LED chip structure with electrode having opening

An LED chip and electrode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of light-emitting diode offset, tilt, and large surface tension of light-emitting diodes, and achieve consistent light-emitting directions, improved flatness, and uniform color mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

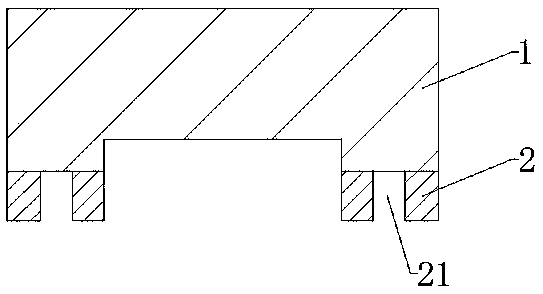

[0039] Such as Figure 10 Shown, embodiment one of the present invention is:

[0040] An LED chip structure with electrodes having openings includes an epitaxial structure 1 and an electrode 2 disposed on the epitaxial structure 1 , the electrode 2 includes a bottom and a top opposite to each other, and a side wall connecting the bottom and the top. The top of the electrode 2 is disposed close to the epitaxial structure 1 , and the bottom of the electrode 2 is disposed away from the epitaxial structure 1 .

[0041] The electrode 2 is provided with more than two openings 21 extending from the bottom of the electrode to the top of the electrode, the opening 21 is in the shape of a circular hole, and the distance between the opening 21 and the side wall of the electrode 2 It is provided that more than two openings 21 are evenly distributed at intervals.

[0042] In a preferred embodiment, the apertures of the openings are gradually reduced from the bottom of the electrode to th...

Embodiment 2

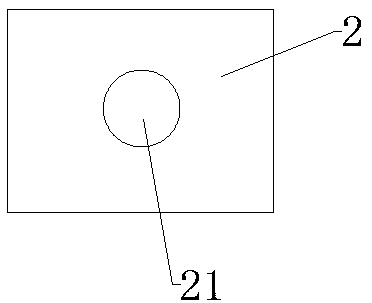

[0043] Such as Figure 11 Shown, embodiment two of the present invention is:

[0044]An LED chip structure with electrodes having openings includes an epitaxial structure 1 and an electrode 2 disposed on the epitaxial structure 1 , the electrode 2 includes a bottom and a top opposite to each other, and a side wall connecting the bottom and the top. The top of the electrode 2 is disposed close to the epitaxial structure 1 , and the bottom of the electrode 2 is disposed away from the epitaxial structure 1 .

[0045] The electrode 2 is provided with more than two openings 21 extending from the bottom of the electrode 2 to the top of the electrode 2, and more than two openings 21 are evenly distributed at intervals, and the openings 21 are in the shape of trapezoidal grooves The opening 21 communicates with two opposite side walls of the electrode 2 , wherein the cross-sectional area of the opening 21 near the top of the electrode 2 is smaller than the cross-sectional area of ...

Embodiment 3

[0047] An LED chip structure with an electrode opening includes an epitaxial structure and an electrode arranged on the epitaxial structure, the electrode includes a bottom and a top oppositely arranged, and a side wall connecting the bottom and the top. The top of the electrode is disposed close to the epitaxial structure, and the bottom of the electrode is disposed away from the epitaxial structure.

[0048] The electrode is provided with more than two openings extending from the bottom of the electrode to the top of the electrode, the openings have rough side walls, and the bottom of the openings has a distance from the epitaxial structure.

[0049] This embodiment can also be applied to the first and second embodiments above.

[0050] In an alternative embodiment, the opening extends from the bottom of the electrode to the top of the electrode, communicating with the epitaxial structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com