Multipurpose plastic honeycomb bundle

A plastic honeycomb and plastic technology, applied in animal husbandry and other directions, can solve the problems of lack and difficulty in implementation, and achieve the effect of good cocoon quality, ensuring basic functions and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

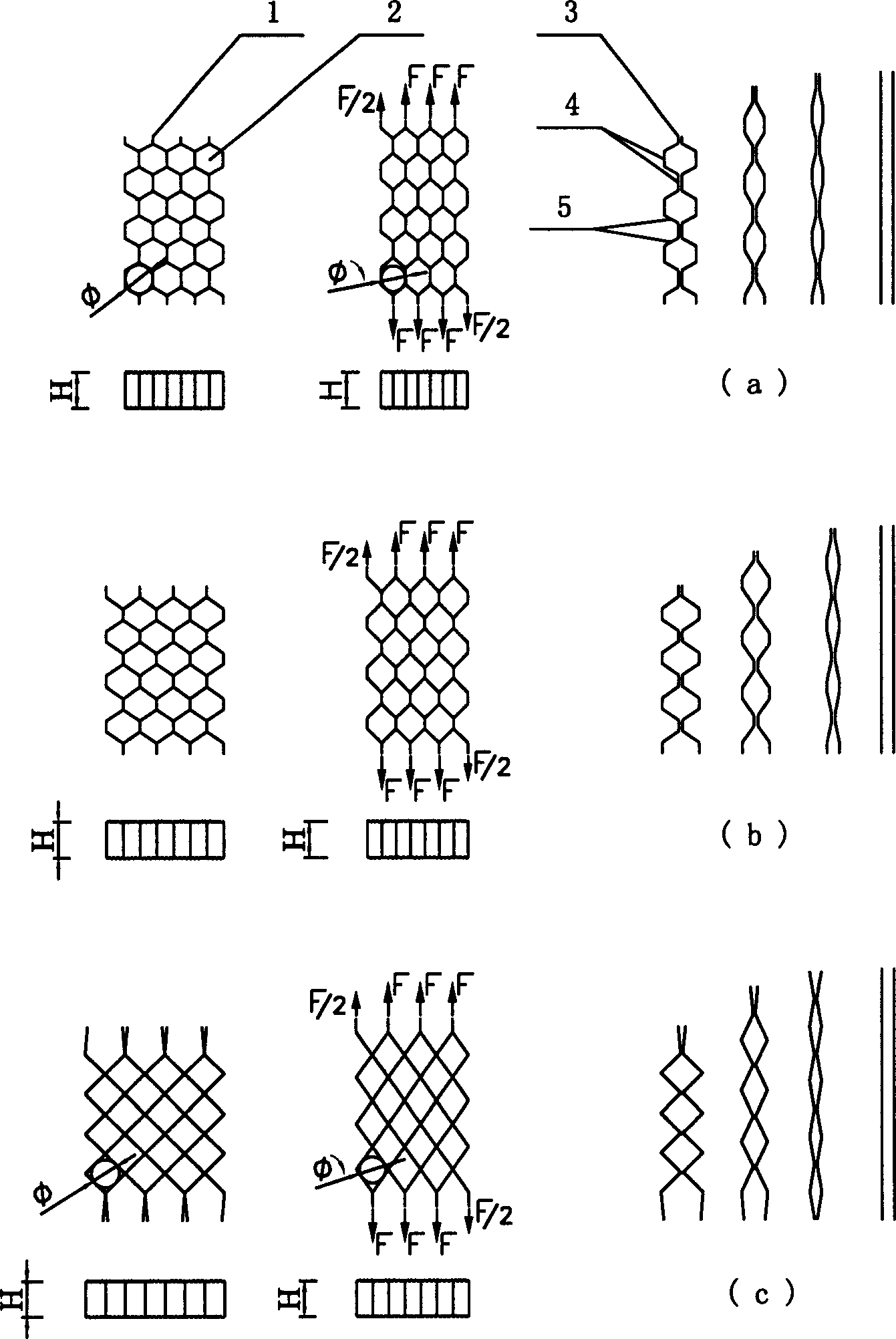

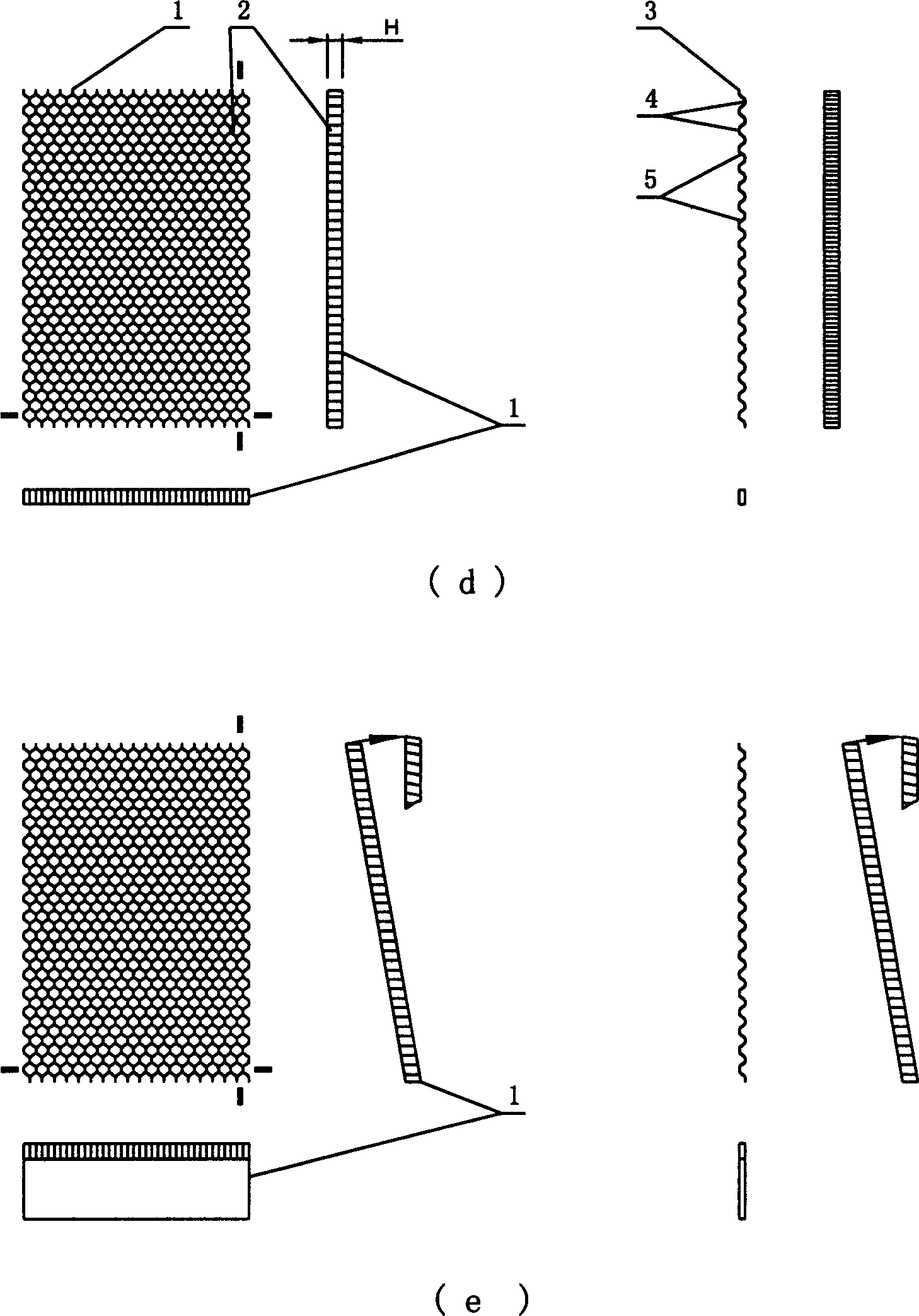

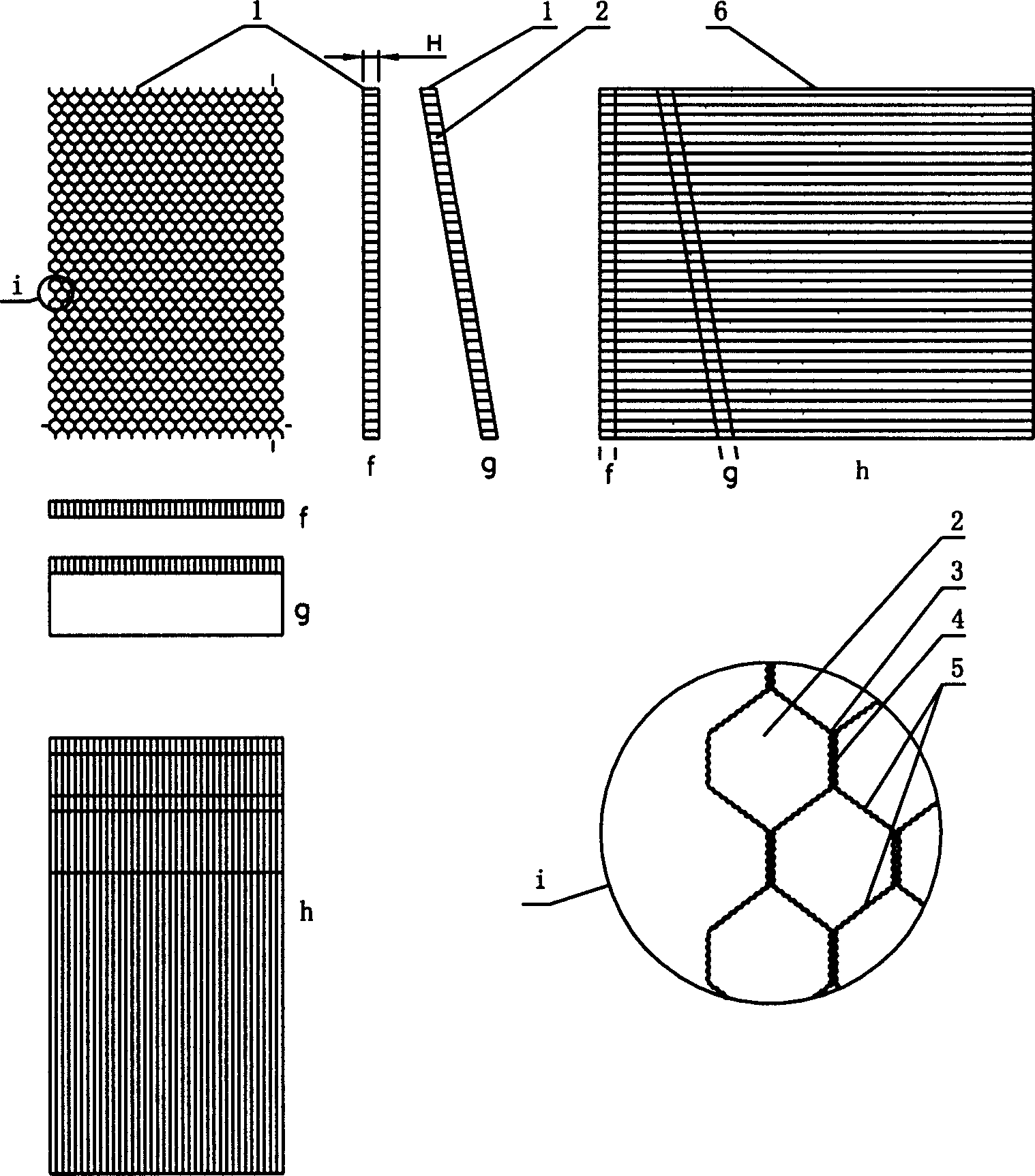

Method used

Image

Examples

example 1

[0079] Example 1, a group of plastic single-hole clusters, which were hand-rolled with embossed PP sheets, 15ml jelly cups (octagonal square cups and rugby cups) with the bottoms removed and fitted, and film cups with the bottoms removed and the lids removed for use. Plastic cocoons that have undergone modification treatment or improper surface modification treatment, no matter artificially introduce cooked silkworms into the holes or carefully lock the cooked silkworms inside with gauze nets, the cooked silkworms will try to escape soon without spinning silk and cocooning in them. The silkworms are excreted outside first; the surface modification treatment is more appropriate plastic cocoon holes, no matter whether the cooked silkworms are artificially put into the holes or the cooked silkworms enter the holes by themselves, the mature silkworms can spin silk and cocoon normally in it, and the tails of the mature silkworms can reach the level Excretion outside the pile hole. ...

example 2

[0080] Example 2, small-scale plastic honeycomb clusters, hand-made with PP film with a thickness of 0.12mm, the nominal size of the cluster holes is Φ30×H40, after the clusters are treated with a relatively appropriate surface modification as described in Example 1, the cooked silkworms are automatically loaded The back cocoons are placed vertically, and the tails of the mature silkworms can reach out of the horizontal cocoons for excretion, and spin silk and form cocoons in them normally.

example 3

[0081] Example 3, 612-hole multi-purpose plastic honeycomb clusters, the nominal size of the clusters is Φ30×H45, and the light white PP alloy sheet with a thickness of 0.35mm is machine-molded and manufactured, supplemented by manual processing, and the overall size of the clusters is 900×555 ×45, the number of sack holes is 18×34, that is, 612. Take one of them and cut dozens of holes, and after appropriate surface modification treatment, the cooked silkworms will automatically go up to the sack and spin silk normally in it, and the cocoon quality is good; Silkworm eggs use 40 silkworm plaques, so each silkworm plaque only needs a multi-purpose plastic honeycomb cluster sheet of 612 holes; the 612 hole cluster sheet of this example is more delicate. see Figure 5 : Example of the appearance of 612-hole multi-purpose plastic honeycomb cluster.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com