Patents

Literature

51results about How to "Even color mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

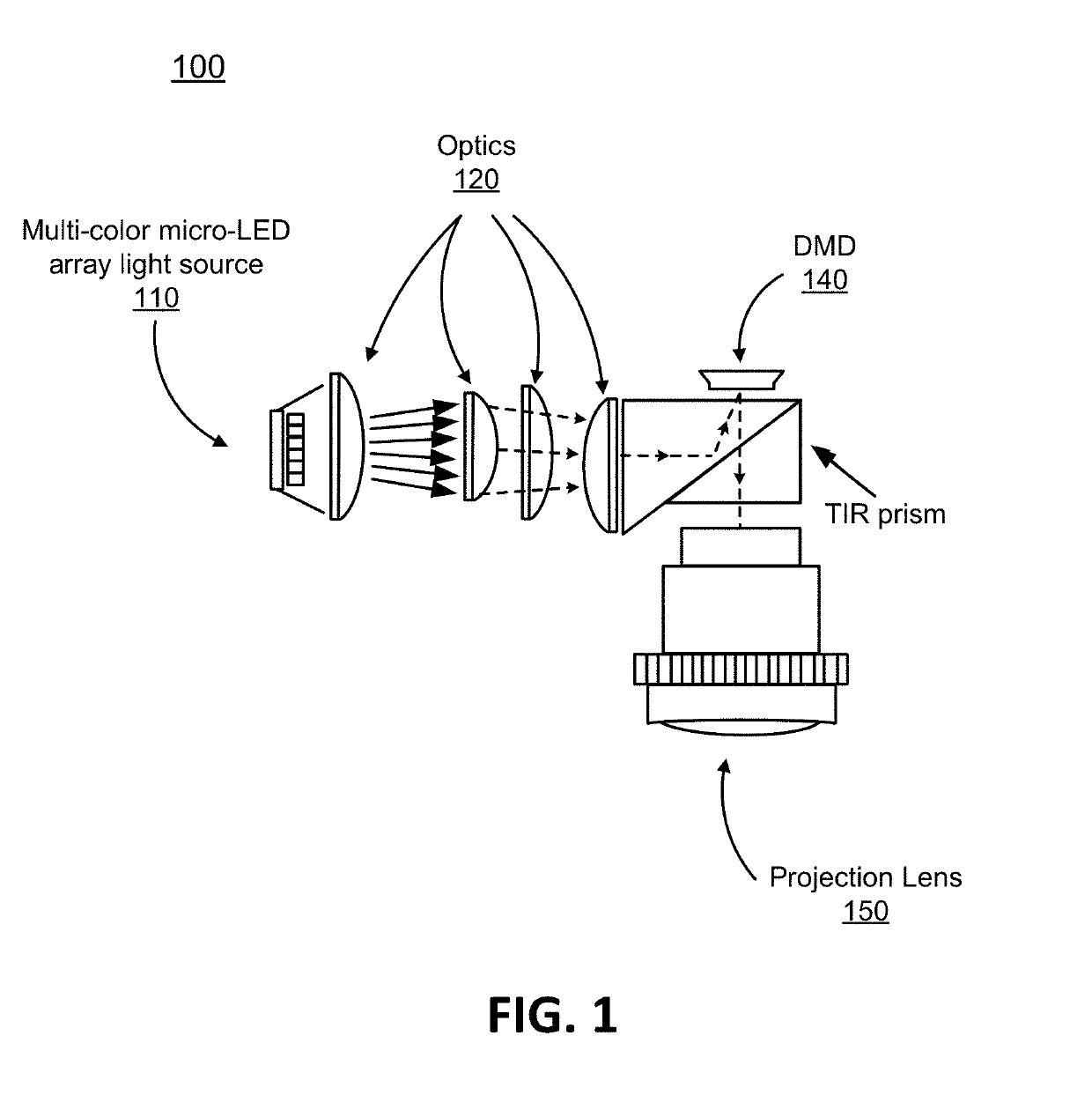

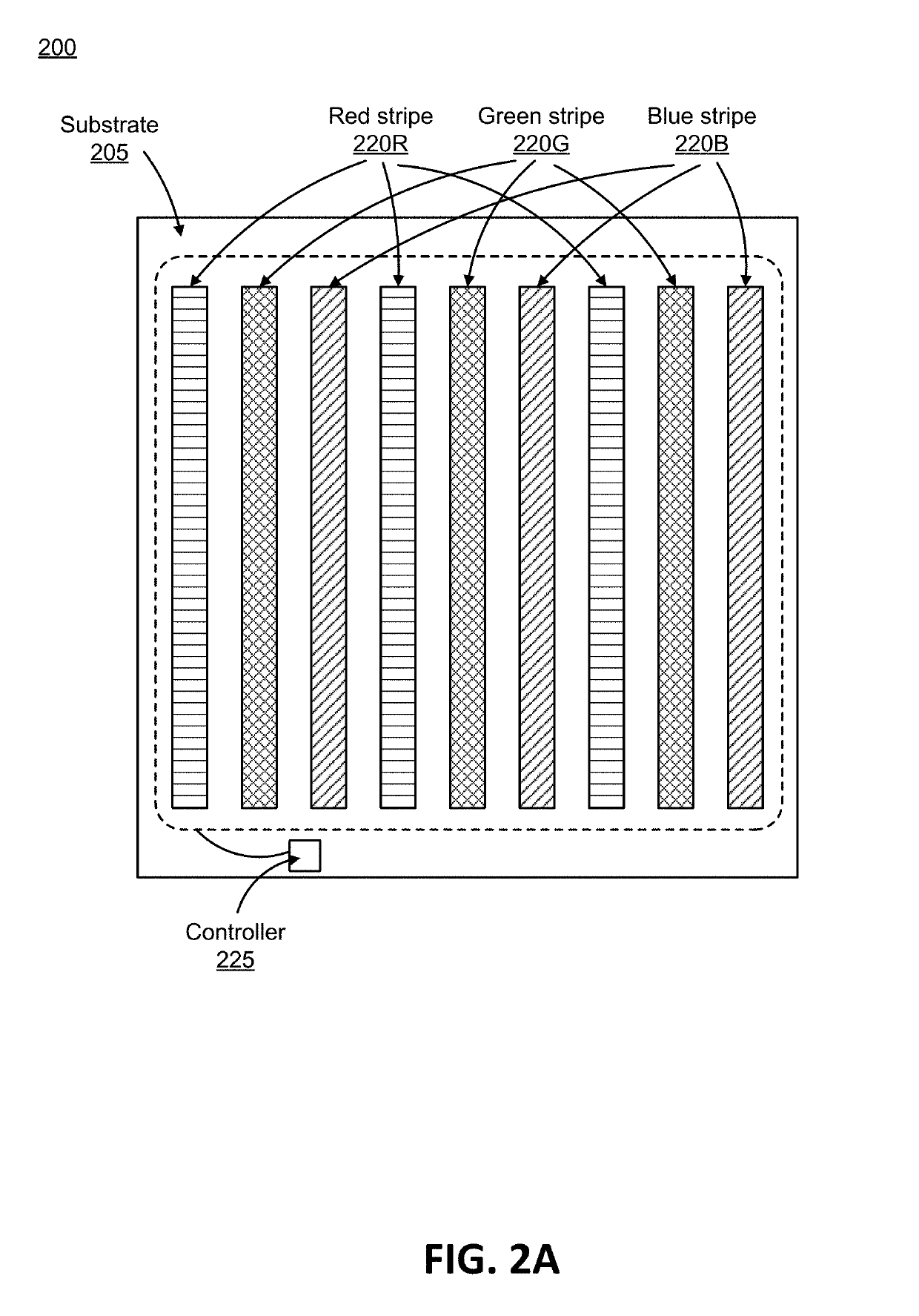

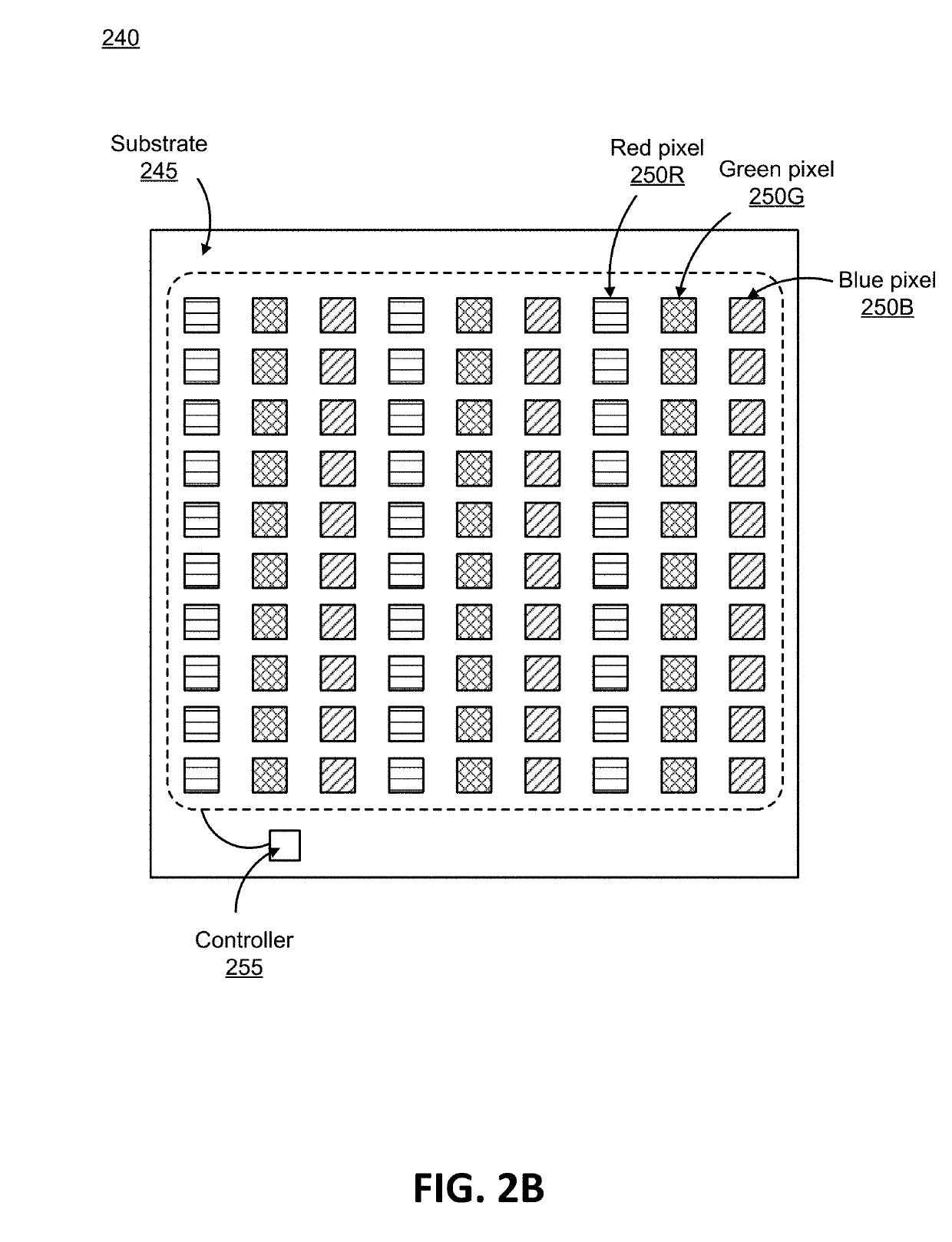

Multi-Color Micro-Led Array Light Source

ActiveUS20180132330A1Reduce artifactsReduce displacementPlanar light sourcesLight source combinationsLed arrayLight beam

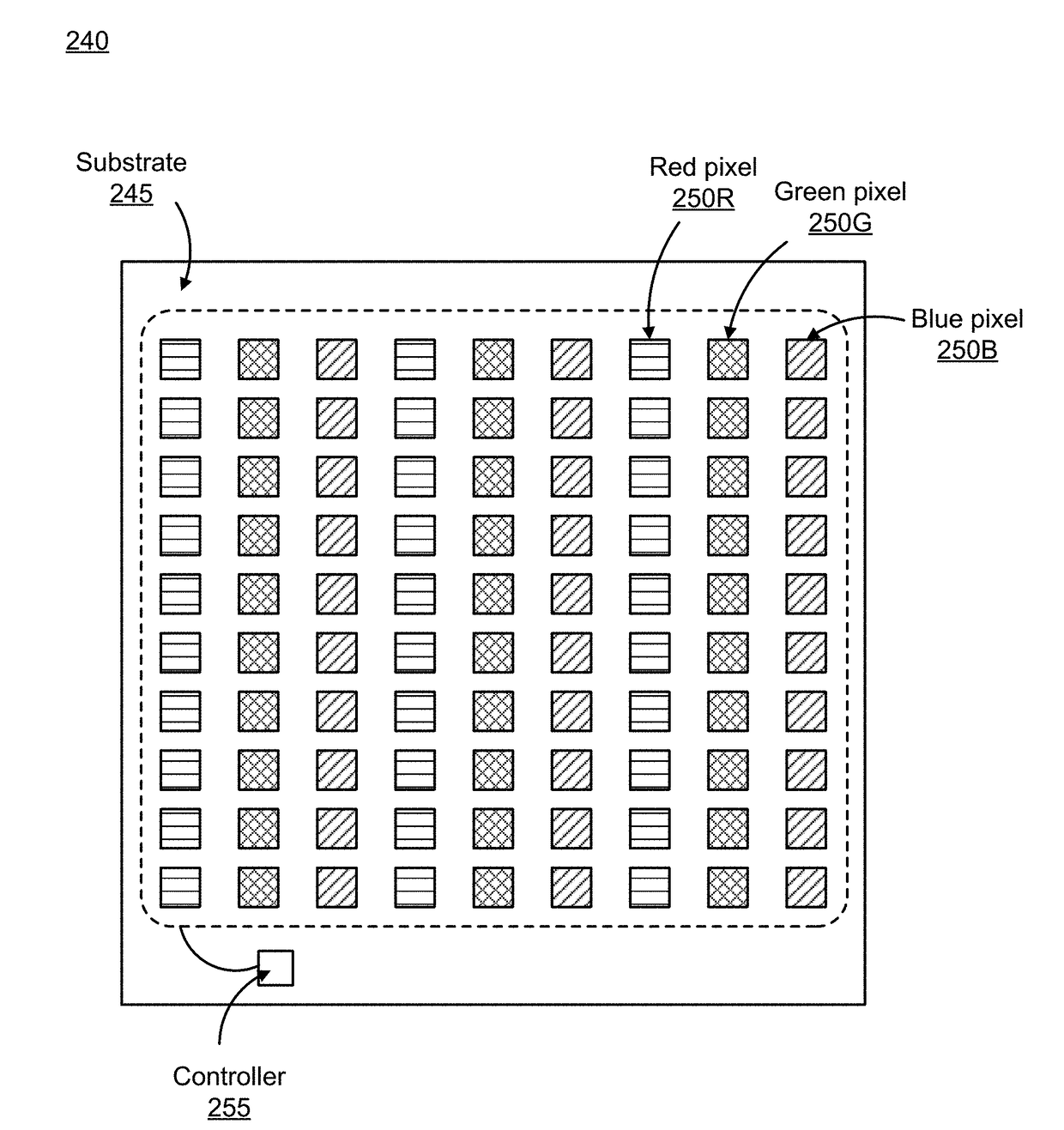

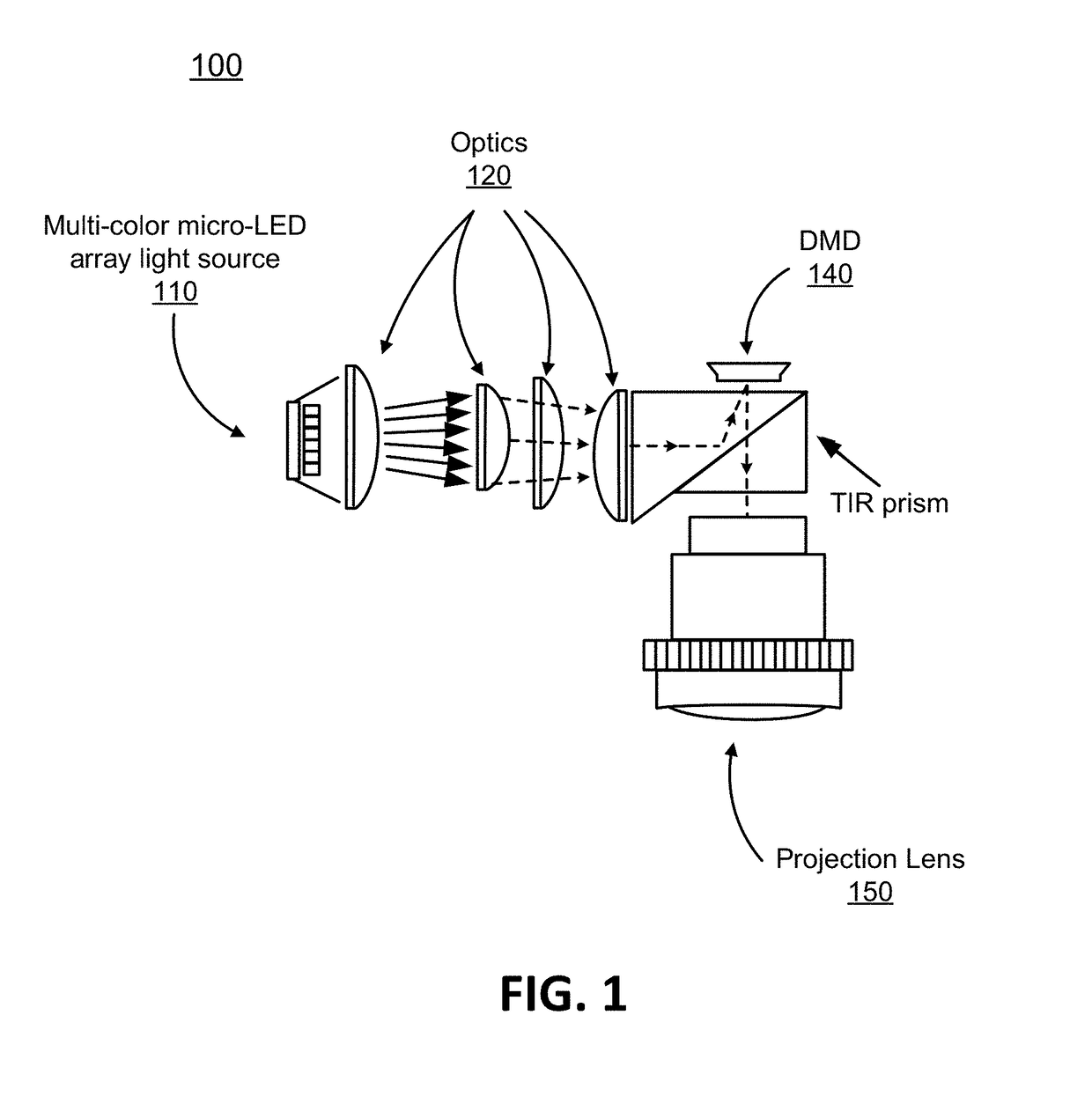

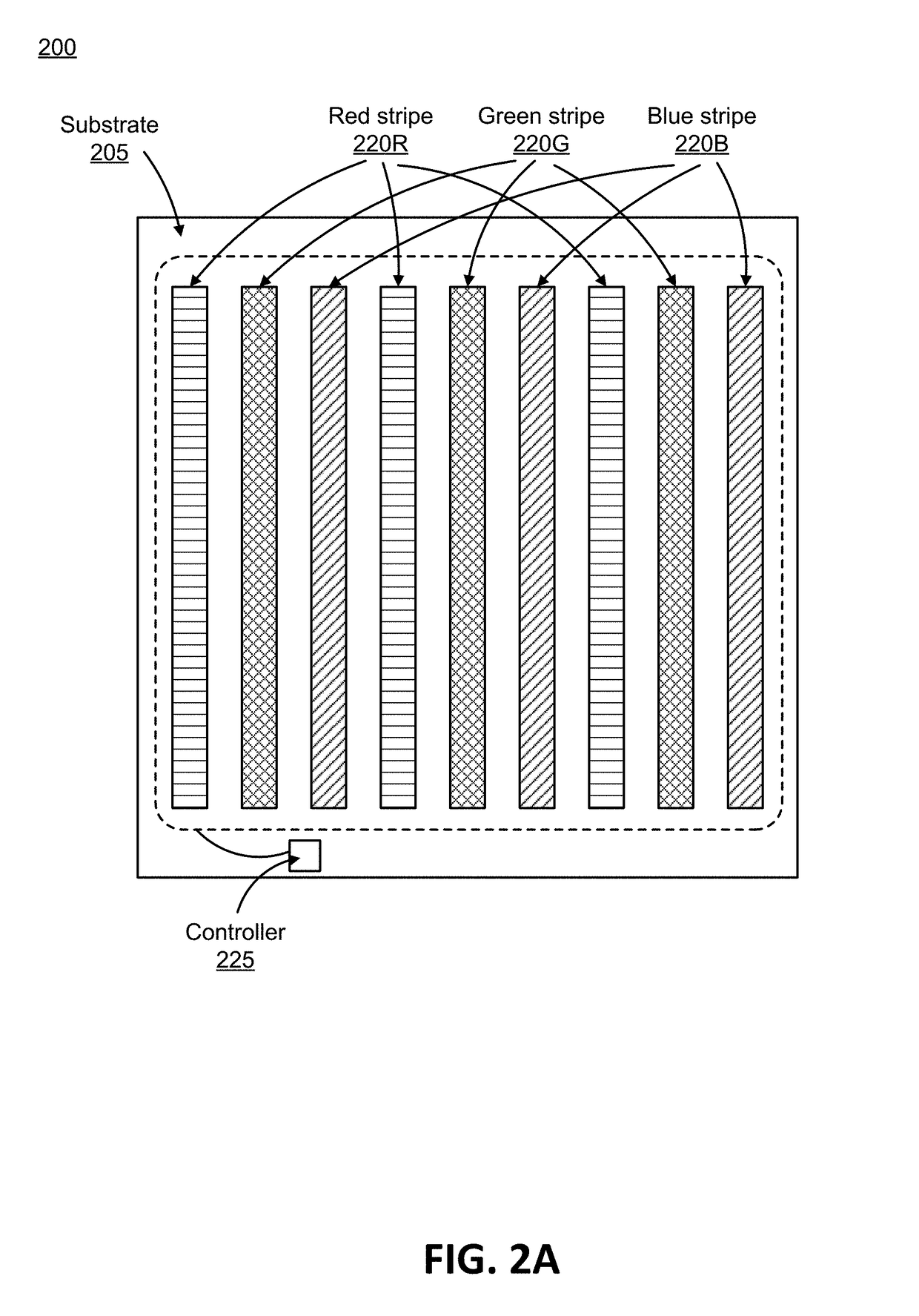

Various embodiments include a multi-color micro-LED array light source that enables well-overlapped light beams of different colors. The multi-color micro-LED array light source includes a thermally conductive substrate and multiple arrays of different color micro-LEDs integrated on the thermally conductive substrate. The micro-LEDs within each array are electrically connected so that they can all be driven in unison. The multi-color array light source also includes a controller that is electrically coupled to and that drives the arrays of micro-LEDs. The controller drives the micro-LEDs in a manner that produces an output light distribution with a spatial wavelength and angular distribution that is suitable for use as a light source.

Owner:JADE BIRD DISPLAY SHANG HAI LTD

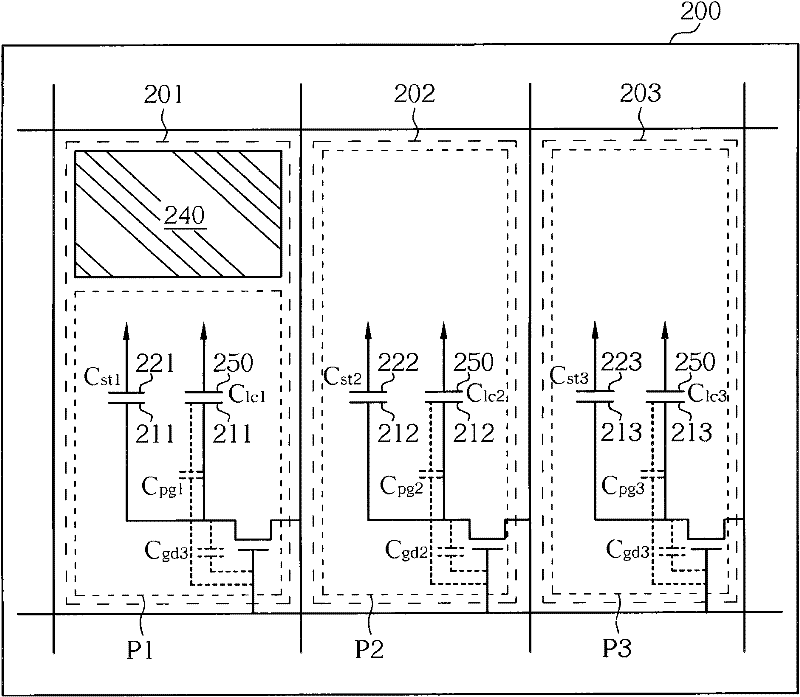

Pixel structure and forming method of in-cell touch display panel

ActiveCN102298227AA slight decrease in brightnessAvoid electrical problemsStatic indicating devicesNon-linear opticsCapacitanceLiquid crystal

The invention provides a pixel structure of an embedded touch display panel. The pixel structure comprises a substrate on which a plurality of subpixel regions are defined and a plurality of subpixels, wherein the subpixels are respectively arranged in the subpixel regions; the transmitting area of at least one subpixel is different from the transmitting areas of the other subpixels in size; each subpixel comprises a liquid crystal capacitor with liquid crystal capacitance Clc, a storage capacitor with storage capacitance Cst and a thin film transistor with capacitance Cgd between a grid electrode and a drain electrode and capacitance Cpg between a grid electrode and a pixel electrode; each subpixel has capacitance ratio which is defined as (Cpg+Cgd) / (Cst+Clc+Cgd+Cpg) respectively; and the capacitance ratios of all the subpixels are the same in general.

Owner:HANNSTAR DISPLAY CORPORATION

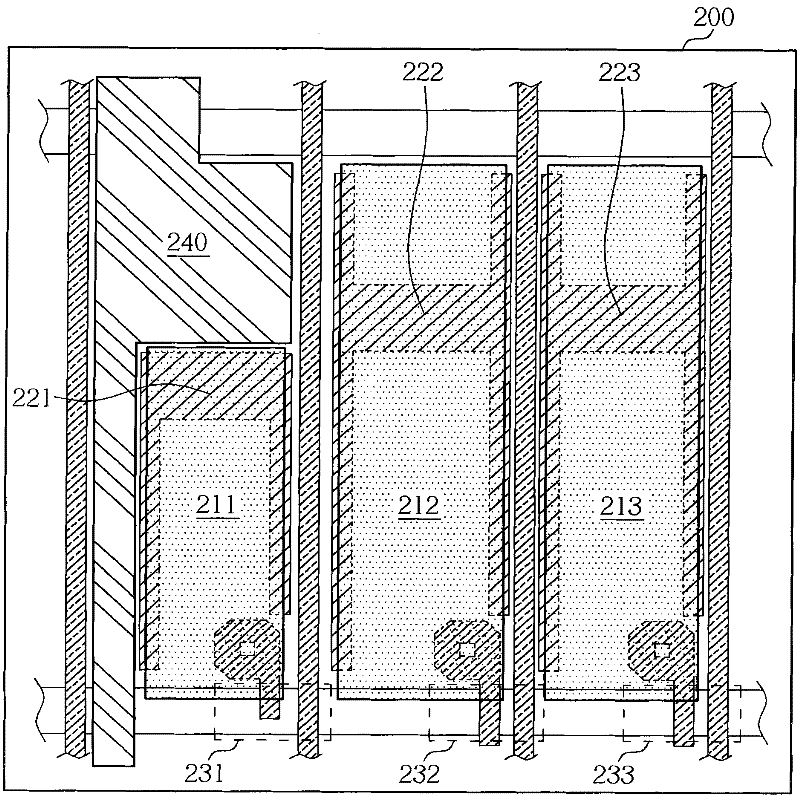

Thin-film transistor array substrate, display panel and display device

InactiveCN105489610AIncrease opening ratioSolve the problem of large occupied area and low pixel aperture ratioSolid-state devicesNon-linear opticsDisplay deviceAperture ratio

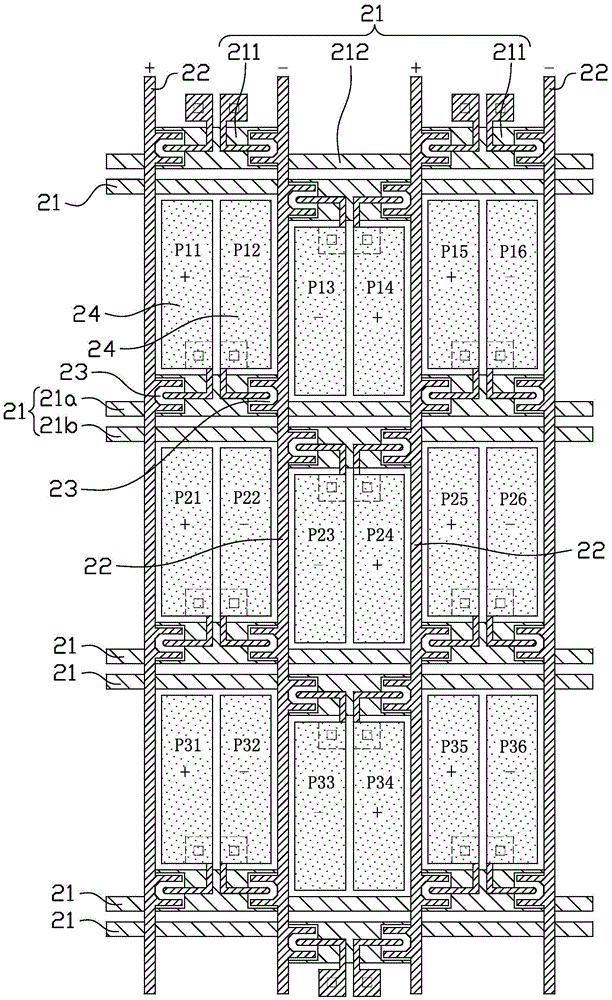

The invention provides a thin-film transistor array substrate. The thin-film transistor array substrate comprises a plurality of scanning lines, a plurality of data lines, a plurality of TFTs and a plurality of pixel electrodes, which are arranged on a substrate, wherein each pixel electrode is connected with the corresponding scanning line and data line through the corresponding TFT; the thin-film transistor array substrate has a double-scanning line pixel array structure; the plurality of data lines divide each scanning line in the plurality of scanning lines into a plurality of first scanning segments and a plurality of second scanning segments; the plurality of first scanning segments are connected with the TFTs; the plurality of second scanning segments are not connected with the TFTs; the first scanning segments and the second scanning segments are located between two adjacent data lines; the first scanning segments and the second scanning segments on each scanning line are alternately distributed along the length direction of the scanning lines; and the line widths of the second scanning segments are smaller than those of the first scanning segments. According to the thin-film transistor array substrate, the area of a pixel electrode can be relatively improved by reducing the line widths of the second scanning segments; and the aperture ratio of the pixel is improved. The invention further provides a display panel and a display device with the thin-film transistor array substrate.

Owner:KUSN INFOVISION OPTOELECTRONICS

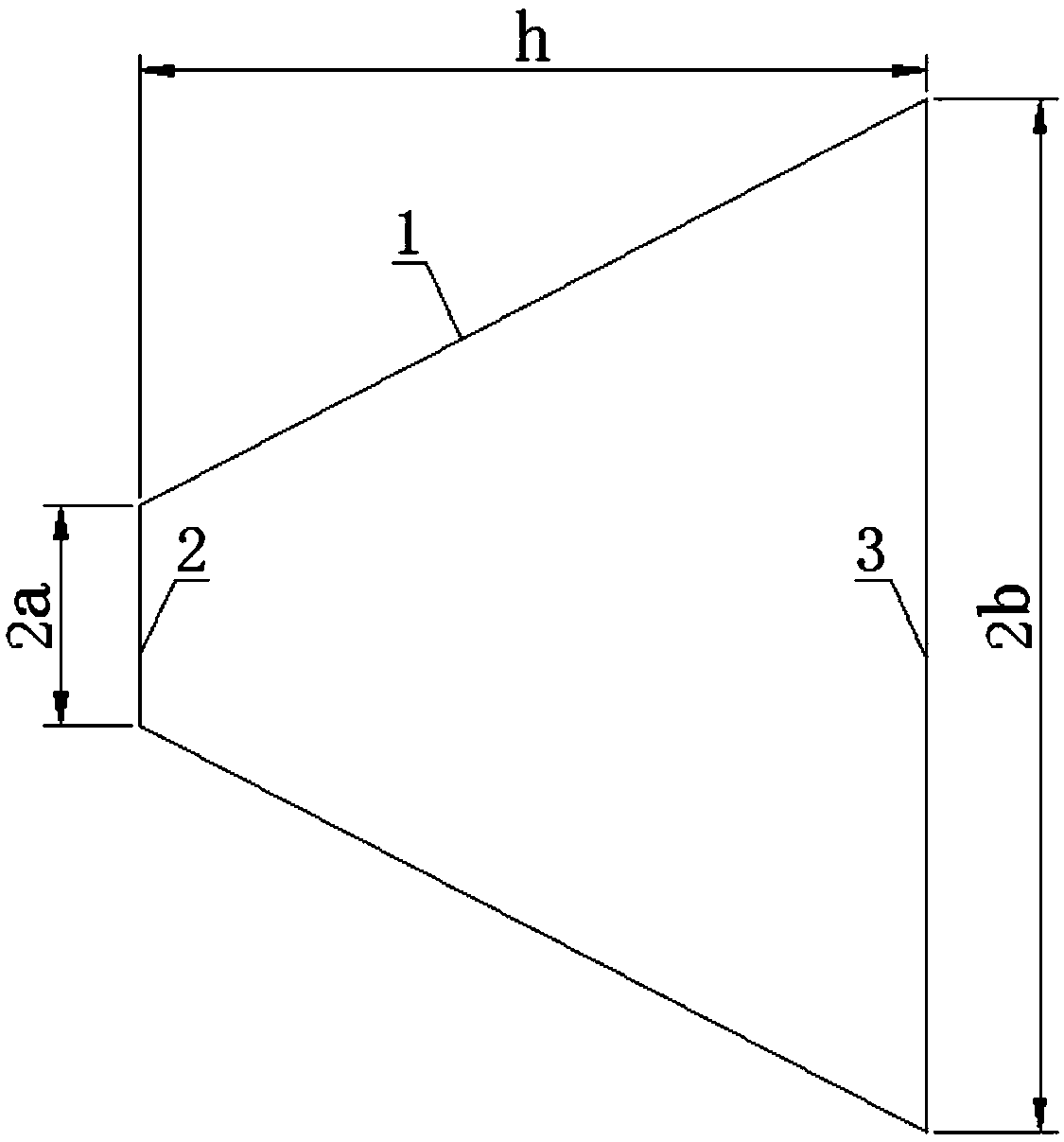

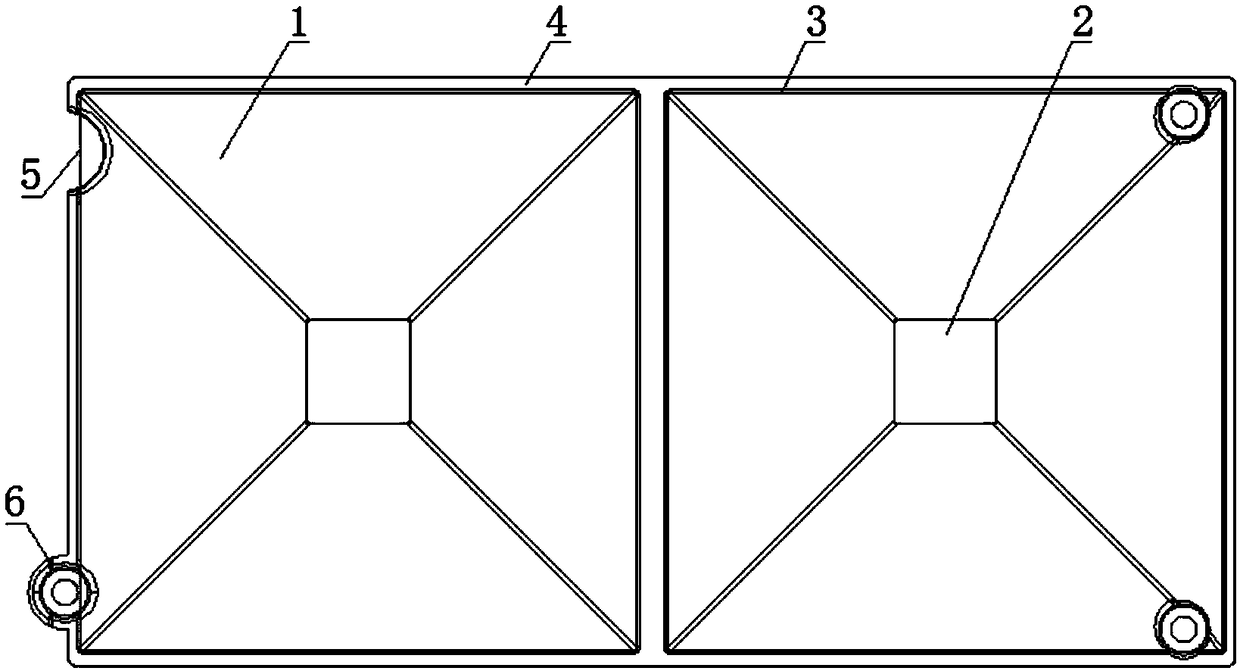

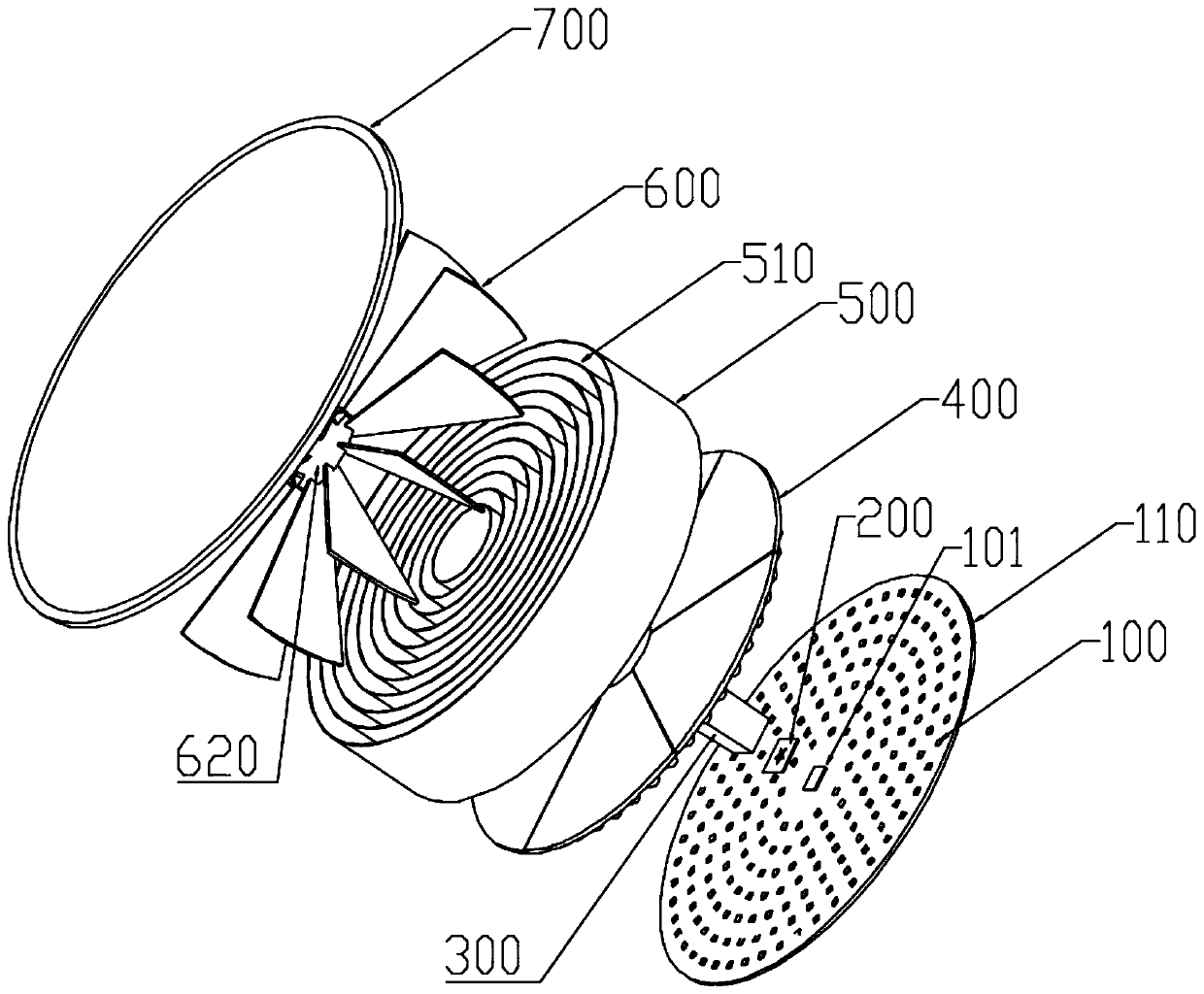

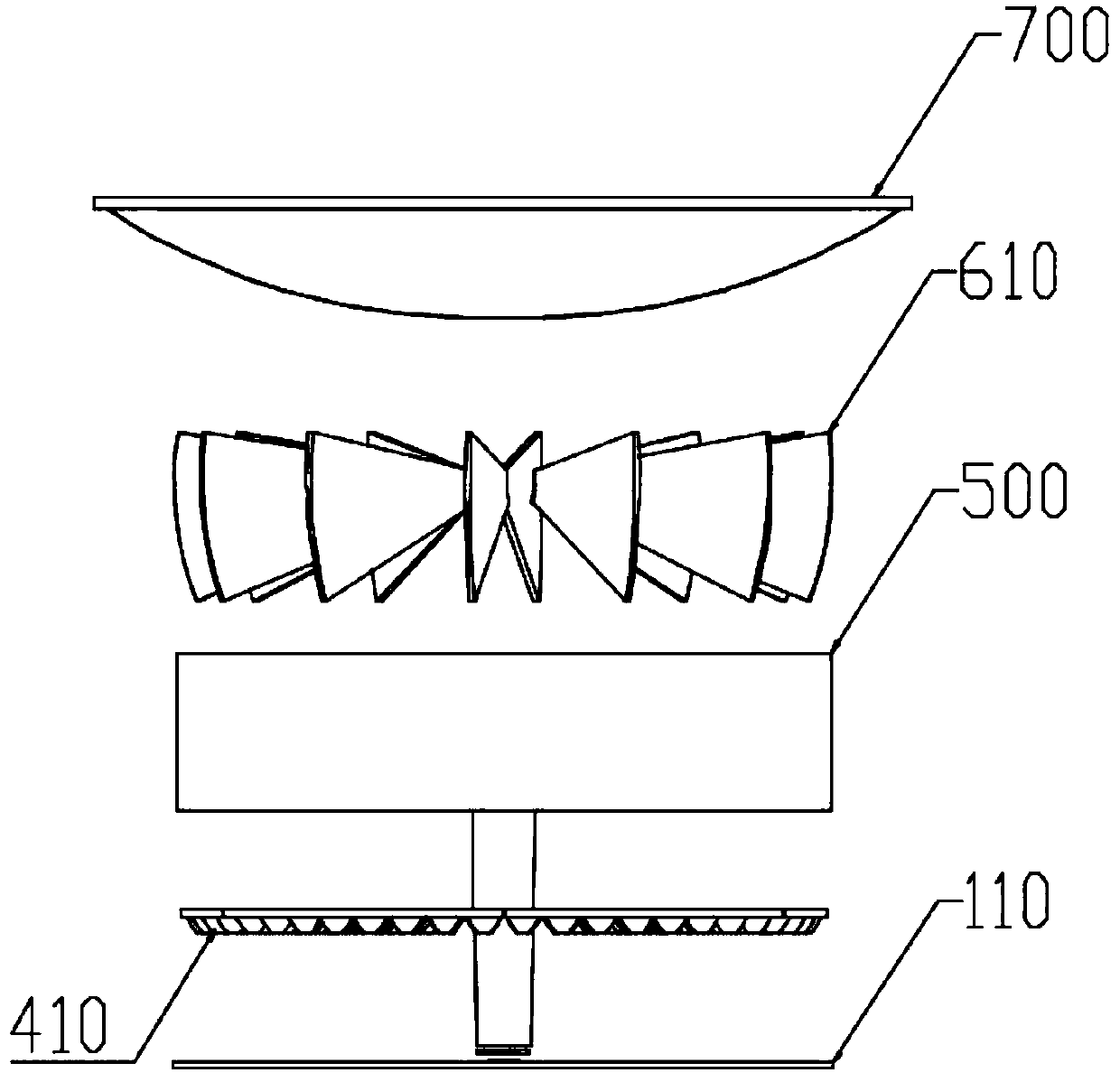

Lens, lens array and lighting device

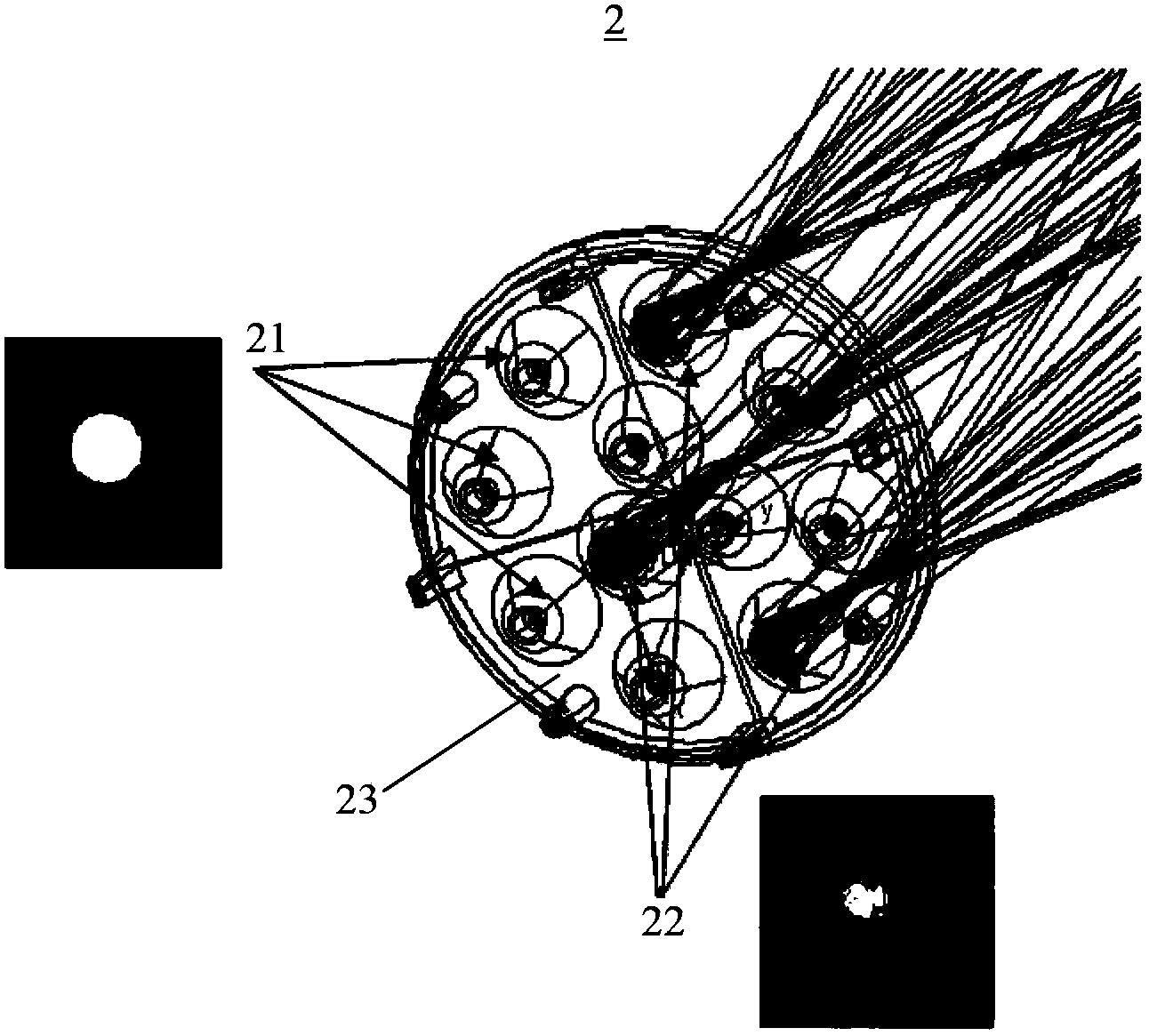

InactiveCN103574501ACompact structureCapable of variable correlated color temperaturePlanar light sourcesLight source combinationsEffect lightThree dimensional surface

The invention provides a lens, a lens array and a lighting device. The lens comprises a first surface and a second surface. The first surface comprises a light incident plane and a full reflecting surface, wherein light enters the lens through the light incident plane, and part of light entering the lens is fully reflected by the full reflecting surface. The second surface comprises a light outlet plane. The light incident plane comprises a plurality of three-dimensional surfaces corresponding to different light sources, part of light coming from one light source enters the lens from the three-dimensional surface corresponding to the light source, and another part of light enters the lens from the three-dimensional surface which does not correspond to the light source. The lens is compact in structure, and colors can be mixed evenly.

Owner:SITECO GMBH

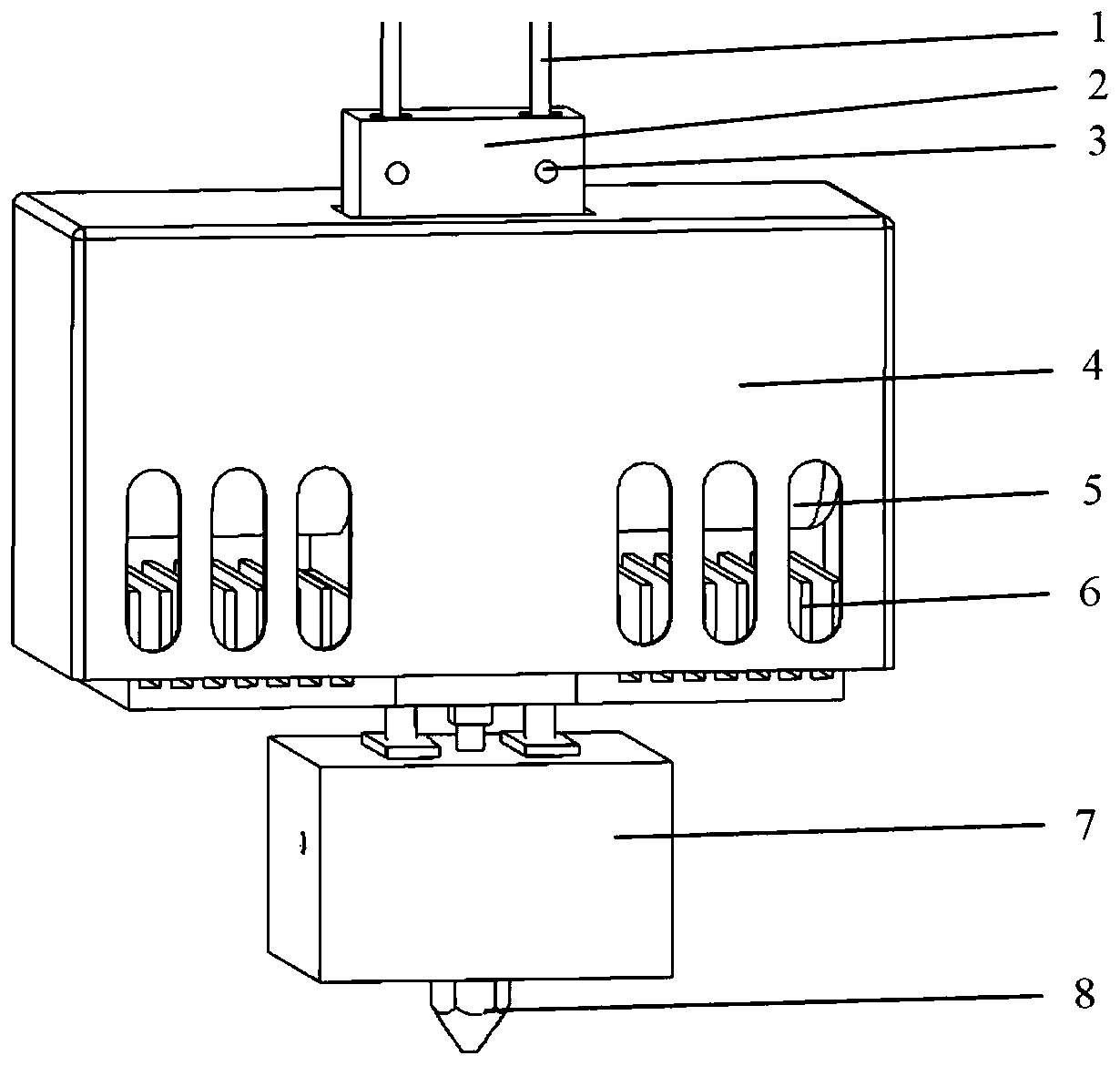

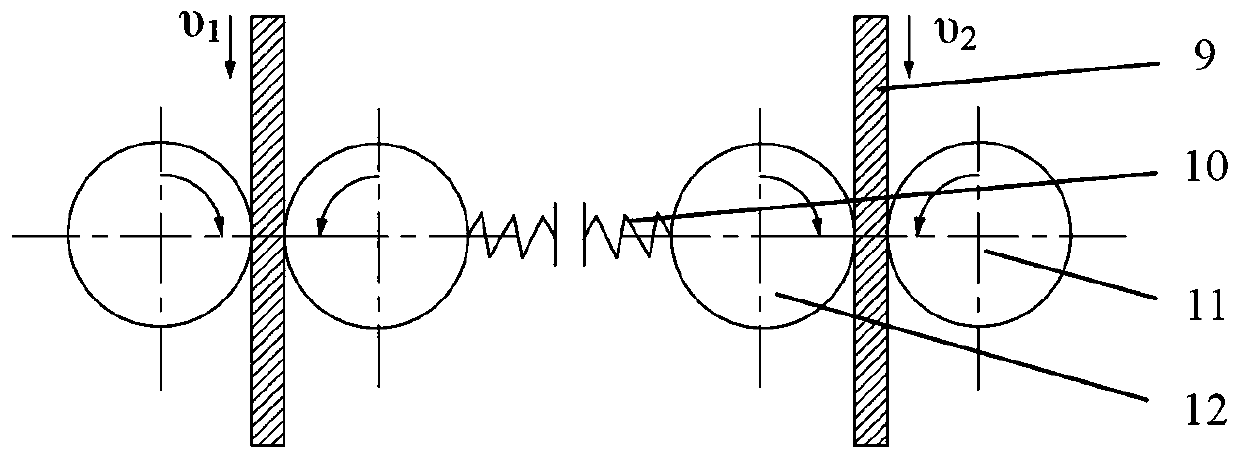

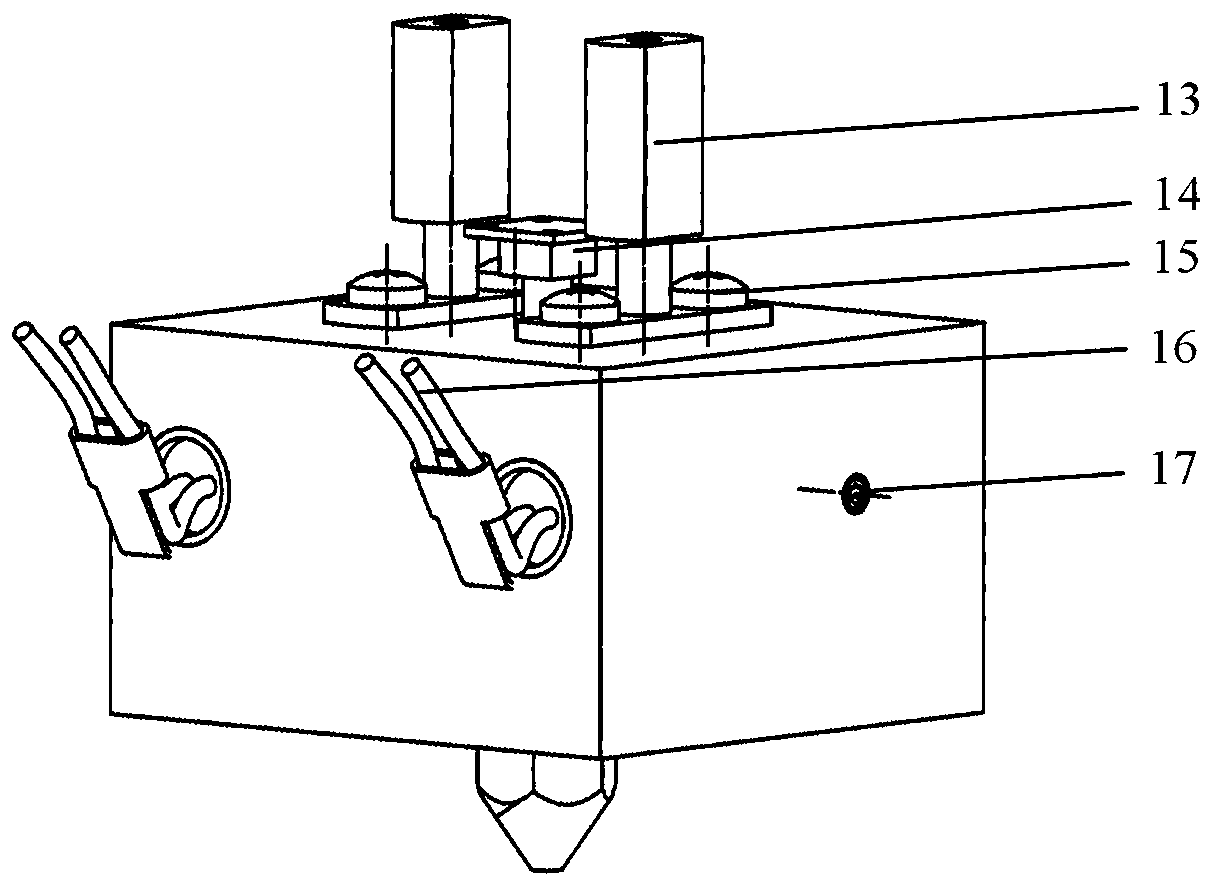

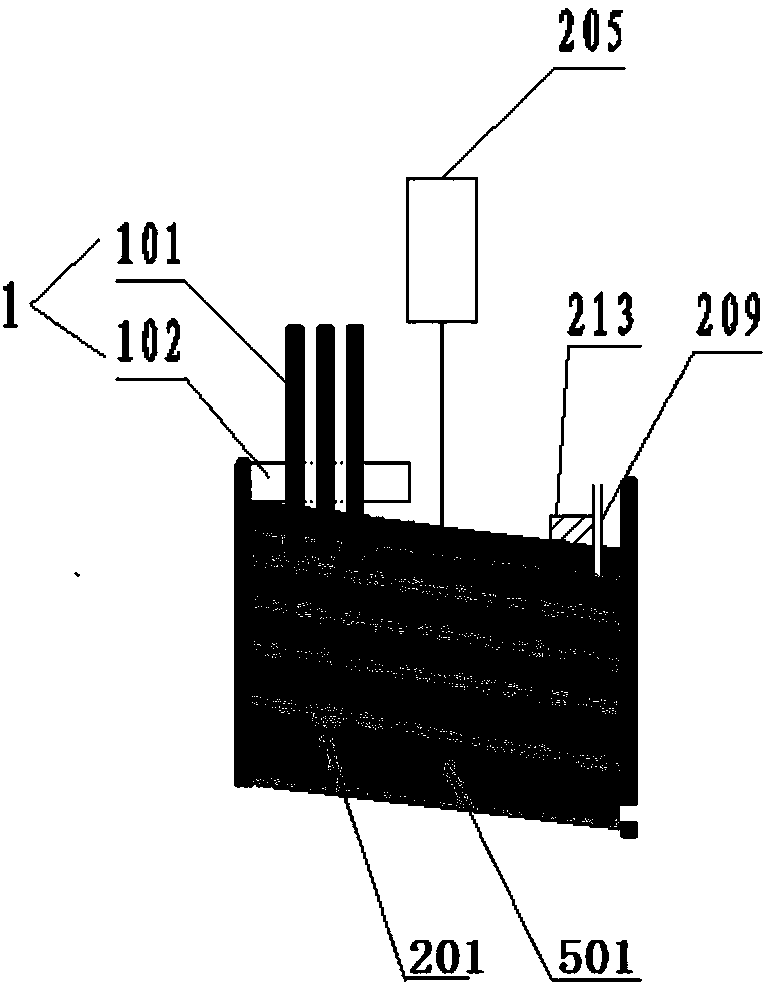

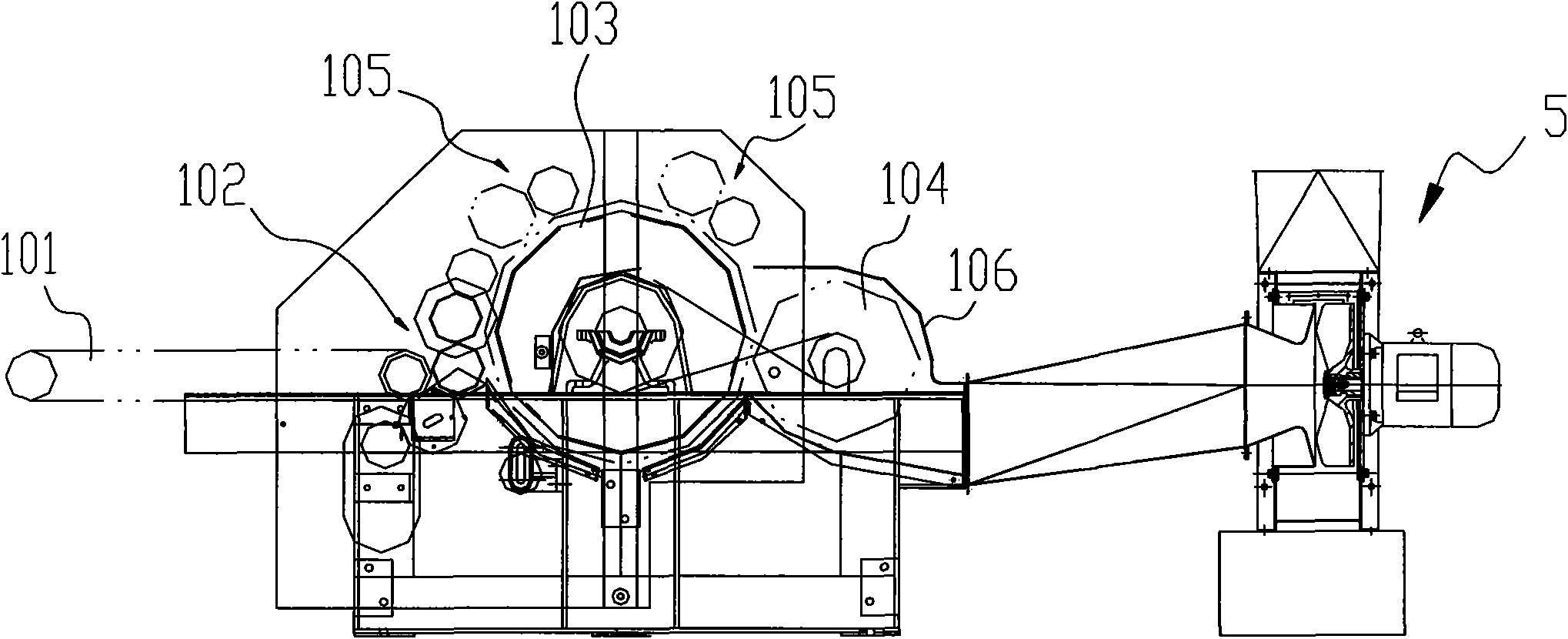

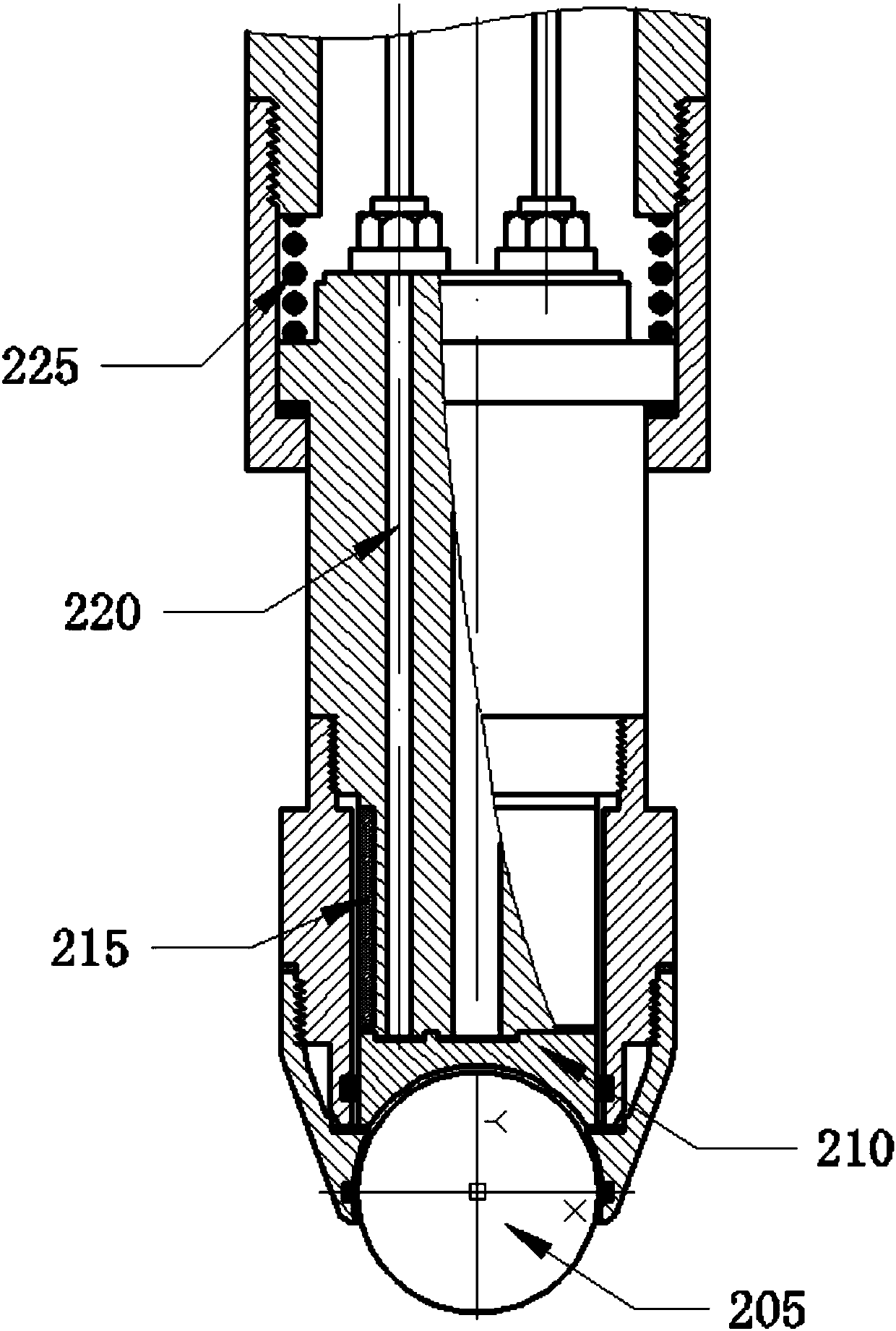

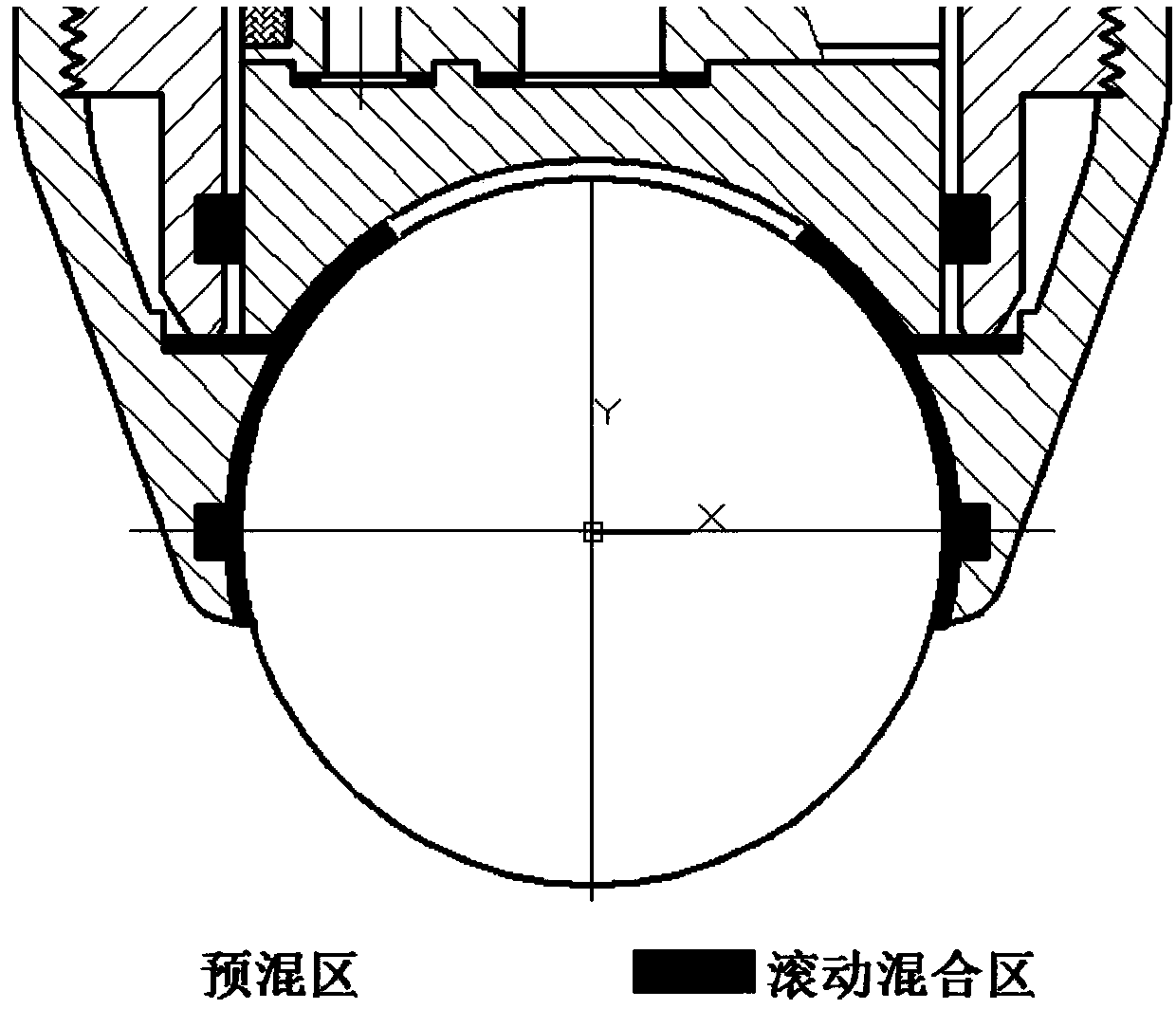

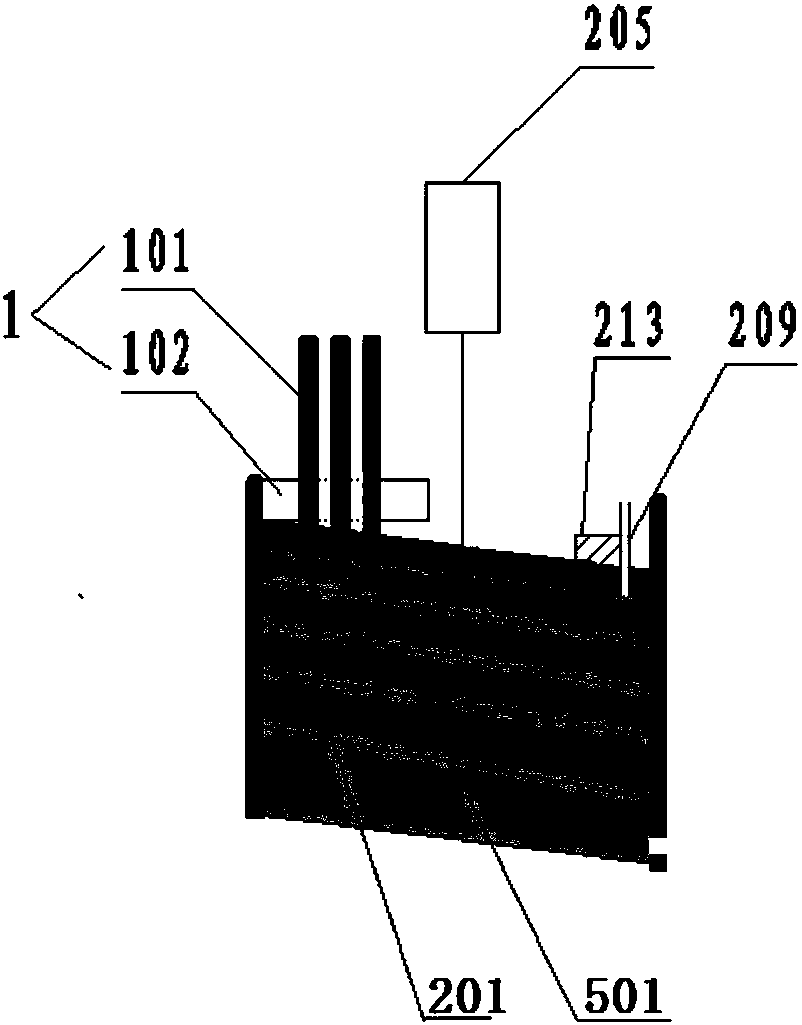

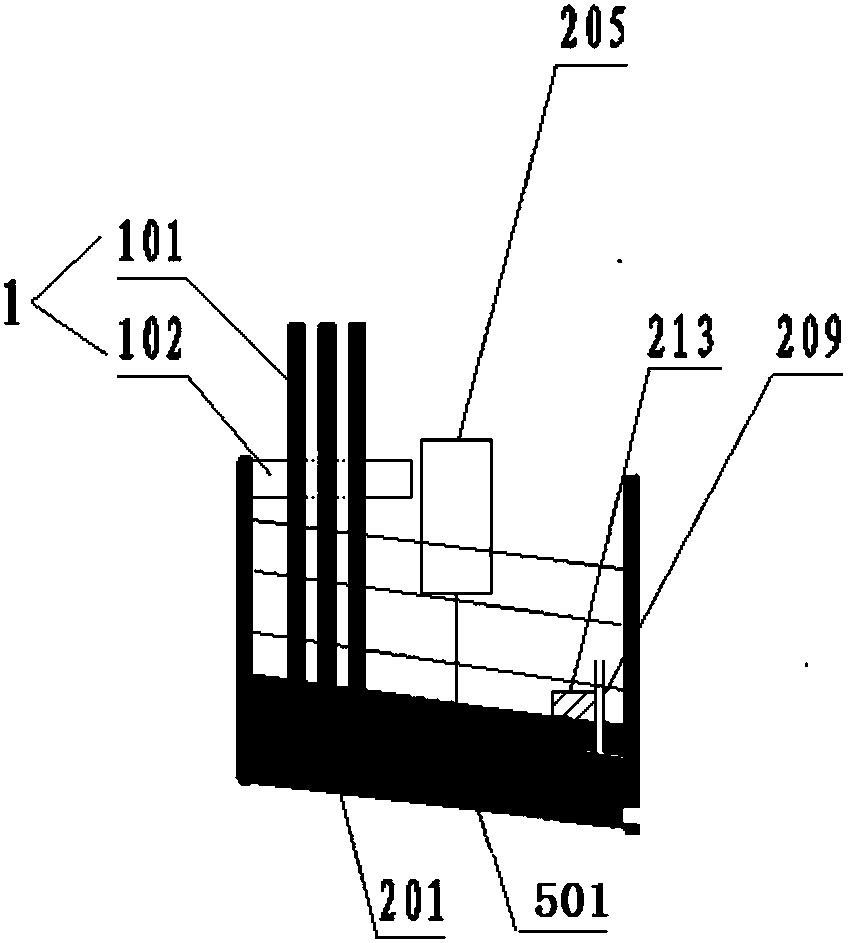

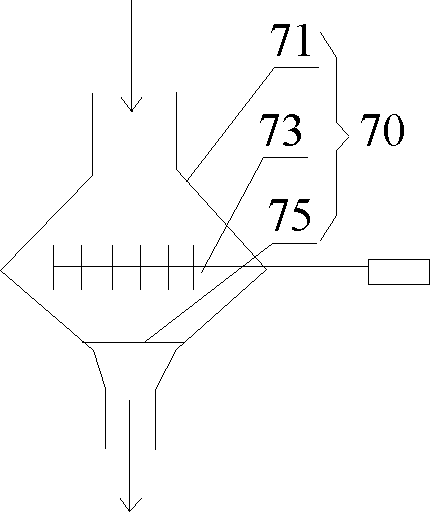

Color mixing 3D printing nozzle device based on FDM technology and discharging method thereof

InactiveCN110435145AIncrease profitEven color mixingManufacturing heating elements3D object support structuresYarnColor printing

The invention discloses a color mixing 3D printing nozzle device based on an FDM technology and a discharging method thereof. Color mixing printing can realize the color of a product and has more advantages compared with single-color printing. The color mixing 3D printing nozzle device based on the FDM technology comprises a feeding mechanism and a mixing heating mechanism. The feeding mechanism comprises a feeding shell, a feeding guide block and a feeding driving assembly. The feeding driving assembly comprises a feeding motor, a driving conveying wheel, an extruding conveying wheel, an extruding sliding block and an extruding spring. The mixing heating mechanism comprises a heating mixing block, a heating guide pipe, a color mixing stirrer, a nozzle, a cooling fin and a heating wire. The color mixing stirrer comprises a connecting shaft, a stirring fan and a stirring motor. According to the two-inlet-one-outlet type color mixing nozzle device, two thermoplastic wire yarns with different colors can be sent to a color mixing cavity of the heating mixing block for color mixing by controlling the mixing proportion of different color wire yarns or setting the change trend of the mixing proportion.

Owner:HANGZHOU DIANZI UNIV

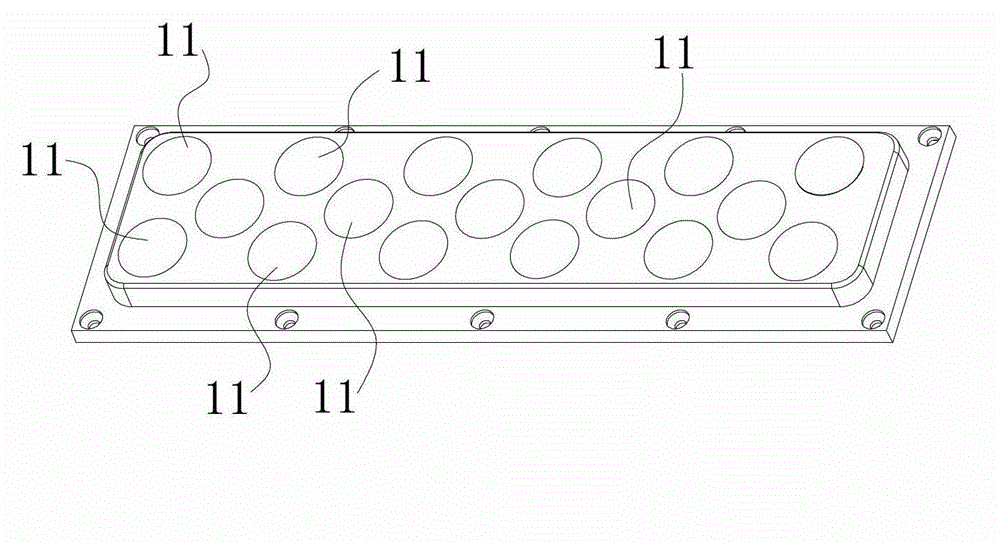

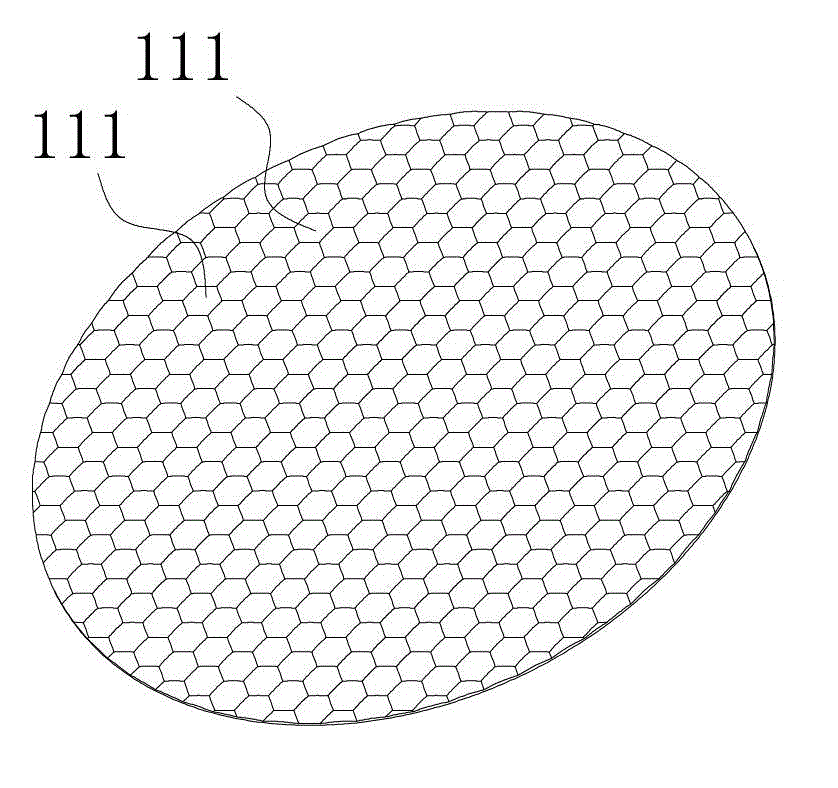

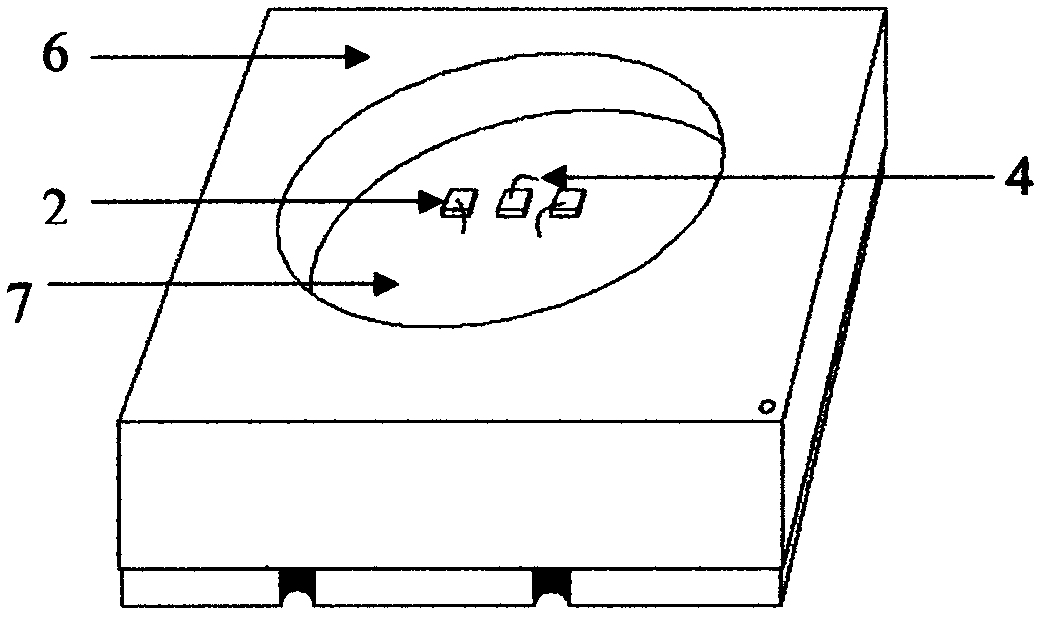

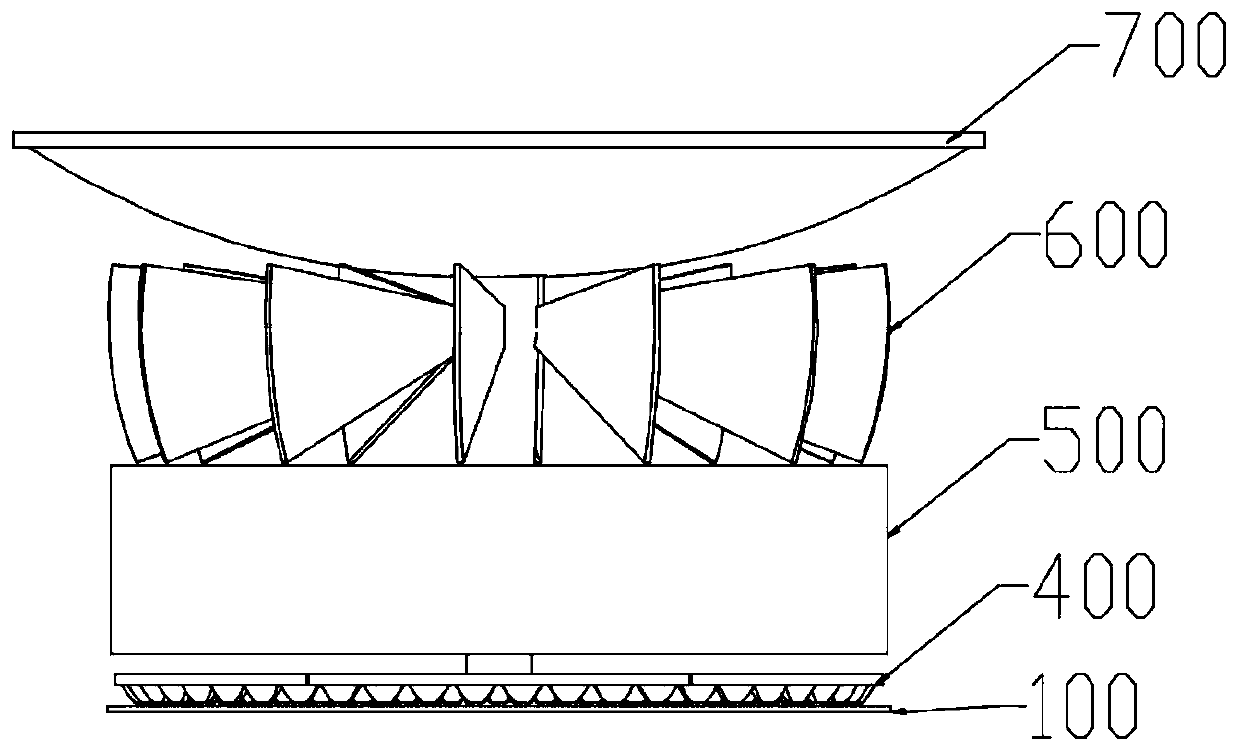

Light mixing lens module

InactiveCN102943992AAchieve the effect of color mixingIncrease the light effect of color mixingLight source combinationsPoint-like light sourceEngineeringMixing effect

The invention discloses a light mixing lens module, which comprises a lens module, a mounting base plate, a heat radiating assembly and a plurality of LED (light emitting diode) lamps, wherein the LED lamps are respectively arranged on the mounting base plate, the mounting base plate is fixedly arranged on the heat radiating assembly, each LED lamp comprises first-color LEDs, second-color LEDs and third-color LEDs, each first-color LED, each second-color LED and each third-color LED are formed into a group, the lens module is provided with a plurality of lens surfaces, each lens surface respectively corresponds to each LED lamp, and each lens surface comprises a plurality of light transmission surfaces which are distributed in an array way. The light-mixing lens module has the advantages that the light mixing effect is good, and the structure is simple.

Owner:ELECTRICITY FACILITIES GUANGRI GUANGZHOU CO LTD

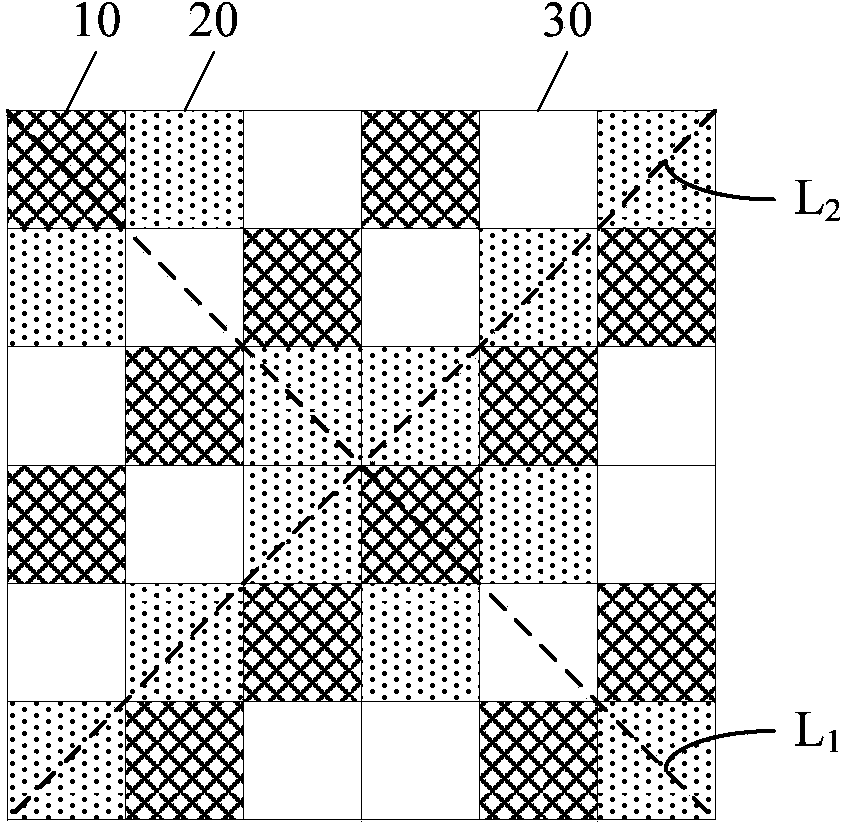

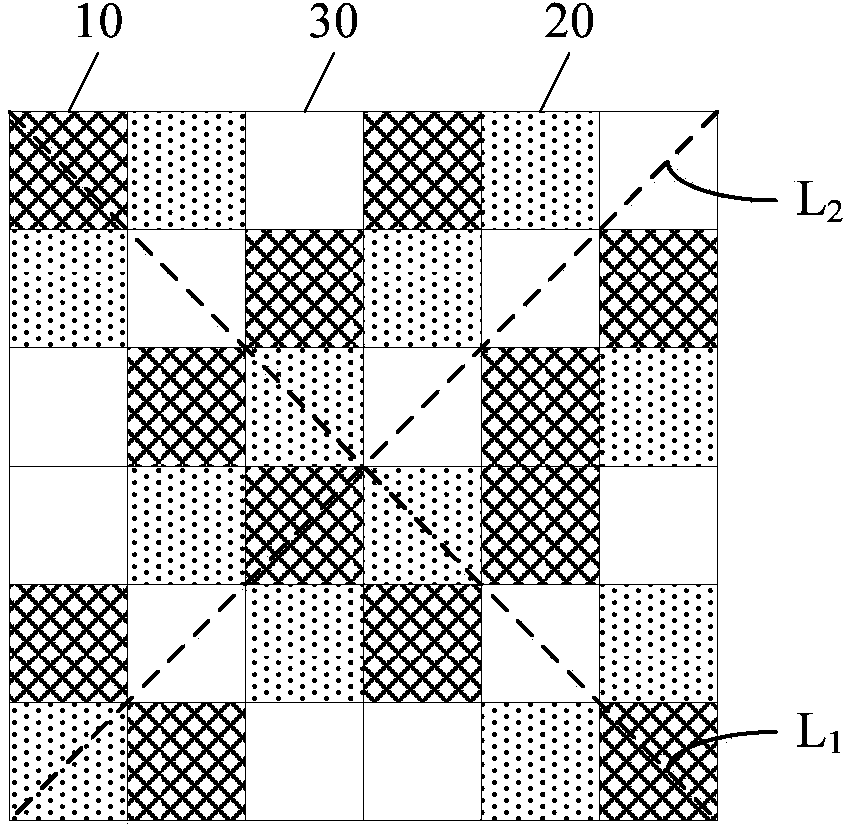

Pixel arrangement structure and display device

InactiveCN104282228AImprove display qualityEven color mixingIdentification meansDisplay deviceComputer science

The embodiment of invention provides a pixel arrangement structure and a display device, relating to the technical field of display. Uniform color mixing can be realized so that the display quality can be improved. The pixel arrangement structure comprises a plurality of 6-order matrix units arranged in an array, wherein each 6-order matrix unit comprises 2*2 3-order matrix subunits, and each 3-order matrix subunit comprises 3*3 sub-pixel units, wherein a first sub-pixel unit, a second sub-pixel unit and a third sub-pixel unit are arranged in each row and each column in each 3-order matrix subunit. The pixel arrangement structure is used for manufacturing the display device.

Owner:BOE TECH GRP CO LTD +1

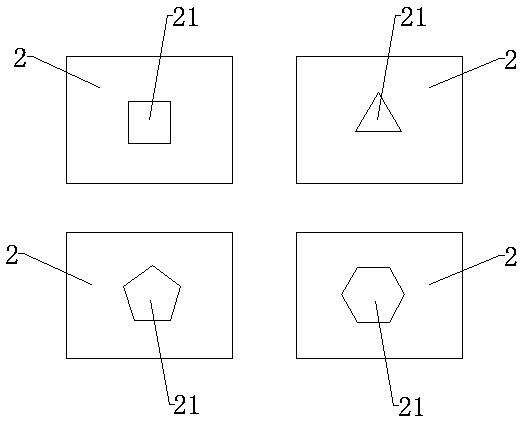

LED chip structure with electrode having opening

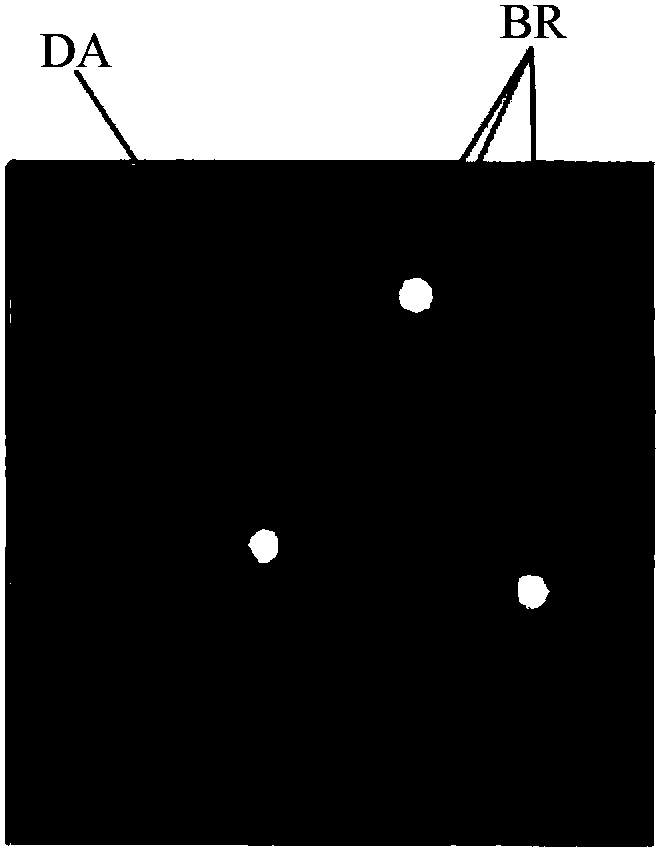

PendingCN109980059AImprove flatnessAvoid spheroidsSemiconductor devicesDisplay deviceSemiconductor chip

The invention provides an LED chip structure with an electrode having an opening. The LED chip structure comprises an epitaxial structure and an electrode disposed on the epitaxial structure, the topof the electrode is disposed adjacent to the epitaxial structure, the bottom of the electrode is disposed away from the epitaxial structure, and the electrode is provided with at least one opening extending from the bottom of the electrode toward the top of the electrode. By adsorbing excess solder at the opening of the electrode, a spheroid is prevented from occurring in a soldering process, so that a semiconductor chip generates no phenomenon of offset or tilt caused by the soldering, and the flatness of a light emitting surface is effectively improved. Especially on displays and visualization products, the LED chip structure has the advantages of uniform light emitting direction, uniform color mixing, etc.

Owner:XIAMEN QIANZHAO SEMICON TECH CO LTD

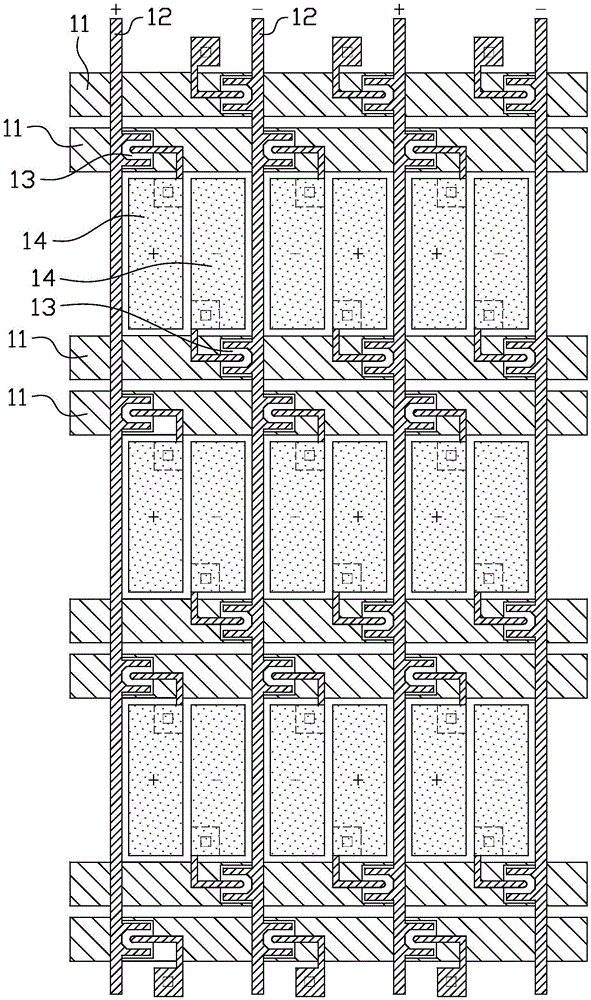

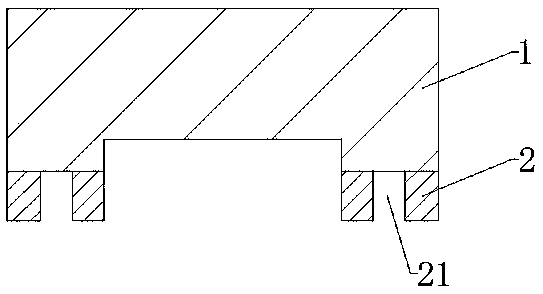

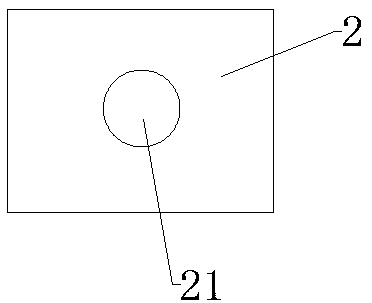

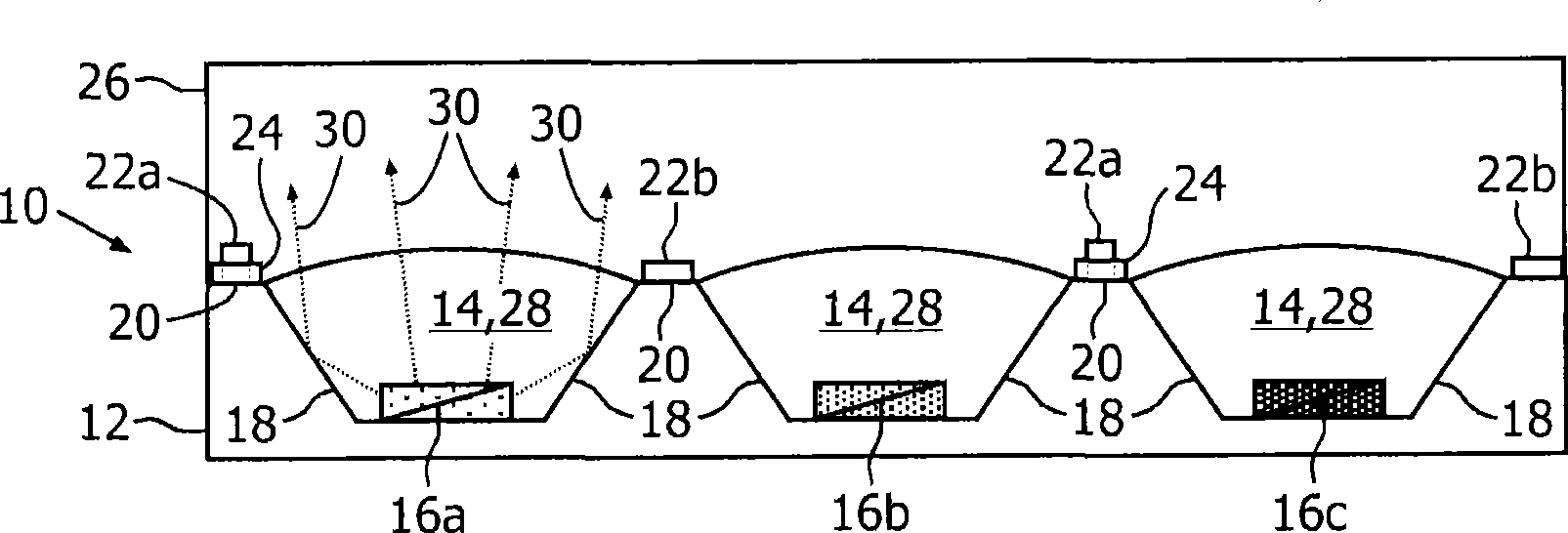

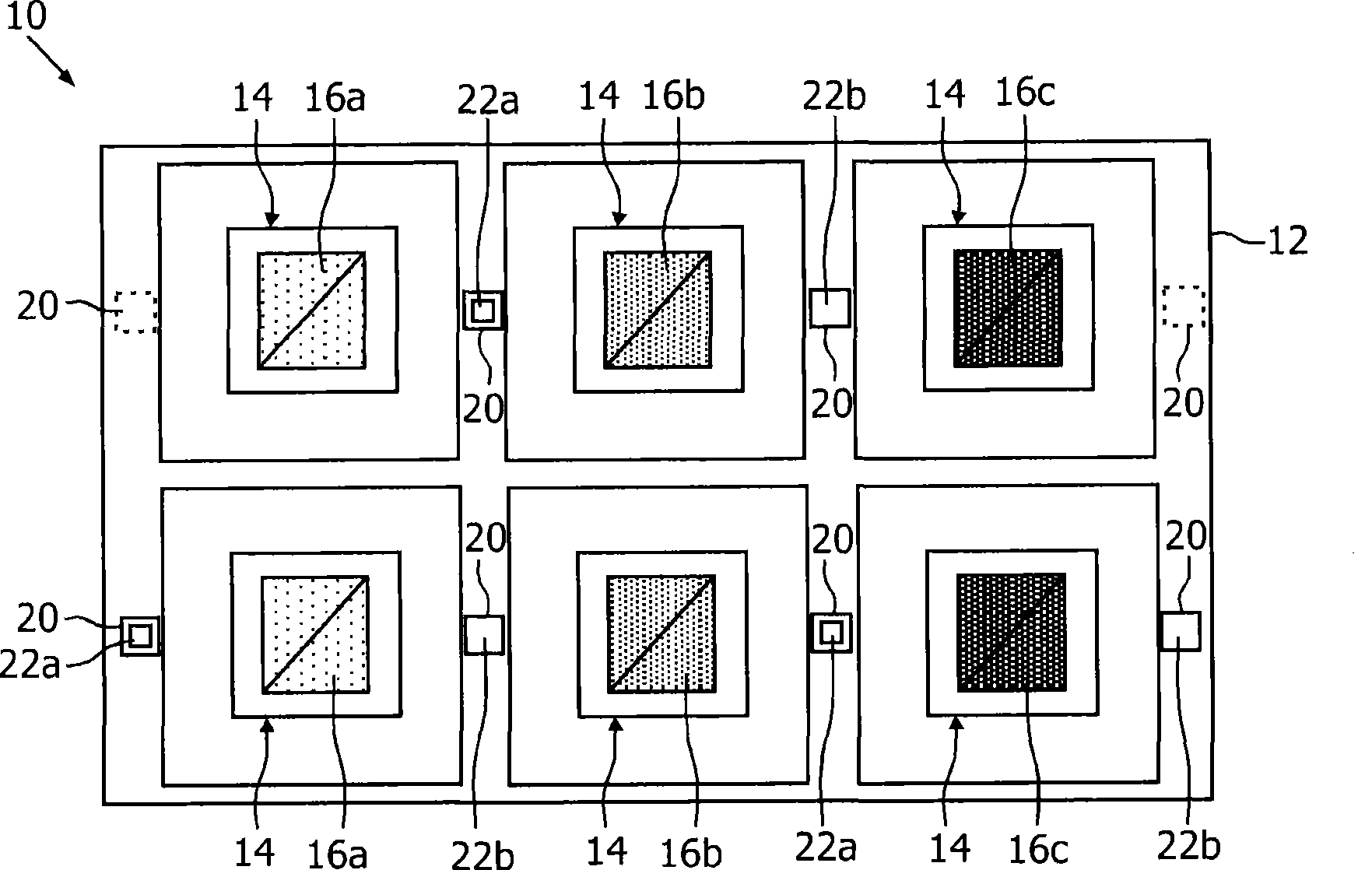

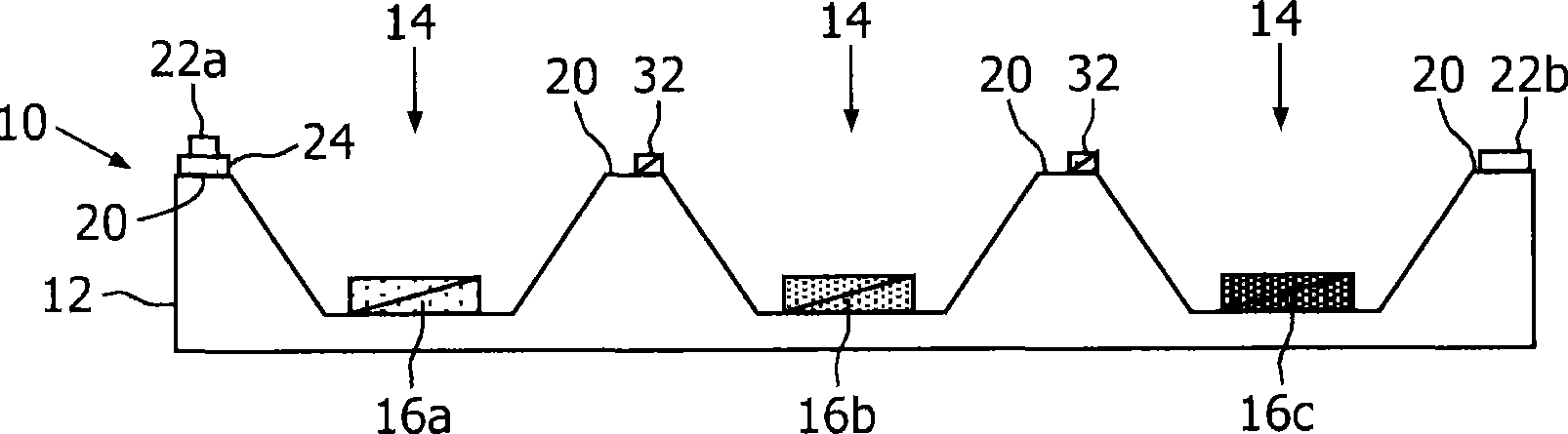

Light emitting diode module

InactiveCN101421844AAccurate detectionReduce outputElectric circuit arrangementsSolid-state devicesColor compensationEngineering

The present invention relates to a light emitting diode (LED) module (10) comprising a substrate (12) having plural indents (14) and flattish portions (20) in between the indents, and LEDs (16) mounted in the indents. The LED module is characterized by at least one of sensors (22) and additional LEDs (32) provided at the flattish portions. This allows increased sensor detection accuracy and / or color compensation. The present invention also relates to a method for the manufacturing of such an LED module.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

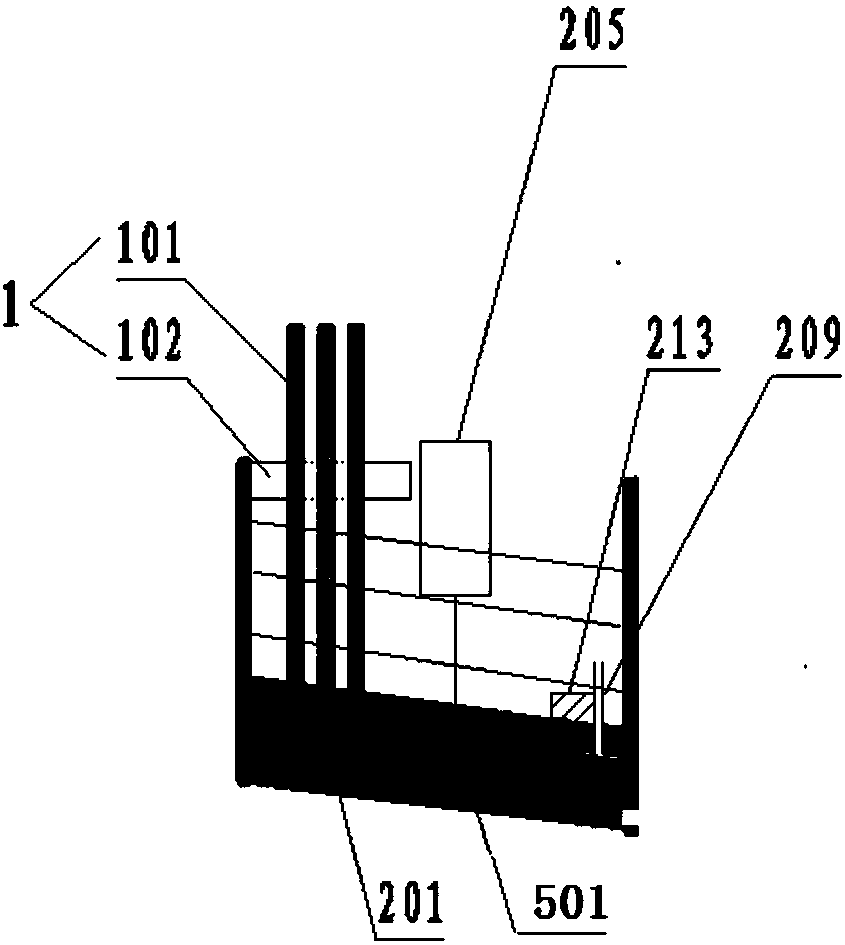

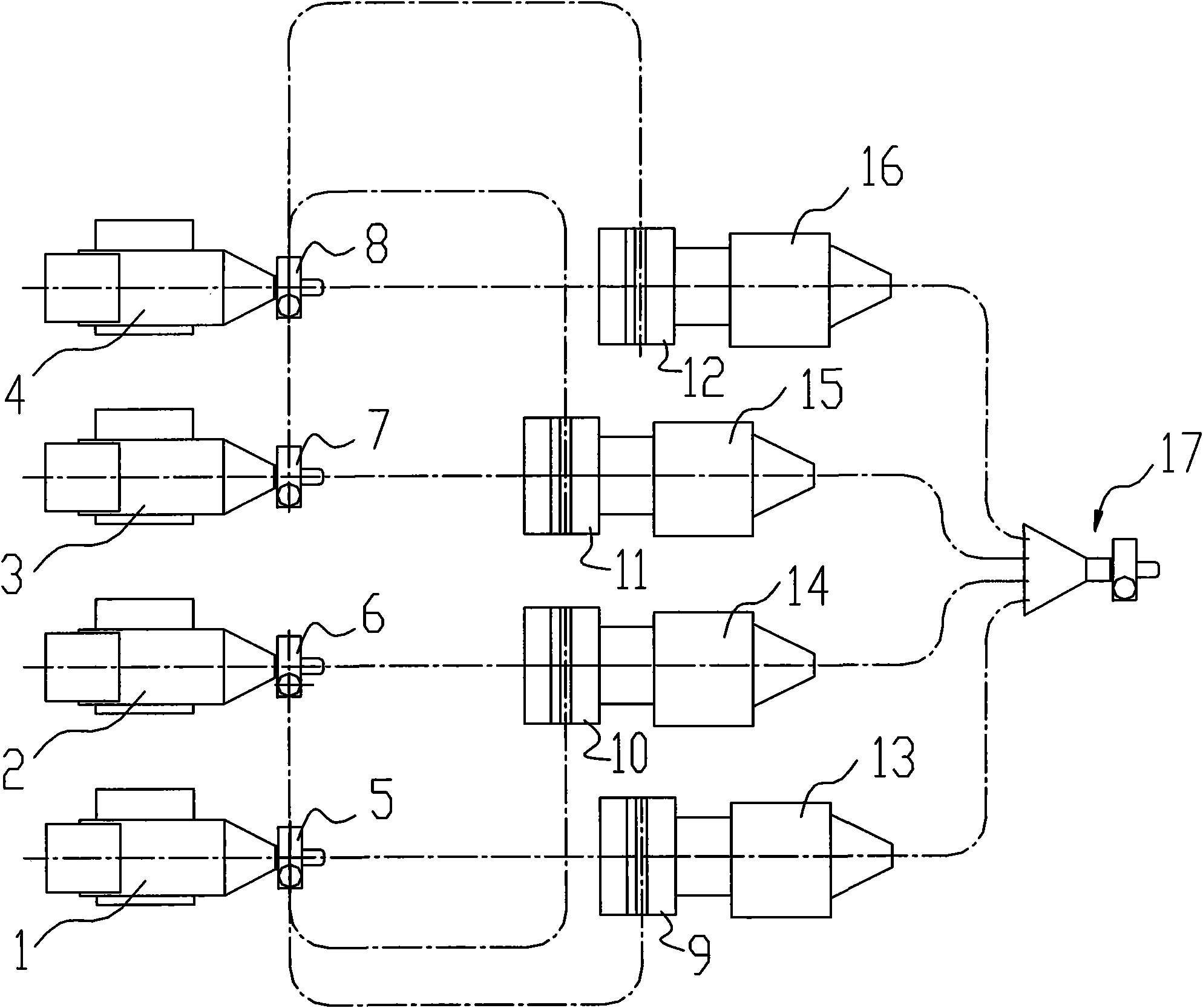

Rapid forming full-color 3D printer device and printing method thereof

PendingCN108215161AEasy to controlSolve single color3D object support structuresApplying layer meansWire rodMelting tank

The invention discloses a rapid forming full-color 3D printer device and a printing method thereof. The device comprises a feeding system, a molten pool system, a sprayer system, a heating system anda control system. The feeding system is connected with the input end of the molten pool system. The output end of the molten pool system is connected with the sprayer system. The heating system is connected with the molten pool system. The control system is connected with the feeding system, the molten pool system, the sprayer system and the heating system. According to the method, various colorsneeded for model printing are calculated, a feeding motor of the feeding system is then controlled, the number of wires different in color is accurately controlled, meanwhile, the temperature of molten pools is controlled, and any color of raw materials can be formed through mixing of red, green, blue, yellow and cyan; and the raw materials are gradually conveyed to a printing sprayer through themolten pool system, and then a full-color model is printed. By means of the rapid forming full-color 3D printer device and the printing method thereof, full-color printing can be achieved, the beneficial effects that color mixing is uniform, feeding is uniform and smooth, sprayer blockage is avoided, the speed is high, the intelligent degree is high, the structure is simple, and cost is low are achieved; and popularization and usage are easy.

Owner:桂林凯歌信息科技有限公司

Method for preparing grey flax yarn

The invention relates to the production field of grey flax yarns, in particular to a method for preparing the grey flax yarn. Before fed onto a slot, a natural color chemical fiber and a black chemical fiber are mixed section by section according to a proportion; by adoption of manual tearing and stirring, a cotton block becomes thinner; and the thinner cotton block is fed to the slot and rolled finally. By adoption of the technical scheme, the process is simple, the cotton roll has uniform mixed color, and the quality is stable.

Owner:李清保

Combined color blending machine

InactiveCN102041587AEven color mixingContinuous productionFibre mixingFibre cleaning/openingDifferential pressureEngineering

The invention discloses a combined color blending machine which comprises a blending and opening machine unit, a conveying fan unit, a pneumatic control hopper unit, an opening machine unit and a blending device, wherein a primary fan is arranged at the output end of each blending and opening machine, each primary fan is equipped with a fiber conveying pipe, and each fiber conveying pipe is connected with an input port at the upper part of each pneumatic control hopper; each pneumatic control hopper is provided with a secondary fan, and a pair of output rollers are arranged at an output port at the lower part of each pneumatic control hopper; the primary fans are controlled by micro-differential pressure sensors arranged in the fiber conveying pipes, the generated wind pressure can keep the total fiber conveying quantity of the fiber conveying pipes unchanged in unit time, the secondary fans are controlled by the micro-differential pressure sensors arranged in the pneumatic control hoppers, and the generated wind pressure can enable fiber entering into the pneumatic control hoppers to pass through the output rollers to form a fiber layer with stable unit weight, and the fiber layer is supplied to an opening machine for processing. The combined color blending machine has the characteristics of uniform color blending, continuous production, high production efficiency and the like.

Owner:青岛东佳纺机(集团)有限公司

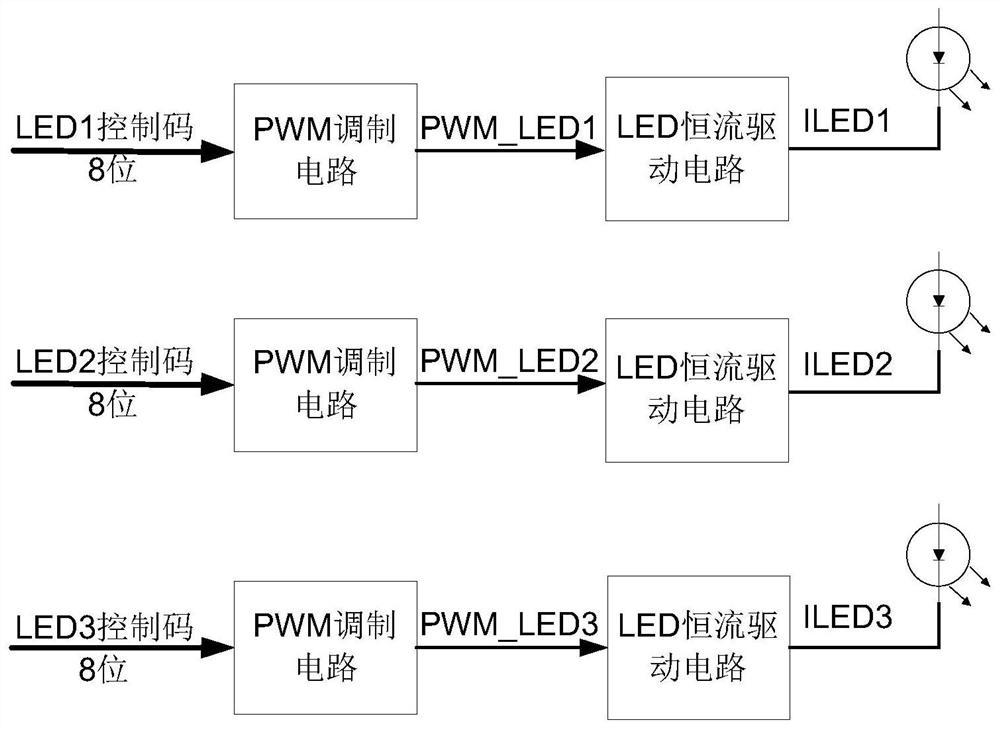

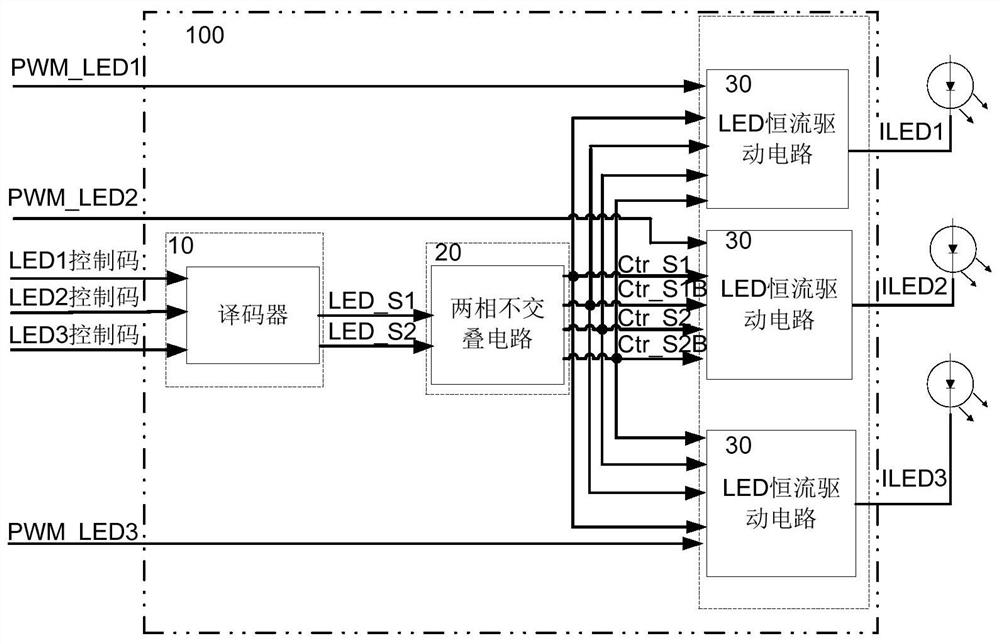

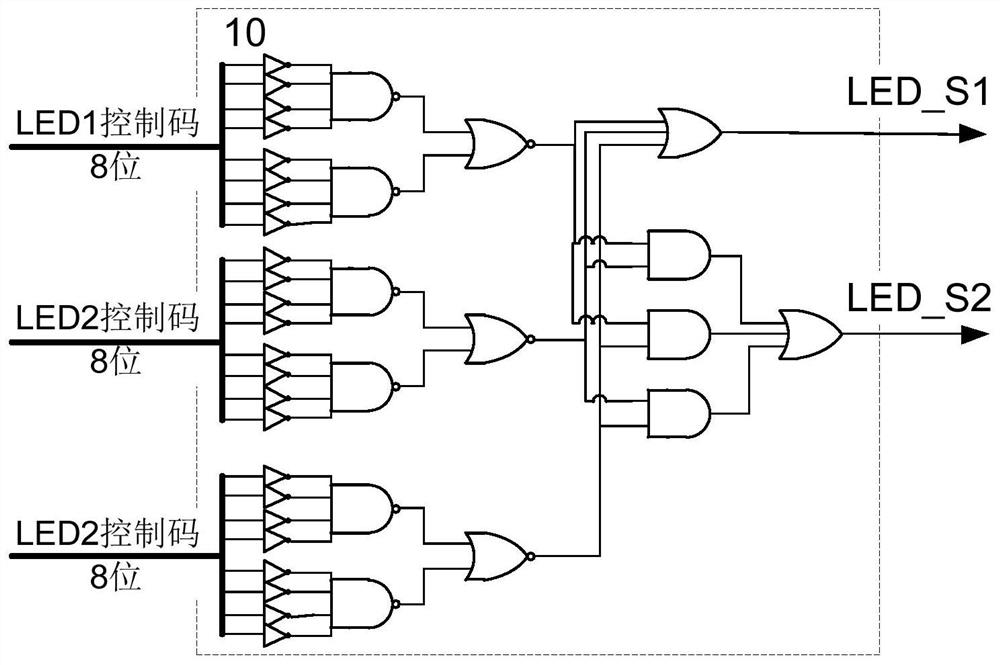

Self-adaptive adjustment three-channel colored lamp LED constant current driving circuit and method

ActiveCN113271702AEven color mixingElectrical apparatusEnergy saving control techniquesControl signalControl theory

The embodiment of the invention discloses a self-adaptive adjustment three-channel colored lamp LED constant-current driving circuit and method. The circuit comprises a decoder, a two-phase non-overlapping circuit and an LED constant-current driving circuit; the decoder is used for judging the number of lightened channels according to a first input signal and generating a first switch control signal and a second switch control signal; the two-phase non-overlapping circuit is used for modulating the first switch control signal into a first two-phase non-overlapping signal and a second two-phase non-overlapping signal, and modulating the second switch control signal into a third two-phase non-overlapping signal and a fourth two-phase non-overlapping signal; and the LED constant current driving circuit is used for controlling the on / off of the LED according to the second input signal, and outputting current according to the first two-phase non-overlapping signal, the second two-phase non-overlapping signal, the third two-phase non-overlapping signal and the fourth two-phase non-overlapping signal to control the brightness of the LED.

Owner:CRM ICBG (WUXI) CO LTD

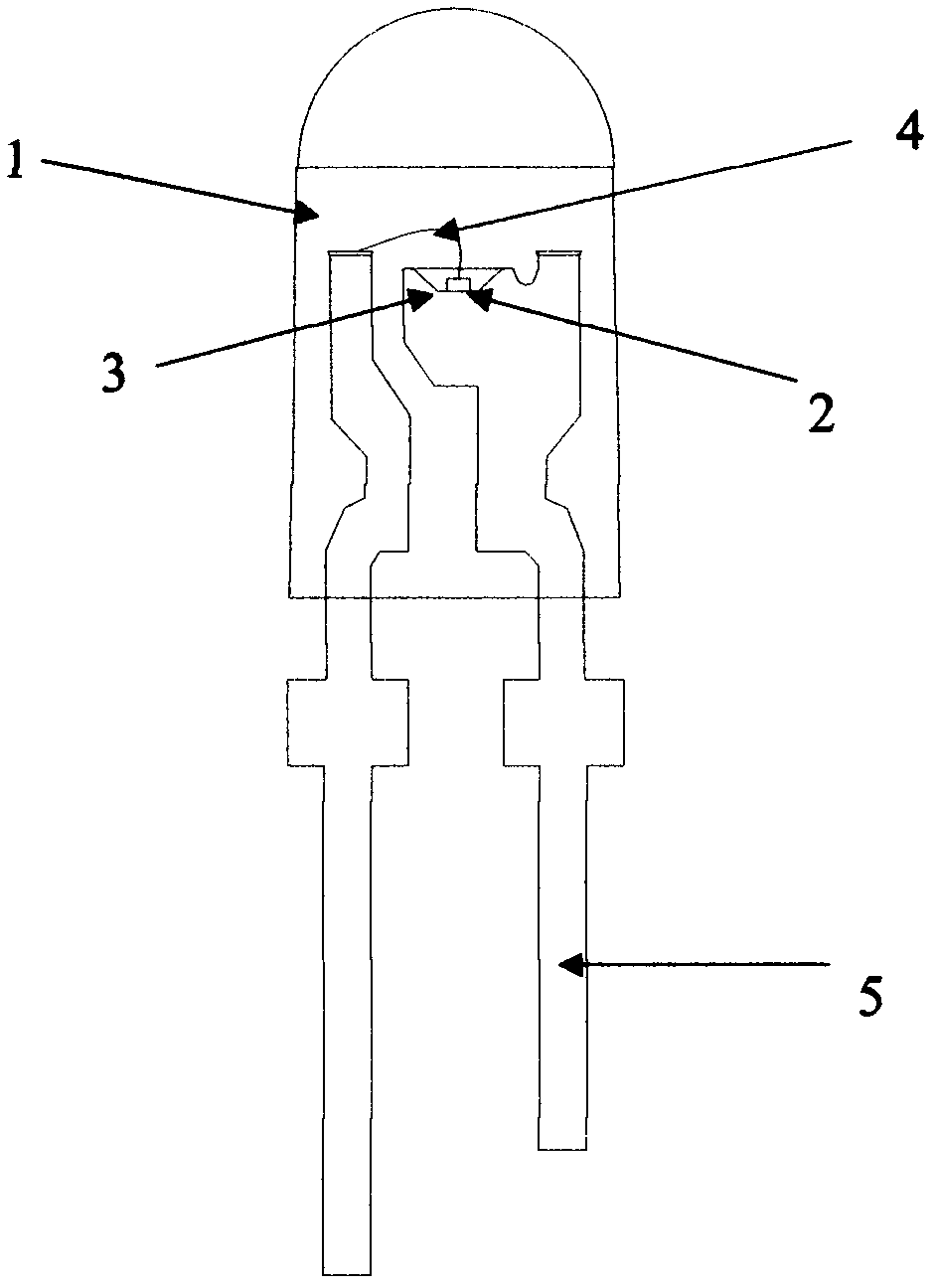

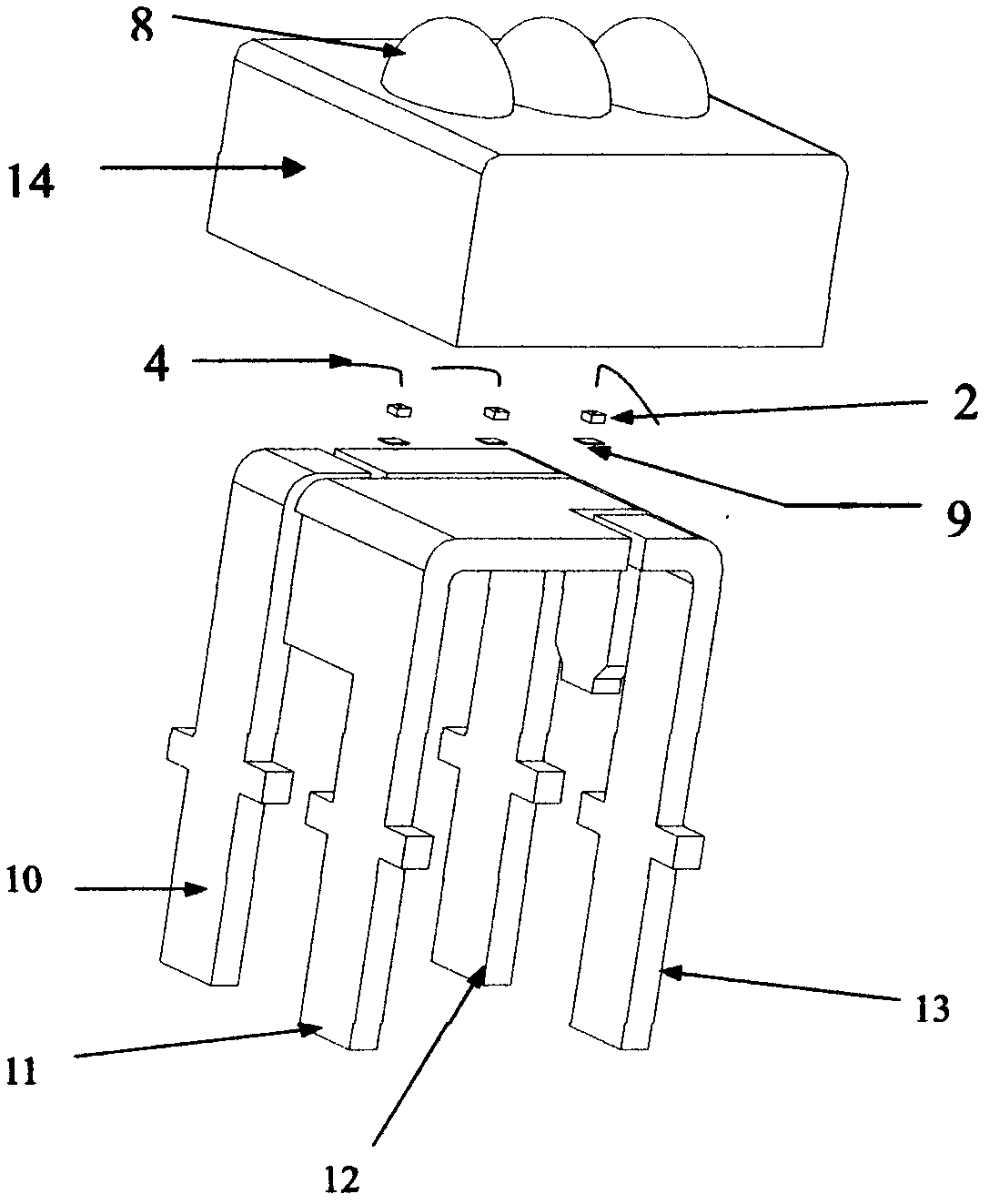

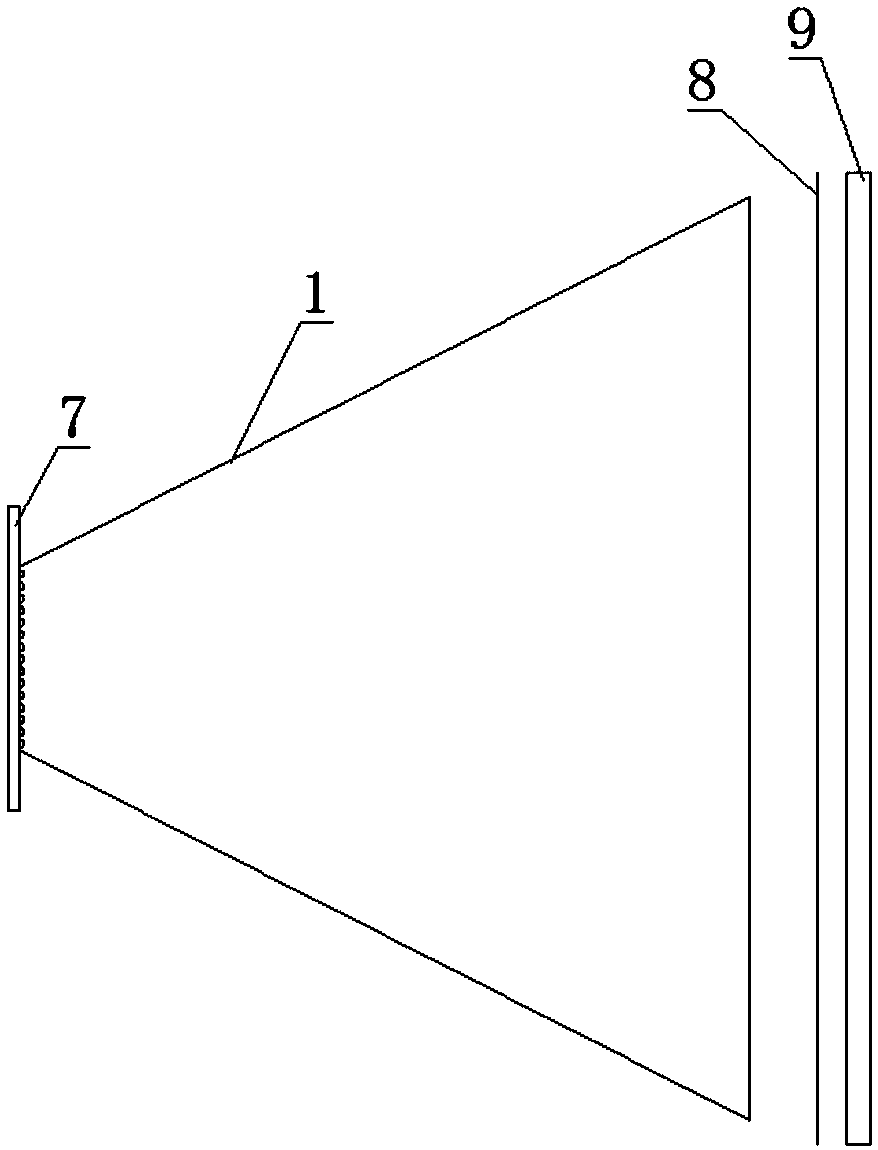

Light-emitting diode (LED) for display screen and production method

InactiveCN103050488AAvoid wire lappingSave wire lengthSolid-state devicesIdentification meansEpoxyEngineering

The invention provides a light-emitting diode (LED) for a display screen and a production method and relates to a plug-in LED for the display screen and a packaging method of the plug-in LED. Welding areas (15, 16, 17, 18 and 19) and die bonding area (20) are arranged at the tops of outer pins (10, 11, 12 and 13). Three groups of die bonding glue (9) are connected onto the die bonding area (20). An LED chip (2) is connected onto each group of die bonding glue (9). The LED chips (2) are connected with the welding areas (15, 16, 17, 18 and 19) through conducting wires (4) and then are sealed by using epoxy resin caps (14). The three LED chips (2) are equidistantly arranged in a line. Three curved-surface body optical structures (8) corresponding to the three LED chips (2) are arranged at the tops of the epoxy resin caps (14). The products which are produced by adopting the production method provided by the invention have the advantages of high brightness, large light output angle and good pixel resolution, and can be widely used in the fields of display screens, advertisement screens and the like.

Owner:SHENZHEN LANKE ELECTRONICS +1

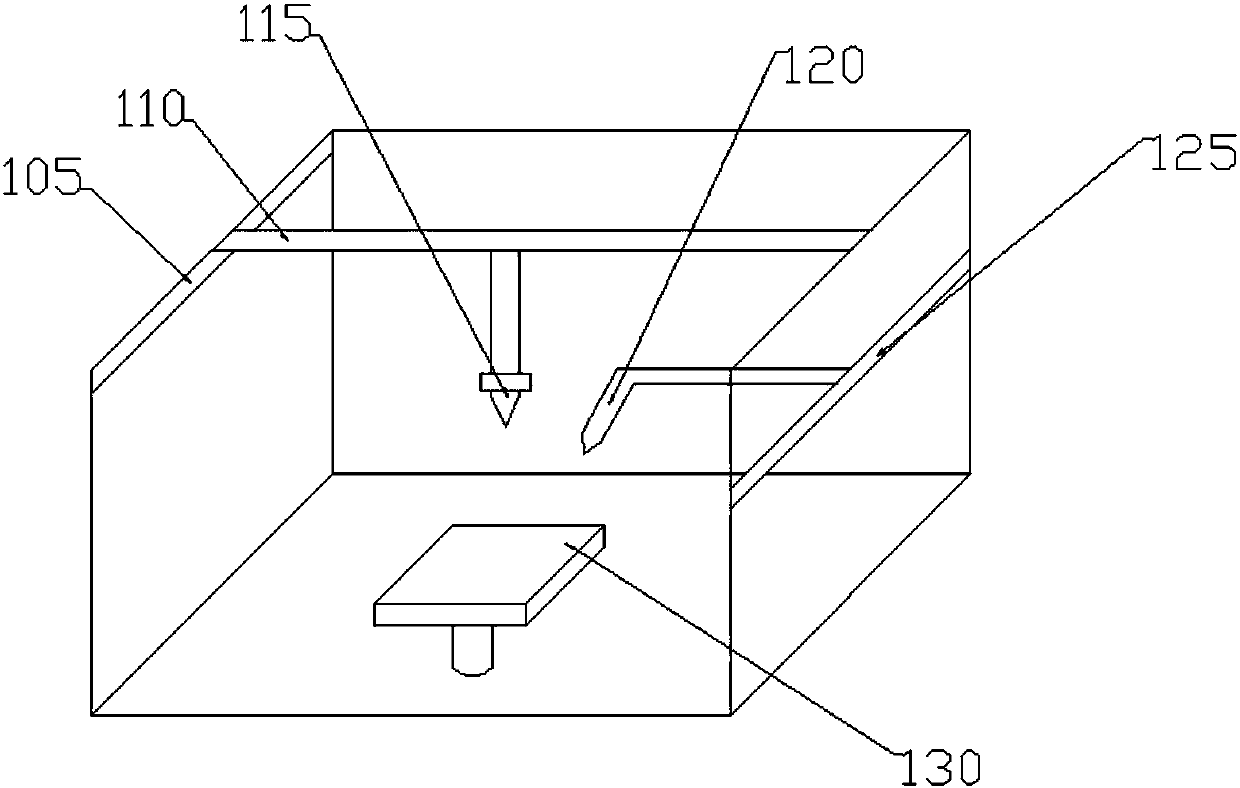

A three-dimensional model-based external coloring device

The invention discloses a three-dimensional model coloring device. The three-dimensional model coloring device comprises movable guide rods (105, 110 and 125), a molding head (115), a coloring head (120) and a supporting platform (130). The molding head is used for extruding a material to form a single layer of a model; and the coloring head is in contact with the peripheral contour of each layer of material of the model to finish coloring. The design can be used for 3D printing and also can be used for coloring the peripheral contour of the model, so that a colored 3D printing effect is realized. The coloring disclosed by the invention is carried out along the normal direction of a contact surface, and a contact part is designed into a spherical contact head, so that a coloring contact region is stressed along the normal direction of a contour all the time. The three-dimensional model coloring device is simple in structural design, parts can be partially or wholly replaced and the cost is relatively low; and the different sizes of the coloring device can be selected according to processing requirements, so that serialization and standardization are convenient to realize. The whole size of the three-dimensional model coloring device is relatively small, so that the probability of color delaying in a coloring process can be easily lowered.

Owner:BEIJING HENGCHUANG ADVANCED MATERIALS & ADDITIVE MFG INST CO LTD +1

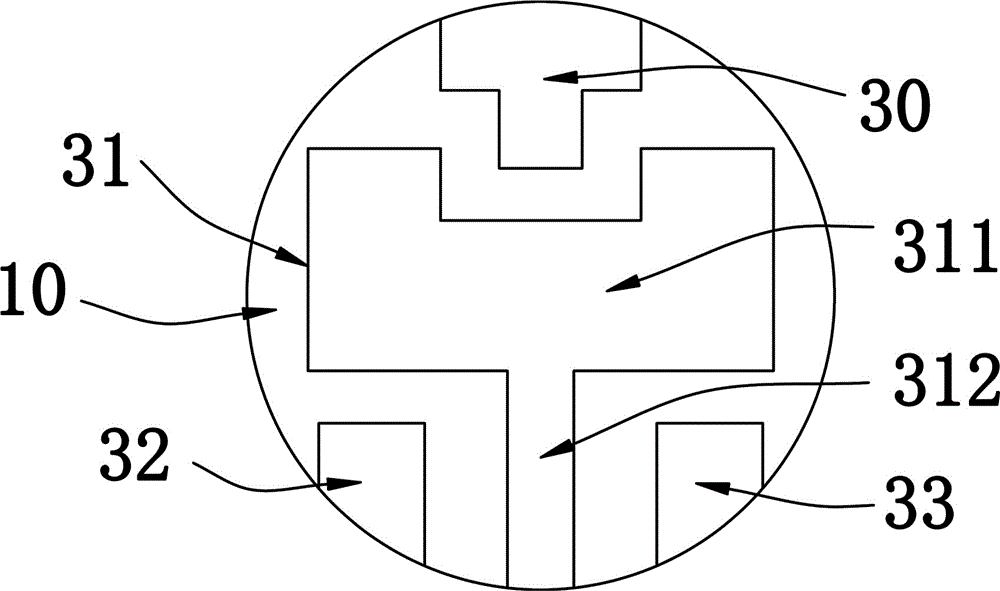

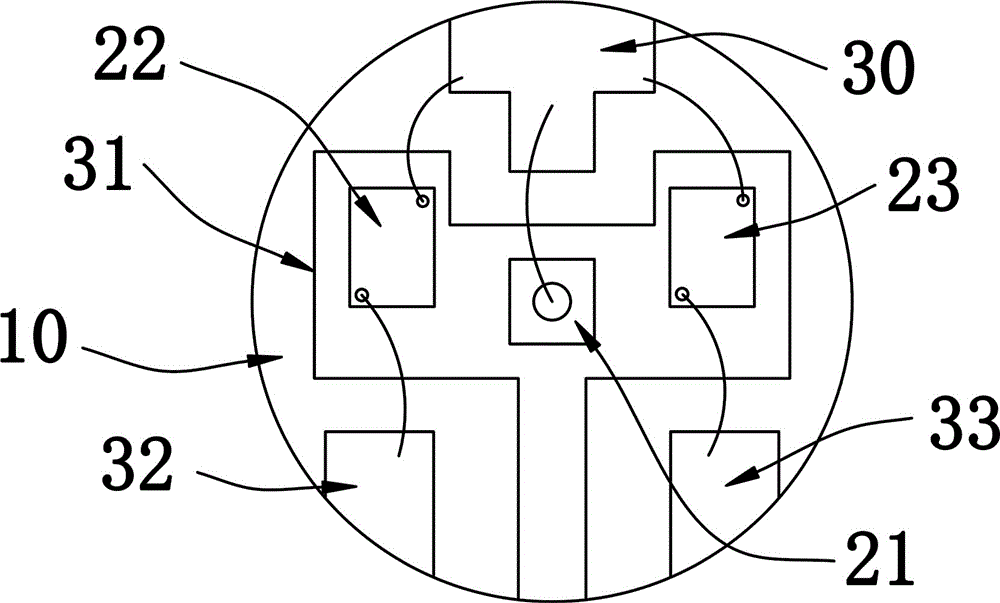

Bonding pad structure for encapsulating full color lamp bead of COB panel

PendingCN106653723AStrong packageEven color mixingSemiconductor/solid-state device detailsSolid-state devicesEngineeringFull color

The invention relates to a bonding pad structure for encapsulating a full color lamp bead of a COB panel. The bonding pad structure for encapsulating the full color lamp bead of the COB panel comprises a lamp cup, a first bonding pad, a second bonding pad, a third bonding pad, a fourth bonding pad, a first wafer, a second wafer and a third wafer, wherein the lamp cup is round; the first bonding pad, the second bonding pad, the third bonding pad and the fourth bonding pad are all arranged in the lamp cup; the first bonding pad is T-shaped and is formed by a cross arm and a vertical arm; the cross arm and the vertical arm are arranged on one diameter of the lamp cup; the second bonding pad is arranged at one side of the vertical arm; the third bonding pad is arranged on the other side of the vertical arm relative to the second bonding pad; and the fourth bonding pad is arranged at one side of the cross arm, which is far away from the vertical arm. According to the bonding pad structure, the encapsulation of the full color lamp bead of the COB panel is more stable, the color mixture is uniform and the emitting angle is larger.

Owner:SHENZHEN AUROLED TECH

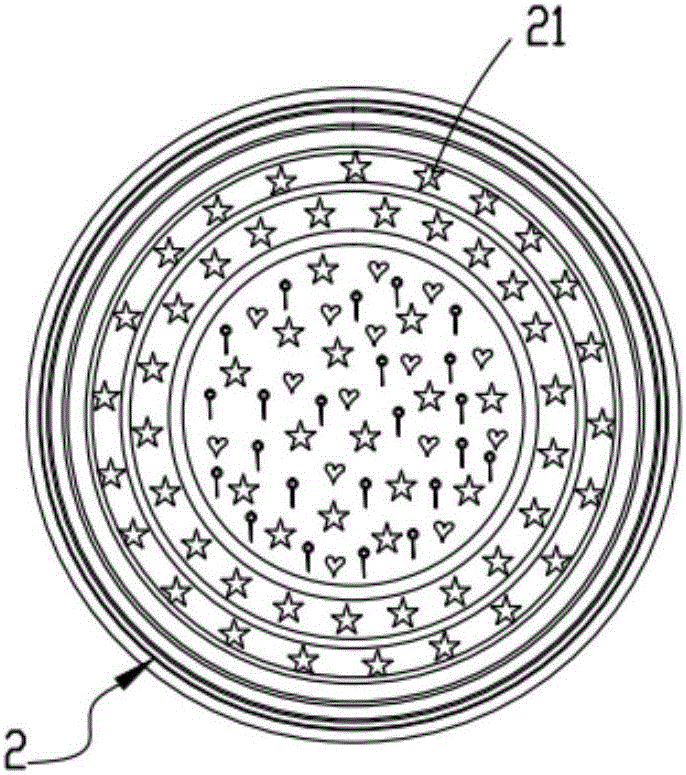

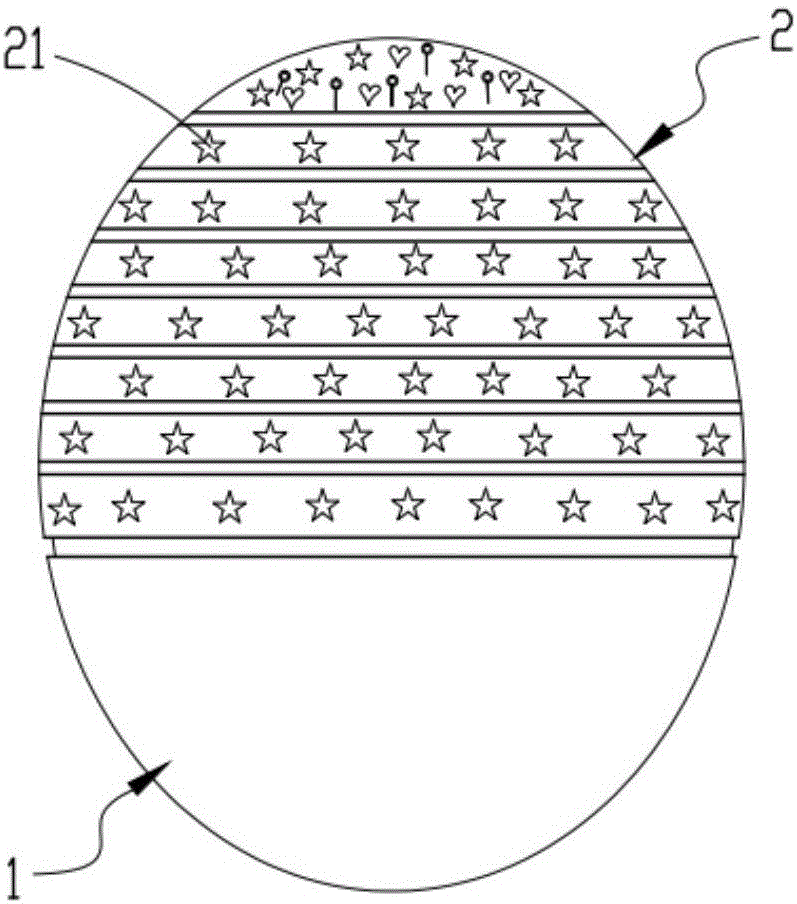

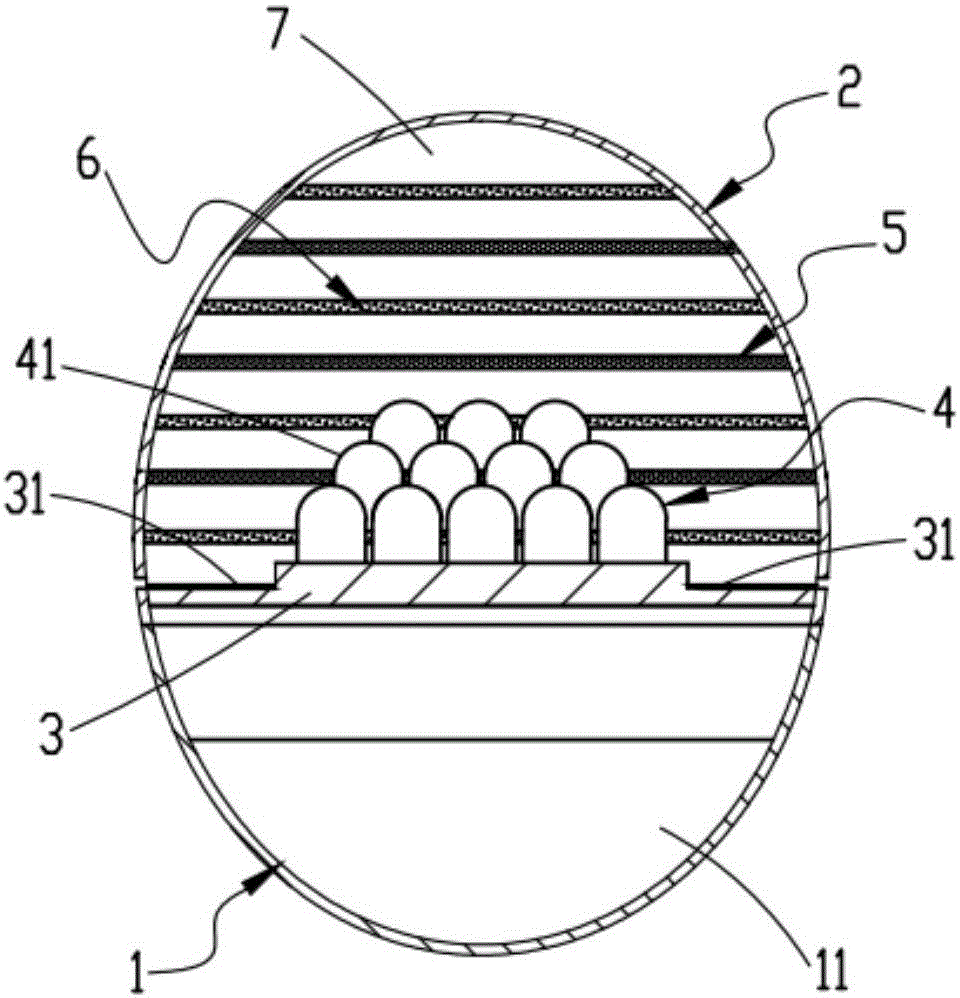

Decorative lamp with pattern changeable

ActiveCN106352298AIncrease pattern change frequencyShort color mixing timeElectric lightingGlobesThermochromismEngineering

The invention relates to a decorative lamp with pattern changeable. The decorative lamp with pattern changeable includes a lamp holder capable of swinging and an outer shell, wherein the tail of the outer shell is in sealing connection with the lamp holder. A base plate is arranged within the lamp holder, and a LED light source group is arranged on the lamp holder. An annular thermochromism unit a and an annular thermochromism unit b are arranged on the inner wall of the outer shell from bottom to top, wherein the annular thermochromism unit a and the annular thermochromism unit b are intersected at equal interval. The annular thermochromism unit a is filled with granular thermochromic materials a, and the annular thermochromism unit b is filled with granular thermochromic materials b. The LED light source group includes at least two groups of LED units which are arranged in a layered mode from bottom to top; the outer shell is provided with a plurality of patterns; when the temperature of the base plate changes, after passing through the thermochromism unit a and the thermochromism unit b, the light emitted by the LED light source group passes through a color mixing region and then the outer shell, so that the surface of the outer shell shows a pattern with corresponding color. According to the decorative lamp with pattern changeable, the color mixing effect of the light is good, the color and intensity of the light in the color mixing region can change continuously, the appearance pattern of the lamp is changeable and the color change effect of the lamp are enhanced.

Owner:滨州市科创孵化器有限公司

Reflector bowl and optical system applied to colored projection lamp

InactiveCN108870321AEven color mixingHigh light efficiencyLight source combinationsGlobesSquare cross sectionOptoelectronics

The invention discloses a reflector bowl and an optical system applied to a colored projection lamp. The reflector bowl comprises a reflector bowl body, wherein the reflector bowl body is provided with a big end and a small end; a light source hole is formed in the small end of the reflector bowl body; the big end of the reflector bowl body is opened to serve as a light outlet; the reflector bowlbody has a square cross section; and an inner surface of the reflector bowl body is a smooth mirror face. According to the reflector bowl, as the reflector bowl body has the square cross section, thelight outlet is also square. Reflected light obtained after light is reflected by the reflector bowl body can be superimposed with direct light of a light source, so that light is uniformly mixed on the smooth face. Meanwhile, as the inner surface of the reflector bowl body is the smooth mirror face, high light efficiency can be guaranteed. The reflector bowl is simple in structure, excellent in using effect and easy to popularize.

Owner:GUANGZHOU YAJIANG PHOTOELECTRIC EQUIP CO LTD

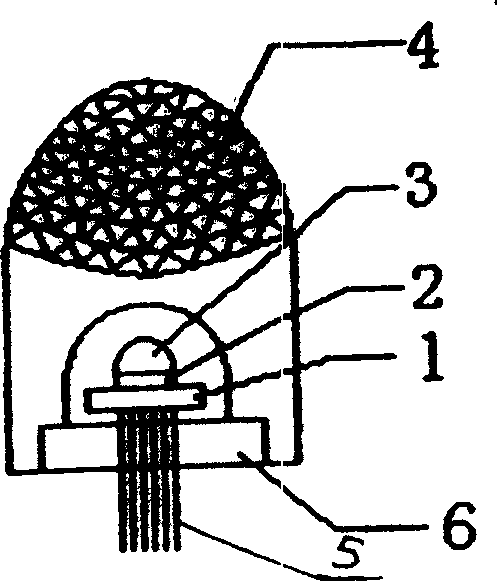

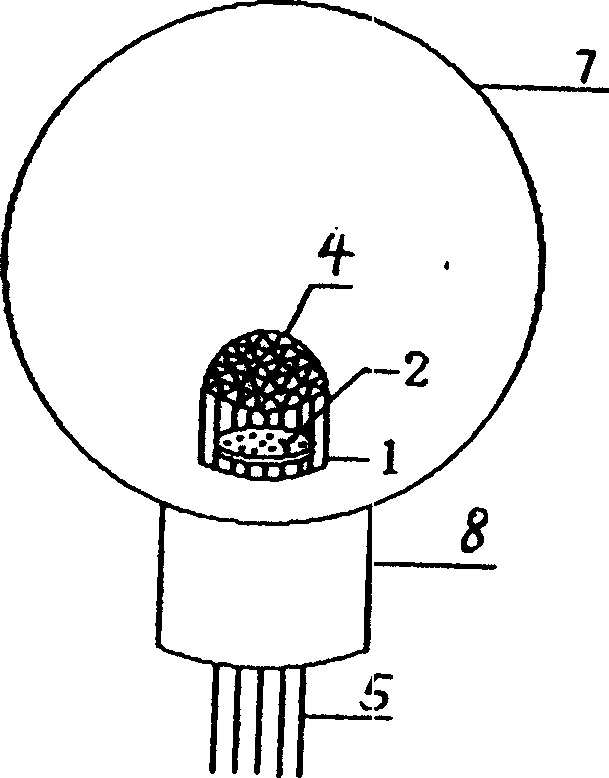

Mixed integrated efficient full-colour LED lamp

InactiveCN1198078CEasy to manufactureEven color mixingNon-electric lightingSolid-state devicesLED lampLight emitting device

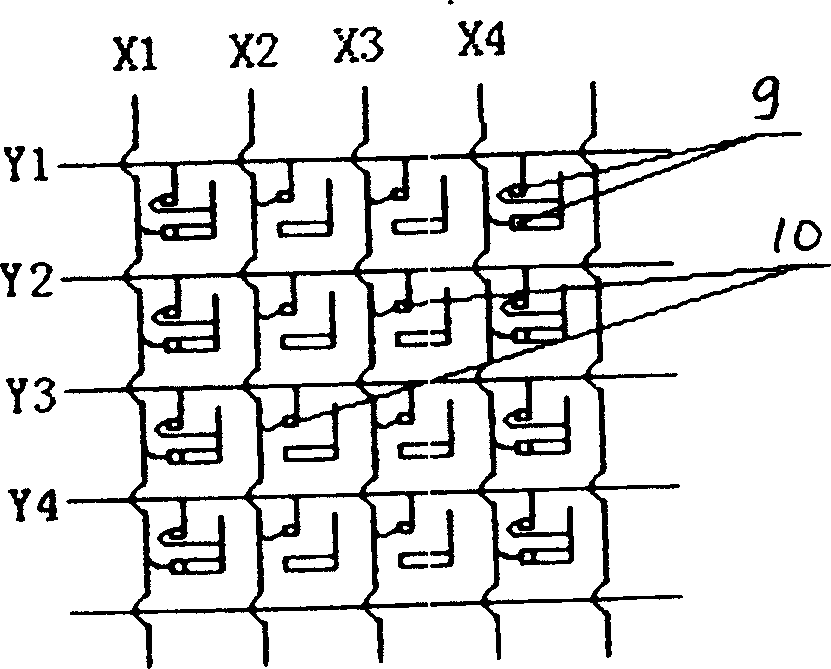

The hybrid integrated LED full-color lamp of the present invention comprises a hybrid integrated LED, a porcelain base, a polygonal spheroid packaging cap, a glass shell and a metal base. Wherein the ceramic base includes a conductive strip of an upper and lower double-layer porcelain substrate, and the conductive strip is an X-Y cross two-dimensional wiring layer. The device has uniform luminous color mixing, high brightness and is easy to manufacture.

Owner:卢景贵

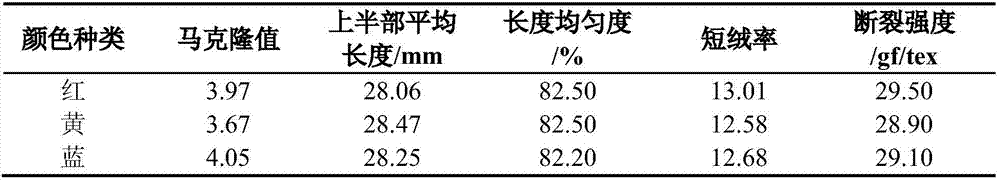

Digital multicolored blending knitted yarn fabric and preparation method thereof

The invention relates to the technical field of spinning, in particular to a preparation method of digital multicolored blending knitted yarn fabric. The method includes the steps of (1) a yarn production process, wherein cotton fibers serve as raw materials, a digital spinner capable of separately controlling the draw ratio of roving feeding is adopted, roving stripes in three colors including red, blue and yellow are selected for conducting direct spinning, the proportion of the red to the blue to the yellow is 50:30:20 by percentage, and meanwhile, string combination and doubling are conducted on yarn, the draw multiple of a rear area is set as 1.2, the range of a twist factor is from 320 to 340, and the spindle velocity is 9000 r / min; (2) a knitting process on a flat knitting machine,wherein knitting is conducted on the computerized flat knitting machine, fabric weave is adopted as knitting fabric and knitted in a single-way plain stitch mode, the horizontal density is 61.5 / 10 cm,the longitudinal density is 40.3 / 10 cm, the needle size is 12 G, and the gram weight of the fabric is 293 g / m<2>. The fabric produced according to the preparation method is soft, stiff and smooth inhand feeling, plentiful in color, distinctive in gradation change and high in three-dimensional performance.

Owner:JIANGYIN XIANGFEI APPAREL

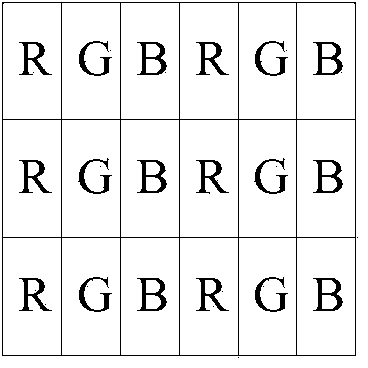

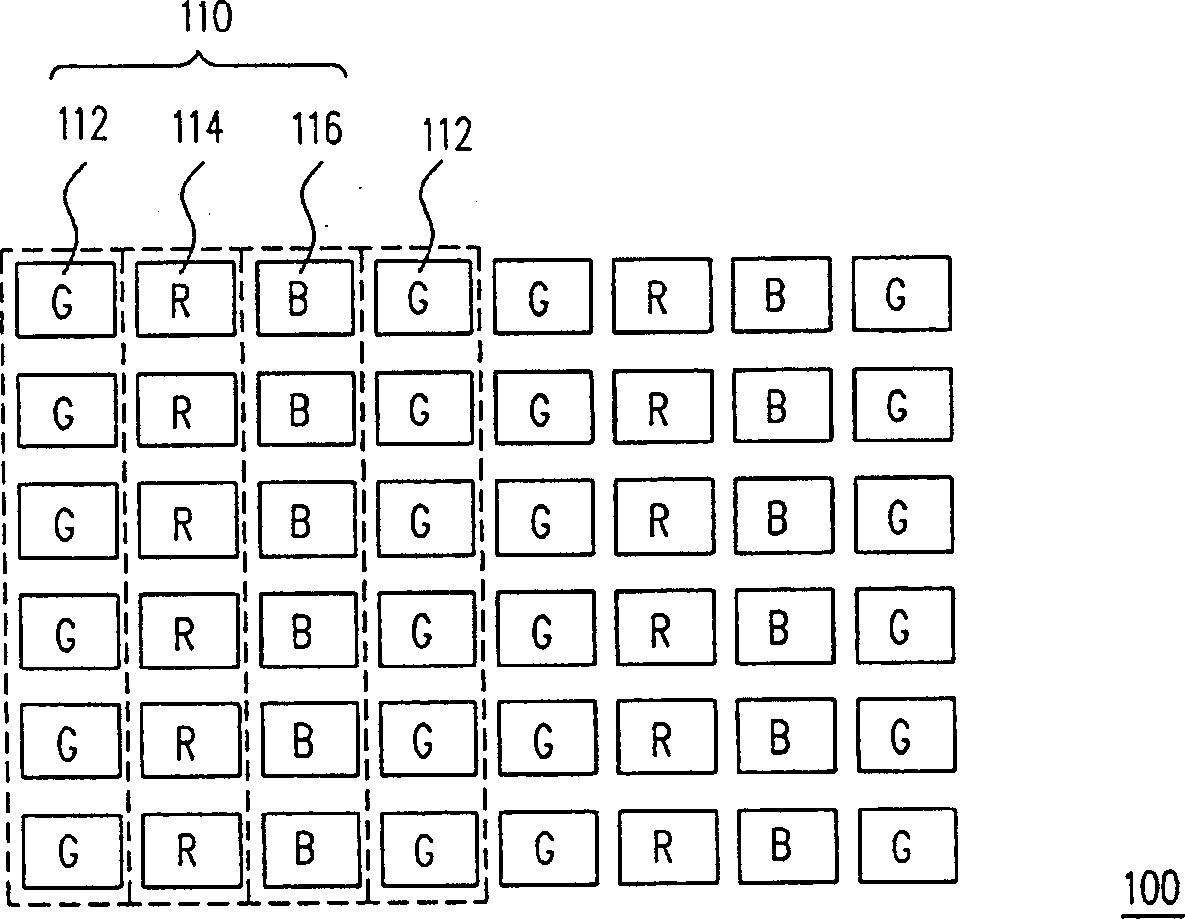

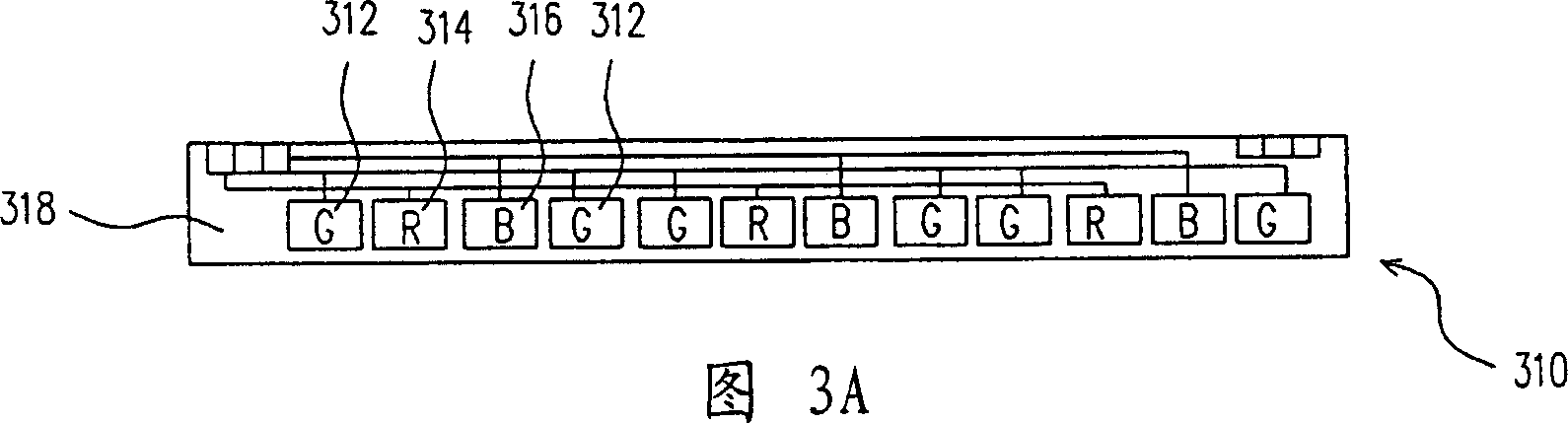

LED array and direct backlight unit

A LED array is prepared as arranging LED with the first color light, LED with the second color light and LED with the third color light in array way, setting two LED with the first color light and one LED with the second color light as well as one LED with the third color light in each 1x 4 matrix of said LED array and in one of 4x 1 array as well as 2x 2 array. The back light module of straight down type formed by multiple LED with the first color light, multiple LED with the second color light, multiple LED with the third color light and multiple bar circuit board is also disclosed.

Owner:INNOLUX CORP

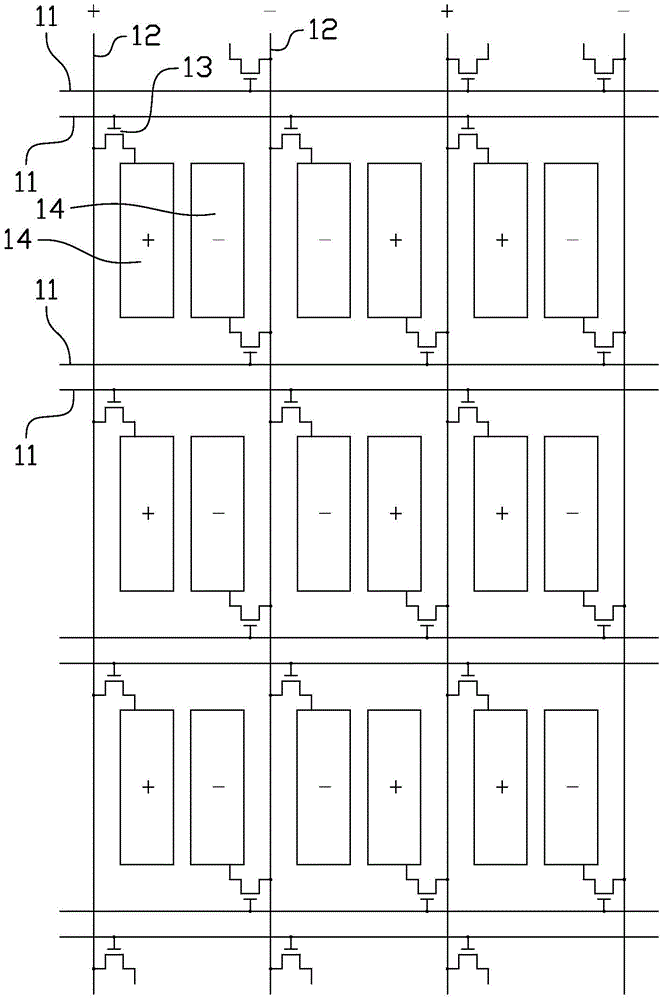

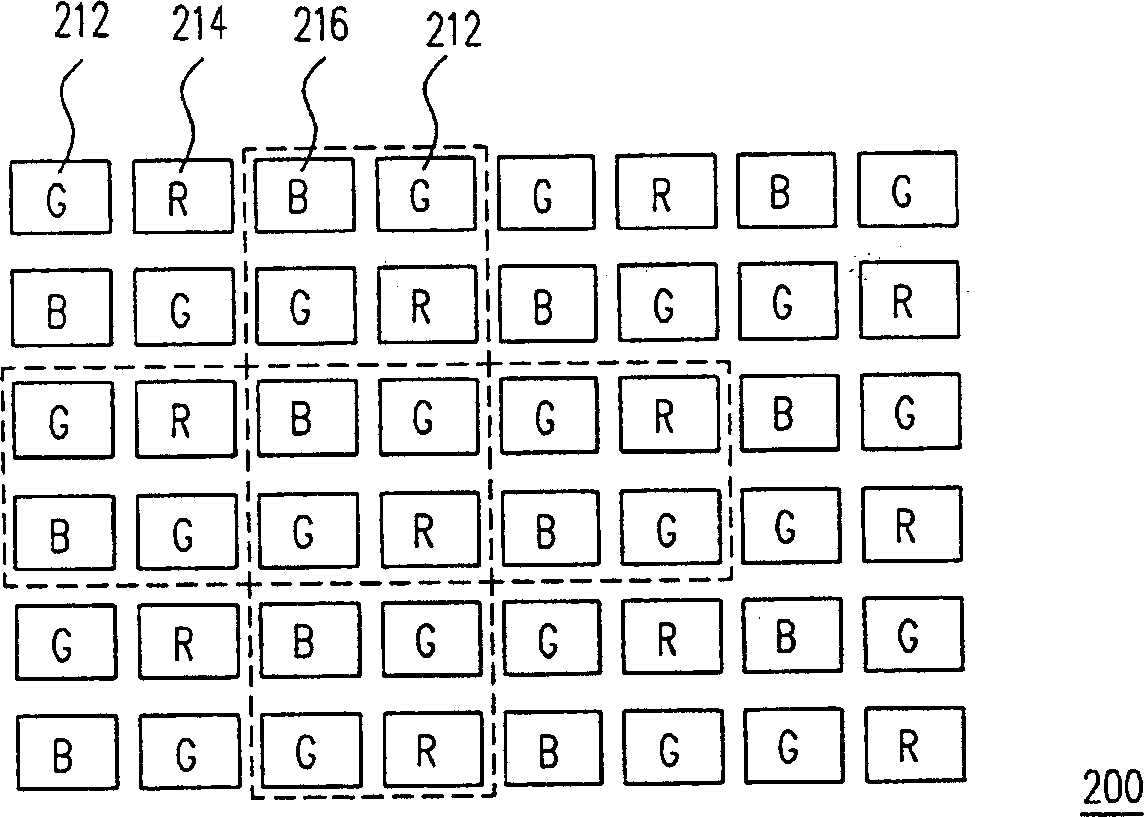

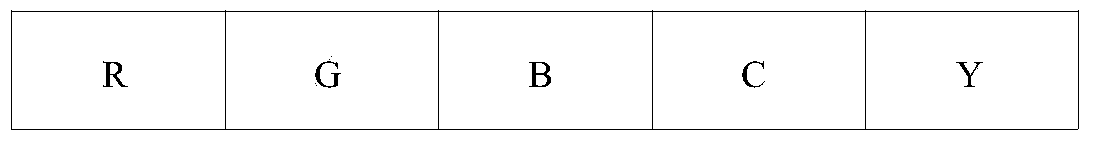

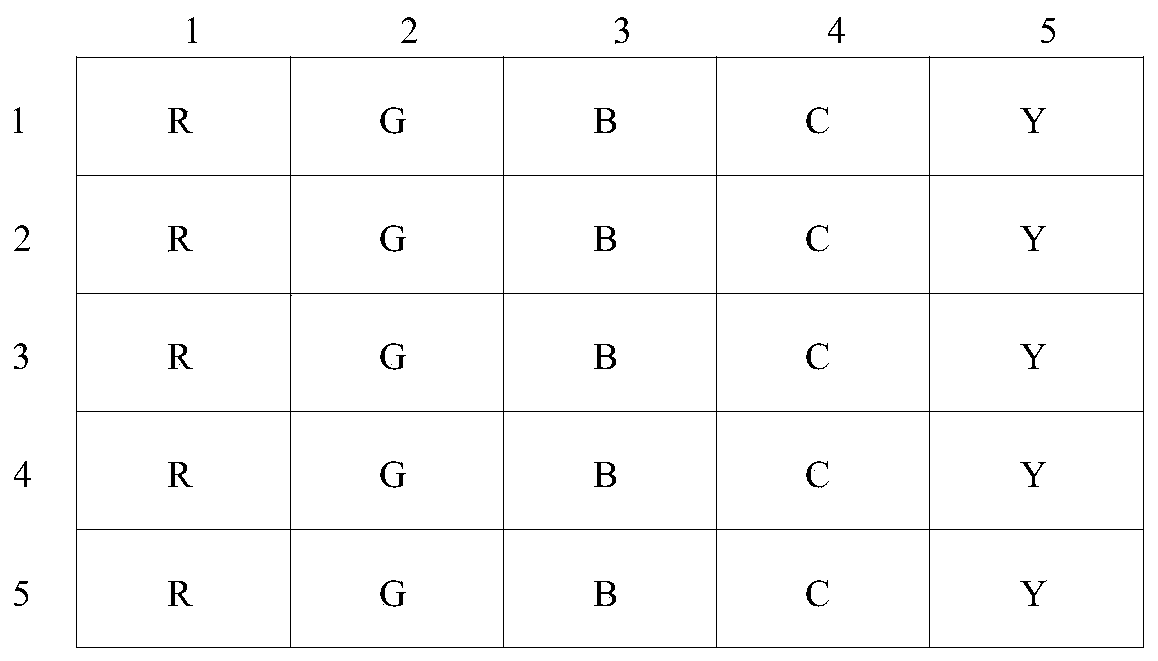

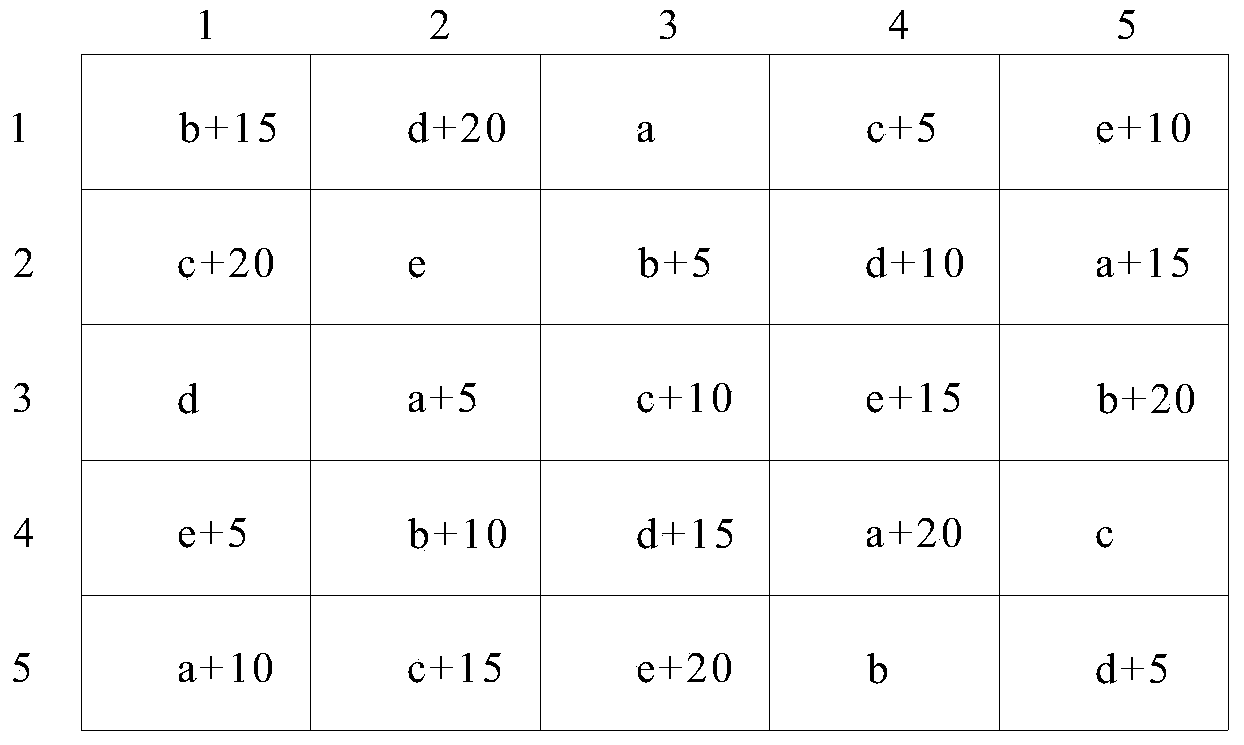

Pixel array, display panel and display device

The invention provides a pixel array, including a plurality of pixel units, wherein each pixel unit comprises five sub-pixels which are mutually different in color, the color of any sub-pixel in the pixel array is different from the colors of the adjacent sub-pixels. As the color of one sub-pixel is different with the colors of the adjacent sub-pixels, more uniform color mixture can be achieved when the pixel array provided by the invention is used for displaying. The invention also provides a display panel and a display device.

Owner:BOE TECH GRP CO LTD +1

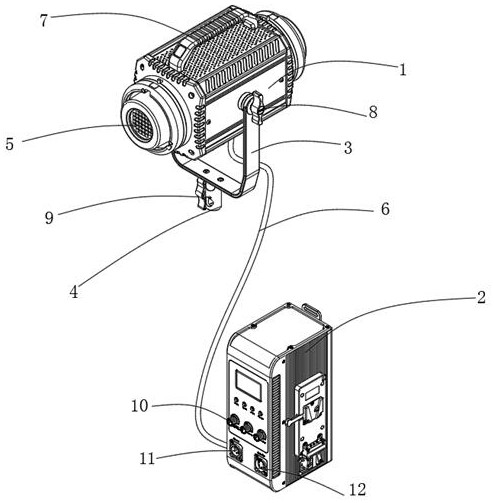

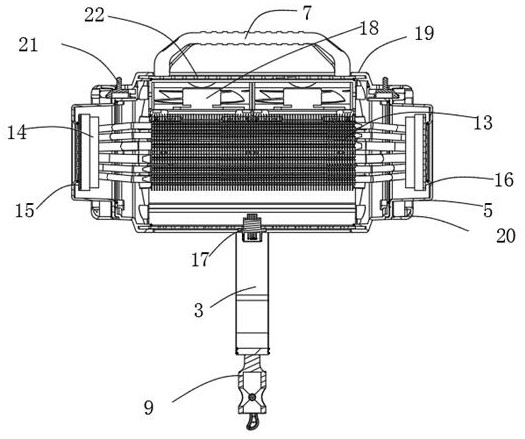

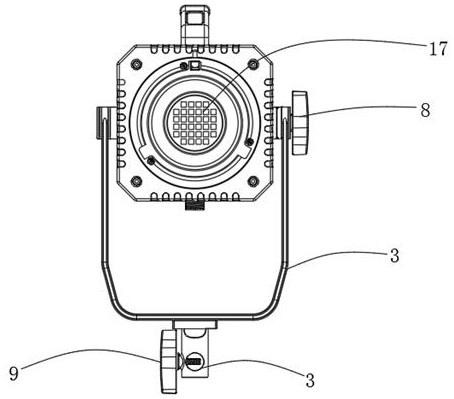

300W double-head spotlight

PendingCN112178476AEasy to carryReduce distressLighting support devicesElectric circuit arrangementsEngineeringLight head

The invention discloses a 300W double-head spotlight, and relates to the technical field of spotlights. The LED lamp comprises a lamp body, a controller and a wire, the lamp body is a double-head spotlight and comprises a lamp shell, lampshades are arranged on the front surface and the rear surface of the lamp shell, RGB lamp beads are installed in the lampshade on the front surface, double-color-temperature lamp beads are installed in the lampshade on the rear surface, a radiator is arranged in the lamp shell, and radiator bases are fixedly installed at the two ends of the radiator. The radiator base is fixedly connected with the RGB lamp beads and the double-color-temperature lamp beads, a plurality of cooling fans are arranged on the upper surface of the radiator, the lamp body is connected with the controller through a wire, and light-emitting points of all colors on the RGB lamp beads and the double-color-temperature lamp beads are distributed at equal intervals. According to theinvention, a unique design mode of two light output lamp caps is adopted, the maximum output power of a single lamp cap is 300W, and the lamp caps can be quickly switched to emit different lights by one key; The spotlight integrates multiple functions, so that the trouble that the lamp is frequently replaced due to switching of different scenes is saved.

Owner:惠州市拉图影视器材有限公司

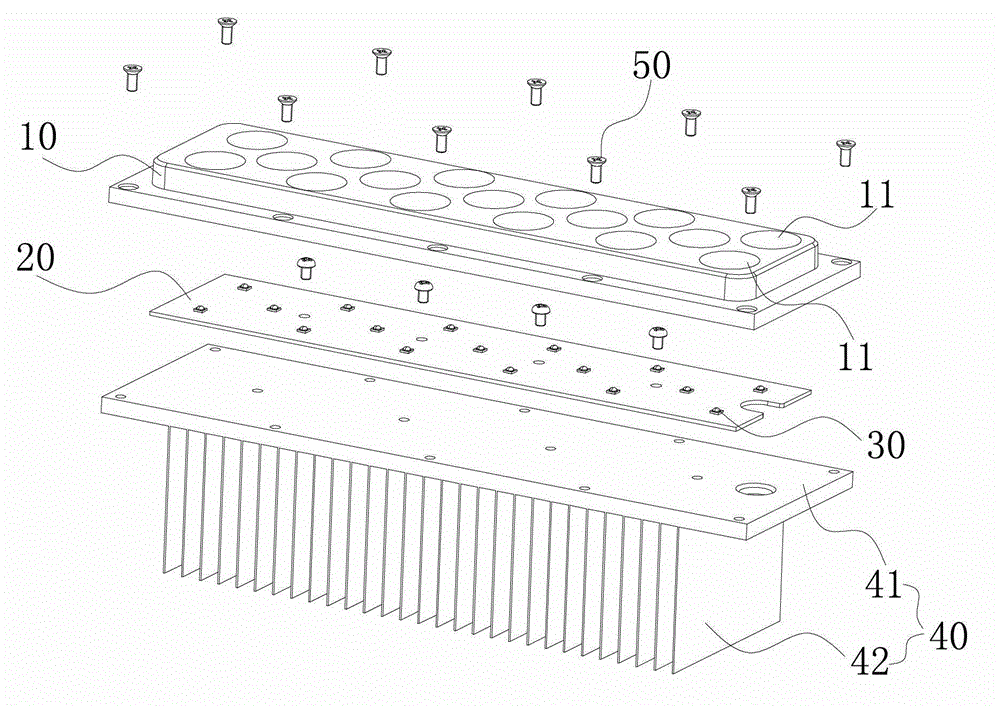

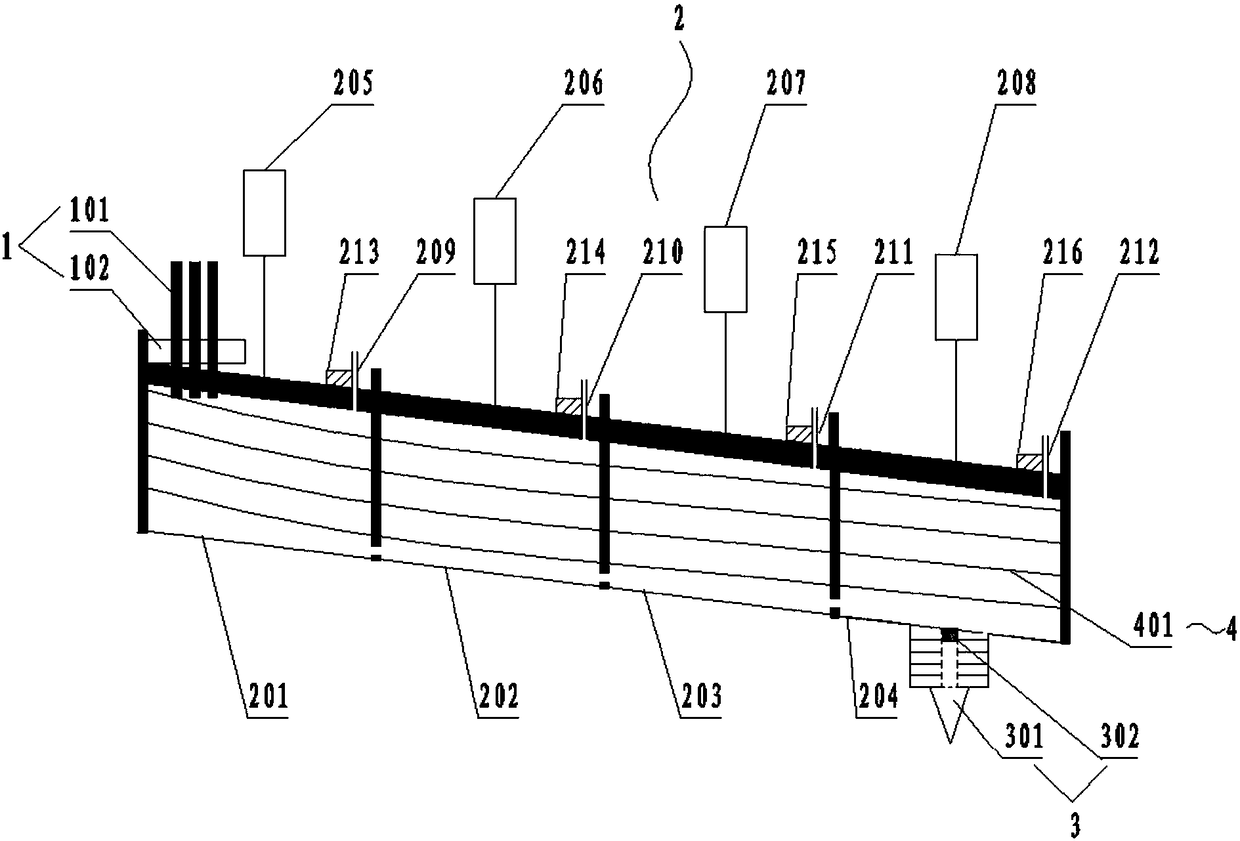

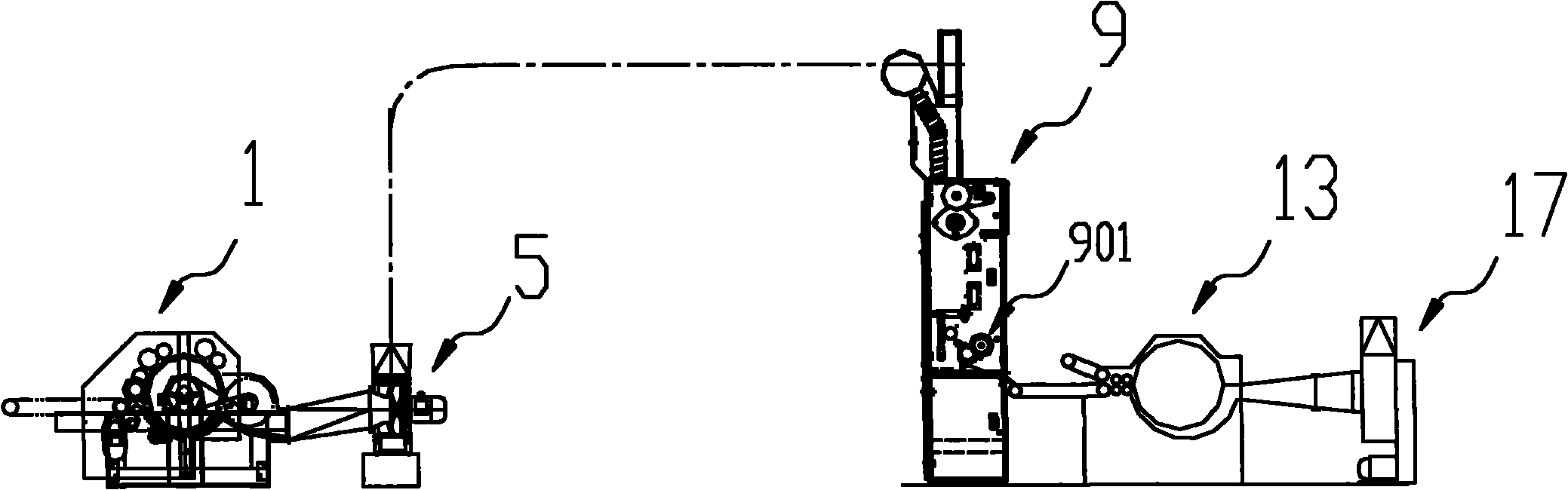

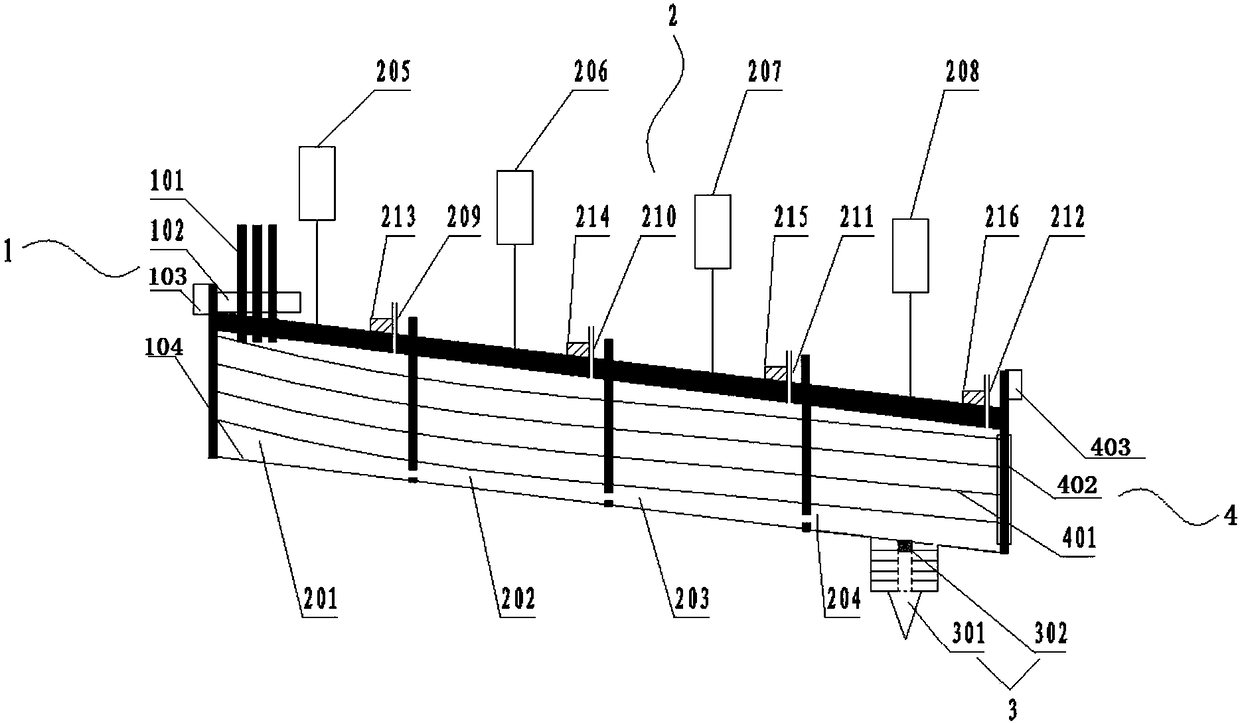

Rapid shaping type full-color 3D (Three Dimensional) printer material conveying system and control method thereof

ActiveCN108527844APrint smoothlyThe effect of preventing incomplete meltingManufacturing heating elements3D object support structuresMelting tankElectric machine

The invention provides a rapid shaping type full-color 3D (Three Dimensional) printer material conveying system and a control method thereof and relates to the technical field of 3D printers. The system comprises a feeding system, a molten pool system, a spraying nozzle system and a heating system, wherein the feeding system is connected with an input end of the molten pool system; an output end of the molten pool system is connected with the spraying nozzle system; the heating system is connected with the molten pool system; the feeding system comprises a feeding pipe, a feeding motor, a motor controller and a material amount sensor; the heating system comprises molten pool heating equipment, a temperature sensor, a heating controller and spraying nozzle heating equipment. The method comprises the following steps: firstly, calculating amounts of wire rods with various colors, which are needed by a printing model; then controlling the feeding motor of the feeding system and accuratelycontrolling the amounts of the wire rods with the various colors; finally, gradually mixing molten materials through controlling the temperature of each molten pool of the molten pool system and conveying a mixture into a printing spraying nozzle. The system provided by the invention has the advantages of smooth printing, no blocking of the spraying nozzle, uniform full-color mixing and good full-color printing quality, has the characteristics of durability, simple structure, low cost and the like and is easy to popularize and apply.

Owner:桂林凯歌信息科技有限公司

LED light mixing system

PendingCN110566825AEvenly mixed lightEven color mixingSemiconductor devices for light sourcesColor mixingCost savings

The invention discloses an LED light mixing system. The LED light mixing system includes a plurality of LEDs arranged in a certain pattern or shape and a PCB board for mounting the LEDs; a light mixing module is arranged in the light output direction of the LED; the shape of the cross section of the light mixing module matches the shape formed by the LED arrangement; the light mixing module is provided with a gap through which the light emitted by the LEDs passes; and at least part of the light emitted by the LEDs is mixed and reflected by the light mixing module and then emitted. According tothe technical scheme, the light mixing module is arranged in the light emitting direction of the LEDs, so that at least part of the light emitted by the LEDs is light-mixed and color-mixed by the light mixing module and then emitted, so as to achieve the beneficial effect of uniform color mixing and light mixing; and compared with the traditional light mixing technology, the LED light mixing system has the beneficial effects of uniform color mixing, simple, effective and cost saving.

Owner:PHILIPS LIGHTING CHINA INVESTMENT CO LTD

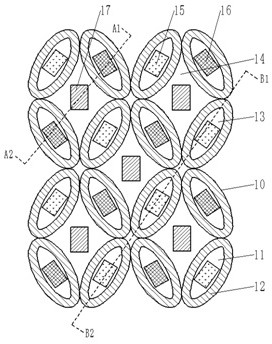

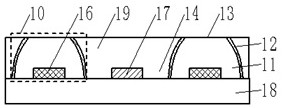

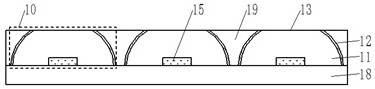

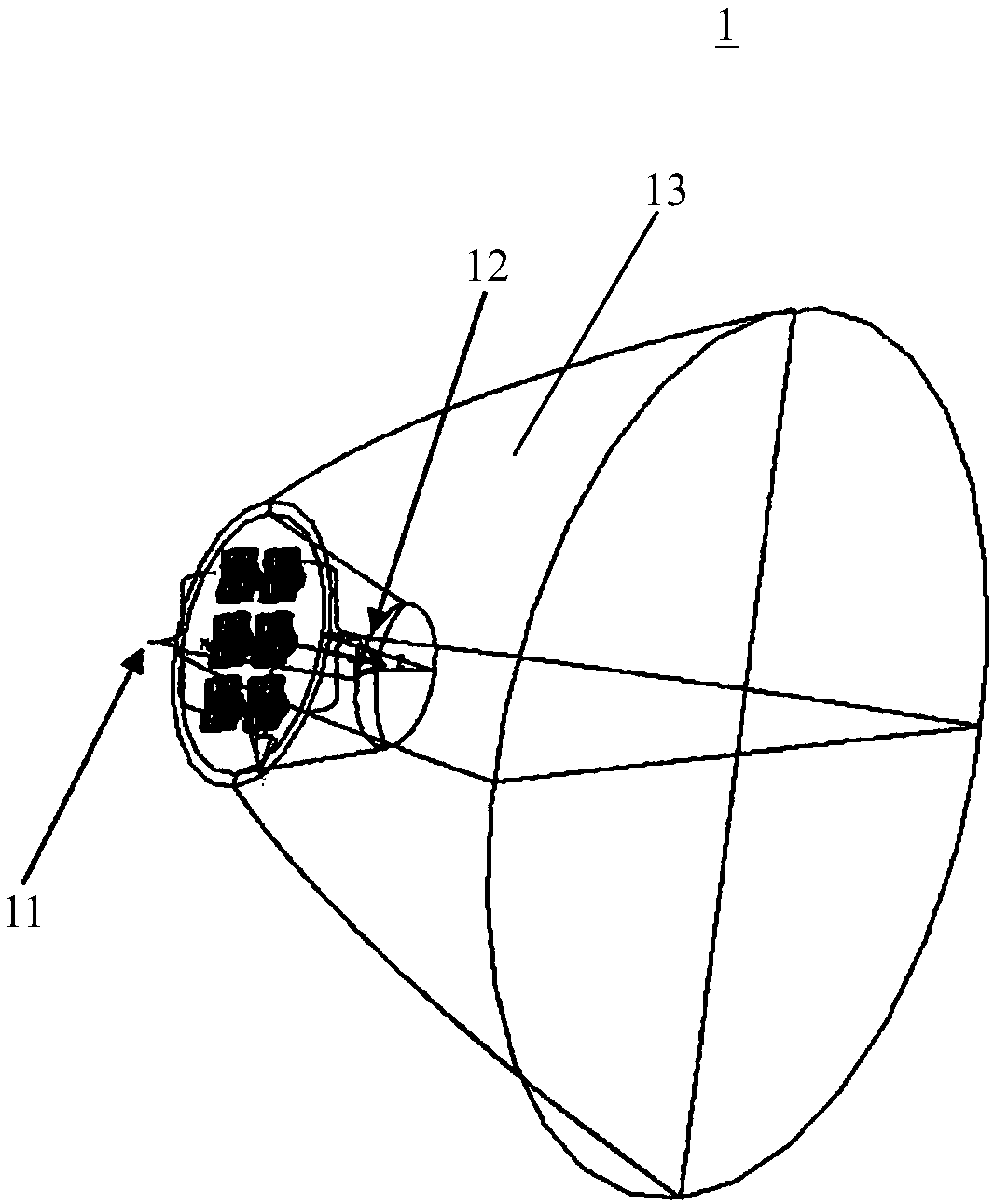

A kind of micro-led display panel and its manufacturing method

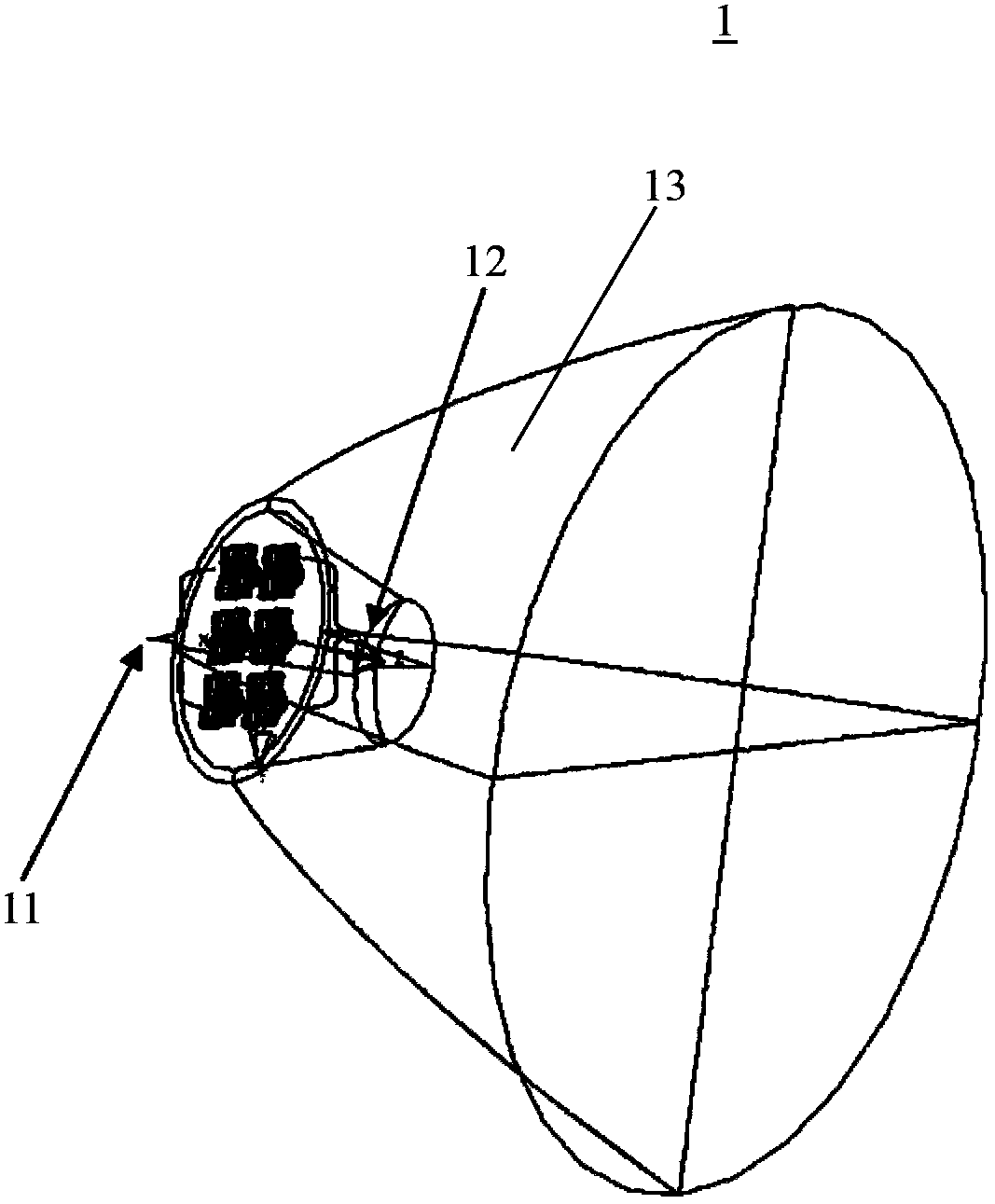

ActiveCN113451283BWide viewing angleSimple forming processSolid-state devicesIdentification meansLED displayEngineering

The present invention provides a micro-LED display panel and a manufacturing method thereof. The present invention utilizes an ellipsoidal raised portion and an elliptical flat surface to realize a wide viewing angle emission of red light and green light, so as to ensure the light from the blue LED Balanced color mixing while ensuring a large viewing angle for the display panel. Furthermore, the manufacturing method of the present invention can form the raised portion through simple injection molding, and the subsequent forming process of the reflective layer and the sealing layer is relatively simplified, which greatly reduces the manufacturing cost.

Owner:罗化芯显示科技开发(江苏)有限公司

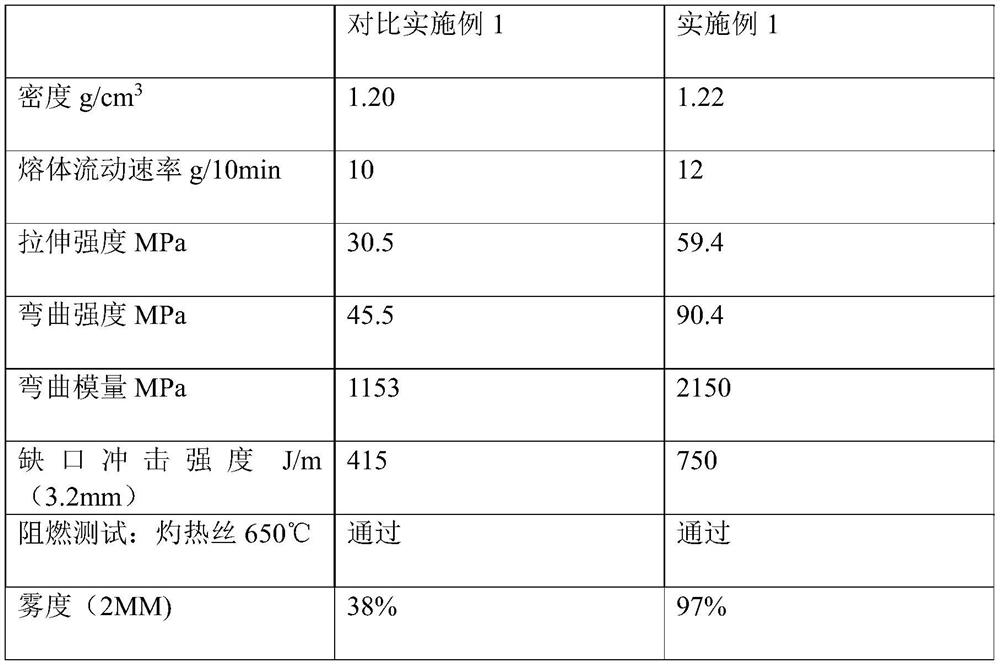

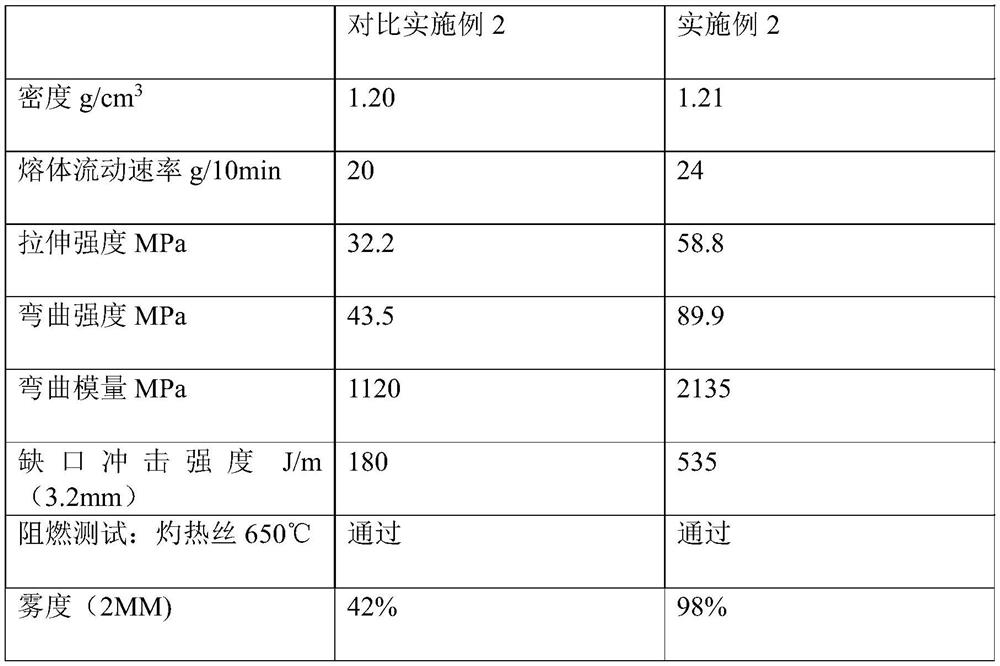

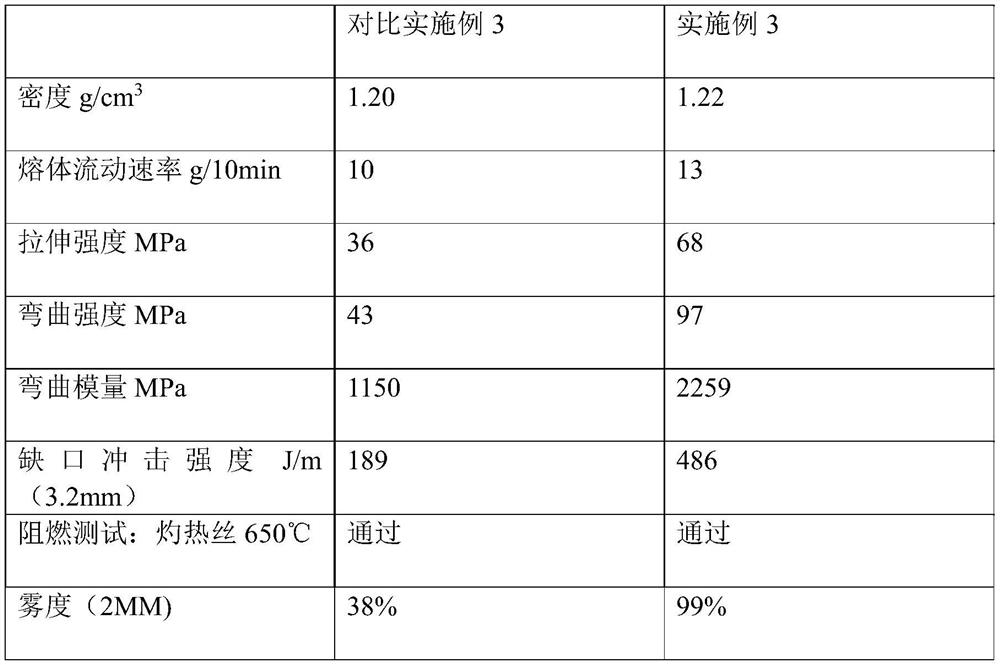

Polycarbonate plastic master batch for LED (light-emitting diode) lamp as well as preparation method and use method of polycarbonate plastic master batch

The invention belongs to the technical field of LED (light-emitting diode) lamp manufacturing, and relates to a polycarbonate plastic master batch for an LED lamp as well as a preparation method and a use method of the polycarbonate plastic master batch. 45 to 50 parts of titanium dioxide; 5-6 parts of color powder; 5 to 15 parts of a toughening agent; 1 to 1.2 parts of an antioxidant; and 1-1.5 parts of a dispersant. The invention also provides a preparation method of the polycarbonate plastic master batch for the LED lamp and a use method of the polycarbonate plastic master batch for the LED lamp. According to the polycarbonate plastic master batch for the lamp as well as the preparation method and the use method of the polycarbonate plastic master batch, provided by the invention, more uniform color mixing, better shading effect and better physical properties can be obtained.

Owner:TAIZHOU KINSUNY PHOTOELECTRIC SCI & TECH CO LTD

Lens, lens array and lighting device

InactiveCN103574501BCapable of variable correlated color temperatureCompact structurePlanar light sourcesLight source combinationsOptoelectronicsThree dimensional surface

Owner:SITECO GMBH

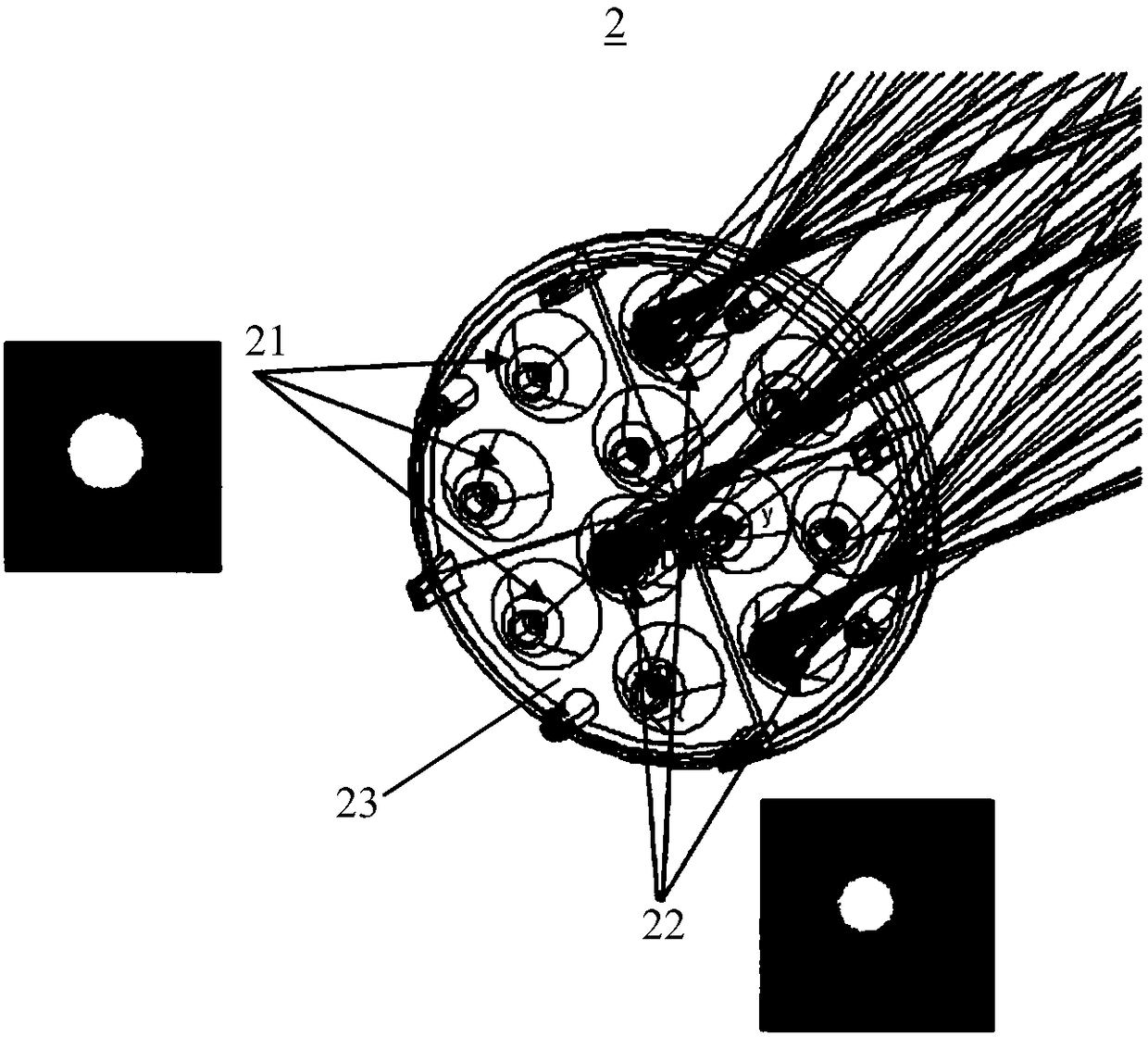

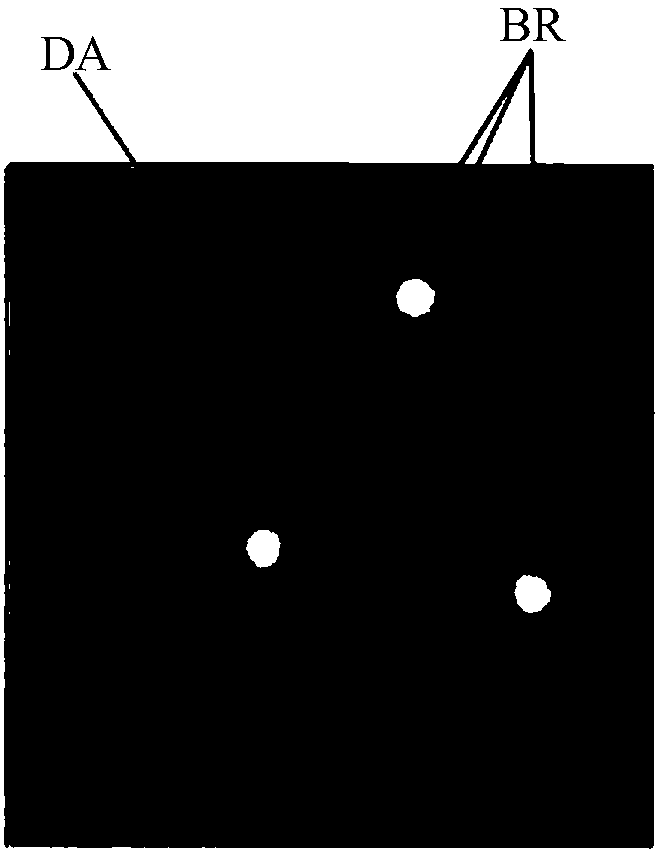

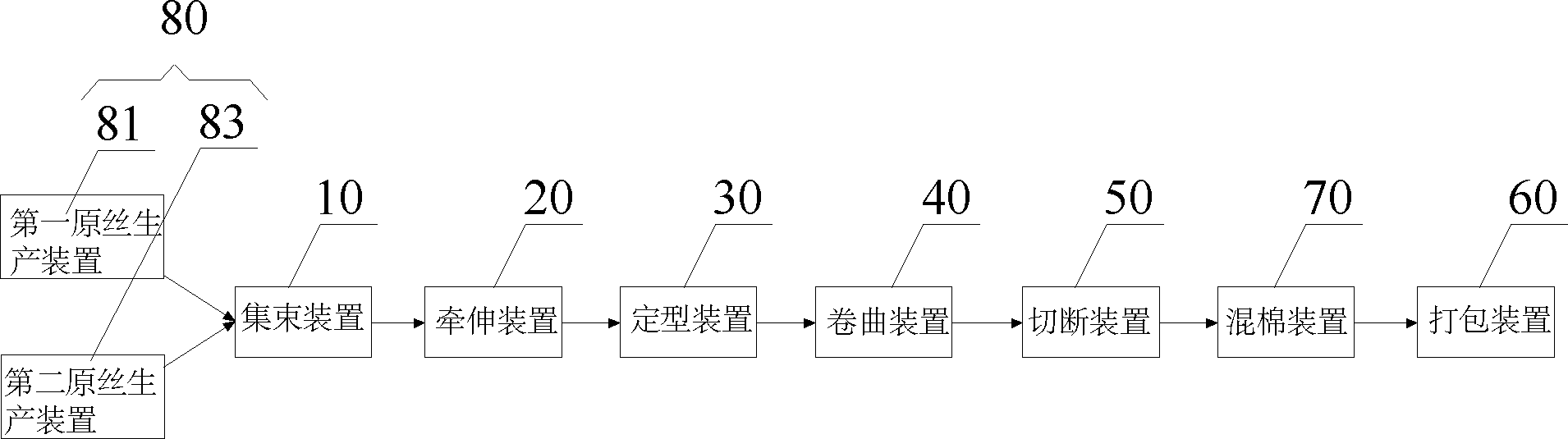

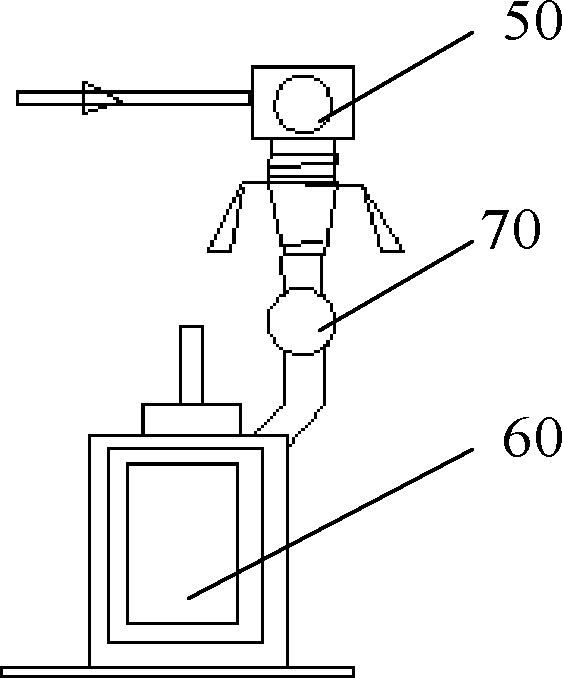

Compound color polyester chopped fiber and production device and method thereof

InactiveCN102358965BLow costSimple structureArtificial thread manufacturing machinesFibre mixingPolyesterYarn

Owner:滁州安兴环保彩纤有限公司

Multi-color micro-LED array light source

ActiveUS10412806B2Reduce color artifactReduce displacementPlanar light sourcesLight source combinationsElectricityLed array

Owner:JADE BIRD DISPLAY SHANG HAI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com