A three-dimensional model-based external coloring device

A 3D modeling and model technology, applied in coating devices, additive processing, etc., can solve the problems of difficult color 3D printing, difficulty in realizing colorful or even full-color printing, and limited printing colors, so as to reduce color delay, Facilitate serialization and standardization, reduce the effect of pigment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is further described:

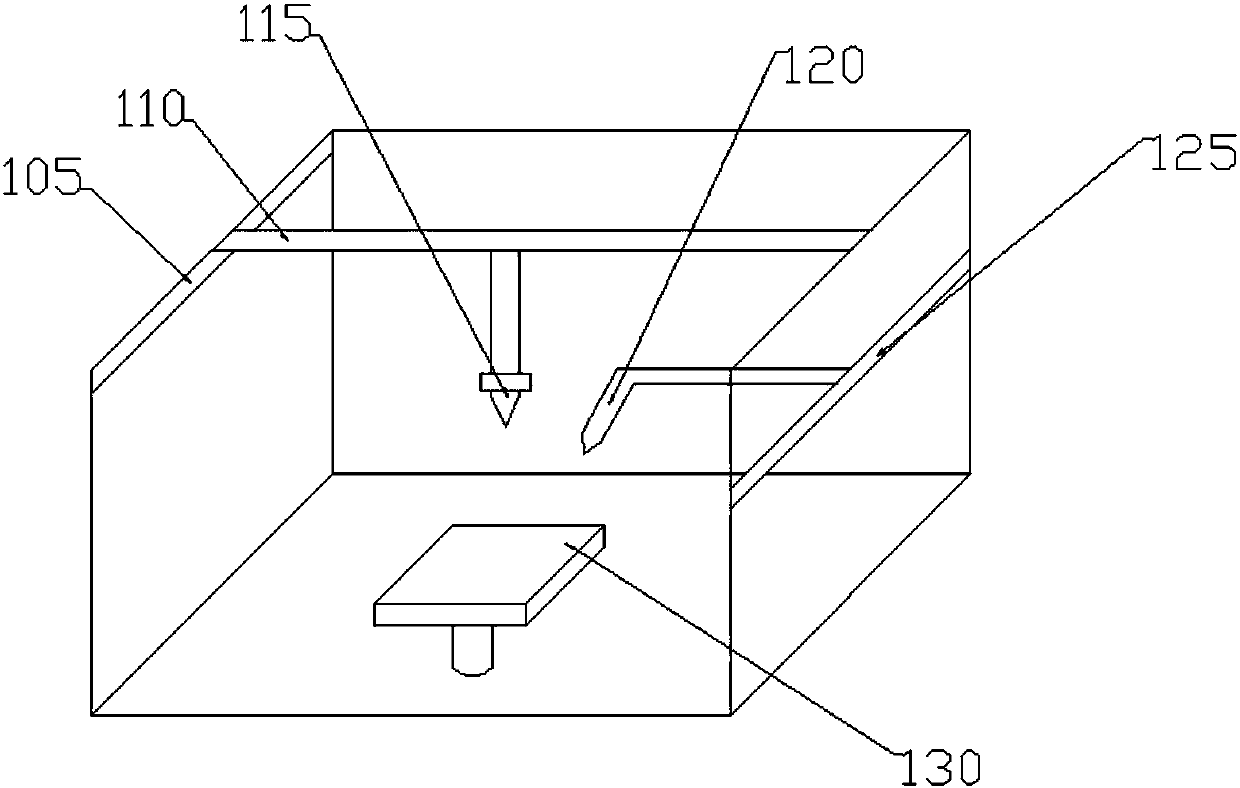

[0023] The device comprises a first guide rod (110), a second guide rod (105), a third guide rod (125), a forming head (115), a coloring head (120) and a supporting platform (130);

[0024] The forming head (115) can move along the y-axis along the first guide rod (110);

[0025] The first guide rod (110) can move along the x-axis along the second guide rod (105);

[0026] The support platform (130) is used to cooperate with the forming head (115) to complete the printing of the single-layer model;

[0027] The coloring head (120) is fixed on a third guide rod (125) for coloring the periphery of the model, and the third guide rod (125) has degrees of freedom of movement in x and y axes.

[0028] In this example, if figure 1 Shown: the supporting platform 130 has a degree of freedom of z-axis movement and rotation around the z-axis. The forming head 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com