Patents

Literature

58results about How to "Avoid falling blocks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Collapsible loess tunnel primary support arch replacement construction method

InactiveCN111456756AAvoid falling blocksAvoid dangerUnderground chambersTunnel liningArchitectural engineeringRapid construction

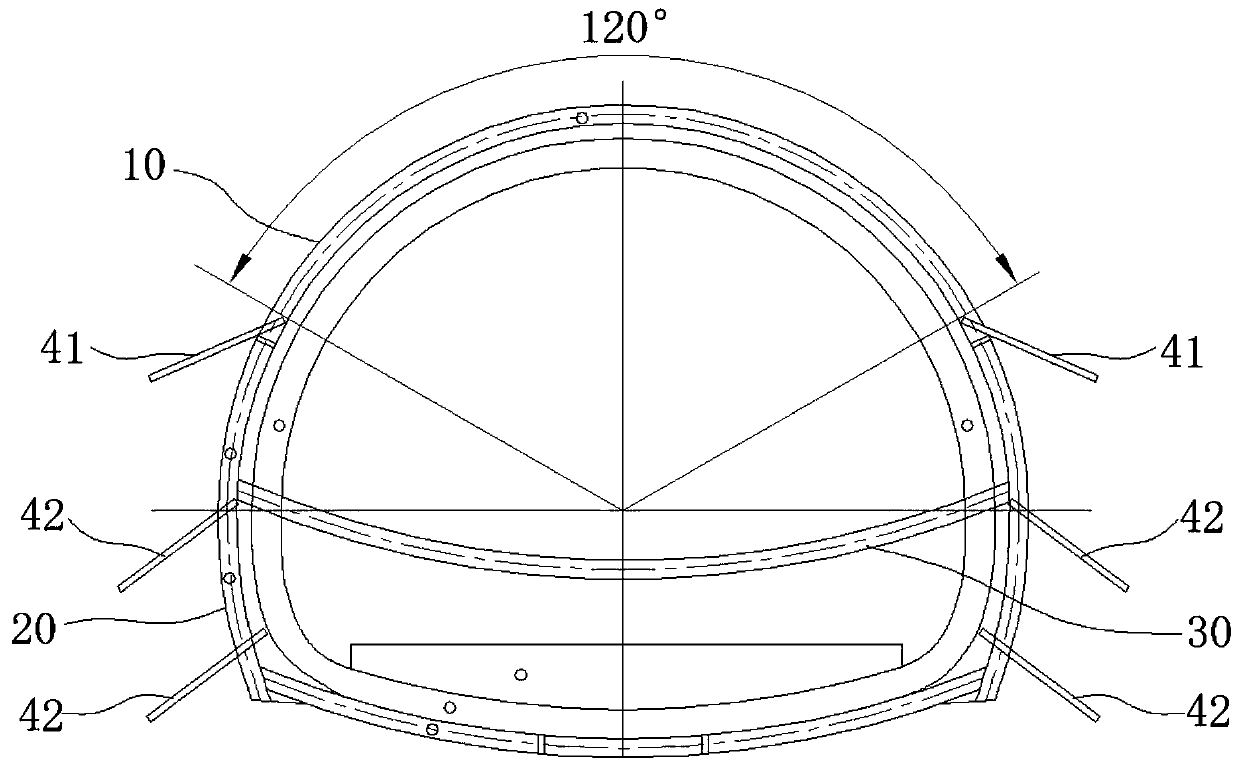

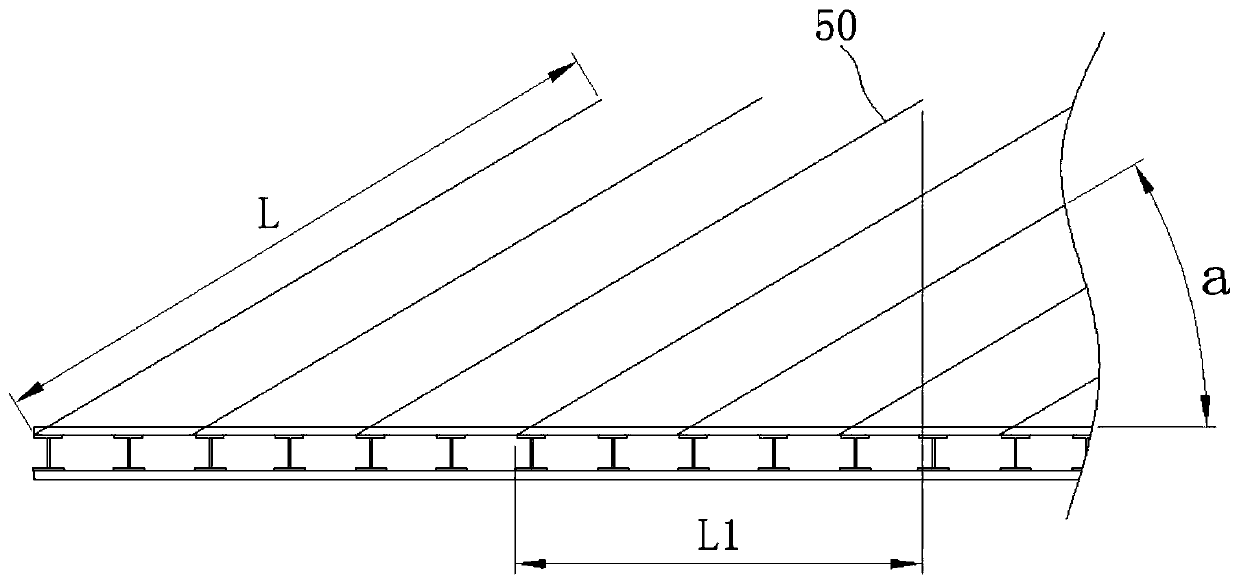

The invention provides a collapsible loess tunnel primary support arch replacement construction method. The method comprises the five steps of carrying out arch replacement construction preparation, temporary measures, soil body reinforcement, primary support steel arch frame pre-reinforcement and arch replacement construction. According to the construction method, a special lining construction rack does not need to be additionally arranged, operation is carried out based on a waterproof plate trolley, rapid construction is facilitated, and the cycle operation time is shortened. Soil body reinforcement and steel arch frame pre-reinforcement are brought into the construction procedure, the safety of operators can be guaranteed, the danger of soil body chipping or collapse in an arch frame dismantling process is effectively avoided, and meanwhile the bearing capacity, integrity and waterproof and anti-permeability performance of tunnel surrounding rock bodies are guaranteed. By adoptingthe arch replacement construction method for construction, the geological problems of collapsible loess tunnel arch crown settlement, peripheral convergence and the like can be effectively solved, thetunnel quality problems of secondary lining cracking, beyond limit and the like caused by large deformation of surrounding rock are prevented, the construction cost is effectively reduced, and the construction period is effectively shortened.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD +1

Preparation method of composite pantograph pan of electric locomotive

ActiveCN108117391AImprove the lubrication effectImprove conductivityRailway vehiclesPower current collectorsGranularityGraphite

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

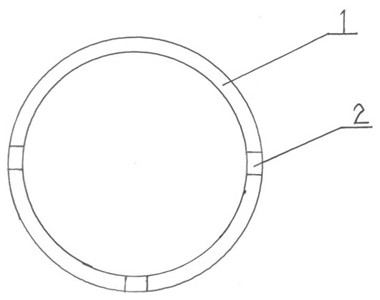

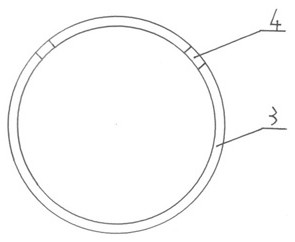

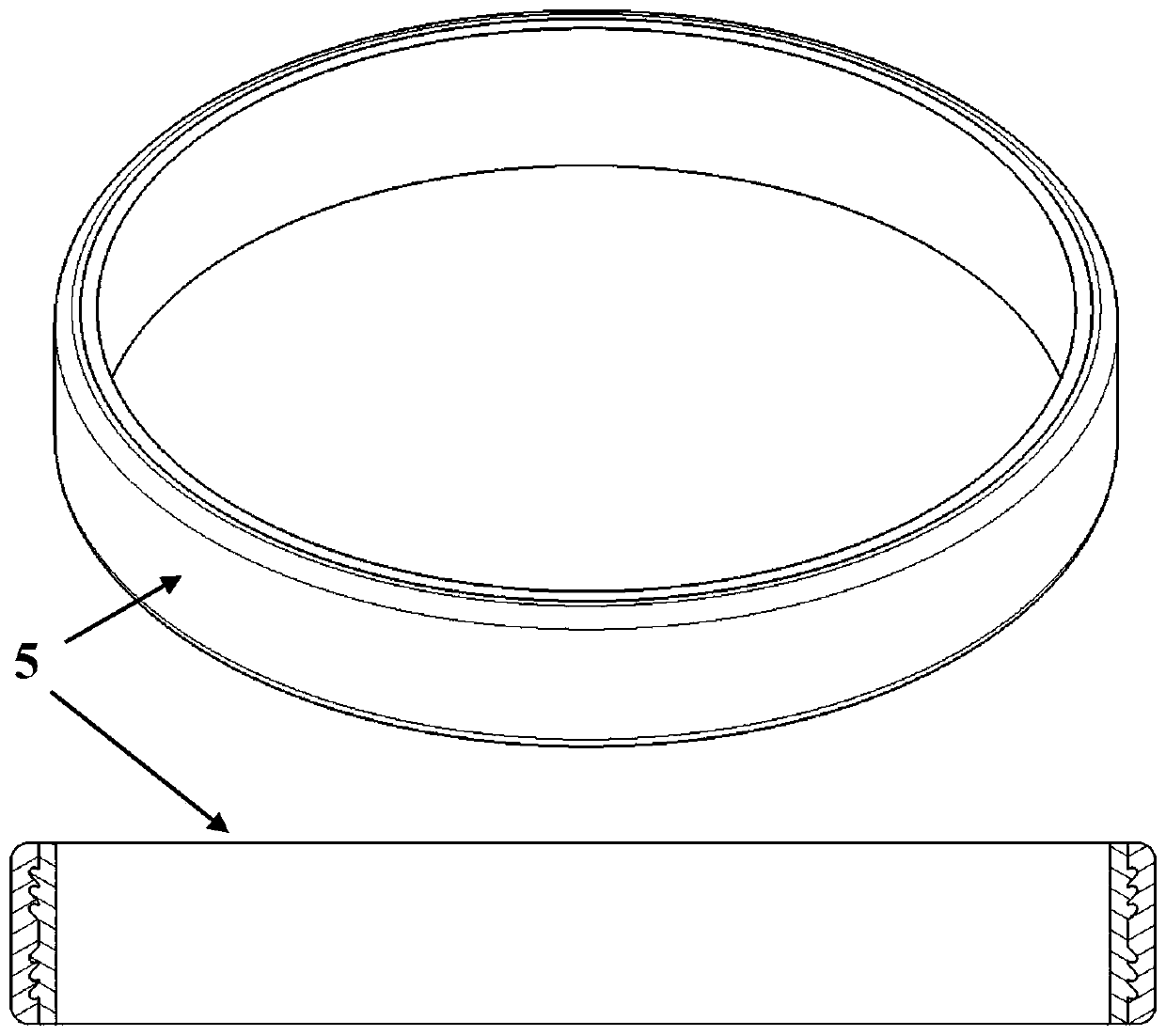

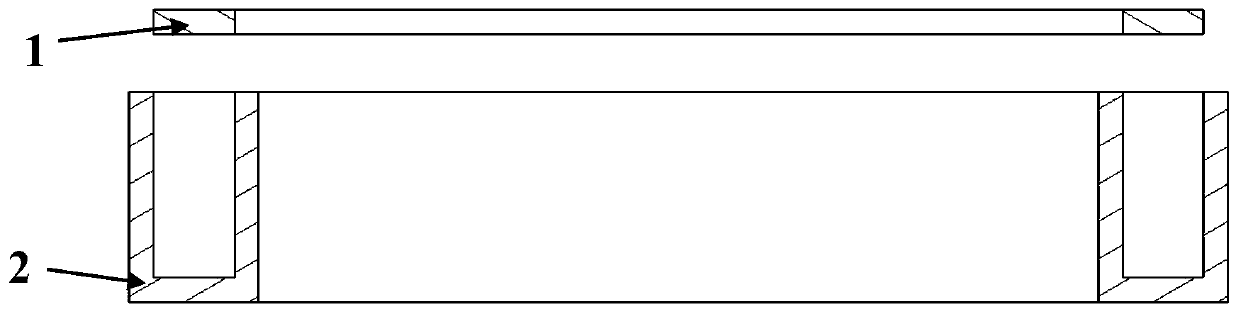

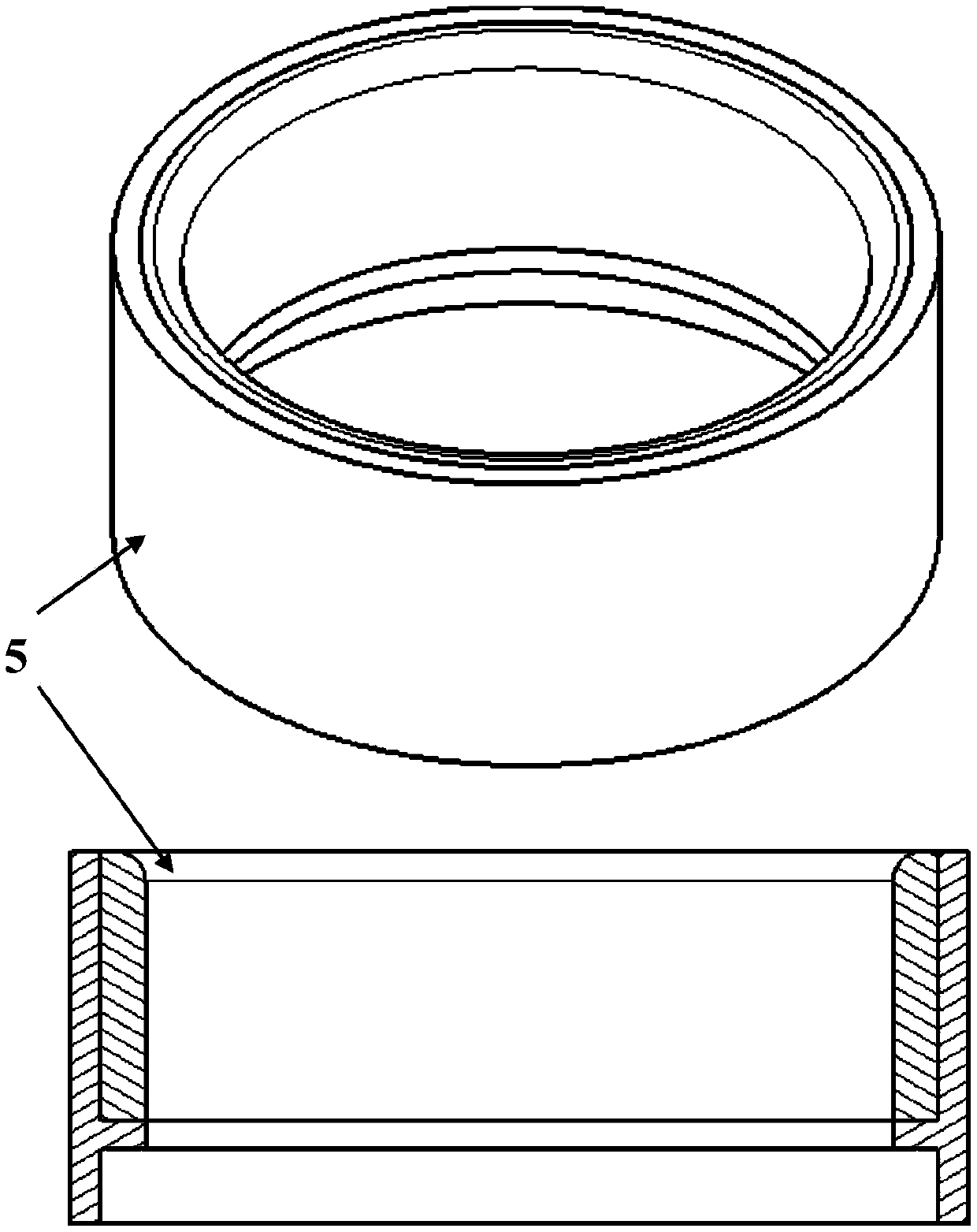

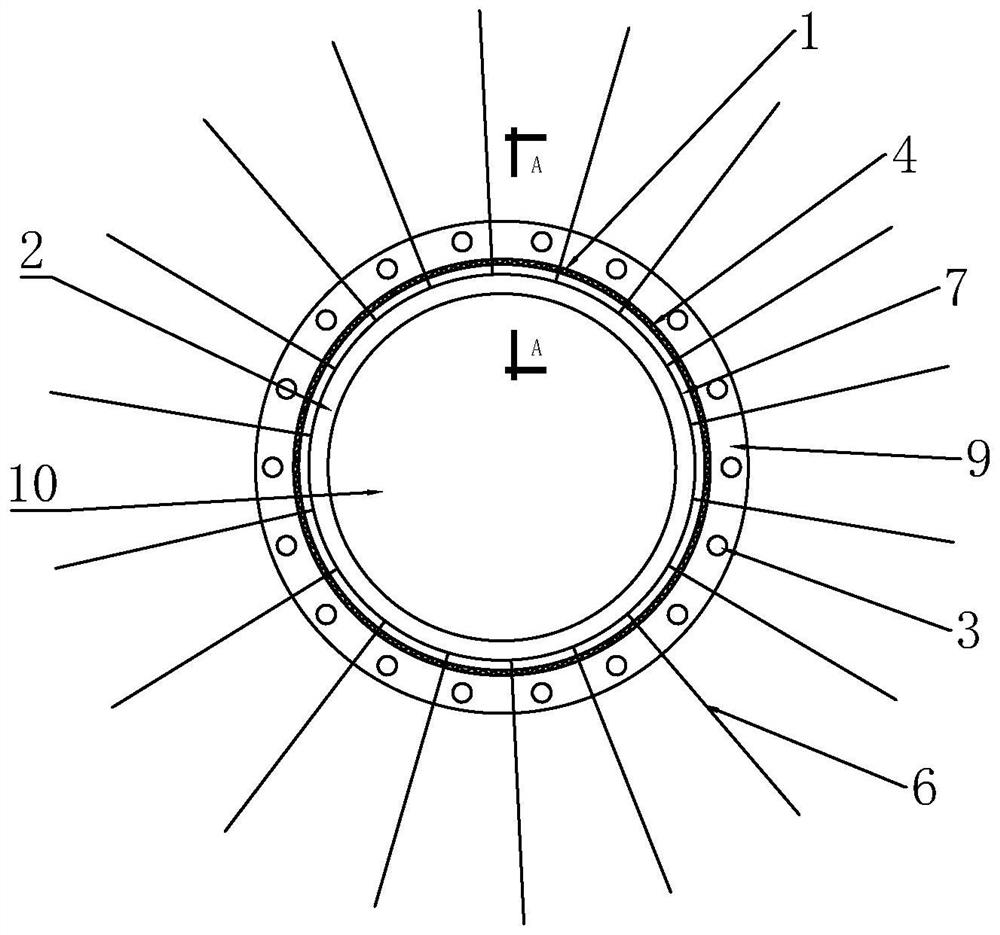

Diffusion connection method between nickel-based high-temperature alloy ring-shaped piece and copper silver alloy

InactiveCN108788655AAchieve connectionPrevent peelingNon-electric welding apparatusSuperalloyHot isostatic pressing

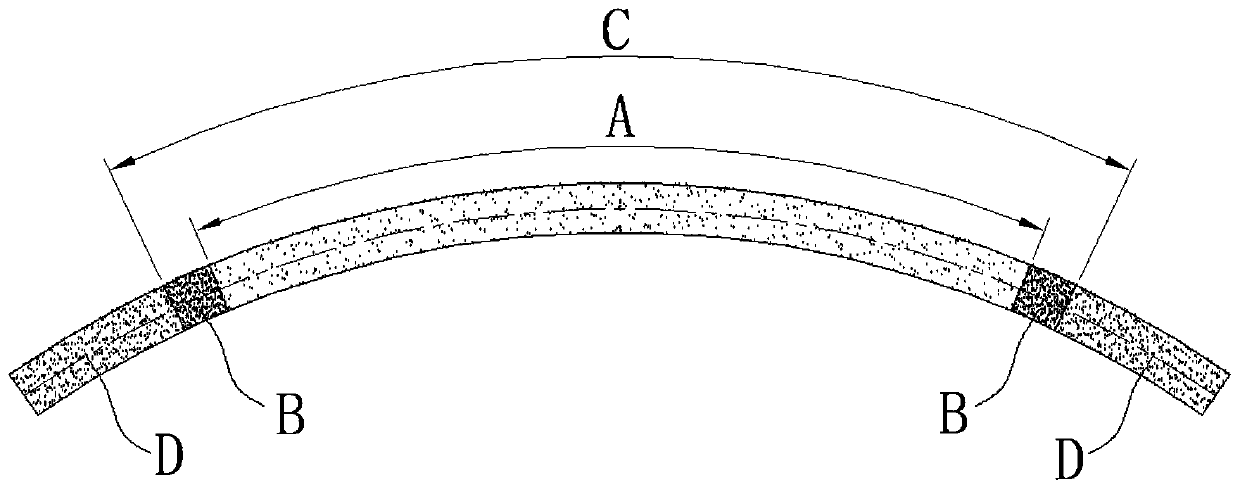

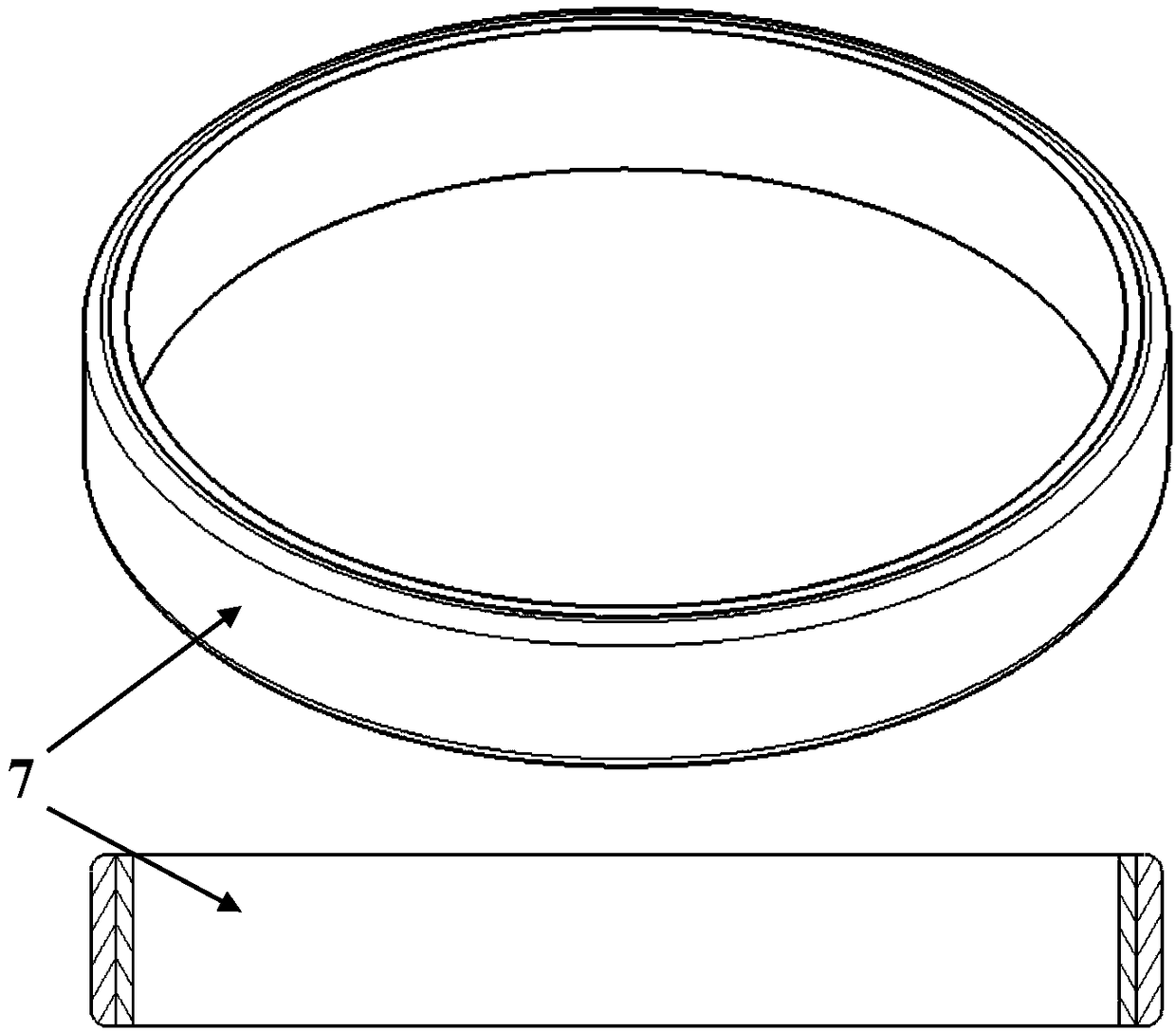

The invention provides a diffusion connection method between a nickel-based high-temperature alloy ring-shaped piece and a copper silver alloy. The method comprises the steps of preparation of a high-temperature alloy ring-shaped piece and a copper silver alloy ring-shaped piece, preparation and assembling of a sheath, hot isostatic pressure pretreatment, hot isostatic pressure process control, post-treatment and the like. According to the diffusion connection method between the nickel-based high-temperature alloy ring-shaped piece and the copper silver alloy, the hot isostatic pressure diffusion connection technology is adopted, the copper silver alloy is subjected to diffusion connection with the high-temperature alloy ring-shaped piece in a high-temperature high-pressure environment, and a connection piece for the high-temperature alloy ring-shaped piece and the copper silver alloy ring-shaped piece is formed. By means of the method, connection between the high-temperature alloy andthe copper silver alloy is well implemented, stripping, chip off-falling and layering of a connection layer and separation of the connection layer from a base body are avoided, the porosity of the connection layer is lowered, and good metallurgical bonding is realized.

Owner:BEIHANG UNIV

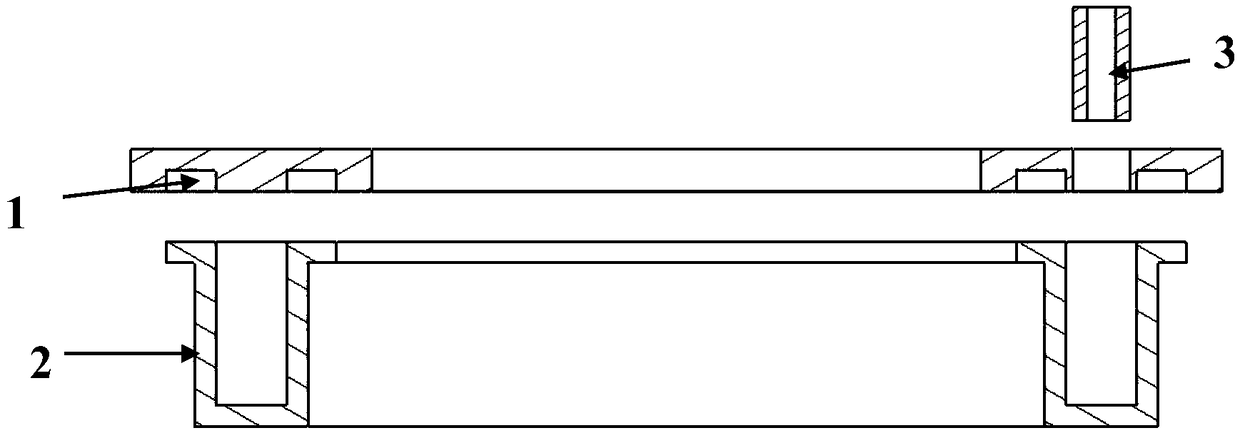

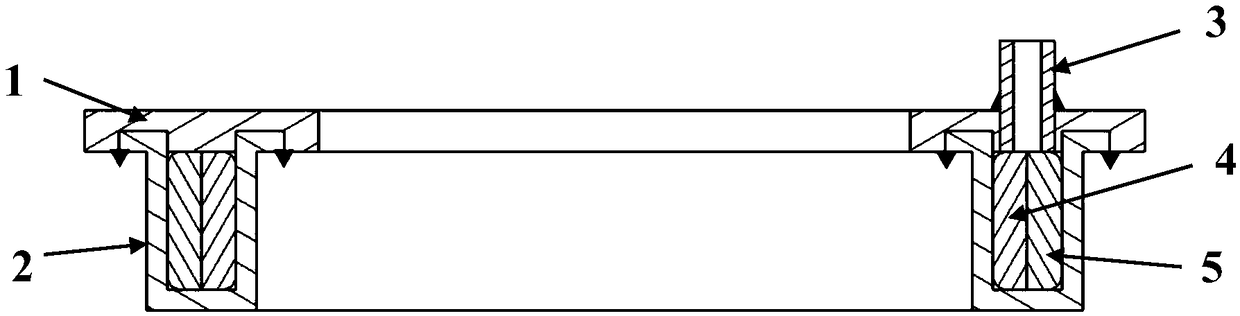

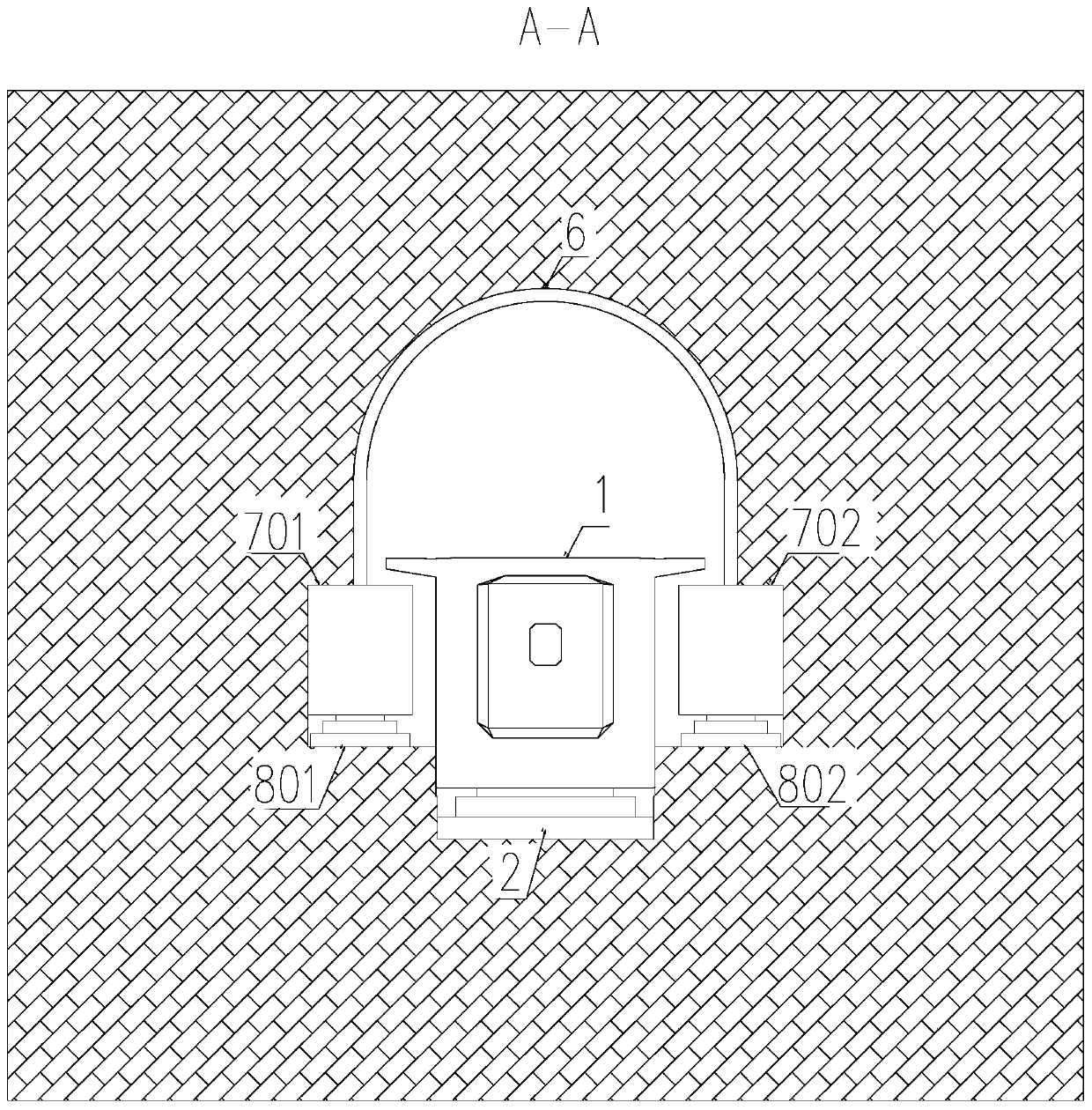

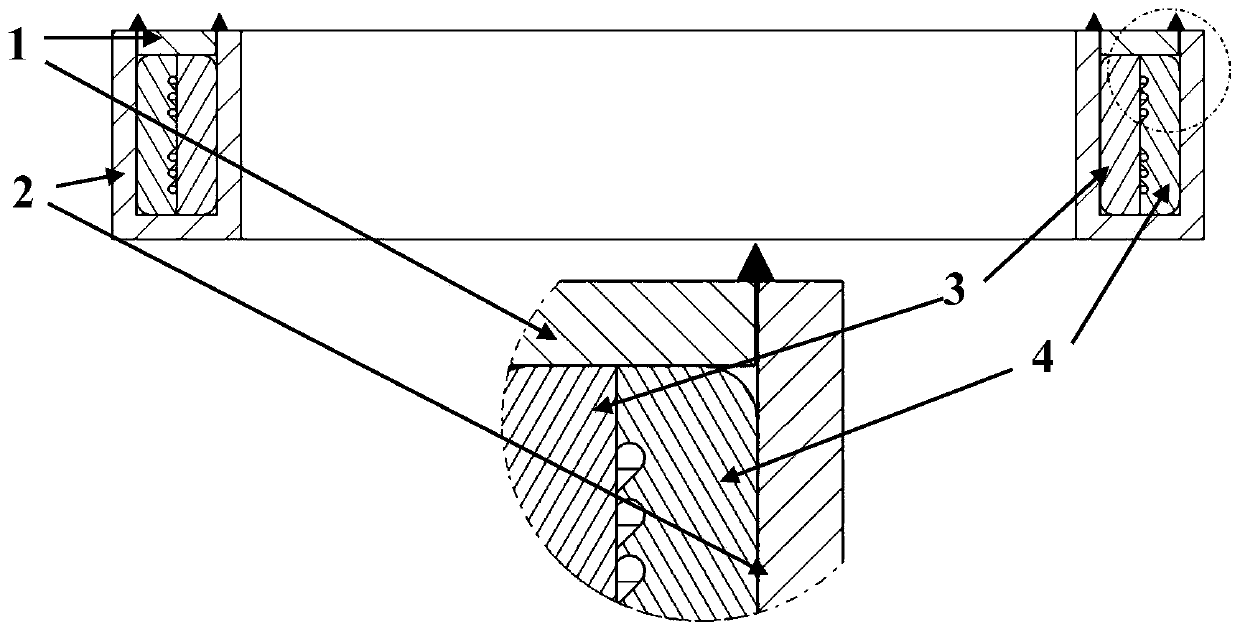

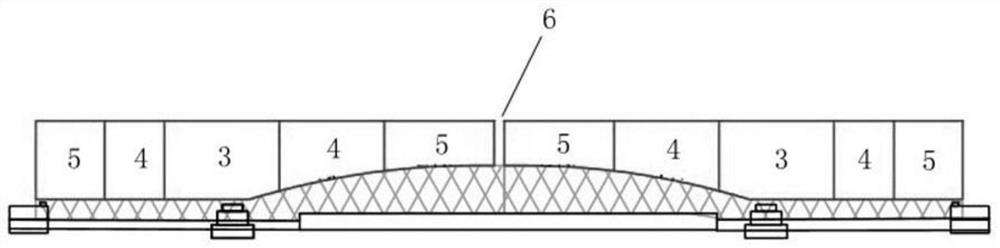

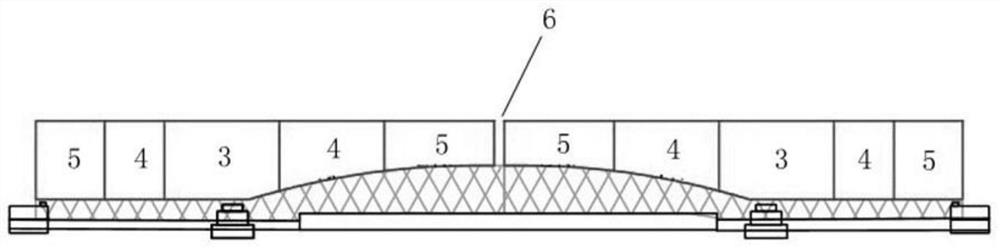

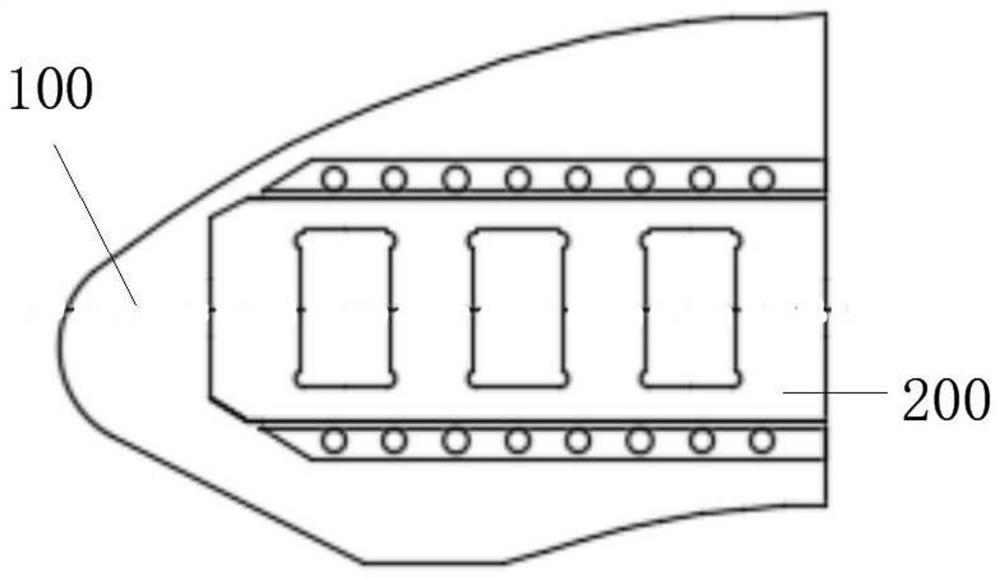

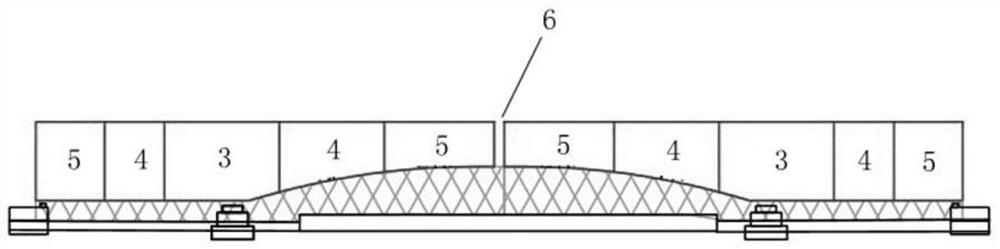

Bridge bearing structure passing through huge karst cave and construction method of bridge bearing structure

PendingCN111411985AEasy constructionReliable structureUnderground chambersTunnel liningEnvironmental geologyStructural engineering

The invention relates to the field of tunnel and underground engineering, in particular to a bridge bearing structure passing through a huge karst cave and a construction method of the bridge bearingstructure. The bridge bearing structure comprises a bridge structure and a protection structure, the protection structure comprises a first supporting beam and a second supporting beam, and further comprises an open cut tunnel structure or a shed tunnel structure, the first supporting beam crosses the karst cave, the two ends of the first supporting beam are arranged on stable foundations on the two sides of the karst cave, the second supporting beam crosses the karst cave, the two ends of the second supporting beam are arranged on the stable foundations on the two sides of the karst cave, thetwo sides of the lower part of the open cut tunnel structure or the shed tunnel structure are fixed to the first supporting beam and the second supporting beam correspondingly, the bridge structure is arranged in the open cut tunnel structure or the shed tunnel structure and crosses the karst cave, and the two ends of the bridge structure are arranged the stable foundations on the two sides of the karst cave. The construction method is used for constructing the bridge bearing structure. Compared with a traditional method for crossing the karst cave through a backfilling method, the karst caveis continuously crossed through prestressed concrete, construction is convenient, the structure is reliable, and the defect of large settling after construction due to tunnel slag backfilling of thehuge karst cave is avoided.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

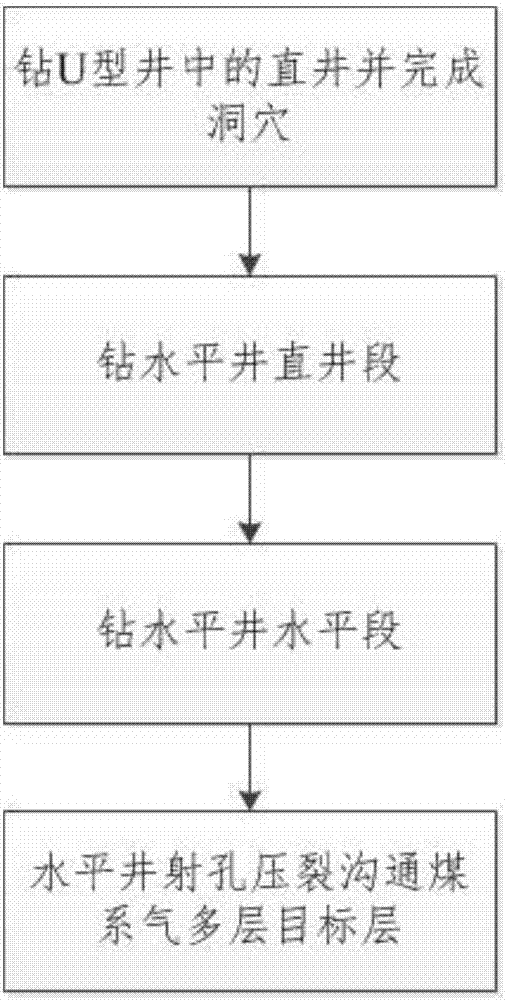

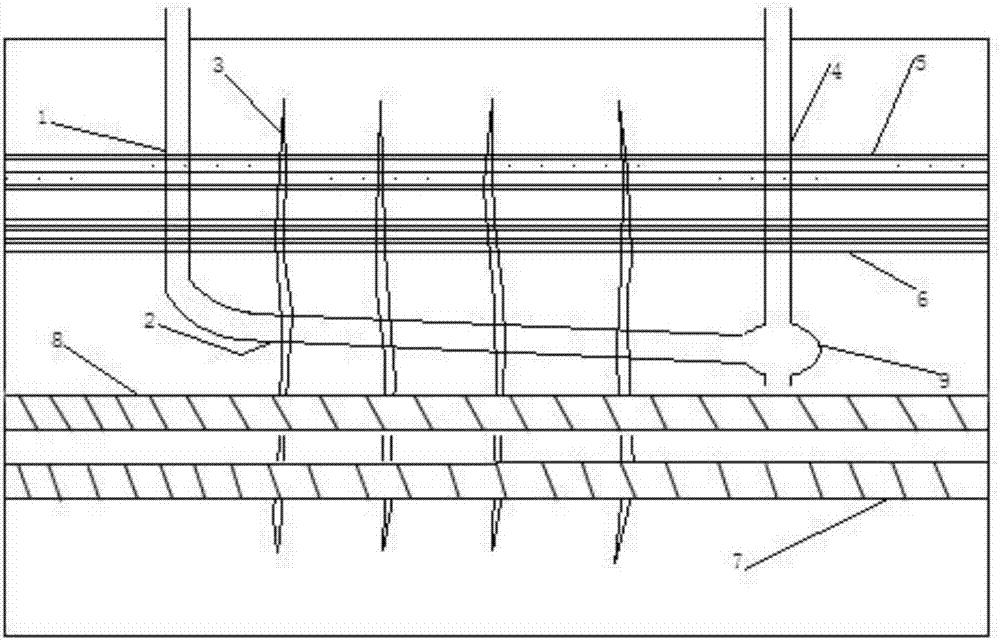

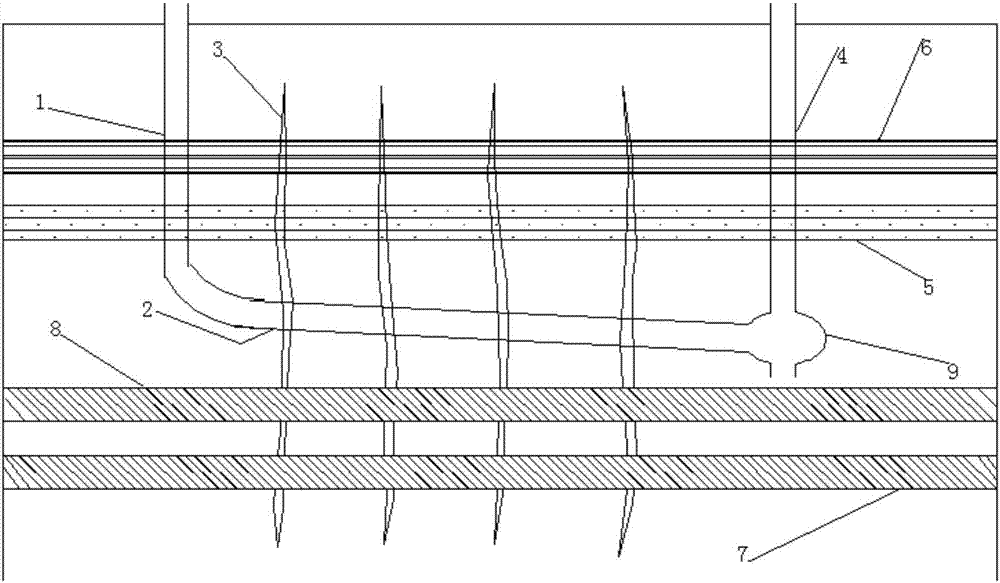

Gas-bearing coal seams U-shaped well drilling and exploiting method

The invention provides a gas-bearing coal seams U-shaped well drilling and exploiting method, and the method comprises the steps of (1) drilling the straight well of the U-shaped well and conducting cavern completion; (2) drilling the straight well segment of the horizontal well; (3) drilling the horizontal segment of the horizontal well; and (4) perforating and fracturing the horizontal well so as to communicate a multilayer object layer of the gas-bearing coal seams. According to the invention, a non-target reservoir is deflected and the horizontal segment is drilled, like a sandstone or a limestone; a borehole is prevented from collapsing, block is prevented from falling off and the well is prevented from leaking when a target reservoir of gas-bearing coal seams is drilled; drilling efficiency is raised; drilling fluid is prevented from soaking the reservoir of the gas-bearing coal seams for a long time, particularly the coalbed gas layer and the shale gas layer; damage of particles in solid phase and drilling cuttings in the drilling fluid to the reservoir of the gas-bearing coal seams is effectively reduced; by communication between the horizontal segment of U-shaped well and the reservoir of the gas-bearing coal seams by pressing crack in a large scope, exploitation swept area and deflation area are increased; multilayer commingled production of the gas-bearing coal seams is realized; the utilization rate of the gas-bearing coal seams is raised; area well drilling quantity and total cost of well drilling are reduced; and the yield of a single well, exploitation degree and economic benefit are greatly increased.

Owner:贵州省地质矿产勘查开发局一一五地质大队 +1

Machining method for aero-engine part sealing coating

InactiveCN105312643AAvoid falling blocksPrevent fallingWorkpiecesMilling equipment detailsNumerical controlAviation

The invention discloses a machining method for an aero-engine part sealing coating. The machining method comprises the steps that a part to be machined is fixed to a numerical control machine tool after spraying is completed; then a hard alloy milling cutter is selected, and parameters of the numerical control machine tool are set; climb milling is conducted through the side edge of the hard alloy milling cutter; the cutting anterior angle and the relief angle are greater than three degrees, and the coating surface of the part to be machined is subjected to milling machining. Due to the fact that climb milling is conducted through the side edge of the hard alloy milling cutter and the cutting anterior angle and the relief angle are greater than three degrees, cutter cutting is in a shearing state and the coating is machined, the cutting force is reduced, and coating particles are prevented from falling down. Meanwhile, the relative grinding efficiency of the same milling mode is greatly improved, coating chip-falling can be avoided and the machining efficiency can be improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

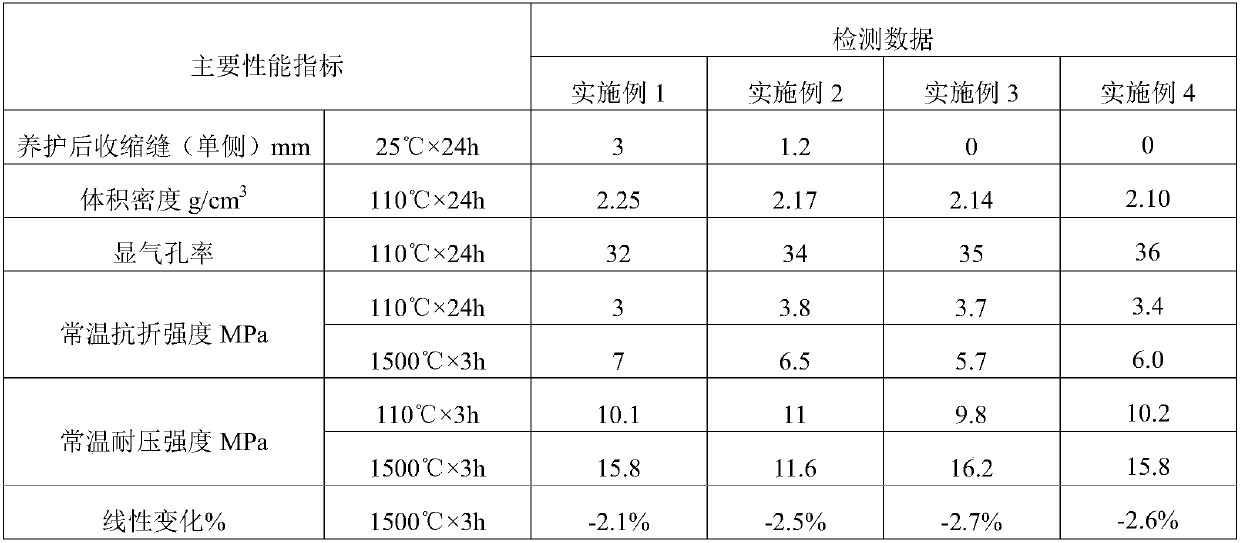

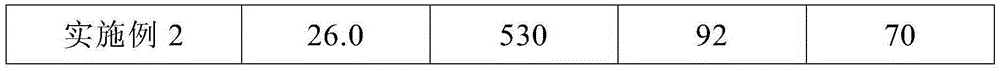

Tundish coating and preparation method thereof

The invention provides tundish coating and a preparation method thereof. The tundish coating is prepared from the following raw materials in percentage by weight: 20% of magnesite clinker with the particle size being 3 mm to 1 mm, 32% of magnesite clinker with the particle size being 1 mm to 0.1 mm, 38-40% of magnesite clinker with the particle size being not greater than 0.075 mm, 1.2-1.5% of fiber, 1-3% of a binding agent, 2-3.5% of a plasticizer, 0.3-0.5% of a dispersant, and 0.5-2.5% of a raising agent; and the raising agent is carbonate or a mixture of the carbonate and acidoid. The tundish coating has the following beneficial effects that the situation that during high-temperature baking, concentrated drainage of water in the coating is extremely fast, consequently, the coating is cracked, peeled, chipped off and even collapsed is prevented; and the construction maintenance time and the online baking time of the coating can be greatly shortened, and the production efficiency of asteel mill is greatly improved.

Owner:北京利尔高温材料股份有限公司

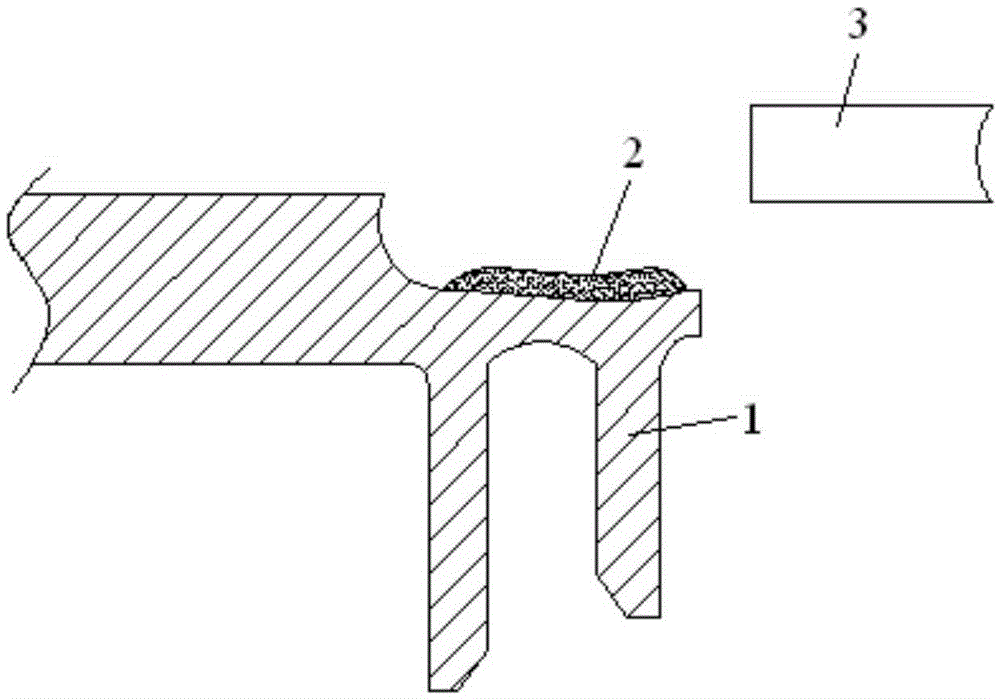

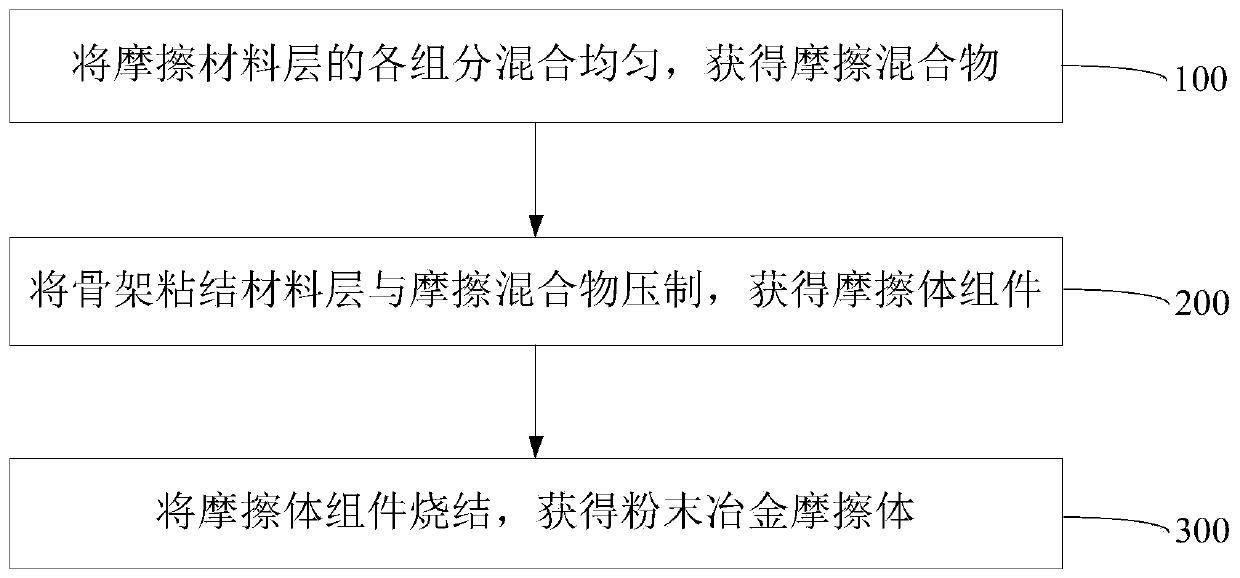

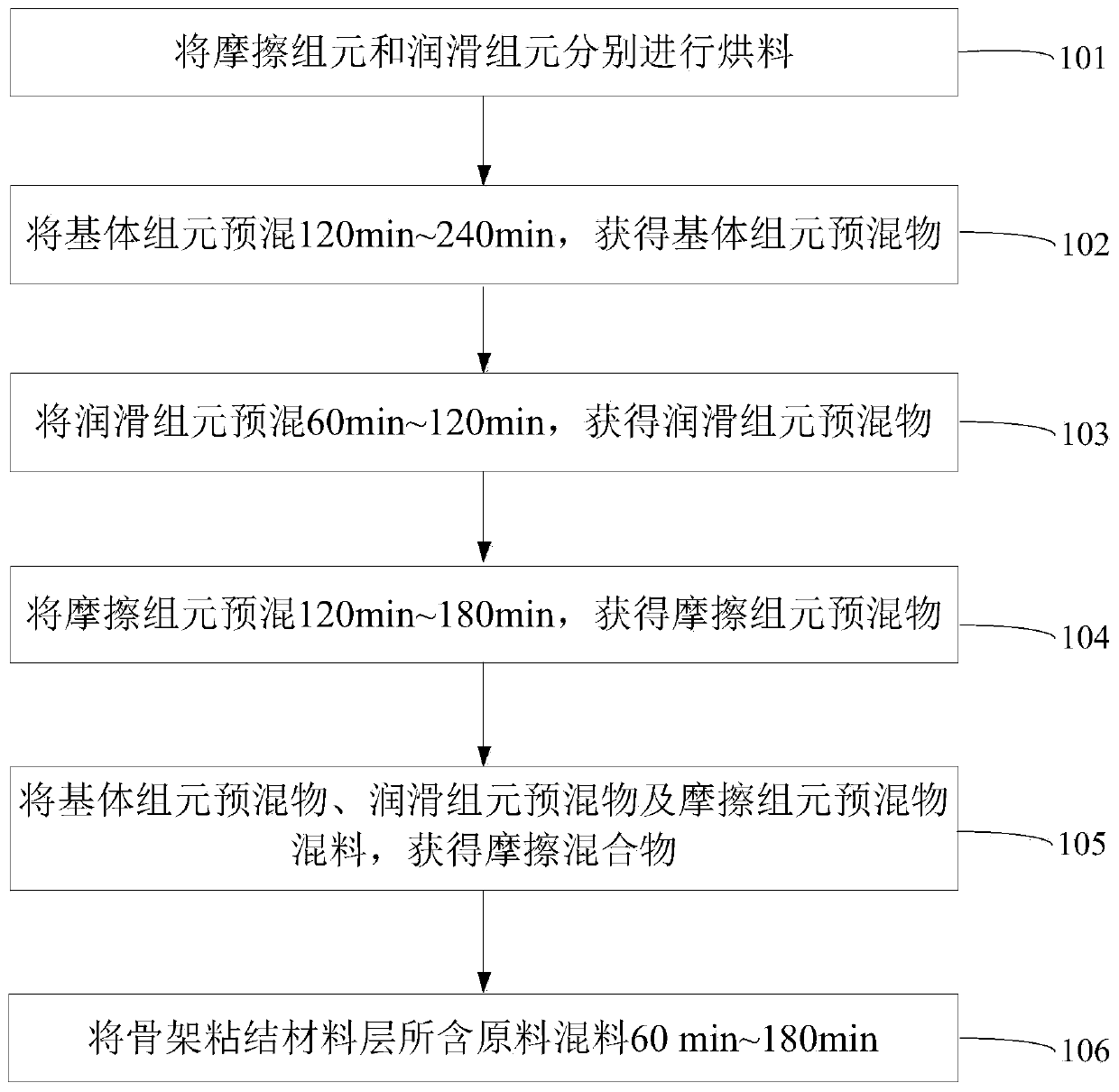

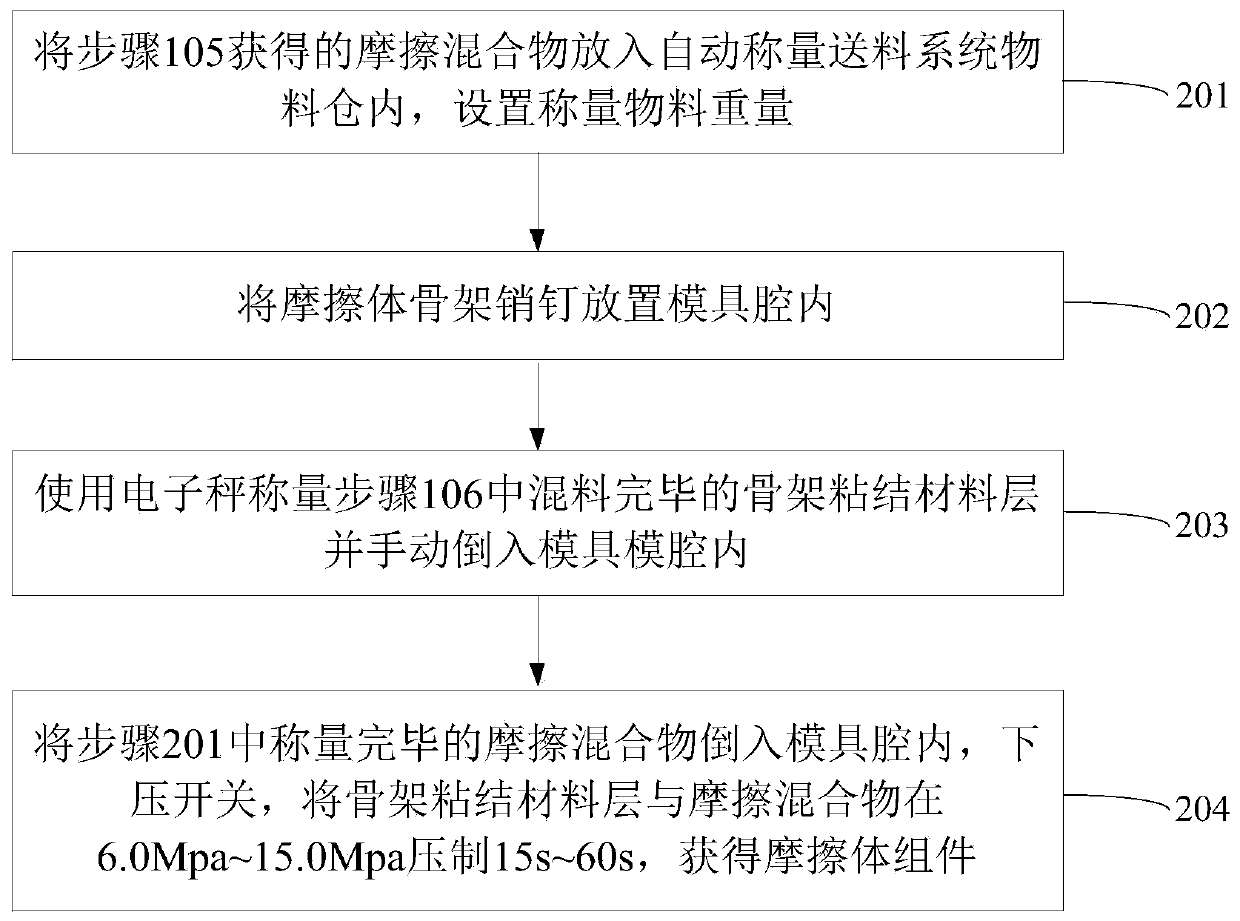

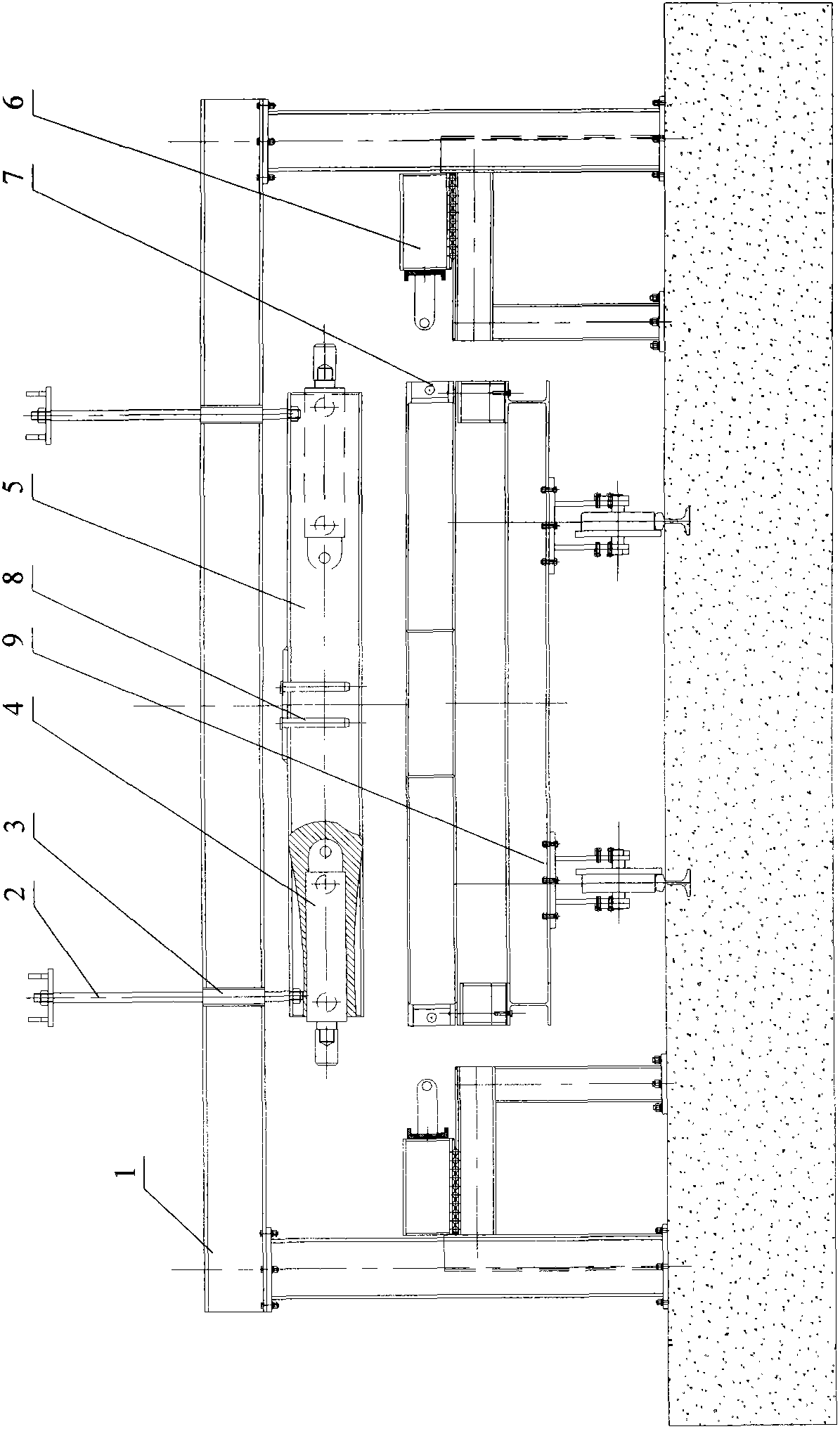

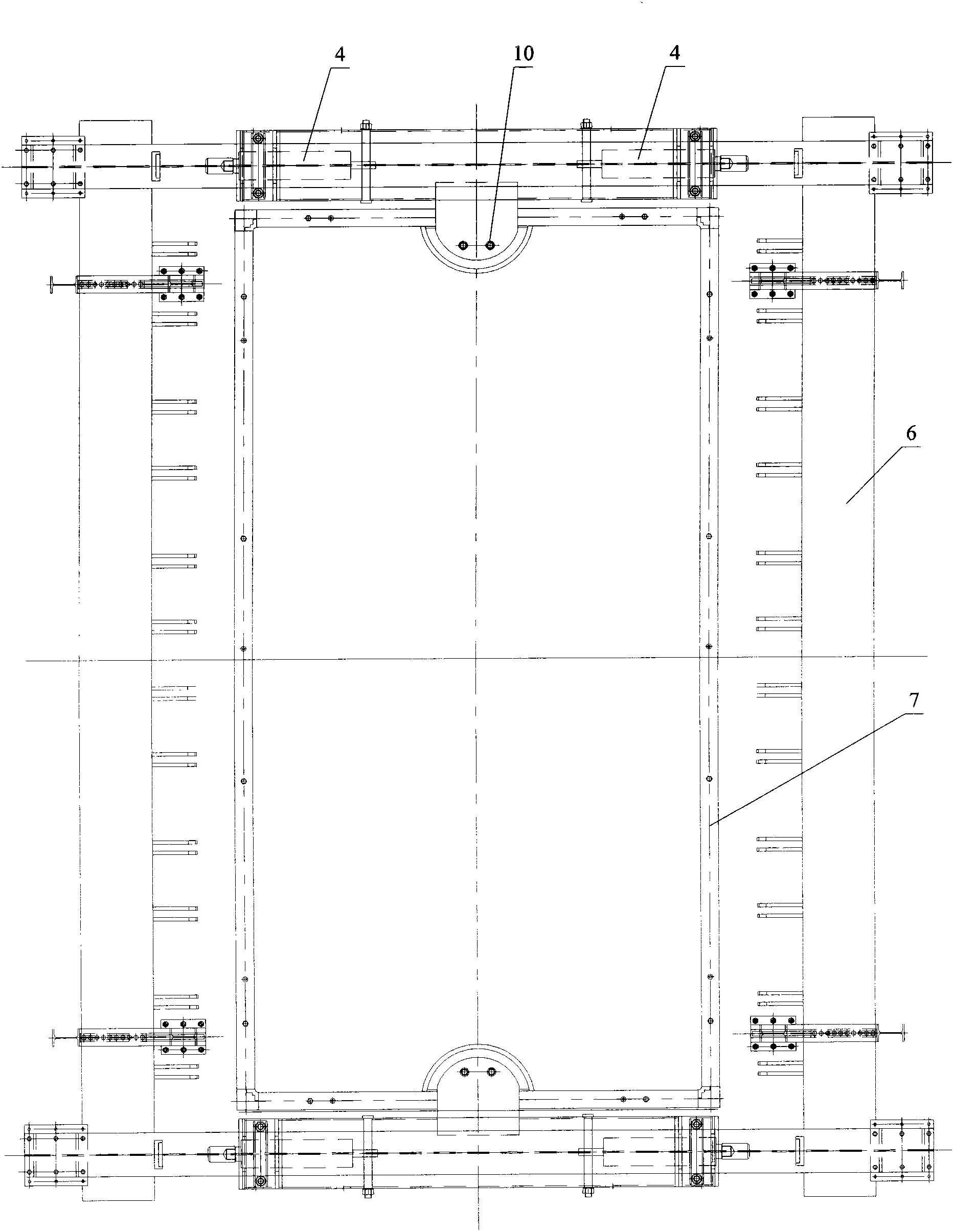

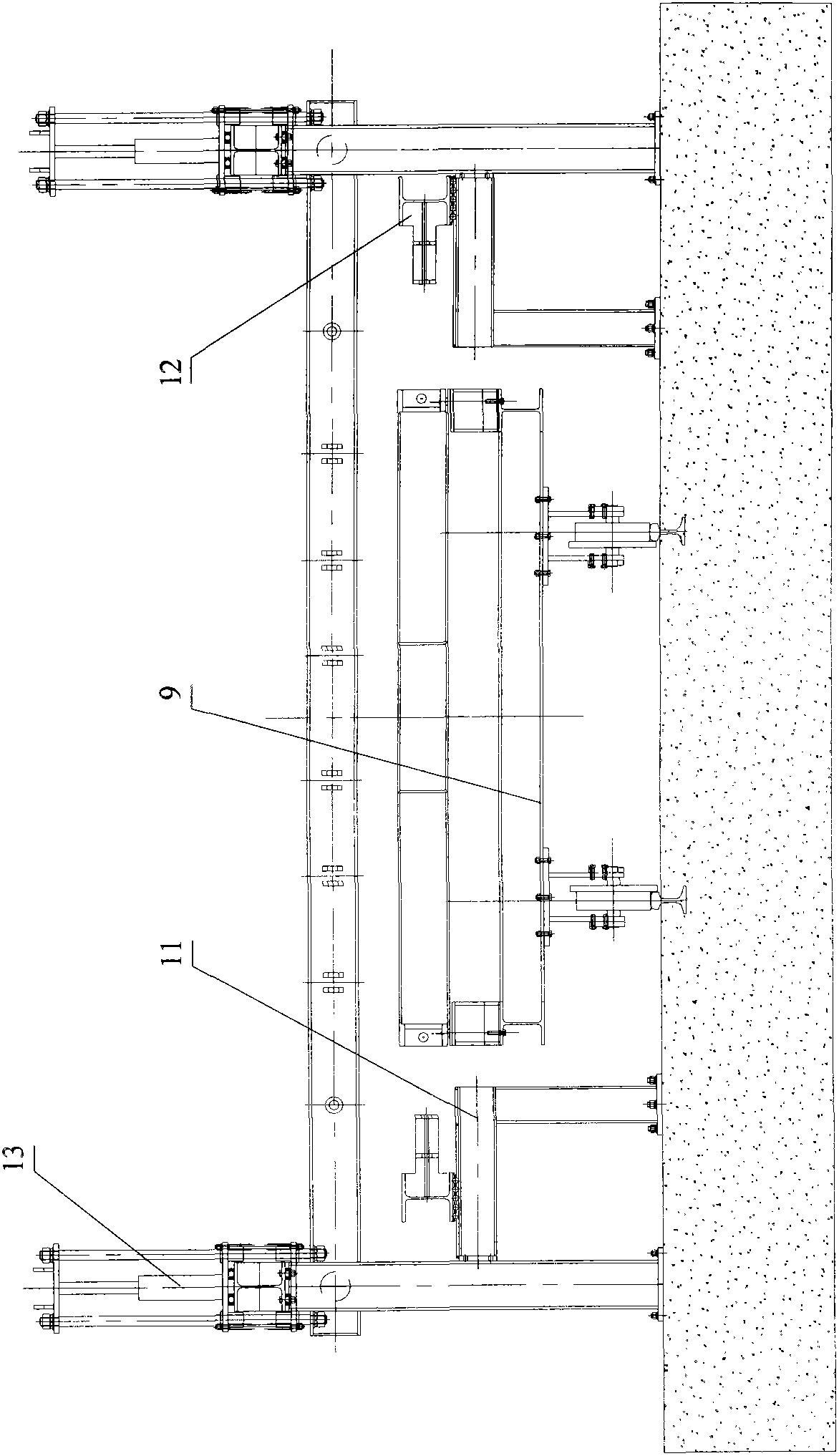

Powder metallurgy friction body and manufacturing method thereof, powder metallurgy brake pad

ActiveCN111570801AImprove matrix strengthExtend your lifeFriction liningActuatorsMolybdenum trioxideFlake graphite

The invention discloses a powder metallurgy friction body and a manufacturing method thereof, and a powder metallurgy brake pad. The powder metallurgy brake pad has relatively strong wear-resisting performance, can solve the phenomena of dreg falling, chip falling and entire friction material fall-off of an existing friction body in the process of vehicle braking, and thereby improves the servicelife of the friction body. The powder metallurgy friction body comprises a friction material layer which is composed of a substrate element, a lubricating element and a friction element, and a skeleton bonding material layer which is used for bonding the friction material layer and a friction body skeleton; the substrate element comprises bronze powder, reduced iron powder, manganese-iron alloy powder and nano molybdenum trioxide; the lubricating element comprises zinc sulfide and crystalline flake graphite; the friction element comprises titanium dioxide, zirconium oxide, feldspar and zirconsand; and the skeleton bonding material layer comprises bronze powder, reduced iron powder, manganese powder, molybdenum powder and tin powder. The powder metallurgy friction body can manufacture thepowder metallurgy brake pad and the powder metallurgy brake pad is applied to the aspect of urban railway transportation.

Owner:北京浦然轨道交通科技股份有限公司 +1

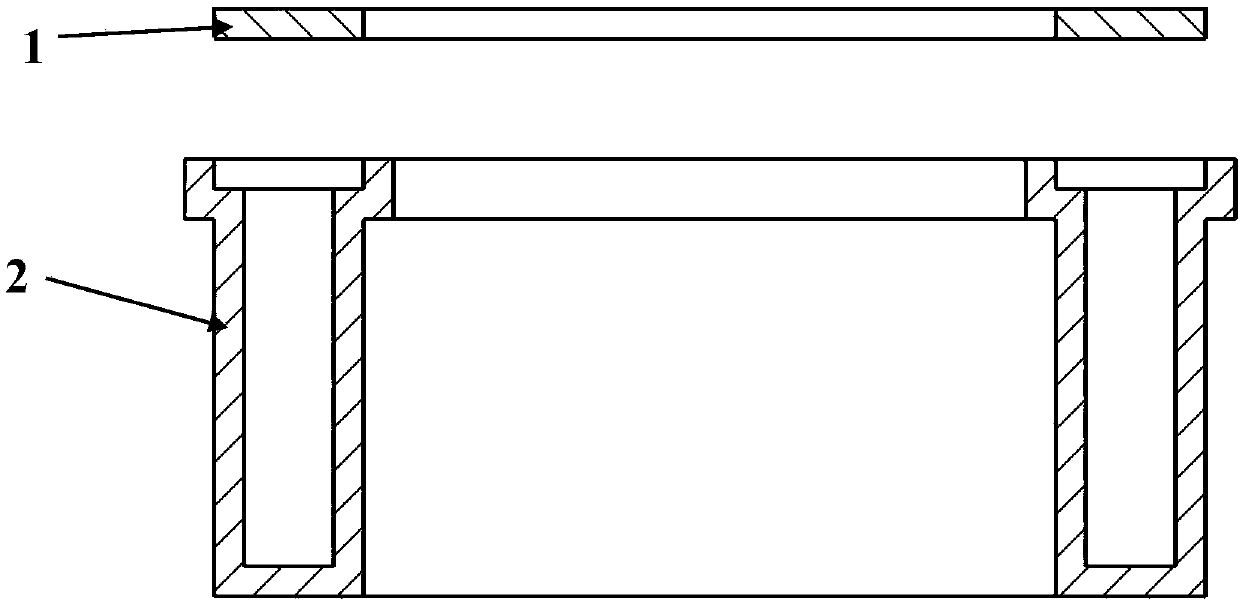

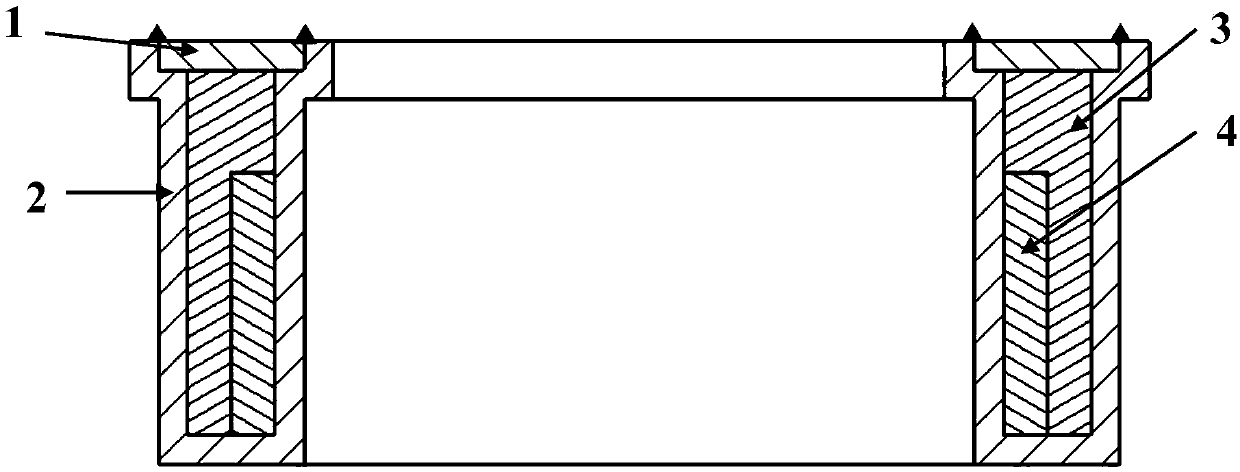

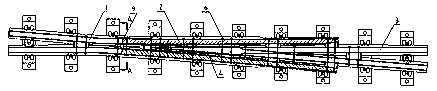

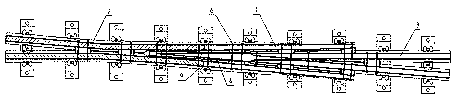

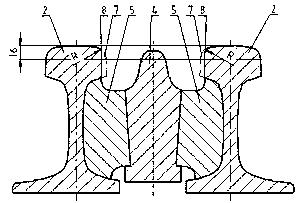

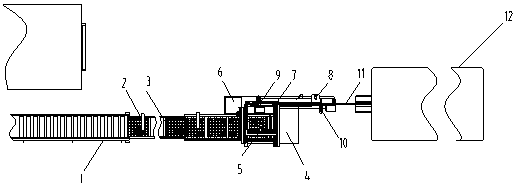

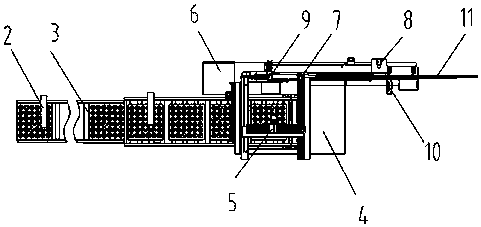

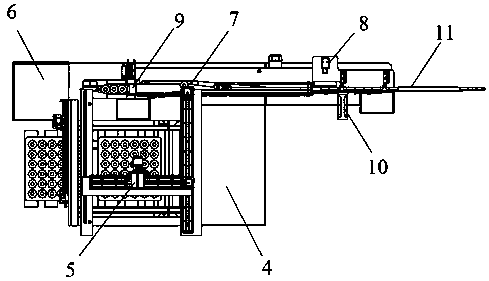

Demolding method and device for end plate of side plate of bilateral pre-tensioned pre-stressed concrete track plate

InactiveCN103213194AHighlight substantiveSignificant progressDischarging arrangementControl systemPre stress

The invention discloses a demolding device for an end plate of a side plate of a bilateral pre-tensioned pre-stressed concrete track plate. The demolding device comprises a side plate demolding device and an end plate demolding device which are used separately or together, and a control system, wherein the side plate demolding device and the end plate demolding device are provided with driving mechanisms which are connected with the control system respectively; and the side plate demolding device and the end plate demolding device work simultaneously or in sequence under the control of the control system, so that the side plate and / or the end plate is separated from the track plate at one time. The invention further relates to a demolding method for the end plate of the side plate of the bilateral pre-tensioned pre-stressed concrete track plate using the demolding device. Preferably, the side plate demolding device and the end plate demolding device are arranged integrally into an integral side plate and end plate demolding device, so that the side plate and the end plate can be separated conveniently and efficiently in sequence or simultaneously. According to the demolding method and the demolding device, the side plate and / or the end plate can be separated conveniently and reliably at one time, so that the appearance of a product is ensured, and the production efficiency is increased.

Owner:欧阳炎

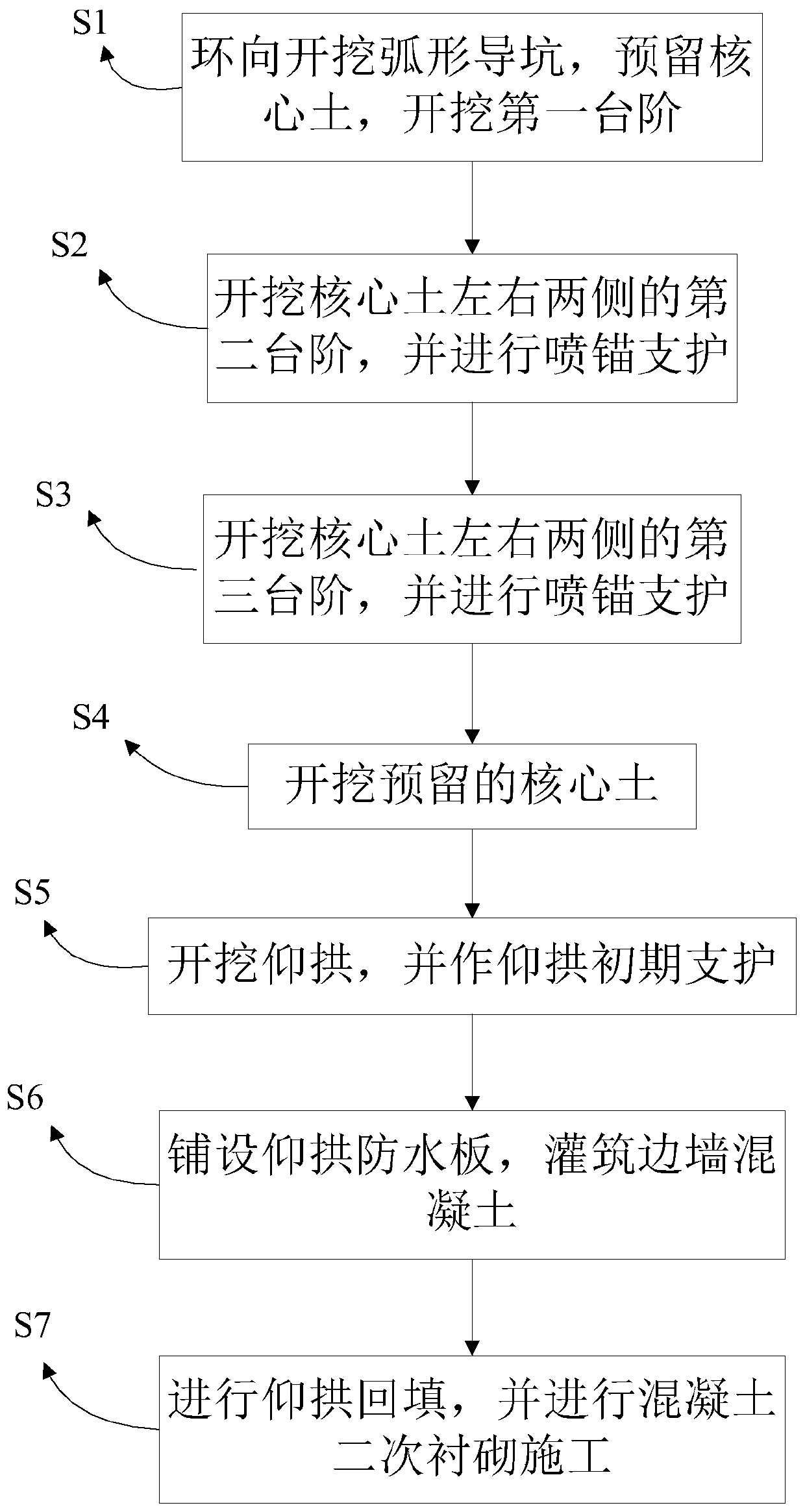

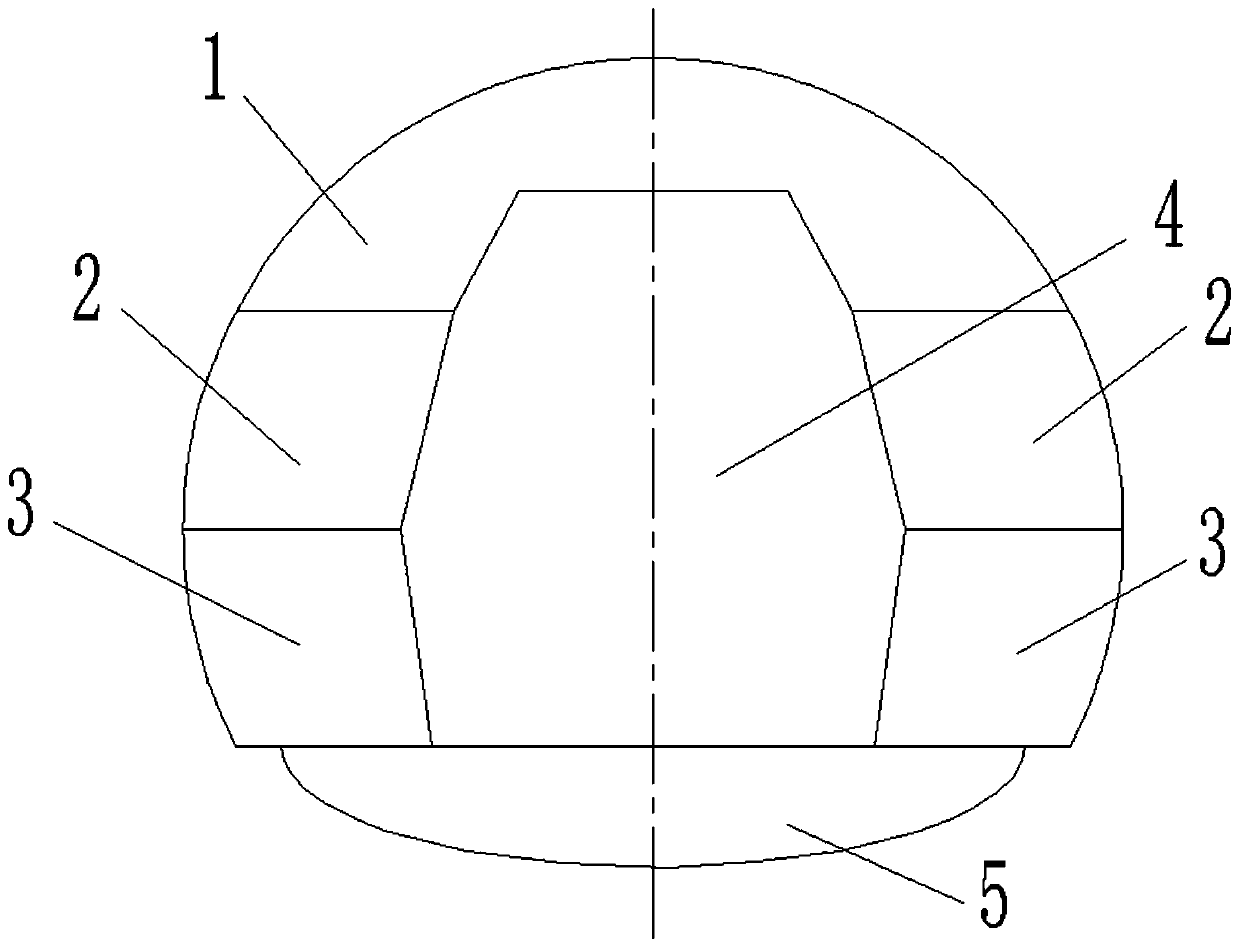

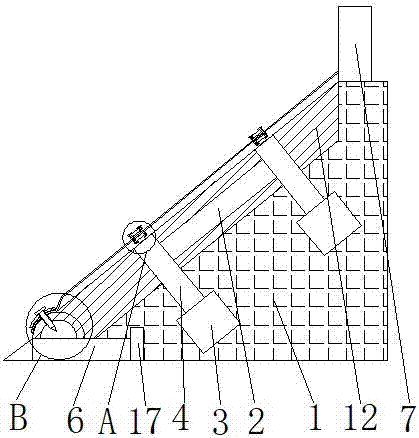

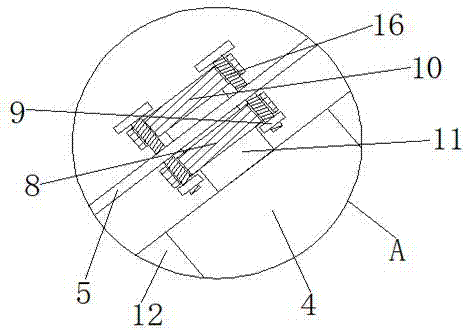

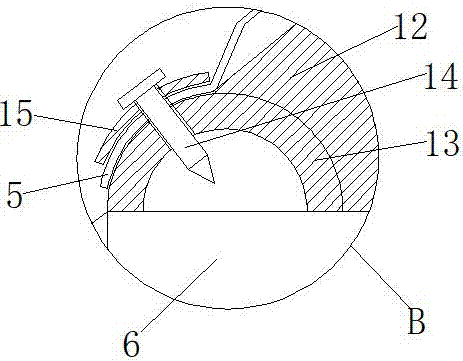

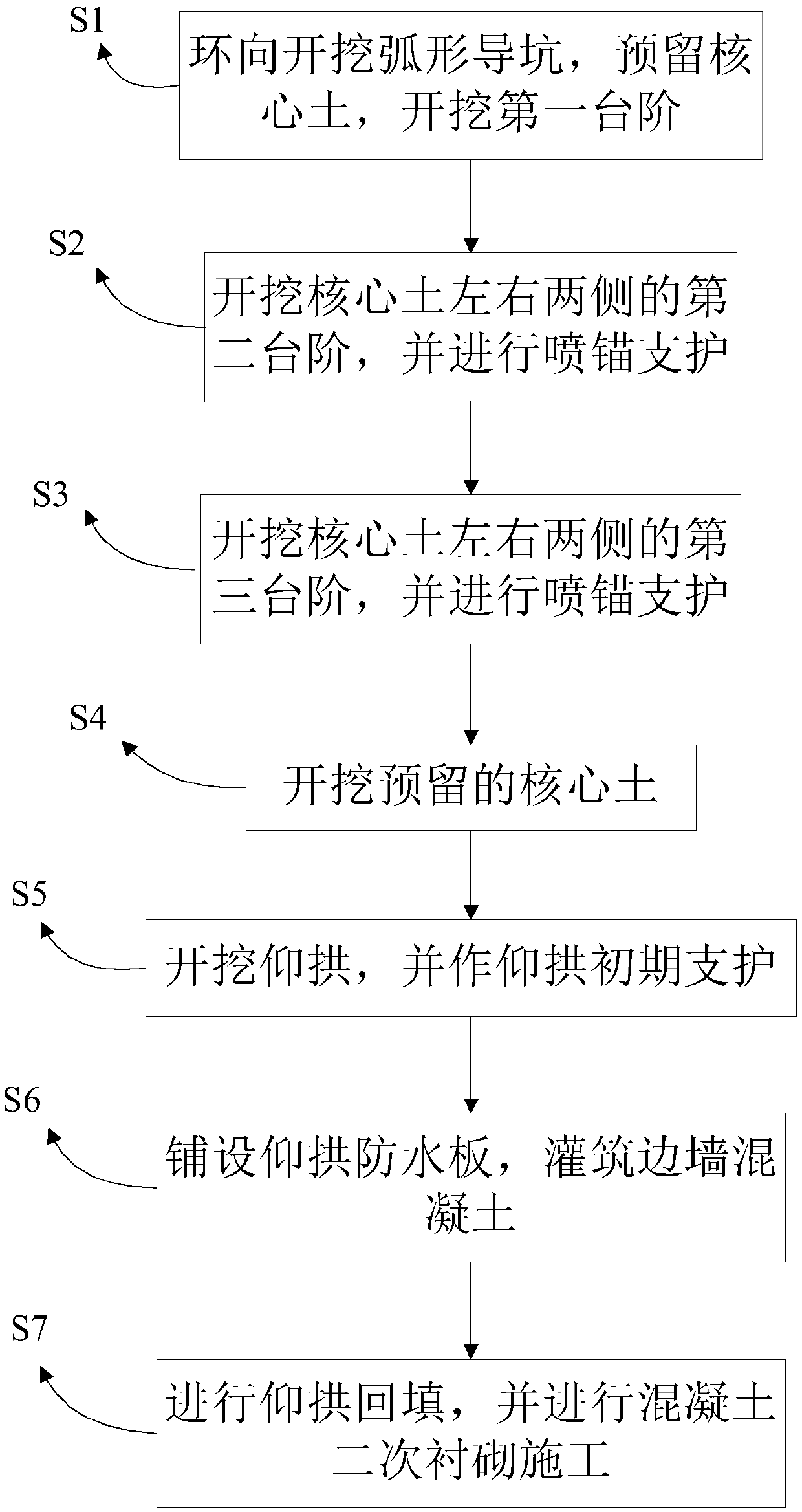

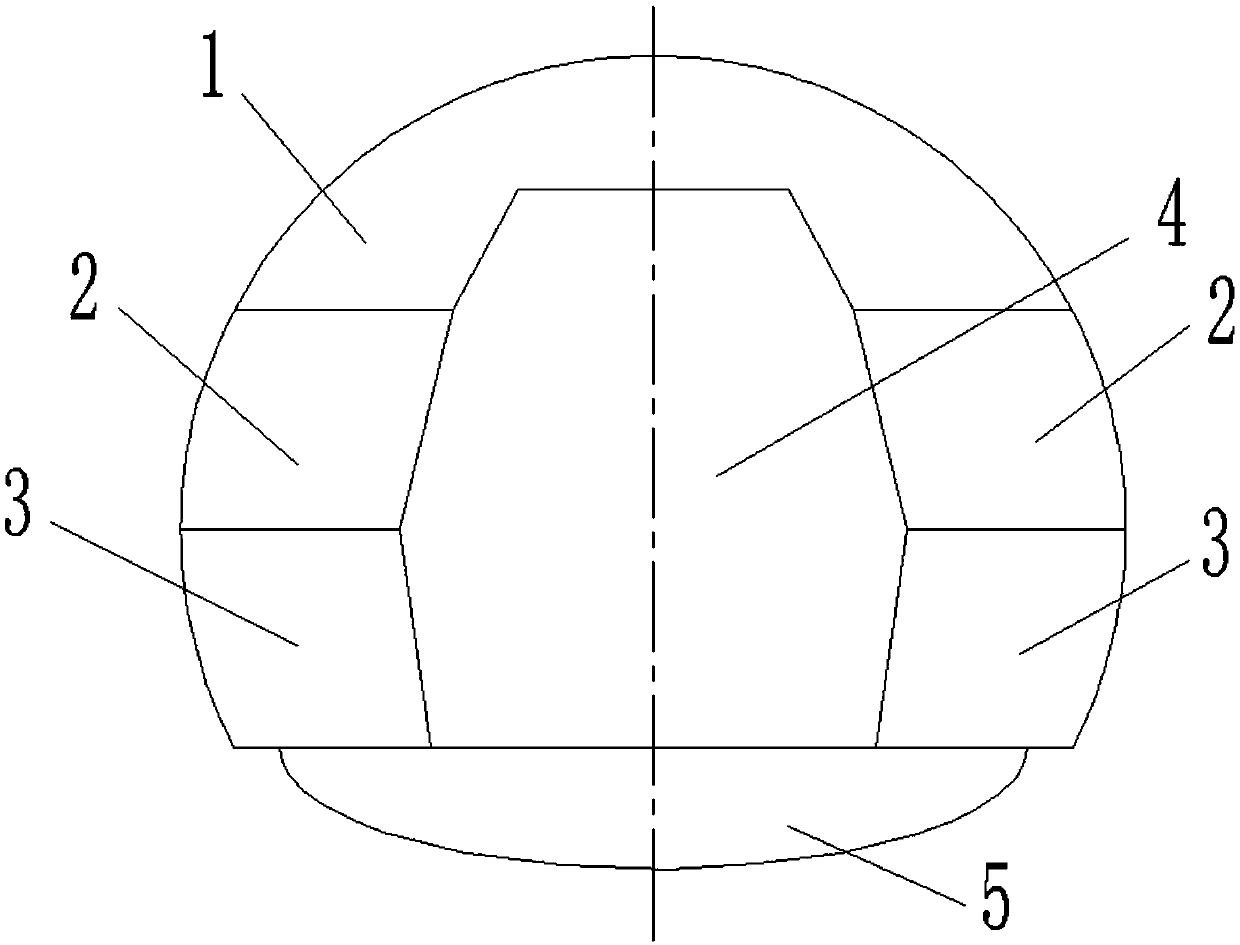

Construction Method of Reversed Slope Tunnel

ActiveCN108678753BAvoid falling blocksPrevent roof fallUnderground chambersDrainageShotcreteWater level

The invention discloses a construction method of a reverse slope tunnel, which comprises the following steps: an arc-shaped heading is excavated in a circular shape, a core soil is reserved, and a first step is excavated; two second steps and two third steps reserved on the left and right sides of the core soil are respectively excavated, and the shotcrete and anchor support is carried out; the reserved core soil is excavated; an inverted arch is excavated and the initial support of the inverted arch is made; a waterproofing plate of the inverted arch is laid, and the side wall concrete is poured; after the pouring of the inverted arch concrete is completed, the inverted arch shall be backfilled in time, and the construction of secondary lining of the concrete shall be carried out. According to the invention, the construction of the reverse slope tunnel under the water level line of the adjacent reservoir is carried out, and the reverse slope is being made positive, so that the water seepage and the water inflow of the first step and the second step tunnel face can be timely discharged to the temporary water collecting pit of a third step to prevent the tunnel surrounding rock fromfalling out of the block, roof falling, landsliding or water inflowing. The integrity of the tunnel surrounding rock can be ensured, and the adverse effect on the reservoir and the surrounding environment can be reduced.

Owner:CHINA COMM NORTH ROAD & BRIDGE

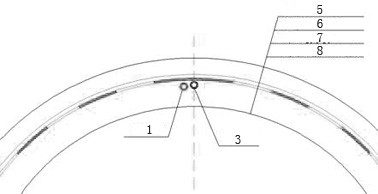

Method and device for treating tunnel secondary lining vault cavity and local loose part

PendingCN113279785AFix bugsImprove integrityUnderground chambersTunnel liningStructural engineeringSlurry

The invention belongs to a method and a device for treating a tunnel secondary lining vault cavity and a local loose part, and the device is characterized in that three slurry outlet holes with the diameter of 4mm are drilled in the positions of 90 degrees, 180 degrees and 270 degrees every 20cm on the pipe wall of a longitudinal grouting pipe, and the outer side of each slurry outlet hole is sealed by a PE (Polyethylene) film. Two exhaust holes with the diameter of 4 mm are drilled in the pipe wall of the longitudinal exhaust pipe at the 45-degree position and the 315-degree position every 20 cm, the outer side of each exhaust hole is sealed through a PE film, and the length of the longitudinal grouting pipe and the length of the longitudinal exhaust pipe are larger than that of a tunnel second lining pouring construction section. The longitudinal grouting pipes in the vertical pipes are communicated. According to the method, when the secondary lining concrete is finally set, the secondary lining concrete poured by the secondary lining is subjected to hole filling treatment grouting through the longitudinal grouting pipe, so that the integrity of the secondary lining concrete and grouting treatment slurry is improved, various concrete defects are repaired, a waterproof plate of a vault can be effectively prevented from being perforated and falling off, and the construction quality is guaranteed.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

Side slope reinforcing device

The present invention relates to the technical field of slopes, in particular to a reinforcement device for slopes, which includes a slope, a plurality of connecting rods are evenly inserted on the surface of the slope, and the end of the connecting rods away from the first fixing block is provided with a A fixed rod, the upper end of the fixed rod is provided with a second fixed block, the upper end of the second fixed block is symmetrically threaded with two bolts, and the outer wall of the second fixed block is sleeved with a splint matching the bolts, Nuts are arranged on the outer wall of the bolt, a metal mesh is arranged between the splint and the second fixed block, a concrete layer is arranged on the surface of the slope, a long rod is arranged on the front bottom of the slope, and the The side wall of the long rod is provided with an arc-shaped plate, and the upper end of the arc-shaped plate is screwed with a threaded nail. The invention can avoid the occurrence of falling off of the metal mesh, improve the slope surface protection ability of the slope, avoid the phenomenon of falling blocks and rocks, and reduce the risk.

Owner:成都知睿科技有限公司

Reverse slope tunnel construction method

ActiveCN108678753AAvoid falling blocksPrevent roof fallUnderground chambersDrainageShotcreteWater level

The invention discloses a construction method of a reverse slope tunnel, which comprises the following steps: an arc-shaped heading is excavated in a circular shape, a core soil is reserved, and a first step is excavated; two second steps and two third steps reserved on the left and right sides of the core soil are respectively excavated, and the shotcrete and anchor support is carried out; the reserved core soil is excavated; an inverted arch is excavated and the initial support of the inverted arch is made; a waterproofing plate of the inverted arch is laid, and the side wall concrete is poured; after the pouring of the inverted arch concrete is completed, the inverted arch shall be backfilled in time, and the construction of secondary lining of the concrete shall be carried out. According to the invention, the construction of the reverse slope tunnel under the water level line of the adjacent reservoir is carried out, and the reverse slope is being made positive, so that the water seepage and the water inflow of the first step and the second step tunnel face can be timely discharged to the temporary water collecting pit of a third step to prevent the tunnel surrounding rock fromfalling out of the block, roof falling, landsliding or water inflowing. The integrity of the tunnel surrounding rock can be ensured, and the adverse effect on the reservoir and the surrounding environment can be reduced.

Owner:CHINA COMM NORTH ROAD & BRIDGE

Method for connecting Fe-based high-temperature alloy ring with internal characteristics and Cu-Ag alloy

The invention provides a method for connecting a Fe-based high-temperature alloy ring with internal characteristics and a Cu-Ag alloy. The method comprises the following steps: preparing a high-temperature alloy and Cu-Ag alloy ring, preparing a capsule, carrying out assembly, carrying out vacuum treatment and sealing, controlling a hot isostatic diffusion bonding process, carrying out aftertreatment and the like. According to the method for connecting the Fe-based high-temperature alloy ring with internal characteristics and the Cu-Ag alloy, provided by the invention, by adopting a hot isostatic diffusion bonding technology, diffusion bonding is carried out on the Cu-Ag alloy and the high-temperature alloy ring with the internal characteristics in a high-temperature and high-pressure environment, and a target ring is formed. The method not only can well realize the bonding of characteristic high-temperature alloy and Cu-Ag alloy, but also can meet the bonding of characterless high-temperature alloy and Cu-Ag alloy and avoid bonded layer peeling, chipping, layering and separation from a base body. The porosity of a bonded layer is low.

Owner:BEIHANG UNIV

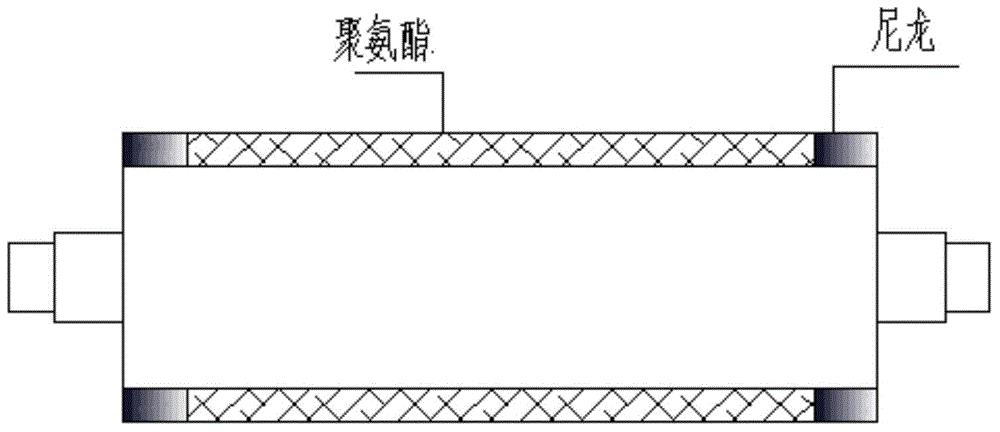

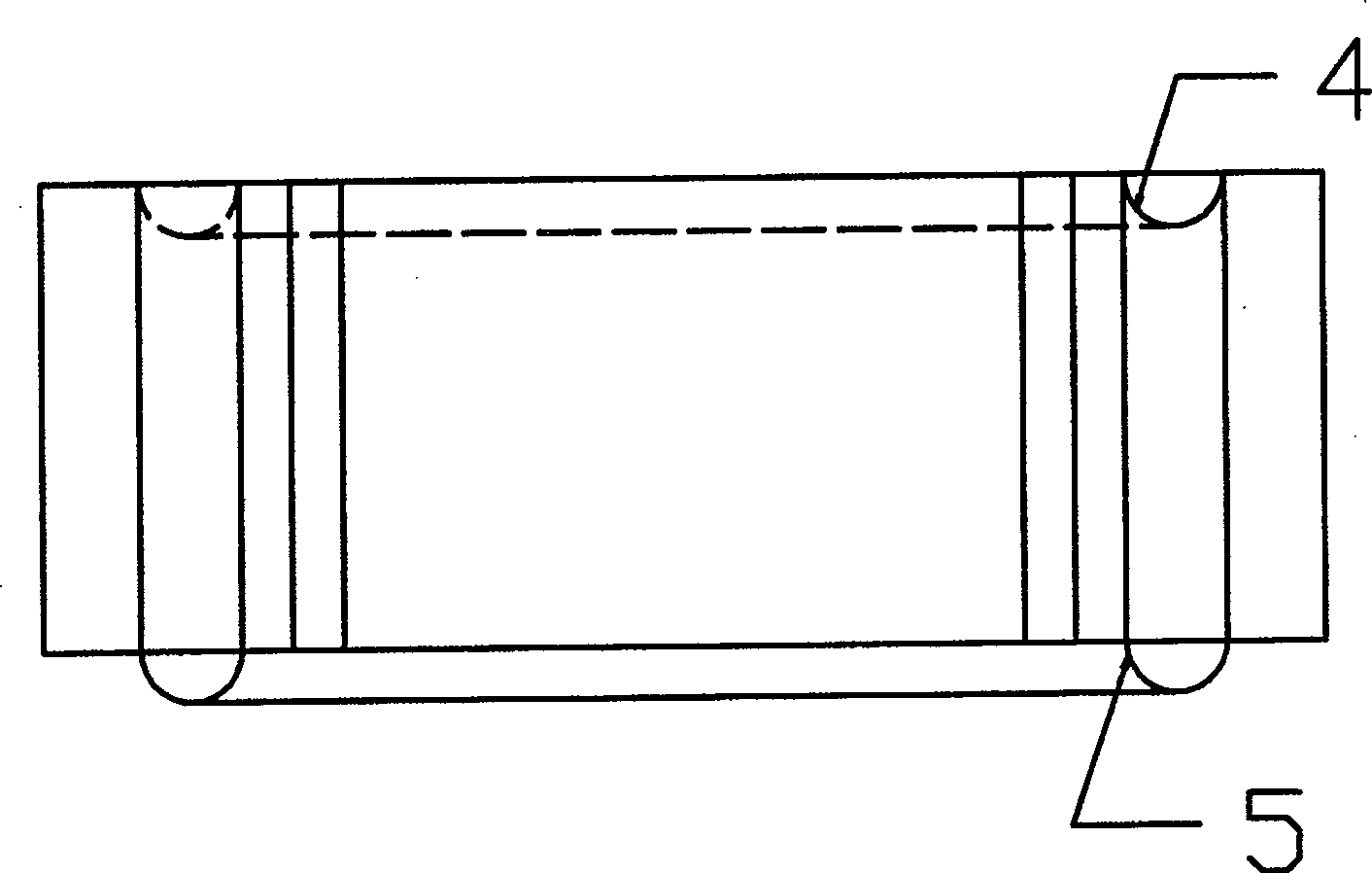

Rubber roller

InactiveCN106142869AExtended service lifeIncrease profitOther printing apparatusButt jointEngineering

The invention provides a rubber roller. The rubber roller comprises a roller core. The surface of the roller core is covered with a polyurethane rubber layer. The parts, located on the two sides of the polyurethane rubber layer, of the surface of the roller core are further covered with high-temperature resisting materials. The high-temperature resisting materials are in seamless butt joint with the polyurethane rubber layer. The width of the polyurethane rubber layer is determined according to the work face width needed during using. The high-temperature resisting materials are nylon materials. The rubber layer wrapping the surface of the rubber roller is divided into a working area in the middle part and non-working areas at the two ends. Different high-temperature resisting materials are adopted in the working area and the non-working areas, and therefore the problems that non-working areas on the two sides of the rubber roller are faster than the working area in aging, products are prone to being polluted, and the updating period is short can be solved.

Owner:南京企航橡塑有限公司

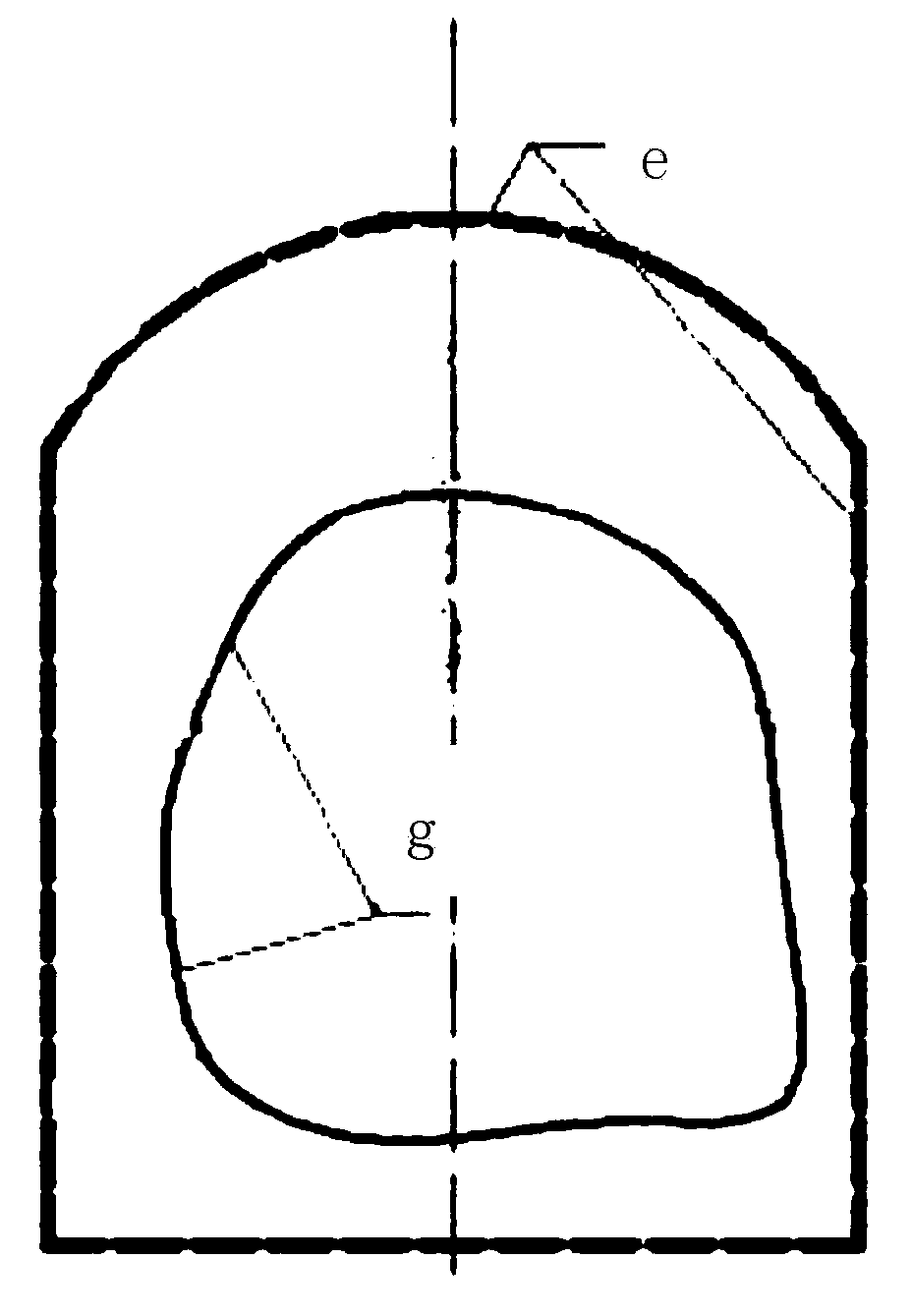

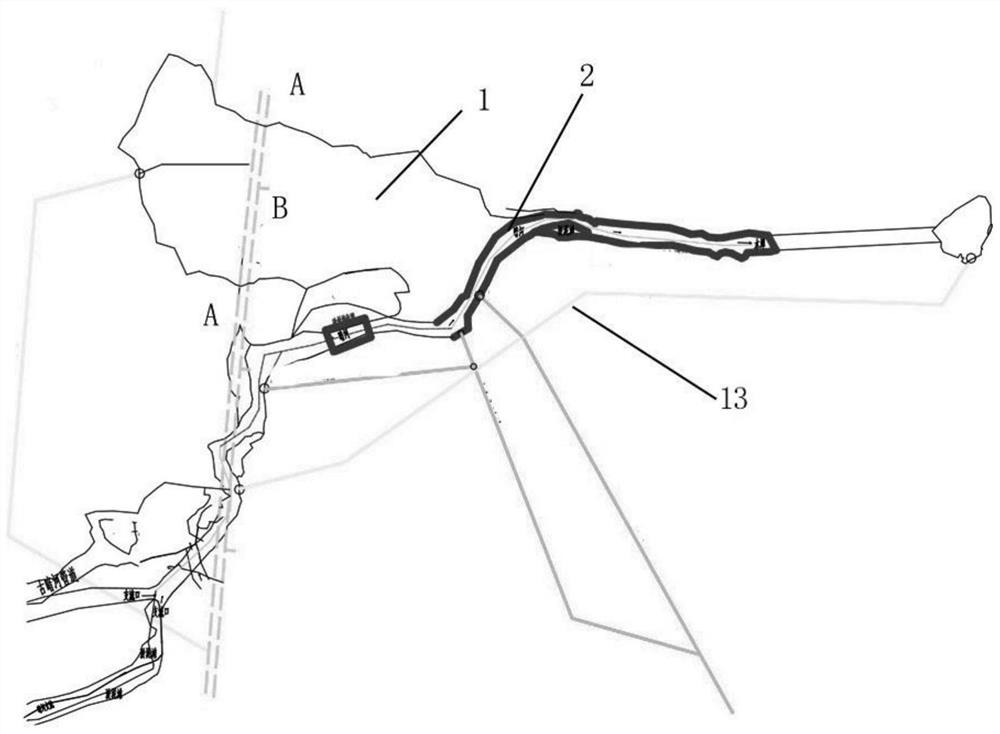

Segmented blasting hole excavation construction method for reconstruction and expansion of tunnel through karst landform water conservancy extra-small section

ActiveCN111472791ASave materialConvenient construction workBlastingTunnelsArchitectural engineeringEconomic benefits

The invention discloses a segmented blasting hole excavation construction method for reconstruction and expansion of a tunnel through a karst landform water conservancy extra-small section. The segmented blasting hole excavation construction method is used for reconstruction and expansion of an original tunnel. The original tunnel is the extra-small section, and the excavation section is designedto be in a city door hole type. The segmented blasting hole excavation construction method comprises the following steps that S1, on-site reconnaissance and investigation are conducted on surroundingrock of the original tunnel, the existing state of the surrounding rock is actually mastered, and the category classification of the surrounding rock is confirmed to be IV or V; S2, advanced reinforcement is conducted on the existing state of the existing surrounding rock found through investigation in the step S1; and S3, classified blasting and segmented blasting of the same tunnel face are conducted on excavated different surrounding rock tunnel faces. A segmented blasting method in the step S3 comprises the steps that firstly, the top part of the original tunnel is excavated through blasting, and then a side wall and an inverted arch are excavated through blasting; or the position of the side wall is blasted firstly, and then the position of an arch crown is detonated. The segmented blasting hole excavation construction method has the characteristics of being safe, reliable, easy to construct and operate, remarkable in economic benefit and the like, can be widely applied to the field of water conservancy, mine and underground engineering widening construction, and is wide in application and popularization prospect.

Owner:中铁贵州工程有限公司

Method for connecting nickel-based high-temperature alloy annular piece with copper-silver alloy through partial diffusion bonding

InactiveCN109676234AAchieve connectionPrevent peelingWelding/soldering/cutting articlesNon-electric welding apparatusPorosityAfter treatment

The invention provides a method for connecting a nickel-based high-temperature alloy annular piece with copper-silver alloy through partial diffusion bonding. The method comprises the steps of nickel-based high-temperature alloy and copper-silver alloy preparation, package sheath preparation, assembling, hot isostatic pressure pretreatment, hot isostatic pressure process control, after-treatment and the like. The method for connecting the nickel-based high-temperature alloy annular piece with the copper-silver alloy through partial diffusion bonding adopts the hot isostatic pressure diffusionbonding technology, the copper-silver alloy is subjected to partial diffusion bonding with the nickel-based high-temperature alloy annular piece under the high-temperature high-pressure environment, and a partial connection annular piece of the nickel-based high-temperature alloy is formed. The method well achieves connecting of the nickel-based high-temperature alloy and the copper-silver alloy,connection layer disengagement, chip off-falling, and layering are avoided, the situation that the connection layer is separated from the substrate is avoided, the porosity of the connection layer isreduced, and good metallurgical bonding is achieved.

Owner:BEIHANG UNIV

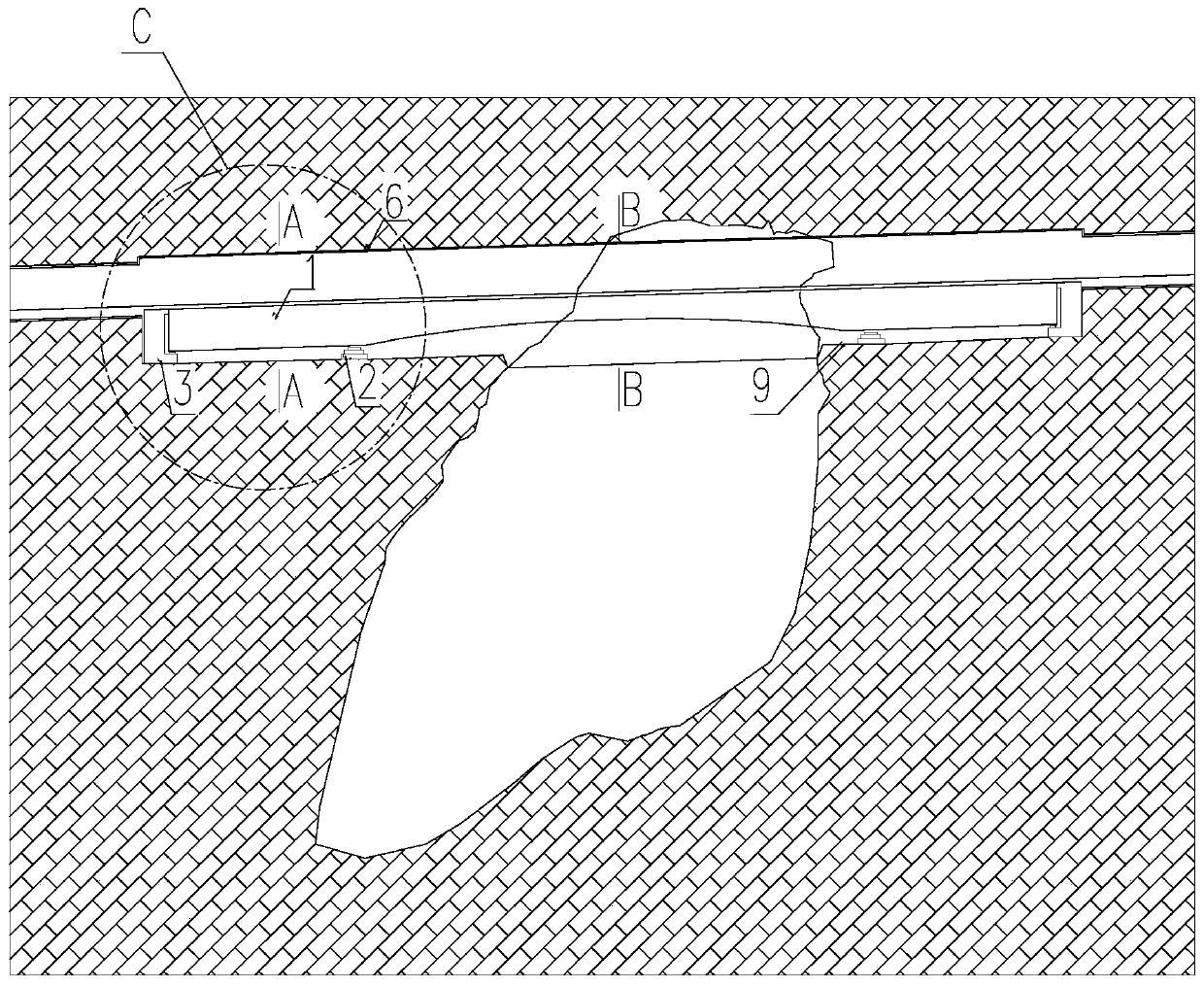

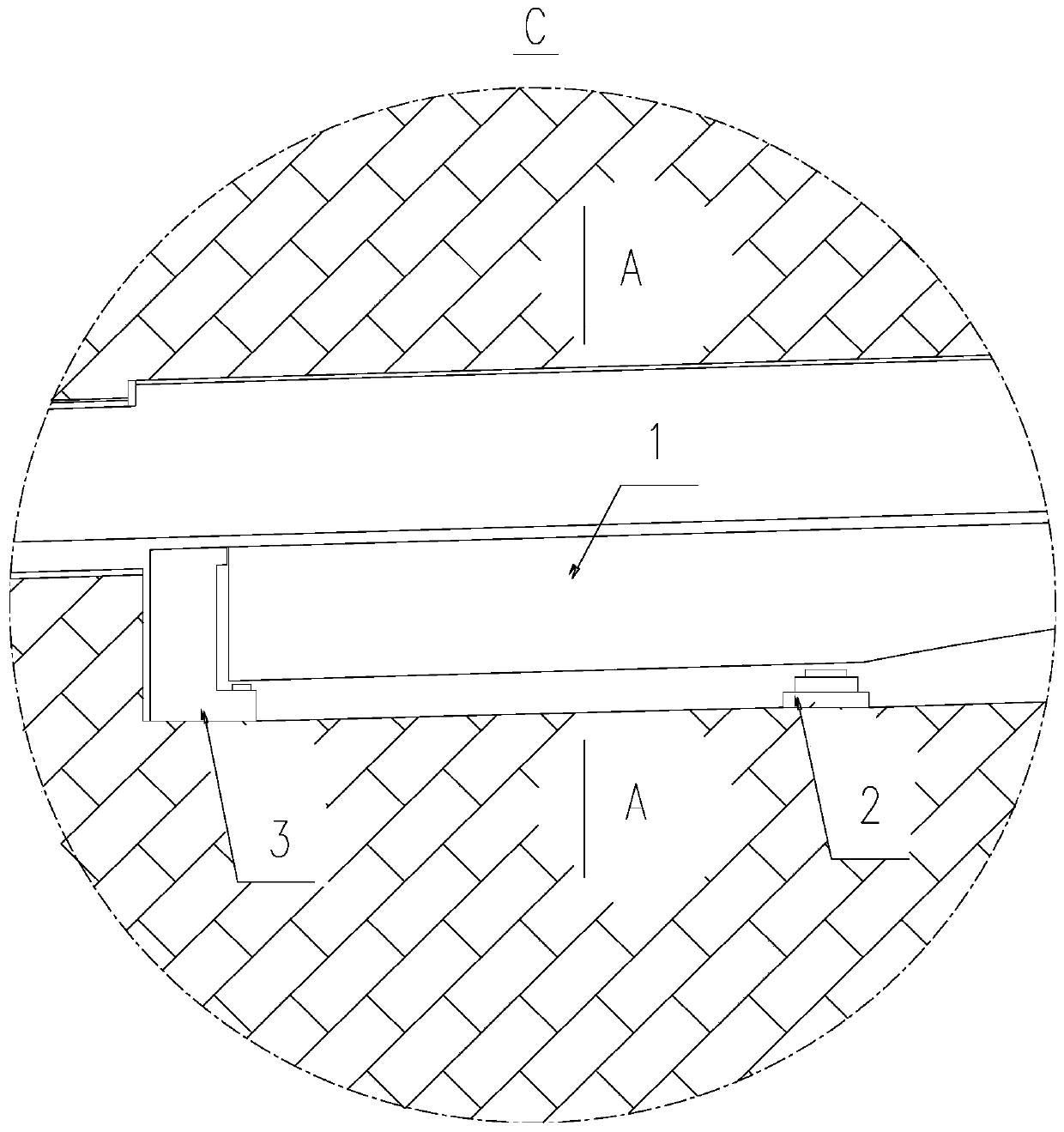

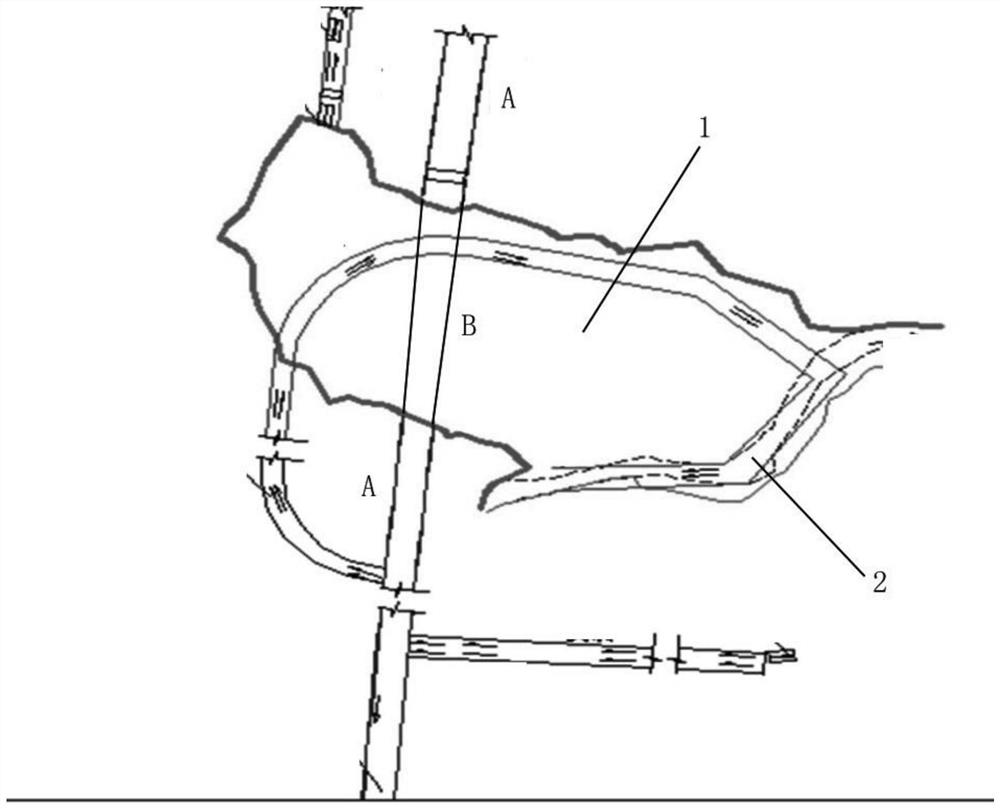

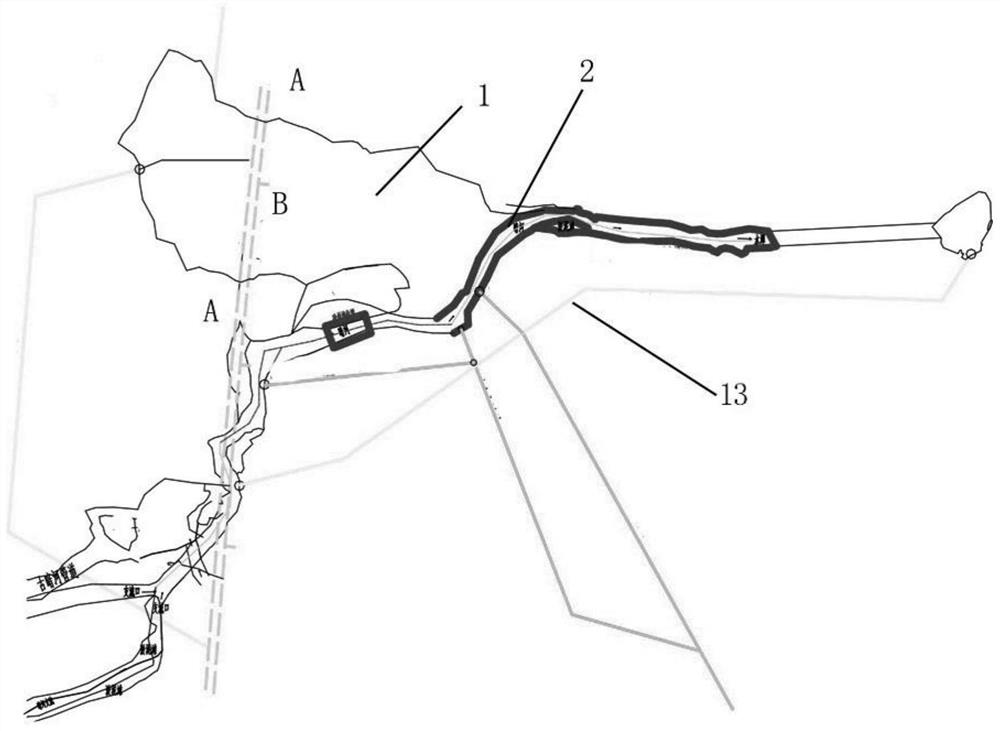

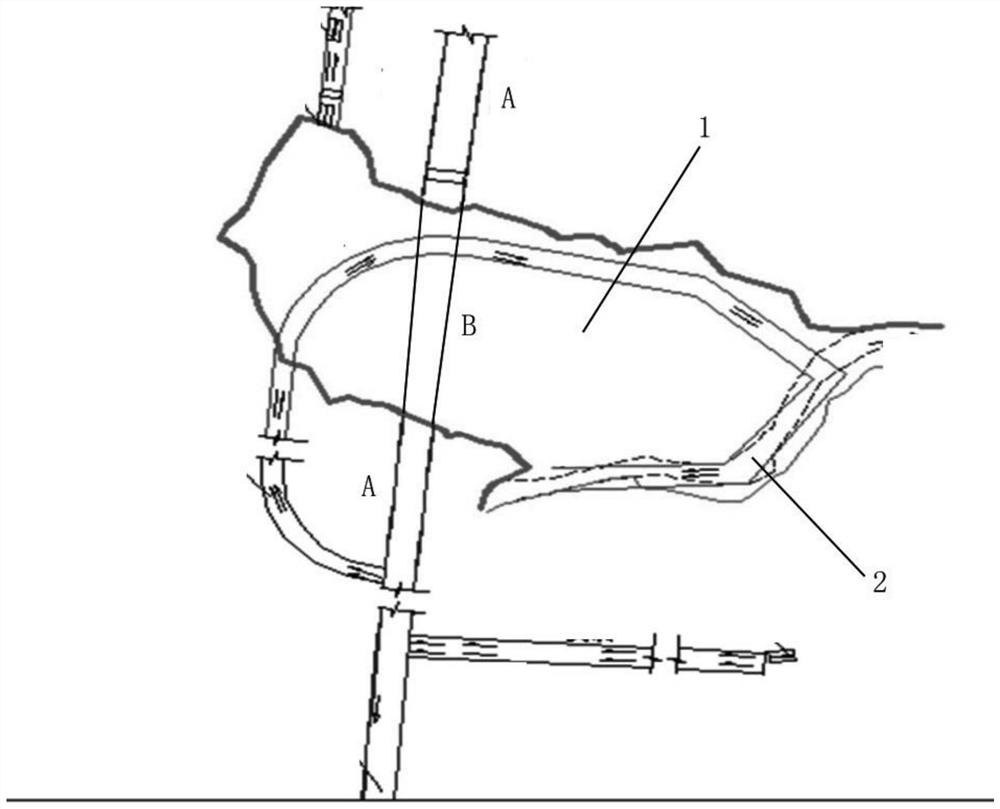

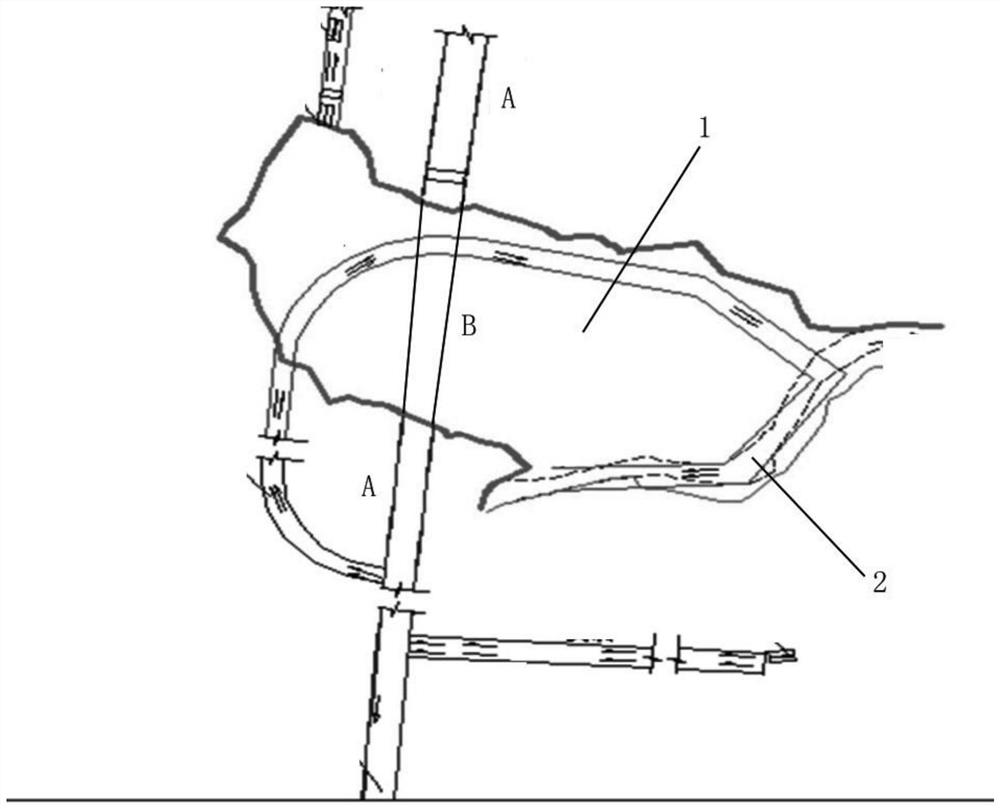

Continuous beam bell mouth friction loss testing method based on karst cave and underground river environment

PendingCN112065439AGuarantee the construction qualityAvoid falling blocksUnderground chambersTunnel liningContinuous beamKarst

The invention provides a continuous beam bell mouth friction loss testing method based on a karst cave and underground river environment. The method comprises the following steps that S1, a tunnel section A is excavated to penetrate through a karst cave; S2, an underground river is diverted; S3, the karst cave is backfilled to a tunnel foundation surface; S4, the cave wall is protected, and a plurality of anchor cables are constructed; S5, the karst cave is filled, and the anchor cables are connected with a backfill body; S6, the backfill body is excavated to form a tunnel section B; S7, abutments are constructed on the tunnel section A; S8, a first section, a second section, a third section and a closure section are divided; S9, a supporting foundation of the tunnel section A is constructed; and S10, continuous beams are continuously constructed from the first section to the closure section according to the section sequence. The method has the advantages of being stable, reliable, high in safety and capable of preventing sedimentation.

Owner:CHINA RAILWAY NO 5 ENG GRP +2

Sequential supporting structure system of soil vertical shaft and construction method

PendingCN112943258AReduce construction proceduresImprove ergonomicsShaft liningRebarStructural system

The invention discloses a sequential supporting structure system of a soil vertical shaft and a construction method. The sequential supporting structure system of the soil vertical shaft and the construction method are reliable in technical scheme, simple in construction, low in investment and capable of effectively realizing safe and efficient excavation of a large-section soil vertical shaft. The structure system comprises a vertical shaft wall, a forepoling structure, a construction period supporting structure and a reinforced concrete shaft wall structure; the forepoling structure comprises a plurality of grouting steel pipe piles arranged around the outer side of the vertical shaft wall; the construction period supporting structure comprises a reinforcing mesh, profile steel walling cribs, supporting anchor rods and a concrete spraying layer, the reinforcing mesh is laid on the inner wall face of the vertical shaft wall, the plurality of profile steel walling cribs are evenly arranged on the inner side of the vertical shaft wall in the longitudinal direction, and the supporting anchor rods are evenly arranged in the longitudinal direction and the circumferential direction of the vertical shaft wall; the inner wall face of the vertical shaft wall is provided with the concrete spraying layer which enables the closed reinforcing mesh, the profile steel walling cribs and the supporting anchor rods to form a whole; and the reinforced concrete shaft wall structure is poured on the inner side face of the concrete spraying layer.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

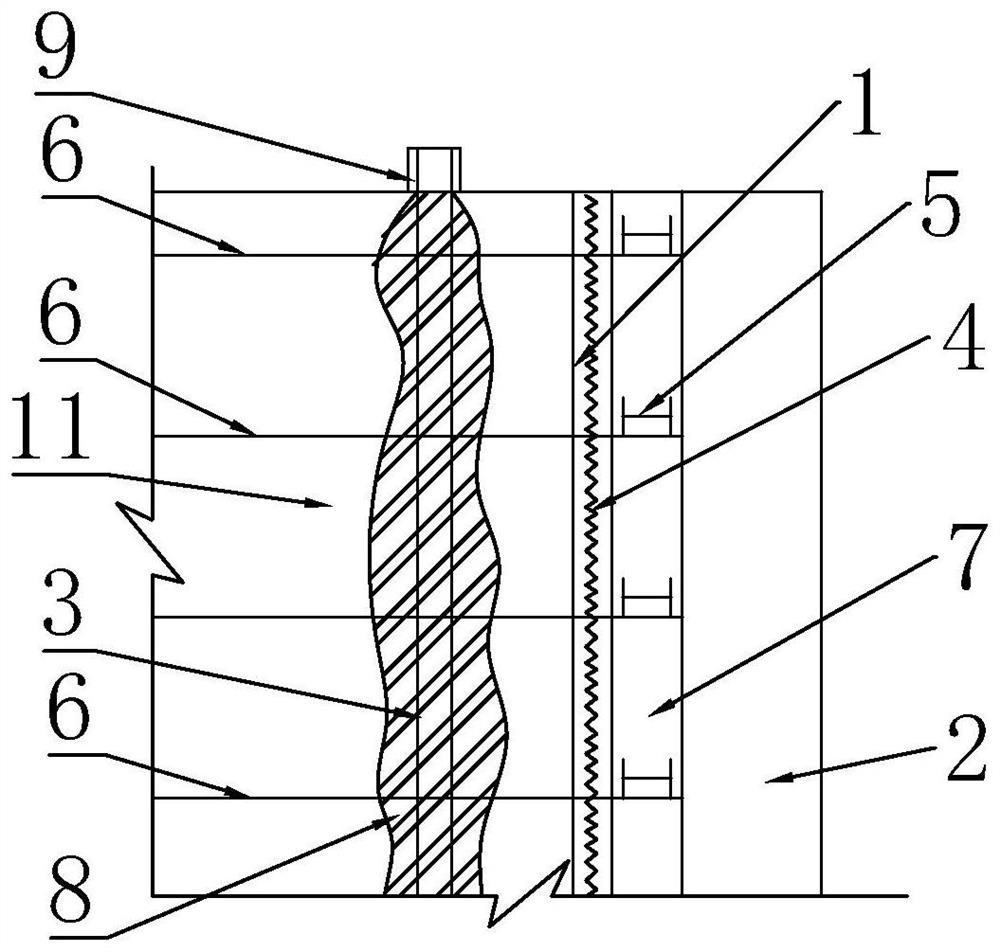

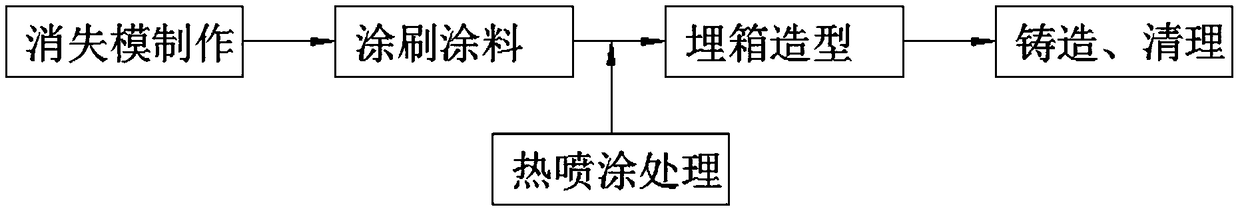

Thermal spraying combined manufacturing process of lost foam cast ductile iron pipe fittings

ActiveCN108907093APrevent sticky sand problemHigh strengthMoulding toolsFoundry mouldsThermal sprayingSurface layer

The invention discloses a thermal spraying combined manufacturing process of lost foam cast ductile iron pipe fittings. The thermal spraying combined manufacturing process comprises the following steps that a, lost foam is manufactured, specifically, foamed plastic is manufactured into real molds corresponding to the ductile iron pipe fittings in part structure and size; b, coating brushing is conducted, specifically, the real molds are assembled, combined and dried, the combined real molds are brushed with high-temperature preventing coating, and then the coating of the real molds is dried; c, thermal spraying treatment is conducted, specifically, the surface layer of the coating is subjected to thermal spraying treatment, the thermal spraying temperature is 50-250 DEG C, and the thickness of a thermal spraying material is no more than 1 mm; d, burying-in-box and modeling are conducted, specifically, the real molds subjected to thermal spraying operation are buried in a sand box and modeled; and e, casting and clearing are conducted, specifically, molten metal is poured into the sand box at the negative pressure, cooling, shot blasting, polishing clearing and a pressure test are conducted, and then finished products are obtained. The strength and flatness of a coating layer are improved through combination of thermal spraying, and the problem that the coating is likely to falloff, brushing is nonuniform, and consequently, the quality of the finished products is affected is well solved.

Owner:SICHUAN CHUANJIAN PIPES

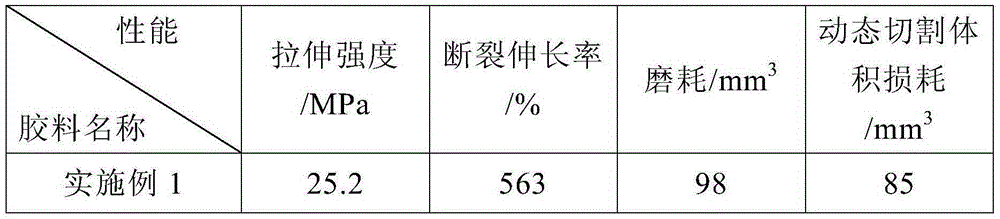

Super-cutting-resistant rubber material for screen plate of vibrating screen and preparation method of super-cutting-resistant rubber material

The invention discloses a super-cutting-resistant rubber material for a screen plate of a vibrating screen and a preparation method of the super-cutting-resistant rubber material. The super-cutting-resistant rubber material comprises the following components in parts by weight: 100 parts of oil-unloaded butadiene styrene rubber, 25-65 parts of reinforcing filler, 0.5-3 parts of sulfur, 0.8-5 parts of a vulcanization accelerator, 3-12 parts of a vulcanization activator, 2-12 parts of a silane coupling agent Si-69, 1-5 parts of cobalt boroacylate, 4-20 parts of a plasticizer and 1-8 parts of an anti-aging agent, wherein the oil-unloaded butadiene styrene rubber contains 22.5-24.5% of styrene. The preparation method comprises the steps of mixing at the first stage; cooling at the first stage; mixing at the second stage; and cooling at the second stage. By using the super-cutting-resistant rubber material, the cutting resistance is greatly improved, and the service life of the screen plate of the vibrating screen is greatly prolonged.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

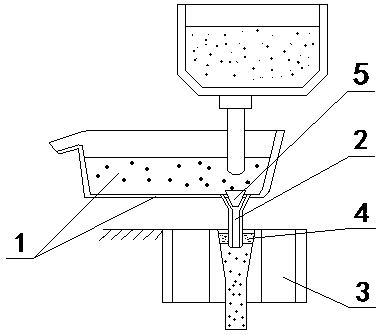

Continuous casting tundish protecting technology

The invention discloses a continuous casting tundish protecting technology and relates to the field of steelmaking technologies. The continuous casting tundish protecting technology comprises the following steps that a, a tundish is baked at a baking position and moved to a pouring position after being baked; b, a protecting sleeve immersed into molten steel in a crystallizer is mounted at a tundish sliding water gap in the lower end of the tundish; c, the molten steel is poured into the tundish through a ladle; and d, the molten steel in the tundish is poured into the crystallizer by the protecting sleeve. The protecting sleeve is replaced on time, when the protecting sleeve is replaced, the liquid level of the molten steel in the crystallizer is lowered through manual operation of a casting speed disc, and after the protecting sleeve is replaced, the liquid level of the molten steel in the crystallizer is heightened through manual operation of the casting speed disc. According to thecontinuous casting tundish protecting technology, the protecting sleeve is replaced in time, so that the phenomena of damage to the protecting sleeve and fracturing or falling blocks of the protecting sleeve due to long-time high-temperature pouring are avoided, the situation that the falling blocks and the like at the protecting sleeve fall into the crystallizer is avoided, and slag inclusion ina continuous cast billet in the continuous casting tundish protecting technological process is avoided.

Owner:XINXING DUCTILE IRON PIPES CO LTD

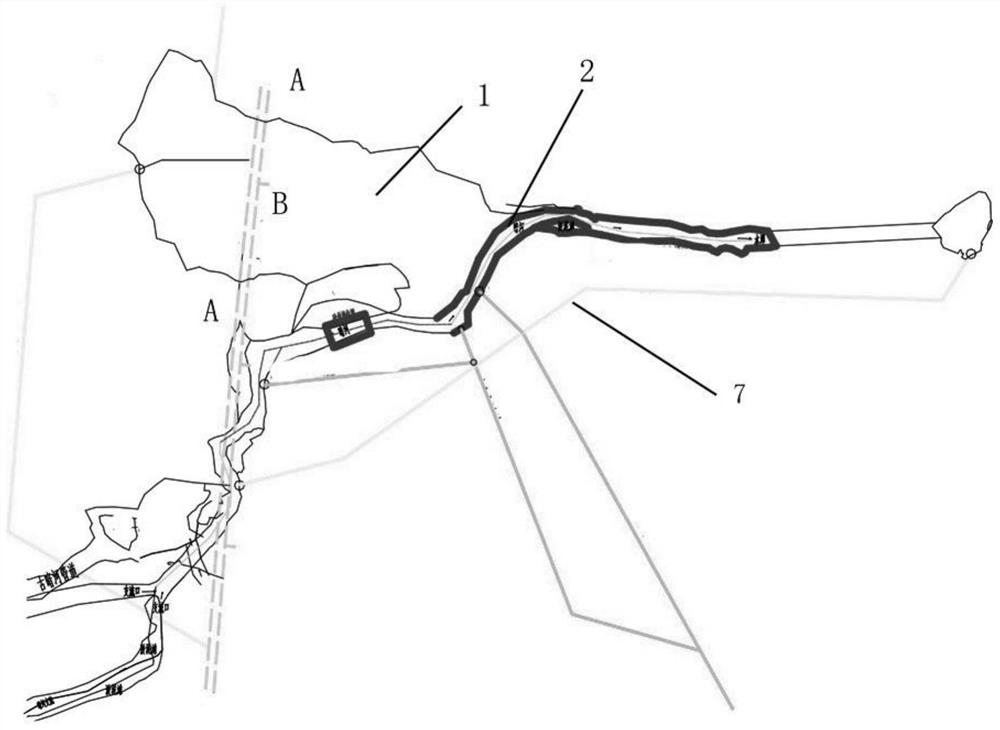

Continuous beam concrete pouring construction method based on karst cave underground river environment tunnel construction

InactiveCN112065441AQuality assuranceEliminate the effects ofUnderground chambersTunnel liningContinuous beamKarst

The invention provides a continuous beam concrete pouring construction method based on karst cave underground river environment tunnel construction. The continuous beam concrete pouring construction method comprises the following steps that S1, a tunnel section A is excavated to penetrate through a karst cave; S2, an underground river is diverted; S3, the karst cave is backfilled to a tunnel foundation surface; S4, the cave wall is protected, and a plurality of anchor cables are constructed; S5, the karst cave is filled, and the anchor cables are connected with a backfilling body; S6, the backfilling body is excavated to form a tunnel section B; S7, an abutment is constructed on the tunnel section A; S8, a first section, a second section, a third section and a closure section are divided;S9, a supporting foundation of the tunnel section A is constructed; and S10, continuous beams are continuously constructed from the first section to the closure section according to the section sequence. The continuous beam concrete pouring construction method has the advantages of being stable, reliable, high in safety and capable of preventing settlement.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

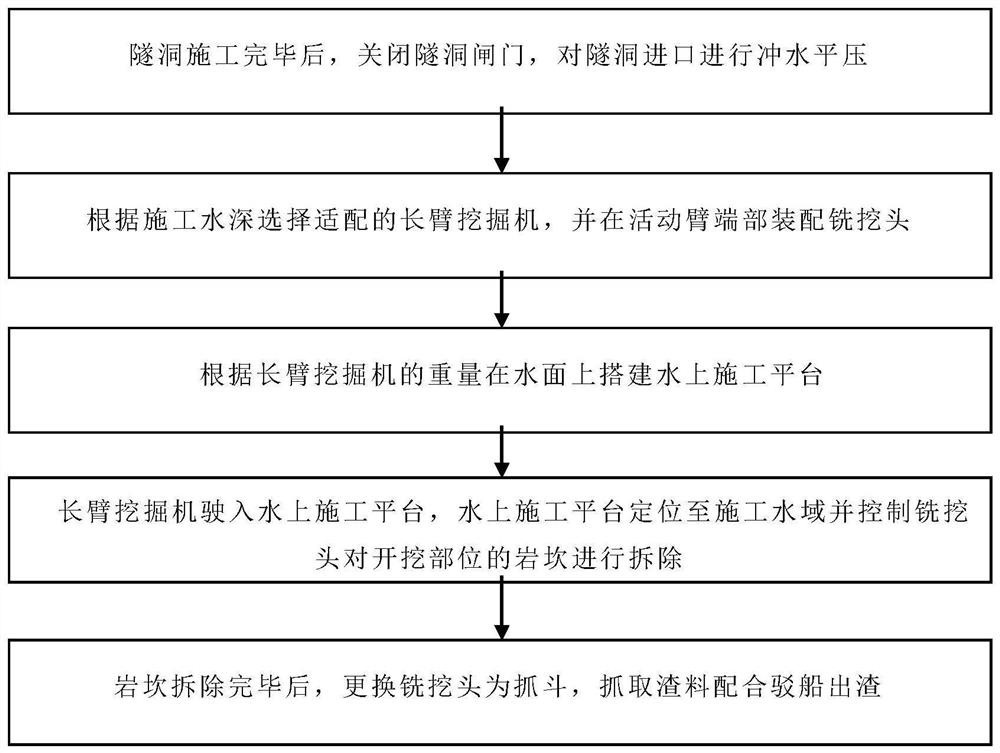

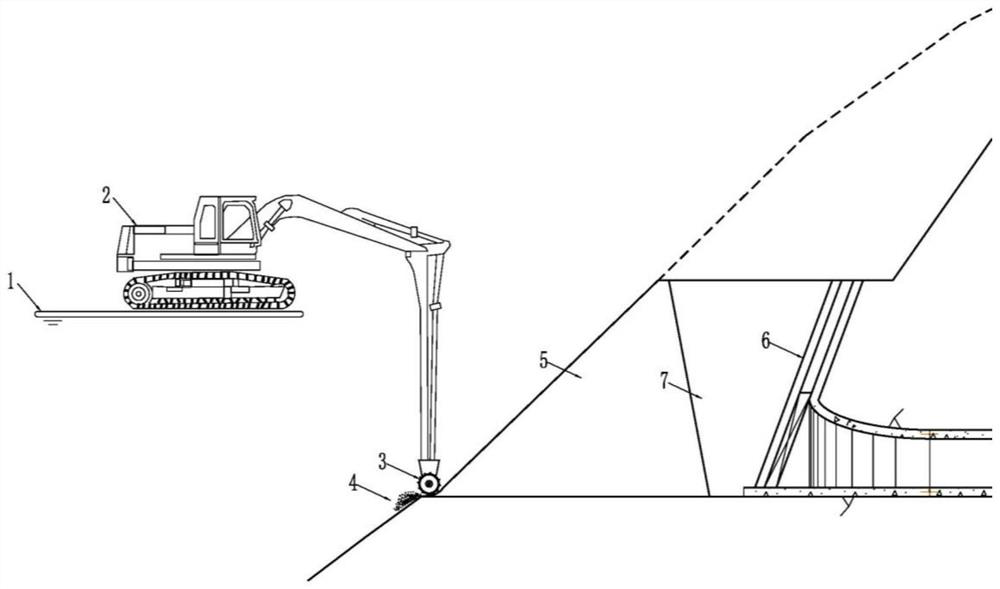

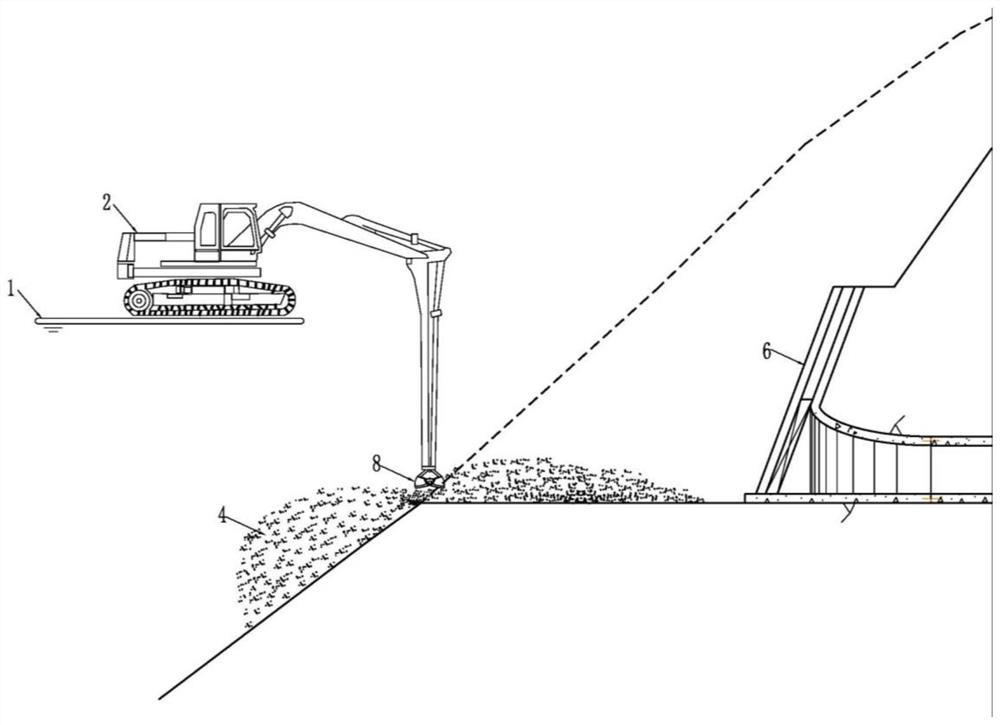

Underwater non-blasting demolition construction method for reserved rock bank

InactiveCN111997008ALittle controllabilityLow geological requirementsWater-power plantsHydro energy generationSlagArchitectural engineering

The invention relates to the technical field of water conservancy and hydropower engineering tunnel construction, in particular to an underwater non-blasting demolition construction method for a reserved rock bank. The method comprises the steps that 1, after tunnel construction is completed, a tunnel inlet gate is closed, and a tunnel inlet vertical shaft is filled with horizontal pressure; 2, anadaptive long-arm excavator is selected according to the construction water depth, and a milling and excavating head is assembled at the end of a movable arm of the long-arm excavator; 3, an overwater construction platform used for bearing the long-arm excavator is built on the water surface according to the weight of the long-arm excavator; 4, the long-arm excavator is driven into the overwaterconstruction platform, and the milling and excavating head is controlled to dismantle the rock bank of the excavated part; and 5, after the rock bank is dismantled, the milling and excavating head isreplaced with a grab bucket, and slag materials are grabbed to be matched with a barge to be discharged. Compared with an underwater rock bank or rock plug blasting construction method, the method hasthe advantages of small construction disturbance, low requirements on geological conditions of a tunnel inlet and high adaptability by building the overwater construction platform to cooperate with the milling and digging head and the grab bucket to demount the reserved rock bank.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Manufacturing method of reinforced wing rail alloy steel frog

PendingCN110877187AImprove anti-wear performanceReduce wearRail switchesStructural engineeringFlash welding

The invention relates to a manufacturing method of a reinforced wing rail alloy steel frog, and the method can solve the problems of quick vertical abrasion of a wing rail and chipping of a point railof a frog. The alloy steel frog comprises a point rail, a frog heel rail connected to the heel end of the point rail and wing rails distributed on the two sides of the point rail. The wing rails aremade of a forged high manganese steel material. Or the wing rails are composed of a section of common steel rail and a section of alloy steel rail, and the common steel rail and the alloy steel rail are welded together through flash welding. One end, connected to the line, of the wing rails is the common steel rail, and the other end of the wing rails is the high manganese steel rail. The method has the advantages that through wing rail strengthening and wheel rail relation optimization, the contact area of the top face of the wing rails and wheels is increased, the smoothness of the rail topface of a point-wing rail transition area is improved, the abrasion resistance of the wing rails is improved, the point rail is protected, and the effects of reducing wing rail abrasion, preventing the point rail from falling off and prolonging the service life of the frog are achieved.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

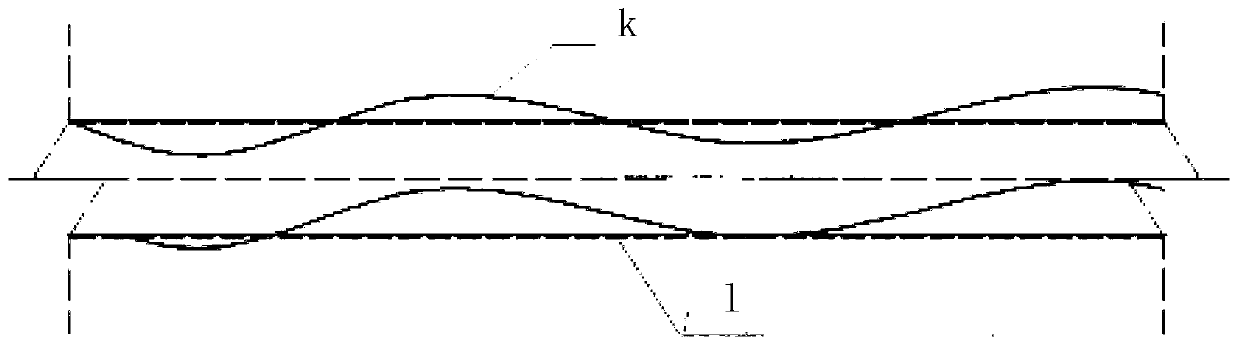

A preparation method of electric locomotive pantograph composite slide plate

ActiveCN108117391BImprove the lubrication effectImprove conductivityRailway vehiclesPower current collectorsCarbide siliconCoke

The invention discloses a preparation method of a composite pantograph pan of an electric locomotive. The preparation method comprises the following steps of (1), uniformly mixing silicon carbide powder, pitch coke powder and graphite powder, then adding molten high-temperature pitch, uniformly mixing at 130 to 150 DEG C, subsequently, cooling, and grinding a cooled mixture into powder with the granularity of 350 to 400 meshes, wherein the contents, in parts by weight, of the silicon carbide powder, the pitch coke powder, the graphite powder and the high-temperature pitch are 5 to 15 parts, 50to 60 parts, 5 to 10 parts and 25 to 30 parts respectively; (2), uniformly dispersing uniformly dispersed reduced graphene oxide dispersion liquid onto the powder obtained in the step (1) through spray drying; (3), predrying the powder obtained in the step (2), curing at 150 to 160 DEG C, enabling the cured powder to pass through a screw extruder, extruding to obtain a carbon pan blank of a required specification, roasting the carbon pan blank, and then discharging from a furnace, so that the composite pan is obtained. The preparation method provided by the invention is brief in process; a product is excellent in performance and good in self-lubricating property, further, does not damage a conducting wire, and is suitable to massively produce, and production equipment is simple.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

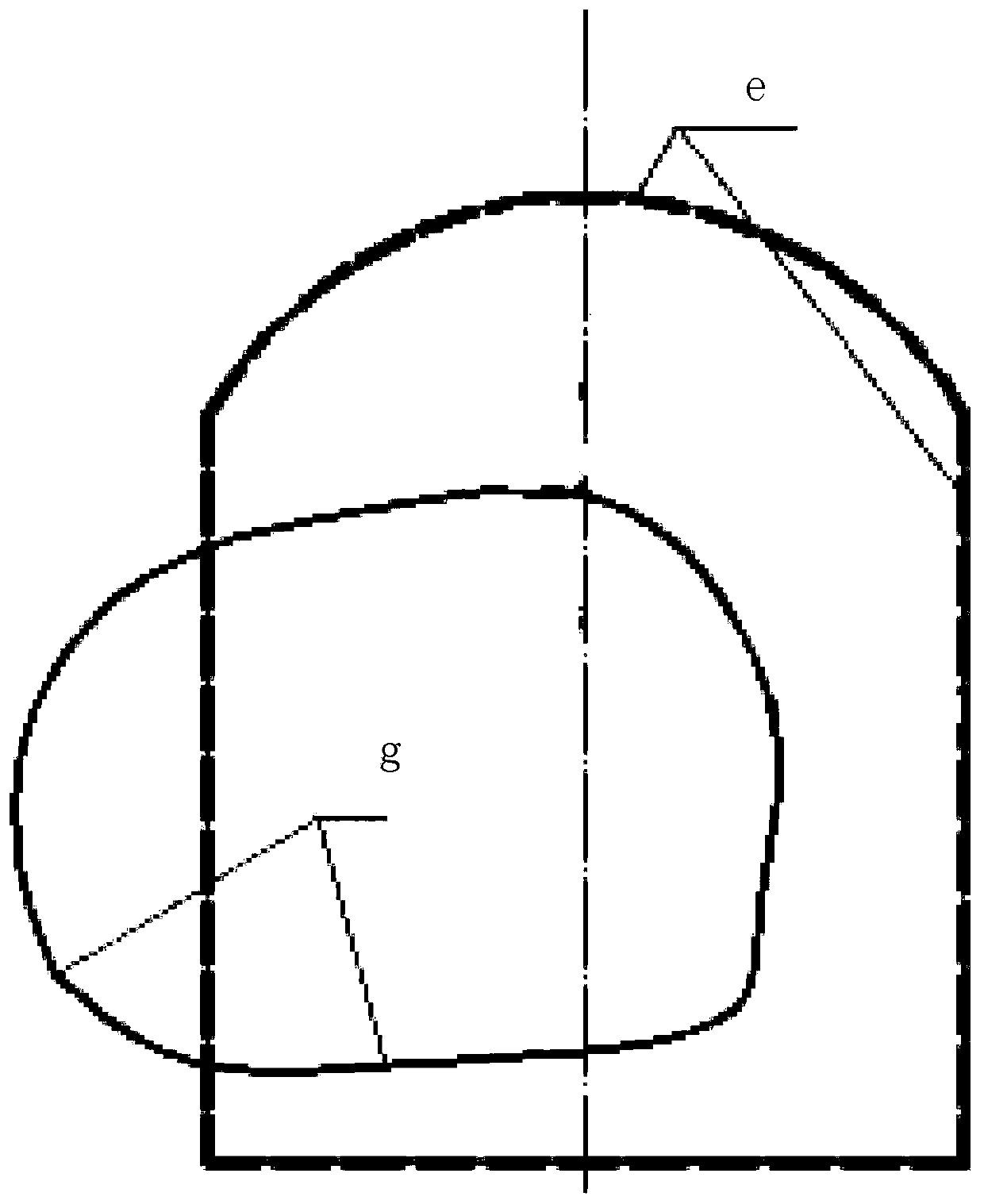

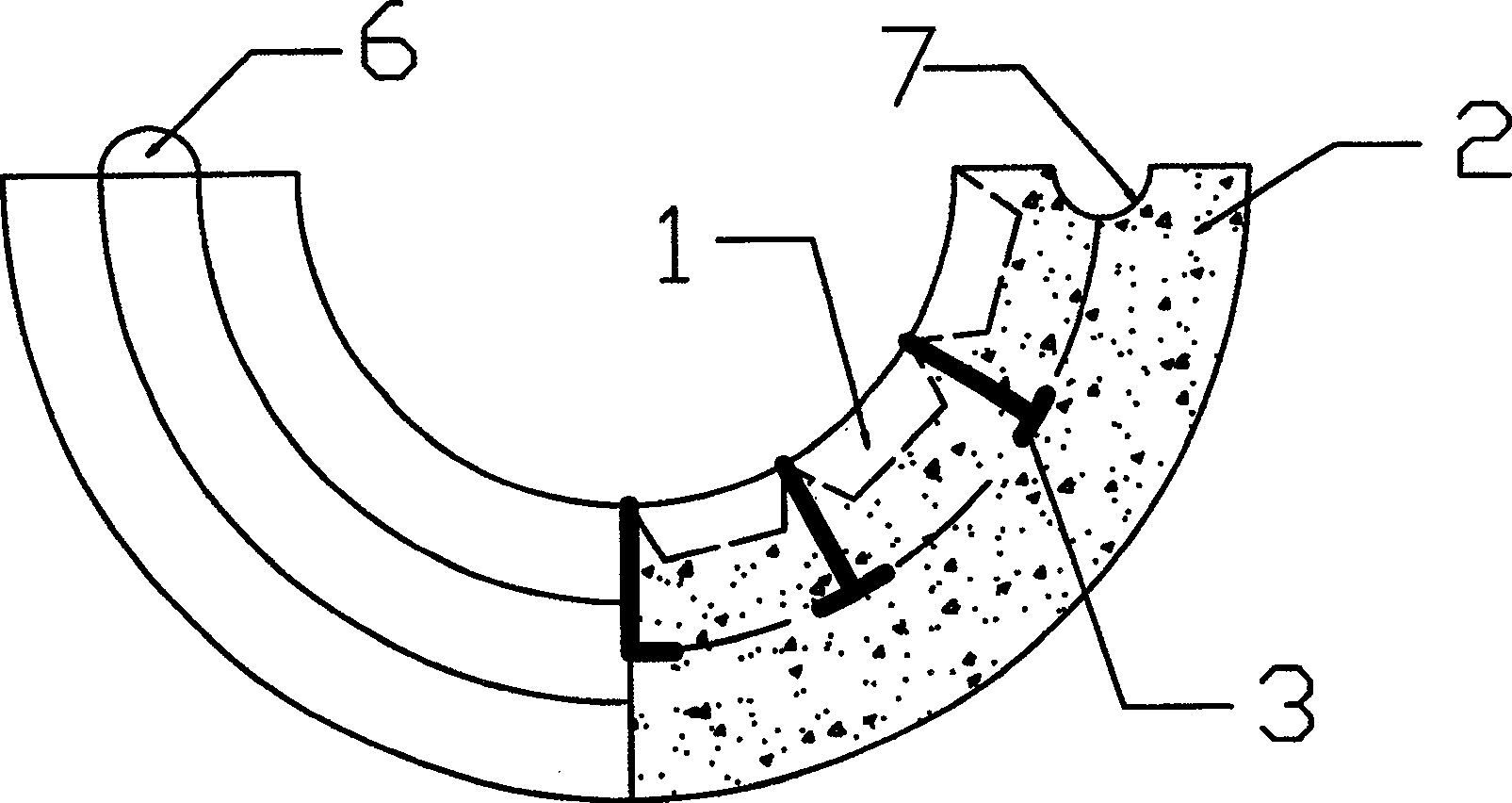

Wind-supplying pipe heat insulation device inside carbon element calcining rotary kiln and its preparation and method for using

InactiveCN100526782CNot easy to fall offExtended service lifeFurnace componentsRotary drum furnacesSEMI-CIRCLEEngineering

A heat insulation device for air supply pipes in a carbon calcined rotary kiln. It is mainly composed of parallel irons, castables, and anchor nails. It is hollow and semi-cylindrical. The inner wall is equipped with parallel irons. Weld a T-shaped or V-shaped anchor nail every 30mm, and set a corresponding outer convex semi-circle II and semi-circular inner groove II on the two ends of the combined heat insulation prefabricated block, and set corresponding ones on the sides An outer convex semicircle I and a semicircular inner groove I. The equipment is prefabricated and fired at high temperature, and the castable used has been baked before the binding block is installed, so its strength and practical performance are not limited by the kiln curve. The equipment and the air supply pipe are welded together by the pad iron attached to the wrapping block, which is convenient for construction and replacement, and can ensure a firm and reliable connection between the two, and the wrapping block is not easy to fall off, which can greatly increase the service life of the air supply pipe.

Owner:NORTHEASTERN UNIV LIAONING +1

Composition brake pad for centralized power EMU of 160 KMh

InactiveCN111677790AReduce pollutionReduce slippageNoise/vibration controlBraking membersControl theoryMechanical engineering

The invention belongs to the technical field of braking systems, and particularly relates to a composition brake pad for a centralized power EMU of 160 KMh. The composition brake pad is composed of afriction body and a dovetail plate, wherein the friction body and the dovetail plate are integrally pressed and formed, the top of the friction body is provided with a groove, the friction body is composed of resin and rubber, and the dovetail plate is a steel plate. A brake pad is replaced with the composition brake pad, a material of the composition brake pad is changed into an organic matter, and the composition of the brake pad is carried out by the resin and the rubber, so that the environmental pollution is effectively reduced, the cost of the brake pad is effectively reduced, and the inconvenience of installation is reduced; and meanwhile, the weight of a whole vehicle is reduced, and also accidents such as breaking, dropping and falling are effectively prevented from occurring by the integrated structural design of the composition brake pad.

Owner:SHENYANG YUANCHENG FRICTION & SEALING MATERIAL CO LTD

Continuous beam pipeline force rib friction loss testing method based on karst cave underground river environment

InactiveCN112095438AGuarantee the construction qualityEliminate the effects ofUnderground chambersBridge applicationsContinuous beamKarst

The invention discloses a continuous beam pipeline force rib friction loss testing method based on a karst cave and underground river environment. The method comprises the following steps that S1, a tunnel section A is excavated to penetrate through a karst cave; S2, an underground river is redirected; S3, the karst cave is backfilled to the tunnel foundation surface; S4, a cave wall is protected,and a plurality of anchor cables are constructed; S5, the karst cave is fully filled, and an anchor cable is connected with a backfill body; S6, the backfill body is excavated to form a tunnel section B; S7, piers and abutments are constructed on the tunnel section A; S8, a first section, a second section, a second section, a third section and a closure section are divided; S9, a supporting foundation of the tunnel section A is constructed; and S10, from the first section to the closure section, continuous beam construction is conducted according to the section sequence. The method has the advantages of being stable, reliable, high in safety and capable of preventing sedimentation.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

Automatic shipping and distribution system from ferrite ring magnet sintering process to grinding process

ActiveCN107650253BReduce intermediate inventoryAvoid bumpingEdge grinding machinesCeramic shaping apparatusDistribution systemEngineering

The invention relates to an automatic loading and distributing system for a ferrite ring from a magnetic sintering step to a grinding step. The system comprises a sintering grinding track and a grinding machine. The system is characterized by being further provided with an automatic loading and distributing device. The sintering grinding track is connected to the automatic loading and distributingdevice, and the automatic loading and distributing device is connected to the grinding machine. Middle inventory can be reduced, collision and chip off-falling of products in the conveying process are avoided, and the production efficiency and the percent of pass of the products are improved.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com