aerial vehicle launching. An existing fixing frame cannot be stopped in time, theejection rack is easy to damage and inconvenient to move, and adjustment is too complex and strenuous. In order to solve the above problems, the following scheme is provided. A support frame is included. The supporting frame is composed of two fixing plates which are arranged in parallel. The two ends of each fixing plate are fixed through iron rods. Chain wheels are symmetrically arranged on an inner wall of one end of the supporting frame, ratchet wheel assemblies are arranged on the two sides of the inner wall of the end, away from the chain wheels, in the supporting frame, the edges of thechain wheels are in transmission connection with the ratchet wheel assemblies through chains, driven gears are fixedly connected to the sides, close to the fixing plates, of the chain wheels, and transmission gears are rotatably engaged with the bottoms of the driven gears. The ejection rack has advantages that an unmanned aerial vehicle fixing device can be stopped slowly, collision is prevented, steering movement is performed automatically, and labor is saved.

Owner:山东万佳达电子科技有限公司

Dust removal device convenient to clean for production and processing of intermediate frequency furnace

InactiveCN110579115ASolve the problem that the shell cannot be cleanedAvoid accumulationHollow article cleaningWaste heat treatmentIntermediate frequencyEngineering

The invention discloses a dust removal device convenient to clean for production and processing of an intermediate frequency furnace. The dust removal device comprises a shell, a short board is connected to the left end of the bottom of the shell in a rotating mode through a pin shaft, a filtering mechanism is arranged at the top of the short board, a support is fixedly connected to the right sideof the shell, and a rotating mechanism is arranged at the bottom of the support. According to the dust removal device convenient to clean for production and processing of the intermediate frequency furnace, through cooperation of the rotating mechanism and cleaning mechanisms, the problem that the interior of a shell of an existing dust removal device for production and processing of an intermediate frequency furnace cannot be cleaned during use can be solved, dust accumulated on the inner wall is avoided, normal work of equipment is guaranteed, the damage to the equipment due to a long timeis prevented, and the maintenance cost is lowered; and in addition, through the cooperation of the filtering mechanism, the pin shaft and the short board, the problem that a filter screen is inconvenient to replace can be solved, the occurrence of blockage is prevented, the occurrence of backflow of air is avoided, reverse movement of the dust is avoided, the working difficulty is lowered, the practicability is improved, and popularization is facilitated.

Owner:福建工友机械有限公司

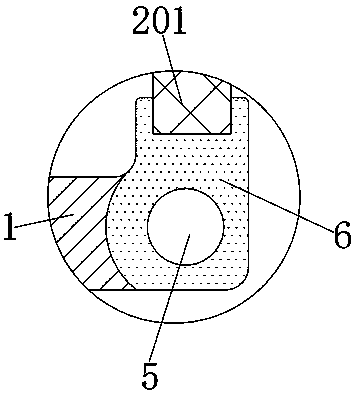

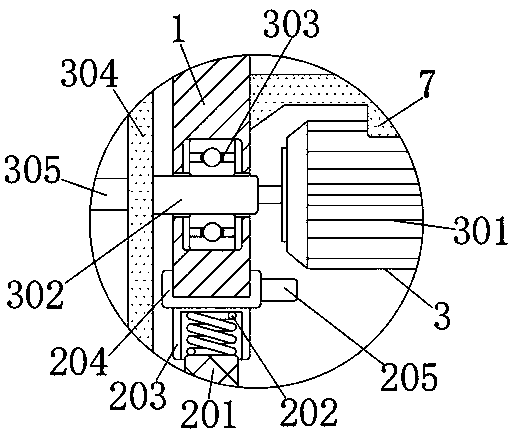

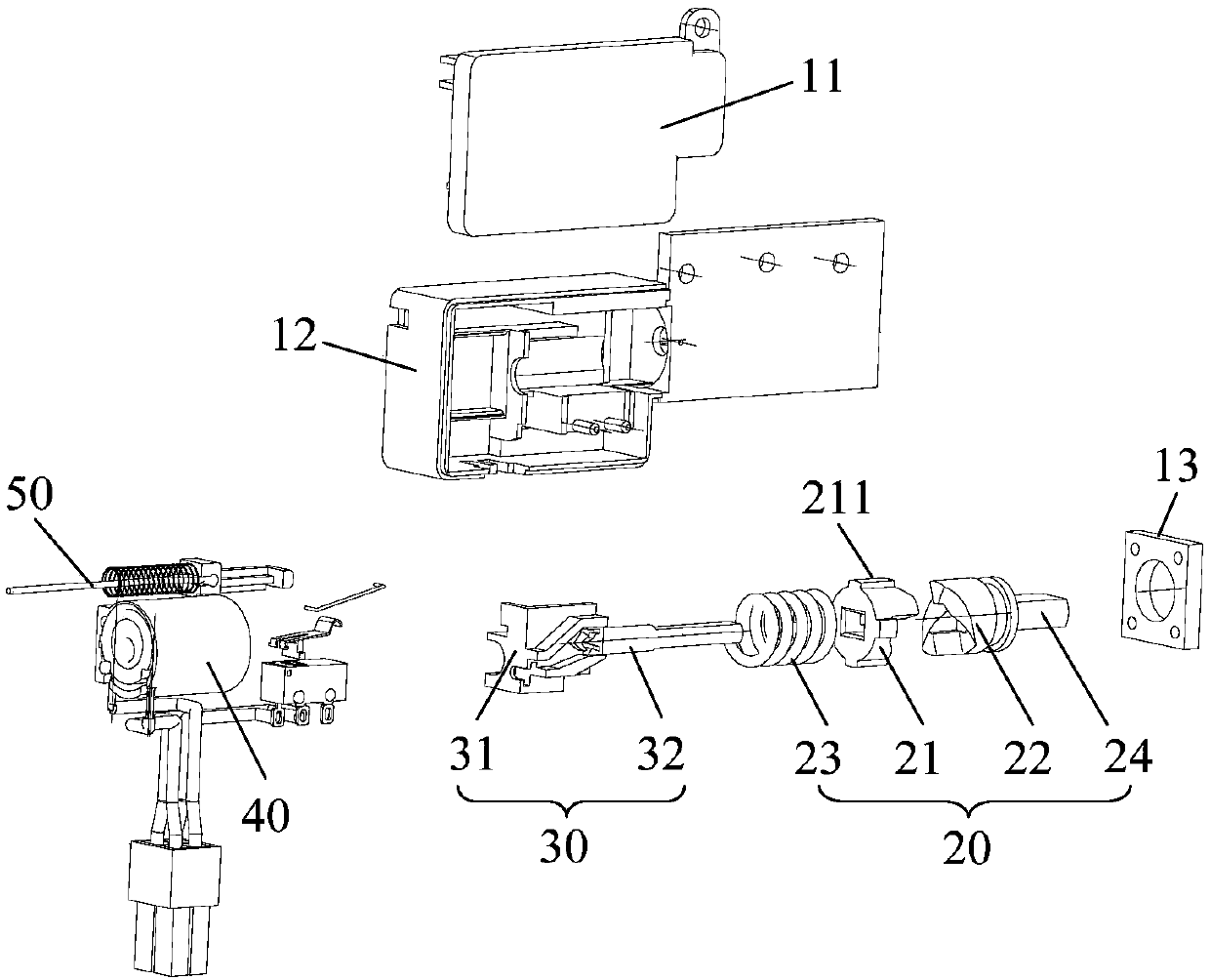

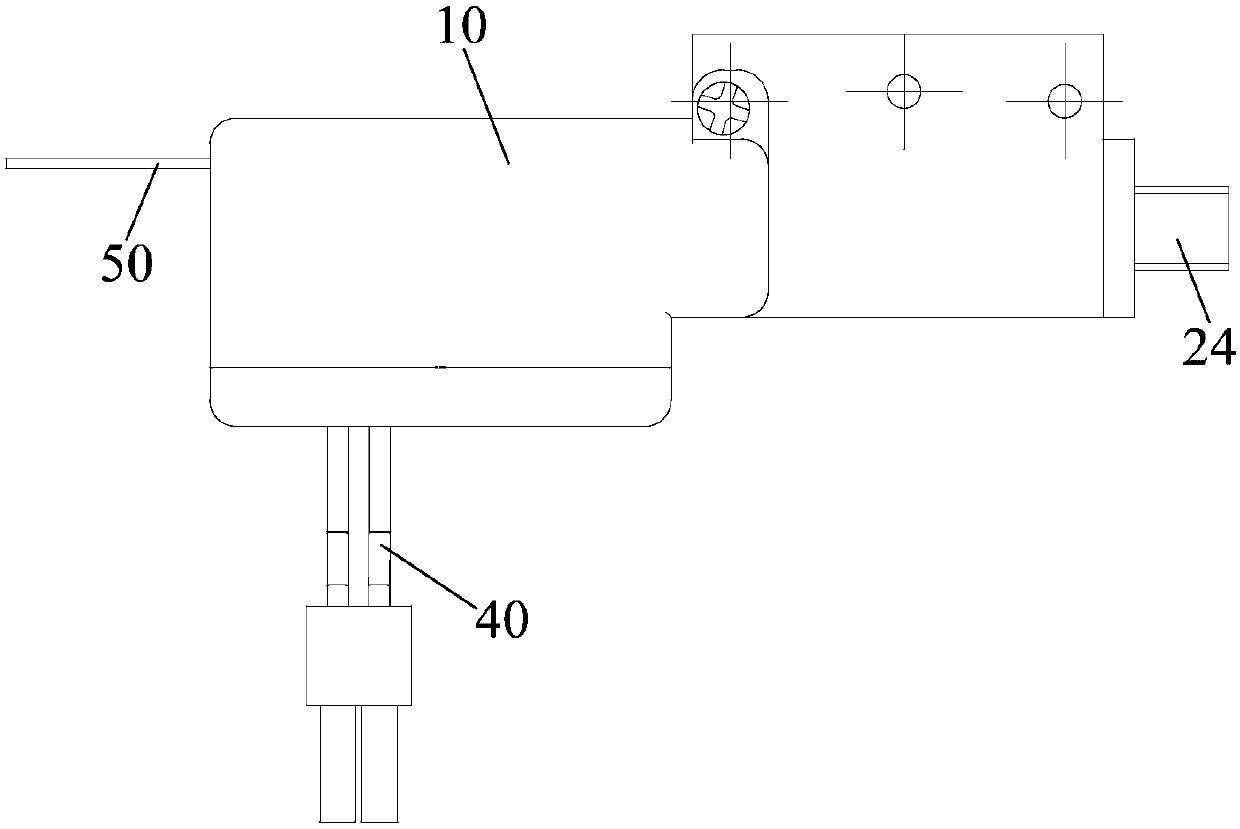

Damping door lock and washing machine

ActiveCN110359235ALimit reverse movementImprove reliabilityOther washing machinesTextiles and paperReciprocating motionWorkbench

The invention provides a damping door lock used for a washing machine. The damping door lock comprises a housing, a damper and a lock cylinder, and the housing is provided with a first connecting part; at least part of the damper is installed in the housing and is used for increasing the resistance of a door cover during closure, the damper is provided with a second connecting part capable of rotating relative to the housing, and one of the second connecting part and the first connecting part can be connected with an engine body while the other one can be connected with the door cover to enable the door cover to be connected with the engine body in a pivoted manner; the lock cylinder is installed in the housing and can move reciprocatingly between the lock position and the unlock positionin the housing, and the second connecting part is locked when moving to the lock position to limit the rotation of the second connecting part relative to the housing, and the second connecting part isunlocked when moving to the unlocked position. The damping door lock indirectly limits the rotation of the door cover through the limitation of the lock cylinder to the damper, so that the function of locking the door is realized without opening holes in the door cover or a workbench; the washing machine is more compact in structure, and high assembly efficiency is achieved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Left-ventricle assisting device and application method

InactiveCN108888813APrevent reverse movementPrecision subendocardial pacingElectrocardiographyIntravenous devicesMicro motorLeft Ventricles

The invention discloses a left-ventricle assisting device and an application method. The left-ventricle assisting device comprises a left-ventricle skeleton and air sacs, wherein the left-ventricle skeleton comprises a primary skeleton and a plurality of secondary skeletons; the multiple air sacs are arranged on the outer side face of the primary skeleton in the axial direction of the primary skeleton, and are arranged between the primary skeleton and the secondary skeletons; the air sacs fit an inner membrane of the left ventricle; the primary skeleton is communicated to the secondary skeletons; the secondary skeletons are communicated to the air sacs; a sensor is arranged at the end, fitting the inner membrane of the left ventricle, of each secondary skeleton; a gas power system comprises a flexible pipe, a pneumatic device and an electric circuit, one end of the flexible pipe is arranged in the primary skeleton, and the other end of the flexible pipe is arranged at an outlet of thepneumatic device; the pneumatic device comprises a shell, a micro motor, a valve and a pushing rod. According to the left-ventricle assisting device and the application method, the ventricular wall ofthe left ventricle is protected and prevented from being fractured, inverse motion of ventricular aneurysm of the left ventricle is prevented, and the device assists the left ventricle in achieving accurate pace-making, and meanwhile assists blood in stroking out of the left ventricle.

Owner:AFFILIATED HUSN HOSPITAL OF FUDAN UNIV

Tin bar granulator

The invention discloses a tin bar granulator which comprises a rotary shaft, an oscillating rod, a one-way bearing, a conveying wheel, a cutting knife block, a first cylindrical cam groove and a disc cam. The first cylindrical cam groove is formed in positions around the outer side surface of the rotary shaft, an end of the oscillating rod is connected with the first cylindrical cam groove, the end, which is far away from the first cylindrical cam groove, of the oscillating rod is connected with the one-way bearing, the conveying wheel sleeves the outer side surface of the one-way bearing, the rotary shaft penetrates the disc cam and is fixed relative to the disc cam, and the cutting knife block is connected with the disc cam in a butted manner. The tin bar granulator has the advantages that tin bars can be driven and conveyed by the rotary shaft and can be positioned and cut by the same rotary shaft when the tin bars are cut to obtain granules, and the one-way bearing can prevent the tin bars from reversely moving.

Owner:ALEADER VISION TECH

Sweet potato skin cleaning device

ActiveCN111345482AAvoid collisionImprove integrityFood treatmentAgricultural engineeringAgricultural science

The invention belongs to the technical field of sweet potato processing, and especially relates to a sweet potato skin cleaning device. The invention aims to solve the problem that surface walls of sweet potatoes are easily damaged by mechanical cleaning. The sweet potato skin cleaning device comprises a cleaning box, wherein a water inlet pipe and a blow-off pipe are fixed to the bottom ends of the two sides of the cleaning box correspondingly; a water return pipe is fixed to the top of the side, away from the water inlet pipe, of the cleaning box; fixed frames are fixed to the two ends of the top of the cleaning box correspondingly; and a feeding conveying belt and a discharging conveying belt are rotationally connected to two sides located between the two fixed frames correspondingly. According to the sweet potato skin cleaning device in the invention, silica gel blocks are used for increasing friction force to guarantee conveying-out of sweet potatoes, so continuous movement and cleaning of the sweet potatoes are realized; the sweet potatoes are prevented from colliding with a stirring mechanism through friction of the silica gel blocks and are thus prevented from surface walldamage, and the sweet potatoes slowly move along an inclined cleaning conveying belt and the feeding conveying belt so as to avoid collision with the inner wall of the cleaning box, so the completeness of the surface walls of the sweet potatoes is further improved after the sweet potatoes are mechanically inclined.

Owner:六安科科达尔生物科技有限公司 +1

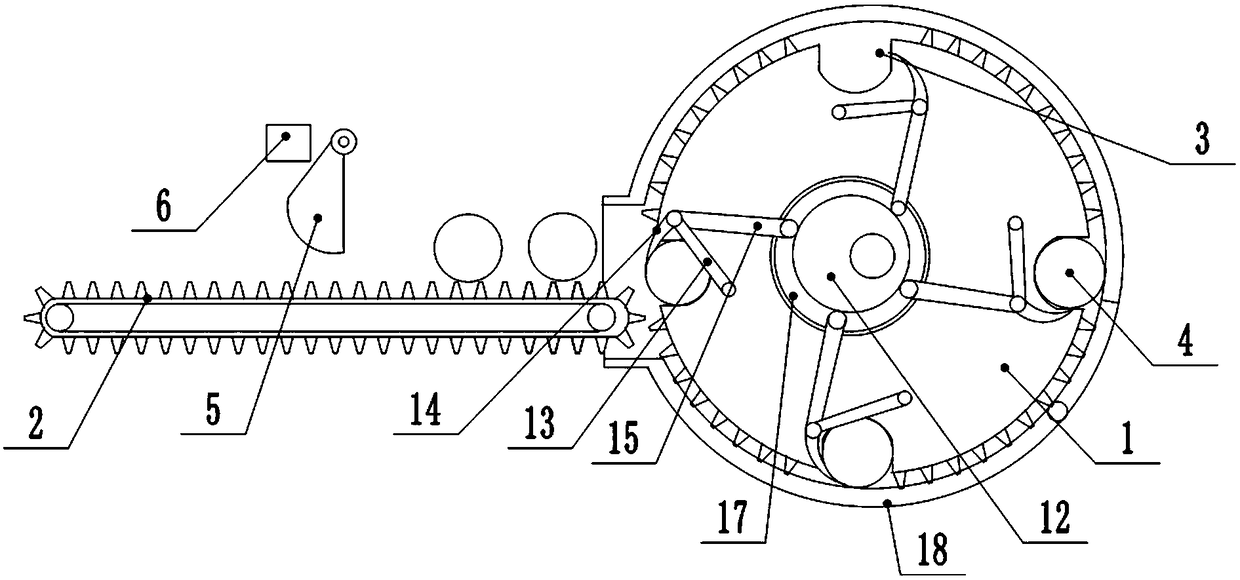

Multi-shaft drilling machine

ActiveCN109500427AReduce frequent start and stopAvoid damageDriving apparatusMetal working apparatusEngineeringConveyor belt

The invention belongs to the technical field of machining, and particularly relates to a multi-shaft drilling machine. The multi-shaft drilling machine comprises a machine frame, a positioning mechanism and a drilling mechanism are arranged on the machine frame, the positioning mechanism comprises a conveyor belt and a positioning gear, and sawteeth are arranged on the surface of the conveyor belt. Arc-shaped notches are formed in the edge of the positioning gear, and the positioning gear is connected with a first power source for driving the positioning gear to rotate. The drilling mechanismcomprises a placing box, a thread rod and a connecting rod, and a plurality of rotating shafts are rotatably connected to the side wall of the placing box. Second power sources for driving the rotating shafts to rotate are connected to the end on which the rotating shafts are located in the placing box, and drill bits are connected to the other end on which the rotating shafts are located in the placing box. The thread rod is fixedly connected with the machine frame, and the connecting rod is slidably connected with the placing box. According to the technical scheme, cylindrical workpieces areenabled to fall into the notches of the positioning gear through the rotation of the positioning gear, the workpieces are automatically fixed, and then the multiple workpieces are drilled at the sametime by using the drilling mechanism.

Owner:重庆全能电器有限公司

Axial vibration crawl device

ActiveCN105604485ASimple structurePrevent reverse movementDrilling rodsDrilling casingsRight triangleEngineering

The invention relates to an axial vibration crawl device which comprises a crawl device body, a male buckle and a female buckle, wherein 4-10 annular teeth equal in size are longitudinally and uniformly arranged on the outer surface of the crawl device body; sand guide grooves equal in size are uniformly formed in each annular tooth; each annular tooth has a right triangular cross section, and the right-angle side of each annular tooth faces the female buckle; the first annular tooth close to the female buckle side has a double bevel cross section. The axial vibration crawl device is simple in structure, and can prevent counter motion of a drill column and accumulation of rock fragments.

Owner:YANSHAN UNIV

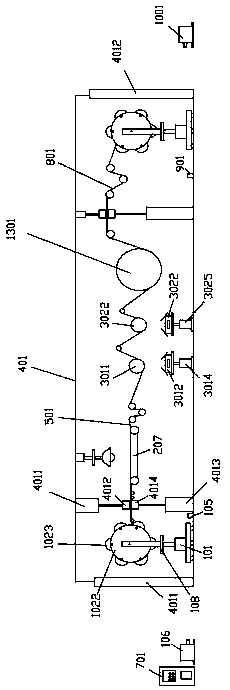

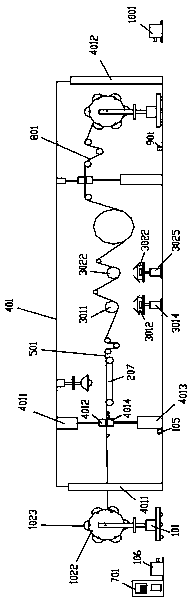

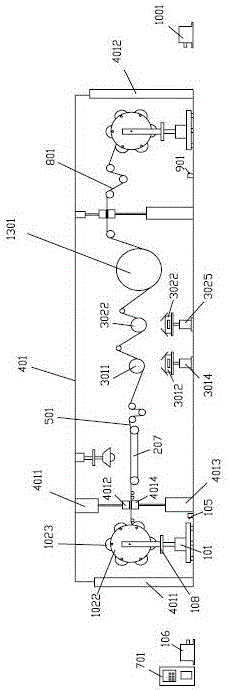

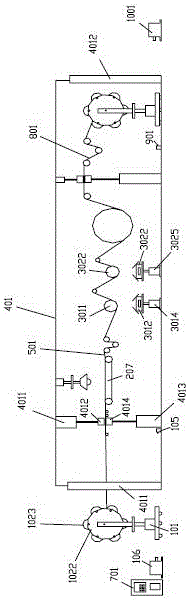

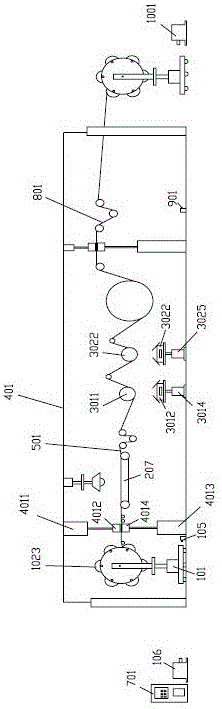

A metallized film vacuum coating machine

InactiveCN106222627BHigh degree of automationConvenience for feeding/receivingVacuum evaporation coatingSputtering coatingVacuum chamberVacuum coating

The invention discloses a metallized film vacuum coating machine. The metallized film vacuum coating machine comprises a vacuum chamber, a feeding mechanism, a coating mechanism and a winding mechanism. The feeding mechanism, the coating mechanism and the winding mechanism are arranged in the vacuum chamber. The feeding mechanism comprises a first lifting mechanism and a feeding device. A preheating mechanism is arranged between the feeding mechanism and the coating mechanism. A first movable plate assembly adjusting the size of an opening of a first evaporator boat is arranged in the top opening area of the first evaporator boat. A second movable plate assembly adjusting the size of an opening of a second evaporator boat is arranged in the top opening area of the second evaporator boat. A film clamping device is arranged between the feeding mechanism and the coating mechanism. A film clamping device is arranged between the coating mechanism and the winding mechanism. The winding mechanism comprises a fifth lifting mechanism and a winding device. The telescopic end of the fifth lifting mechanism is matched with the winding device and used for driving the winding device to move up and down. The metallized film vacuum coating machine has the advantages that the automation degree is high, material supplementary / material receiving is convenient and in time, preheating is uniform, preheating quantity is adjustable, the metallized film vacuum coating machine is suitable for machining of various models of films, and the coating thickness is adjustable.

Owner:TONGLING CHAOYUE ELECTRON CO LTD

Novel winding reel

InactiveCN103640931ASimple and convenient structurePrevent reverse movementRight triangleEngineering

Owner:WUJIANG XINJINHUA TEXTILE

Quick battery replacement device for pure electric automobile by employing gas pressure linkage principle

InactiveCN109606327AAvoid bumpingNot to be bumpedElectric propulsion mountingVehicle servicing/repairingProduct gasEngineering

The invention discloses a quick battery replacement device for a pure electric automobile by employing a gas pressure linkage principle. A structure of the device includes a placement plate, a chassisframe, an engine bracket, a storage battery, and a connection bracket. When a battery needs to be replaced, air pressure is compressed by driving of a compression button, is introduced in pressure linkage mechanisms in a disassembly mechanism, and is converted by pneumatic paddle sheets to achieve linkage, and finally a rotation shaft is driven to control swinging of settlement plates to make thestorage battery lower, thereby completing quick disassembly; and hanging boards can tow and suspend the storage battery to avoid falling directly to the ground, an overall disassembly step does not require the aid of peripheral tools, and the storage battery is guaranteed not to be bumped during a disassembly process, so that the service life is improved, and the safety is greater.

Owner:庄高墅

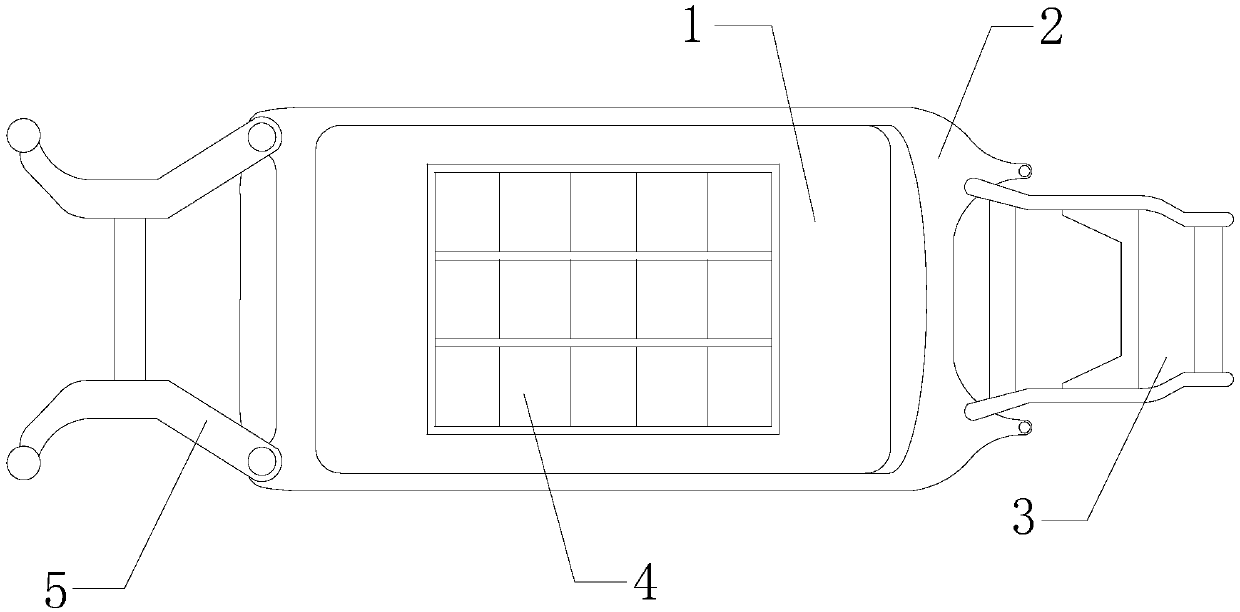

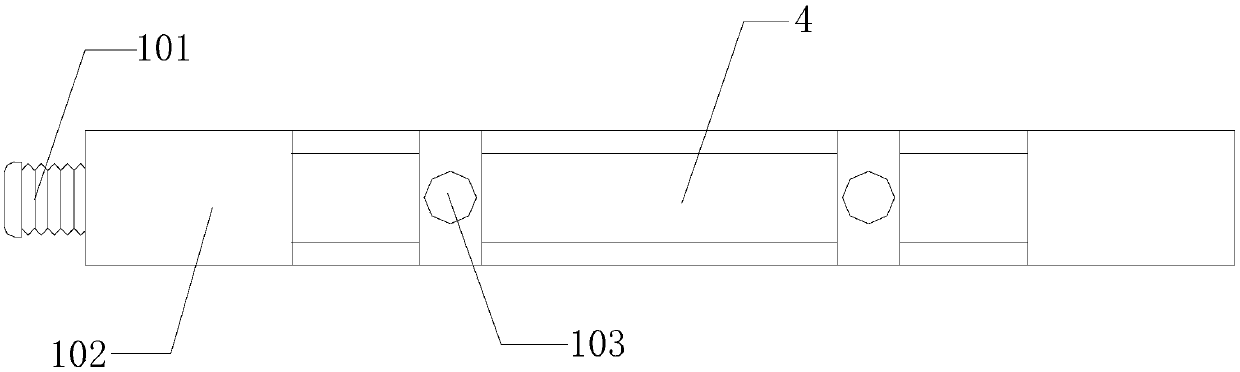

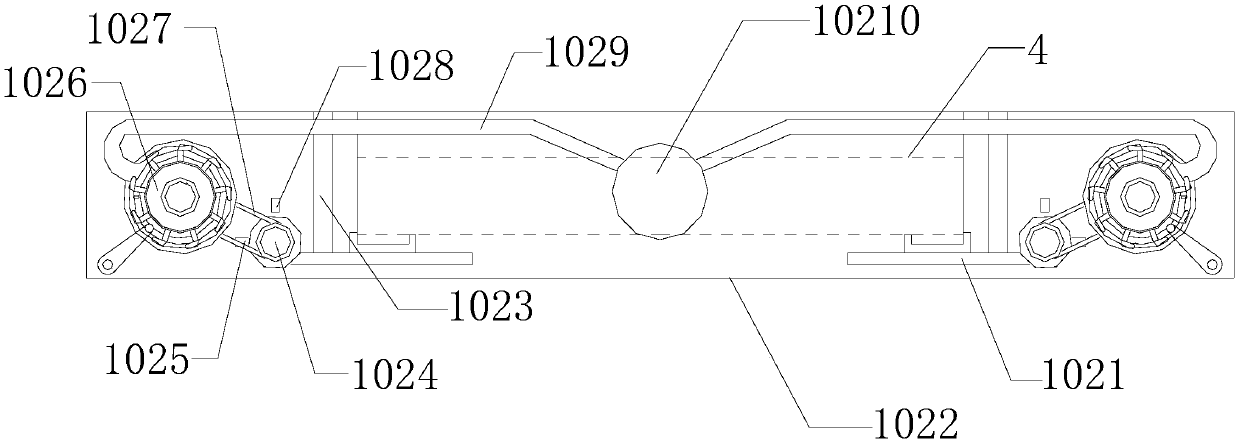

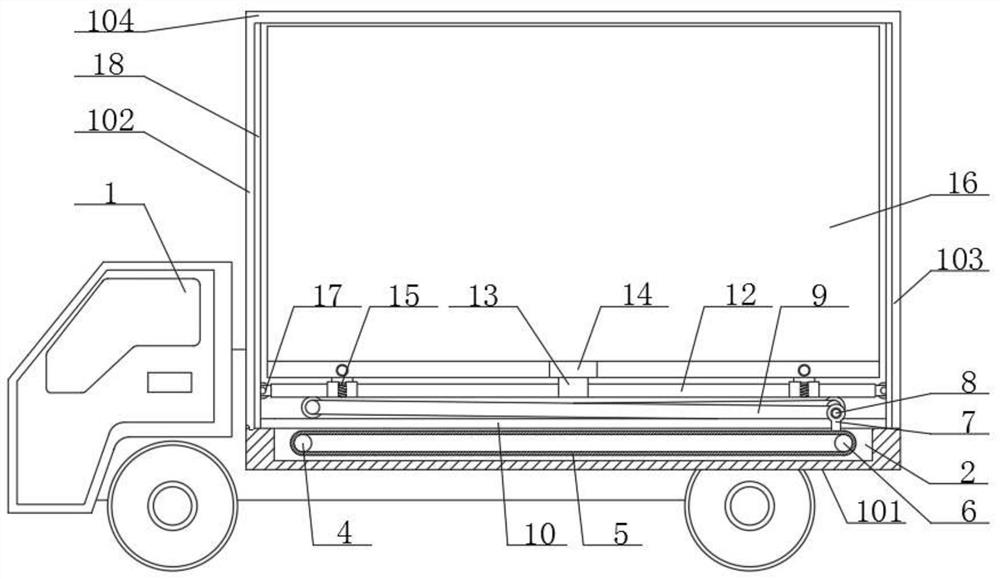

LED display screen flexible conversion type advertisement propaganda vehicle

InactiveCN112248902ATake advantage ofEasy to placeVehicle componentsItem transportation vehiclesLED displayElectric machinery

The invention relates to the technical field of advertisement propaganda vehicles, in particular to an LED display screen flexible conversion type advertisement propaganda vehicle which is characterized in that a carriage bottom plate is arranged on a vehicle body, a carriage front plate and a carriage rear plate are connected to the carriage bottom plate, and the upper end of the carriage front plate and the upper end of the carriage rear plate are connected with the same carriage top plate; two display screens are arranged on the vehicle body, two mounting grooves are formed in the lower portion of each display screen, driving motors are connected to the inner walls of the mounting grooves, and first rollers are connected to the output ends of the driving motors. According to the invention, the display screens can rotate and ascend and descend; when the display screens move to the upper positions, the two sides of the carriage are opened, the operation area is increased, and objectsin the carriage can be placed and taken conveniently; the display screen can be rotatably arranged, and when the advertisement propaganda vehicle is parked, the display screen located on the inner side is rotated to the direction facing people, so that sufficient utilization of the display screens is achieved.

Owner:安徽国润翔专用汽车有限公司

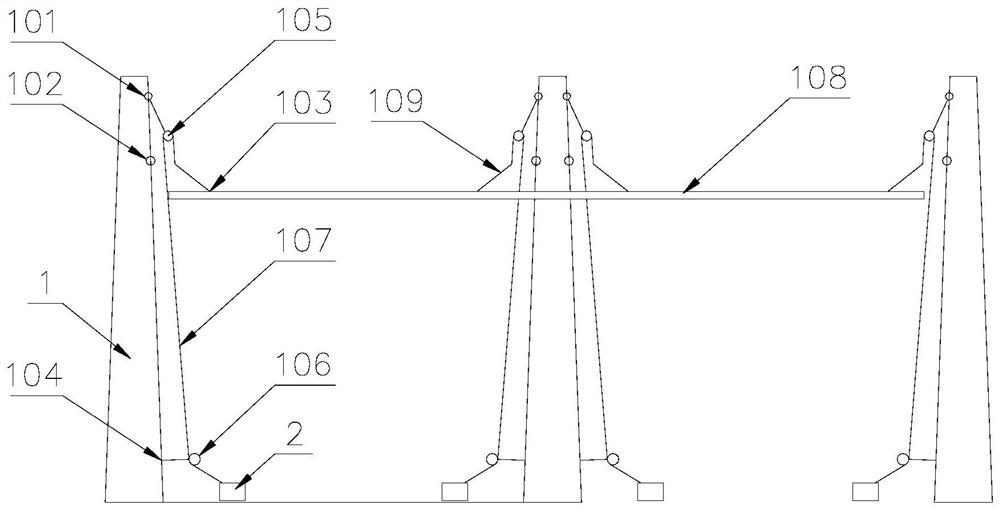

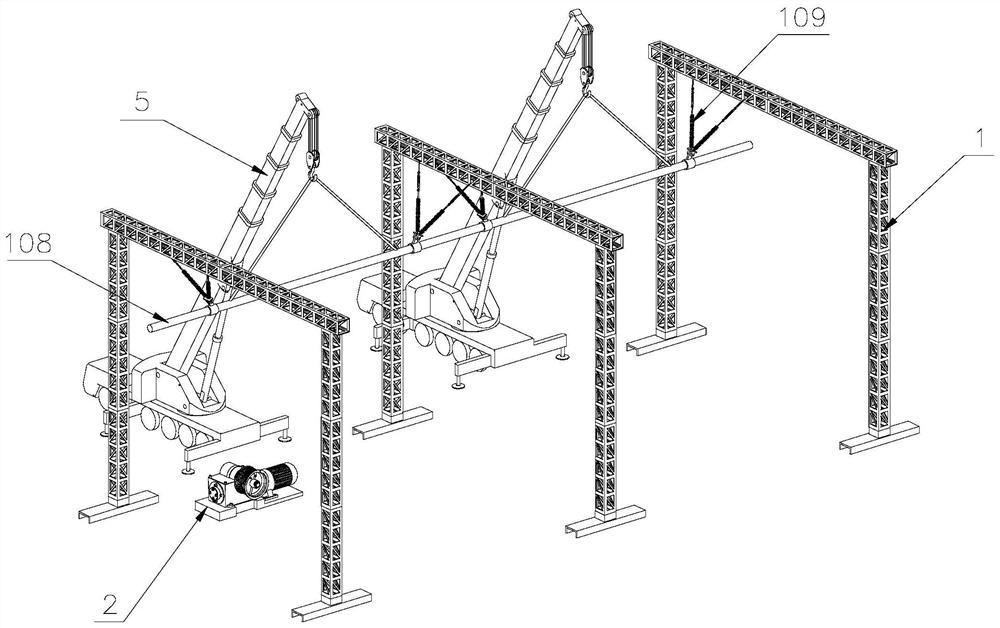

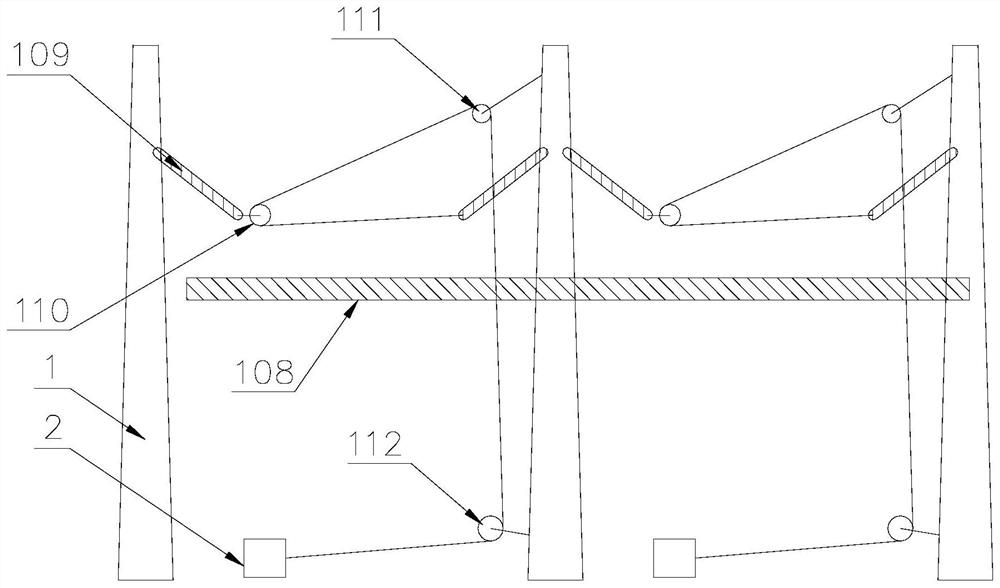

Hoisting method of obliquely-pulling type insulator string ultra-long tubular bus

ActiveCN112320650AImprove securityImprove construction efficiencyBus-bar installationPortable liftingBlock and tackleWinch

The invention discloses a hoisting method for a obliquely-pulling type insulator string ultra-long tubular bus. The hoisting method comprises the following steps of S1, hoisting a V-shaped insulator string, S2, installing a pulley block, S3, obliquely pulling an insulator string, S4, hoisting a tubular bus, S5, fitting connection and S6, fitting adjustment. The V-shaped insulator string is connected with a portal frame in advance by using a crane, the insulator string is obliquely pulled to a fixed angle in advance by using a winch, a steel wire rope and a pulley block, at the moment, the tubular bus is hoisted to an installation height and can be directly connected with the V-shaped insulator string, the whole tubular bus only has tension in the vertical direction, the safety coefficientis high, the overhead operation time of personnel is shortened, and the construction efficiency is obviously improved.

Owner:QINGHAI POWER TRANSMISSION & TRANSFORMATION ENG +2

Metallized film vacuum coating machine

InactiveCN106222627AHigh degree of automationConvenience for feeding/receivingVacuum evaporation coatingSputtering coatingEngineeringVacuum chamber

The invention discloses a metallized film vacuum coating machine. The metallized film vacuum coating machine comprises a vacuum chamber, a feeding mechanism, a coating mechanism and a winding mechanism. The feeding mechanism, the coating mechanism and the winding mechanism are arranged in the vacuum chamber. The feeding mechanism comprises a first lifting mechanism and a feeding device. A preheating mechanism is arranged between the feeding mechanism and the coating mechanism. A first movable plate assembly adjusting the size of an opening of a first evaporator boat is arranged in the top opening area of the first evaporator boat. A second movable plate assembly adjusting the size of an opening of a second evaporator boat is arranged in the top opening area of the second evaporator boat. A film clamping device is arranged between the feeding mechanism and the coating mechanism. A film clamping device is arranged between the coating mechanism and the winding mechanism. The winding mechanism comprises a fifth lifting mechanism and a winding device. The telescopic end of the fifth lifting mechanism is matched with the winding device and used for driving the winding device to move up and down. The metallized film vacuum coating machine has the advantages that the automation degree is high, material supplementary / material receiving is convenient and in time, preheating is uniform, preheating quantity is adjustable, the metallized film vacuum coating machine is suitable for machining of various models of films, and the coating thickness is adjustable.

Owner:TONGLING CHAOYUE ELECTRON CO LTD

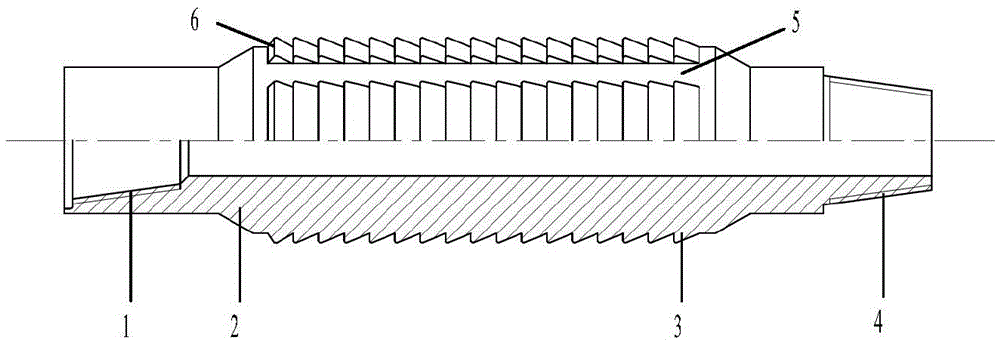

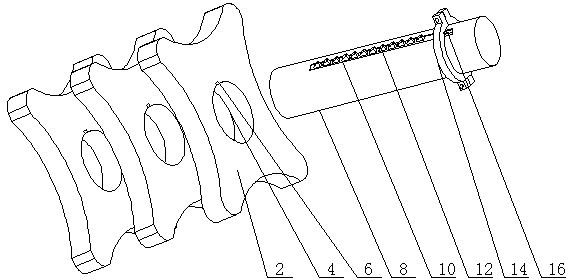

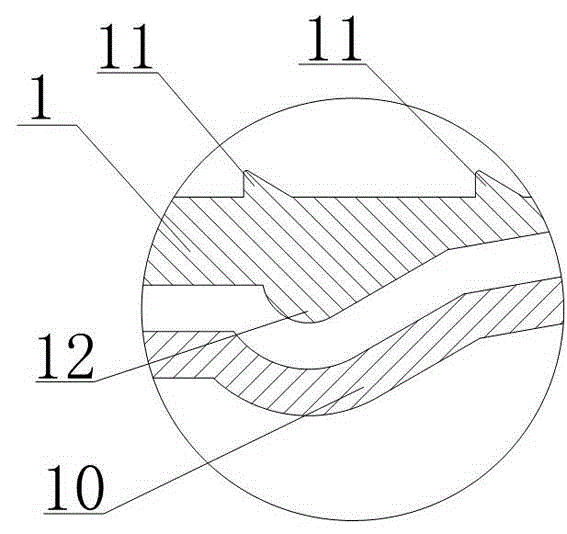

Quick connecting method for metal hose

InactiveCN105570584AAchieve axial positioningReduce usageHose connectionsEngineeringStainless steel wire

The invention discloses a quick connecting method for a metal hose. The quick connecting method involves a cylindrical nozzle (1); an outer nut (3) sleeves the side, where a stop (2) is positioned, of the nozzle (1); a groove (4) of which a cross section is semicircular is formed in the inner cavity of the outer nut (3); a fitting groove (5) matched with the groove is formed in the nozzle (1), and a steel wire (6) is mounted in a space defined by the groove (4) and the fitting groove (5). According to the quick connecting method for the metal hose, a plurality of sharp-edge flange and core tube structures are adopted, which can be reasonably deformed under the assistance of a withholding apparatus to achieve excellent tightness; one flange and outer cover structure is adopted such that a stainless steel wire reinforcement layer can be clamped, and therefore, reliable connection can be achieved, and the application of a welding process is avoided; moreover, an annular clamping structure is adopted, in which a steel wire is assembled during assembly, allowing normal use without welding.

Owner:CHENGDU BAIRUI BUILDING INSTALLATION ENG CO LTD

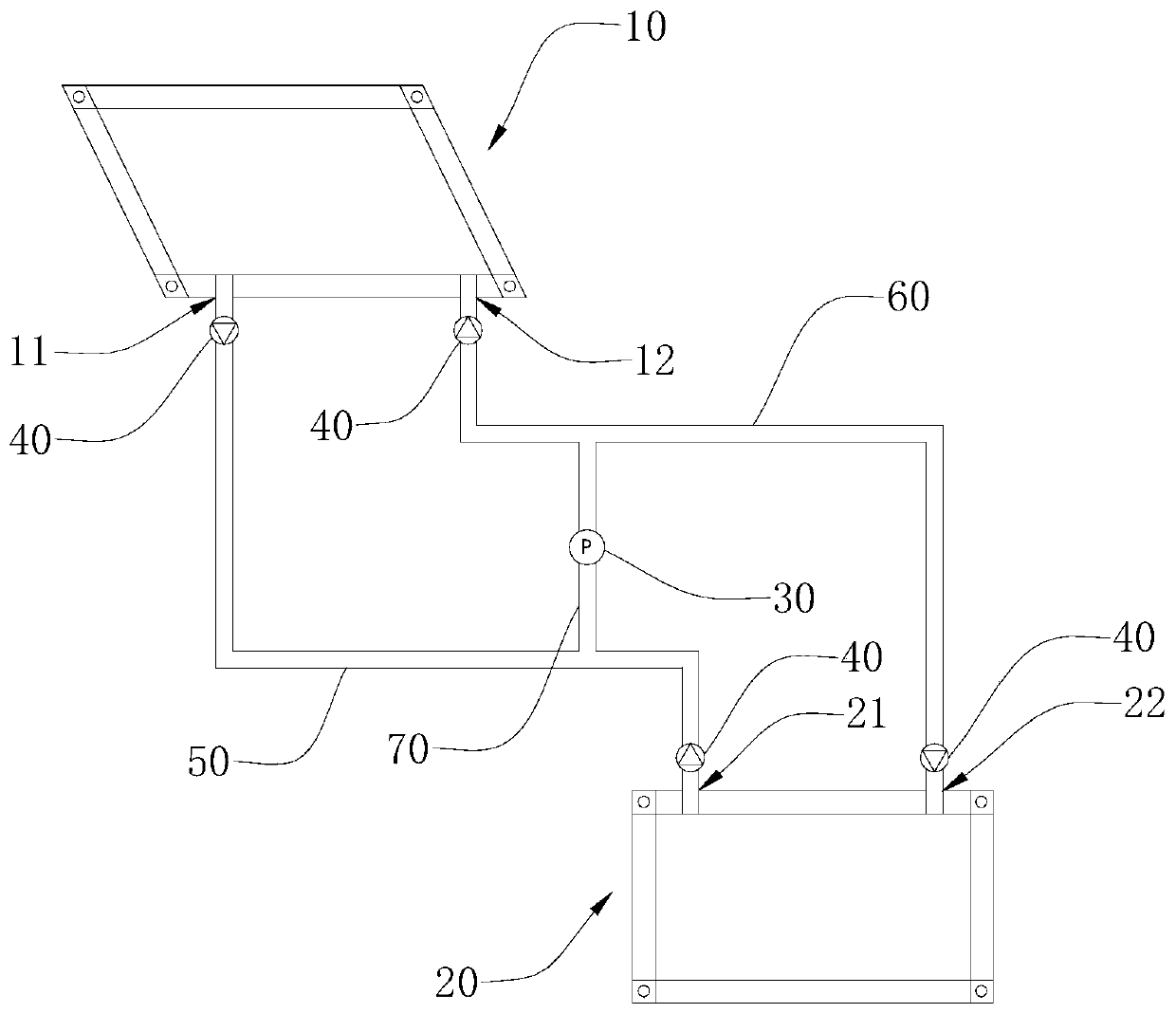

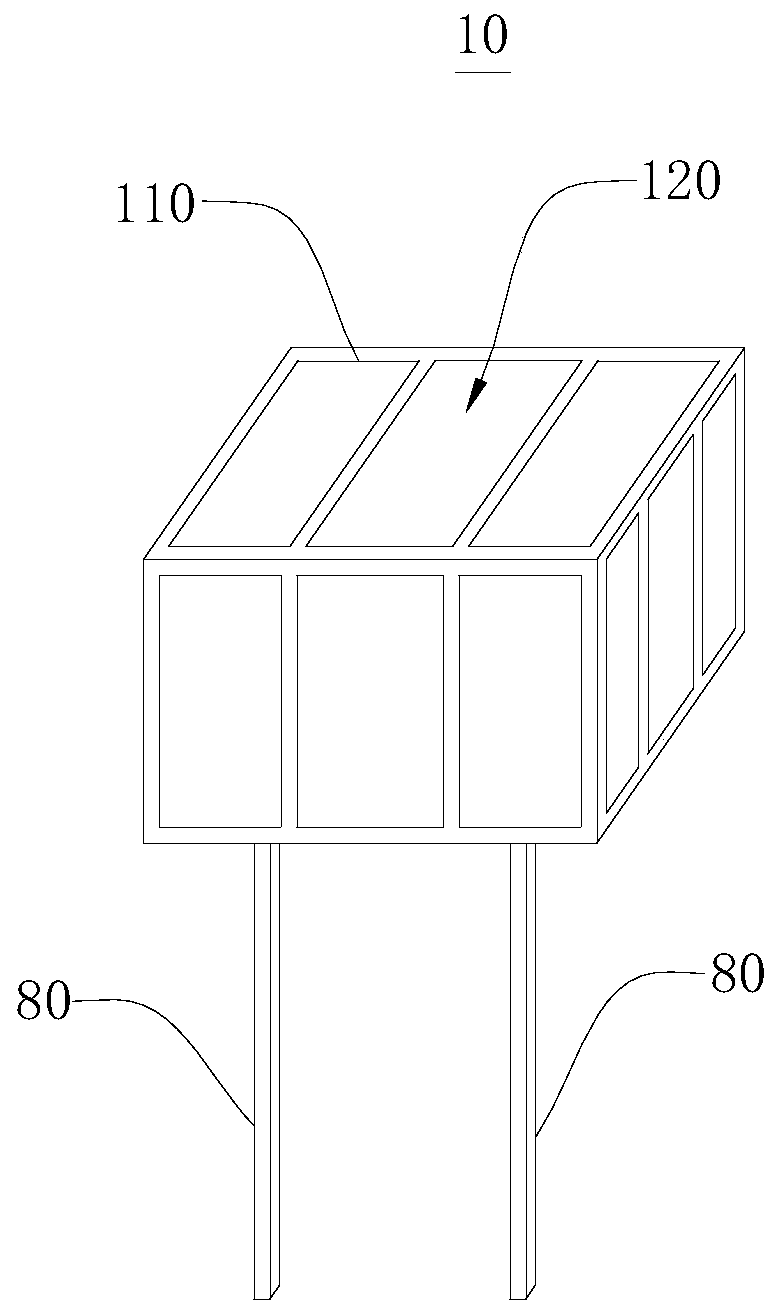

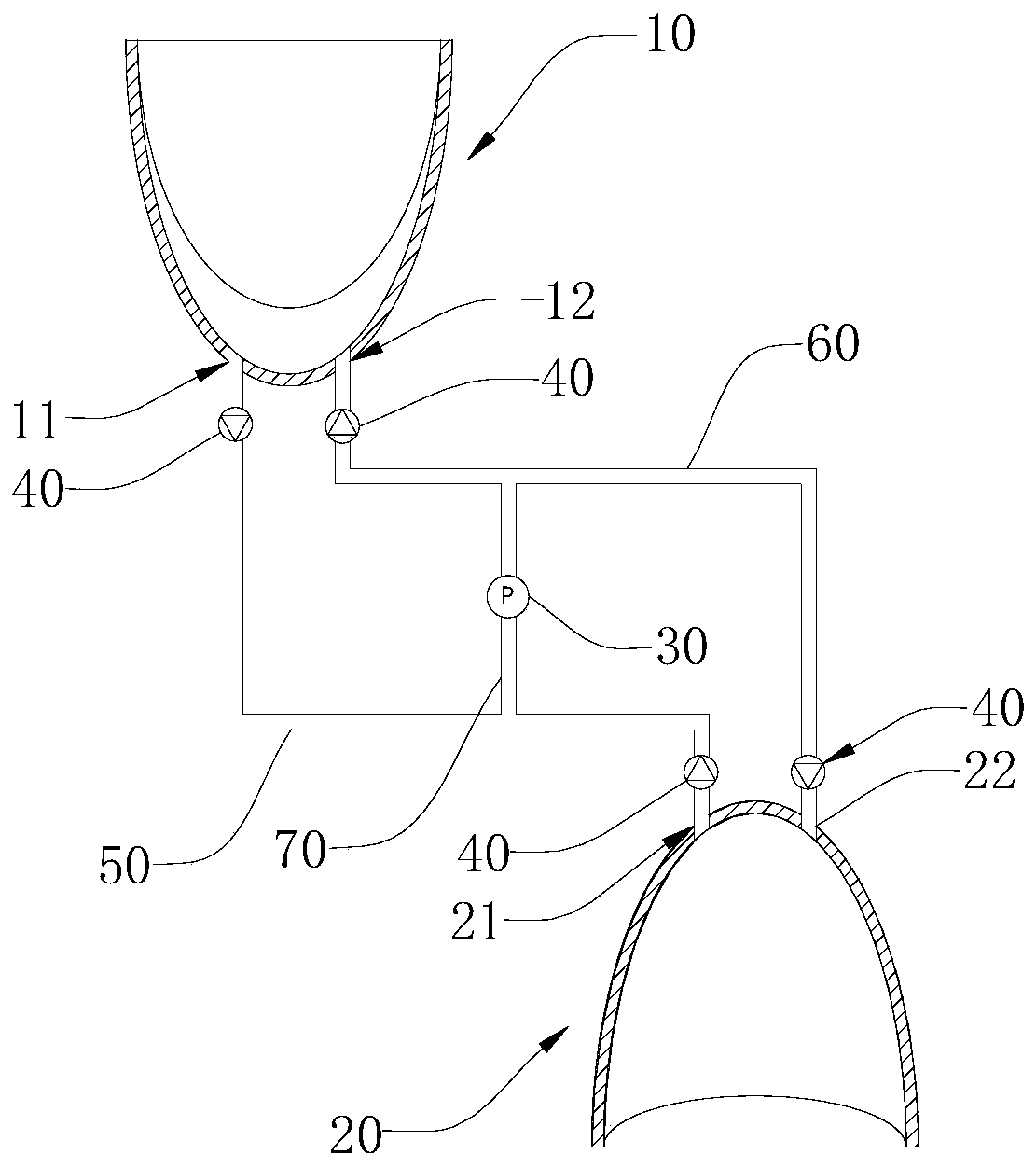

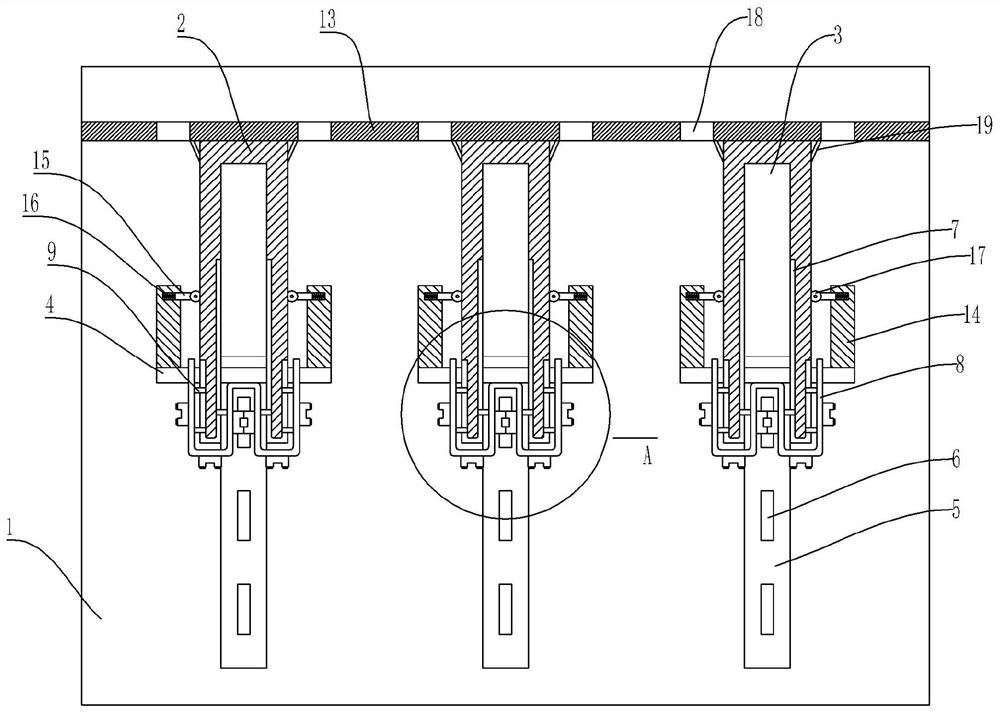

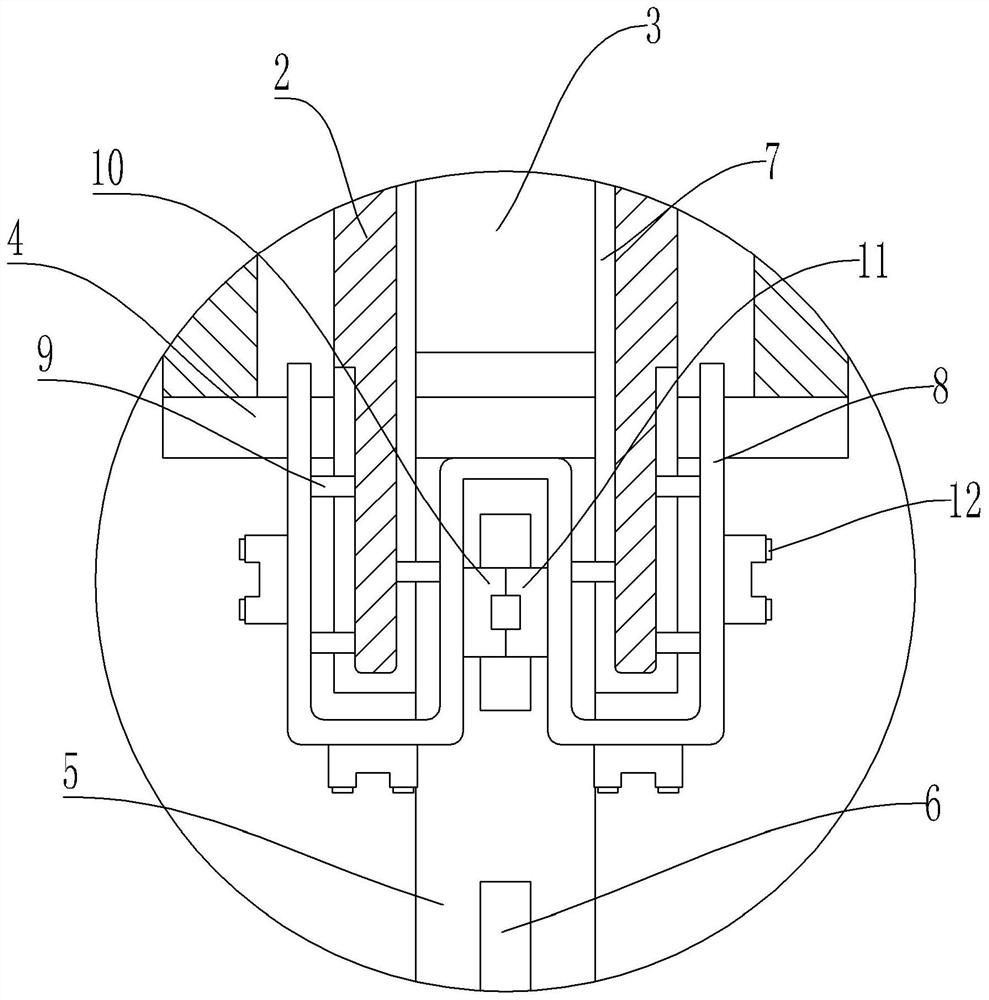

Sea wave energy conversion device and sea wave energy conversion method

InactiveCN111255619AThe overall simplicity of the deviceReduce intermediate linksMachines/enginesEngine componentsPhysicsEngineering

The invention discloses a sea wave energy conversion device and a sea wave energy conversion method, and belongs to the technical field of wave energy conversion. The sea wave energy conversion deviceincludes a first deformation component, a power generation device and a second deformation component which communicate in sequence; the first deformation component and the second deformation component are arranged in a staggered mode along the direction from far sea to the coast, and the first deformation component and the second deformation component are each provided with a deformation cavity.Through cooperative deformation of the first deformation component and the second deformation component, fluid flows between the first deformation component and the second deformation component and drives the power generation device to work, so that energy conversion is realized, the whole device is simple, intermediate process are few, sea waves in the direction from the far sea to the coast canbe utilized, sea waves in the direction from the coast to the far sea can also be utilized, the energy conversion efficiency is high, and power output is stable.

Owner:蔡欣蓬

A storage device for sporting goods

ActiveCN113018822BAvoid damageExtended service lifeRacket sportsStructural engineeringMechanical engineering

Owner:CHONGQING VOCATIONAL INST OF ENG

Foaming equipment for producing polyurethane foam plastic and production process

The invention discloses foaming equipment for polyurethane foam plastic production and a production process, and relates to the field of polyurethane foam. The foaming equipment comprises a workbench, a mounting frame is fixedly mounted on the top side of the workbench, and two multi-layer gear rings are rotatably mounted on the top side of the mounting frame; circular shafts are fixedly mounted on the inner walls of the two sides, away from each other, of the mounting frame correspondingly, and fixing rings are fixedly mounted at the ends, close to each other, of the two circular shafts correspondingly. A rotating disc is rotated to drive an adjusting lead screw to rotate, the adjusting lead screw rotates to drive a U-shaped block to move, the U-shaped block moves to drive a lantern ring to move, the lantern ring moves to drive two gears to slide on the two multi-layer gear rings through a rotating shaft, and therefore injection proportion of two raw materials is adjusted by adjusting transmission ratio of rotation of the two multi-layer gear rings, the best foaming effect can be achieved by finely adjusting the proportion according to different shapes, strengths and functions of foaming forming, foaming effect of the foaming equipment is good, and performance of the formed polyurethane foam plastic is good.

Owner:HUIZHOU YUANAN NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com