Powder metallurgy friction body and manufacturing method thereof, powder metallurgy brake pad

A technology of powder metallurgy and manufacturing method, which is applied in the direction of friction linings, mechanical equipment, gear transmission mechanisms, etc., can solve the problems of friction material falling off, etc., and achieve the effects of improving service life, high feasibility, and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An embodiment of the present invention provides a powder metallurgy friction body, including: a friction material layer composed of a matrix component, a lubricating component, and a friction component, and a skeleton adhesive for bonding the friction material layer and the metal skeleton together. material layer. The chemical properties and physical and mechanical properties of each component in the matrix component determine the performance and process characteristics of the powder metallurgy friction material to a large extent. The matrix component ensures the bearing capacity, thermal stability, wear resistance and high temperature resistance of the friction body. Ability to hold abrasive and lubricant particles while in operation. The role of lubricating components and friction components is mainly to keep the coefficient of friction stable.

[0028] Specifically, the above matrix components include: bronze powder, reduced iron powder, ferromanganese alloy powder ...

Embodiment 2

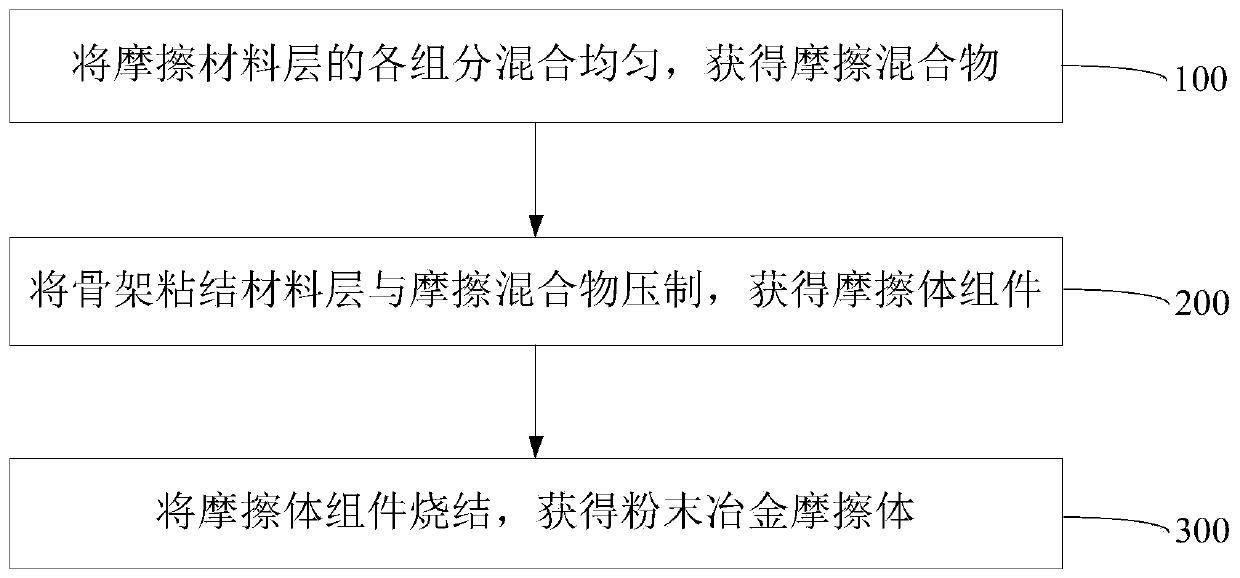

[0037] An embodiment of the present invention provides a method for manufacturing a powder metallurgy friction body, which is applied to the above powder metallurgy friction body. Such as figure 1 As shown, the manufacturing method of the powder metallurgy friction body includes:

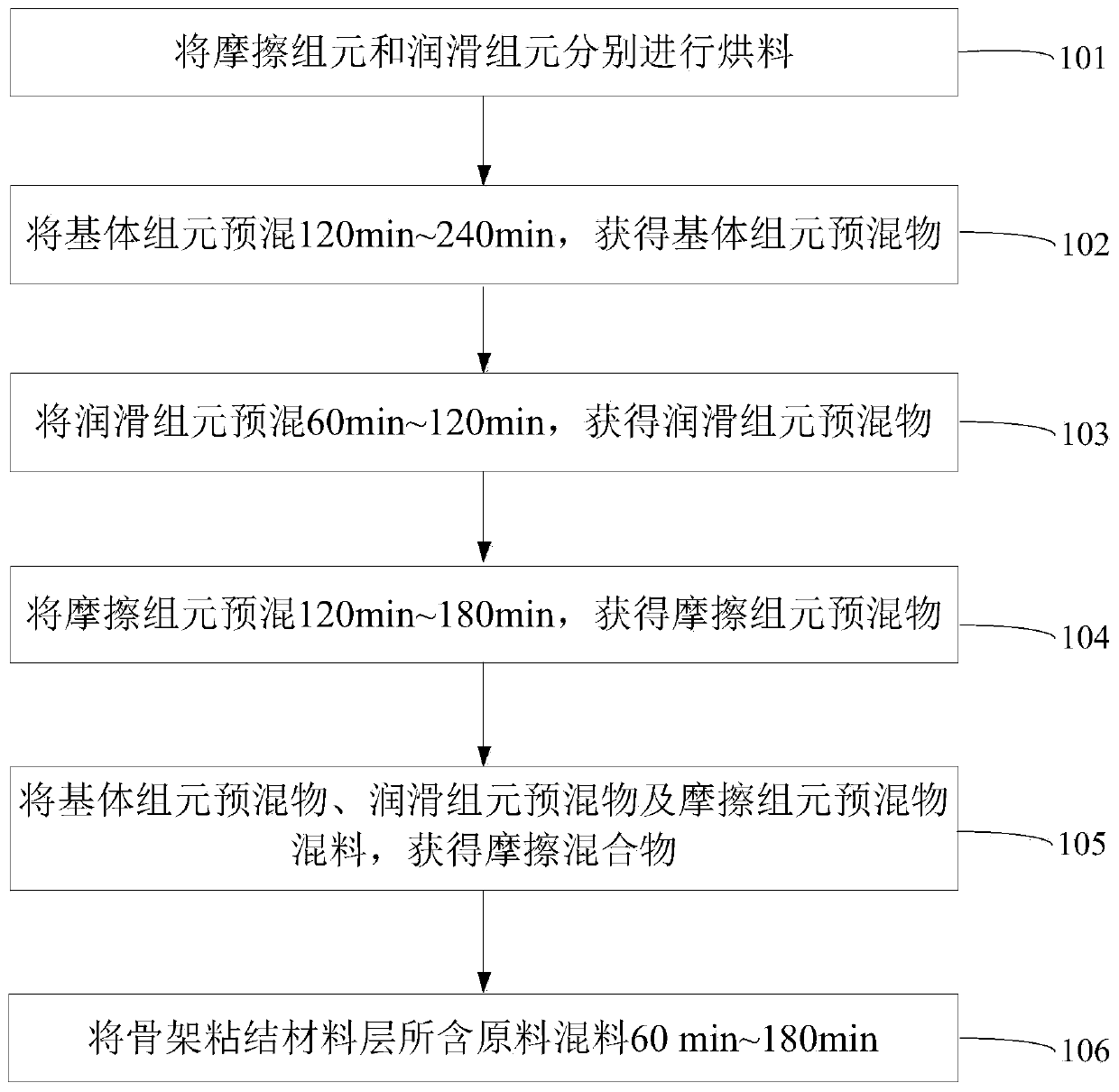

[0038] Step 100, uniformly mixing components of the friction material layer to obtain a friction mixture.

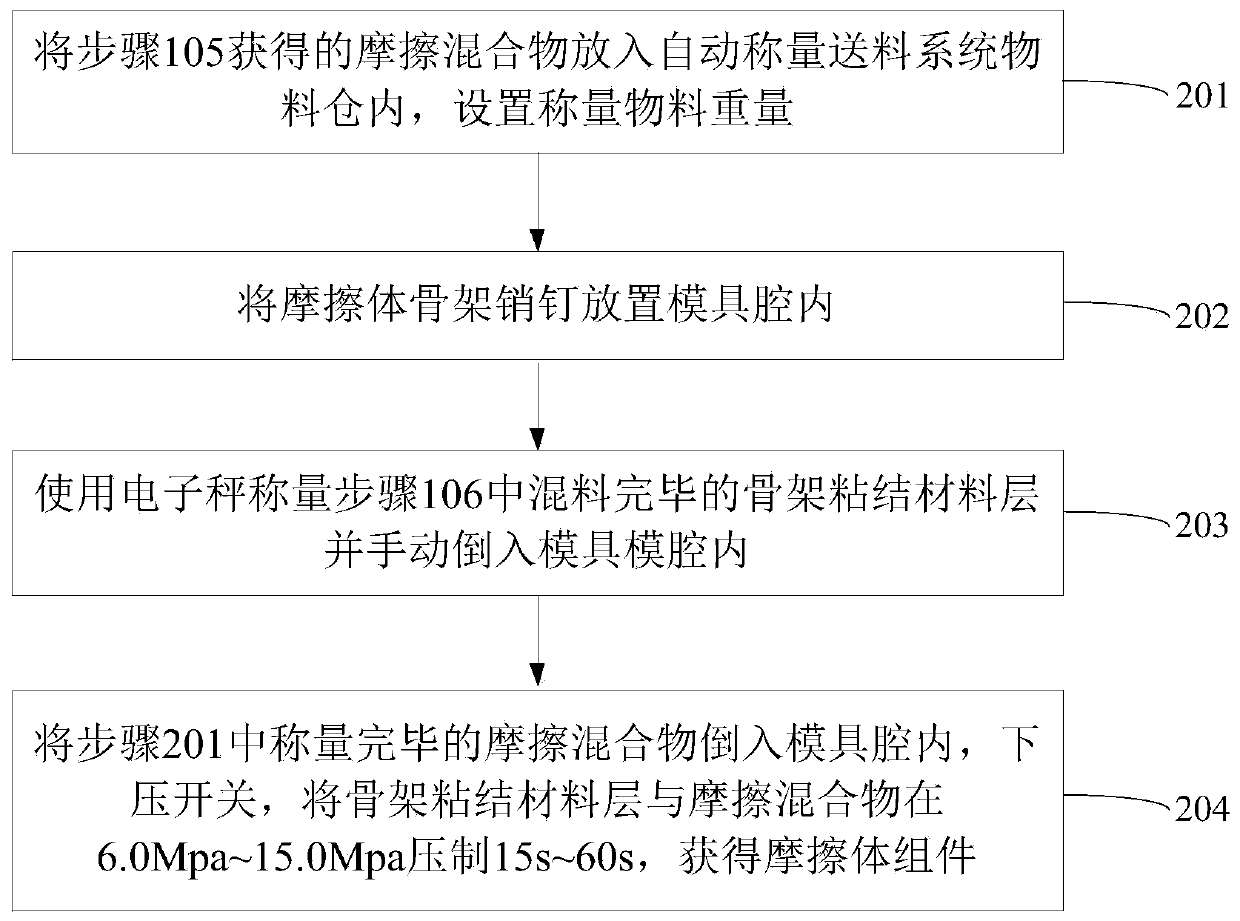

[0039] Step 200, pressing the skeleton bonding material layer and the friction mixture to obtain a friction body assembly.

[0040] Step 300, sintering the friction body assembly to obtain a powder metallurgy friction body.

[0041] In the manufacturing method of the powder metallurgy friction body provided by the embodiment of the present invention, pressing the powder metallurgy friction body with a skeleton can improve the bonding force between the friction material and the skeleton, effectively prevent the friction body from falling off, and avoid the occurrence of dislocation between th...

Embodiment 3

[0071] An embodiment of the present invention provides a method for manufacturing a powder metallurgy friction body. The powder metallurgy friction body includes: a friction material layer composed of a matrix component, a lubricating component and a friction component, and a skeleton bonding material layer for bonding the friction material layer and the skeleton of the friction body together. The matrix components include: bronze powder, reduced iron powder, ferromanganese alloy powder and nanometer molybdenum trioxide. Lubricating components include: zinc sulfide and flake graphite; friction components include: titanium dioxide, zirconia, feldspar and zircon sand. The skeleton bonding material layer includes: bronze powder, reduced iron powder, manganese powder, molybdenum powder and tin powder.

[0072]The friction material layer in the powder metallurgy friction body contains the following raw materials in terms of mass fraction: the mass fraction of bronze powder is 45%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com