Polycarbonate plastic master batch for LED (light-emitting diode) lamp as well as preparation method and use method of polycarbonate plastic master batch

A technology for polycarbonate plastics and LED lamps, which is applied in the field of polycarbonate plastic masterbatches for LED lamps, can solve the problems of inability to meet the requirements of LED lamps, unsatisfactory shading effect, and aggravation, and achieve good use value and market value. Prospect, good flame retardant effect, strong universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

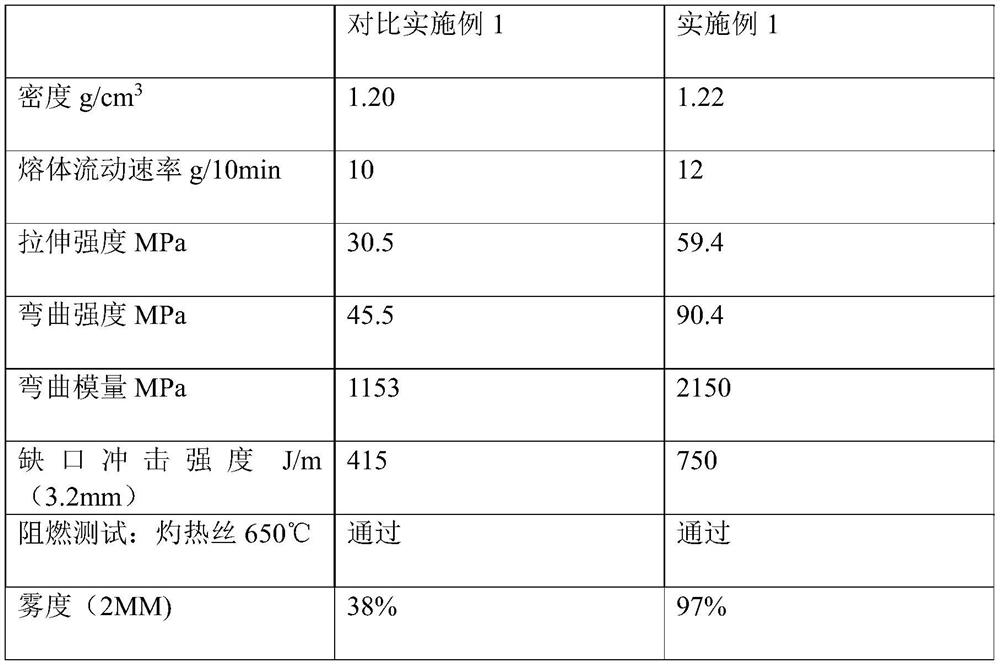

Embodiment 1

[0031] (1) Preparation of masterbatch:

[0032] Take the following raw materials: titanium dioxide 45 parts, polycarbonate raw materials 40 parts, color powder 5 parts, toughening agent (methyl methacrylate - butadiene - styrene ternary copolymer) 5 parts; antioxidant (phosphite) 1 part; dispersant (pentaerythrityl stearate) 1 part.

[0033] In the polycarbonate raw materials add an appropriate amount of white oil mixed for 3-5 minutes, and then add the corresponding number of tougheners, titanium dioxide, dispersants, antioxidants, etc. mixed for 5-10 minutes, mixed evenly, the high-speed mixer premixed raw material mixture into the twin screw extruder hopper, melting, mixing, extrusion, cooling, drying, granulation.

[0034]The extruder process conditions are: the use of twin screw extruder, the first section is the feeding section, the second section is the mixed compression section, the third and fourth sections are the melting section, and the latter section is the homogeniz...

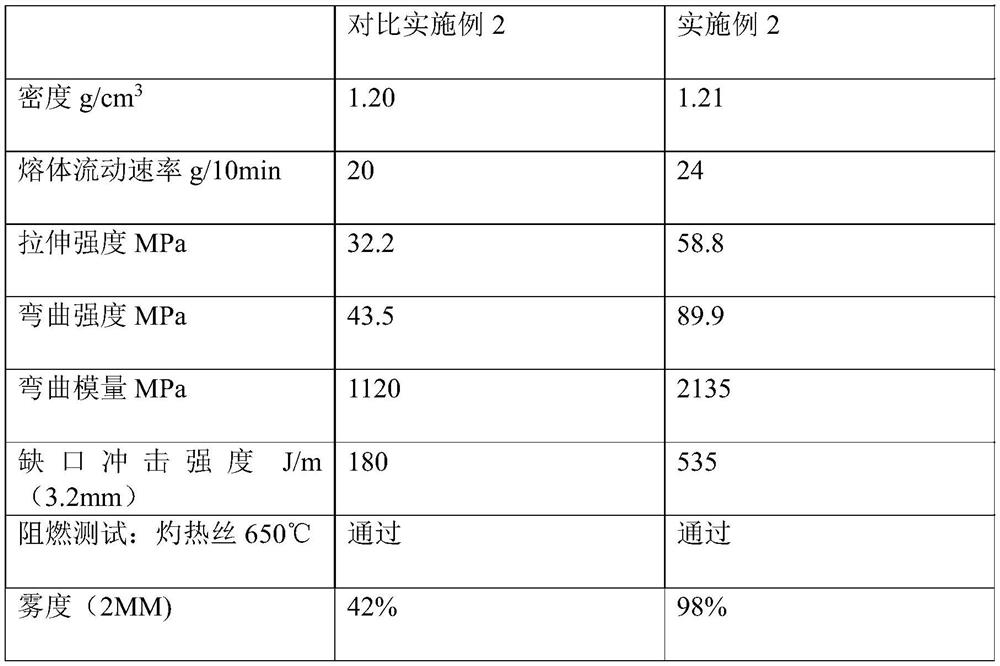

Embodiment 2

[0047] (1) Preparation of masterbatch:

[0048] Take the following components of raw materials: titanium dioxide 50 parts; polycarbonate raw materials 45 parts; color powder 6 parts; toughening agent (methyl methacrylate - butadiene - styrene terpolymer mixed with silicone 1:1 mixed) 15 parts; antioxidant (phosphite and octadecahydrate propionate 1:1 mixed) 1.2 parts; dispersant (pentaerythrityl stearate and ethylene double stearic acid 1:1 mix) 1.5 parts.

[0049] In the polycarbonate raw materials add an appropriate amount of white oil mixed for 3-5 minutes, and then add the corresponding number of tougheners, titanium dioxide, dispersants, antioxidants, etc. mixed for 5-10 minutes, mixed evenly, the high-speed mixer premixed raw material mixture into the twin screw extruder hopper, melting, mixing, extrusion, cooling, drying, granulation.

[0050] The extruder process conditions are: the use of twin screw extruder, the first section is the feeding section, the second section is...

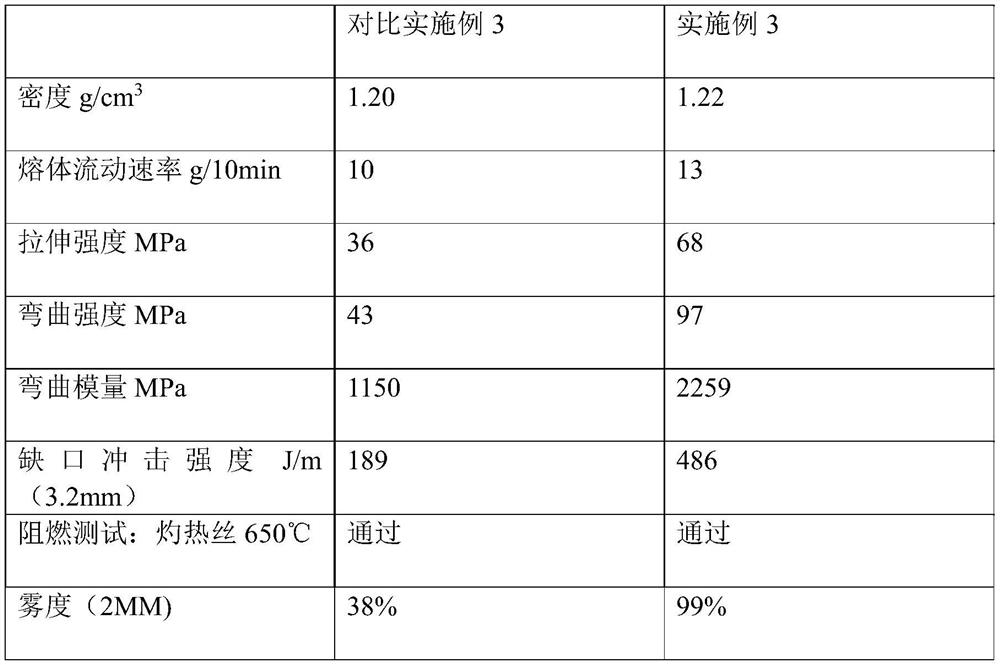

Embodiment 3

[0063] (1) Preparation of masterbatch:

[0064] Take the raw materials of the following components: 50 parts of titanium dioxide, 45 parts of polycarbonate raw materials, 6 parts of color powder, 15 parts of toughening agent (silicone), 1.2 parts of antioxidant (octadecahydrate propionate), 1.5 parts of dispersant (ethylene double stearic acid).

[0065] In the polycarbonate raw materials add an appropriate amount of white oil mixed for 3-5 minutes, and then add the corresponding number of tougheners, titanium dioxide, dispersants, antioxidants, etc. mixed for 5-10 minutes, mixed evenly, the high-speed mixer premixed raw material mixture into the twin screw extruder hopper, melting, mixing, extrusion, cooling, drying, granulation.

[0066] The extruder process conditions are: the use of twin screw extruder, the first section is the feeding section, the second section is the mixed compression section, the third and fourth sections are the melting section, and the latter section is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com