Long and short yielding anchor rod type combined control method suitable for large deformation of soft rock tunnel

A technology of letting the anchor rod and joint control, applied in the direction of tunnel, tunnel lining, installation of anchor rod, etc., can solve the problems of increasing construction cost and progress, danger of engineering construction, deformation of steel frame, etc., to reduce exposure time, support Simple protective structure and low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

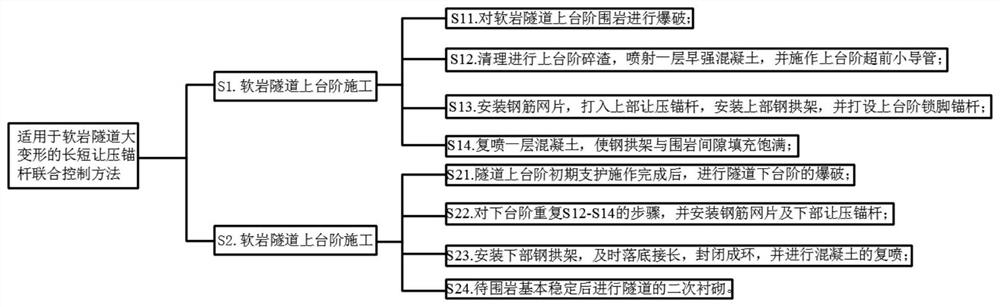

Method used

Image

Examples

Embodiment 1

[0102] Taking Songpan Tunnel as an example, the support effect analysis of ordinary anchors and long and short yielding anchors is carried out. Through the simulation results, it can be concluded that the anchor axial force of long and short anchors is smaller than that of ordinary anchors, and the effective It reduces the breakage and loss of function of the anchor rod due to excessive tension during construction, and the effect is better for tunnel support in areas with large deformation of soft rock;

[0103] The tunnel settlement and bolt axial force obtained from the simulation results are as follows: Figure 10 , Figure 11 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com