Automatic temperature control fan with thermal expansion and contraction principle

A technology of thermal expansion and cold contraction, automatic temperature control, applied in engine control, pump control, machine/engine, etc., can solve the problems of complex structure and high cost, and achieve the effect of simplified structure, simple structure and economical materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

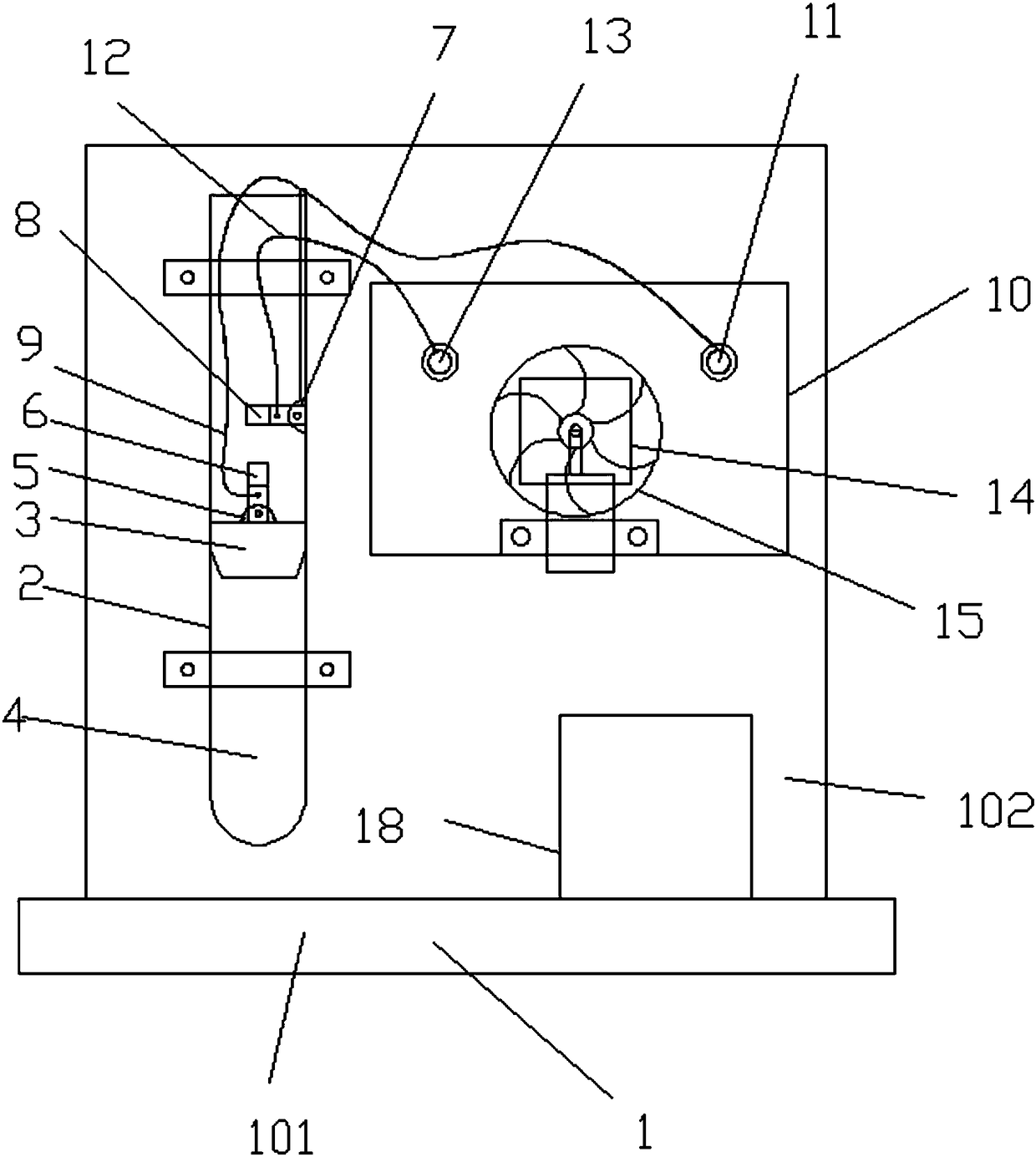

[0022] Embodiment 1: The principle of thermal expansion and cold contraction automatic temperature control fan, (such as figure 1 Shown) has the mounting frame 1 that can be placed on the desktop and is inverted T shape, and described mounting frame 1 has vertical plate 102, and the plate body of described vertical plate 102 is fixedly installed bottle mouth upwards vertical glass test tube 2; The inside of the glass test tube 2 is sealed and fitted with a moving piston 3 that can slide freely up and down along the tube wall in the axial direction and closely fits the tube wall, and the outer circumference of the moving piston 3 and the glass test tube 2 tube wall The surface is coated with lubricating grease; and the closed cavity formed by the sealing of the moving piston 3 in the lower part of the glass test tube 2 is sealed with a gas medium 4 that can push the moving piston 3 to move up and down for a certain distance after thermal expansion and cold contraction; the movin...

Embodiment 2

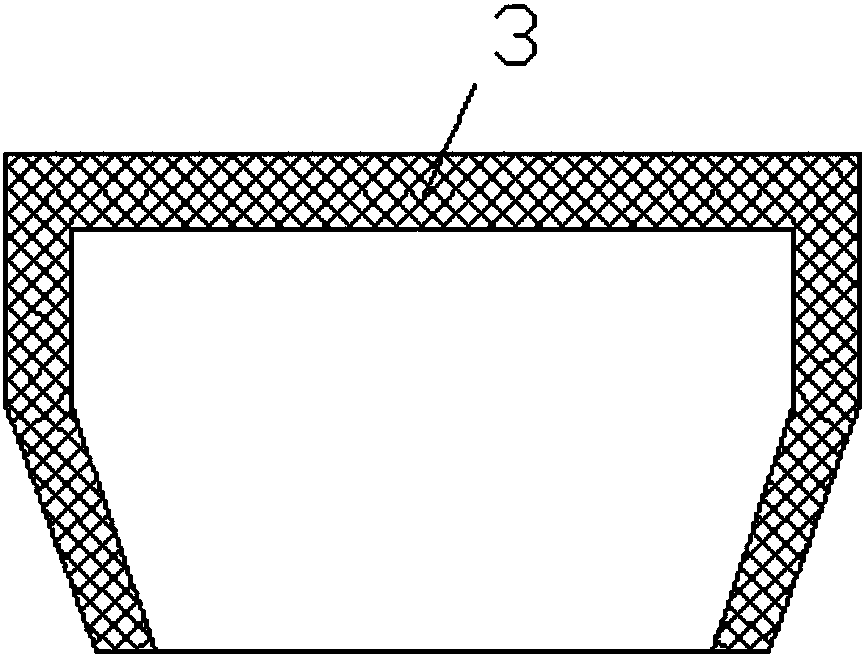

[0023] Embodiment 2: On the basis of the structure of Embodiment 1, in order to reduce the excessive influence of the rising resistance caused by the gravity of the moving piston 3 during the upward movement in the smooth glass test tube 2 by the expanding gas of the moving piston 3; and in combination For the lubricating and sealing effect of grease, select more suitable materials to improve the sealing effect of the moving piston 3 on the sealed gas medium 4 at the bottom of the glass test tube 2: the moving piston 3 is a hollow cover structure, (such as image 3 shown) and made of Styrofoam.

Embodiment 3

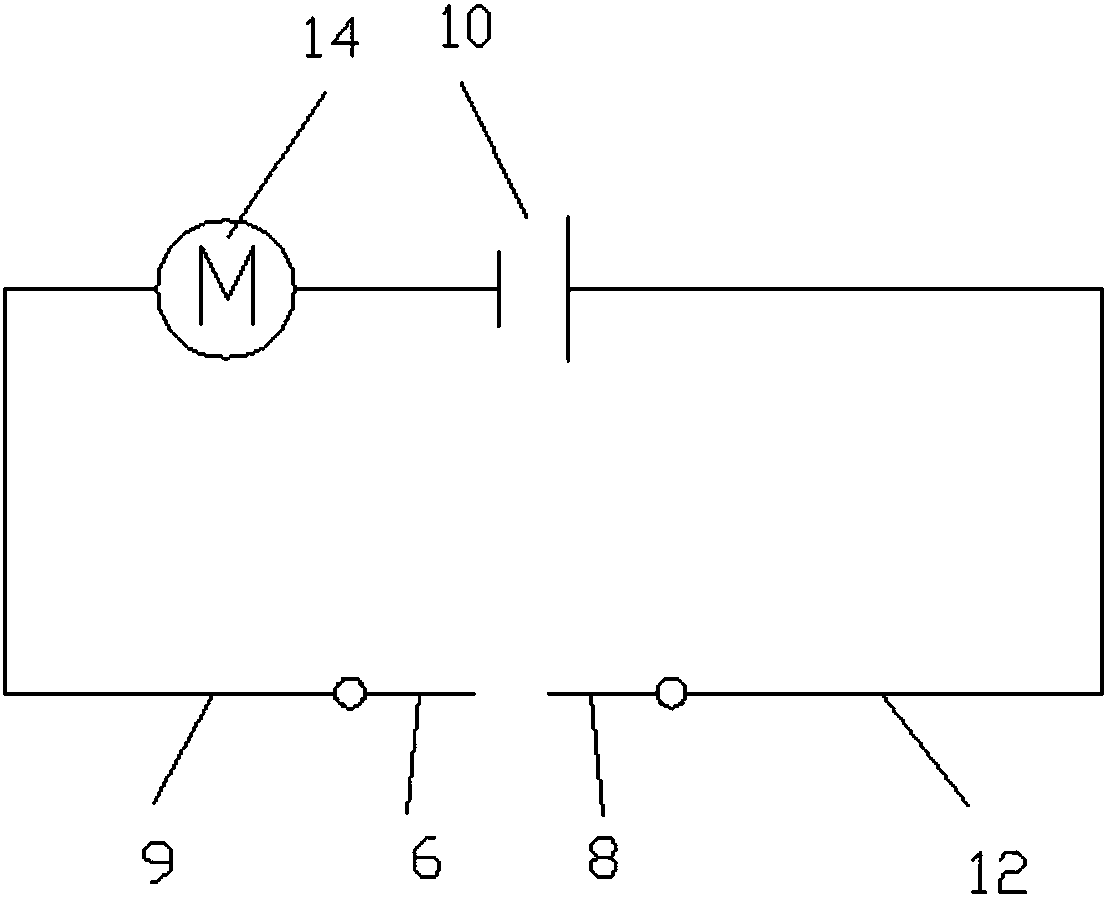

[0024] Embodiment 3: On the basis of the structure of Embodiment 1, as another embodiment of the present invention, in order to achieve a better and more stable connection between the rechargeable battery 10 and the positive and negative metal sheets: the positive and negative electrodes of the rechargeable battery 10 The extreme end is fixedly installed on the positive terminal 11 on the vertical plate 102 through the exposure and is connected to the positive metal sheet 6 through the wire I9; II12 is connected to the negative metal sheet 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com