Structure of air guiding hood and its manufacturing method

An air guide hood and a manufacturing method technology, applied in the field of the air guide hood, can solve the problems of increasing the manufacturing cost of the air guide hood, increasing the inventory of the air guide hood and the space occupied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

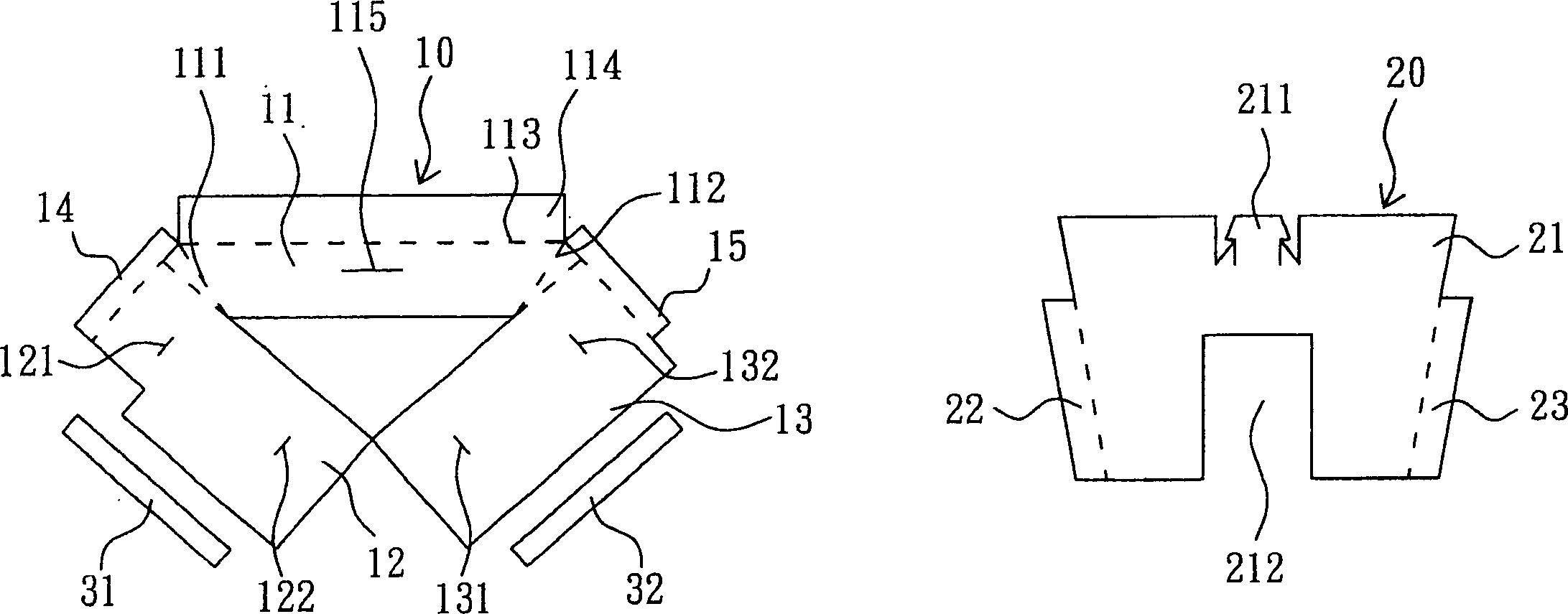

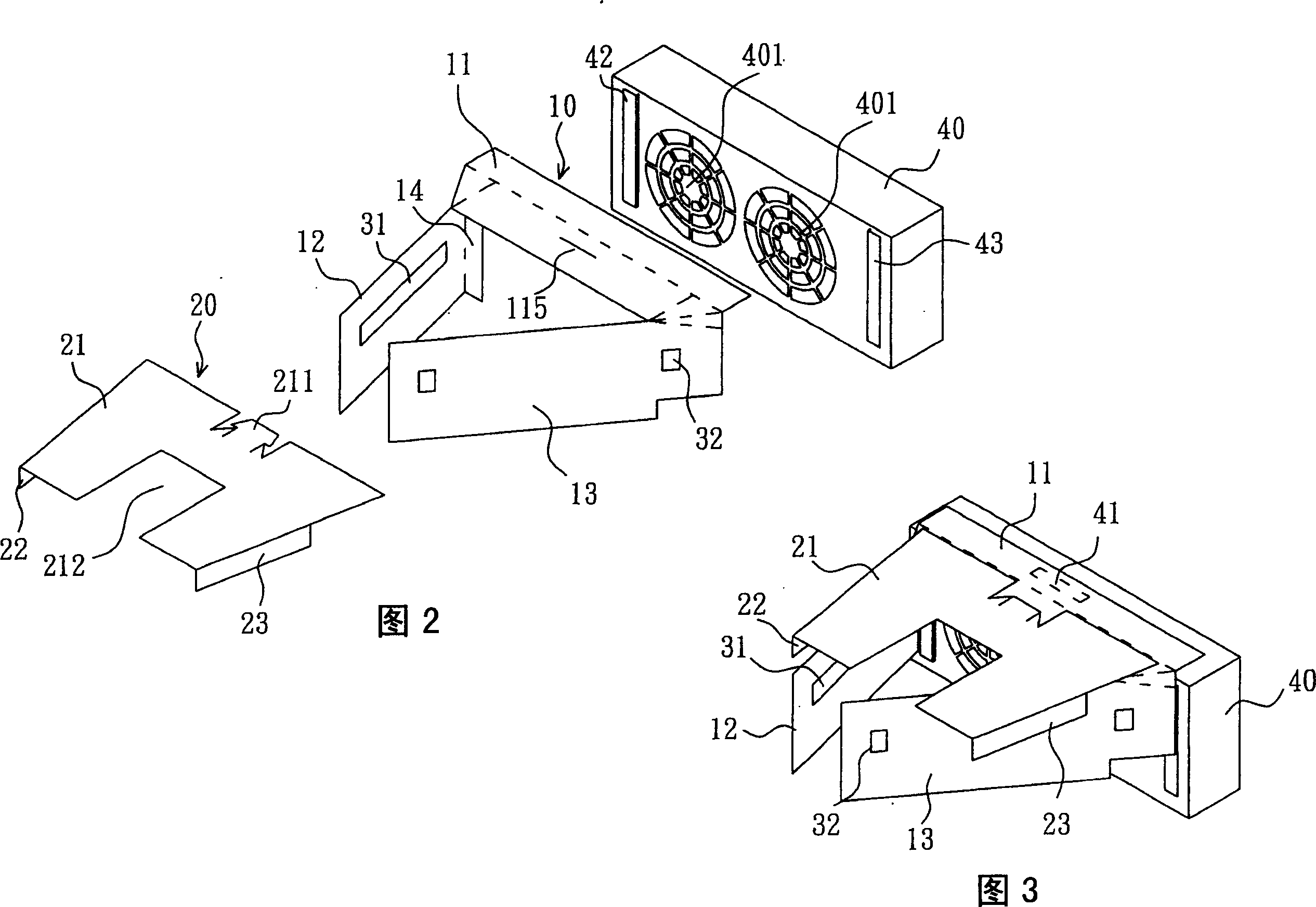

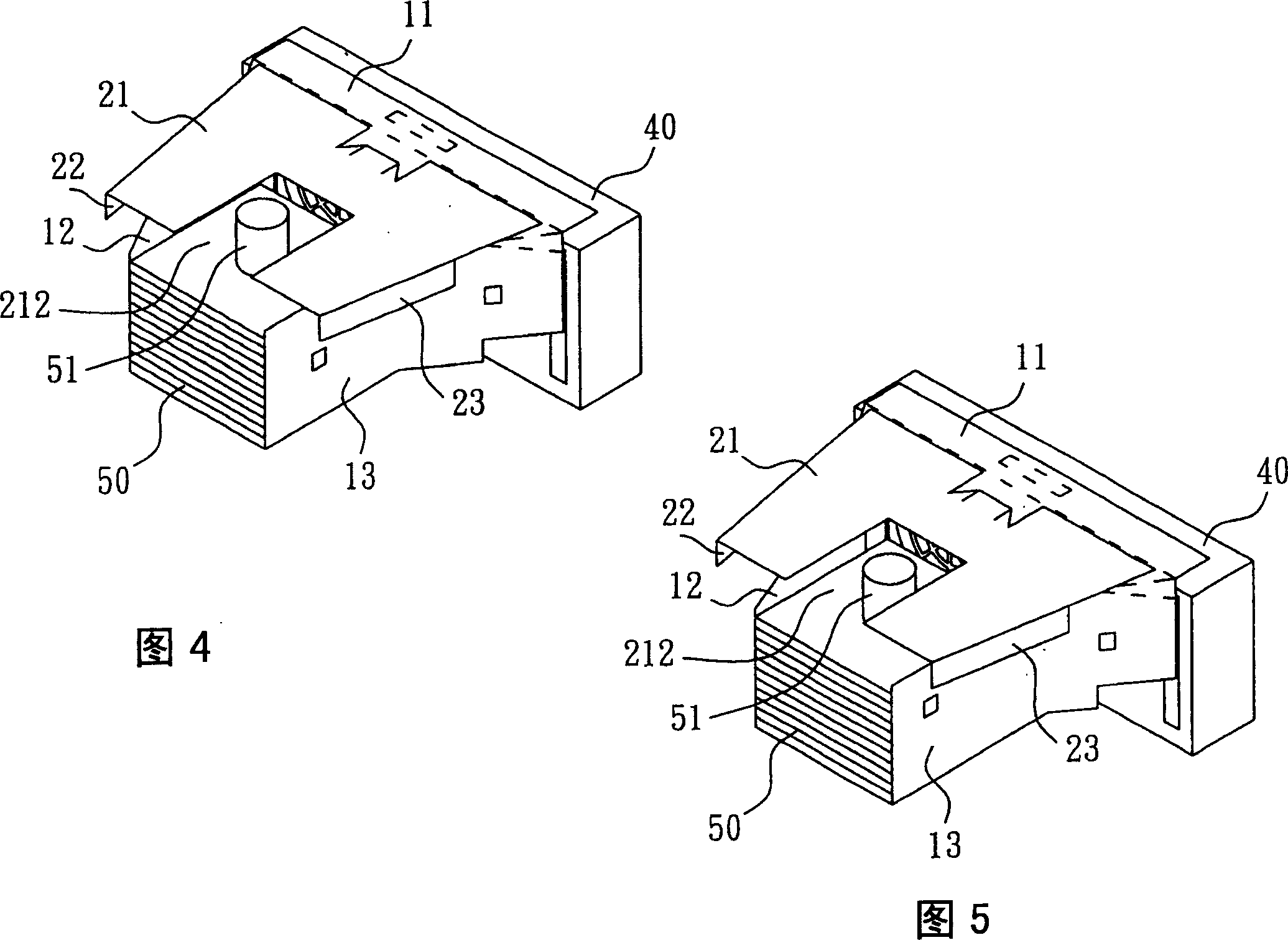

[0036] see figure 1 , as shown in Figure 2. The structure of the air guide cover of the present invention comprises a plurality of board bodies such as a main board 10 , a sub-board 20 and two reinforcement boards 31 , 32 . The main board 10 is formed by cutting a thin sheet with a cutting die, and has a plurality of bendable lines. The main board 10 is bent along a plurality of bending lines, and a front panel 11 , two side panels 12 , 13 and two joining panels 14 , 15 can be distinguished and folded. That is, the side panels 12, 13 are bent on both sides of the front panel 11, and extend to the bottom of both sides of the front panel 11, forming a cover with the front panel 11 above and the side panels 12, 13 on both sides. The bendable lines 111 , 112 connecting the front panel 11 with the side panels 12 , 13 are inclined to the inner side ends of the front panel 11 respectively. Therefore, after the two side plates 12 and 13 are bent, the distance between them is wide i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com