Patents

Literature

40results about How to "Material economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

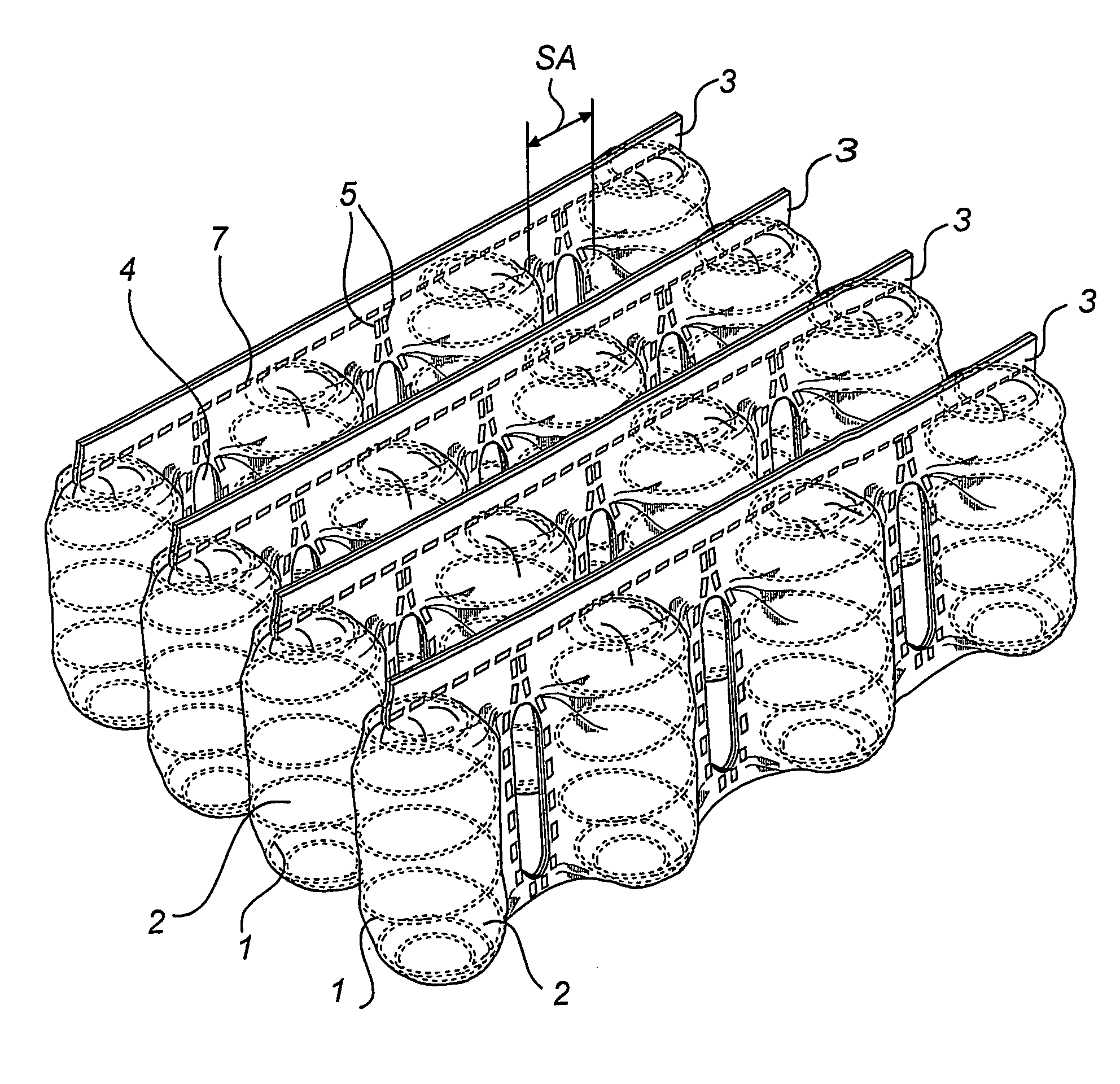

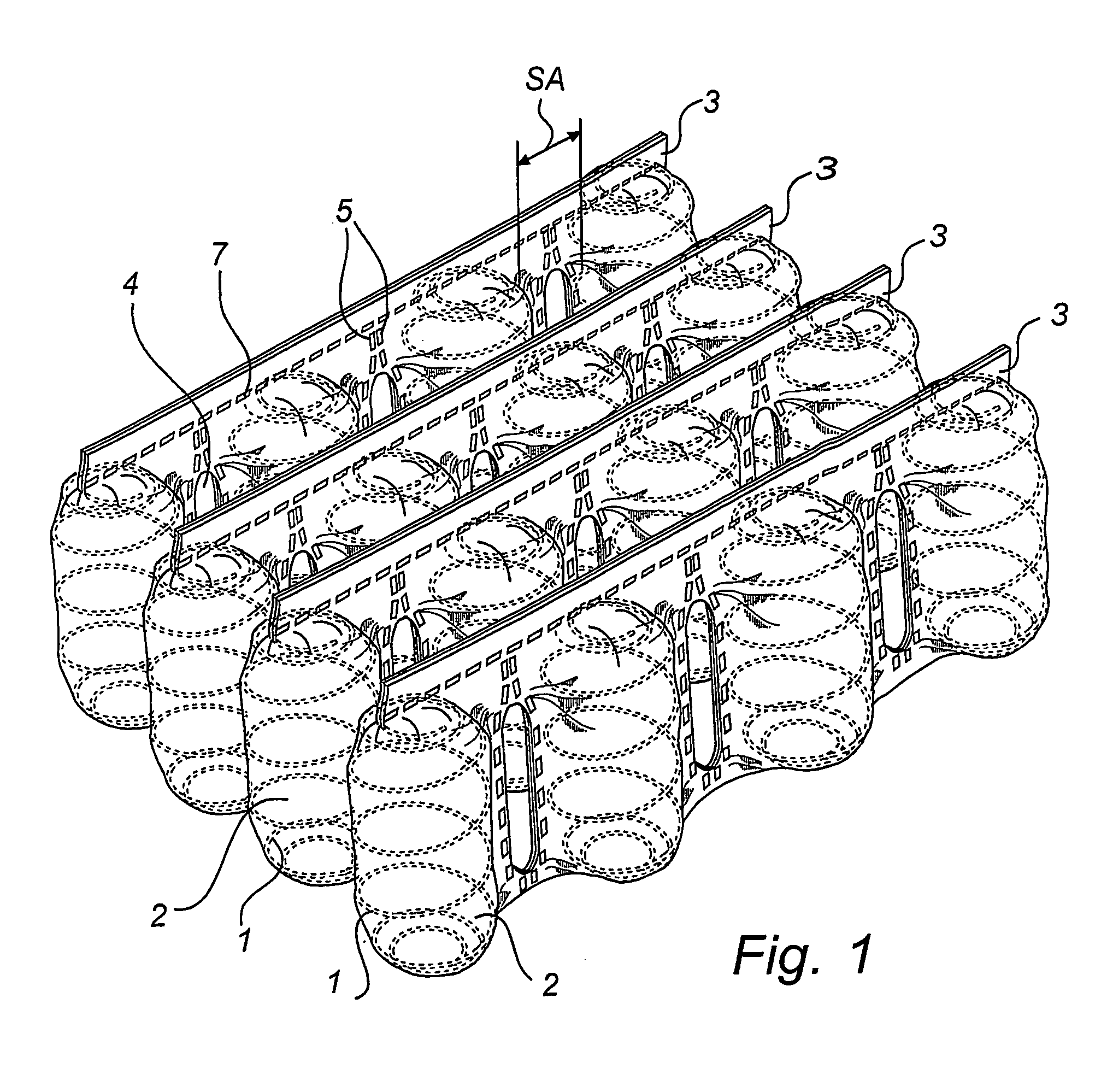

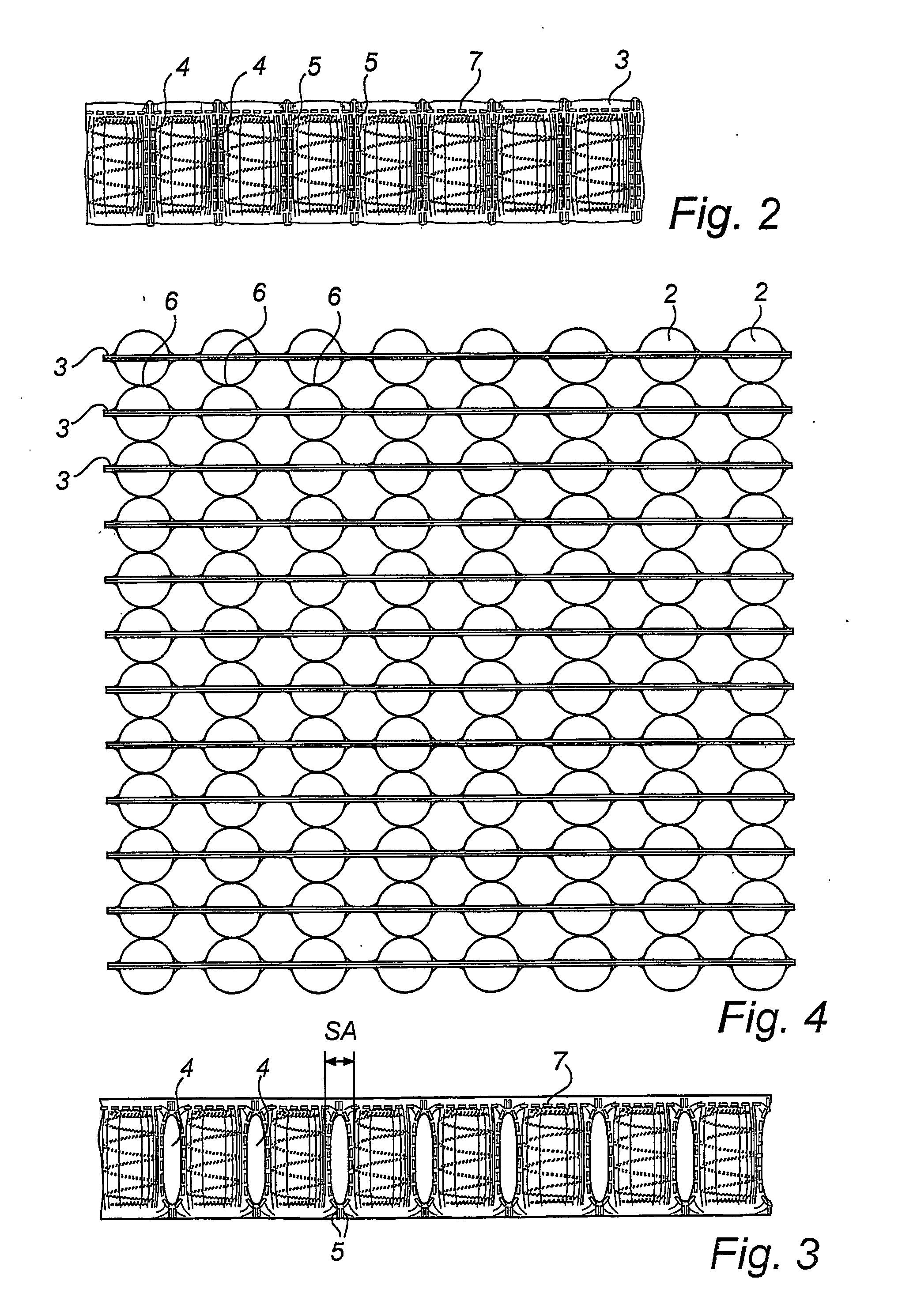

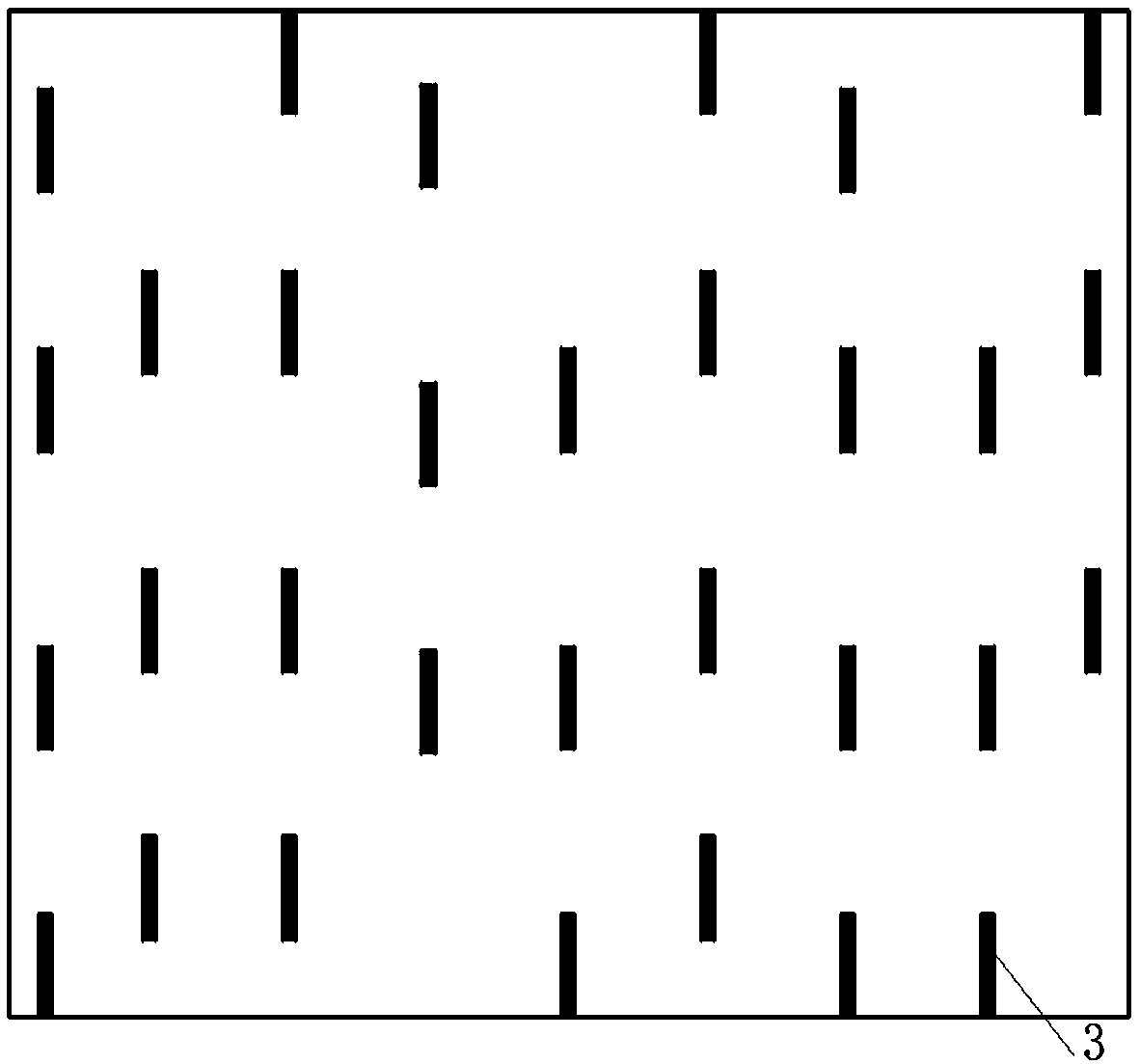

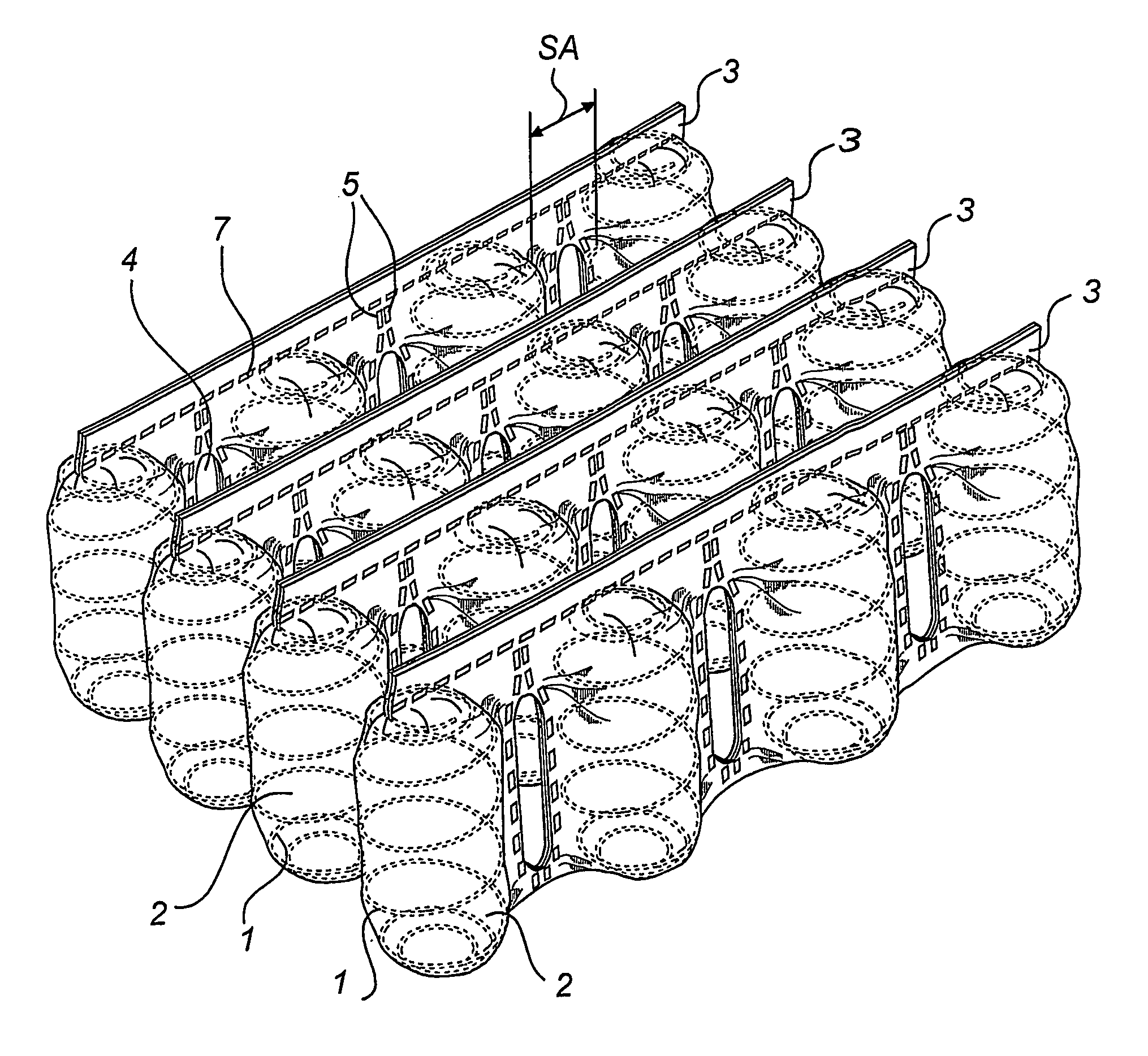

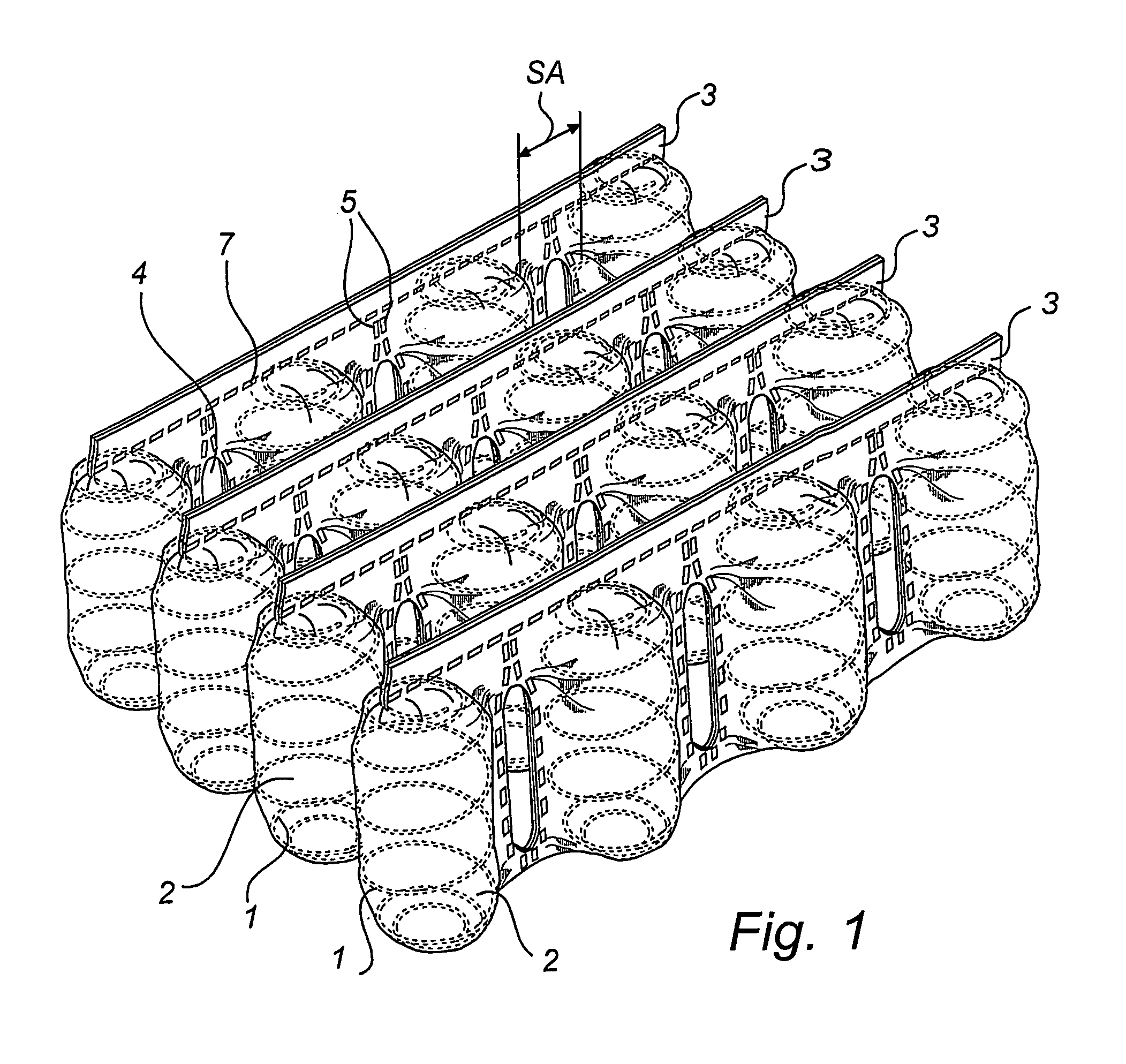

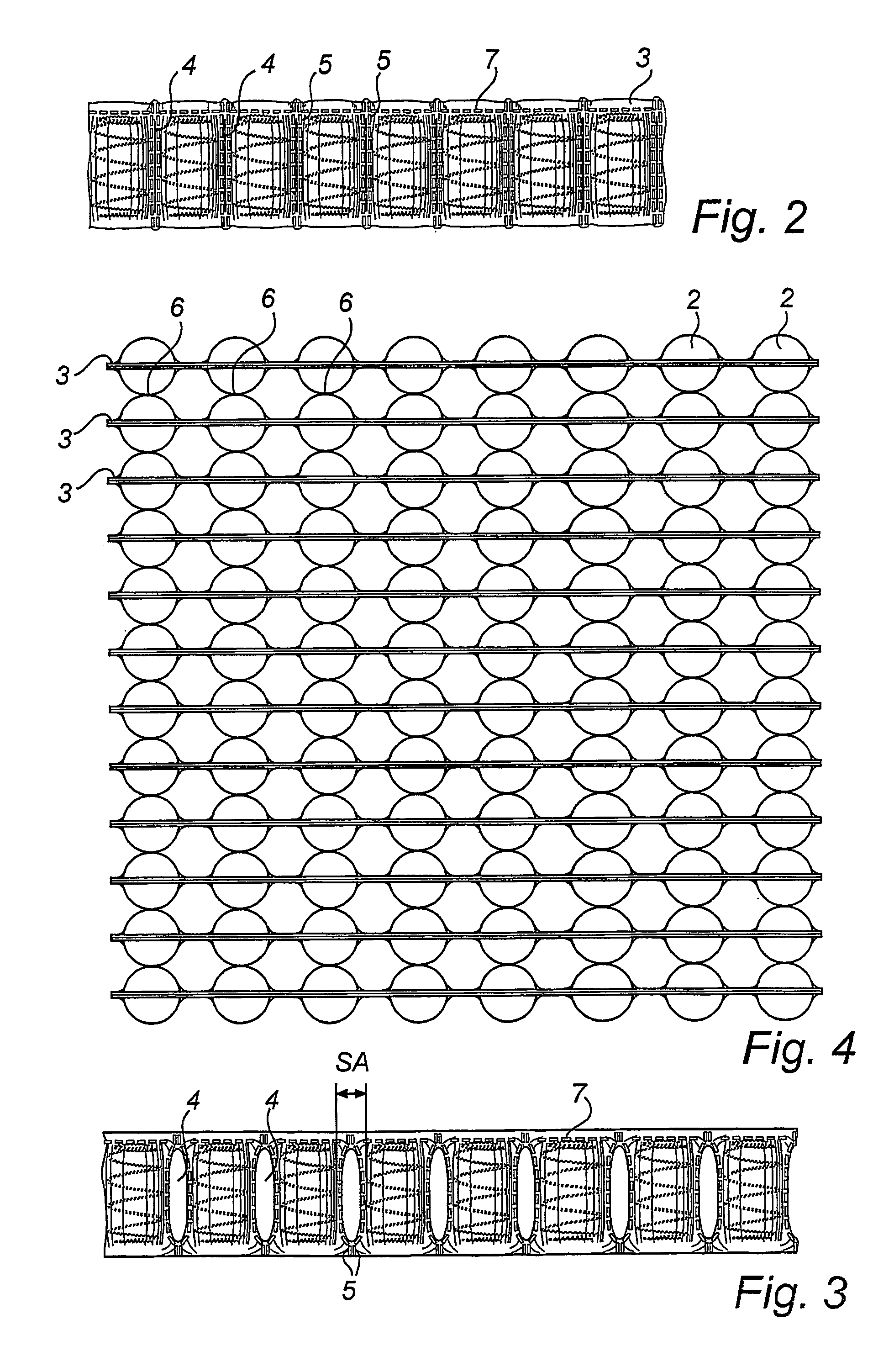

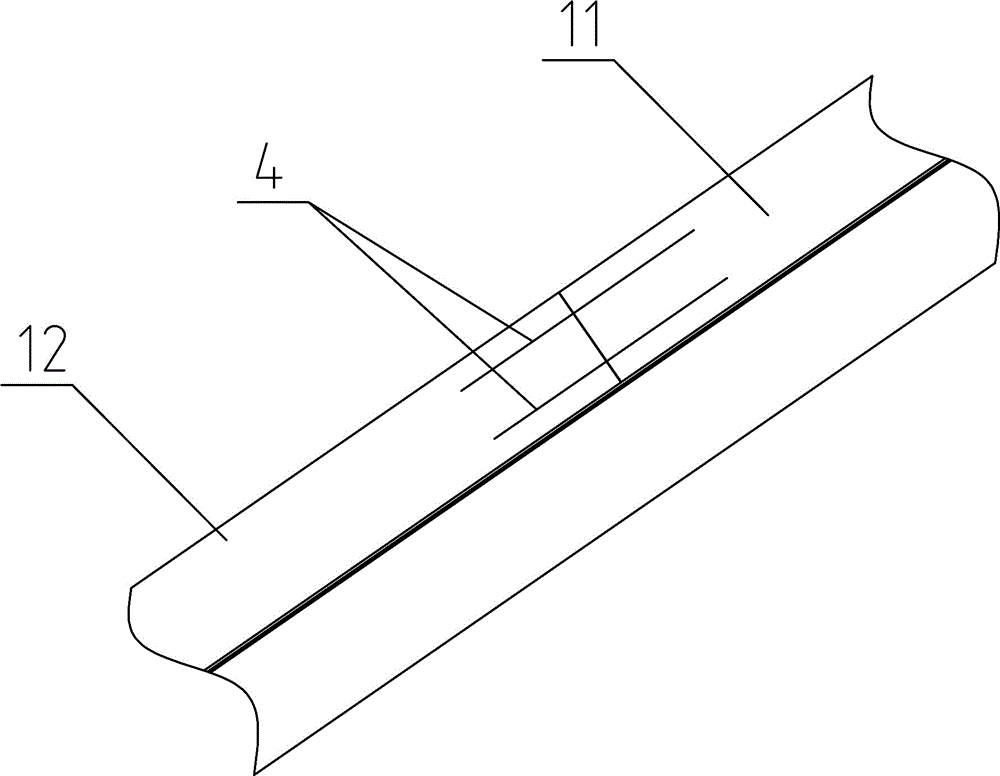

Separated pocket spring mattress with cut through string, and method and apparatus for production of such mattress

ActiveUS20070124865A1Easy to provideMaterial economyStuffed mattressesSpring mattressesCoil springBiomedical engineering

Owner:STARSPRINGS AB

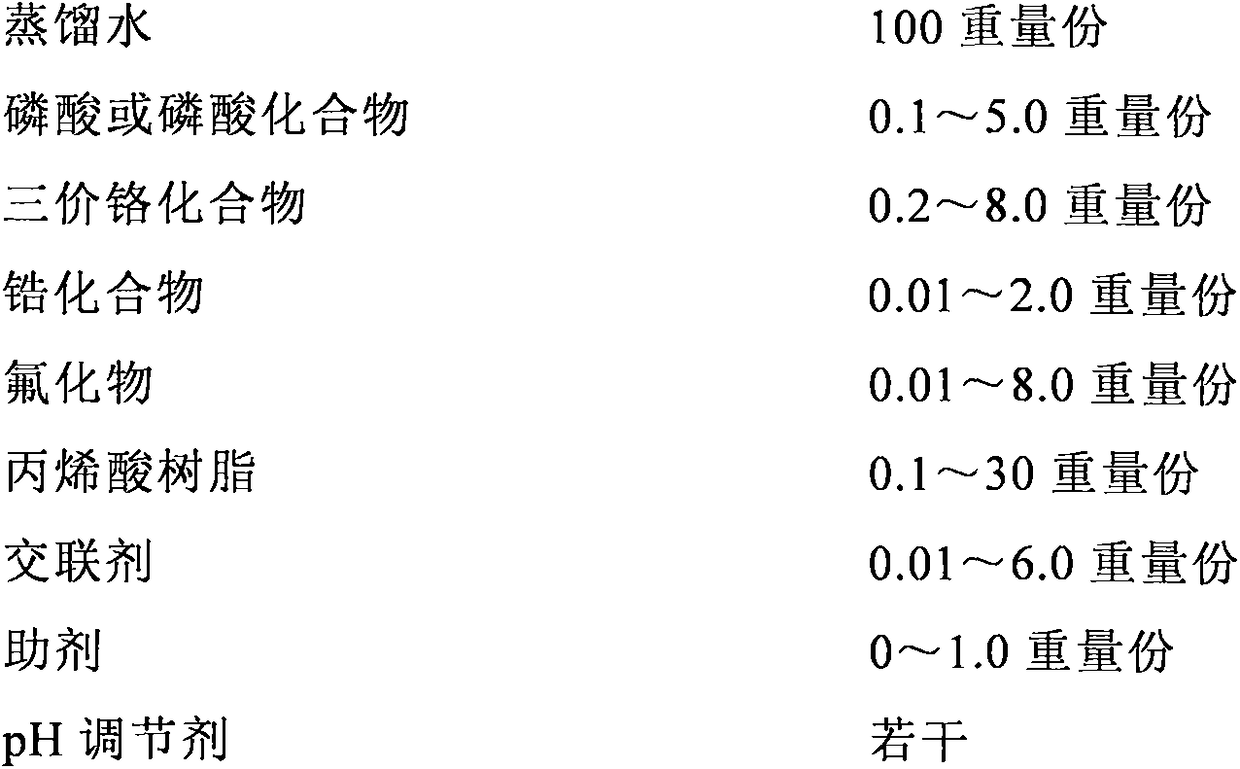

Passivation solution suitable for processing aluminum foil of aluminum-plastic film

InactiveCN108754472AImprove corrosion resistanceImprove bindingMetallic material coating processesChromium CompoundsPolyolefin

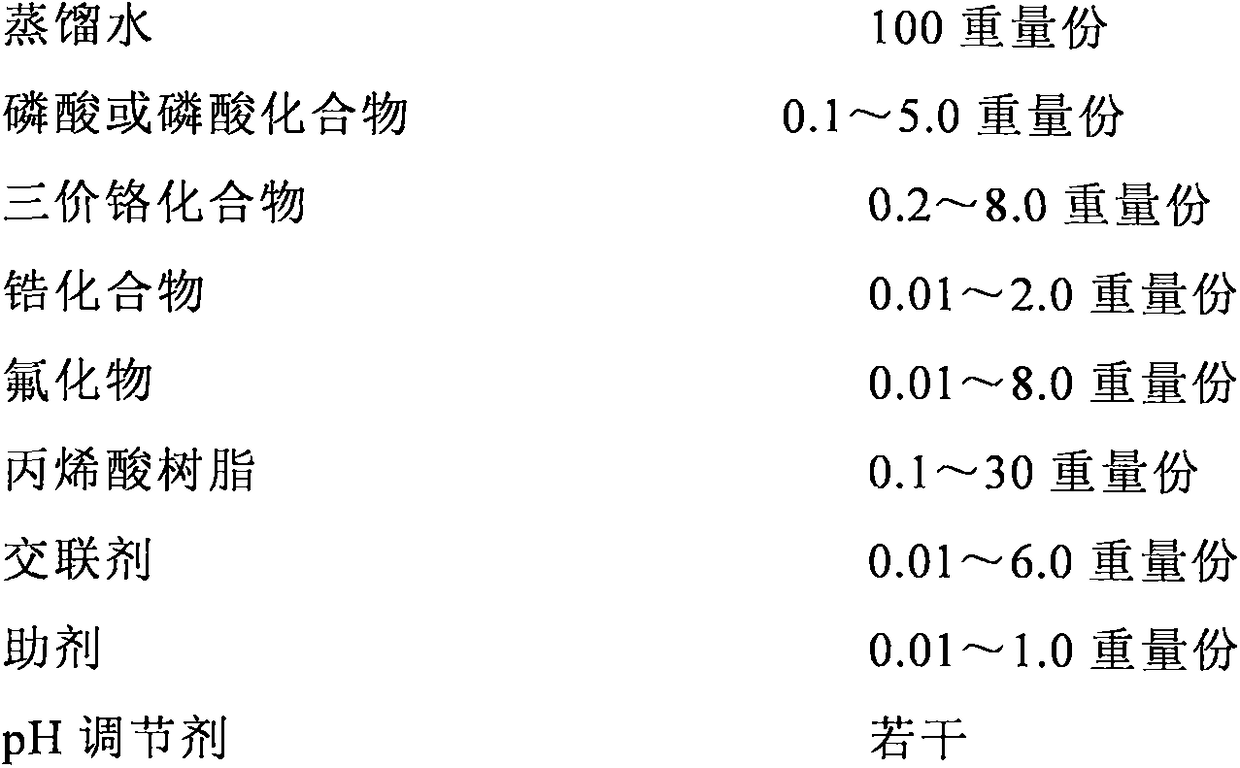

The invention relates to a passivation solution suitable for processing the aluminum foil of an aluminum-plastic film. The passivation solution comprises, by weight, 100 parts of distilled water, 0.1-5.0 parts of phosphoric acid or phosphate compound, 0.2-8.0 parts of trivalent chromium compound, 0.01-2.0 parts of zirconium compound, 0.01-8.0 parts of fluoride, 0.1-30 parts of acrylic resin, 0.01-6.0 parts of crosslinking agent, 0-1.0 part of auxiliary and a certain amount of pH regulator. 8021 aluminum foil processed by the passivation solution has excellent corrosion resistance, and the processed aluminum foil combined with CPP through modified polyolefin-based glue has excellent binding force, electrolyte resistance and water resistance.

Owner:惠州市广麟材耀科技有限公司

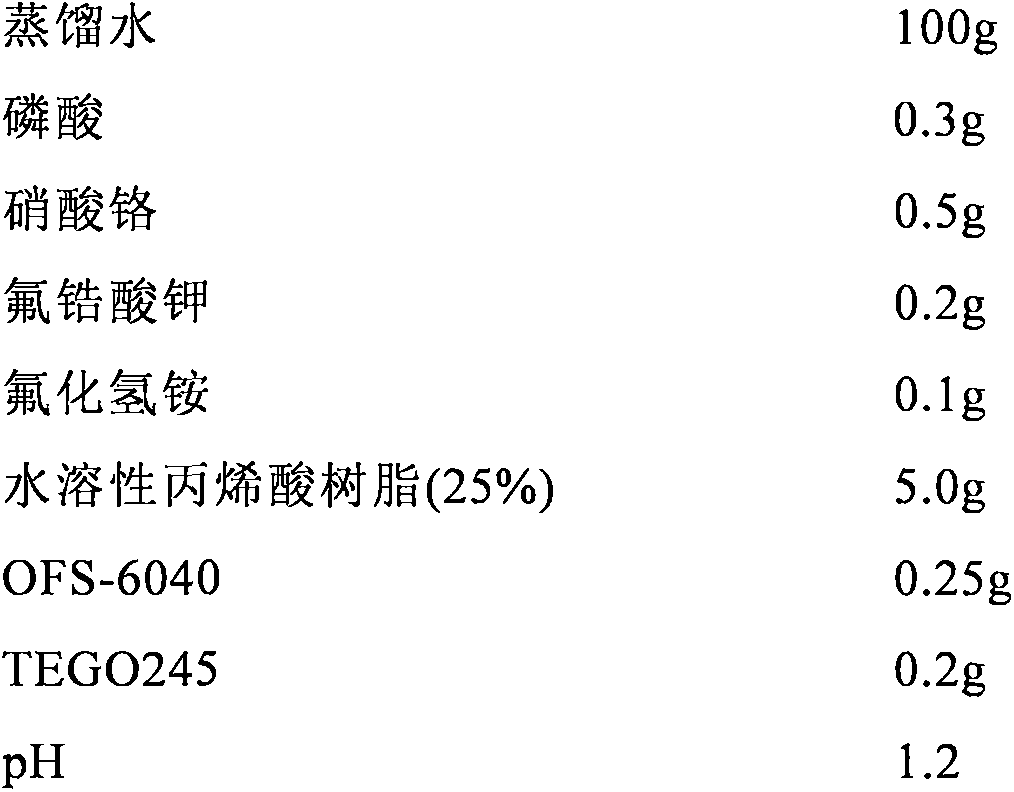

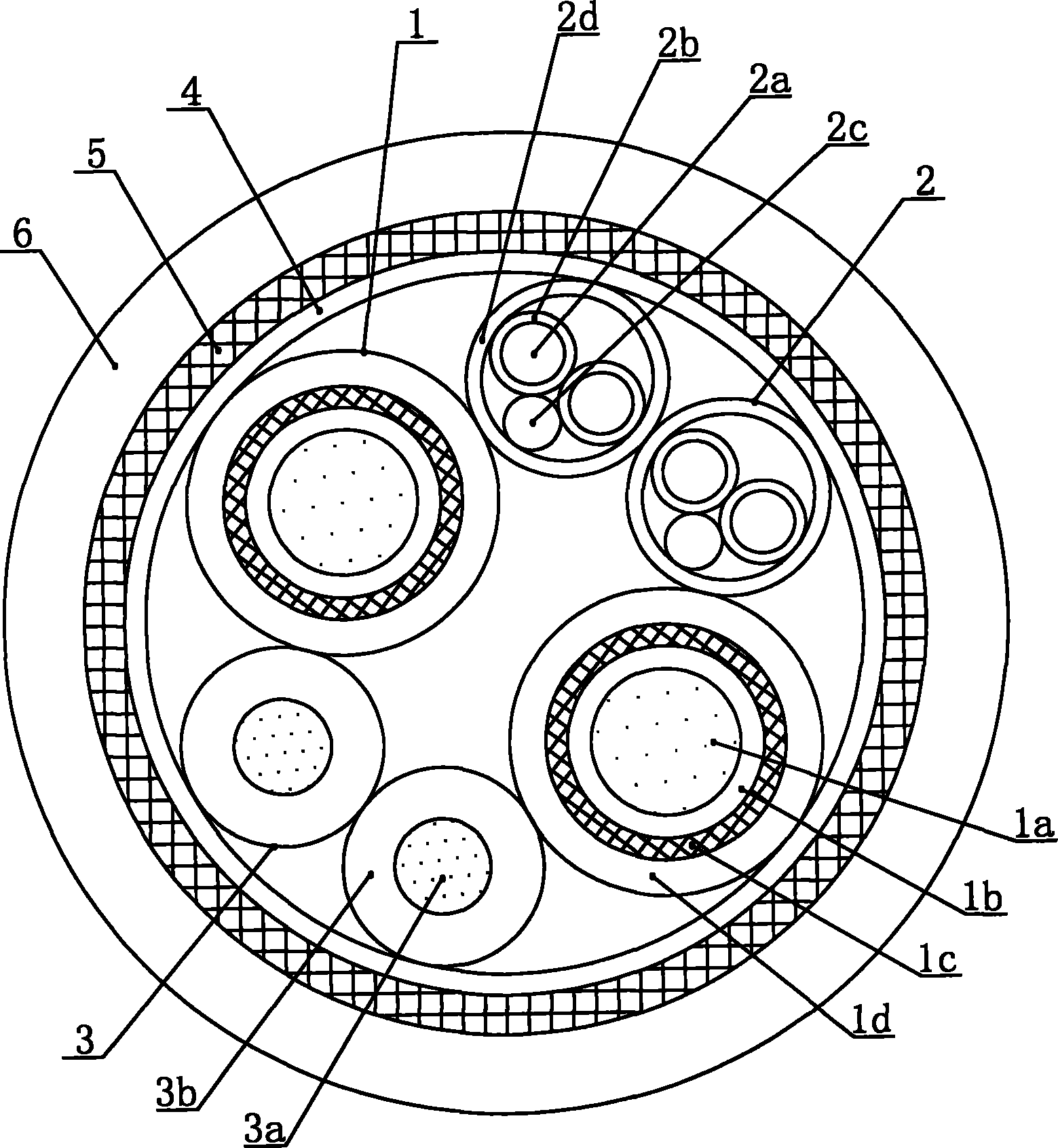

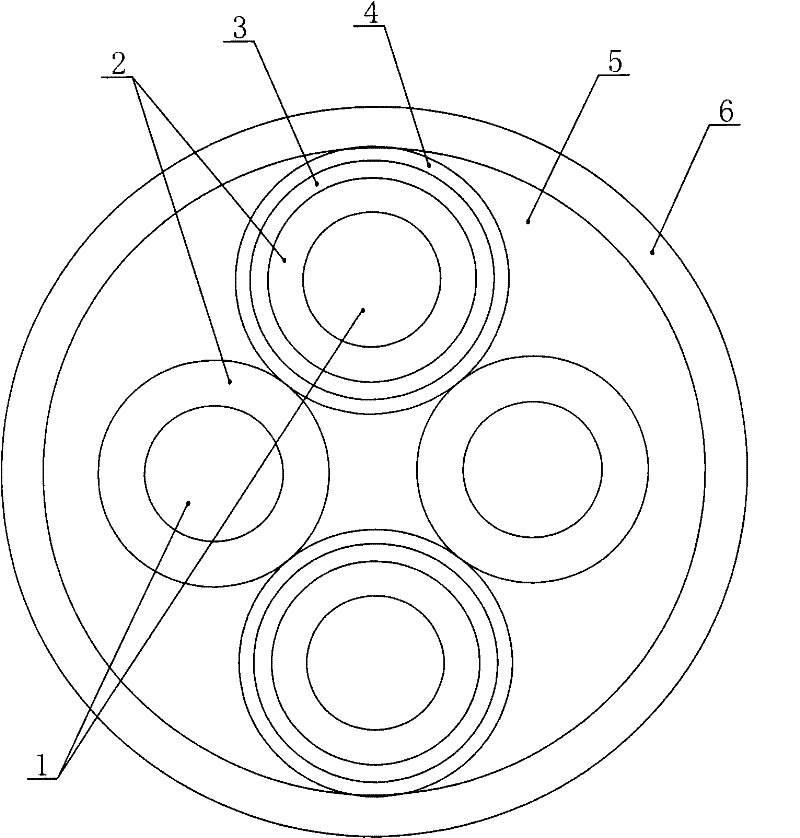

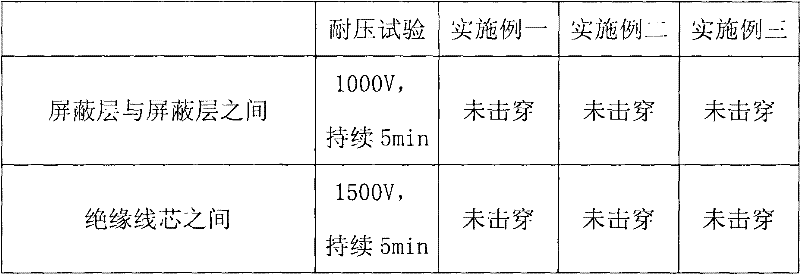

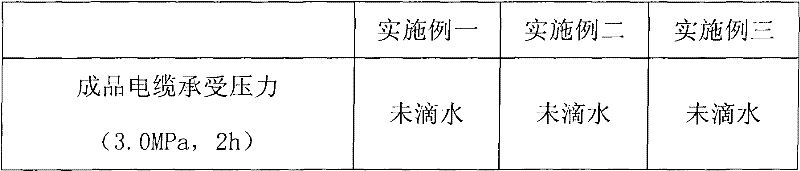

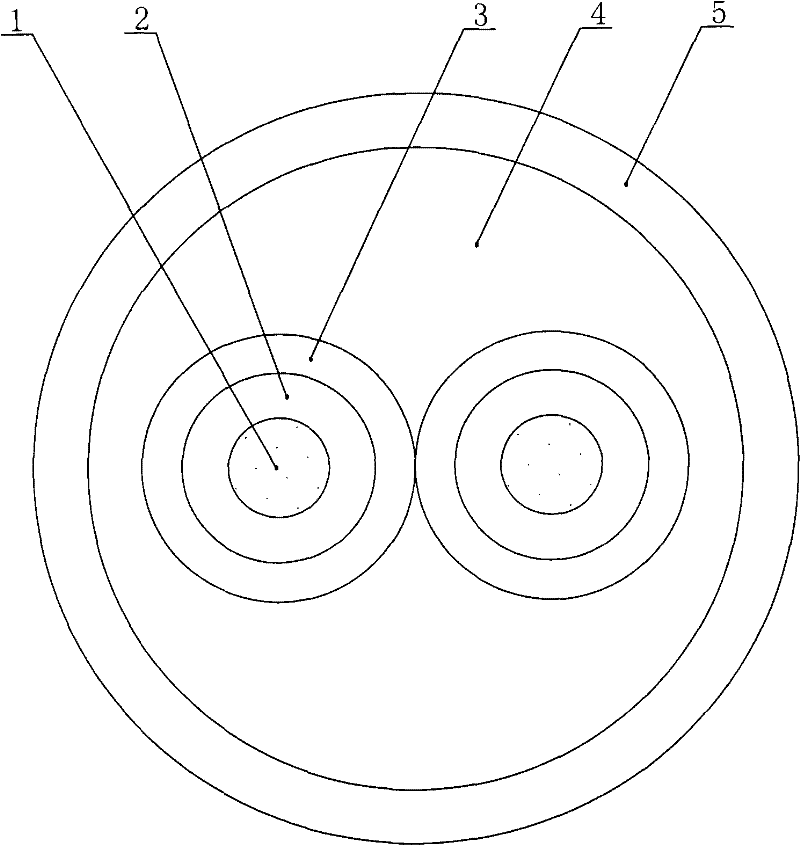

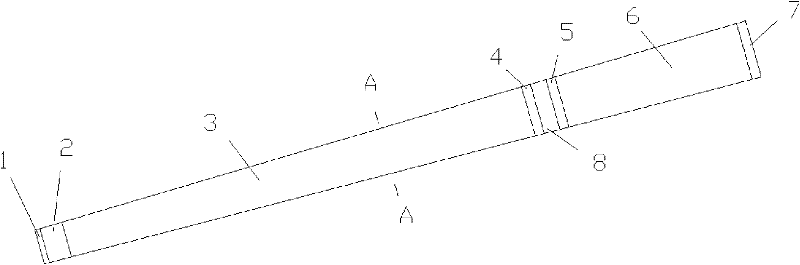

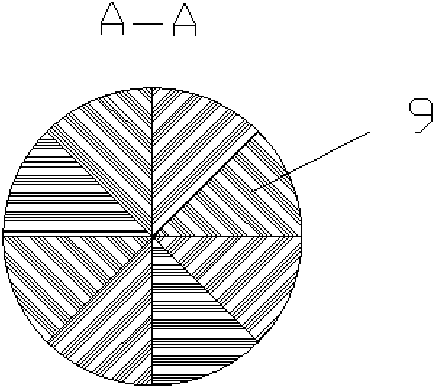

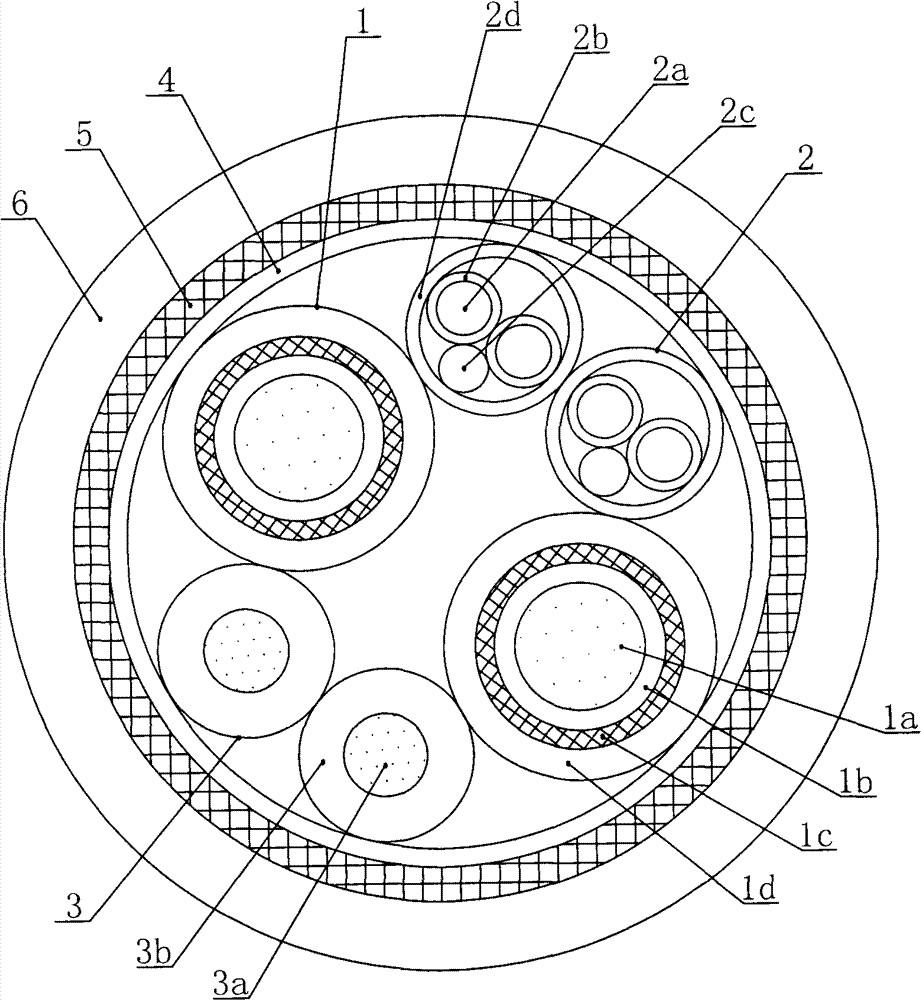

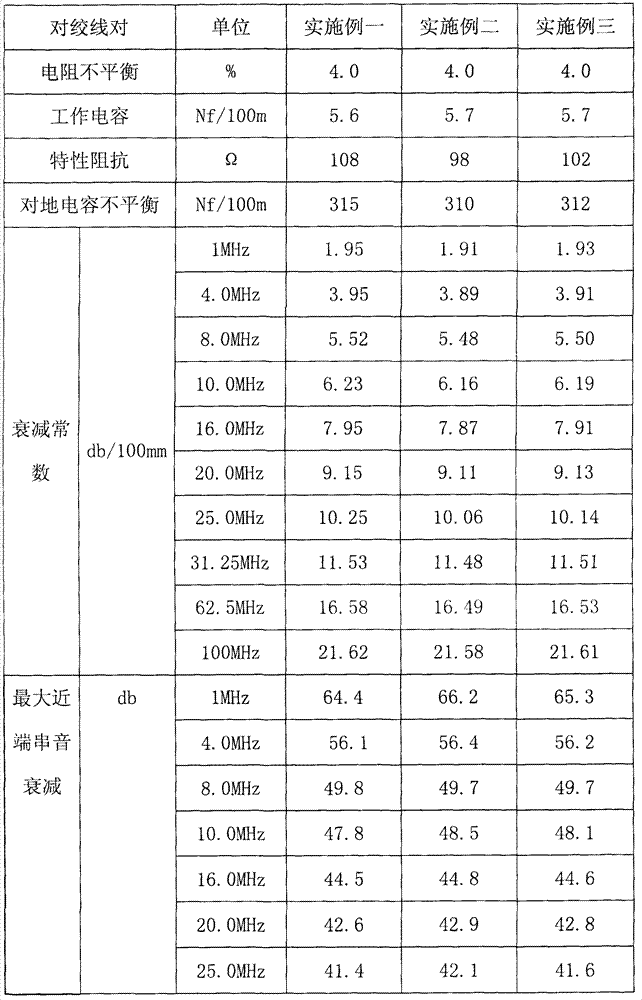

Cable for ship marine closed circuit television camera and manufacturing method thereof

InactiveCN102097161AImprove conductivityImprove insulation performanceInsulated cablesInsulated conductorsCopper conductorPower cable

The invention discloses a cable for a ship marine closed circuit television camera and a manufacturing method thereof, belonging to the field of cables. A cable core comprises a coaxial cable, a twisted pair core wire and a power cable and is peripherally wrapped with a polyester tape lapped layer; the polyester tape lapped layer is peripherally wrapped with a tinned copper wire shielding layer which is peripherally wrapped with an outer sheath; a center conductor of the coaxial cable is outwardly wrapped with a coaxial cable insulating layer, a coaxial cable shielding layer and a coaxial cable sheath in order; the center of the twisted pair core wire comprises a group of twisted pair wire pair and a non-insulating copper conductor leakage wire; the twisted pair wire pair is formed by mutually twisting two single-stranded insulating core wires; each single-stranded insulating core wire comprises a twisted pair wire conductor in the center and a twisted pair wire insulating layer wrapping outside the twisted pair wire conductor, and the twisted pair wire pair and the leakage wire are externally wrapped with aluminum foil polyester composite tapes; the leakage wire is in electric contact with the aluminum layers of the aluminum foil polyester composite tapes; and the power cable comprises a power cable core wire conductor and a power cable insulting layer wrapping outside the power cable core wire conductor.

Owner:JIANGSU YUANYANG DONGZE CABLE

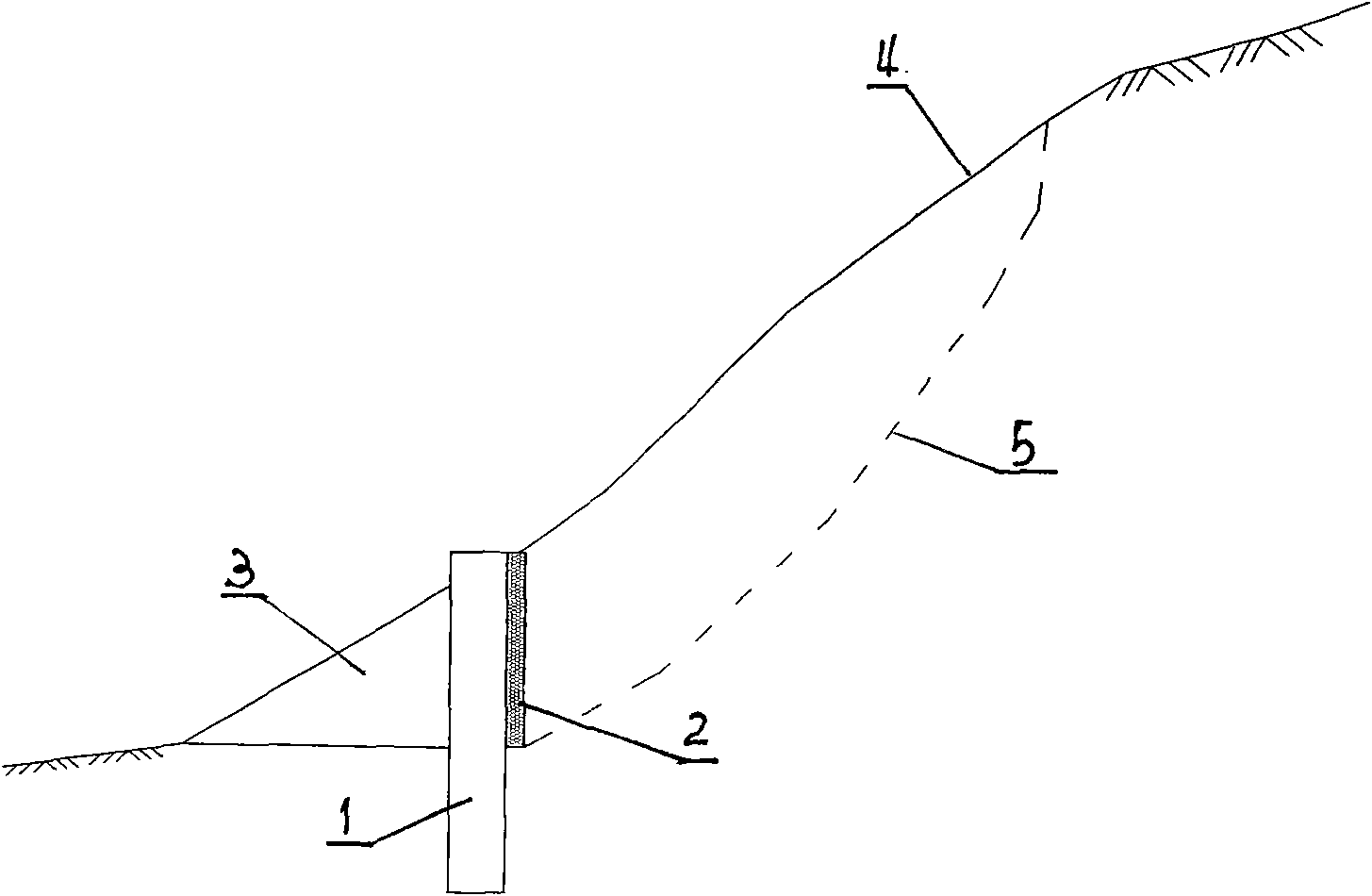

High cutting slope advanced supporting construction method

InactiveCN101624829ASimple structural designSimple designExcavationsBulkheads/pilesPolystyreneUltimate tensile strength

The invention relates to a high cutting slope advanced supporting construction method which is characterized in that: before digging a high cutting slope, an advanced supporting pile is dug and constructed firstly, polystyrene foam carpet material with a certain thickness is arranged above the digging surface of the backing side of the advanced supporting pile, and then a pile body concrete is poured, so as to form a novel structure of the advanced supporting pile with the polystyrene foam material, after the advanced supporting structure has 70 percent of intensity, the high cutting slope is dug; by adopting the self deformation of the polystyrene foam material (EPS), the soil pressure on the advanced supporting pile is reduced and the section size and reinforcing bars of the advanced supporting pile are optimized, thereby greatly reducing the construction investment of the high cutting slope advanced supporting structure and ensuring the whole stability and construction safety of the high cutting slope.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

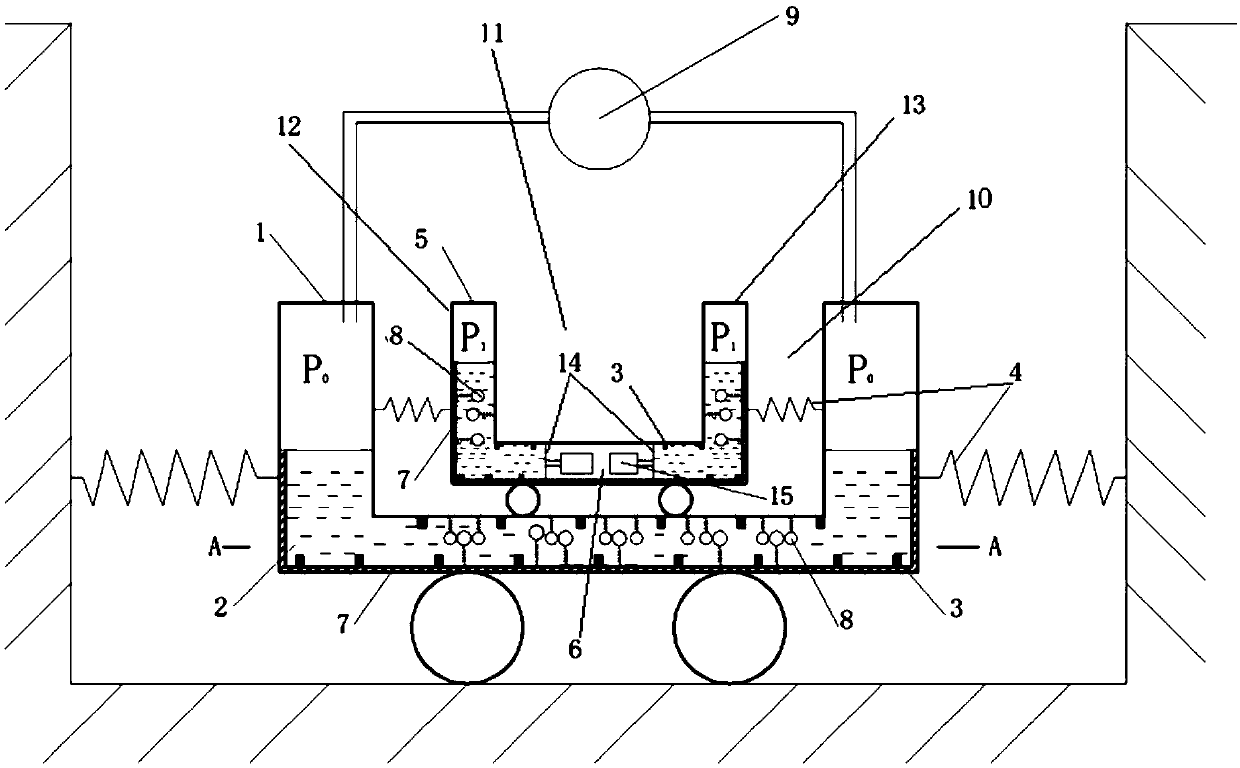

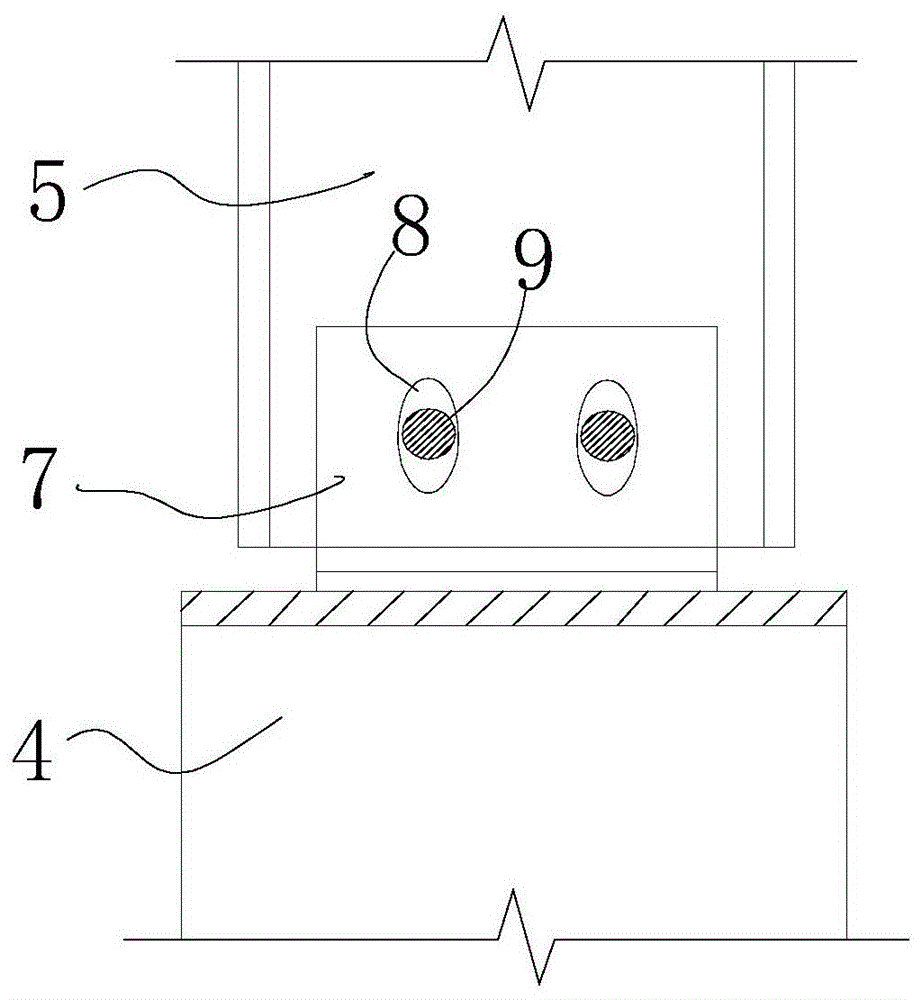

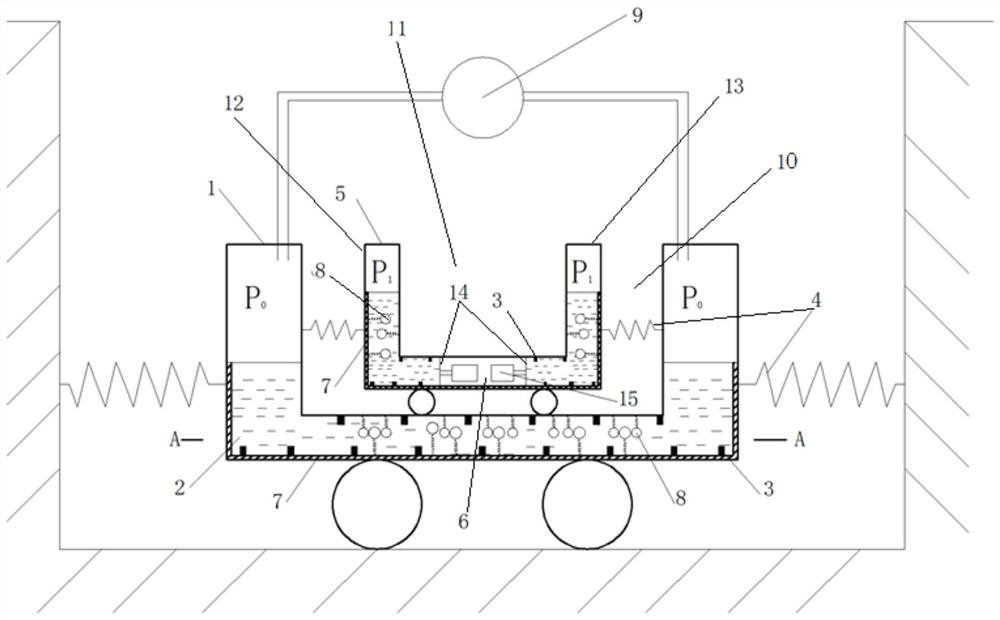

Tuned damper of controllable jacket type marine wind-driven generator

ActiveCN109595292AImprove energy consumptionPlay the role of energy consumptionNon-rotating vibration suppressionMagnetic springsWind drivenControl theory

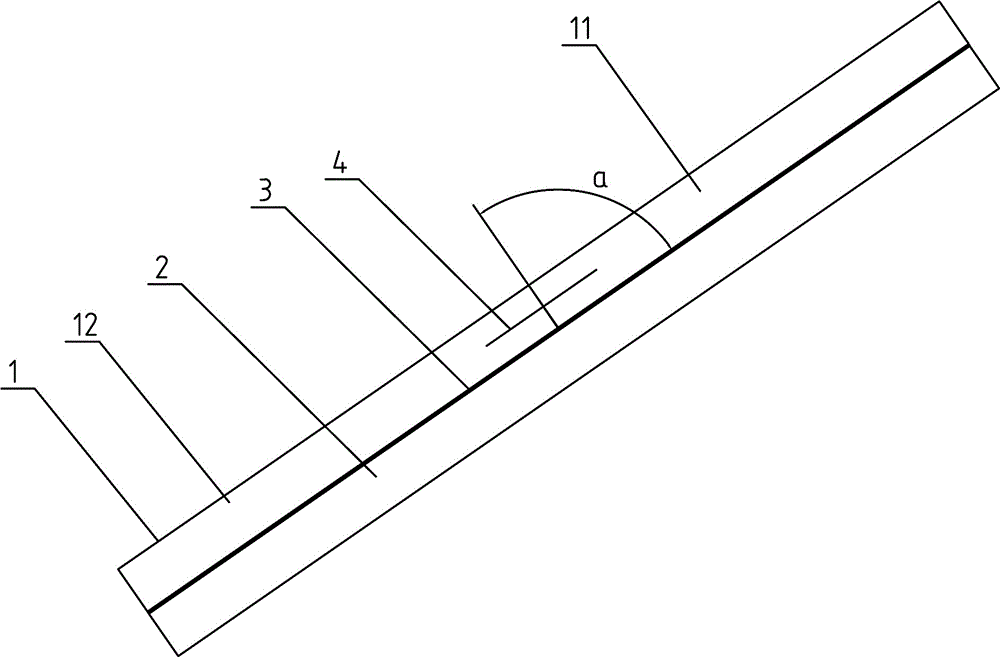

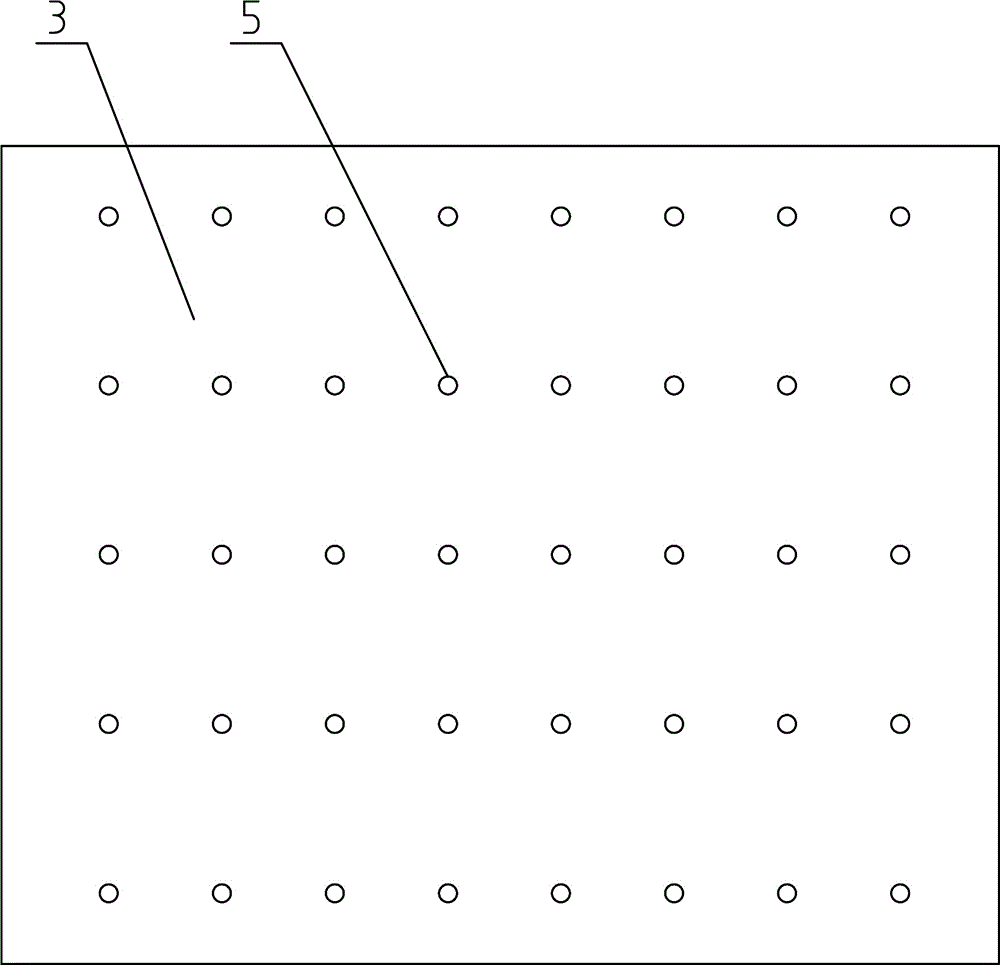

The invention relates to a tuned damper of a controllable jacket type marine wind-driven generator. The tuned damper comprises an external damping cavity unit (1) which is arranged on the ground in asliding manner and an internal damping internal damping unit (5) which is arranged on the external damping cavity unit (1) in a sliding manner, wherein the outer wall of the external damping cavity unit (1) is connected with the wind-driven generator through energy consumption springs (4); a cavity (10) which is sunken downwards is formed in the middle part of the external damping cavity unit (1);the internal damping cavity unit (5) is arranged on a bottom plate of the cavity (10) in a sliding manner; the side wall of the internal damping cavity unit (5) is connected with the inner wall of the cavity (10) through the energy consumption springs (4); the inner part of the external damping cavity unit (1) and the inner part of the internal damping cavity unit (5) are sealed; and liquid (2) is loaded in the external damping cavity unit (1) and the internal damping cavity unit (5), and air is left. Compared with the prior art, the tuned damper disclosed by the invention has various energyconsumption mechanisms under the effect of wind or / and earthquake, and the energy consumption capacity is high.

Owner:TONGJI UNIV

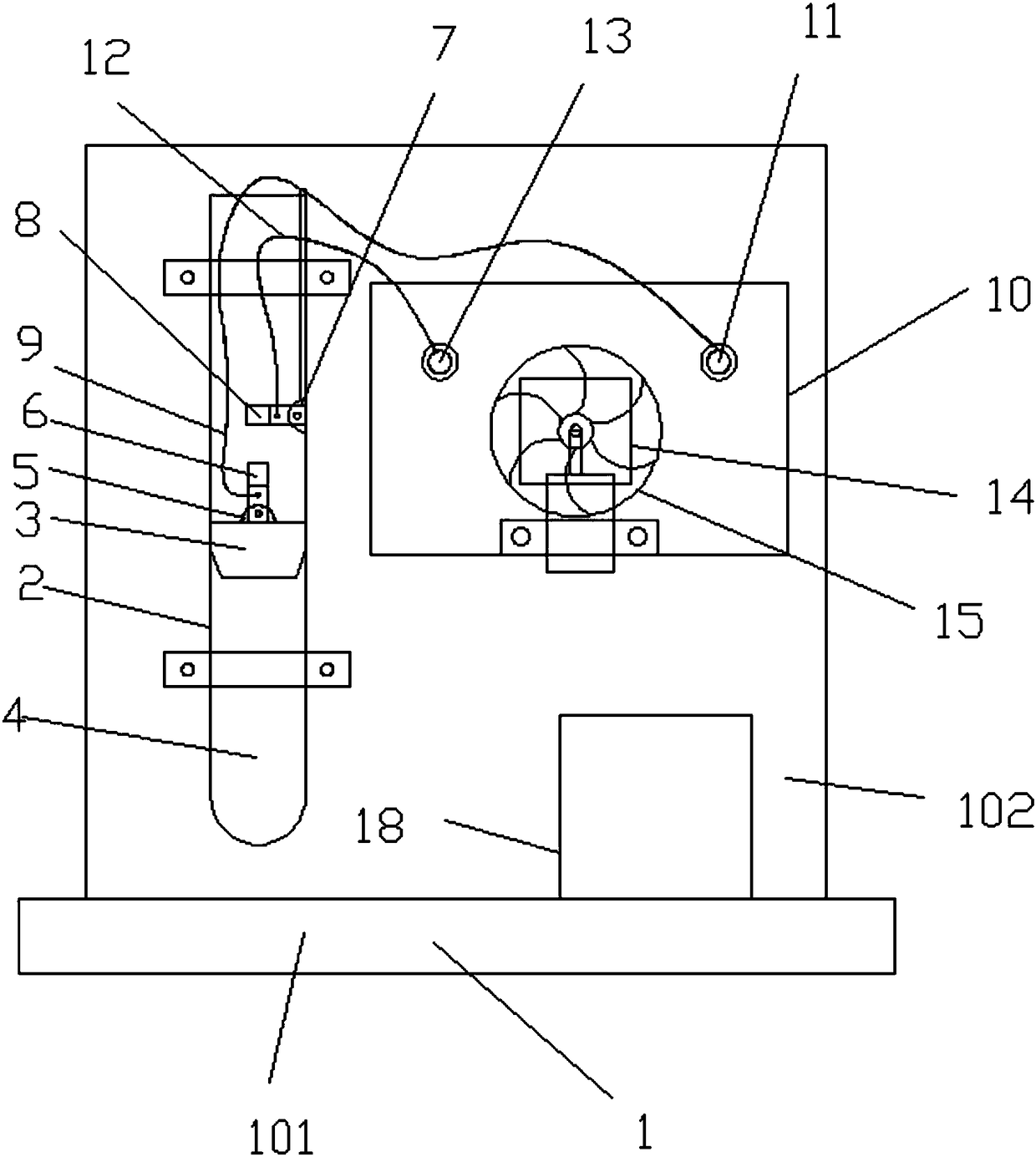

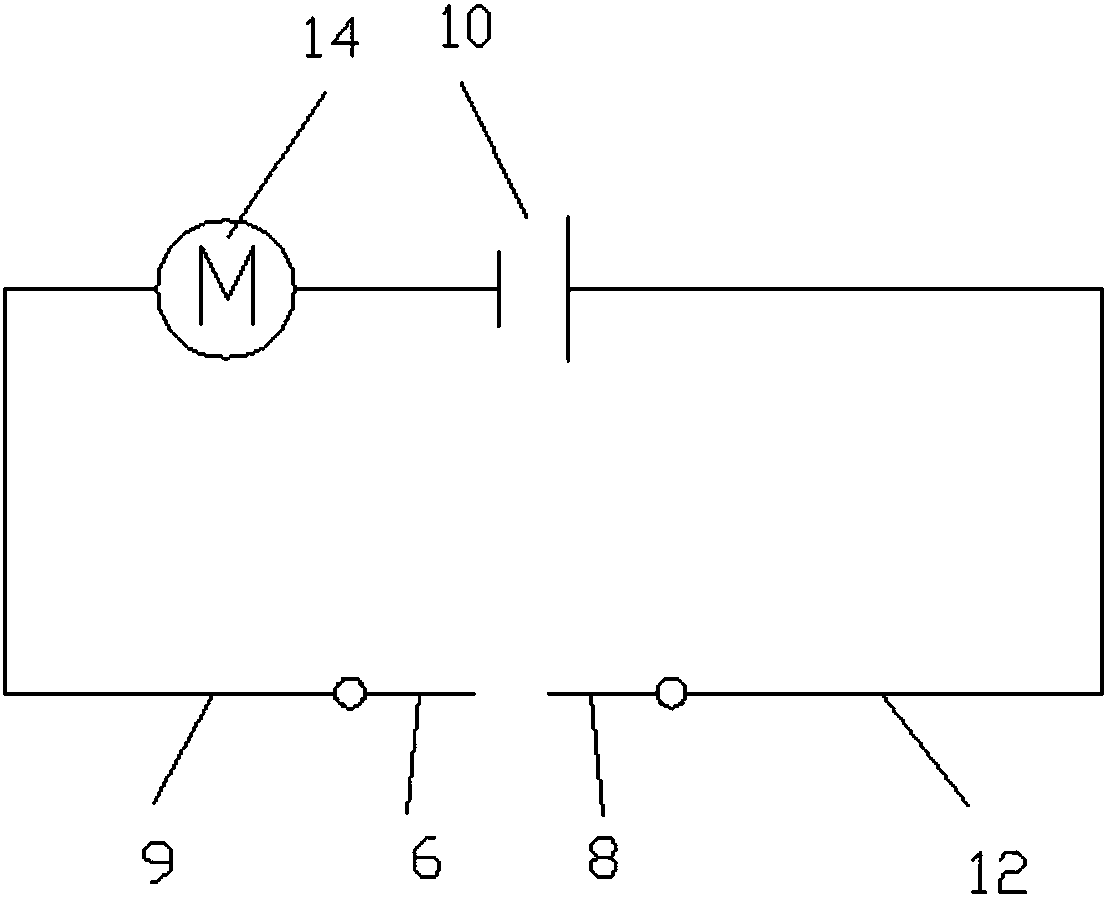

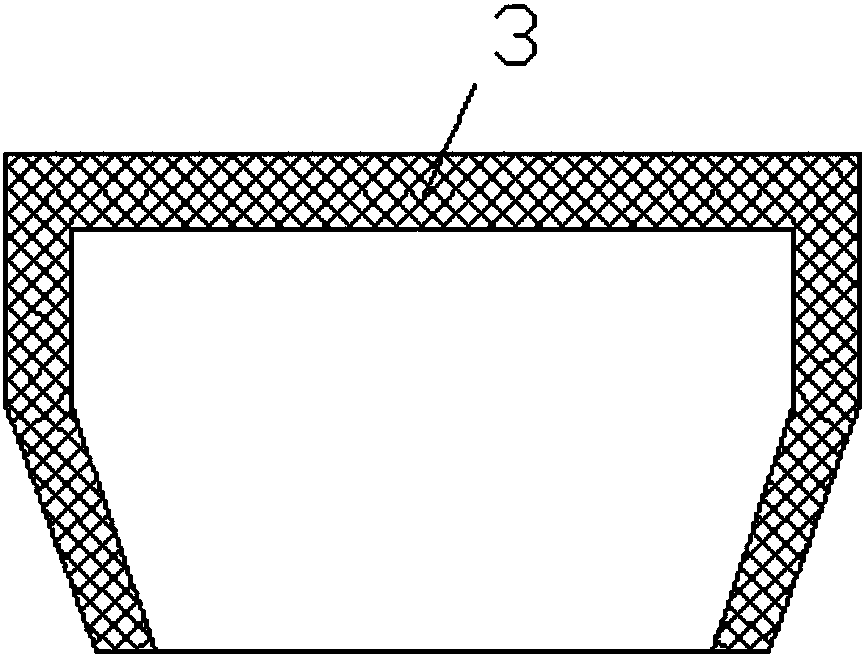

Automatic temperature control fan with thermal expansion and contraction principle

InactiveCN108386378ASimple structureMaterial economyEngine controlPump controlImpellerEnvironmental resistance

The invention provides an automatic temperature control fan with the thermal expansion and contraction principle. The automatic temperature control fan is composed of a mounting frame, a glass test tube, a moving piston, a positive electrode metal sheet, a negative electrode metal sheet, a small direct-current motor, fan impellers, a rechargeable battery and a solar cell panel, wherein lubricatinggrease coats the moving piston, the positive electrode metal sheet moves up and down along with the piston, the position of a fixed negative electrode metal sheet are fixedly arranged on a negative metal sheet mounting frame, the positive electrode metal sheet and fixed negative electrode metal sheet are used as an automatic switch. According to the fan, the property that gas heat expansion and cold contraction is utilized, the moving piston moves up and down, so that the positive electrode metal sheet and the negative electrode metal sheet are enabled to be combined or separated to realize automatic connection or disconnection of the power supply circuit of the small direct-current motor and the design of the automatic temperature-controlled fan; and the structure is simple and economic,the electric energy supply is green and environment-friendly.

Owner:孙佳庆

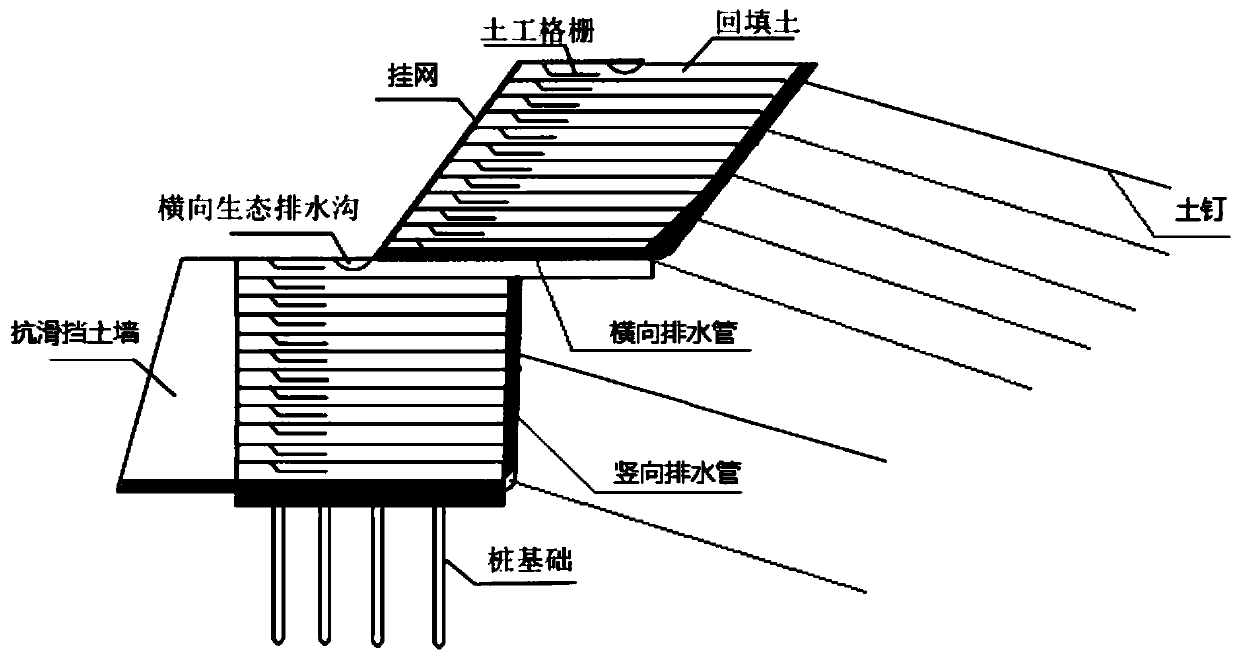

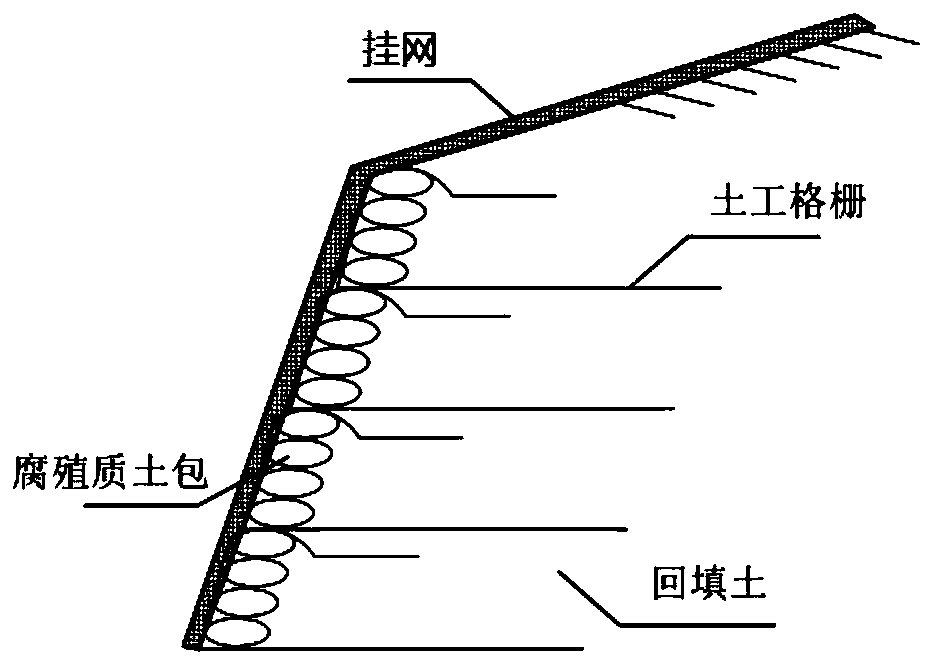

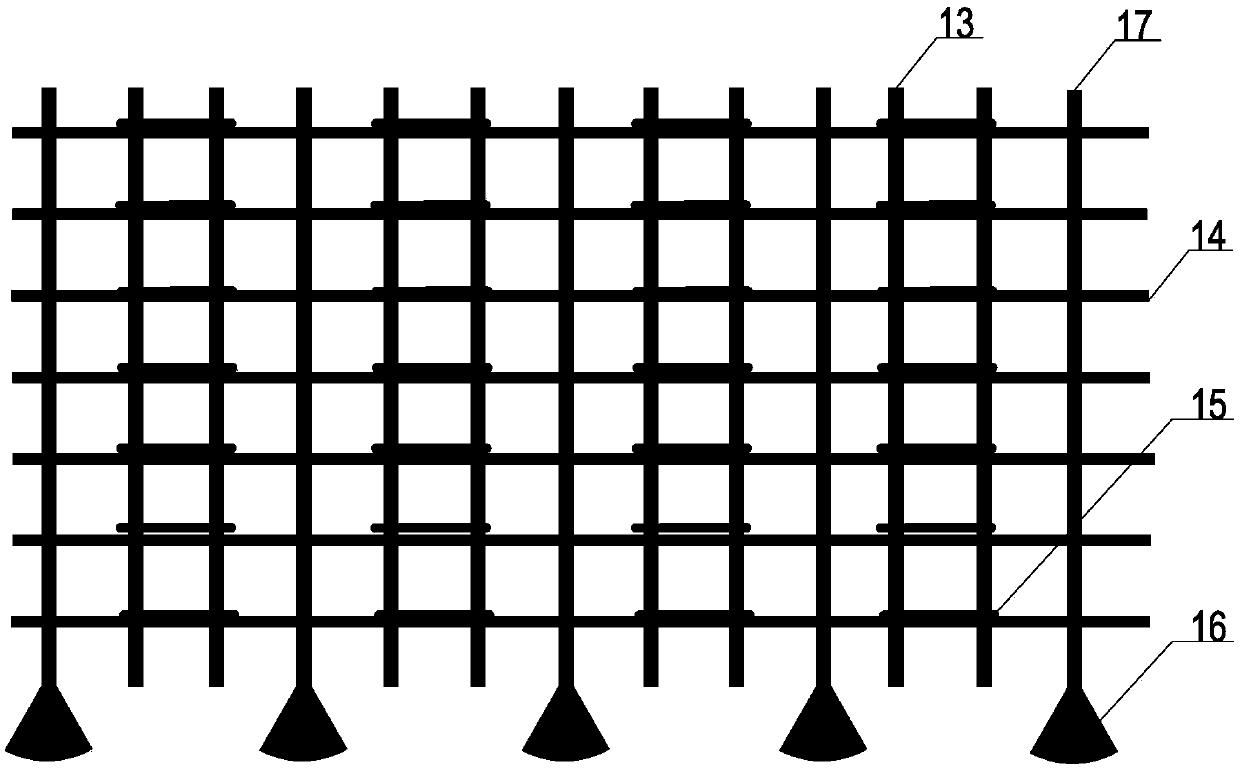

Green environment-friendly comprehensive management method for high-steep loess landslide

InactiveCN109763502APlay the role of stabilizing the slopeHas a green ecological effectSewerage structuresExcavationsGreen environmentEngineering

The invention discloses a green environment-friendly comprehensive management method for high-steep loess landslide. The green environment-friendly comprehensive management method comprises the following steps: carrying out step-by-step cutting on the slope side of a high-steep loess landslide body; leveling the steps of each stage and backfilling reinforced soil on the steps of each stage; filling soil and covering after the reinforced soil is backfilled; pumping soil nails into the reinforced soil; driving a pile foundation into the bottom end of the backfilled reinforced soil at the front edge of the bottom of the high-steep loess landslide; then arranging an anti-slip retaining wall on the outer side of the backfilling reinforced soil; arranging vertical drainage pipes in a slope body;arranging horizontal drainage pipes at the top of the slope body, at the steps of each stage and at the bottom of the slope body; screening, fertilizing and shotcreting the slope side. The comprehensive prevention and control method disclosed by the invention has the advantages that the stress in the slope can be well dispersed and plastic failure is avoided; a perfect drainage system ensures thedrainage of the whole side slope and avoids the effect of rainfall infiltration on the stability of the side slope; in addition, the method disclosed by the invention is a green construction method,and has the advantages of economical raw materials, convenience in construction and suitability for wide application in high-steep landslide treatment in loess areas.

Owner:NORTHWEST UNIV(CN)

Separated pocket spring mattress with cut through string, and method and apparatus for production of such mattress

ActiveUS9554656B2Material economyIncrease the separation distanceStuffed mattressesSpring mattressesCoil springBiomedical engineering

Owner:STARSPRINGS AB

Cable for ship hydrophone equipment and manufacturing method thereof

InactiveCN102176343AImprove insulation performanceGuaranteed waterproof performanceRubber insulatorsBraided wire conductorsHydrophoneElectrical conductor

Owner:JIANGSU YUANYANG DONGZE CABLE

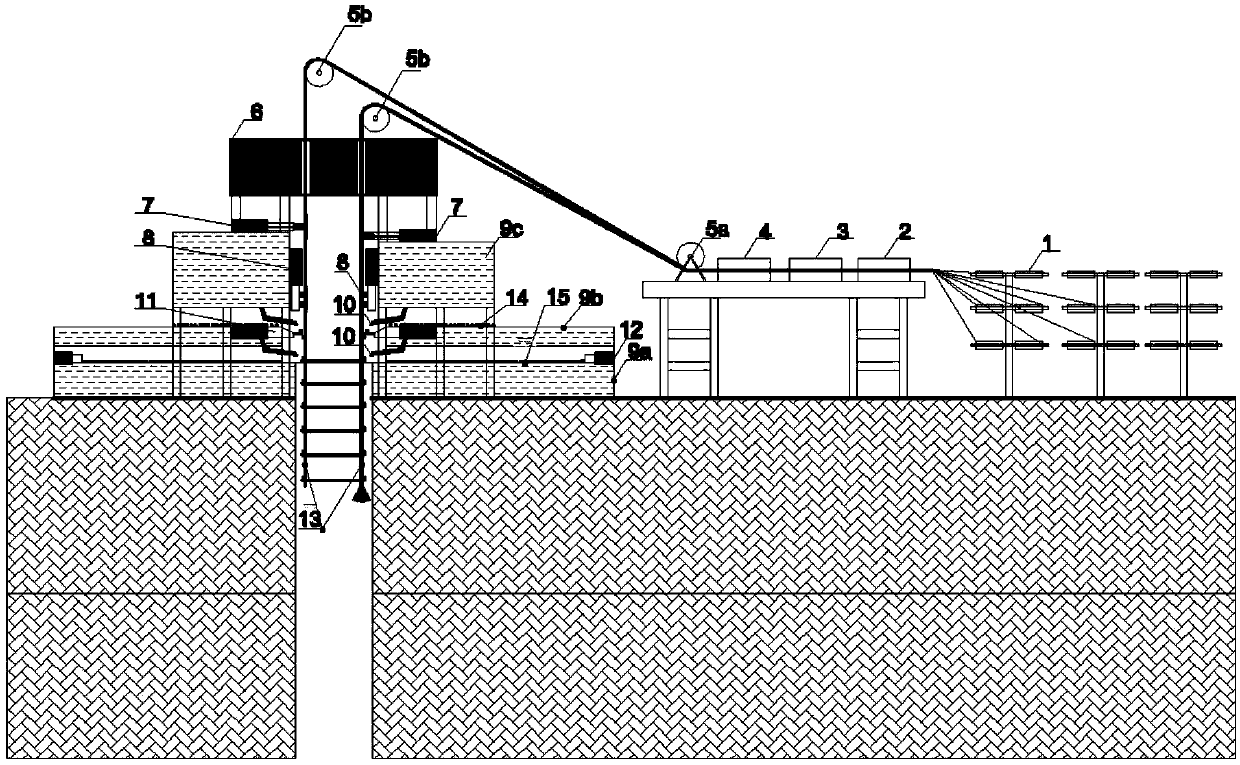

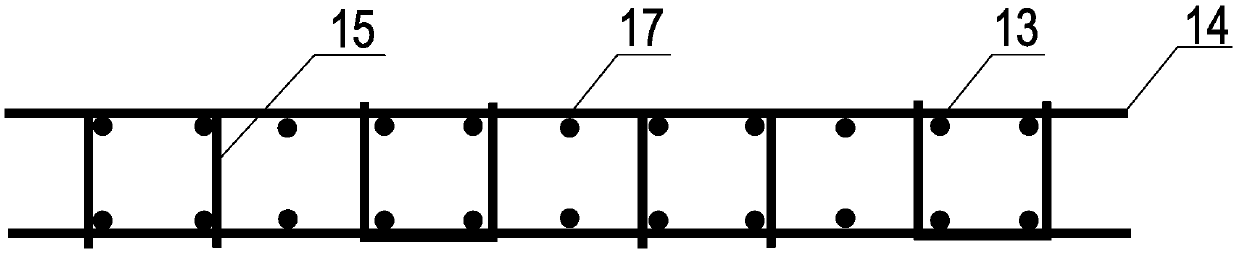

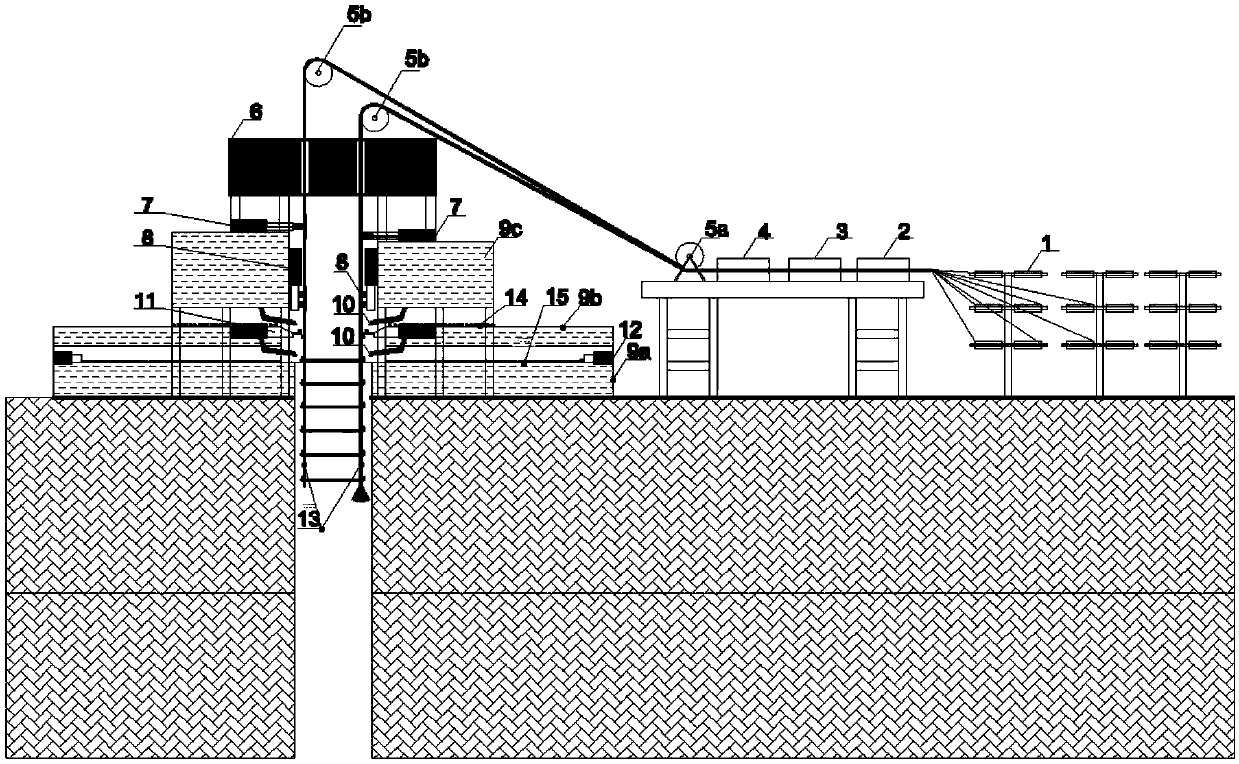

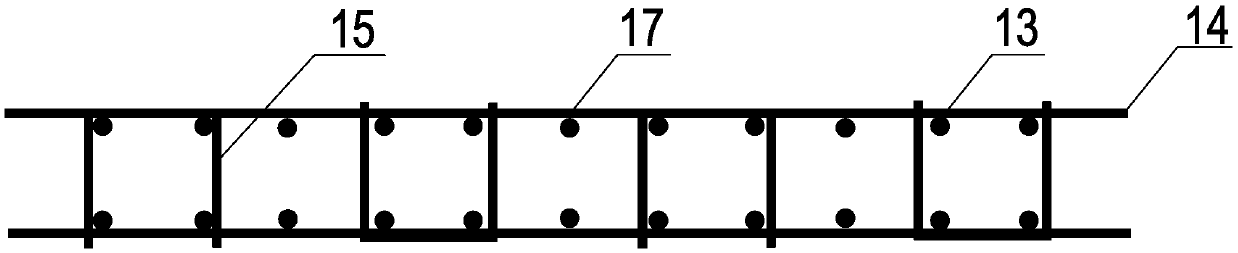

Fiber reinforced polymer (FRP) fiber bar-steel bar composite steel bar cage production device and use method thereof

PendingCN109555110AAuto fit sizeAutomatically adapt to special unfavorable situations such as irregularitiesBulkheads/pilesEpoxySteering wheel

The invention discloses afiber reinforced polymer (FRP) fiber bar-steel bar composite steel bar cage production device and a use method thereof. A fiber frame body, a glue soaking groove containing epoxide resin, a plurality of temperature curing machines, a plurality of bar material secondary curing molding devices, a plurality of first steering wheels, a plurality of second steering wheels, a bar material pushing device, a steel bar fixing fastener emitter, a horizontal transverse steel bar distributing device, a 'U-shaped' rachelbar distributing device, and two operation frames arranged onthe two sides of a diaphragm wall groove are adopted. According to the fiber reinforced polymer (FRP) fiber bar-steel bar composite steel bar cage production device and the use method thereof, pull-extrusion molding of FRP bars, and integrative, mass, and industrial production of the multifaceted functions such as organic assembly of the FRP bars and ordinary steel bars can be realized, and the difficult problemsof lifting and molding of a super deep diaphragm wall steel cage under the narrow space are solved; in addition, a diaphragm wall framework formed by combining the flexible FRP bars and the ordinary steel bars generated by the fiber reinforced polymer (FRP) fiber bar-steel bar composite steel bar cage production device can automatically adapt to the size of the diaphragm wall groove and deal with the special unfavorable conditions such as the irregular groove wall, has higher carrying capacity, more economical materials, and more convenient construction.

Owner:SHANGHAI NO 4 CONSTR

Ship underwater sonar transducer cable and manufacturing method thereof

InactiveCN102184757AImprove insulation performanceImprove mechanical propertiesRubber insulatorsNon-insulated conductorsSonarElectrical conductor

The invention discloses a ship underwater sonar transducer cable of the cable field and a manufacturing method of the cable. A cable core is formed by inter-stranding two shielding insulated cores with a stranding pitch diameter ratio of 10-12. The shielding insulated core includes a core conductor which is arranged in the center of the shielding insulated core. The core conductor is formed by inter-stranding a plurality of tinned copper wire bundles which have a diameter of 0.3 mm-0.35 mm, a single fiber elongation at break of 15%-20%, and a stranding pitch diameter ratio of 8-11. A rubber insulating layer having a thickness of 0.8-0.9 mm is extruded around the core conductor, and the maximum thickness of the same cross section is not larger than 1.25 times the minimum thickness. The rubber insulating layer is peripherally coated with a shielding layer. The cable core is peripherally extruded with an inner sheath and an outer sheath. The cable is good in waterproofness and insulatibity, has a long service lifetime, and is able to work underwater for a long time.

Owner:JIANGSU YUANYANG DONGZE CABLE

Method for preparing medical valve-attached canal by use of cow jugular vein

InactiveCN1961971ALow antigenicityGood tissue compatibilitySurgeryPharmaceutical containersJugular veinVia jugular vein

Owner:重庆市中山医院

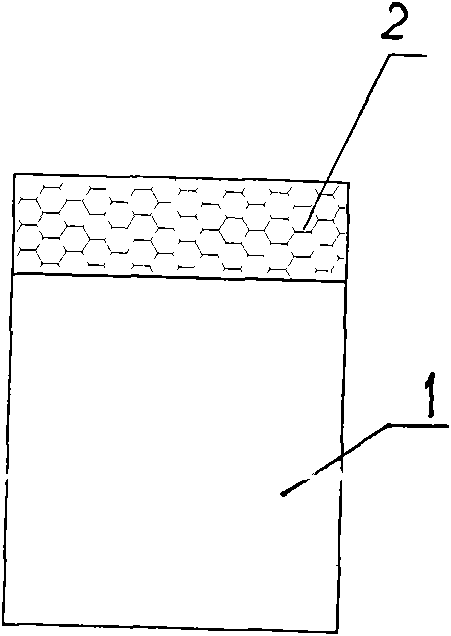

Rockfill dam face plate cushion layer and construction method

ActiveCN105544469AAvoid opening cracksAvoid bending damageBarrages/weirsEarth-fill damsStructural engineeringPlastic film

The invention provides a rockfill dam face plate cushion layer and a construction method. A film layer is arranged between a face plate and a concrete foundation, a plastic film serves as the film layer, and the film layer is fixed on the concrete foundation through multiple fixing parts. The construction method of the rockfill dam face plate cushion layer comprises the following steps that 1, the concrete foundation is poured; 2, the film layer is arranged on the surface of the concrete foundation; 3, the face plate is poured. In this way, the crack defect of the face plate is reduced. By means of the film layer arranged between the concrete foundation and the face plate, constraint between rockfill dam face plate concrete and the concrete foundation surface is basically eliminated, and the situation that due to the fact that when the size of a rockfill dam is changed, the face plate concrete is constrained by the foundation, a large number of cracks occur is avoided to the maximum extent.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

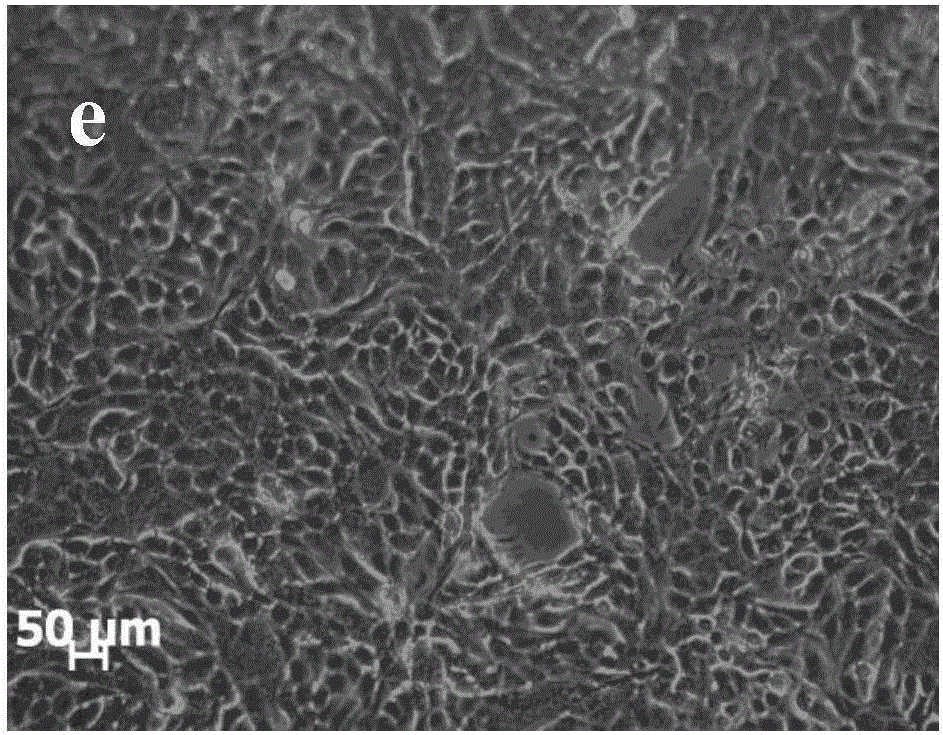

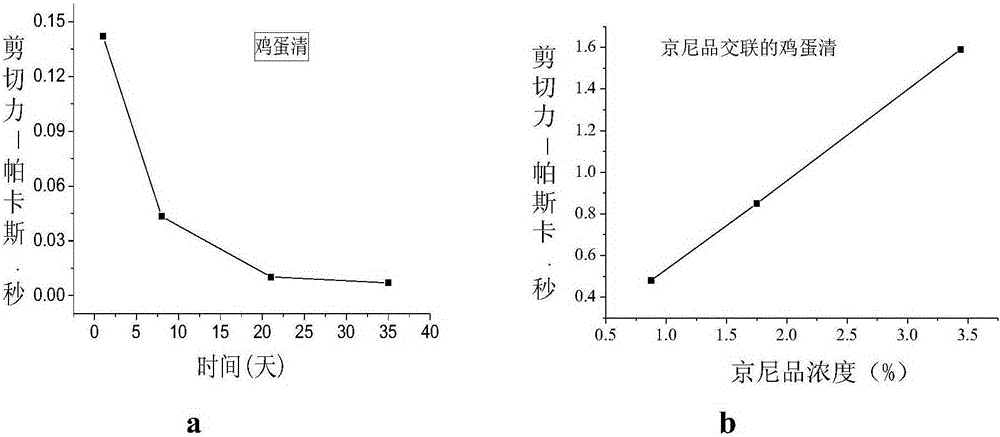

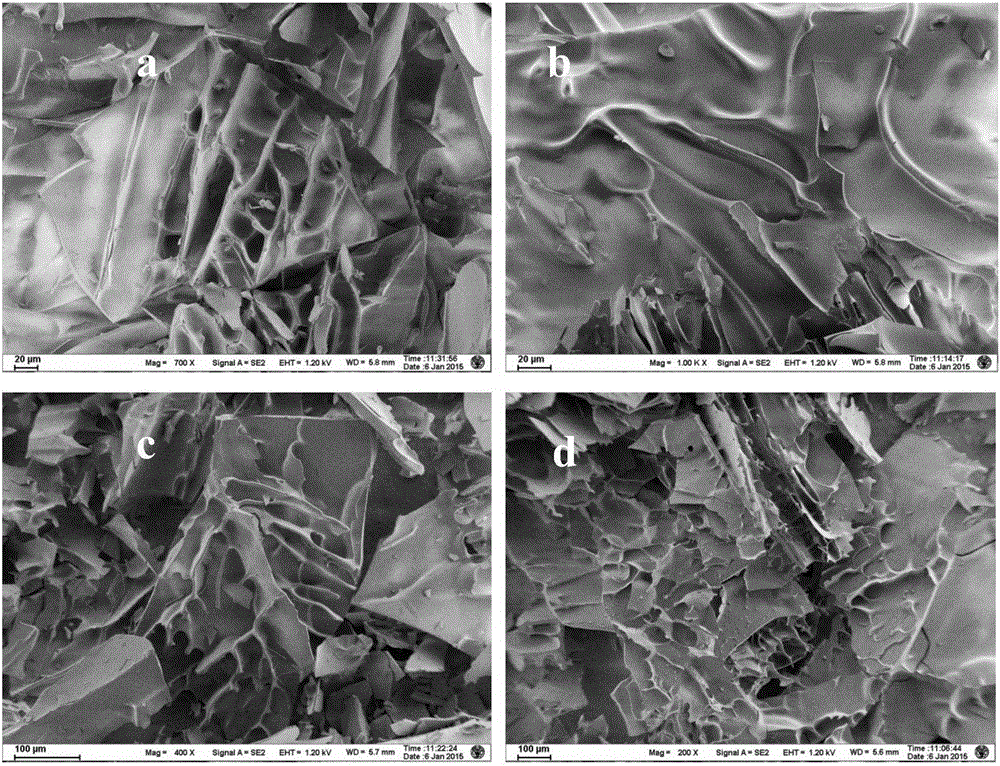

Preparation method and application of novel modified egg white cell culture scaffold material

ActiveCN105296417APromotes Adhesive GrowthHardness gradient is easy to controlTumor/cancer cellsBiotechnologyPipette

The invention relates to a preparation method and application of a novel modified egg white cell culture scaffold material. The method includes: step one, adding genipin into sterile ultrapure water, stirring, oscillating ultrasonically and completely, thoroughly dissolving at 25-40 DEG C, adding 0.2ml of the genipin solution into a reaction vessel containing 2ml of fresh egg white, and well mixing; step two, putting the egg white with the genipin serving as a crosslinking agent into a thermostat to realize complete crosslinking; step three, using a pipette for dripping a modified egg white cell culture scaffold material obtained at the step two into a PBS solution drop by drop to guarantee immersion of materials without overflowing, standing for more than 12 hours to remove surplus genipin molecules, and repeating for several times; step four, putting a modified egg white cell culture scaffold material obtained after reaction on a cell clean bench, and performing ultraviolet radiation for sterilization to obtain the novel modified egg white cell culture scaffold material. The hardness gradient of the novel modified egg white cell culture scaffold material is easy to control, and safety and avoidance of toxic and side effects are realized.

Owner:SOUTHEAST UNIV

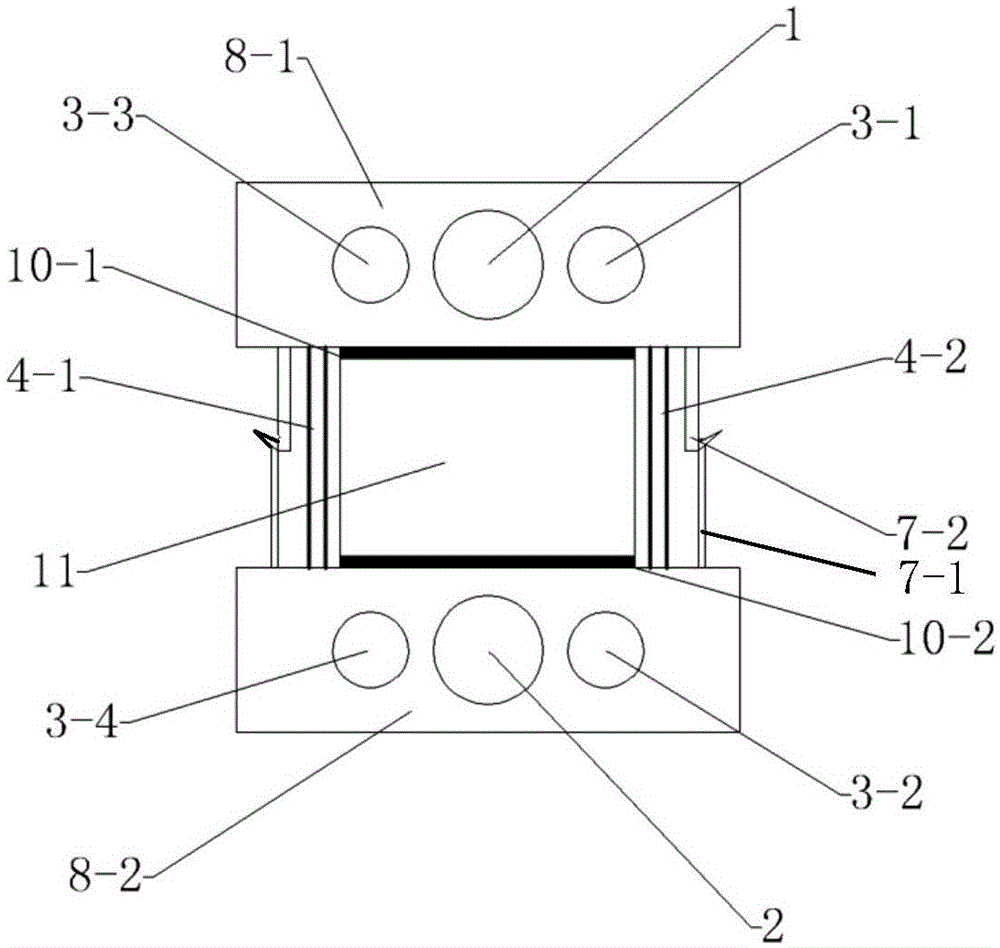

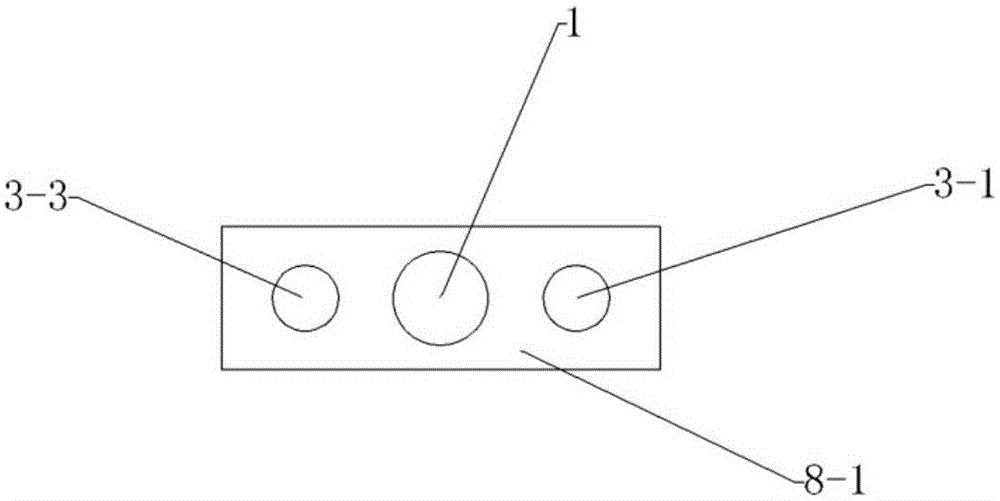

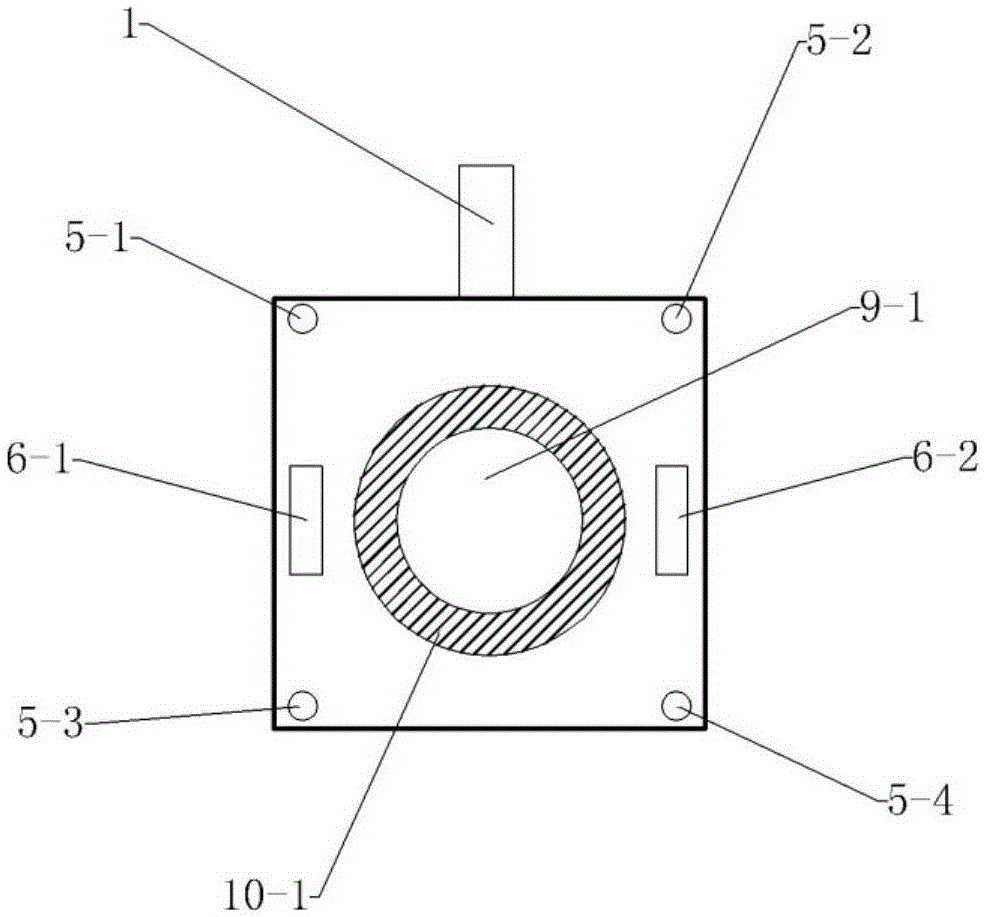

Clamping slot type electric flux fixture

ActiveCN105158140AMaterial economyReasonable and environmentally friendly materialsMaterial analysis by electric/magnetic meansPermeability/surface area analysisElectricityRubber ring

The invention provides a clamping slot type electric flux fixture, and particularly relates to a clamping slot type electric flux fixture developed based on a concrete electric flux experiment. According to the clamping slot type electric flux fixture, the sealing between the fixture and a test piece can be realized more conveniently, and the conditions that the fixture leaks a solution due to poor sealing property can be reduced. The clamping slot type electric flux fixture comprises three parts, namely a fixture main body, a clamping slot and a bolt, wherein the fixture main body comprises a positive electrode jig, a negative electrode jig, a positive electrode, a negative electrode, a copper gauze, an infusion inlet, a rubber ring and a clamping slot port. The clamping slot type electric flux fixture, disclosed by the invention, has the advantages of convenience, quickness and the like, and provides convenience for researching electric flux of concrete; according to the clamping slot type electric flux fixture, the sealing between a test trough and the test piece can be better realized more conveniently, and the difficulty of an electric flux test is reduced.

Owner:HARBIN ENG UNIV

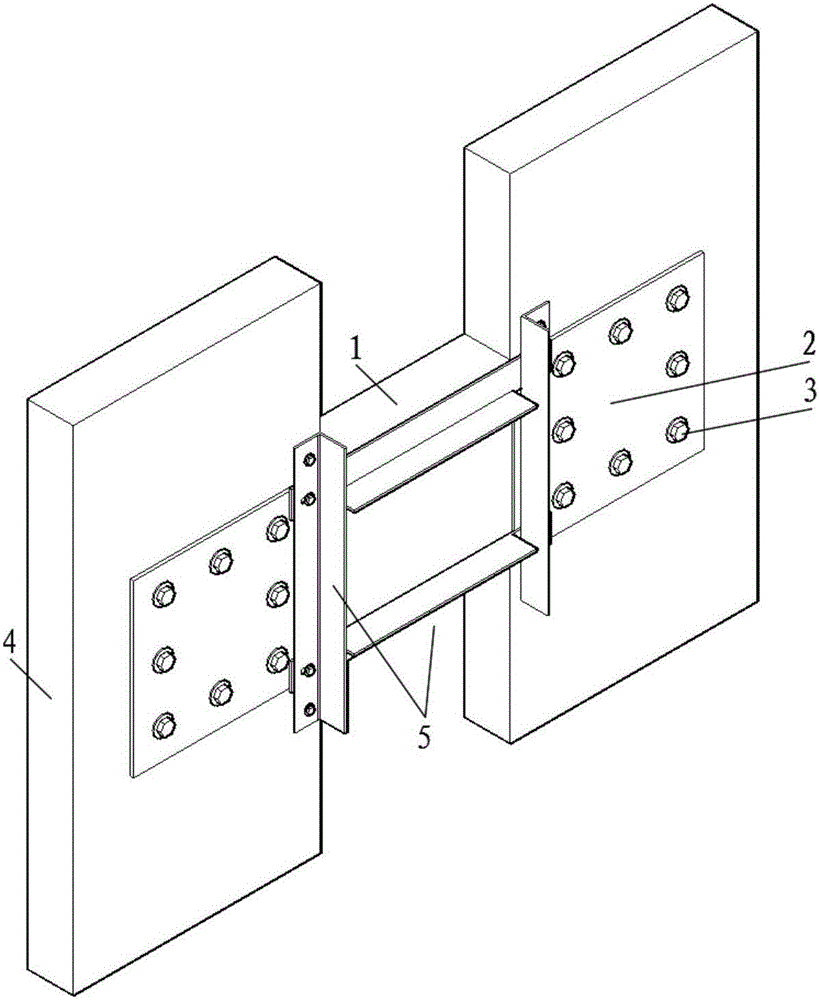

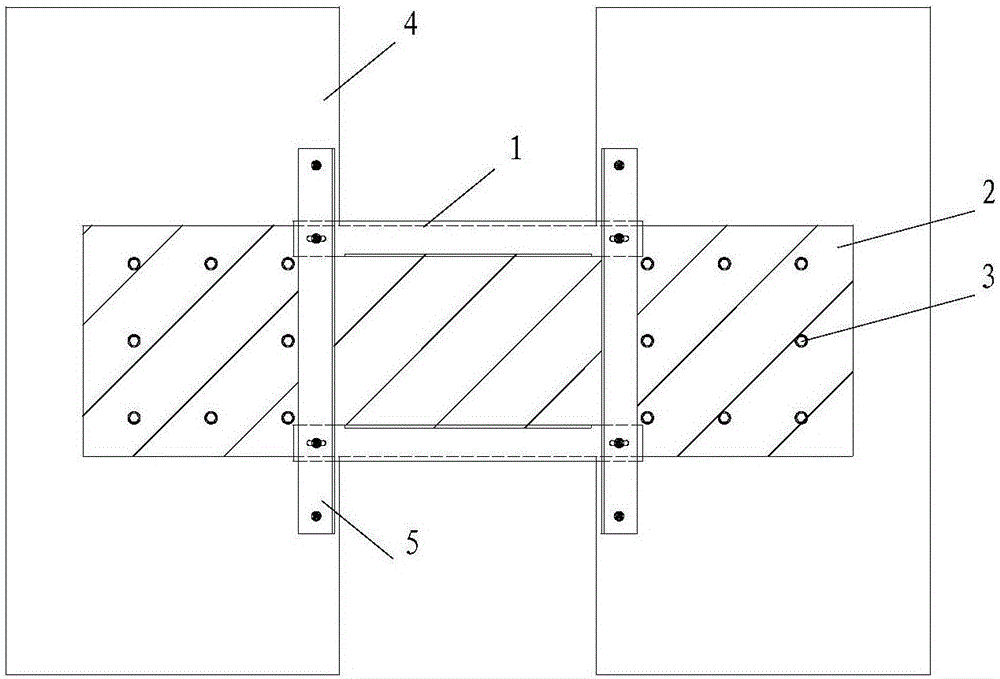

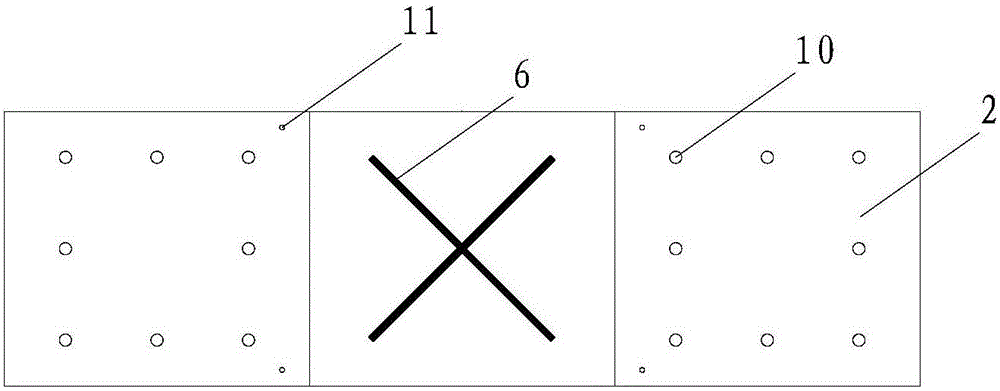

Reinforced structure for coupling beam of reinforced concrete

The invention discloses a reinforced structure for a coupling beam of reinforced concrete, comprising a coupling beam, a steel plate and shear walls at the two ends of the coupling beam, wherein the steel plate is set along the vertical side of the coupling beam and connected with the shear walls by a first fastening connection piece; the reinforced structure further comprises a buckling constraint frame; the vertical side frames a the two sides of the buckling constraint frame are respectively connected with the steel plate located o the shear walls at the two sides of the coupling beam by a second fixing connection piece. The vertical side frame extends the upper and lower ends of the steel plate and connected with the corresponding shear wall by the second fastening connection piece; and the intersection of the buckling constraint frame and the steel plate is levelly provided with circular holes. The steel plate and buckling constraint frame in the invention are designed and processed ahead of time with high prefabricating degree, and the field majors in assembly. The buckling constraint frame is adopted, so that the steel plate can develop the strength effectively and improve the shock resistance of the coupling beam. When bending the constraint steel plate, the rigidity of the increased coupling beam is avoided by setting level long circular hole, and the reinforced structure is beneficial for earthquake resistant design requirement.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

Self-adhesive and self-heating bag and preparation method thereof

InactiveCN101943478AEasy to useEasy to carryExothermal chemical reaction heat productionExothermal chemical reactions for heatingActivated carbonComposite film

The invention provides a self-adhesive and self-heating bag and a preparation method thereof. The self-heating bag consists of contents and a bag body, wherein the bottom layer of the bag body is provided with an airproof plastic composite film layer and a layer of tearable adhesive sticker paper; the surface layer of the bag body is provided with a non-woven fabric composite film with certain air permeability; and the contents are iron powder, activated carbon, aluminum powder, calcium chloride, diatomite, zeolite and water. The temperature of the self-adhesive and self-heating bag can be quickly increased after the adhesive sticker paper is torn, and can be kept between 40 and 50 DEG C. The self-adhesive and self-heating bag has the advantages of over 12 hours heat dissipation time and no toxicity of safe raw materials to human bodies.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

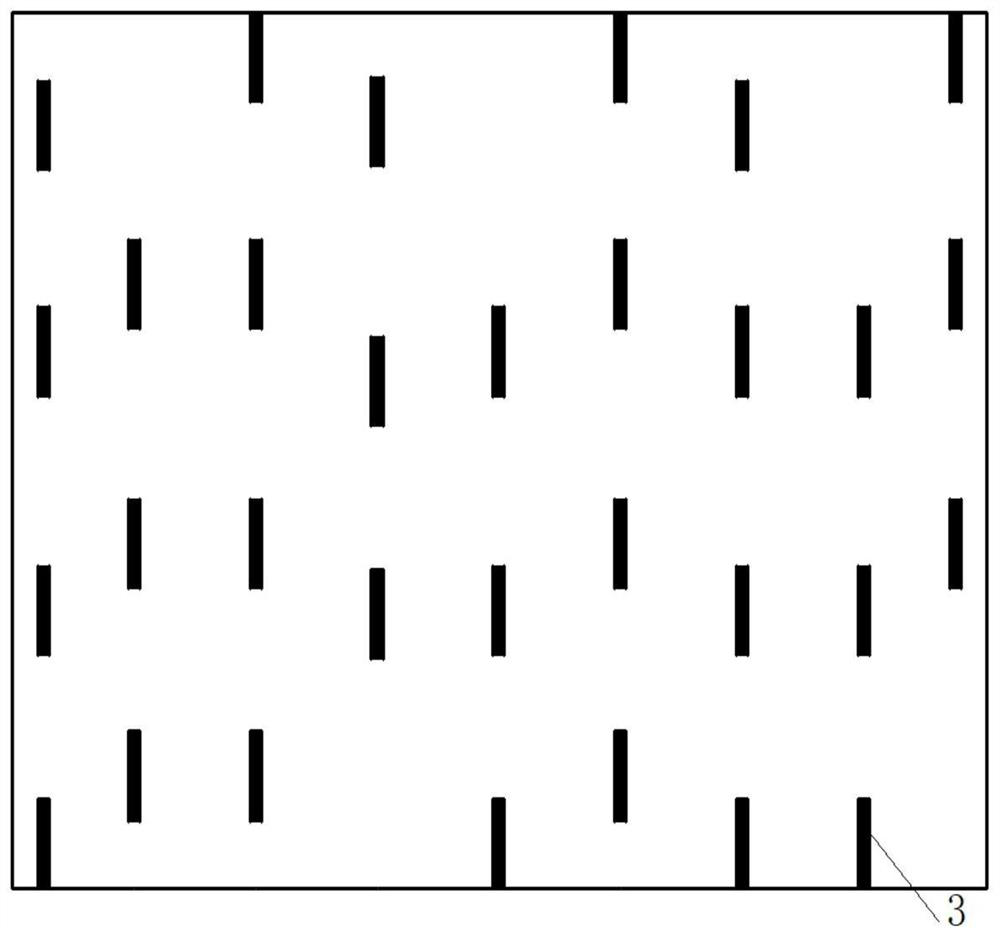

Novel composite diaphragm wall structure under low clearance and construction method of novel composite diaphragm wall structure

PendingCN109555111AIncreased bending stiffnessImprove carrying capacityBulkheads/pilesPre stressEngineering

The invention discloses a novel composite diaphragm wall structure under the low clearance and a construction method of the novel composite diaphragm wall structure. A diaphragm wall frameworkis assembled and formed by directly connecting fiber reinforced polymer (FRP) bars and ordinary steel bars in a groove of a diaphragm wall, the fiber reinforced polymer (FRP) bars are arranged longitudinallyinto two rows to be used as vertical longitudinal bars along a wall body of the diaphragm wall, and the corresponding row, close to the excavation side of a foundation pit, of the vertical longitudinal bars are fiber reinforced polymer (FRP) prestressed bars; the diaphragm wall framework is directly arranged in the ground of the diaphragm wall after continuous pultrusion molding through the fiberreinforced polymer (FRP) bars, no lifting and splicing is required, and the diaphragm wall framework is not limited by the clearance. According to the novel composite diaphragm wall structure under the low clearance and the construction method of the novel composite diaphragm wall structure, a prestressed technology is applied, the flexural rigidity of the composite diaphragm wall is automaticallyadjusted and lifted while the tensile strength of the flexible fiber reinforced polymer (FRP) bars is fully utilized, and thus load-bearing performance of thediaphragm wall can meet the force suffering requirements under different working conditions; and in addition, the diaphragm wall framework formed by combining the flexible fiber reinforced polymer (FRP) bars and the ordinary steel bars can automatically adapt to the groove size of the diaphragm wall anddeal with the special adverse conditions such as irregular groove walls, the load-bearing capacity is higher, materials are more economical, and construction is more convenient.

Owner:SHANGHAI NO 4 CONSTR

Green lightweight tensile bamboo reinforced concrete precast block

The invention discloses a green lightweight tensile bamboo reinforced concrete precast block. Raw materials of the concrete precast block comprise bamboo sheet fibers, jute fibers, kraft paper, broken stones, recycled concrete, fly ash, perlite and phosphate cement. The green lightweight tensile bamboo reinforced concrete precast block produced in the invention has the advantages of light weight, large tensile strength, great reduction of the self-weight and the cracking probability of walls built by using the concrete precast block and the cracking probability of pavement bricks, good heat insulation property and good noise prevention performance. Materials used in the invention are more environmentally-friendly and economical than traditional brick materials, so the demand for clay is reduced, and the fertile land is protected. Waste concrete is reused, so resources are reasonably used.

Owner:FUJIAN AGRI & FORESTRY UNIV

Acid and alkali corrosion resisting electric adhesive tape and preparation method thereof

InactiveCN105585971AImprove corrosion resistanceExtended service lifeNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntioxidantElectrical tape

The invention discloses acid and alkali corrosion resisting electric adhesive tape and a preparation method thereof. The adhesive tape is composed of a base layer and an adhesive layer. The adhesive layer is prepared from, by weight, 35-40 parts of high styrene rubber, 35-40 parts of polyacrylate rubber, 25-35 parts of styrene-butadiene copolymer, 20-25 parts of benzyl salicylate, 20-25 parts of hexamethylene diisocyanate, 20-25 parts of dioctyl phthalate, 15-25 parts of polyimide, 10-15 parts of activated carbon, 8-10 parts of copper sulfate, 8-10 parts of zeolite powder, 2-5 parts of anthracene oil, 2-5 parts of plasticizer and 1-3 parts of antioxidant. Accordingly, the prepared insulated adhesive tape has the good corrosion resistance. In addition, the invention further discloses the preparation method of the acid and alkali corrosion resisting electric adhesive tape.

Owner:SUZHOU JIN TENG ELECTRONICS TECH

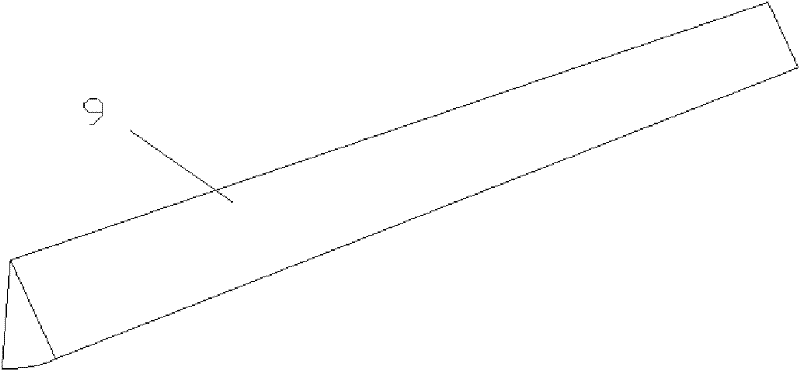

Bamboo-made deformation-resisting cue

The invention discloses a bamboo-made deformation-resisting cue, comprising a cue body, which is conical cue body formed by the steps of gluing and hot-press shaping, by mold, a plurality of axially arranged bamboo sheets with the same quality and consistent specification, wherein the bamboo sheet, which is subject to cooking at high temperature, removal of original juice, sugar and protein of bamboo, disinfestation, bleaching and drying, is Mao bamboo. The bamboo-made deformation-resisting cue according to the invention, capable of maintaining vertical axis center and free from bending and deformation, settles the problem of inferior bending and deformation properties of the cue, enhances competition level of billiard ball players and ensures fair competition.

Owner:周凯

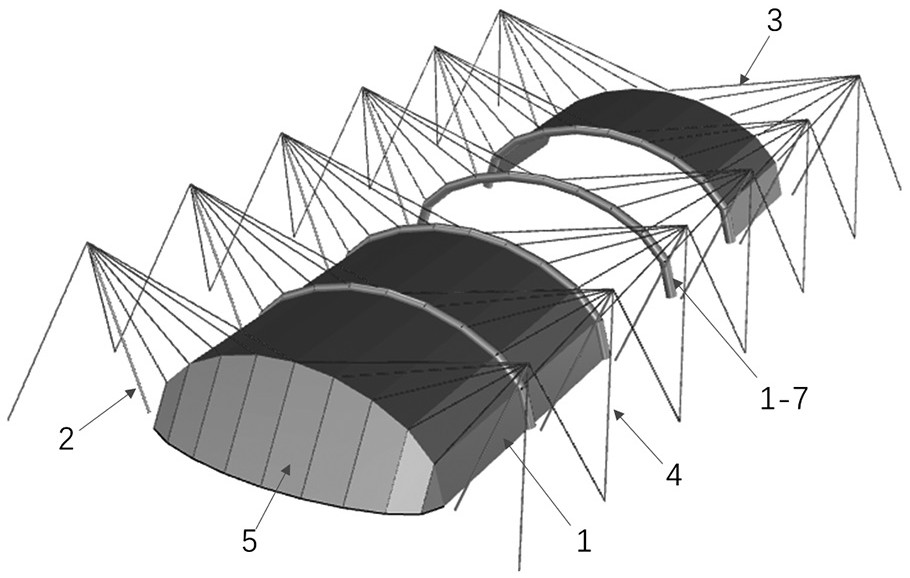

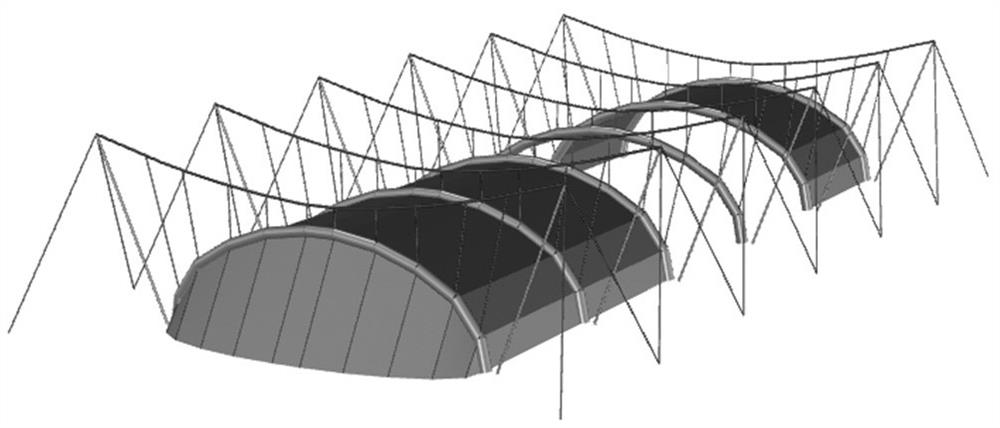

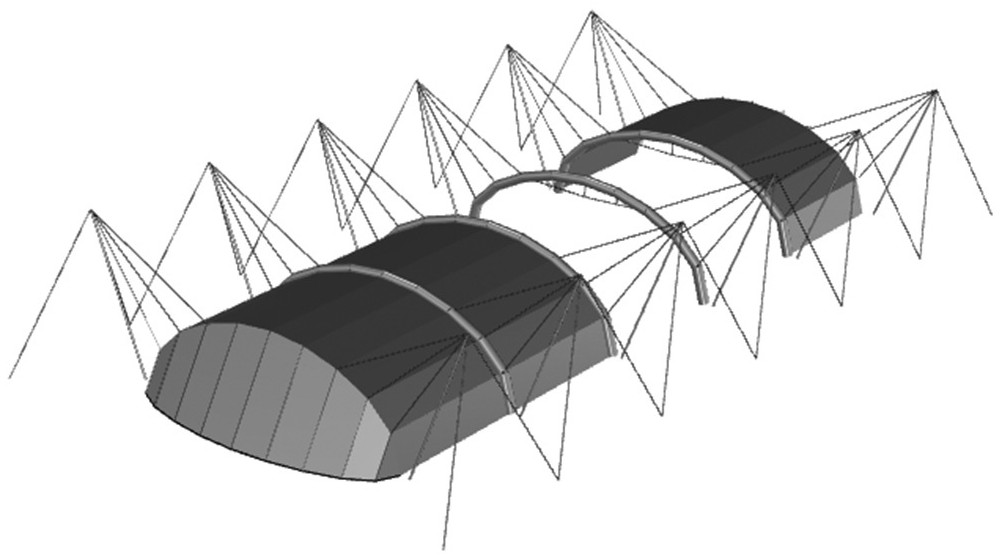

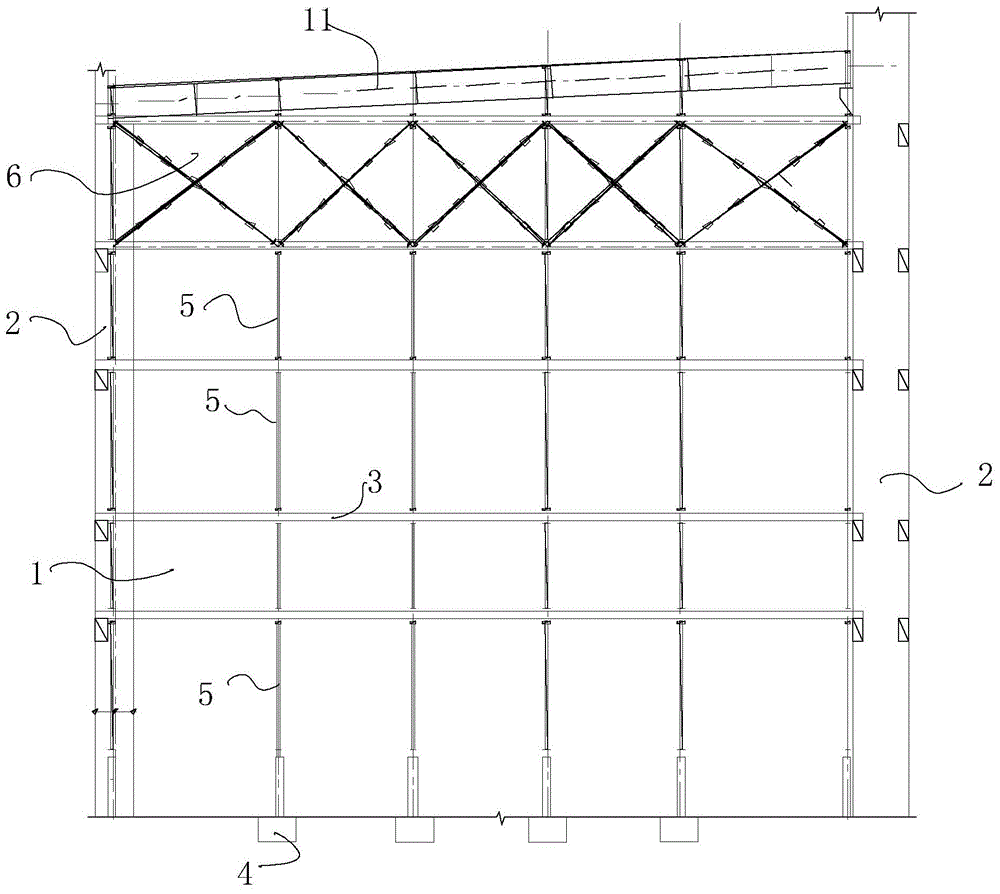

Unidirectional tension metal sheet space structure and construction method

ActiveCN114517532AReasonable forceLess materialBuilding roofsArched structuresPre stressSpatial structure

The invention relates to a one-way tension metal sheet space structure, which is used for a large-span building, and comprises a metal sheet which is formed by tension and forms the space structure; the steel columns are arranged on the two sides of the space structure span; one ends of the tension cables are fixedly connected to the top ends of the steel columns on the two sides, and the other ends are connected with the metal sheets from the two sides of the space structure span; one end of the back cable is connected with the top end of the steel column; and the gable plates are arranged at the two ends of the metal thin plate and provided with gable back cables. The stress structure and the building envelope structure are integrally designed, the metal sheets are formed by applying in-plane prestress in a tensioning mode, the whole structure can be continuously arranged in a multi-span mode, and good plane adaptability and good economic performance are achieved. The structure system can be used for building a super-large-span temporary and permanent closed stockyard engineering structure system with the span exceeding 300 m, and has the advantages of being safe, reliable, reasonable in design, economical in material, easy and convenient to construct and the like.

Owner:NORTH CHINA INST OF SCI & TECH

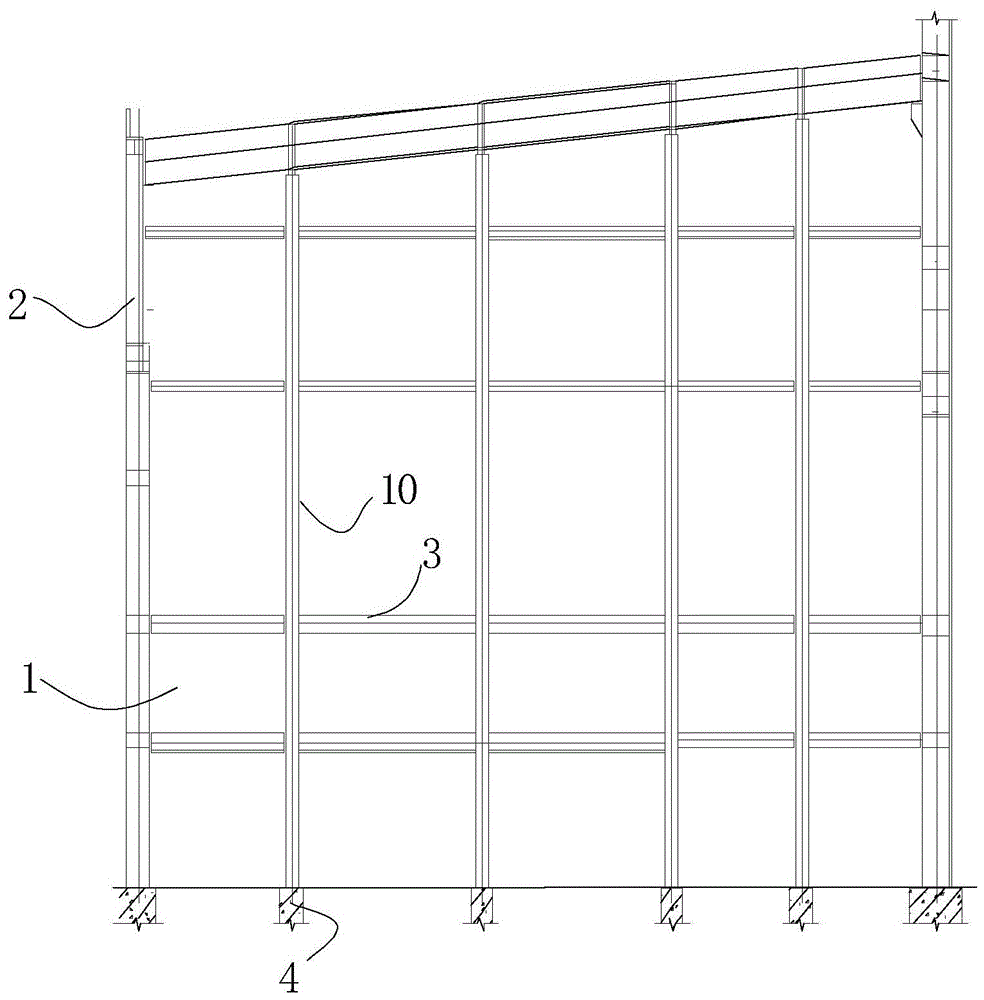

hanging gable

ActiveCN103556751BImprove mechanical performanceAvoid stability controlWallsShock proofingVertical barEngineering

The invention relates to a gable of a house, in particular to a gable of a factory building and a warehouse, and discloses a hanging gable with higher seismic performance. The suspended gable includes a wall, end columns, wind-resistant beams, roof trusses and gable foundations, the end columns are located at both ends of the wall, the wind-resistant beams are located on the wall, and the two ends of the wind-resistant beams are connected to the end columns , the gable foundation is located at the bottom of the wall, the roof truss is located at the top of the wall, a vertical bar connected to it is arranged under the roof truss, the wind-resistant beam is hung on the roof truss through the vertical bar, and the gable foundation is connected by the vertical bar The rods are connected to the wind beams. The suspended gable can be widely used in various factories, warehouses and other large buildings. It has superior mechanical performance, economical materials, excellent seismic performance, and the gable foundation can be set shallower, so that the underground layout is more convenient.

Owner:四川电力设计咨询有限责任公司

High-voltage-resistant insulating tape and preparation method thereof

InactiveCN108300358AImprove pressure resistanceGood weather resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesAntioxidantPolyvinyl chloride

The invention discloses a high-voltage-resistant insulating tape. The tape is composed of a base layer and an adhesive layer. The adhesive layer is prepared from the following components by weight: 15-20 parts of polyimide, 10-12 parts of polytetrafluoroethylene, 20-25 parts of polyvinyl chloride, 2-5 parts of acetate, 30-35 parts of styrene-butadiene rubber, 40-45 parts of vinyl polyurethane rubber, 20-25 parts of an ethylene acrylic acid copolymer, 8-12 parts of pigment carbon black, 5-8 parts of zinc sulfate, 10-12 parts of quartz powder, 1-4 parts of anthracene oil, 3-7 parts of a plasticizer and 2-5 parts of an antioxidant. The invention has the advantages that the prepared insulating tape has high voltage resistance, good weather resistance and good flame retardancy, and is particularly applicable to high voltage conditions; the used raw materials are economical; the preparation method is simple in process and suitable for large-scale industrial production; and an isopropyl alcohol solution with a specific concentration is employed for cleaning the bonding surface of the base layer, so subsequent bonding process is more easily realized, a prepared composite layer is more compact, and the service life of the insulating tape is prolonged.

Owner:JIANGSU YONGJIA ELECTRONICS MATERIALS

Cable for ship marine closed circuit television camera and manufacturing method thereof

InactiveCN102097161BImprove conductivityImprove insulation performanceInsulated cablesInsulated conductorsCopper conductorPower cable

The invention discloses a cable for a ship marine closed circuit television camera and a manufacturing method thereof, belonging to the field of cables. A cable core comprises a coaxial cable, a twisted pair core wire and a power cable and is peripherally wrapped with a polyester tape lapped layer; the polyester tape lapped layer is peripherally wrapped with a tinned copper wire shielding layer which is peripherally wrapped with an outer sheath; a center conductor of the coaxial cable is outwardly wrapped with a coaxial cable insulating layer, a coaxial cable shielding layer and a coaxial cable sheath in order; the center of the twisted pair core wire comprises a group of twisted pair wire pair and a non-insulating copper conductor leakage wire; the twisted pair wire pair is formed by mutually twisting two single-stranded insulating core wires; each single-stranded insulating core wire comprises a twisted pair wire conductor in the center and a twisted pair wire insulating layer wrapping outside the twisted pair wire conductor, and the twisted pair wire pair and the leakage wire are externally wrapped with aluminum foil polyester composite tapes; the leakage wire is in electric contact with the aluminum layers of the aluminum foil polyester composite tapes; and the power cable comprises a power cable core wire conductor and a power cable insulting layer wrapping outside the power cable core wire conductor.

Owner:JIANGSU YUANYANG DONGZE CABLE

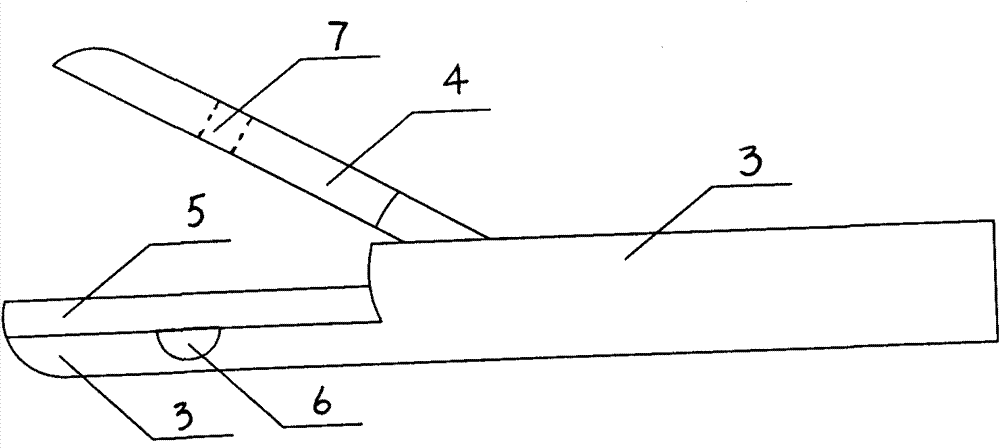

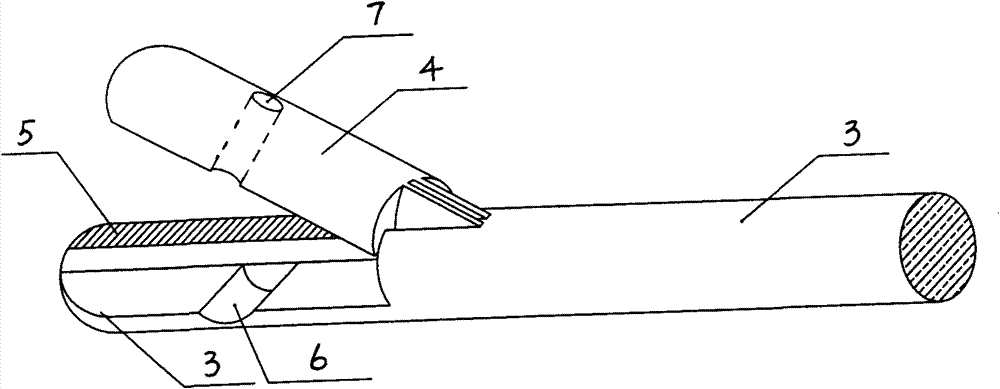

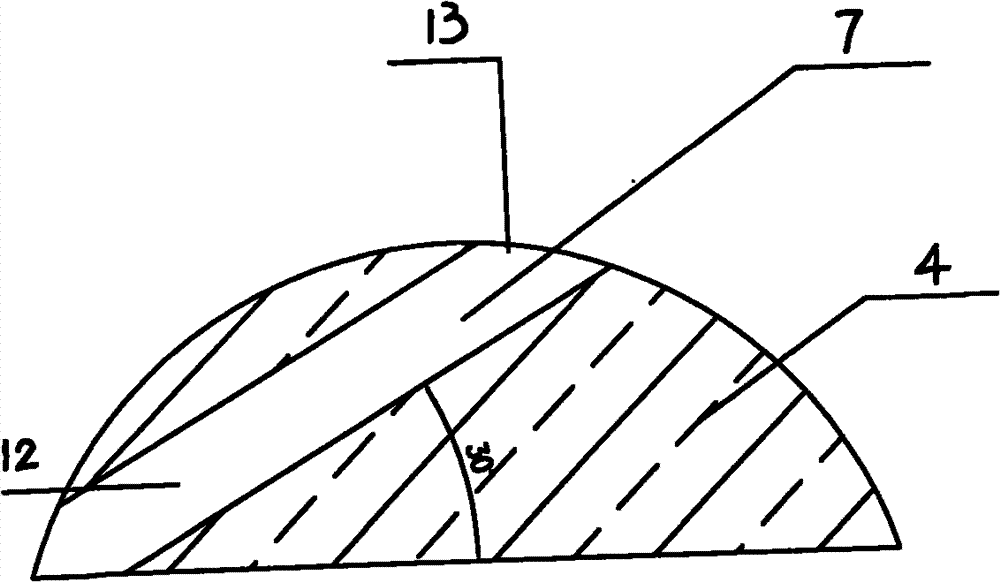

Forceps end mechanism of blocking forceps with puncture hole and no damage to renal artery for celioscope

InactiveCN102078211BProtect kidney functionDoes not interfere with surgical field of viewWound clampsPartial resectionPERITONEOSCOPE

The invention discloses a forceps end mechanism of a pair of blocking forceps with a puncture hole and no damage to a renal artery for a celioscope, comprising a forceps rod and a movable arm, wherein the movable arm is pivoted on an external side section of the forceps rod; a protruding blocking edge is arranged at one side of an upper plane of the external side section of the forceps rod, and arenal artery groove is arranged at the other side of the upper plane; and the movable arm is provided with the puncture hole which is communicated with the renal artery groove. When the blocking forceps manufactured by the forceps end mechanism in the invention are utilized to perform celioscope partial nephrectomy and the like, the renal artery is effectively blocked, therefore, an operation is performed in a bloodless state; and meanwhile, renal artery puncture and low temperature perfusion can be performed, thereby protecting kidney functions to the maximum degree. The mechanism has the advantages of reasonable design, simple structure, high success rate, convenient of use and the like.

Owner:沈瑞林

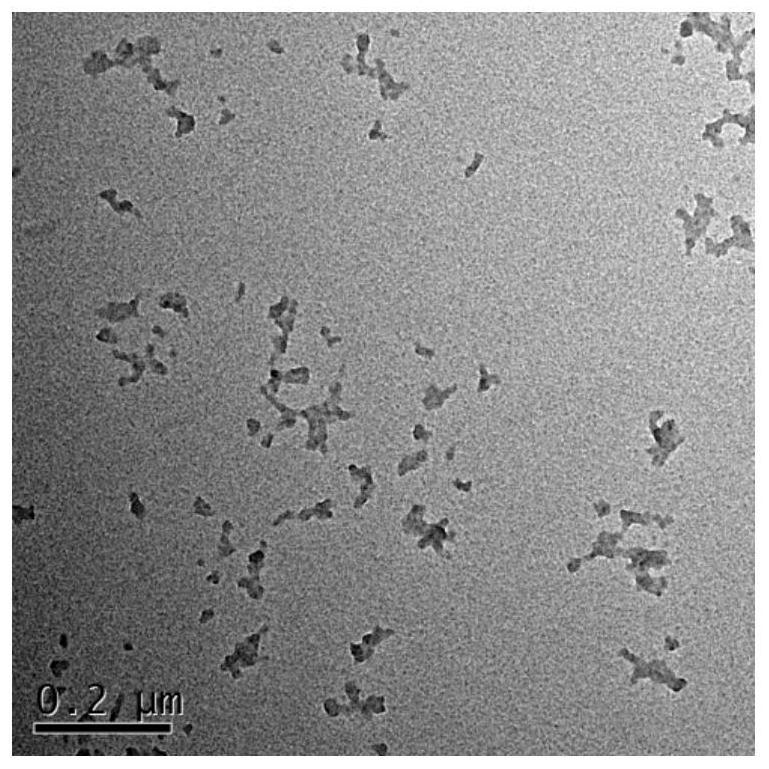

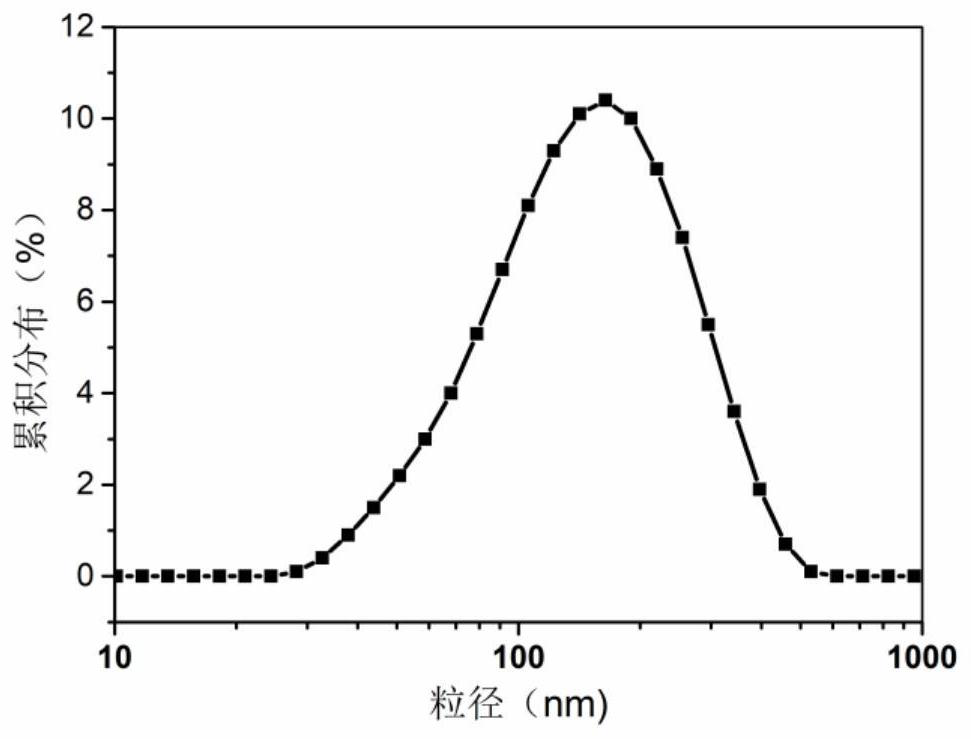

Hyaluronic acid baicalein iron nanoparticles and preparation method thereof

InactiveCN113304265AImprove solubilityEasy to makePowder deliveryOrganic active ingredientsBaicaleinActive agent

The invention discloses hyaluronic acid baicalein iron nanoparticles and a preparation method thereof. According to the hyaluronic acid baicalein iron nanoparticles provided by the invention, baicalein is used as a basic raw material, and a one-pot method is adopted to synthesize the novel active targeting photo-thermal nanoparticles with high drug loading capacity and uniform size. An in-vitro photo-thermal experiment proves that the hyaluronic acid baicalein iron nanoparticles have excellent photo-thermal performance. A cell experiment proves that the hyaluronic acid baicalein iron nanoparticles have a remarkable tumor inhibition effect and are expected to be combined with photothermal therapy and chemotherapy to be used for tumor treatment. The hyaluronic acid baicalein iron nanoparticles are simple in process and high in repeatability, do not use toxic organic reagents and surfactants, and have high operability and wide application prospects.

Owner:CHONGQING MEDICAL UNIVERSITY

An adjustable jacketed tuned damper for offshore wind turbines

ActiveCN109595292BImprove energy consumptionPlay the role of energy consumptionNon-rotating vibration suppressionMachines/enginesEngineeringDamper

The invention relates to a tunable damper for a jacket-type offshore wind power generator, comprising an outer damping cavity unit (1) slidably arranged on the ground and an inner damper slidably arranged in the outer damping cavity unit (1). The cavity unit (5), the outer wall of the outer damping cavity unit (1) is connected with the wind turbine through the energy dissipation spring (4), and the middle of the outer damping cavity unit (1) is provided with a downwardly concave cavity (10) ), the inner damping cavity unit (5) is slidably arranged on the bottom plate of the cavity (10), and the side wall of the inner damping cavity unit (5) is connected with the inner wall of the cavity (10) through the energy dissipation spring (4) , the interior of the outer damping cavity unit (1) and the inner damping cavity unit (5) are sealed, and the liquid (2) is installed inside the outer damping cavity unit (1) and the inner damping cavity unit (5), and is kept There is air. Compared with the prior art, the present invention has multiple energy consumption mechanisms under the action of wind or / and earthquake, and has strong energy consumption capability.

Owner:TONGJI UNIV

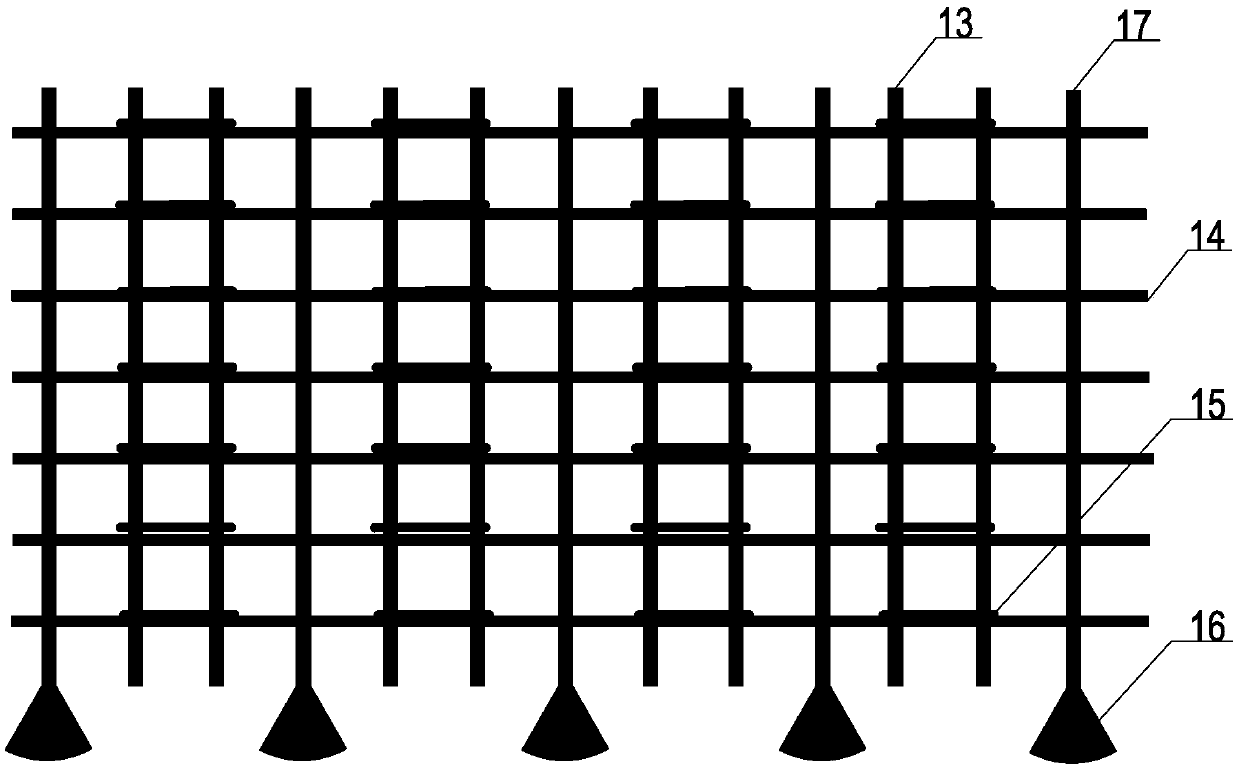

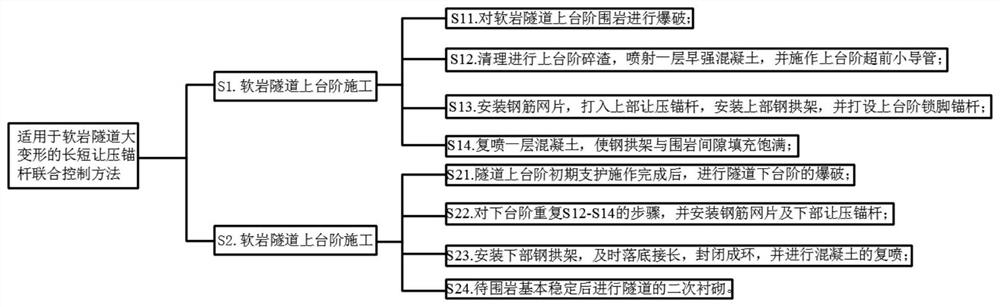

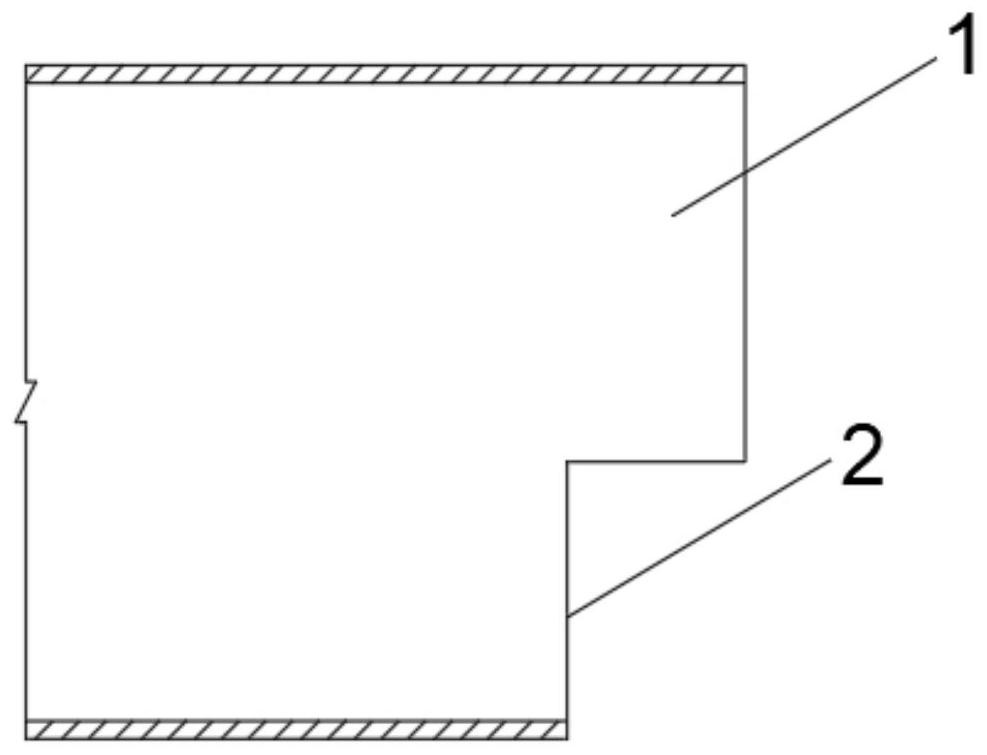

Long and short yielding anchor rod type combined control method suitable for large deformation of soft rock tunnel

PendingCN113216978AReduce exposure timeGuaranteed stabilityUnderground chambersTunnel liningSupporting systemMesh reinforcement

The invention discloses a long and short yielding anchor rod type combined control method suitable for large deformation of a soft rock tunnel. The method comprises the steps of upper step construction of the soft rock tunnel and lower step construction of the soft rock tunnel. According to the method, after tunnel excavation is completed, guniting treatment is carried out on a surrounding rock in time, the exposure time of the surrounding rock is shortened, then installation of a reinforcing mesh and yielding anchor rods are carried out, the yielding anchor rods are arranged in two times, setting of a primary support steel frame is carried out, and finally a layer of concrete is sprayed again; and releasing can be carried out on the internal energy of the surrounding rock in a deformation mode, firstly, the force acts on the yielding anchor rods, when the supporting force provided by the yielding anchor rods and a steel arch is equal to the deformation force of the surrounding rock, the deformation of the surrounding rock stops, at the moment, a primary supporting system composed of the yielding anchor rods and the steel arch is in a relative balance state, the rigid-flexible combined supporting effect is formed, engineering accidents caused by large deformation are avoided, and the method has the advantages of being good in surrounding rock supporting effect, simple in supporting structure and economical in material consumption.

Owner:中铁二十五局集团第四工程有限公司 +1

Green lightweight tensile bamboo reinforced concrete prefabricated blocks

The invention discloses a green lightweight tensile bamboo reinforced concrete precast block. Raw materials of the concrete precast block comprise bamboo sheet fibers, jute fibers, kraft paper, broken stones, recycled concrete, fly ash, perlite and phosphate cement. The green lightweight tensile bamboo reinforced concrete precast block produced in the invention has the advantages of light weight, large tensile strength, great reduction of the self-weight and the cracking probability of walls built by using the concrete precast block and the cracking probability of pavement bricks, good heat insulation property and good noise prevention performance. Materials used in the invention are more environmentally-friendly and economical than traditional brick materials, so the demand for clay is reduced, and the fertile land is protected. Waste concrete is reused, so resources are reasonably used.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com