High cutting slope advanced supporting construction method

A technology of advanced support and construction method, applied in excavation, foundation structure engineering, sheet pile wall and other directions, can solve the problems of high engineering investment, large cross-section size of supporting piles, large earth pressure, etc., to reduce engineering investment, material Economical, earth pressure reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

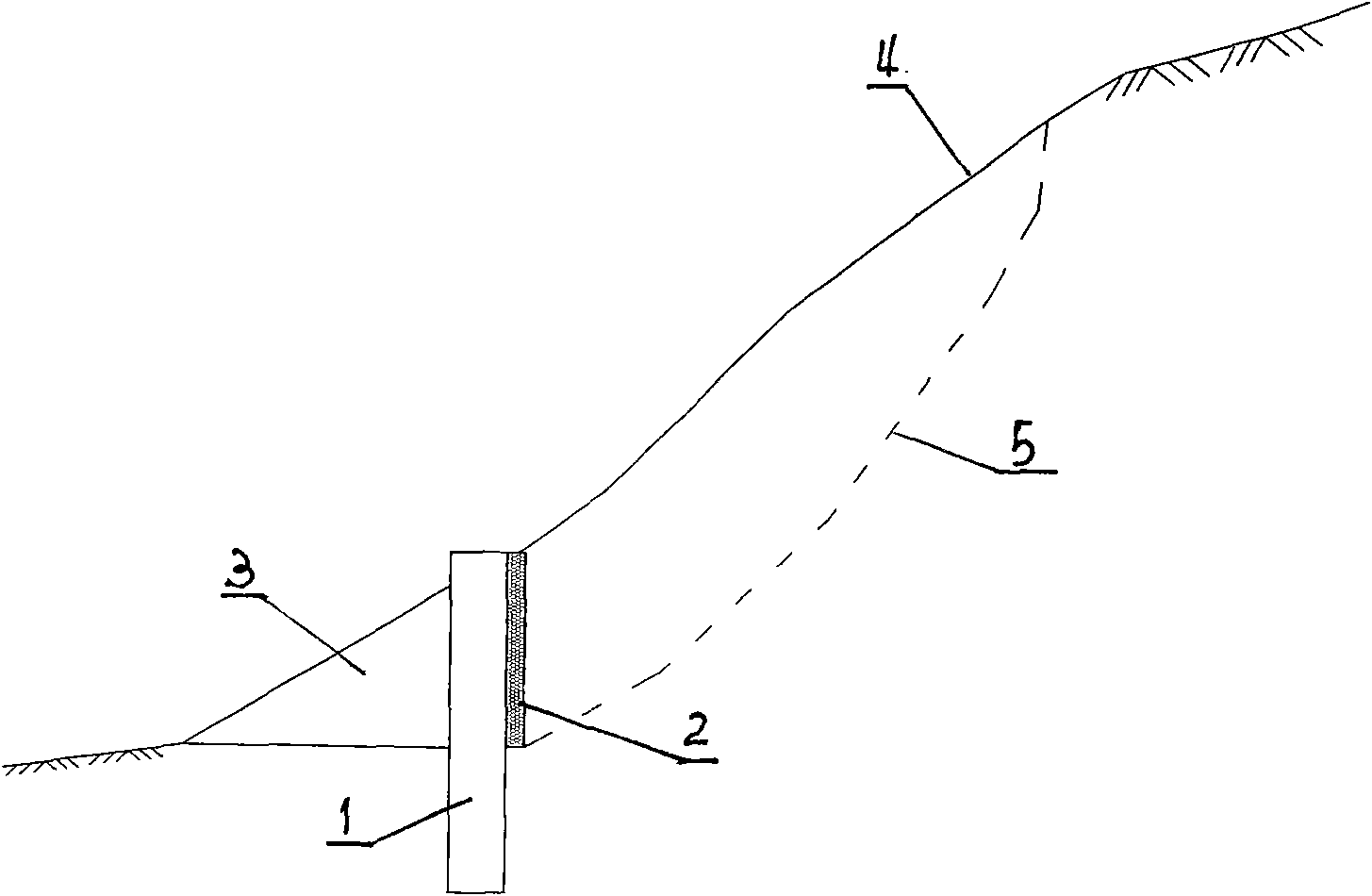

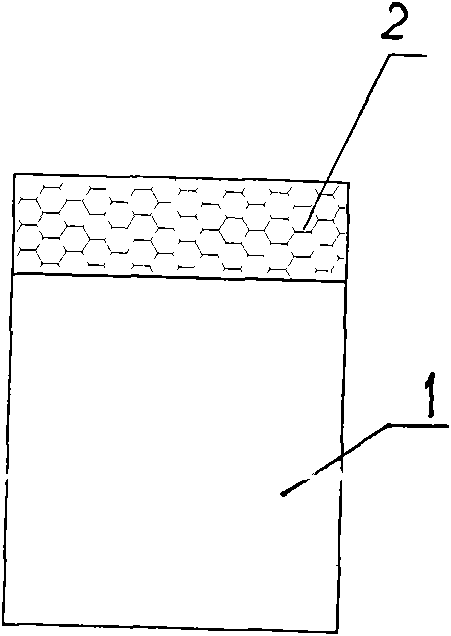

[0016] Example: see figure 1 figure 2 , before the excavation of the high slope, first excavate the advance support pile 1, and set a certain thickness of polystyrene foam cushion material 2 above the excavation surface on the side of the advance support pile, and then pour the pile body concrete, A new structure of polystyrene foam advanced support piles is formed, and the high slope is excavated after the advanced support structure reaches 70% strength. The polystyrene foam cushion material is a numerical test method to determine the optimal setting thickness of the polystyrene foam cushion material.

[0017] For dangerous high cut slopes, the advance support piles are excavated first, and a certain thickness of polystyrene foam cushion material (EPS) is installed on the side above the excavation surface of the advance support piles. The material type and thickness can be verified by numerical tests. Obtain (so as to determine its replacement setting thickness), then pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com