Continuous casting tundish protecting technology

A continuous casting tundish and tundish technology, applied in casting equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as loss, and achieve the effect of avoiding slag inclusion and damage in continuous casting slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment the present invention is described in further detail:

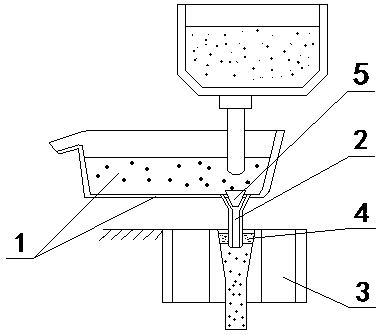

[0026] Such as figure 1 As shown, a continuous casting tundish protection process includes the following steps:

[0027] a. Move the tundish 1 to the baking position, bake the tundish 1, move to the pouring position after baking, stop the fire of the toaster, lay a layer of slag cotton on the tundish along the edge, check the tundish body and Whether there is a gap between the covers, cover the cover of the tundish 1 on the upper edge of the package body of the tundish 1, and apply a sealing paint between the cover of the tundish 1 and the package body of the tundish 1;

[0028] b. Install a protective sleeve 2 immersed in molten steel in the crystallizer at the sliding nozzle 5 of the tundish at the lower end of the tundish 1;

[0029] c. The ladle is placed on the rotary table, the ladle is poured, and molten steel is injected from the ladle into the tundish 1, and the molte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com