Low-carbon steel coil plate for oil filter thread cover plate and manufacturing method thereof

A technology of oil filter and threaded cover plate, which is applied in the field of metal material manufacturing, can solve the problems of burrs, non-conformity, uneven wall thickness reduction and other problems in turning threads, so as to improve material strength and reaming flanging performance , good stamping performance and surface quality, and the effect of increasing directional performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment produces a low-carbon steel coil plate with a thickness of 3.5mm for the threaded cover plate of an oil filter, which is used to manufacture a high-performance threaded cover plate for an oil filter with a pressure of 2.1 MPa. The low-carbon steel coil plate :

[0051] S1, through converter smelting, RH furnace refining, continuous casting into the slab described in component number 1;

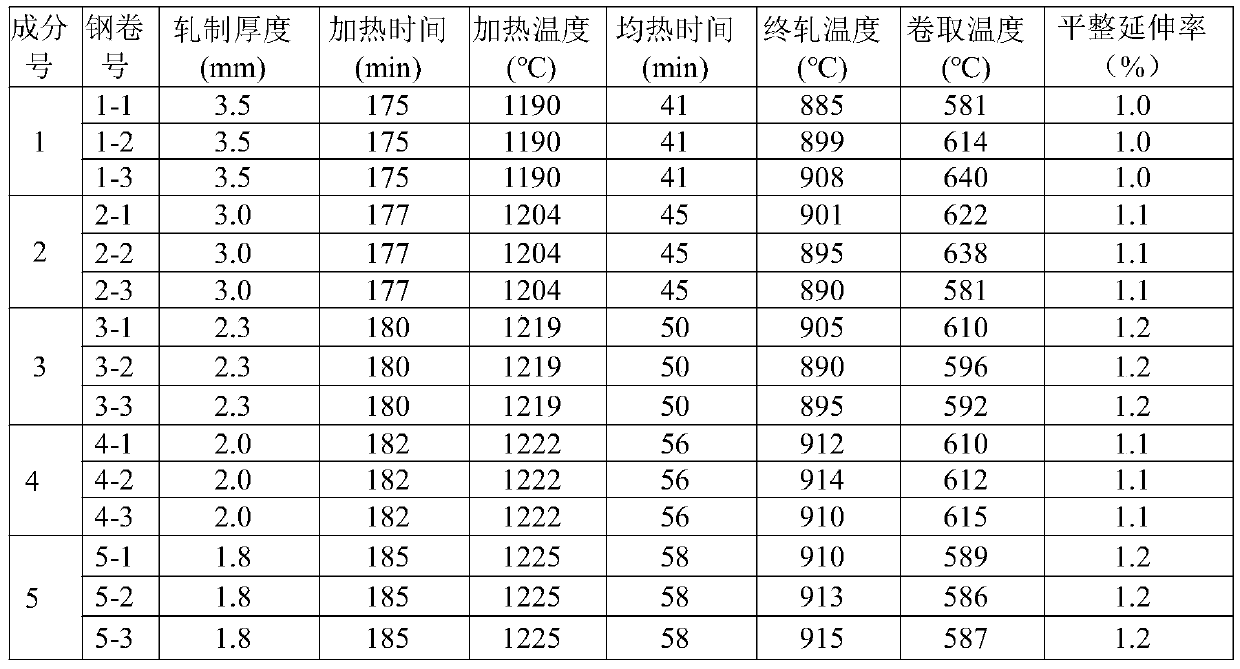

[0052] S2, hot rolling: Divide the slab with component number 1 into three pieces for heating, mark the steel coil numbers as 1-1, 1-2, 1-3, target hot rolling thickness of 3.5mm, and pass the billet for 175min Heating time, heating temperature 1190°C, soaking time 41min, rough rolling, finish rolling to obtain hot-rolled sheet, final rolling temperature 885°C ~ 908°C, then laminar cooling of the hot-rolled sheet, coiled into hot rolled sheet after cooling Rolled coil, the coiling temperature is 581~640℃, and it is hot-rolled and smoothed, and the flattening elongation ...

Embodiment 2

[0055] This embodiment produces a low-carbon steel coil with a thickness of 3.0mm for the threaded cover of an oil filter, which is used to manufacture a high-performance threaded cover for an oil filter with a pressure of 2.0 MPa. The low-carbon steel coil :

[0056] S1, through converter smelting, RH furnace refining, continuous casting into the slab described in component number 2;

[0057] S2, hot rolling: Divide the slab with component number 2 into three pieces for heating, mark the steel coil numbers as 2-1, 2-2, 2-3, target hot rolling thickness of 3.0mm, and pass the billet for 177min Heating time, heating temperature 1204°C, soaking time 45min, rough rolling, finish rolling to obtain hot-rolled sheet, final rolling temperature 890°C ~ 901°C, then laminar cooling of the hot-rolled sheet, coiled into hot rolled sheet after cooling Rolled coil, the coiling temperature is 581 ~ 638 ℃, and it is hot-rolled and flattened, and the flattening elongation is 1.1%;

[0058] S...

Embodiment 3

[0060] This embodiment produces a low-carbon steel coil plate with a thickness of 2.3mm for the threaded cover plate of an oil filter, which is used to manufacture a high-performance threaded cover plate for an oil filter with a pressure of 1.9MPa. The low-carbon steel coil plate :

[0061] S1, through converter smelting, RH furnace refining, continuous casting into the slab described in component number 3;

[0062] S2, hot rolling: Divide the slab with component number 3 into three pieces for heating, mark the steel coil numbers as 3-1, 3-2, 3-3, target hot rolling thickness of 2.3mm, and pass the billet for 180min Heating time, heating temperature 1219°C, soaking time 50min, rough rolling, finish rolling to obtain hot-rolled sheet, final rolling temperature 890°C-905°C, then laminar cooling of the hot-rolled sheet, coiled into hot rolled sheet after cooling Rolled coil, the coiling temperature is 592~610℃, and it is hot-rolled and smoothed, and the flattening elongation is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com